Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49 results about "Numerical control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (drills, boring tools, lathes) and 3D printers by means of a computer. A CNC machine processes a piece of material (metal, plastic, wood, ceramic, or composite) to meet specifications by following a coded programmed instruction and without a manual operator.

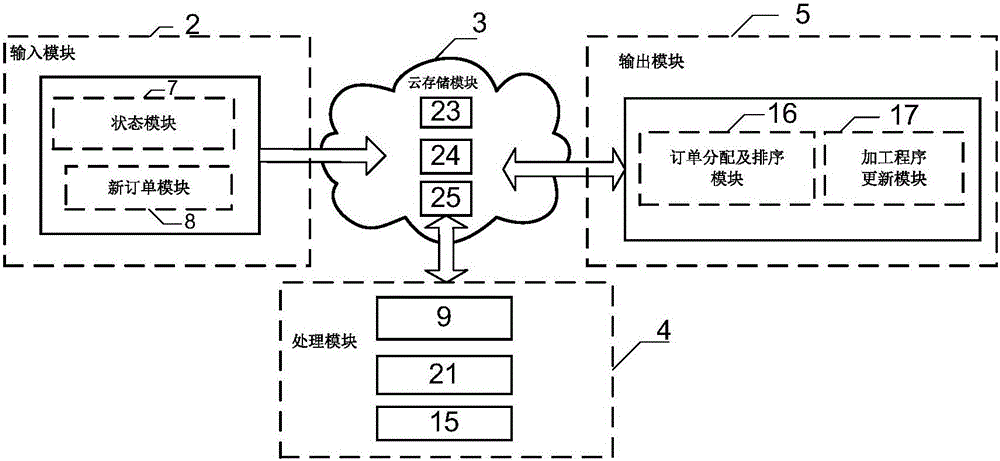

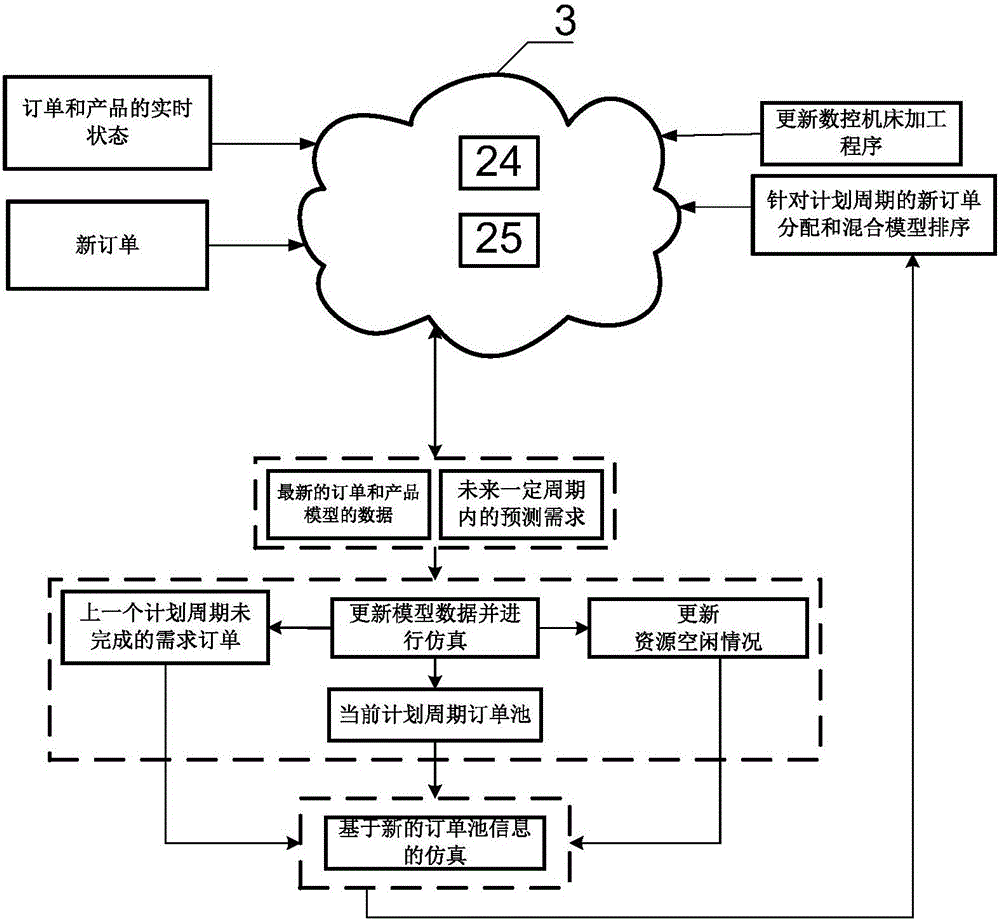

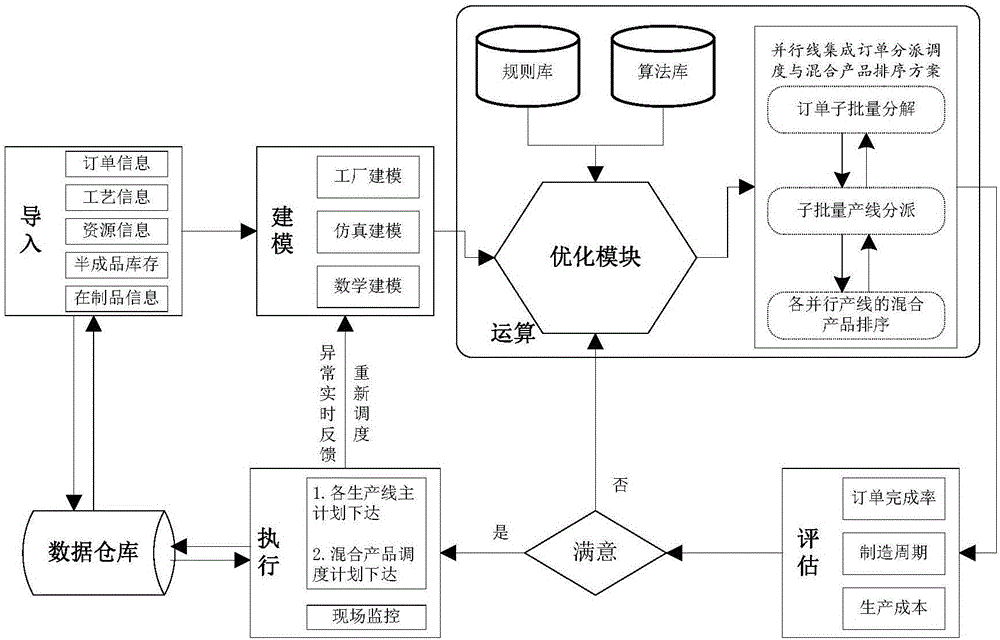

Order distribution scheduling and mixed product ordering system and method

ActiveCN106444643ASimple module structureEasy to installProgramme controlComputer controlNumerical controlProduction line

Owner:HUAZHONG UNIV OF SCI & TECH

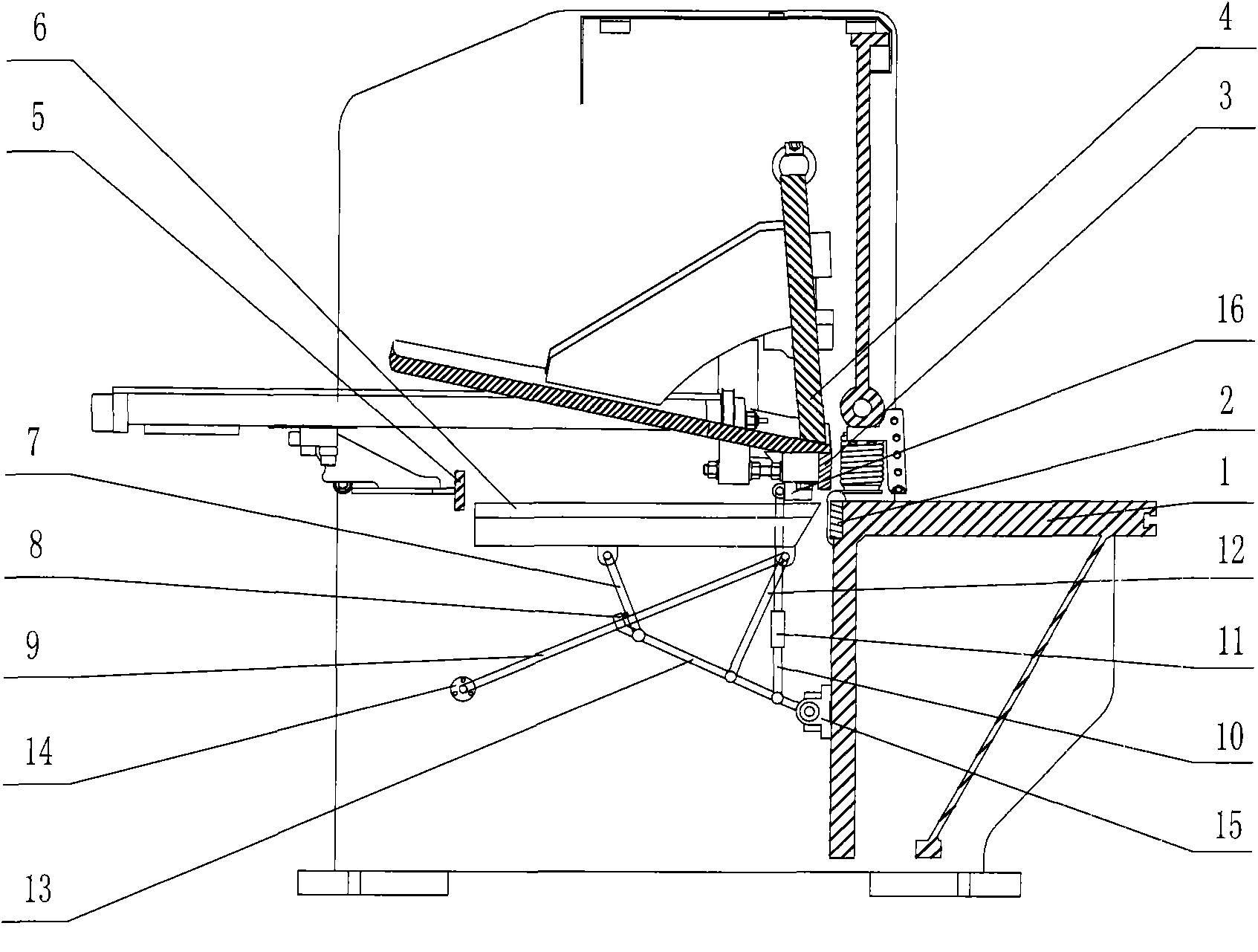

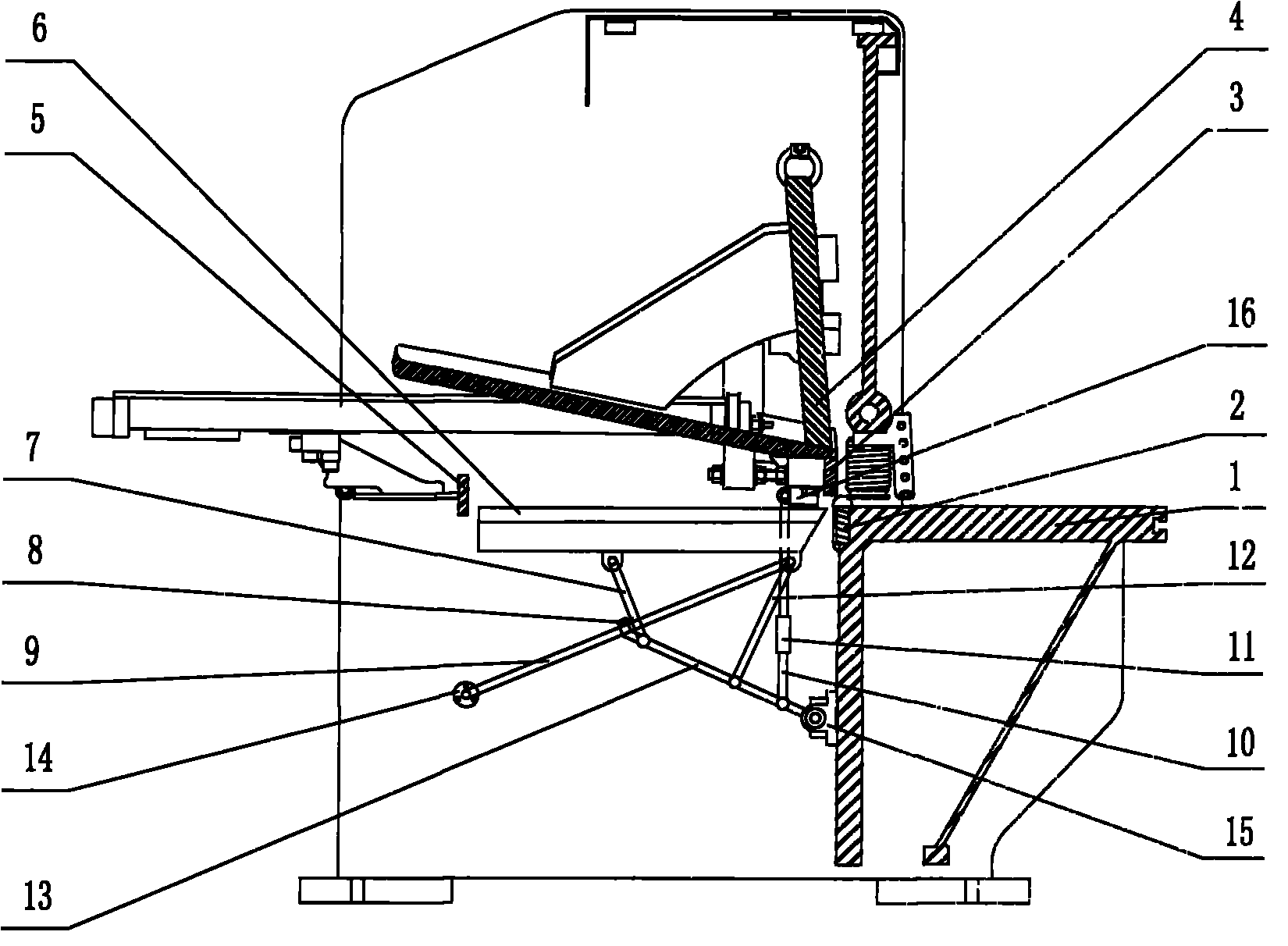

Linked rear materials supporting device of numerical control plate shearing machine

ActiveCN101870005ASave energyImprove work efficiencyShearing machinesShearing machine accessoriesNumerical controlEngineering

Owner:爱克(苏州)机械有限公司

Method for processing pin hole of intermediate case lining

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

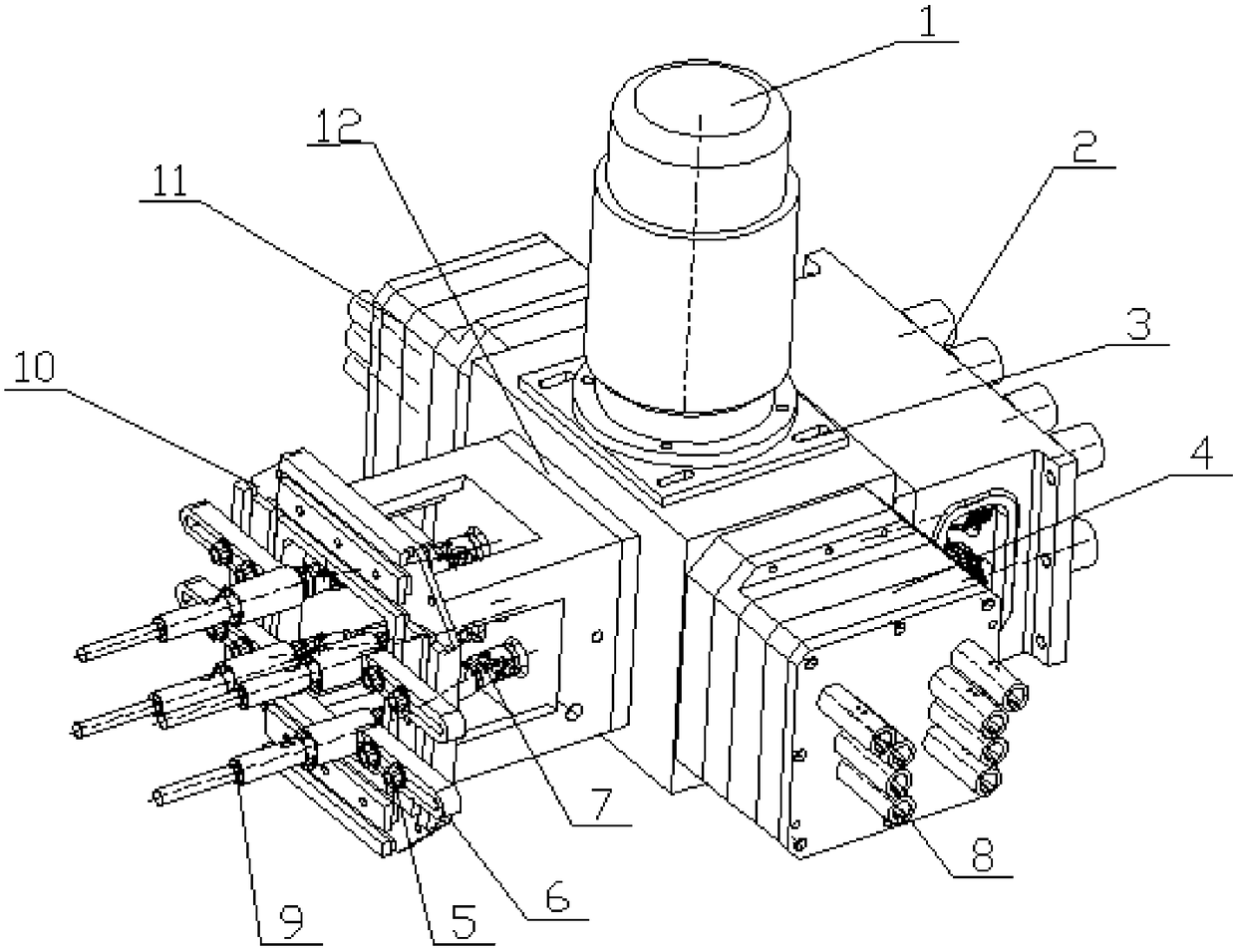

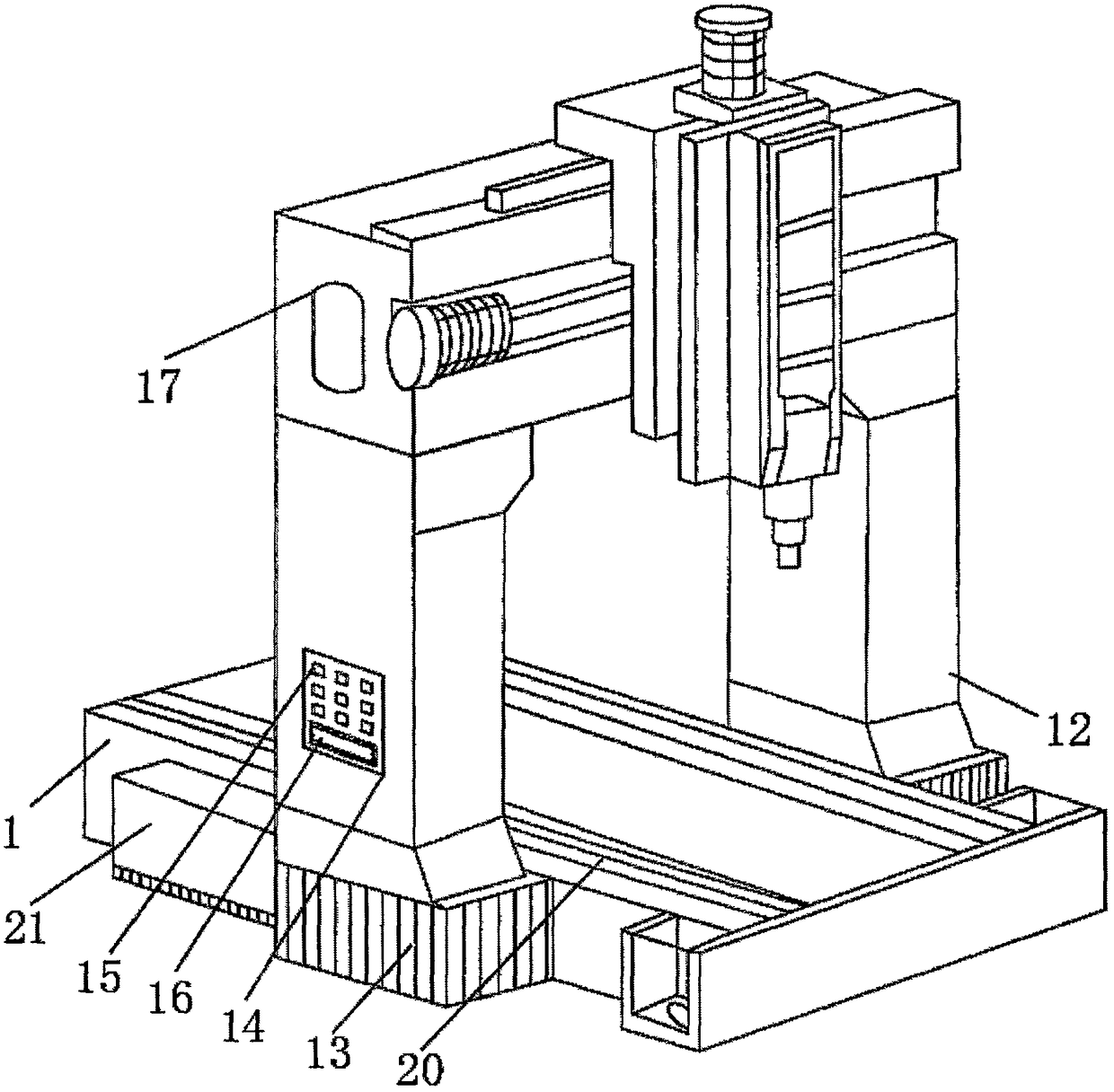

Novel precise numerical-control machine tool

InactiveCN107791023AAdaptableFeeding apparatusOther manufacturing equipments/toolsNumerical controlEngineering

The invention relates to the technological field of precise numerical-control machine tool equipment and provides a novel precise numerical-control machine tool comprising a machine tool body. A spindle box and an auxiliary spindle box are arranged on the machine tool body. A cutter rest is arranged between the spindle box and the auxiliary spindle box. A first machining cutter is arranged on thecutter rest. The auxiliary spindle box comprises an auxiliary spindle and a clamp which is detachably installed on the auxiliary spindle and used for clamping a special-shaped workpiece. The clamp isan internal expanding mandrel or a chuck. During work, the first machining cutter can machine the workpiece on the auxiliary spindle box. A workpiece in a regular shape is clamped by the spindle box,and the auxiliary spindle box clamps the special-shaped workpiece. Specifically, when the first machining cutter machines the workpiece on the auxiliary spindle box, since the clamp is detachably installed on the auxiliary spindle box and is the internal expanding mandrel or the chuck, different clamps, such as the internal expanding mandrel or the chuck, are selected according to different special-shaped workpieces. In this way, the novel precise numerical-control machine tool achieves the purpose that both the workpiece in the regular shape and the special-shaped workpieces can be machined,and the novel precise numerical-control machine tool is wide in application range and high in applicability.

Owner:TODAY STANDARD PRECISION MASCH TOOL CO LTD

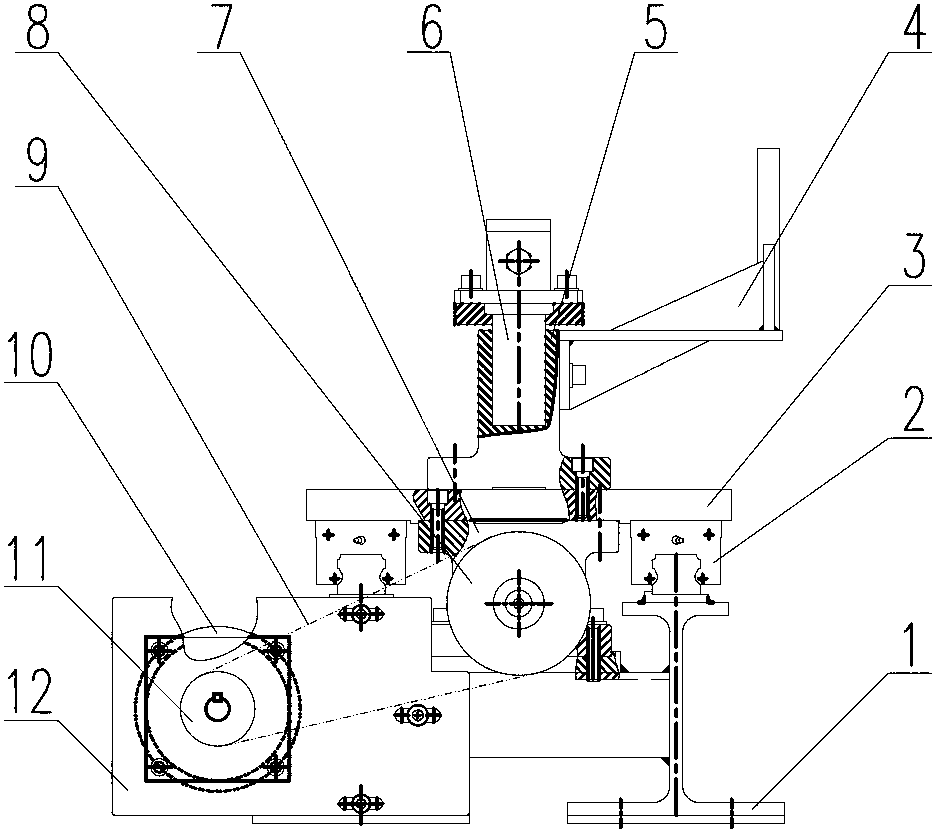

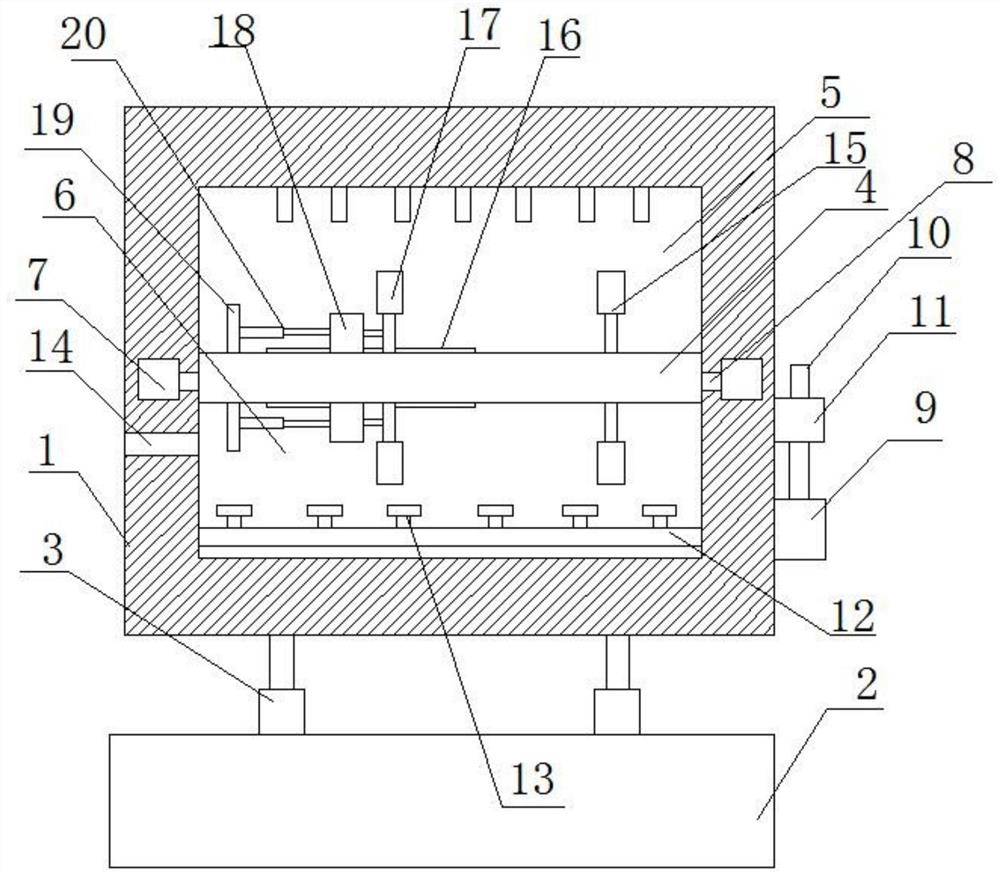

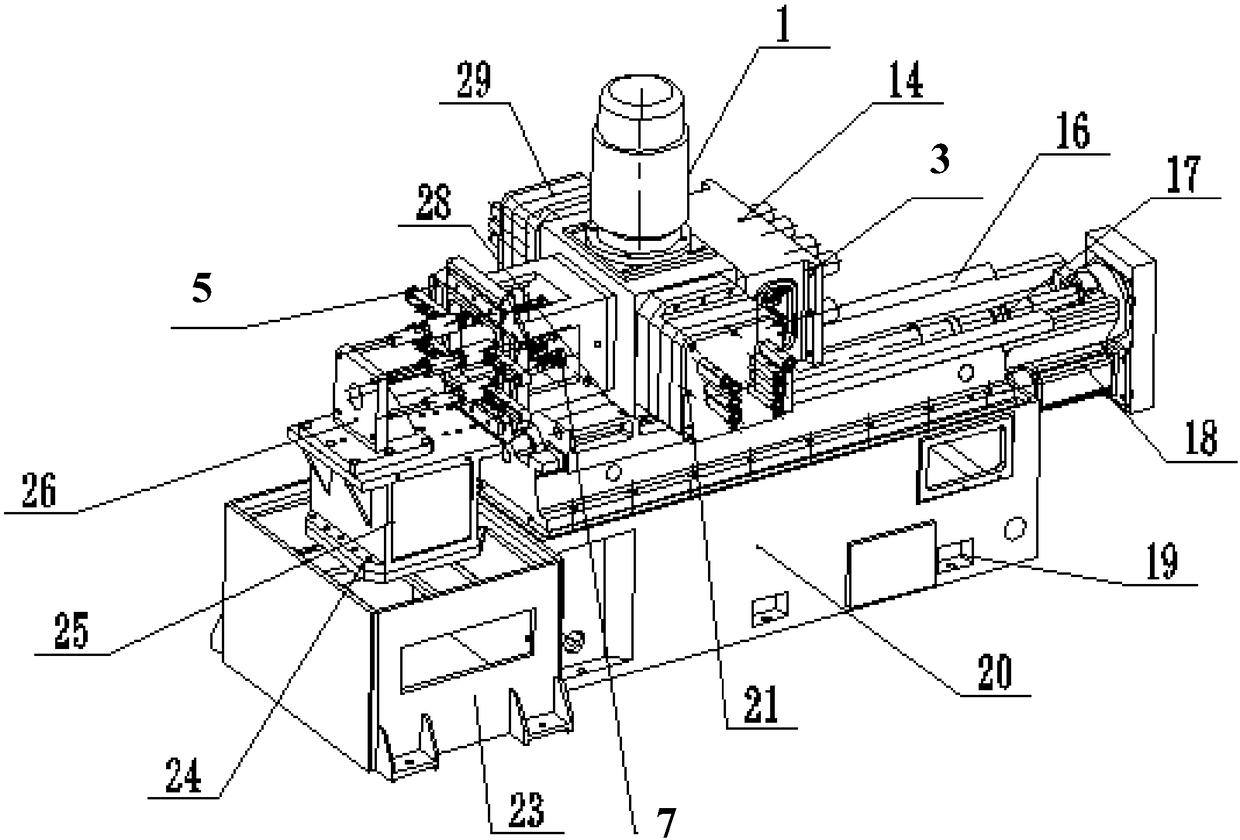

Numerical control machining device for key bit tooth punching

InactiveCN107262625AThe delivery path is reasonableEasy to controlMetal-working feeding devicesKeysNumerical controlPunching

The invention discloses a numerical control machining device for key bit tooth punching. The numerical control machining device for key bit tooth punching comprises a rack which is provided with a feeding mechanism, a clamping mechanism, a tooth punching mechanism, a discharging mechanism, a ring stringing mechanism and a numerical control unit; the clamping mechanism is fixed behind the feeding mechanism which conveys a key to the clamping mechanism to be clamped; the tooth punching mechanism is arranged behind the clamping mechanism, and is used for punching teeth of the key clamped by the clamping mechanism; the discharging mechanism is connected with the feeding mechanism and the ring stringing mechanism, and is used for conveying the key subject to tooth punching to the ring stringing mechanism from the clamping mechanism; and the numerical control unit is connected with the feeding mechanism, the clamping mechanism, the tooth punching mechanism, the discharging mechanism and the ring stringing mechanism, and is used for controlling overall running of the device. According to the numerical control machining device for key bit tooth punching, the conveying path in the key tooth punching process is optimized, the whole tooth punching process of the key is smoother, machined tooth bits are more accurate, the work efficiency is improved, and the control cost is reduced.

Owner:ZHEJIANG XINGYU MASCH TECH CO LTD

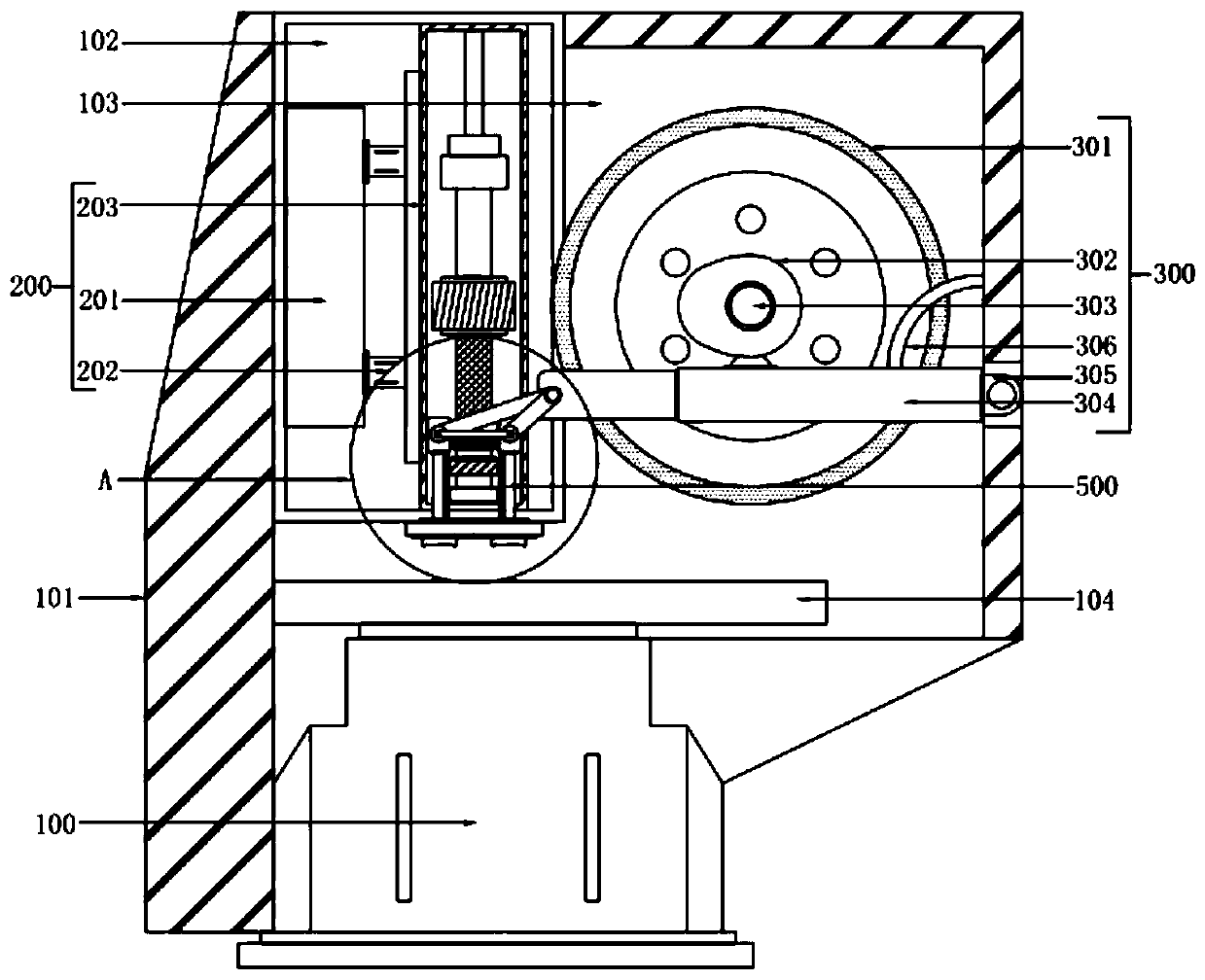

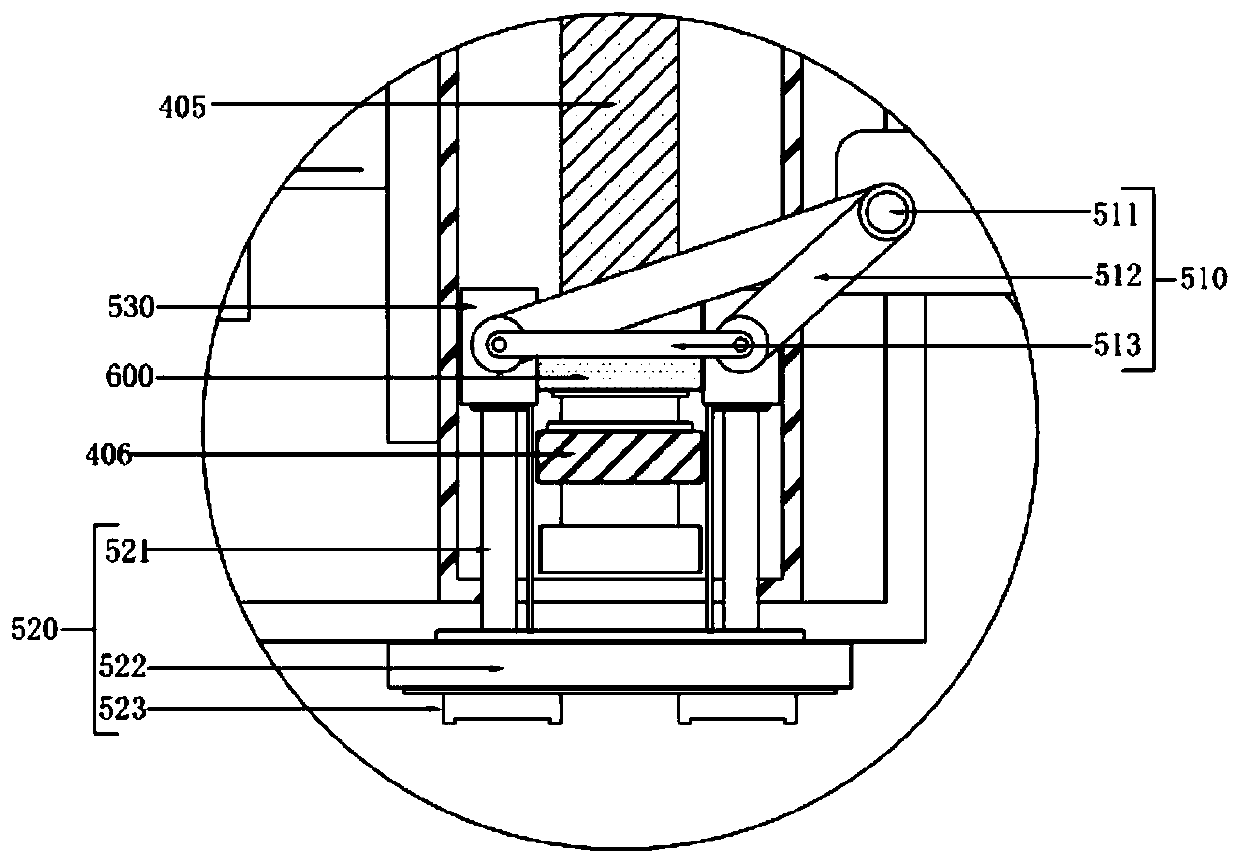

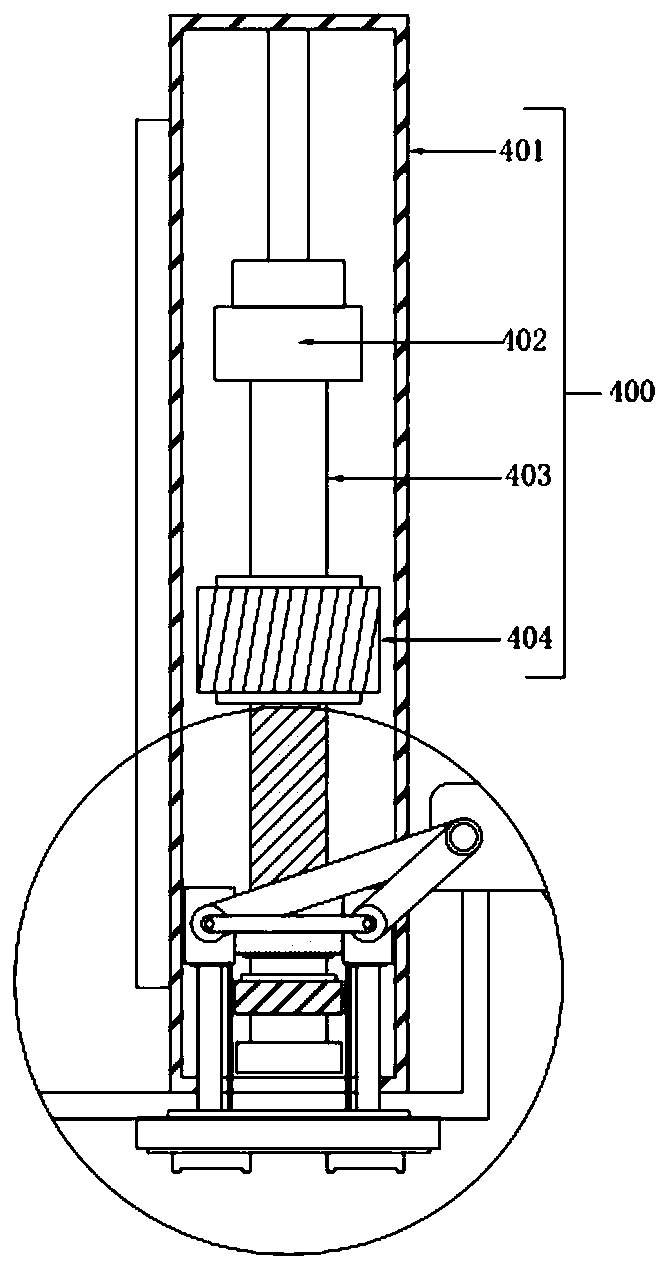

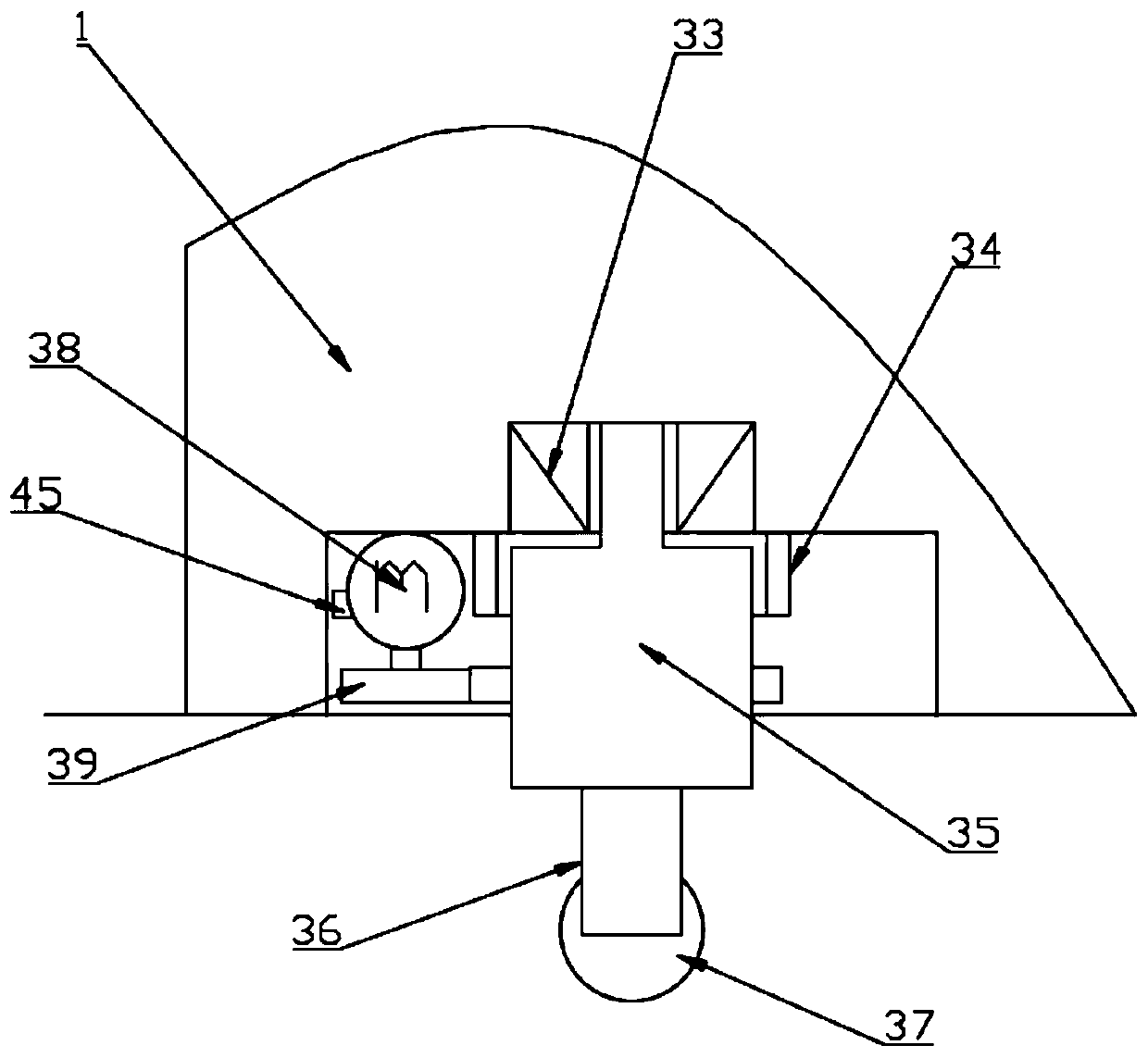

Machine tool cutting force simulation loading device

ActiveCN103737431AHigh simulationSimple structureProgramme controlMeasurement/indication equipmentsNumerical controlHydraulic cylinder

Owner:通用技术齐齐哈尔二机床有限责任公司

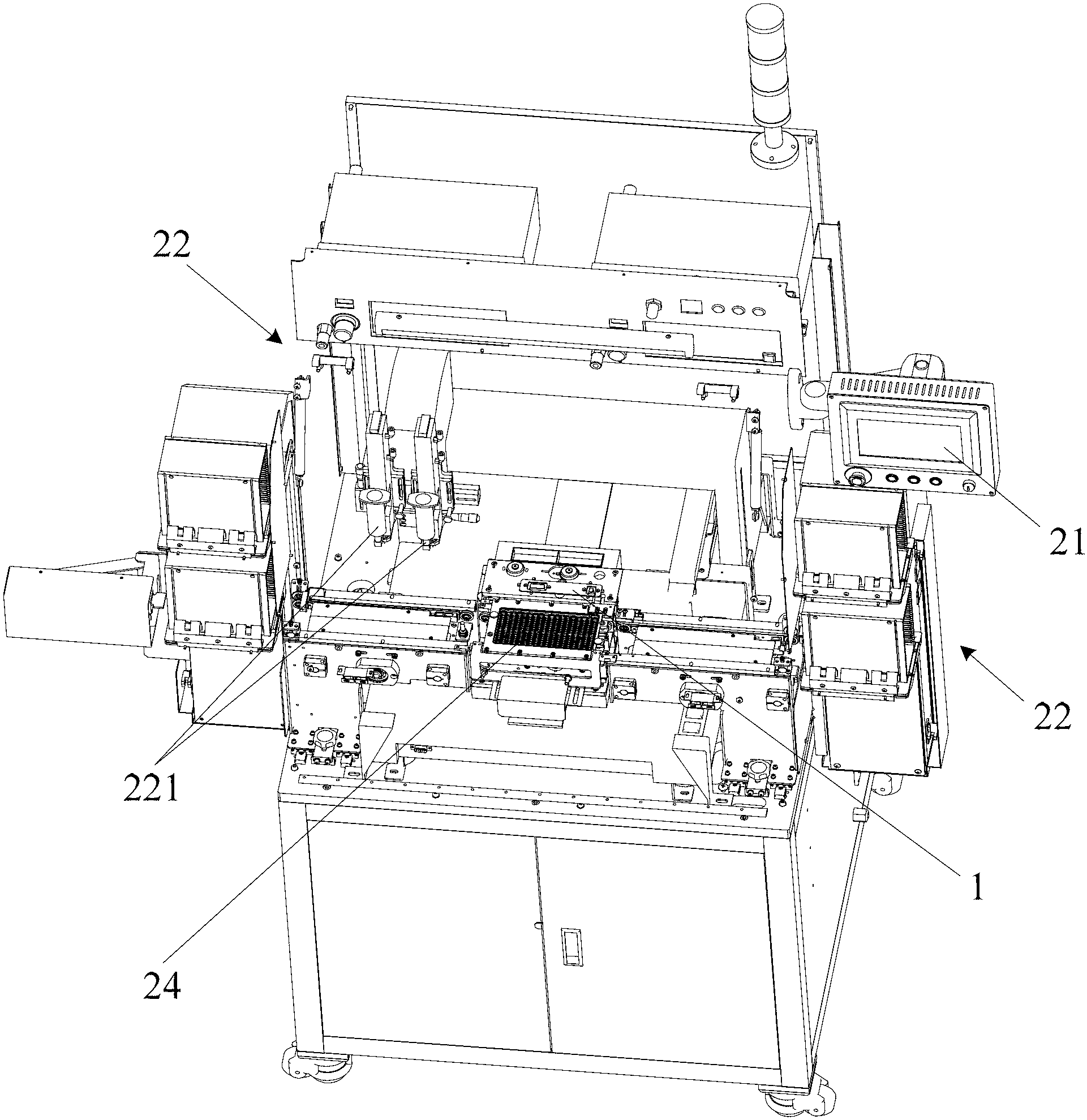

Pilot dispensing device, dispensing machine and dispensing method of dispensing machine

ActiveCN103071606AGuaranteed accuracyGuaranteed efficiencyLiquid surface applicatorsCoatingsNumerical controlMechanical engineering

Owner:SHENZHEN DINGJING TECH CO LTD

Band sawing machine

InactiveCN105057786AEasy to installQuick installationMetal sawing devicesNumerical controlEngineering

Owner:SINOMA SCI & TECH CHENGDU CO LTD

Metal bottom casing mobile terminal

InactiveCN104582376AImprove securityImprove stabilityCasings/cabinets/drawers detailsMetal casingsNumerical controlState of art

The invention relates to the technical field of electronic equipment, and particularly relates to a metal bottom casing mobile terminal. The metal bottom casing mobile terminal comprises a metal bottom casing, a middle frame and a display screen assembly, wherein the middle frame is clamped at the upper part of the metal bottom casing; the display screen assembly is mounted in the middle frame; the metal bottom casing comprises a metal base and a plastic body filled in the metal base. Compared with the metal case made by profile aluminum block CNC (computer numerical control) in the prior art, the metal bottom casing structure formed by metal plate stamping and nano injection molding has the advantages that on the basis of keeping all the properties required by the mobile terminal, the production cost is greatly reduced, and the production efficiency is improved; moreover, due to the adoption of a metal frame and a structure of an injection molding piece embedded into the inner side of the metal frame, the intensity of the whole equipment is improved, and the production cost is reduced; moreover, the hard contact between the metal frame and a display screen assembly is buffered, so that the mobile terminal is higher in security, stability and reliability.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Automatic clamping device for computerized numerical control machine tool

InactiveCN107175343AImprove qualityPrevent fallingMetal working apparatusPositioning apparatusWrinkle skinNumerical control

Owner:张艳

Cam push rod type material pressing device with numerical control punch press frame and method

InactiveCN111545656AImprove stabilityImprove work efficiencyMetal-working feeding devicesPositioning devicesNumerical controlPunch press

Owner:新昌县羽林街道全利机械厂

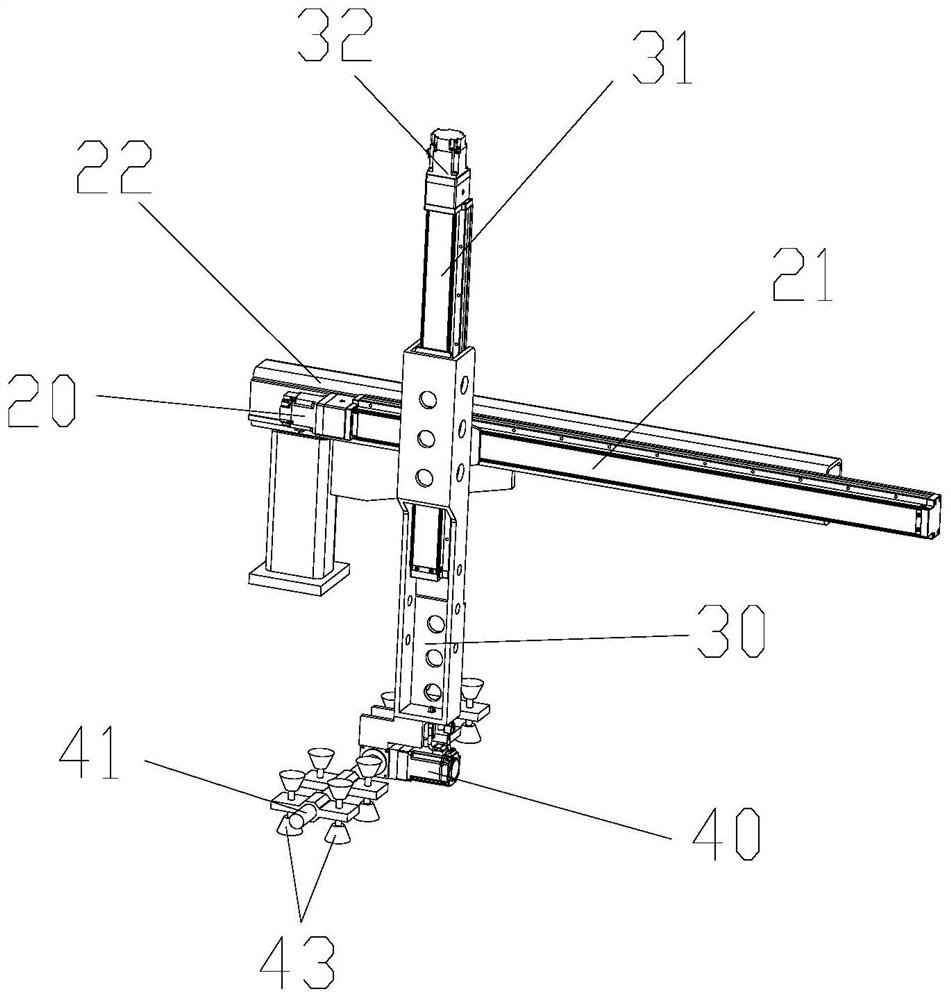

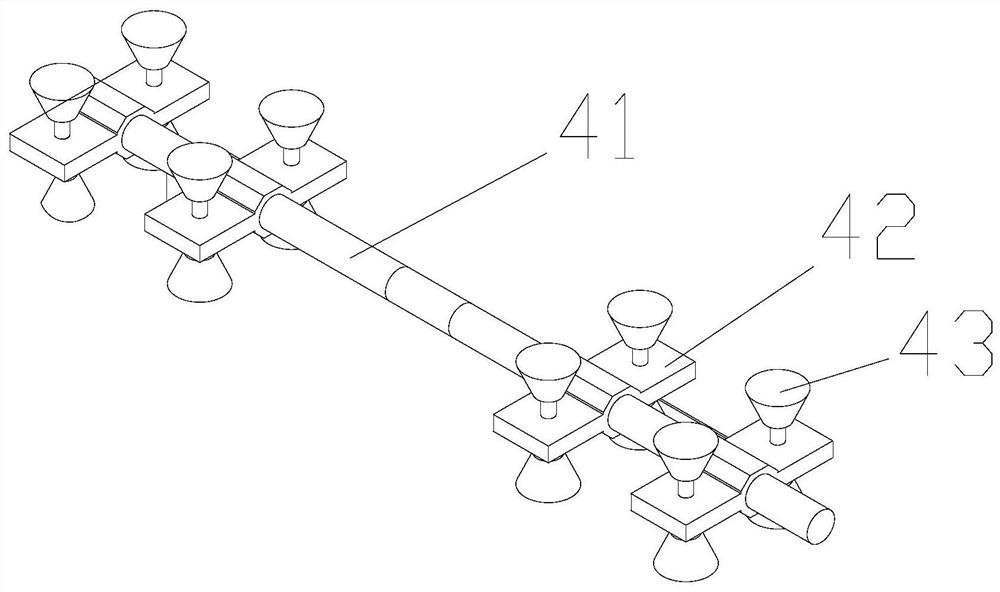

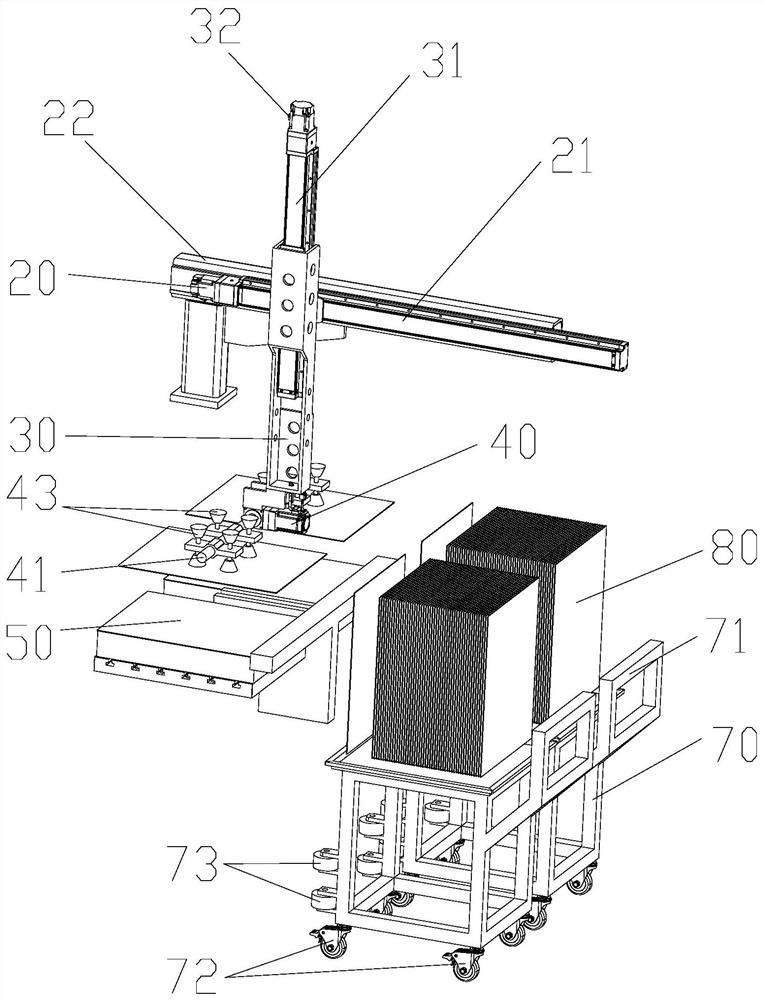

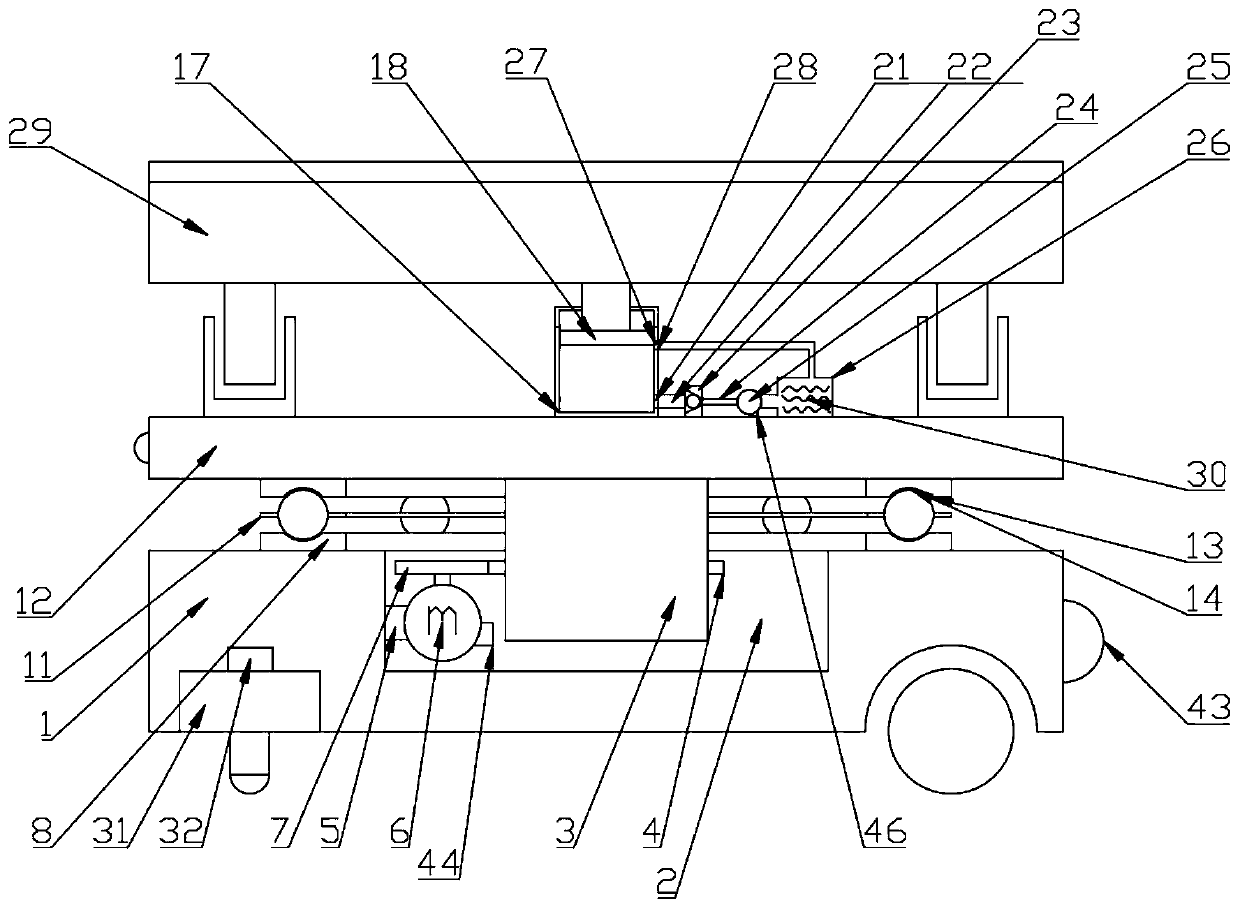

Wheel type conversion feeding and discharging device and numerically-controlled machine tool

PendingCN112338618AImprove loading and unloading efficiencySave time for loading and unloadingMetal working apparatusNumerical controlEngineering

Owner:湖南翘楚智能科技有限公司

Multipath all-phase microwave numerical-control phase shifter control system and method

InactiveCN105974369AReduce volumeFirmly connectedWave based measurement systemsNumerical controlTransceiver

The invention discloses a multipath all-phase microwave numerical-control phase shifter control system, and the system comprises a far end and a local end. The far end comprises control software, a computer and an optical fiber transceiver A, wherein the control software, the computer and the optical fiber transceiver A are connected sequentially. The local end comprises an optical fiber transceiver B, a serial port server, a time sequence controller and a numerical control phase shifter, wherein the optical fiber transceiver B, the serial port server, the time sequence controller and the numerical-control phase shifter are connected sequentially. The optical fiber transceiver A and the optical fiber transceiver B are used for receiving and transmitting optical fiber signals in a paired manner. The system enables a numerical-control phase shifter to achieve large-scale phase shift (0-360 degrees) in a high-frequency range, employs a mode of the serial port server + the time sequence controller for design , simplifies the connection of external cables, improves the reliability of systems, effectively solves problems that the phase precision decreases after the phase shifter carries out 180-degree shift (reverse) and there is a nonlinear change, and guarantees that the phase precision is less than 2.5 degrees.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

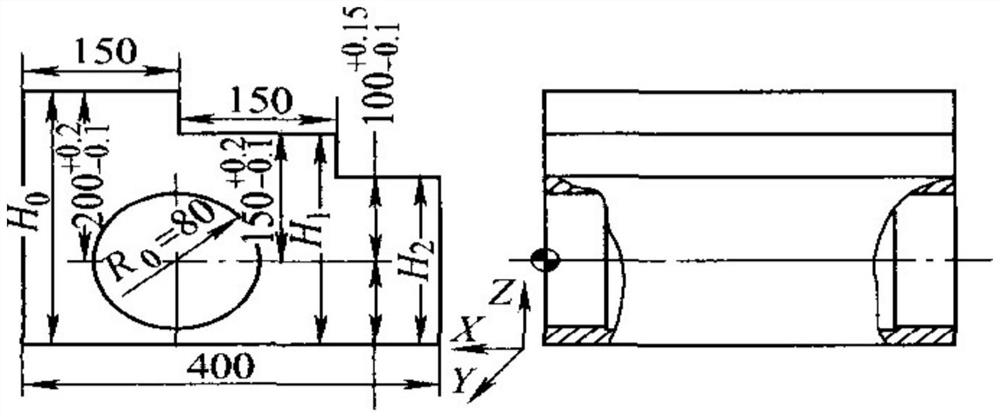

Automatic setting and online measuring method for coordinate system in numerical control machining

PendingCN113009881AGuaranteed working conditionGuaranteed machining accuracyProgramme controlComputer controlNumerical controlControl engineering

Owner:BEIJING POWER MACHINERY INST

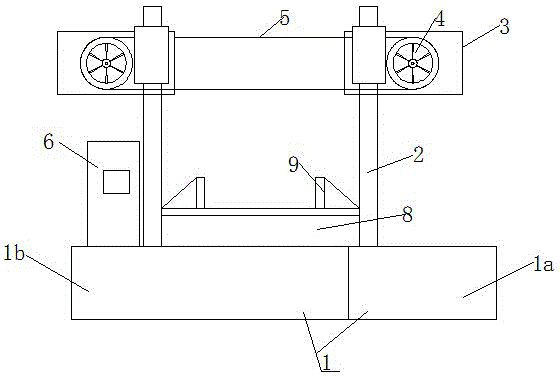

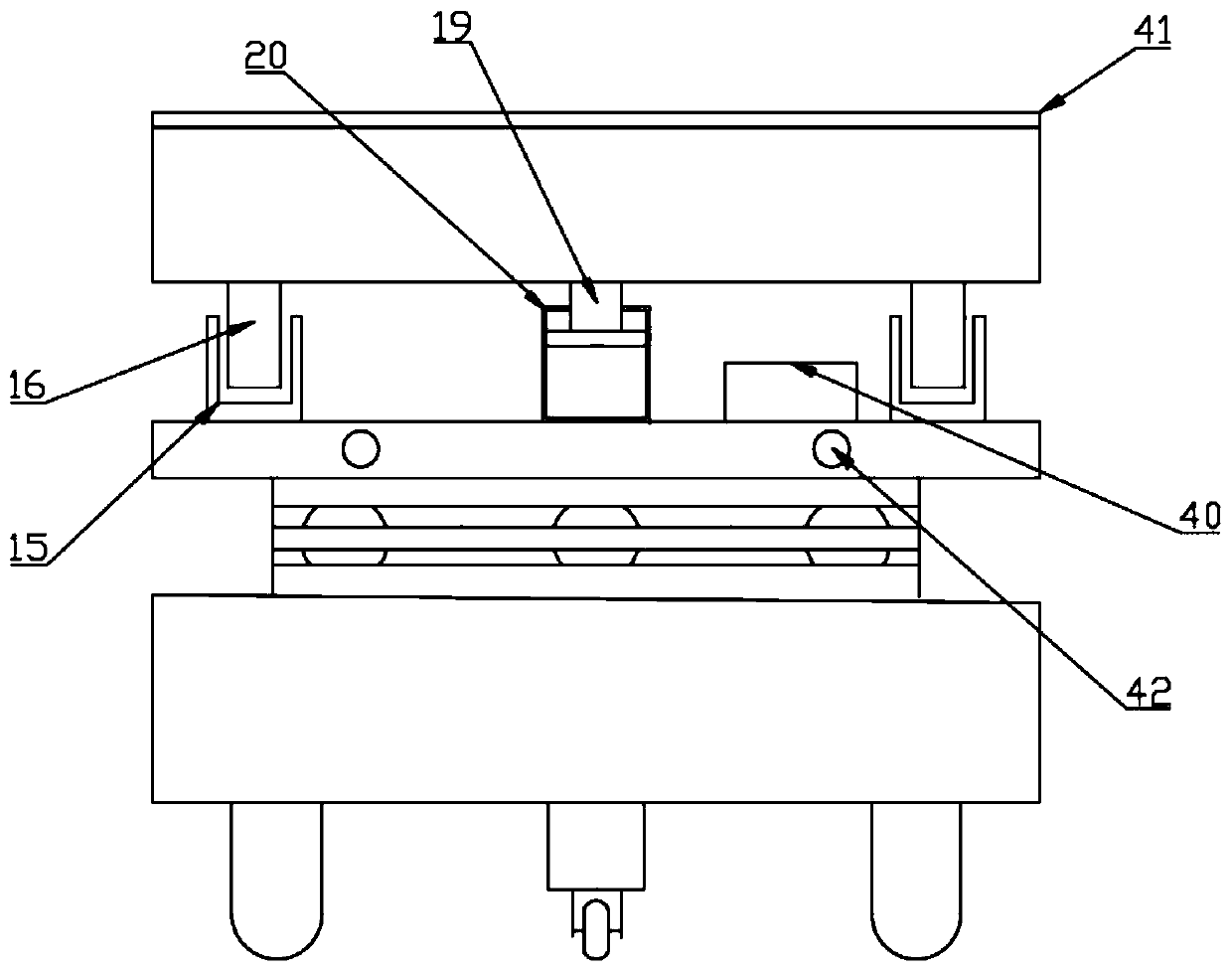

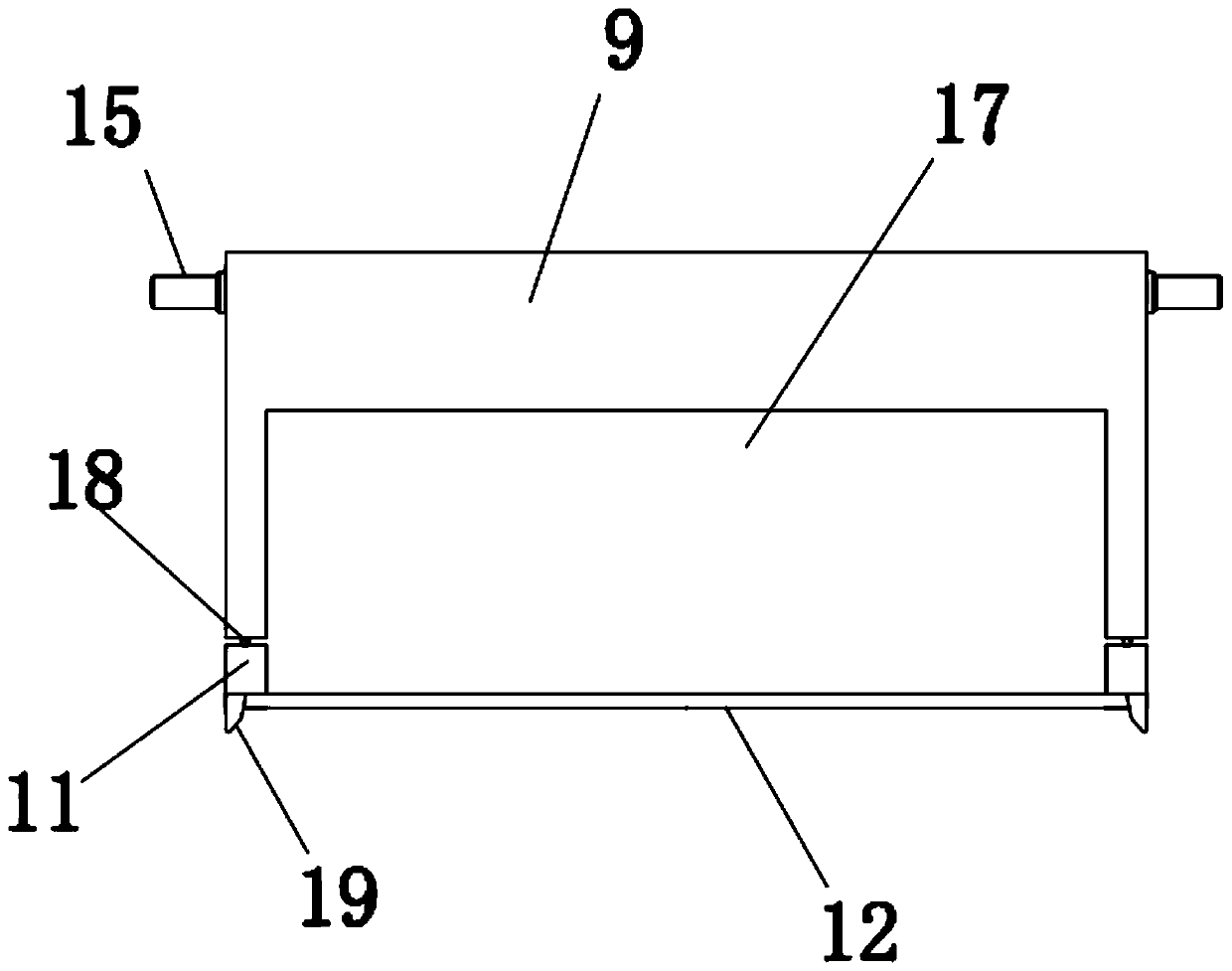

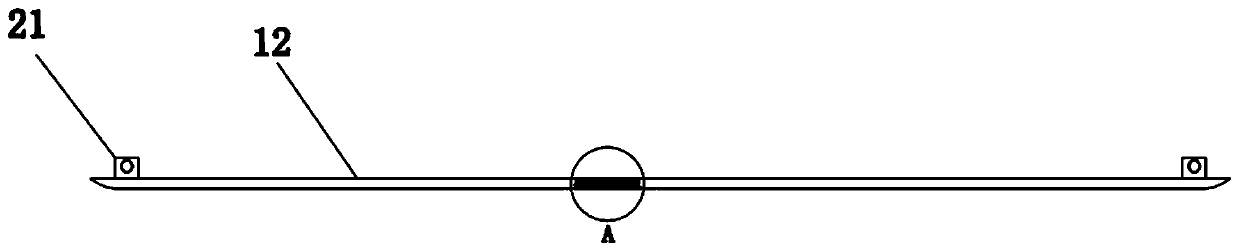

Flexible roll bending numerical control plate bending machine

PendingCN113458197AEasy to move up and downAvoid deformationMetal-working feeding devicesPositioning devicesNumerical controlHydraulic cylinder

The invention relates to the technical field of plate bending machines, in particular to a flexible roll bending numerical control plate bending machine. The machine comprises a base. A feeding box body and supporting columns are fixedly connected to the outer surface of the upper end of the base, the supporting columns are distributed behind the feeding box body in a bilateral symmetry manner, a driving roller and a driven roller are arranged between the two supporting columns, and the driving roller is located over the driven roller, and first hydraulic cylinders are fixedly connected to the outer surfaces of the upper ends of the supporting columns correspondingly. Plates with different diameters in the bending treatment process are lifted up through supporting blocks, the situation that the plates hang down and deform under the influence of gravity is avoided, the application range is widened, meanwhile, when the plates are fed, the plates with different widths are clamped and limited through limiting rollers on the two sides, the bending effect is prevented from being affected by position deviation generated during manual feeding, feeding is assisted through feeding rollers, the friction force is reduced, the pushing force of a worker for pushing a plate is conveniently reduced, and the overall working efficiency is improved.

Owner:汪新纪

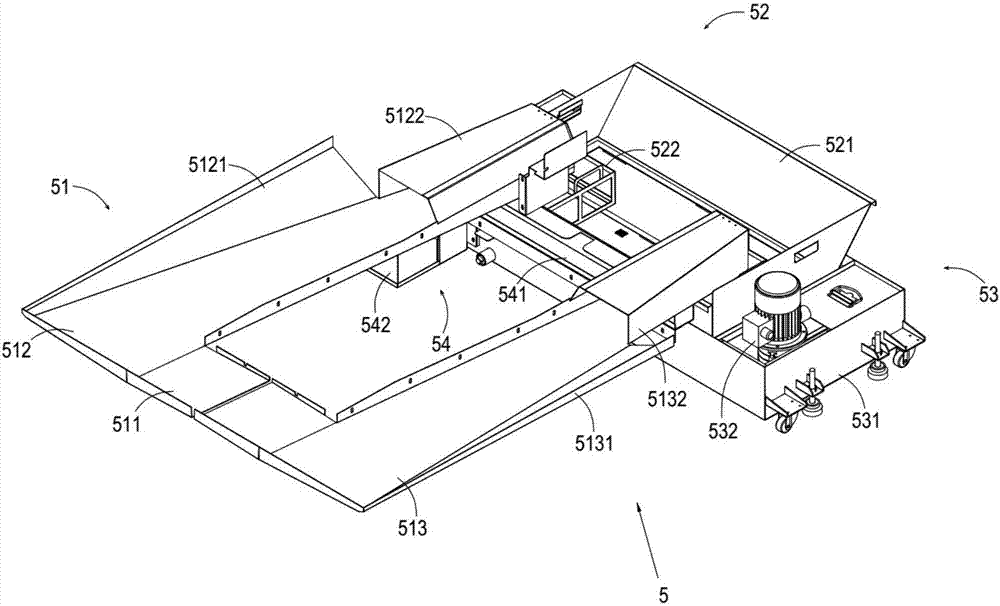

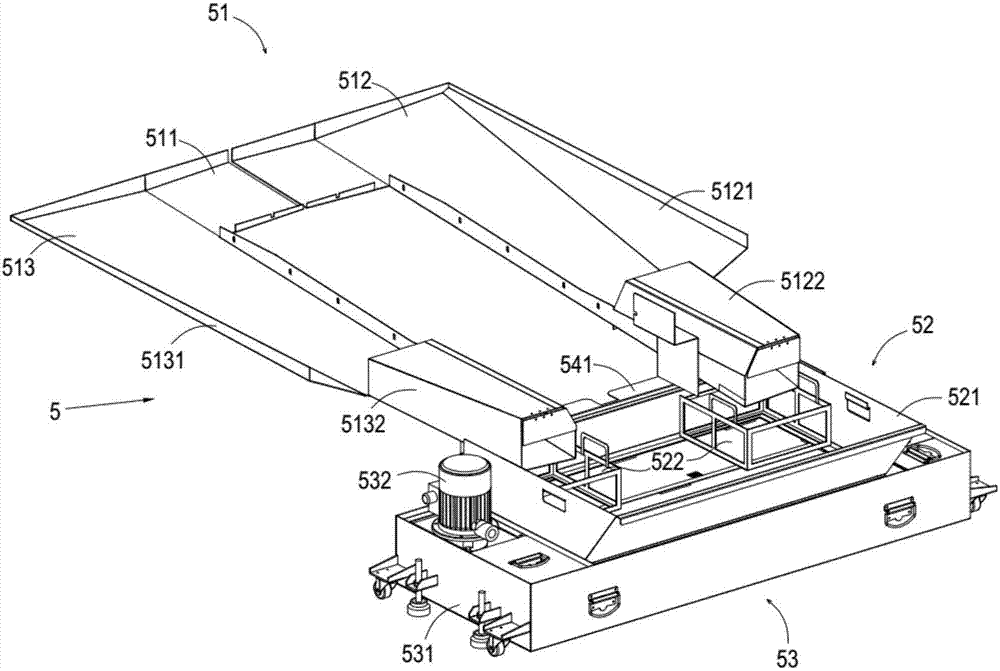

Near-water-surface cutting platform of numerical control plasma cutting machine

InactiveCN104526141AExtend the life cycleImprove cooling effectWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlEngineering

The invention relates to a near-water-surface cutting platform of a numerical control plasma cutting machine. The near-water-surface cutting platform of the numerical control plasma cutting machine comprises a water tank and a plurality of supporting columns, wherein the supporting columns are evenly arranged on the bottom face of the water tank; a detachable partition plate is arranged in the middle of the water tank, a step used for supporting the partition plate is arranged on the inner wall of the water tank, and a plurality of through holes for the supporting columns to conveniently pass are formed in the partition plate; the bottom faces of the supporting columns are provided with cooling grooves communicated with the interiors of the supporting columns, the water tank is provided with a plurality of connecting pieces for conveniently installing the supporting columns, one connecting piece corresponds to one supporting column, the connecting pieces and the supporting columns are fixedly connected through threads, and water passing holes used for being communicated with the cooling grooves in the supporting columns are formed in the connecting pieces. The near-water-surface cutting platform of the numerical control plasma cutting machine has the advantages that the near-water-surface cutting platform can be used for eliminating more than 90% of dust, and the using period of the cutting platform is prolonged by more than 3 times compared with the original using period. Certain water columns exist in the cooling grooves, and therefore heat dissipation of the supporting columns is facilitated.

Owner:HUBEI NAFU GEARING MACHINERY

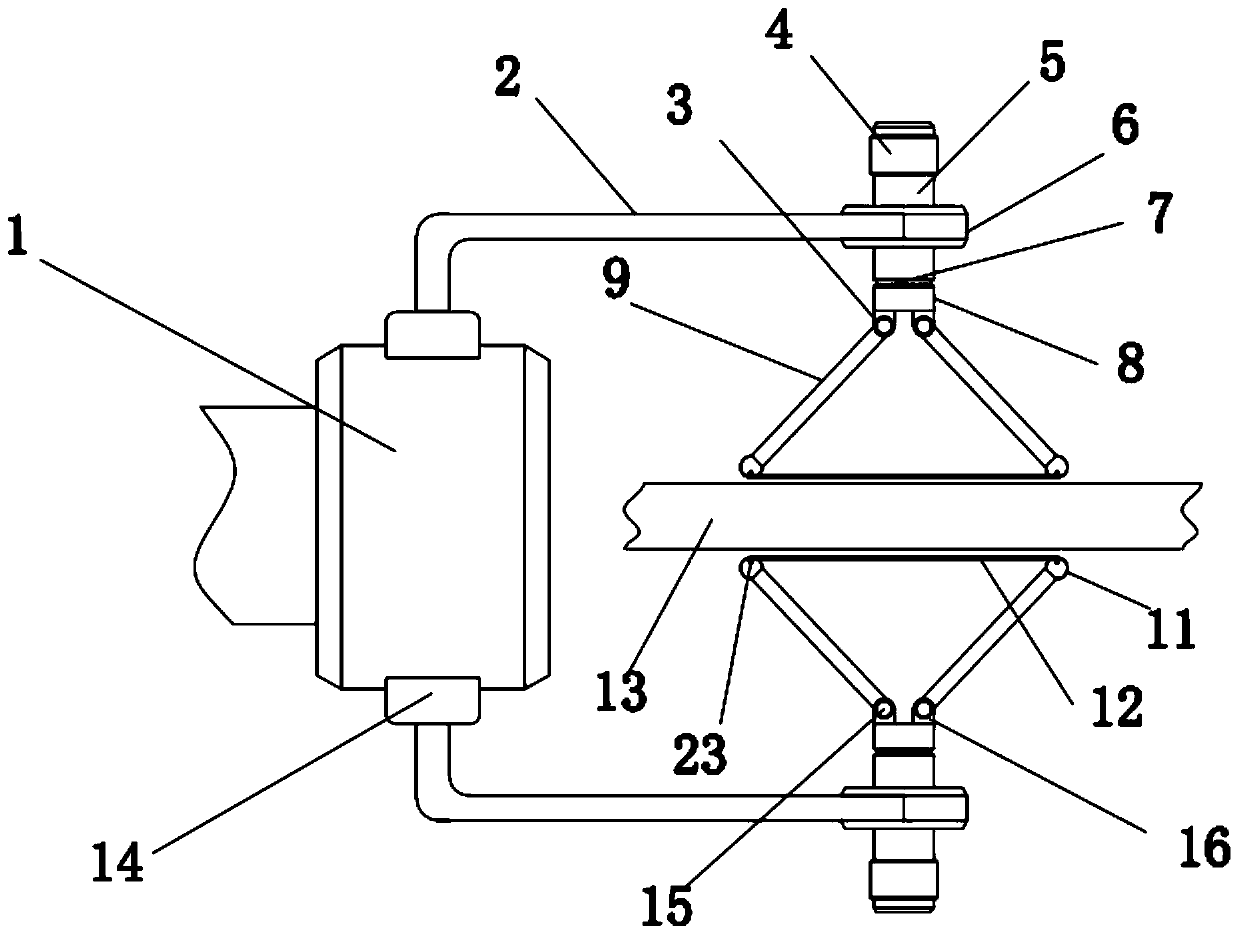

Cooling liquid recovery device for numerical control machine tool

PendingCN107470976AEfficient collectionImprove recycling rateMaintainance and safety accessoriesNumerical controlEconomic benefits

Owner:苏州富强加能精机有限公司

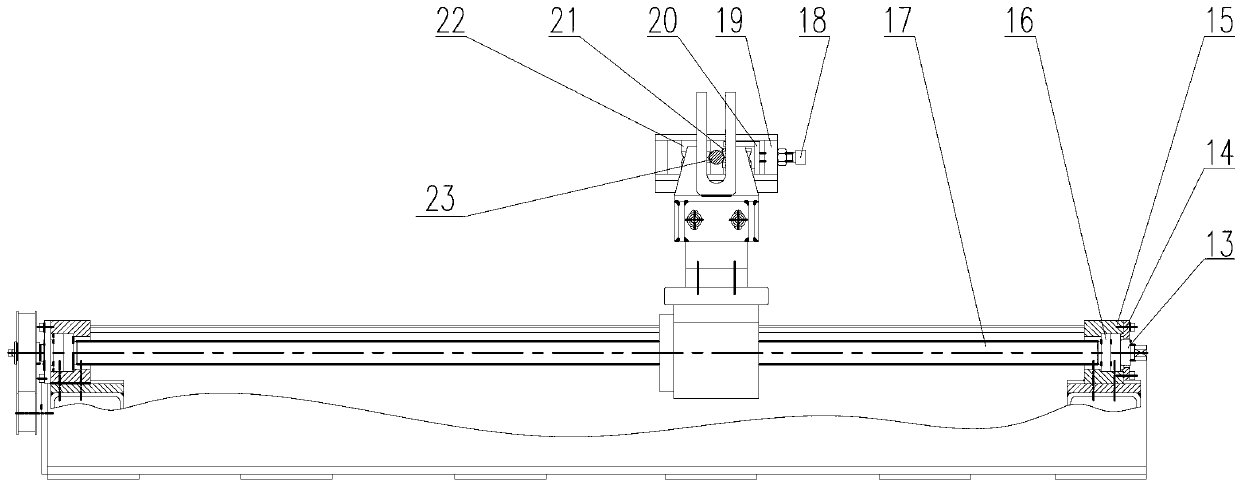

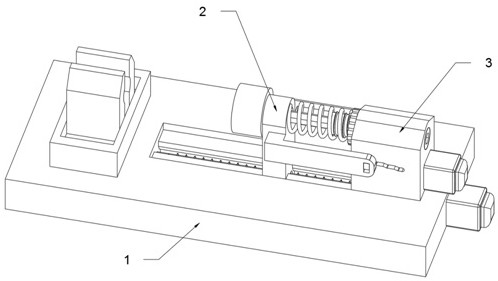

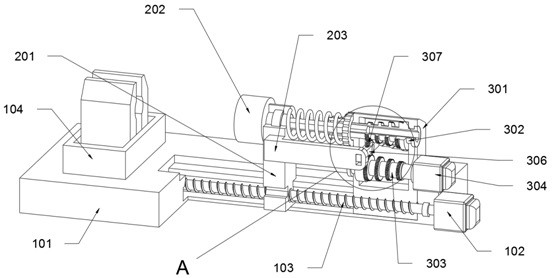

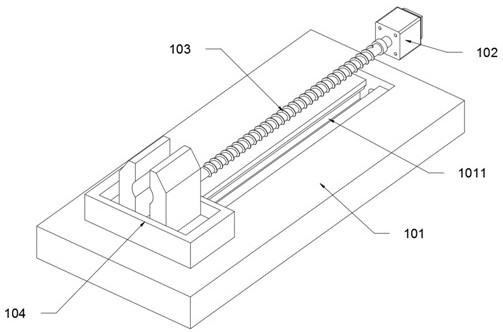

Numerical-control rope moving mechanism

InactiveCN103341749AReduce labor intensityIt takes two people to solveMetal working apparatusNumerical controlBall screw

Owner:WUXI HONGYUAN DEVFLEX

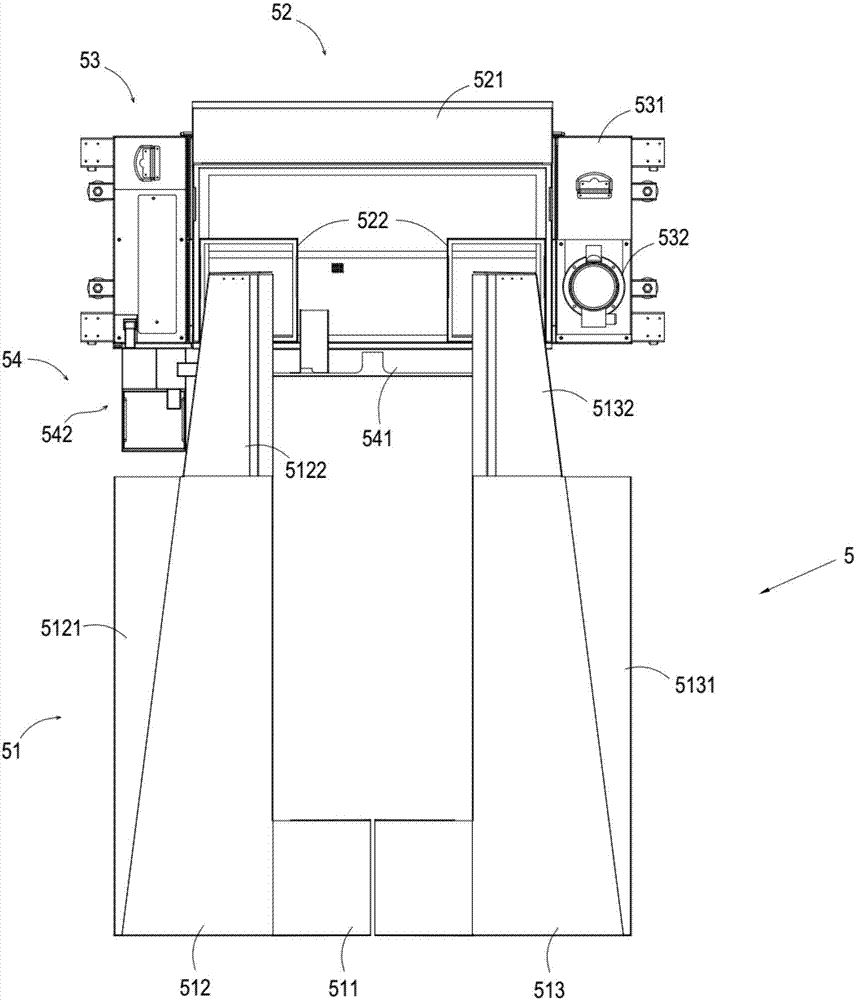

Remote-control and portable type numerical control machine tool carrier vehicle device

InactiveCN110271588AEasy to moveEasy to useTransmission systemsHand carts with multiple axesHydraulic cylinderNumerical control

Owner:陈承榜

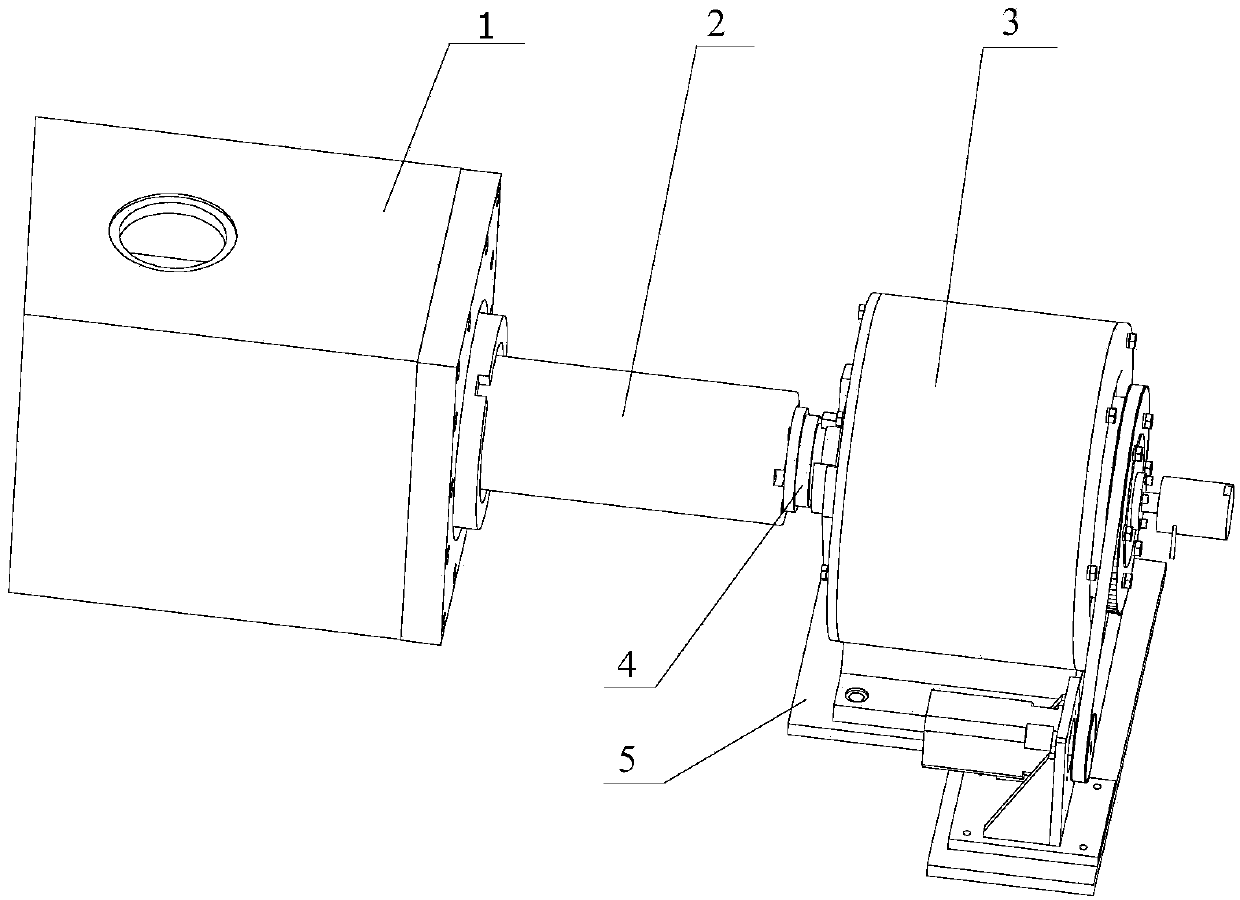

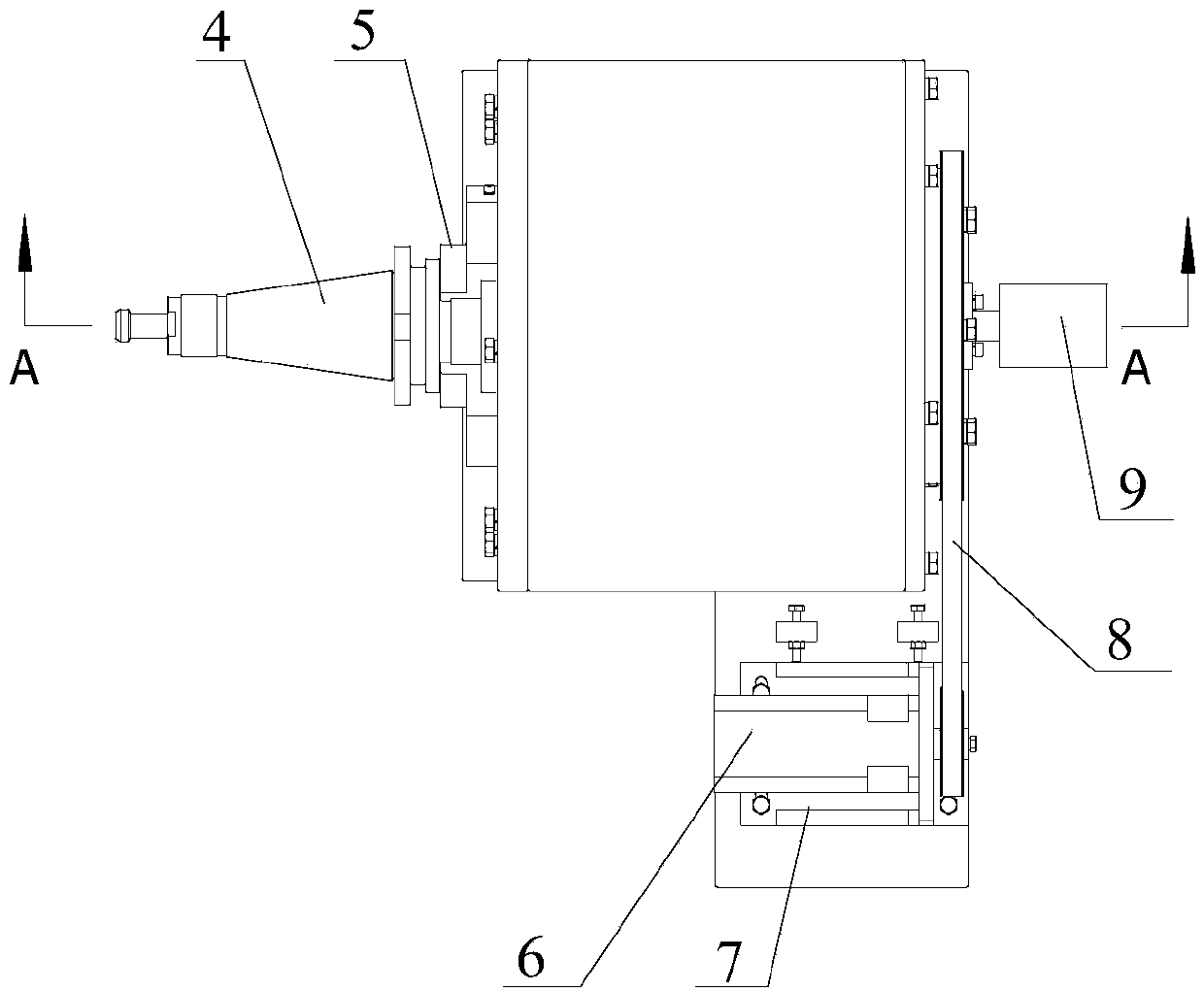

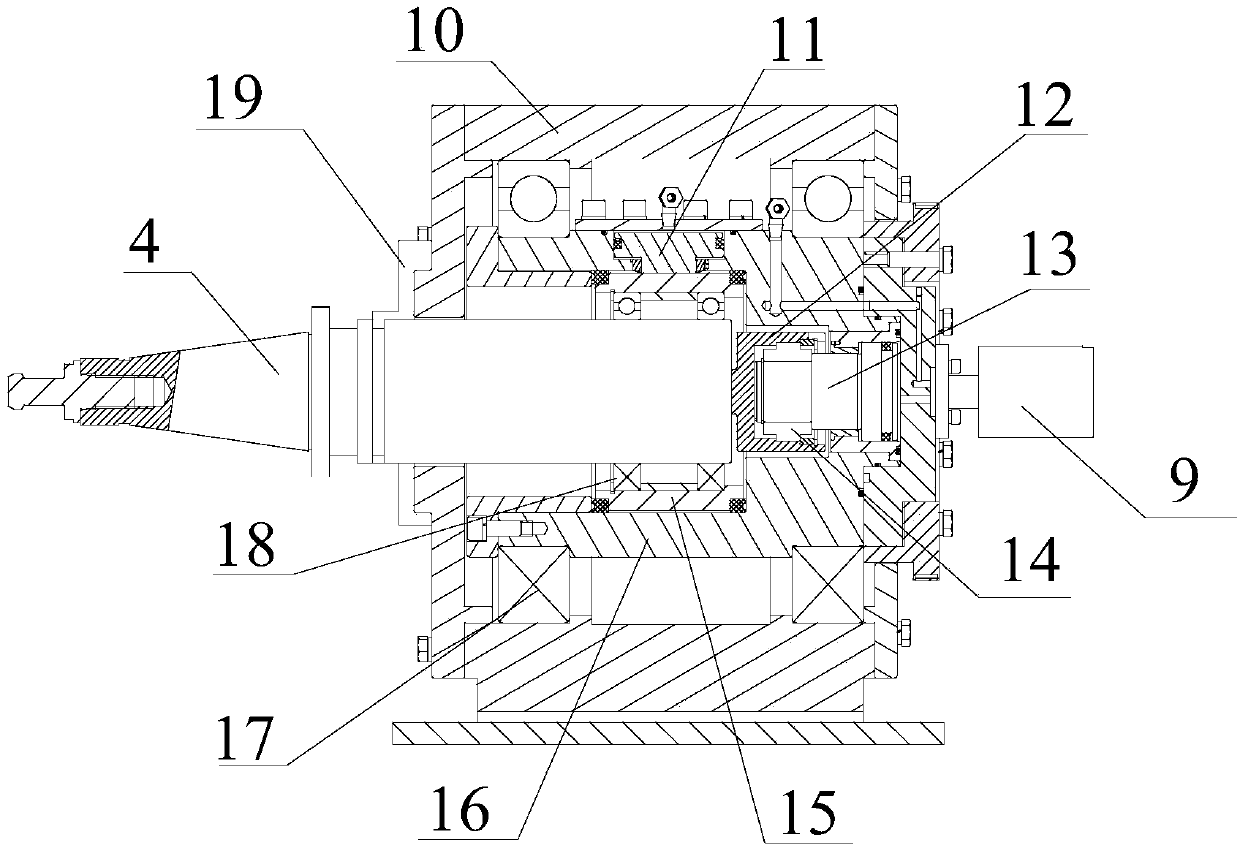

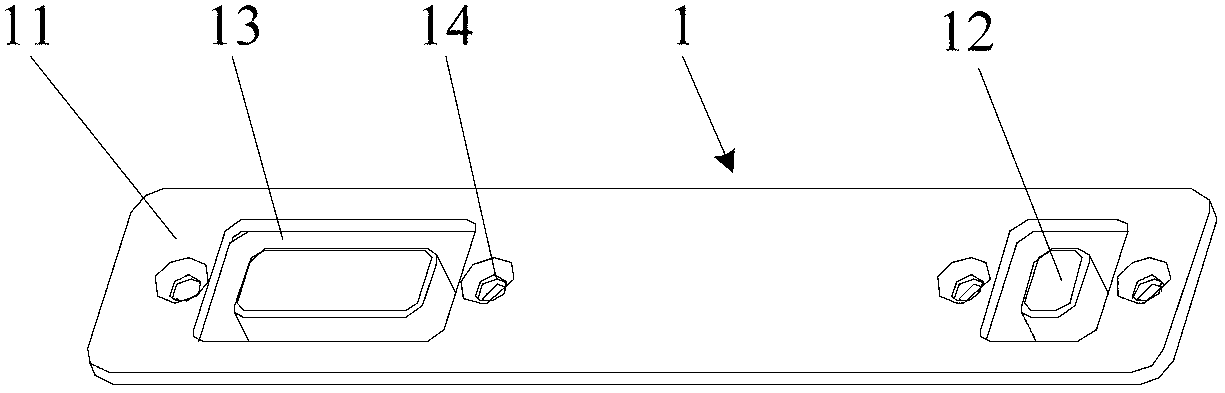

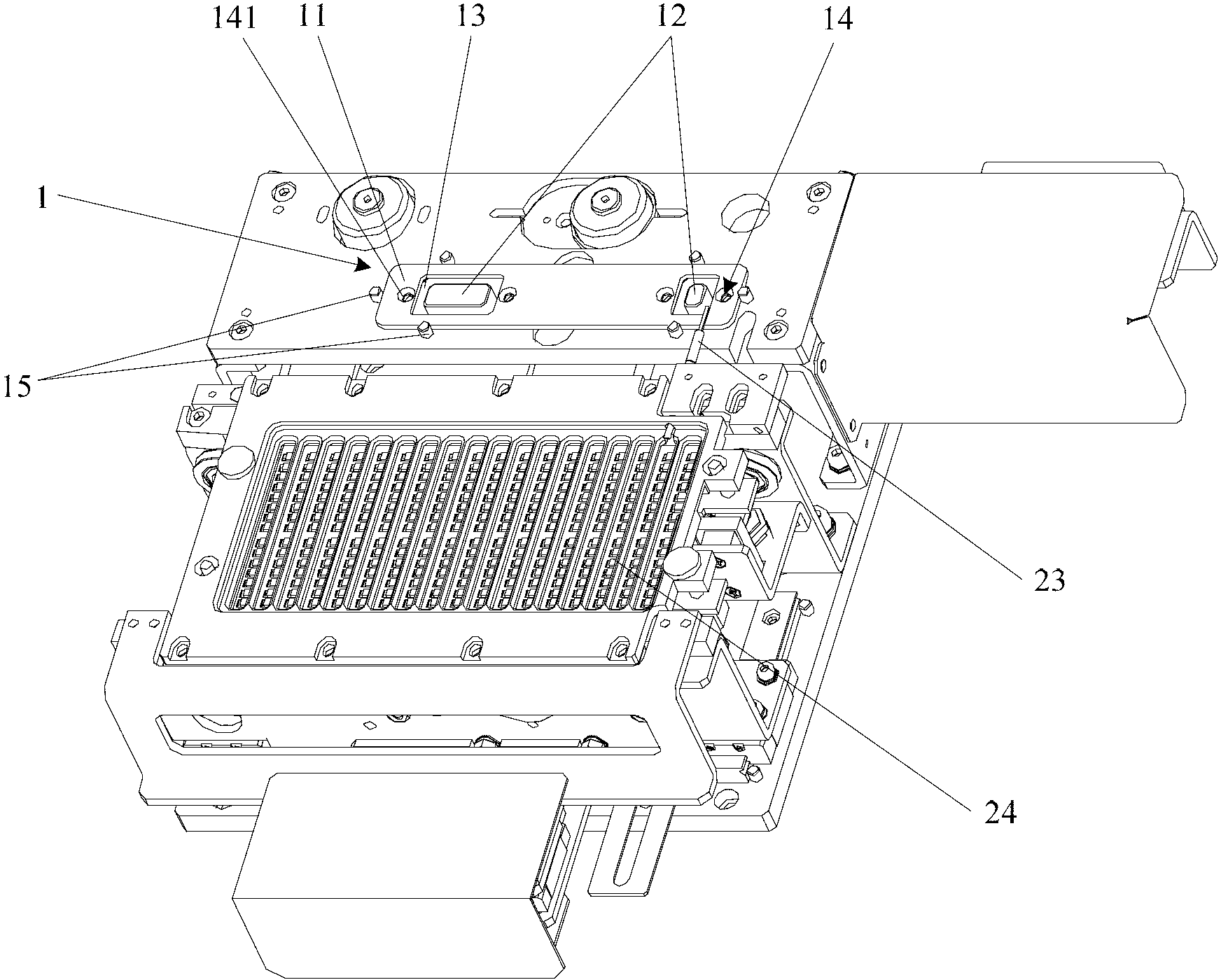

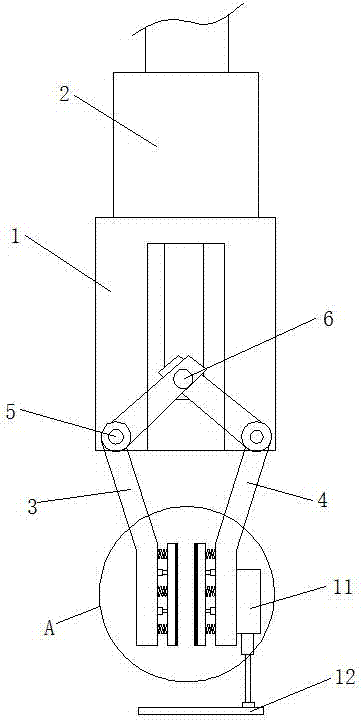

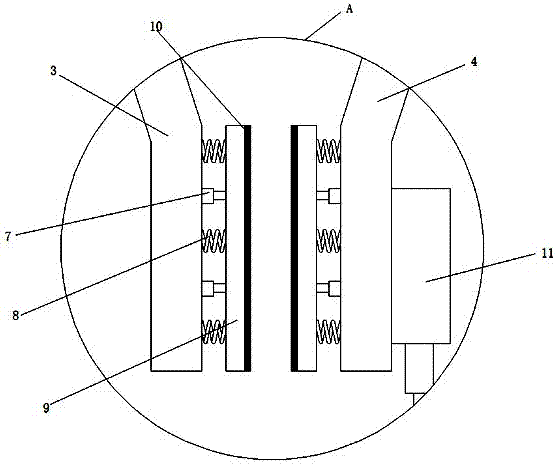

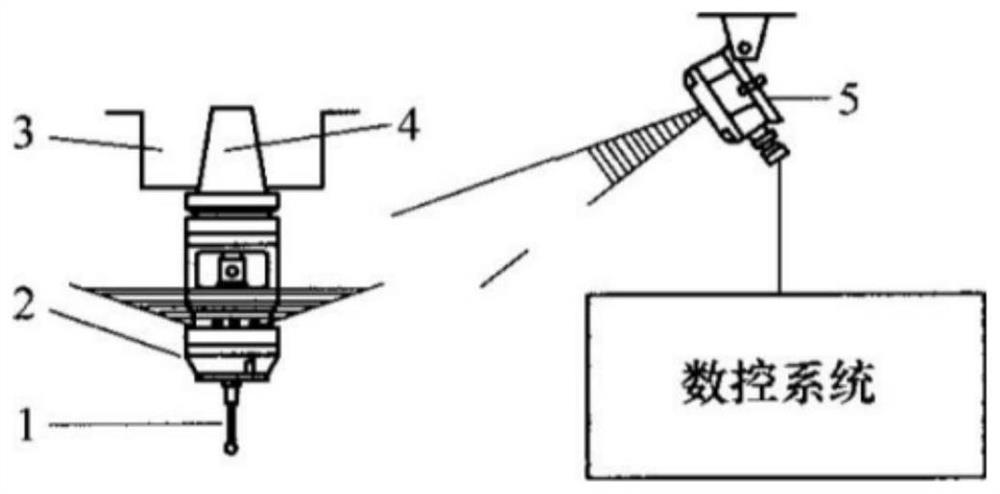

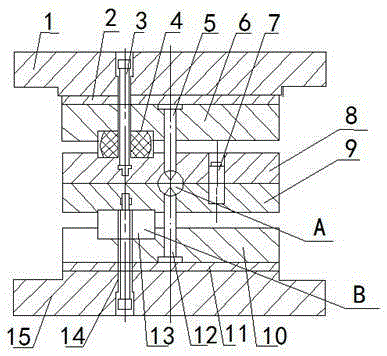

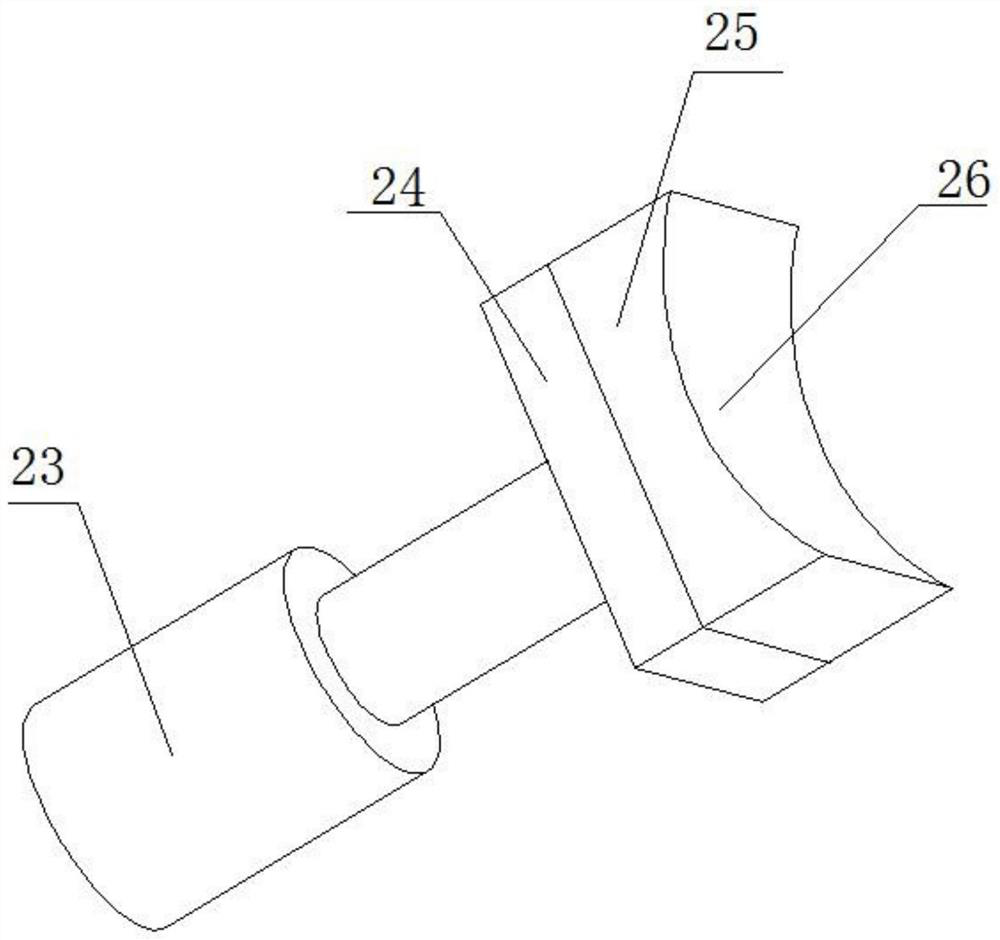

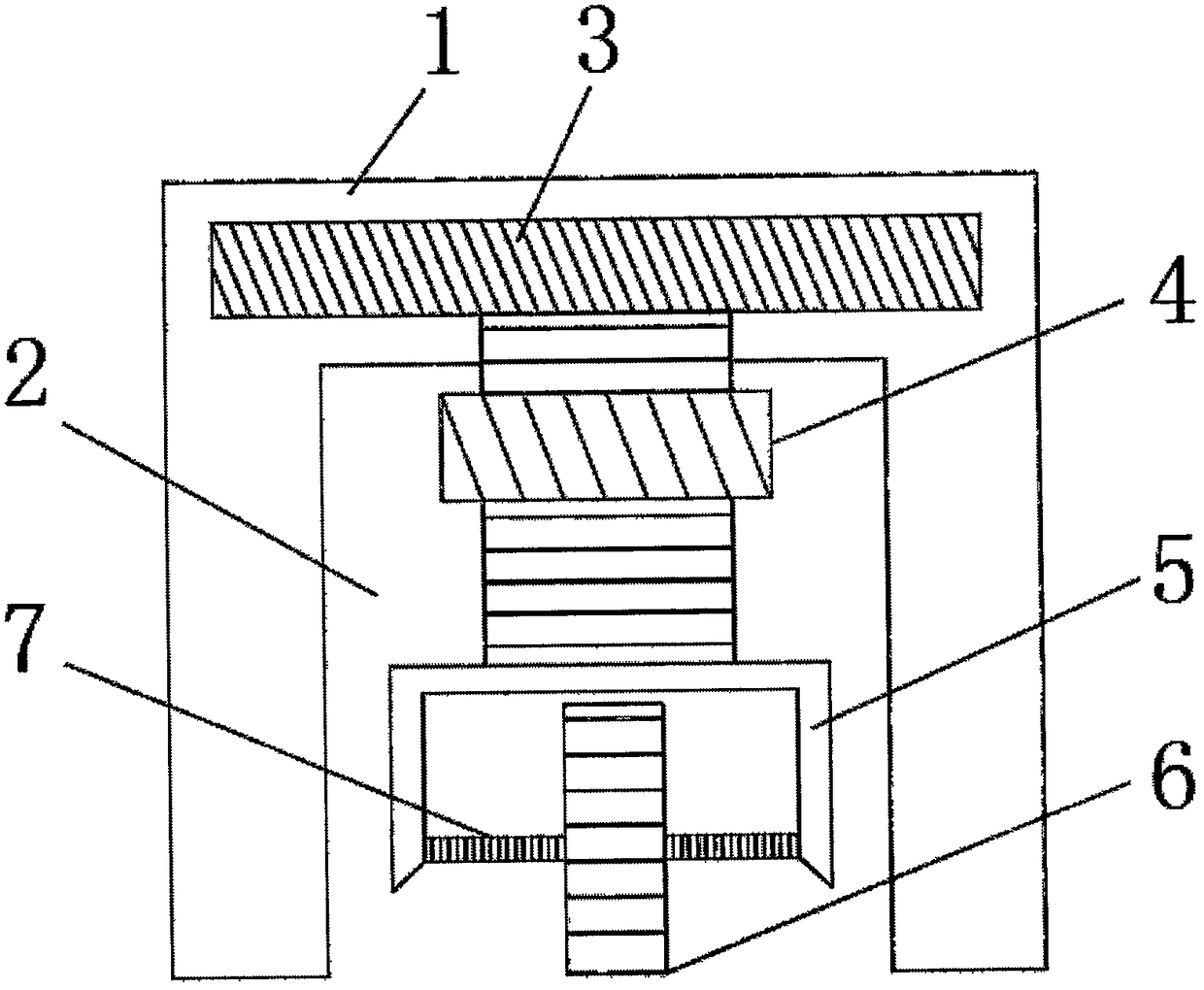

Cutter system for super-speed cutting of numerically-controlled machine tool

ActiveCN107020535AHigh cutting speedImprove machining accuracyDriving apparatusNumerical controlAviation

The invention discloses a cutter system for super-speed cutting of a numerically-controlled machine tool. The system comprises a main shaft, a housing, a locking sleeve and a cutter. The system is characterized in that the upper end of the main shaft is connected with the numerically-controlled machine tool; an input bearing is mounted at the lower end of the main shaft and positioned on the housing; the main shaft is connected with a rotating frame, and a crankshaft is mounted on the rotating frame; an epicycloidal wheel and a cycloidal wheel bearing are mounted in the middle part of the crankshaft, and a planet gear which is engaged with a sun gear is mounted at the lower end of the crankshaft; an output bearing is mounted on the sun gear and positioned on the housing; the sun gear is connected with the upper end of the locking sleeve, and the lower end of the locking sleeve is connected with the cutter. The system has the beneficial effects that the cutting rotation speed is extremely high during the processing of aviation and precision optical devices; the processing effect is good; the processing accuracy is high; extremely high surface roughness can be obtained; the actual engineering requirement of high-speed cutting can be met; the technological gaps can be filled; and moreover, the social benefit and the economic benefit are high.

Owner:TIANJIN POLYTECHNIC UNIV

Numerical control punching die structure for round pipe

Owner:CHANGZHOU JINHAIJI MACHINERY MFG

Pneumatic numerical control threading machine

ActiveCN114406366AStable processing and useImprove stabilityThread cutting machinesNumerical controlElectric machinery

Owner:江苏中动机械科技有限公司

Heating tensile test device for numerically-controlled machine tool spindle environment reliability test

ActiveCN112485105AEasy to replaceNo lossMaterial strength using tensile/compressive forcesNumerical controlElectric machinery

Owner:JILIN UNIV

Clamping device special for numerical control machine tool

InactiveCN110449933AClamping area adjustmentPositioning apparatusMetal-working holdersNumerical controlMachine tool

Owner:ZHEJIANG YANGMING IND & TRADE CO LTD

Numerical-control four-station rotary table type tool

InactiveCN109352005AImprove work efficiencyHigh precisionBoring/drilling machinesNumerical controlUniversal joint

Owner:十堰义展机电设备有限公司

Full-automatic numerical control machine tool equipment with cleaning function

InactiveCN108453559AEasy to moveEasy to cleanMaintainance and safety accessoriesHydraulic cylinderNumerical control

Owner:珠海市技师学院

Method for carrying out planing machining for narrow grooves by virtue of numerically-controlled boring and milling machine

InactiveCN105642990ASolve processing problemsImprove processing efficiencyPlaning/slotting toolsPlaning/slotting machinesNumerical controlMilling cutter

Owner:YICHANG MARINE DIESEL ENGINE

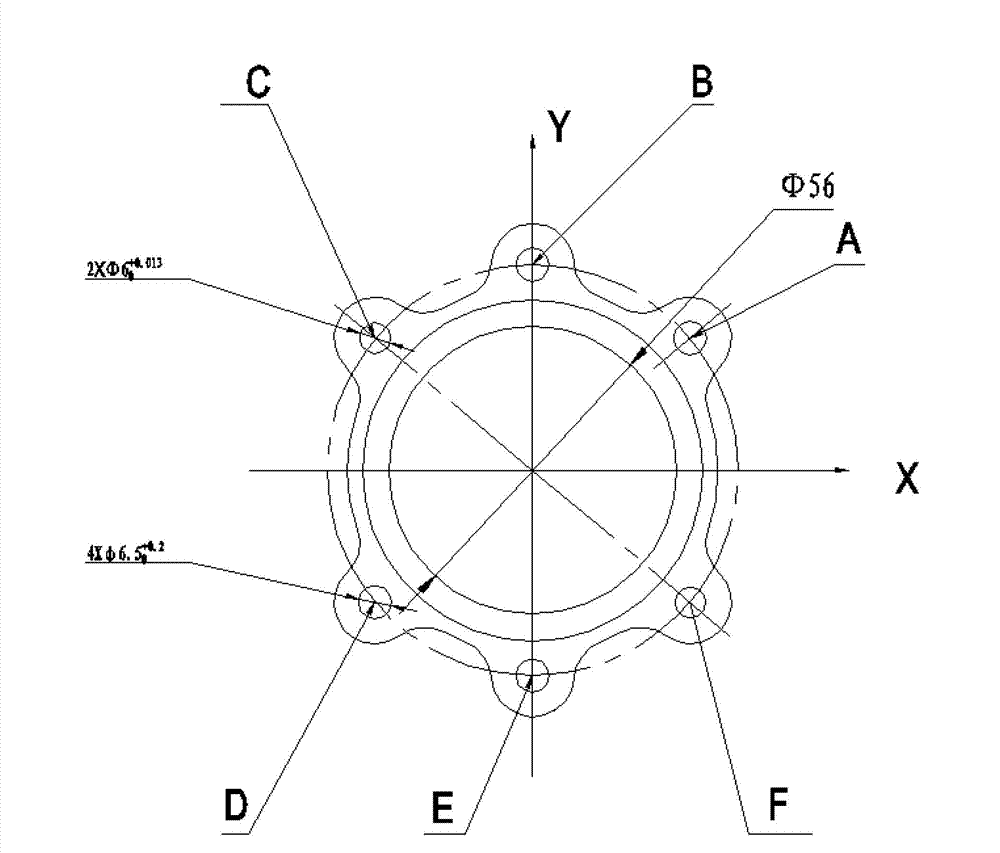

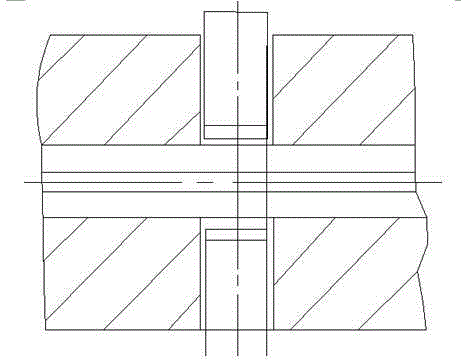

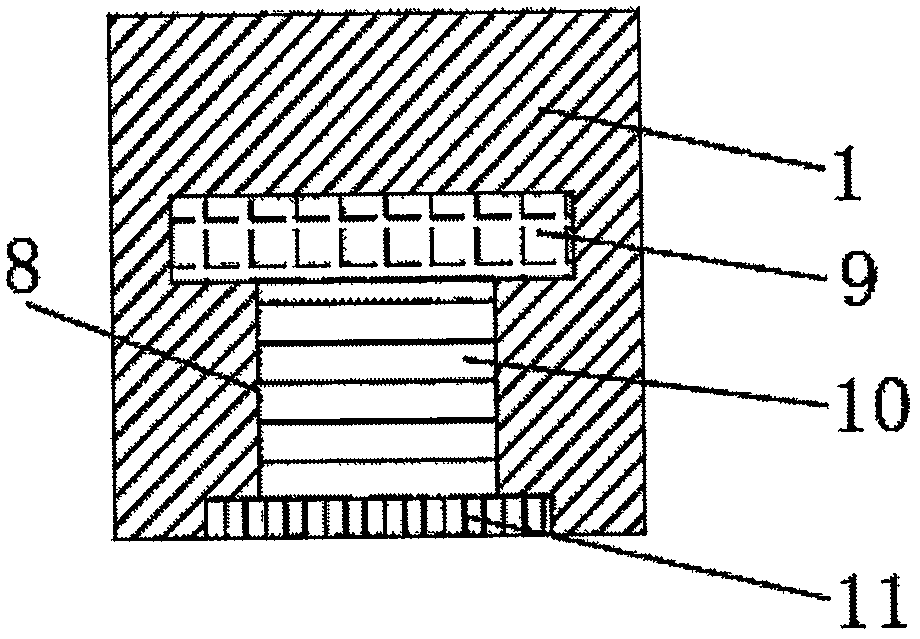

Special bush machining clamp of numerical-control vertical lathe

InactiveCN105619101AIncrease contact areaPrecise positioningPositioning apparatusMetal-working holdersNumerical controlEngineering

Owner:HARBIN

Five-axis numerical control cutting machine

ActiveCN114571276ASolve the problem that a single processing angle affects processing efficiencyEasy to operateAutomatic control devicesFeeding apparatusNumerical controlEngineering

The invention provides a five-axis numerical control cutting machine, which relates to the technical field of machining, and comprises a workbench, a mounting mechanism and a machining mechanism, a first guide rail is arranged on the workbench; the mounting mechanism comprises a first sliding seat, a second sliding seat and a mounting assembly mounted on the first sliding seat, one end face of the first sliding seat is in sliding connection with the first guide rail, the other end face of the first sliding seat is provided with a second guide rail in sliding connection with the second sliding seat, and the mounting assembly is rotationally connected with a rotating part used for placing a profile; the machining mechanism comprises a cutting assembly, a machining assembly and a fixing frame arranged on the workbench, and the cutting assembly and the machining assembly are both in sliding connection with the fixing frame. The problem that the machining efficiency is affected by the single machining angle of a traditional cutting machine is solved, and the cutting machine has the advantages of being compact in structure, replacing part of manual labor force and being high in machining efficiency.

Owner:FOSHAN NANHAI FUDA PRECISION MACHINERY

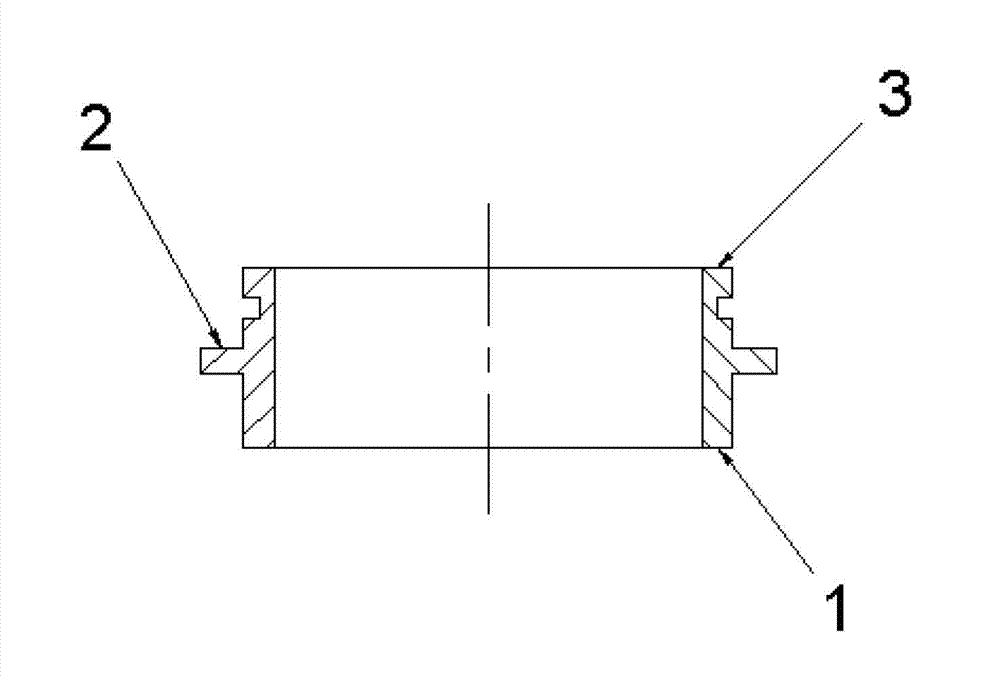

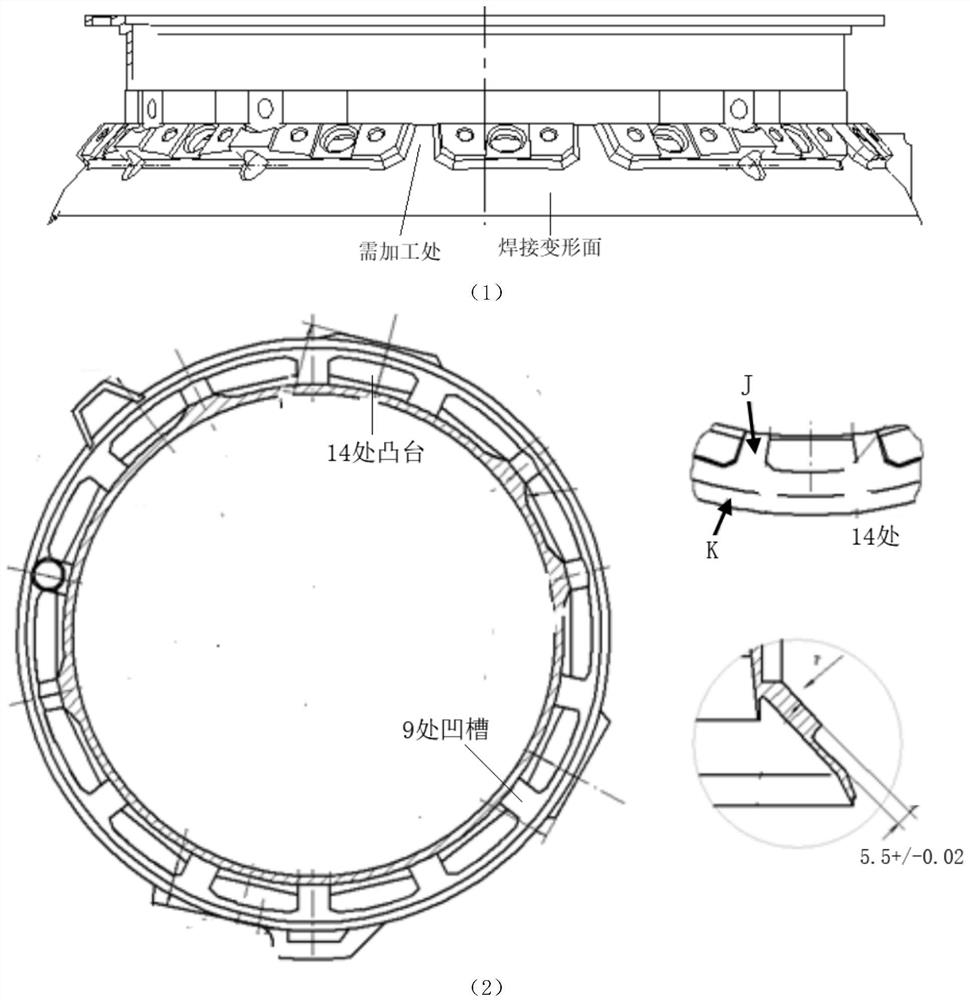

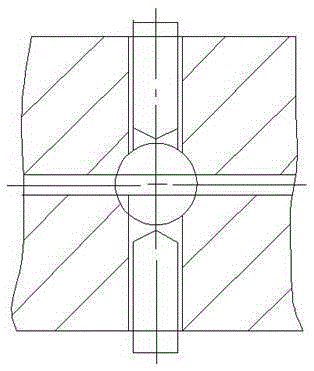

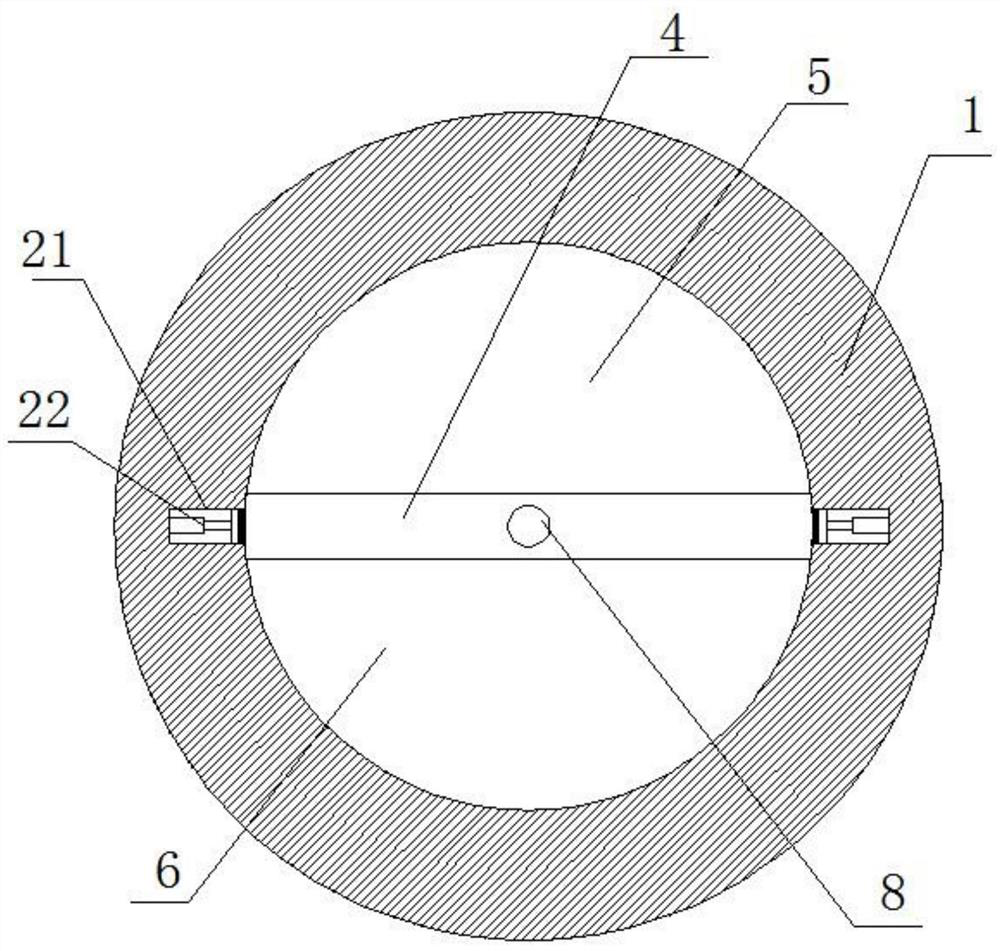

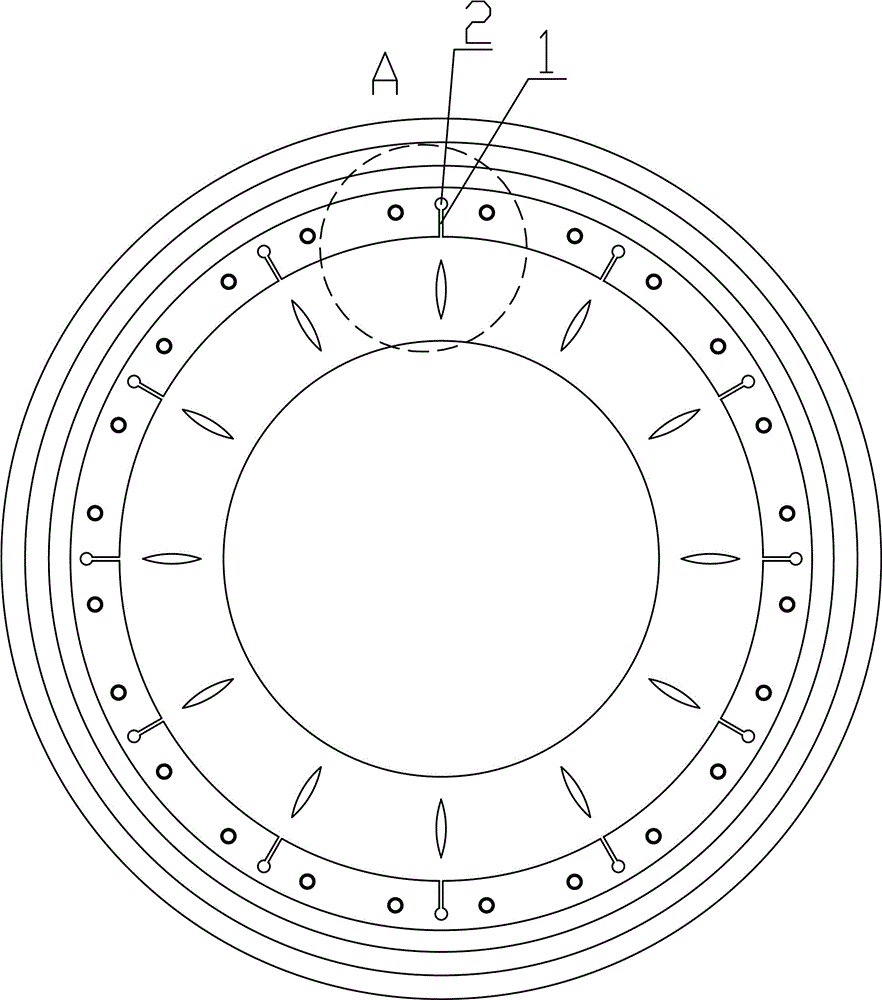

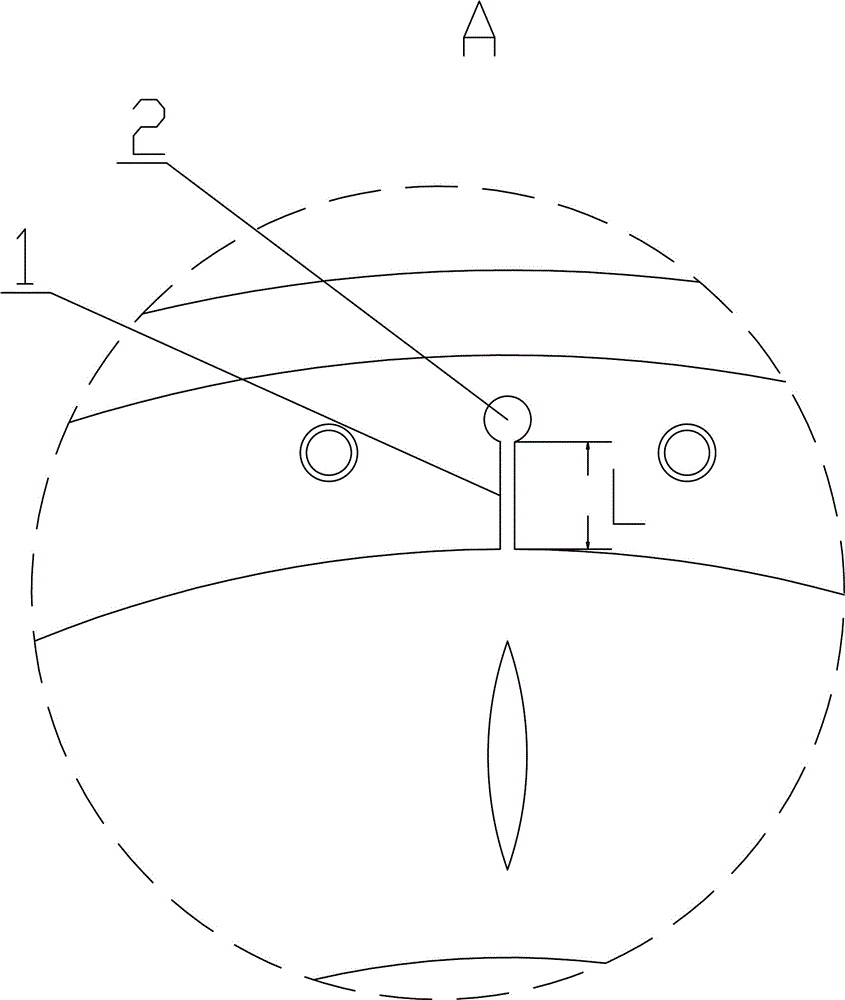

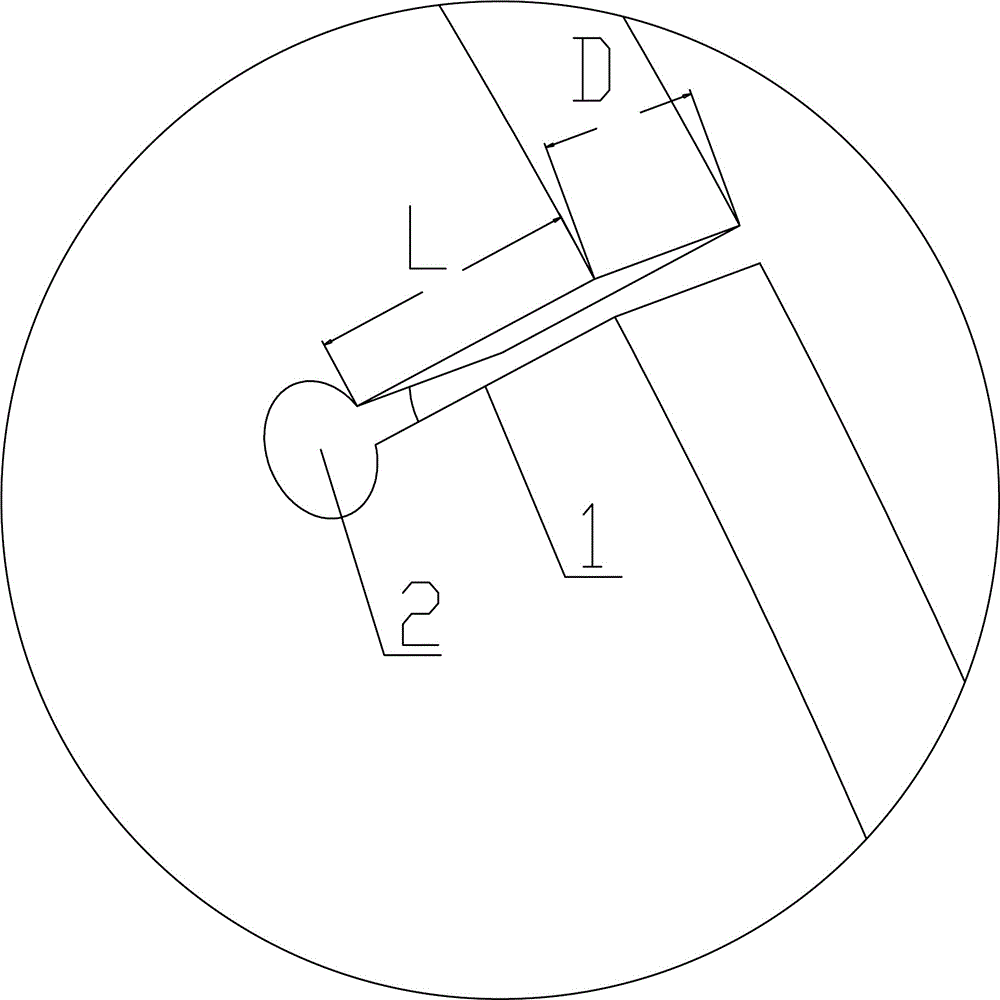

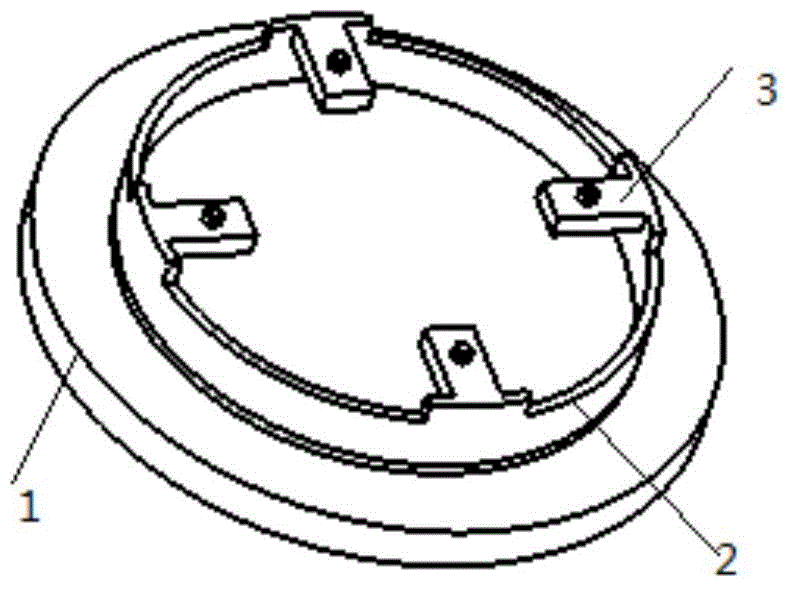

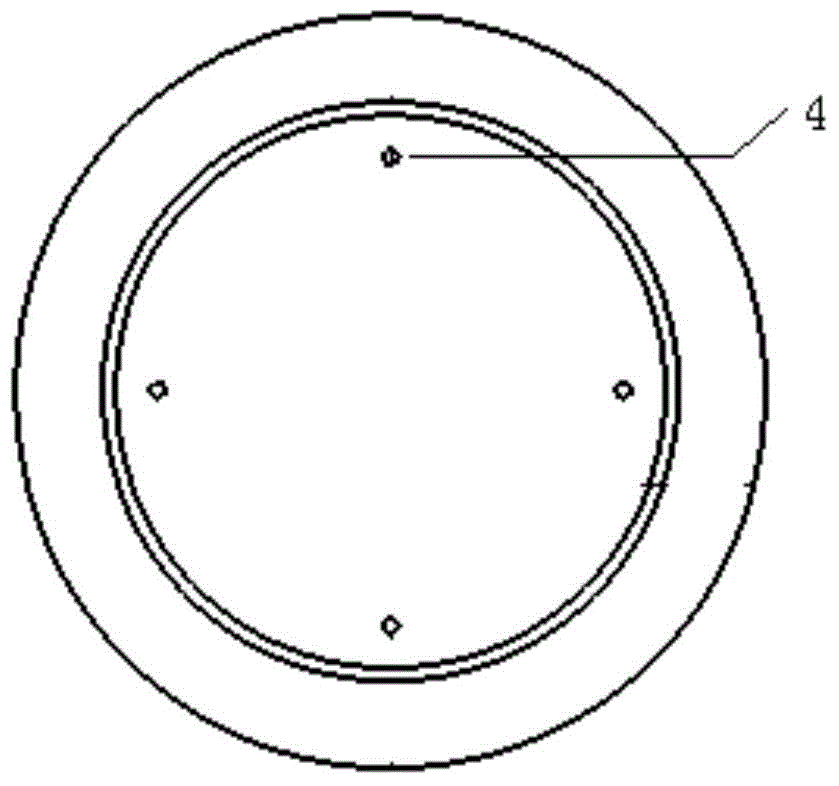

Numerically-controlled machine tool for turning of elevator guide wheels

InactiveCN102950294AEnsure consistencyHigh concentricity precisionTurning machinesNumerical controlMachine tool

The invention relates to a numerically-controlled machine tool for turning of elevator guide wheels. The numerically-controlled machine tool for turning of the elevator guide wheels comprises bases, a transverse guide rail, a guide wheel, tool rests and two cutting tools, wherein the transverse guide rail is arranged on the bases, the guide wheel is arranged on the transverse guide rail, the tool rests are arranged on two sides of the guide wheel, and the two cutting tools are fixed on the tool rests and are aligned with two ends of the guide wheel so as to coaxially turn the guide wheel. Compared with the prior art, the numerically-controlled machine tool for turning of the elevator guide wheels has the advantages of convenience in use, accuracy in positioning, easiness in mounting and demounting and the like.

Owner:SHANGHAI LONGYU ELEVATOR ACCESSORIES

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap