Pilot dispensing device, dispensing machine and dispensing method of dispensing machine

A technology for experimenting with dispensing glue and dispensing machine, which is applied to the device and coating of the surface coating liquid, which can solve the problems of inconsistent dispensing amount of products, unqualified product quality, too much glue or too little glue, etc., and reach the guarantee point Glue precision and efficiency, manpower saving, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

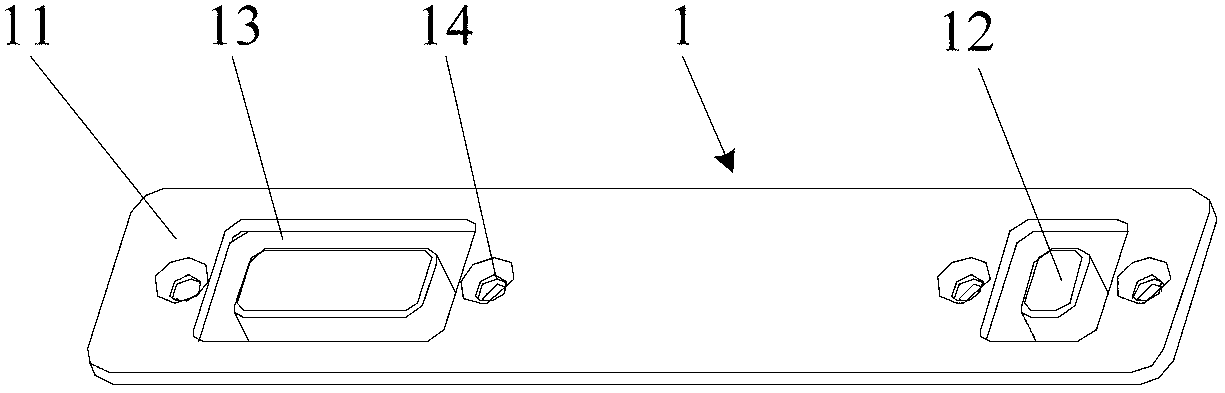

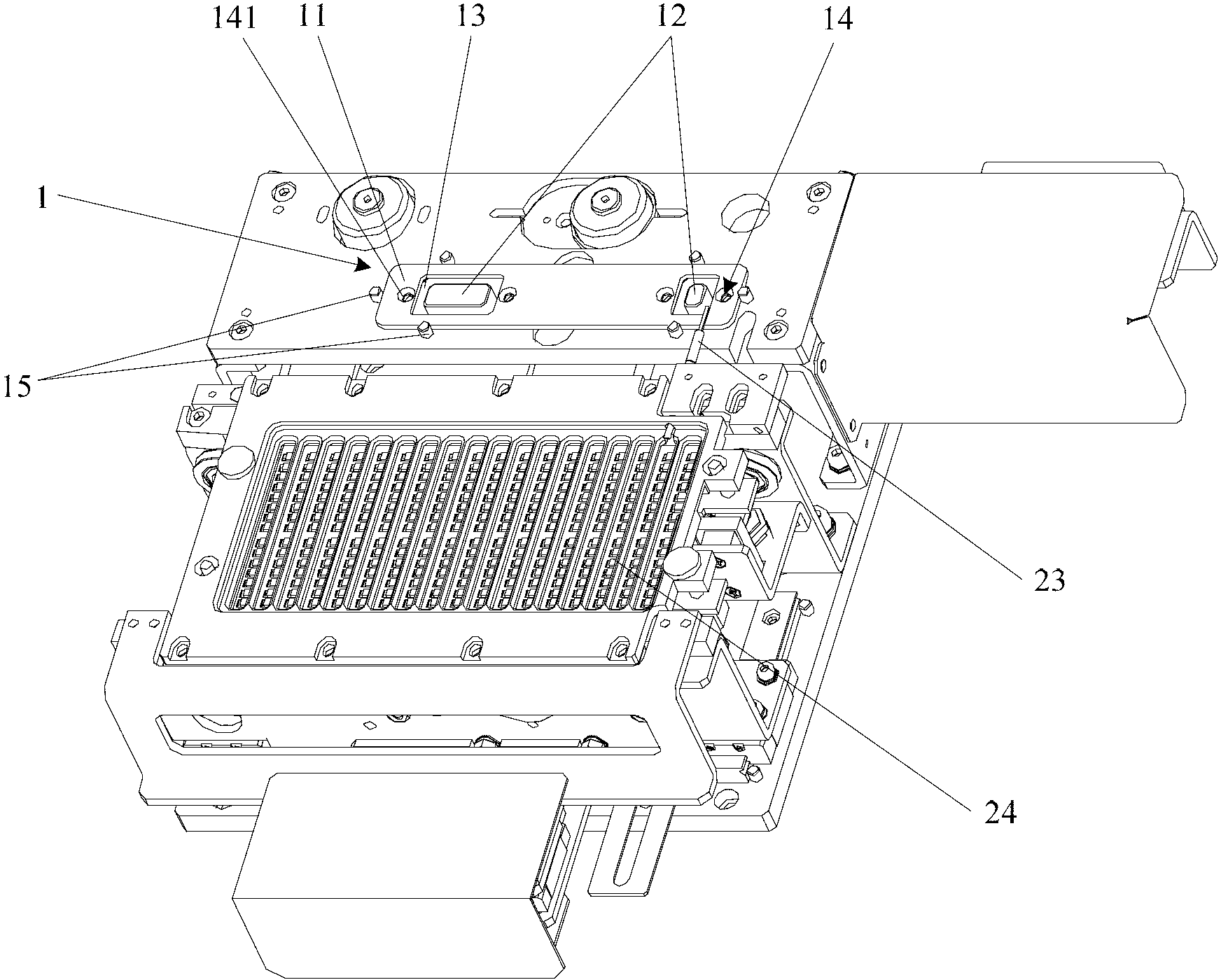

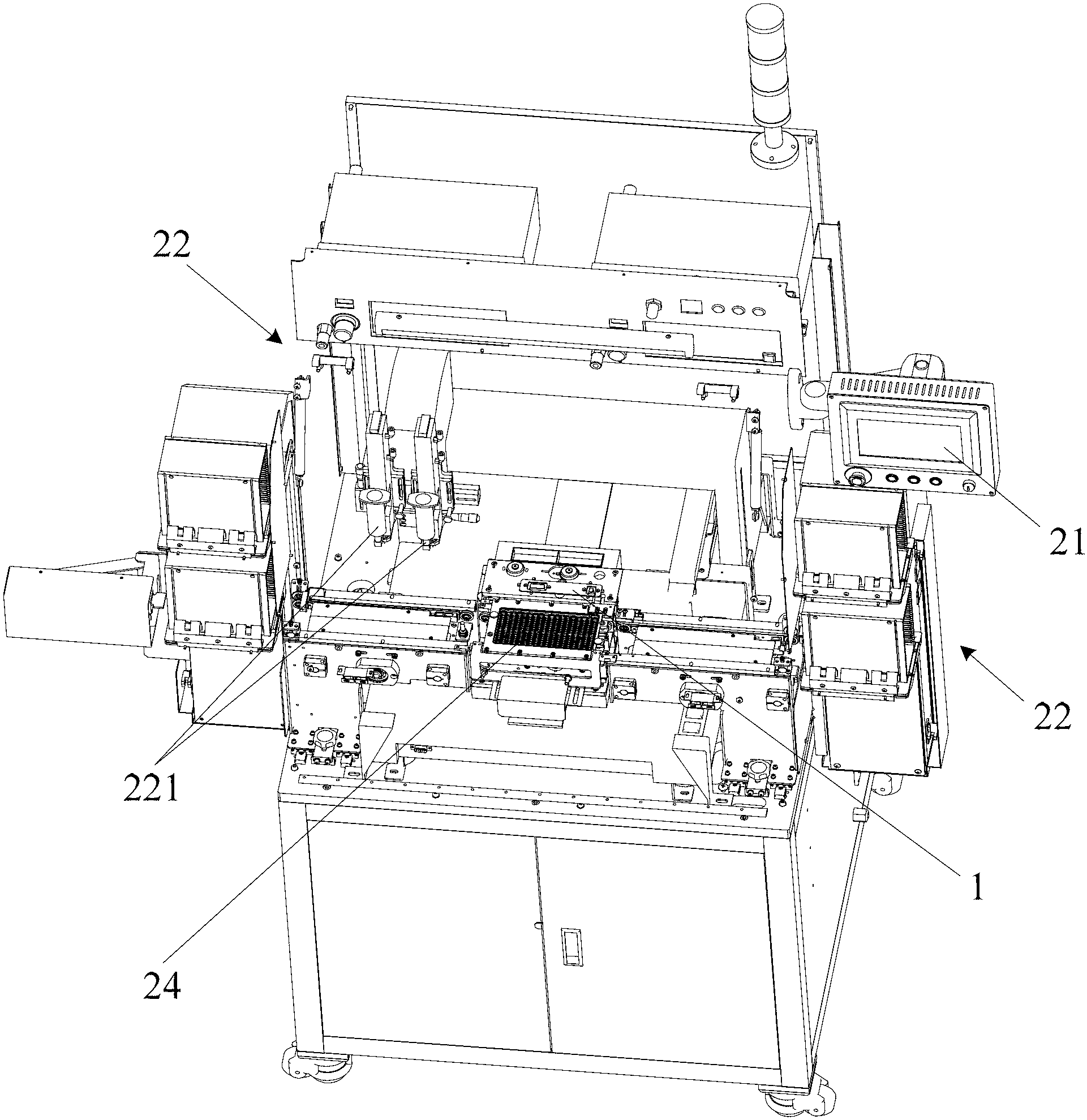

[0025] refer to figure 1 , figure 1 It is a structural schematic diagram of an embodiment of the pilot dispensing device of the present invention; the present invention provides a pilot dispensing device 1, comprising: a body 11, an adsorption platform 12 arranged on the body 11, and a ring groove recessed around the adsorption platform 12 13. The adsorption platform 12 absorbs glue, and the absorbed glue flows into the annular groove 13 along the periphery of the adsorption platform 12 .

[0026] In this embodiment, when the glue drops onto the adsorption platform 12 of the pilot glue device 1 and a certain amount of glue is accumulated on the adsorption platform 12 ,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap