Numerical-control four-station rotary table type tool

A four-station, desktop technology, used in manufacturing tools, metal processing equipment, boring/drilling, etc., can solve the problems of complex operation, low precision, low work efficiency, etc., to achieve simple operation process, high precision, improved The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

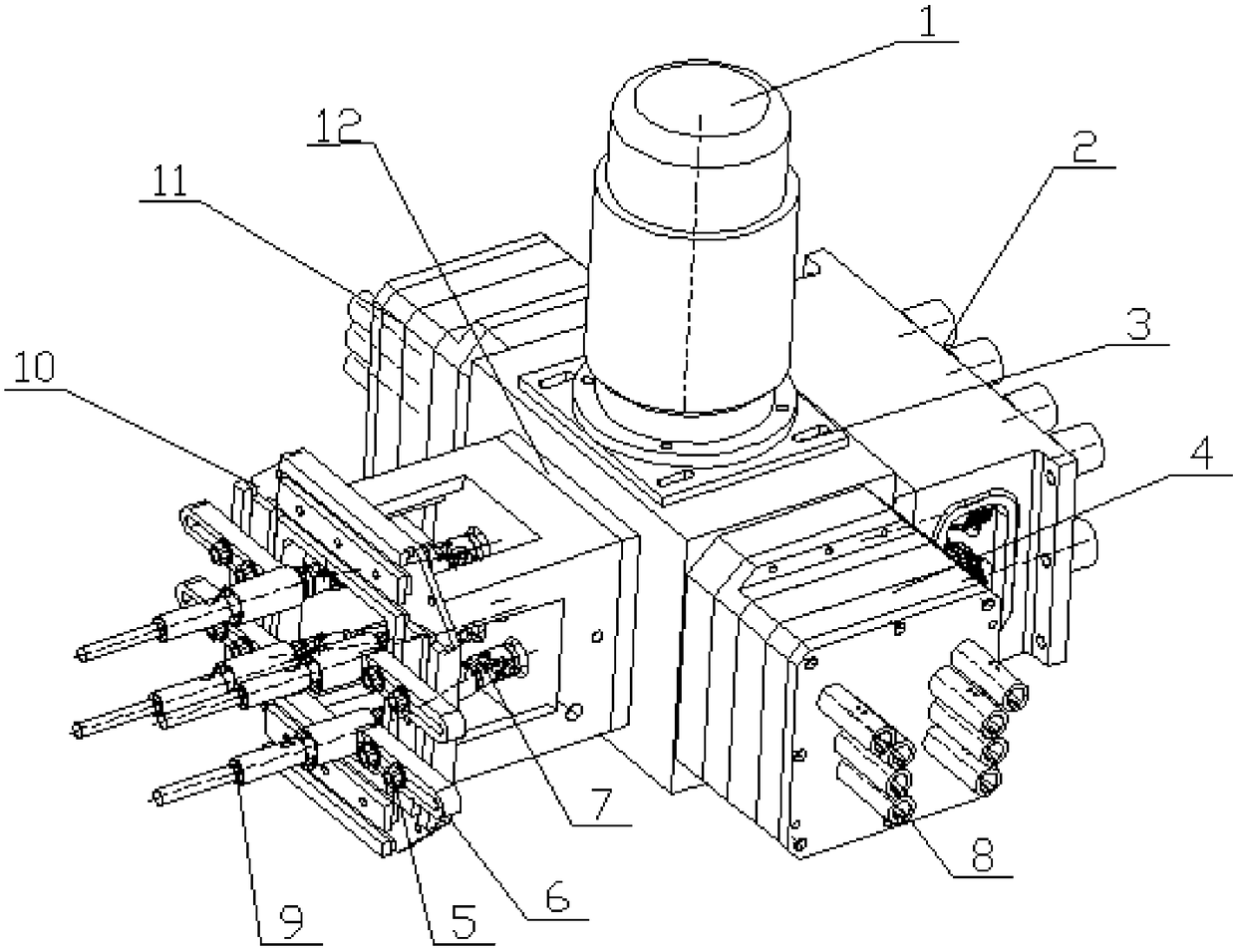

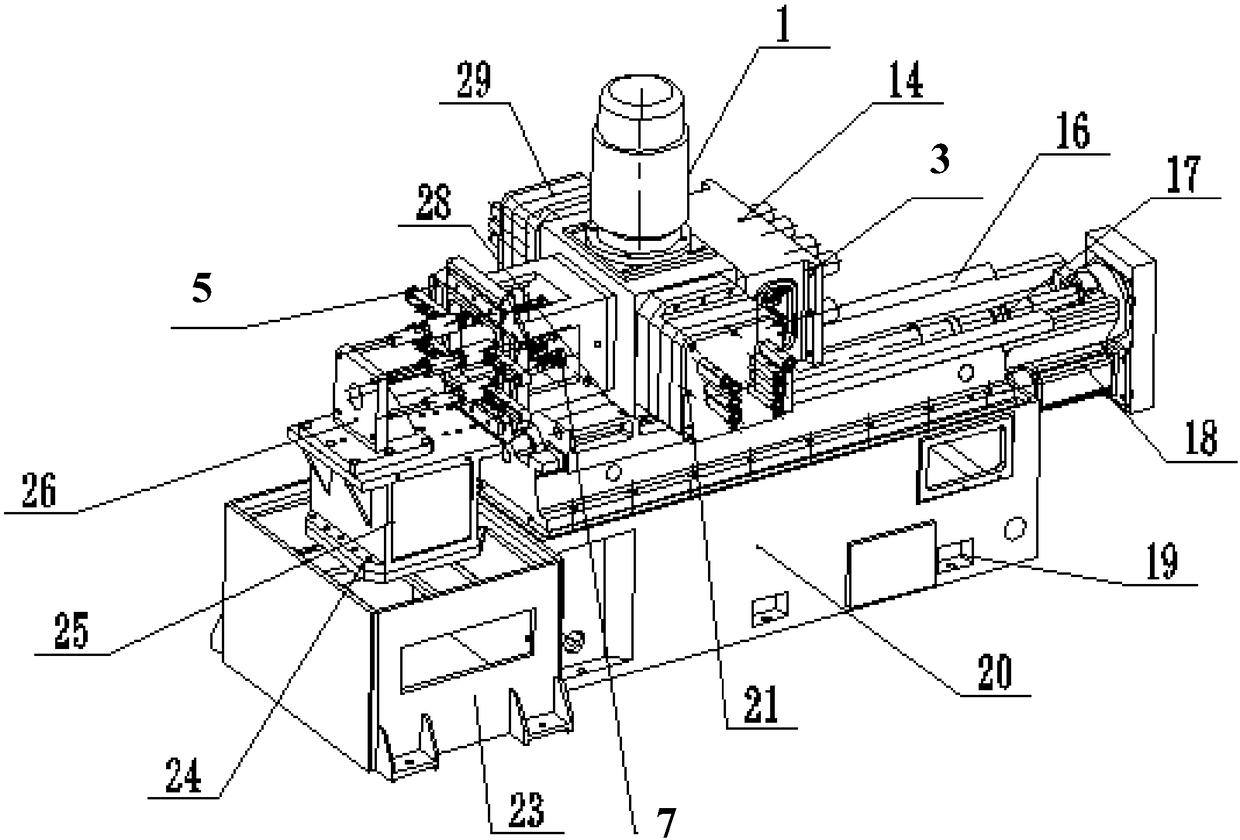

[0016] refer to Figure 1-2 , a CNC four-station turntable tooling, including a frequency conversion motor 1, an eight-axis fixed drill shaft 2, a frequency conversion motor bracket 3, a spindle box 4, an adjustable drill clamp 5, an adjustable drill chuck adjustment bolt 6, and a universal Section 7, six-axis fixed drill shaft 8, drill bit 9, transition plate 10, four-axis fixed drill shaft 11, transition plate 12, fixed eight-drill bit clamp 14, slide table 16, lead screw 17, servo motor 18, fixed position Hole 19, right base 20, fixed six drill chucks 21, middle base 23, workbench fixing hole 24, workbench support 25, clamping platform 26, rotary table

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap