Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about "Material strength using tensile/compressive forces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

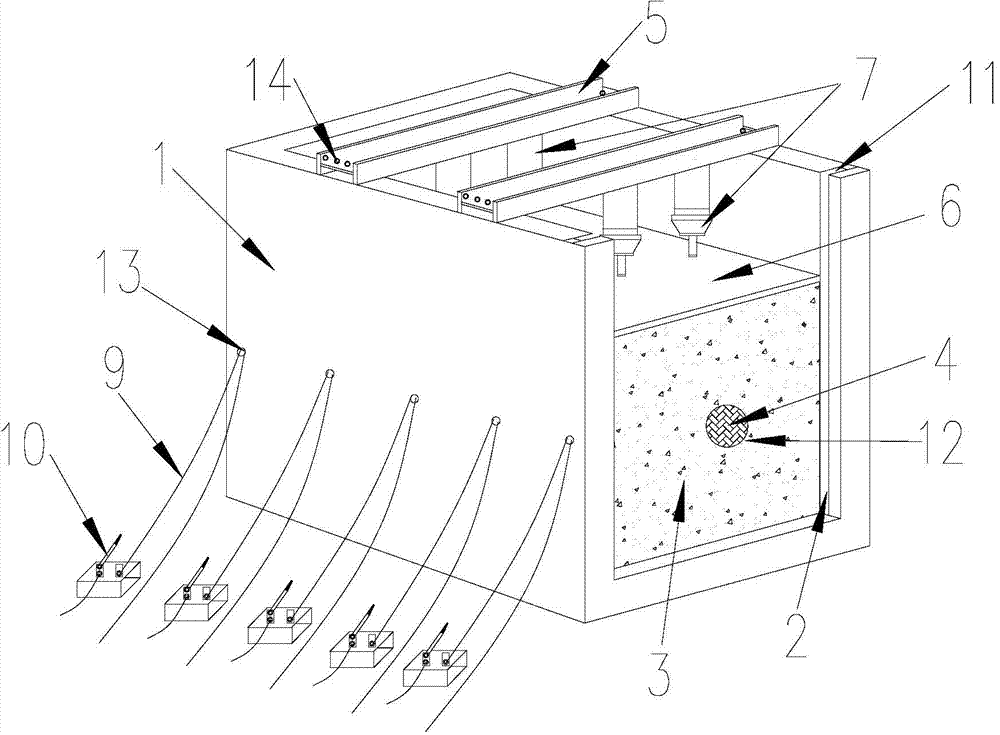

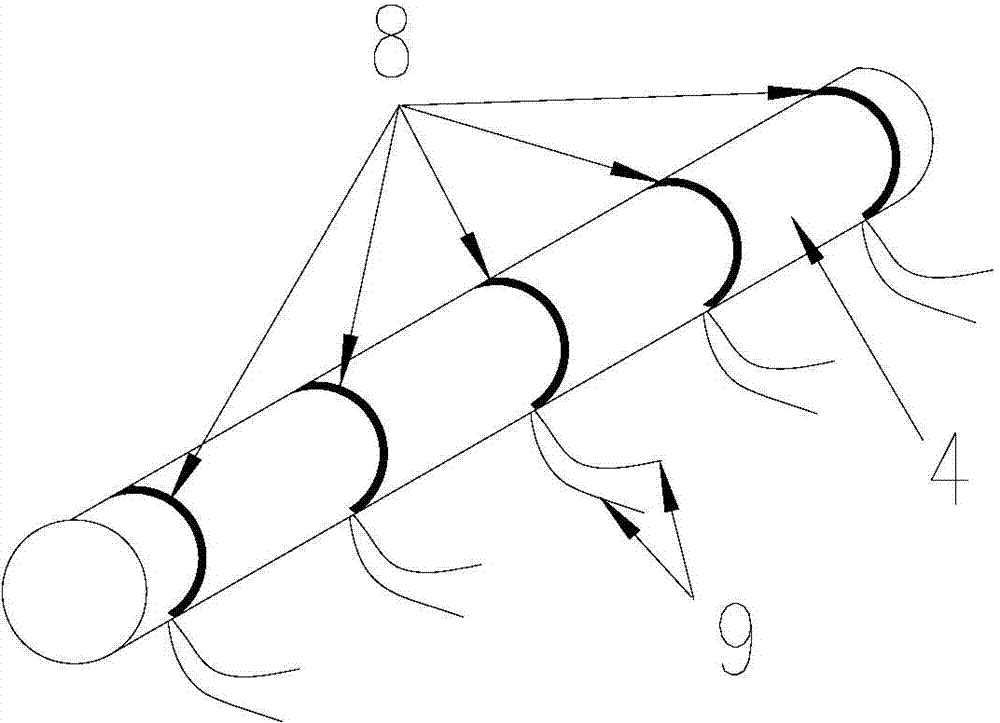

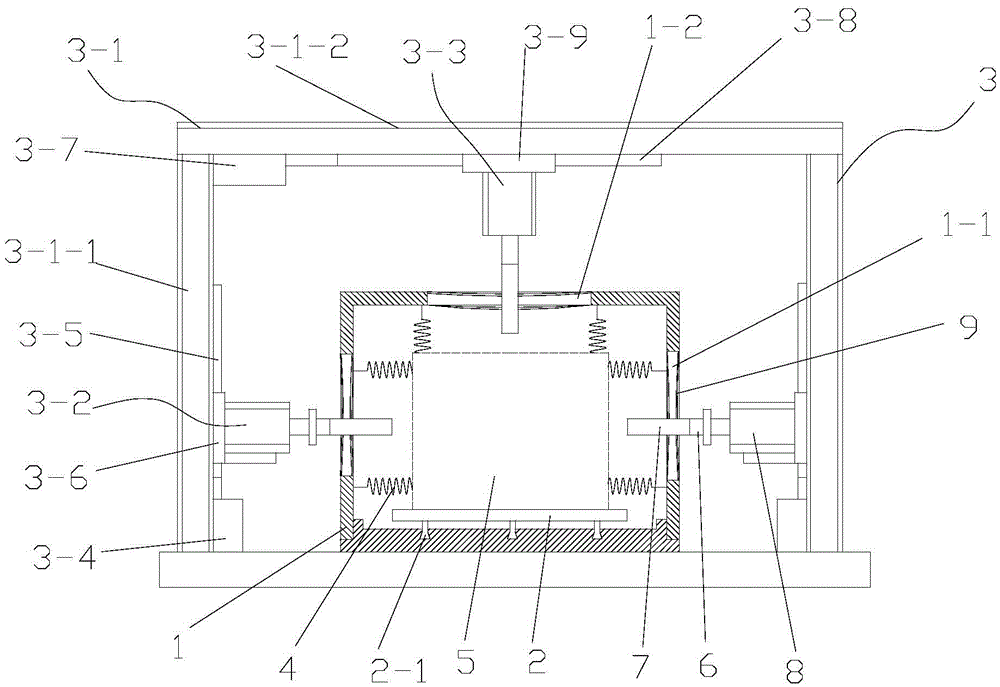

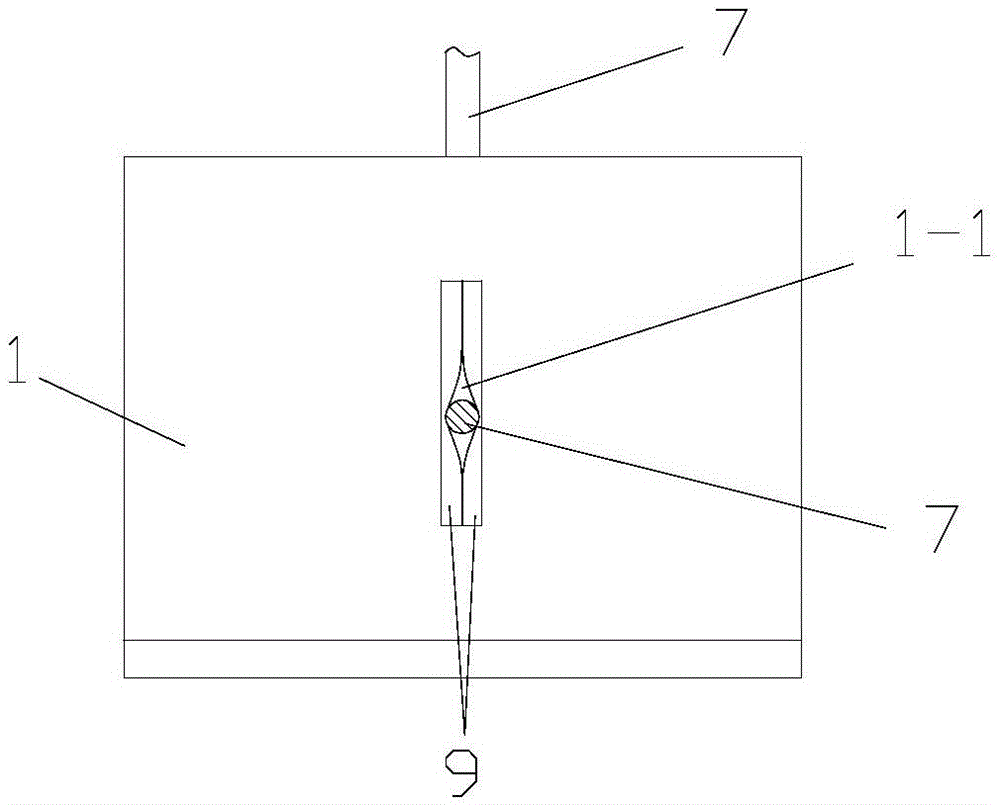

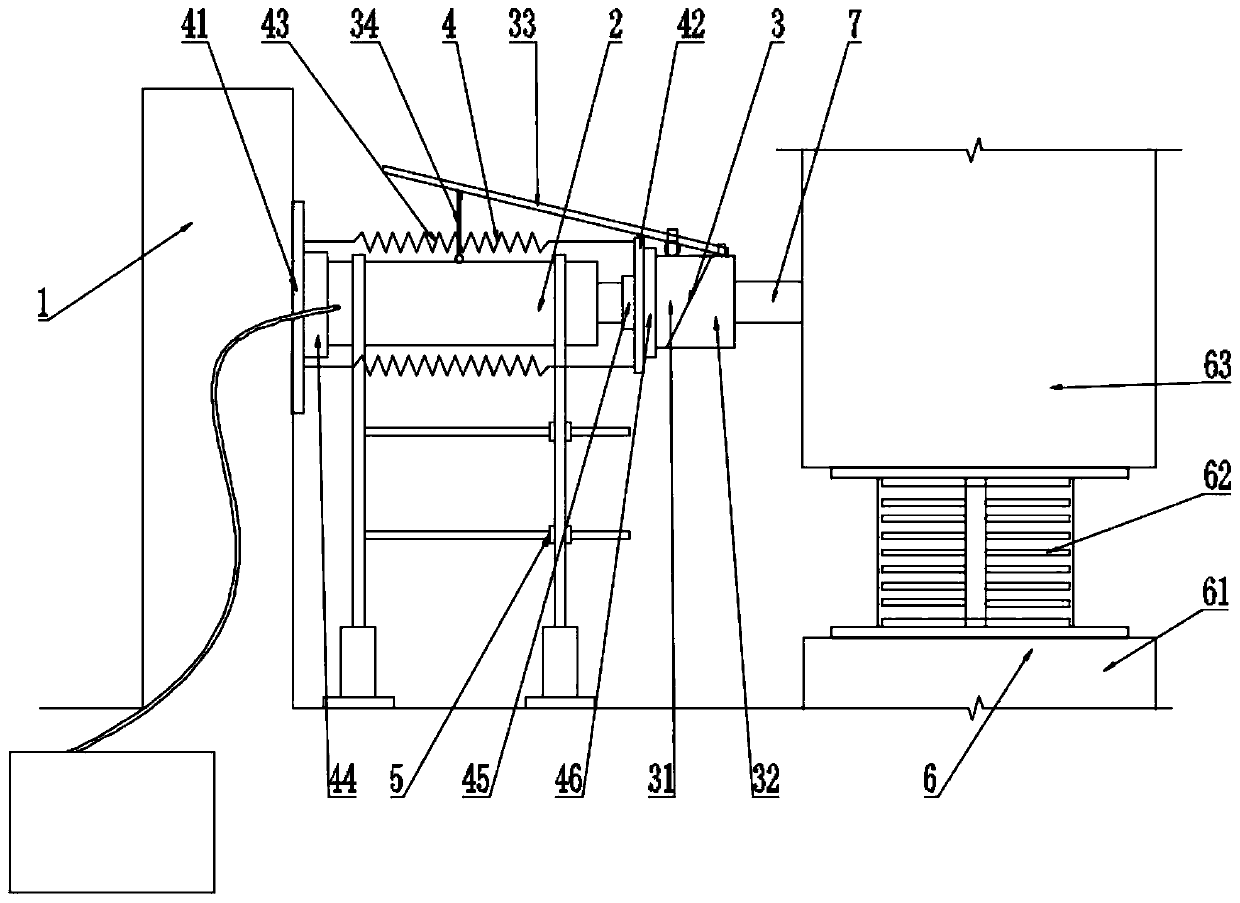

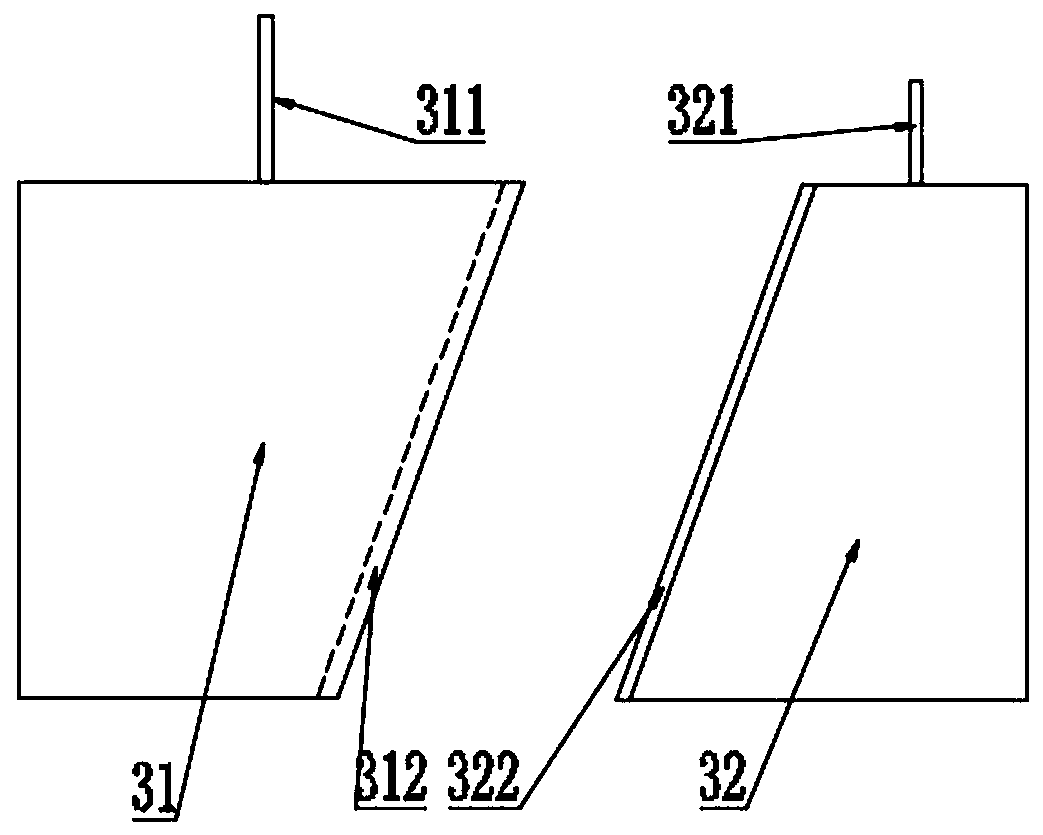

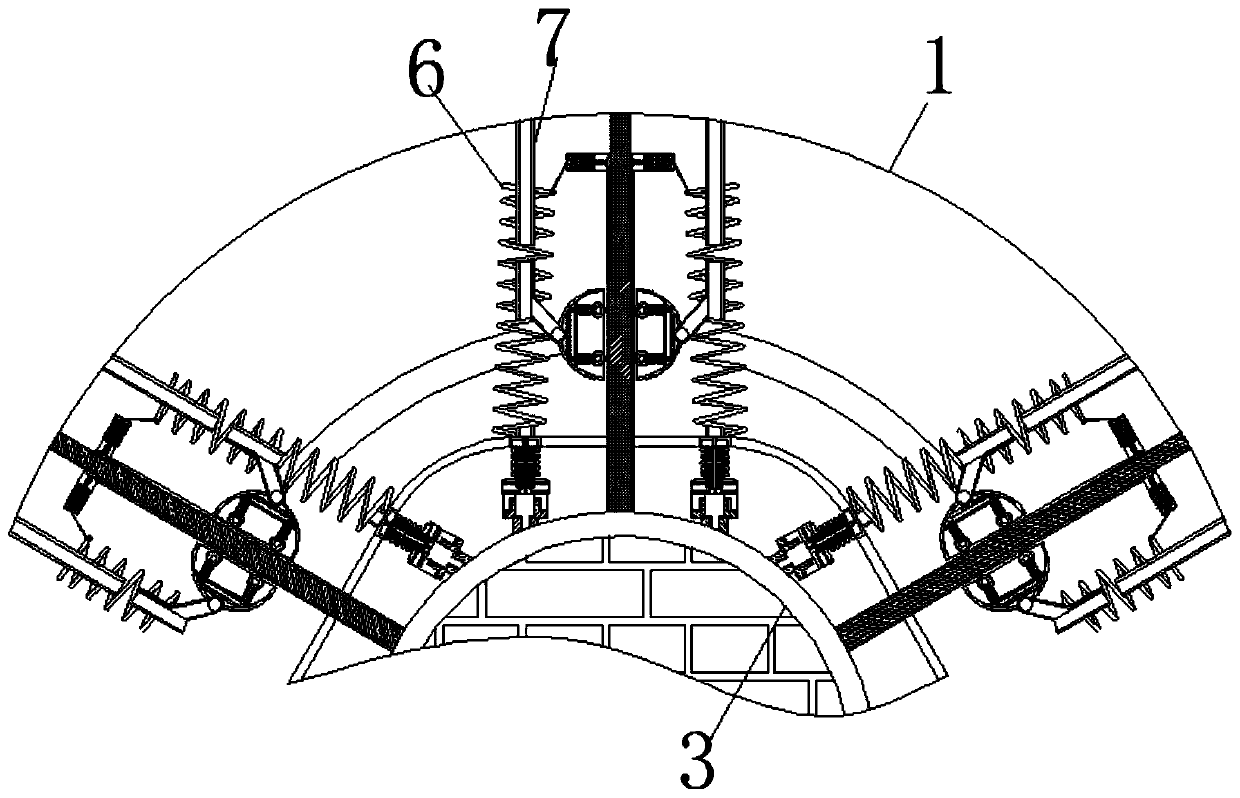

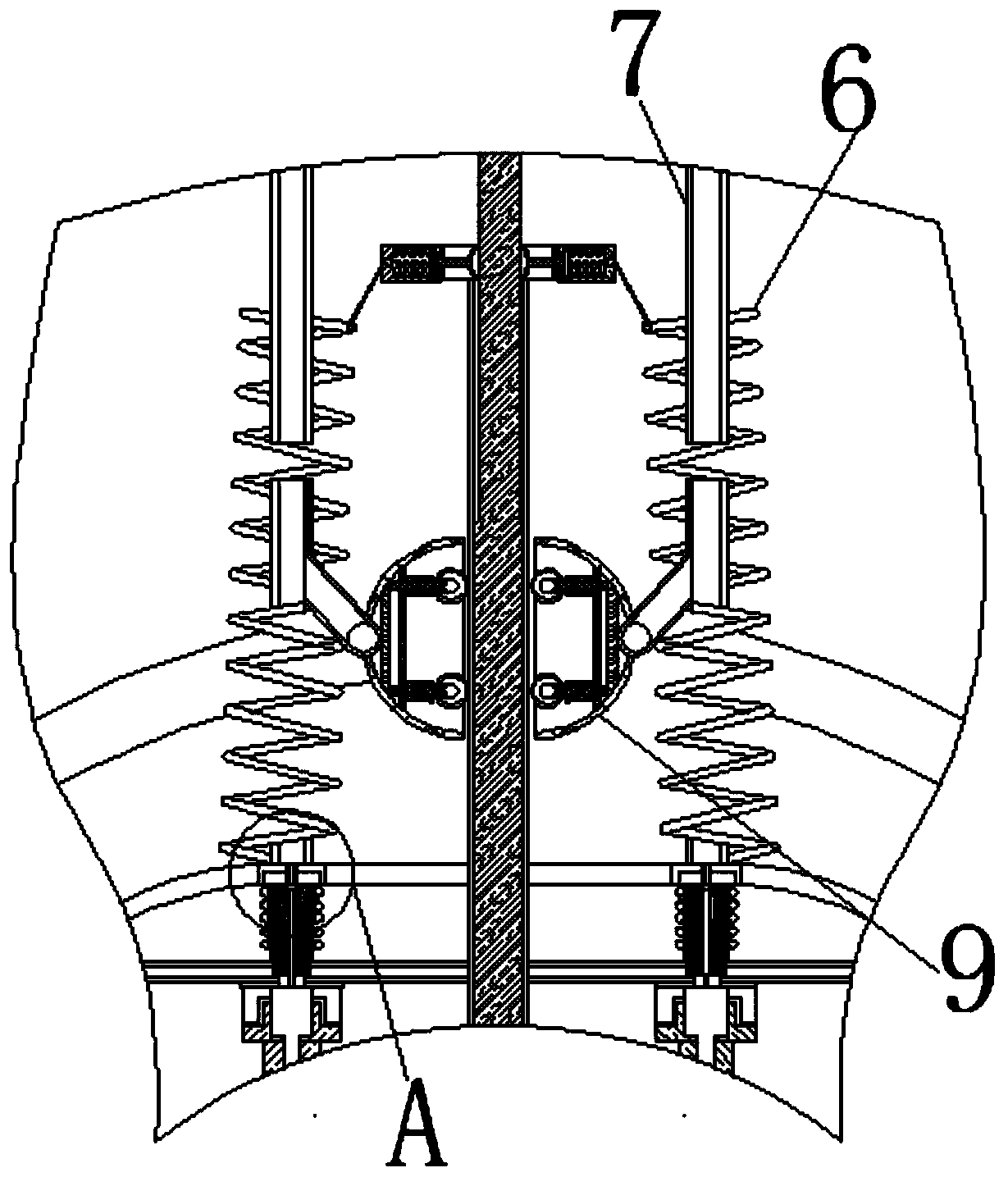

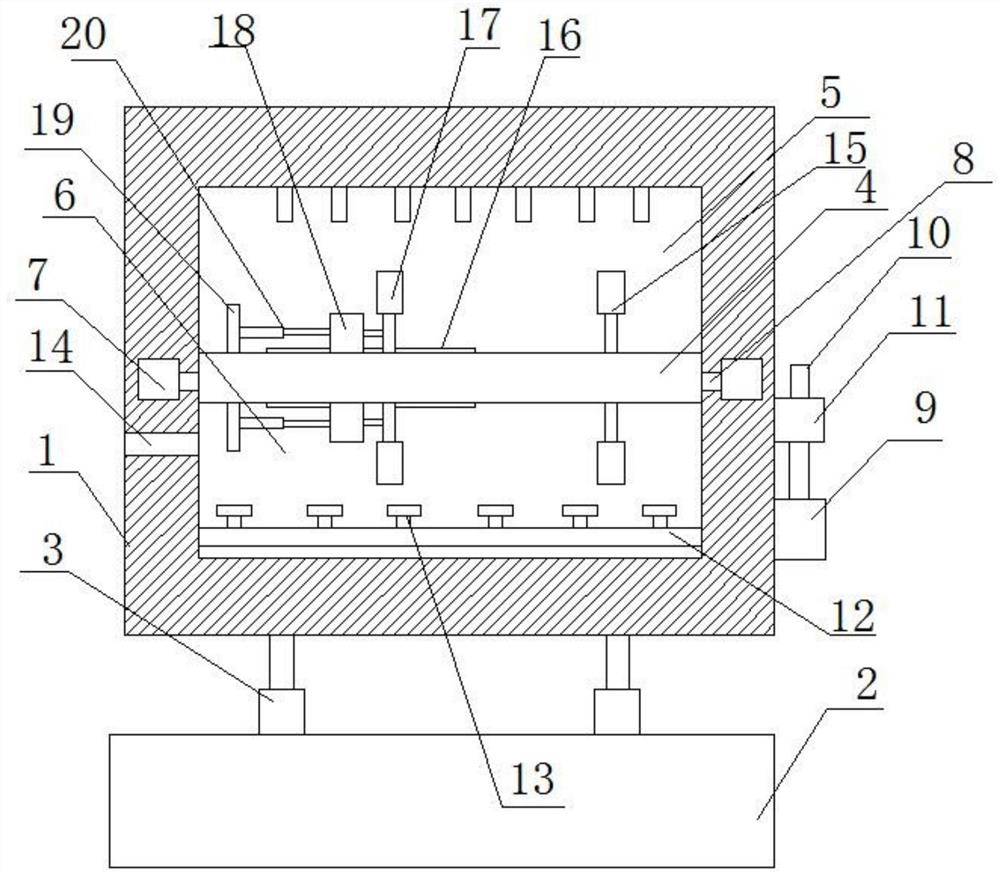

Laboratory model testing device for tunnel excavation

InactiveCN103616287AHigh simulationAvoid the influence of surrounding fillersMaterial strength using tensile/compressive forcesModel testingEngineering

Owner:HUNAN UNIV

Concrete cracking overall process testing device based on true environment

ActiveCN105372171AWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesEngineeringSimulation system

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

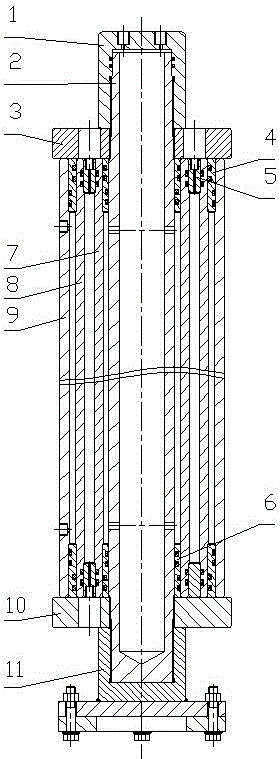

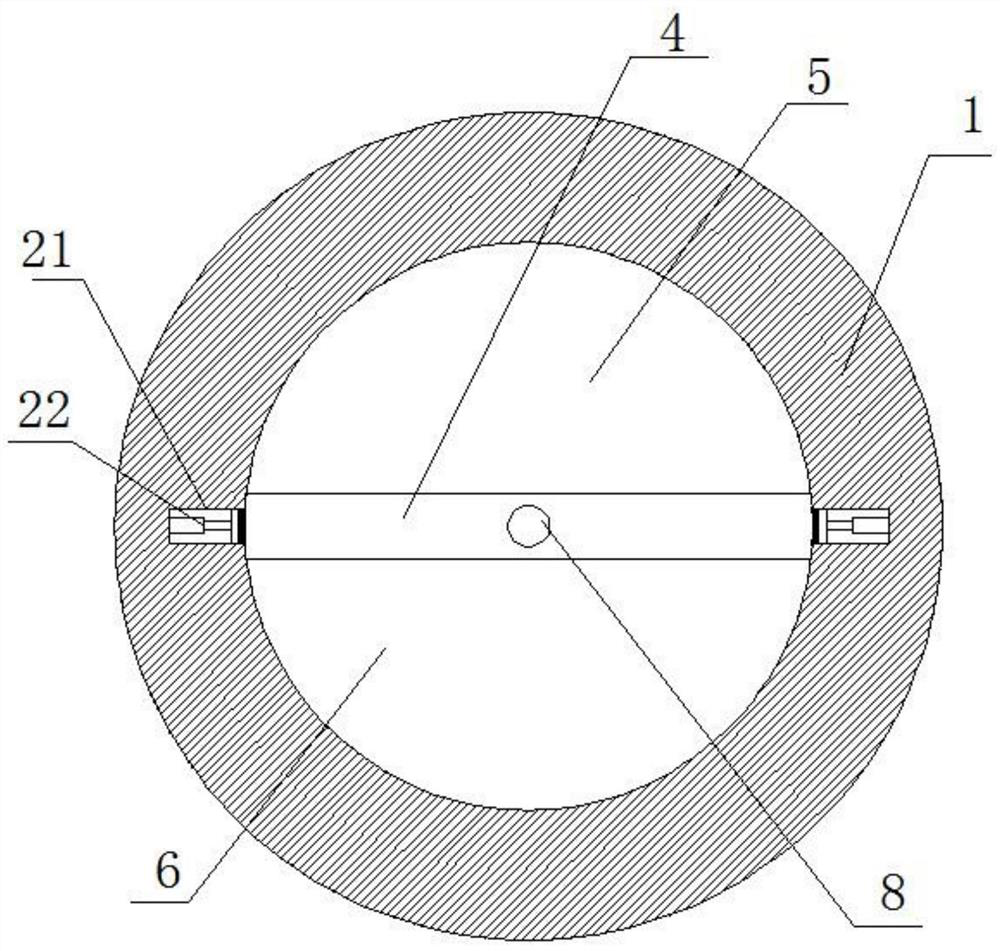

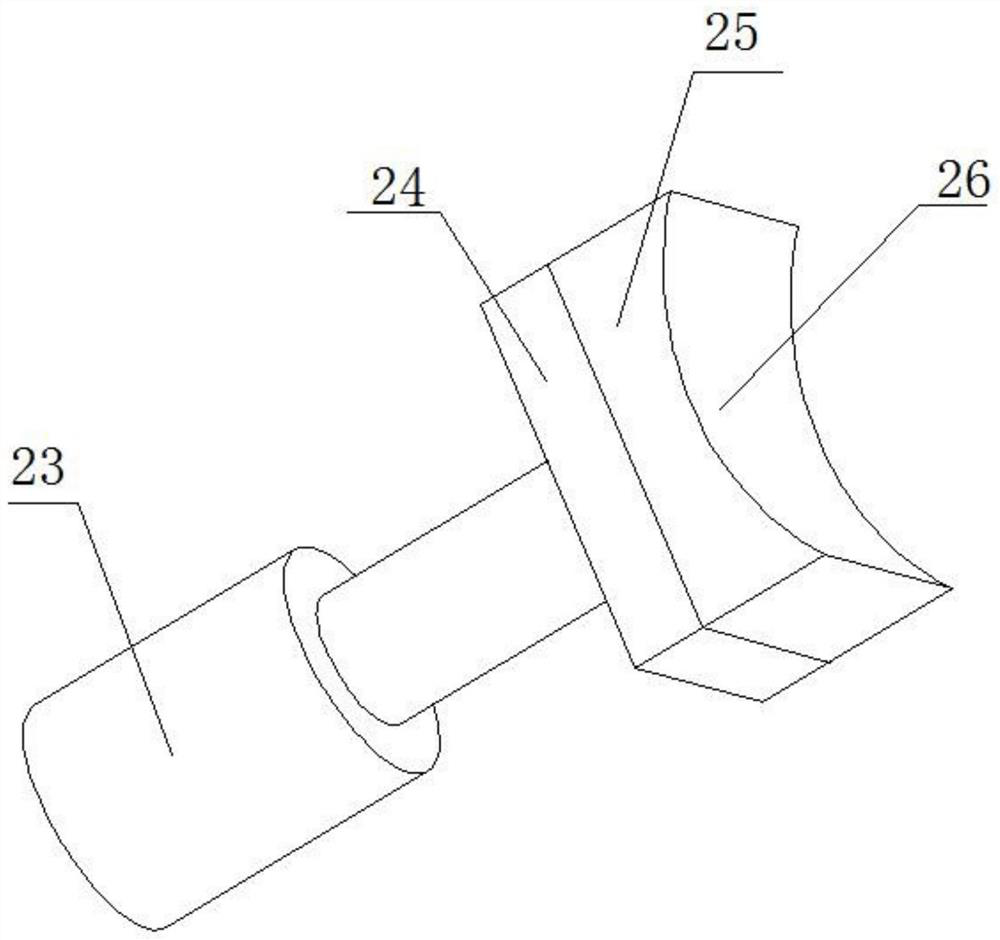

Method for performing expansion test of combined loads on solid expansion pipe

InactiveCN102023118AMeasure displacement in real timeMeasure speed in real timeMaterial strength using tensile/compressive forcesMechanical stretchingData acquisition

The invention relates to a method for performing an expansion test of combined loads on a solid expansion pipe, which comprises the following steps of: 1) preparing a sample and an expansion cone; 2) expanding an end part; 3) preparing an expansion test; 4) performing the expansion test, wherein the expansion test can be any one of the following tests: a, a mechanical stretching expansion test; b, a hydraulic expansion test; and c, a mechanical hydraulic combined expansion test; and 5) performing data acquisition and data analysis. In the method, the mechanical stretching expansion test or the hydraulic expansion test or the combined expansion test of mechanical stretching and hydraulic pressure is realized, and the displacement, speed, stretching loads and hydraulic pressure of the expansion cone and the radial deformation data of the solid expansion pipe in the process of the expansion test can be measured in real time by using axial controlled mechanical stretching loads and the hydraulic pressure and matching the corresponding expansion conical head. The invention provides a method for the expansion test for simulating actual working conditions in laboratories effectively for the detection of expansion performance and study evaluation of the solid expansion pipe and the study and improvement of a connecting structure of the expansion pipe.

Owner:XIAN SANHUAN TECH DEV GENERAL

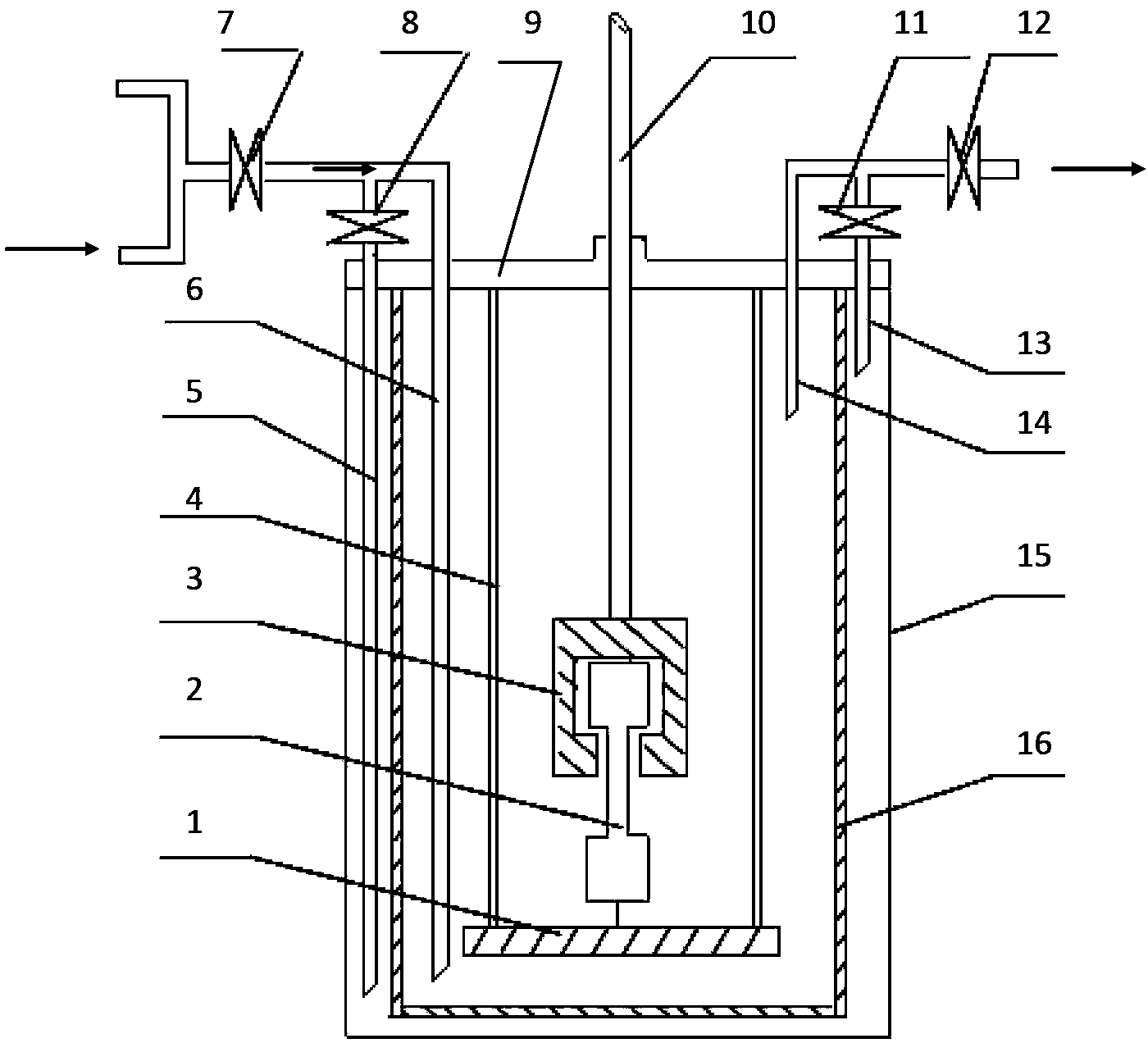

Anti-gas-channeling simulation test apparatus in later stage of well cementation

ActiveCN103335888ARealize simulationRealize the change of hydraulic pressure in the pipeMaterial strength using tensile/compressive forcesMaterial testing goodsWell cementingCement slurry

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Equipment used for air sac test

InactiveCN106124140AMeasurement of fluid loss/gain rateMaterial strength using tensile/compressive forcesData transmissionElectric machinery

Owner:KUNSHAN HAOSHUO PRECISION MECHANISM CO LTD

Fatigue performance testing device and method for bolt bearing large load at low temperature

Owner:PEKING UNIV

Horizontal biaxial extension testing machine and tension testing method thereof

Owner:SOUTHEAST UNIV

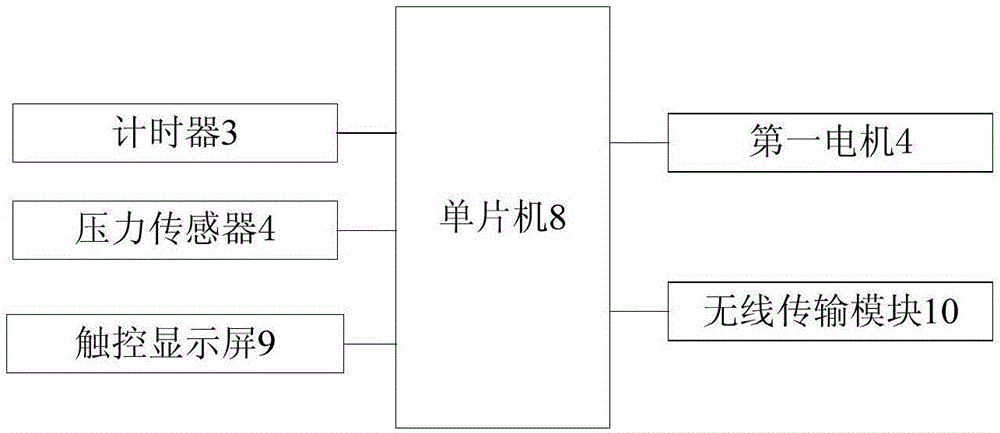

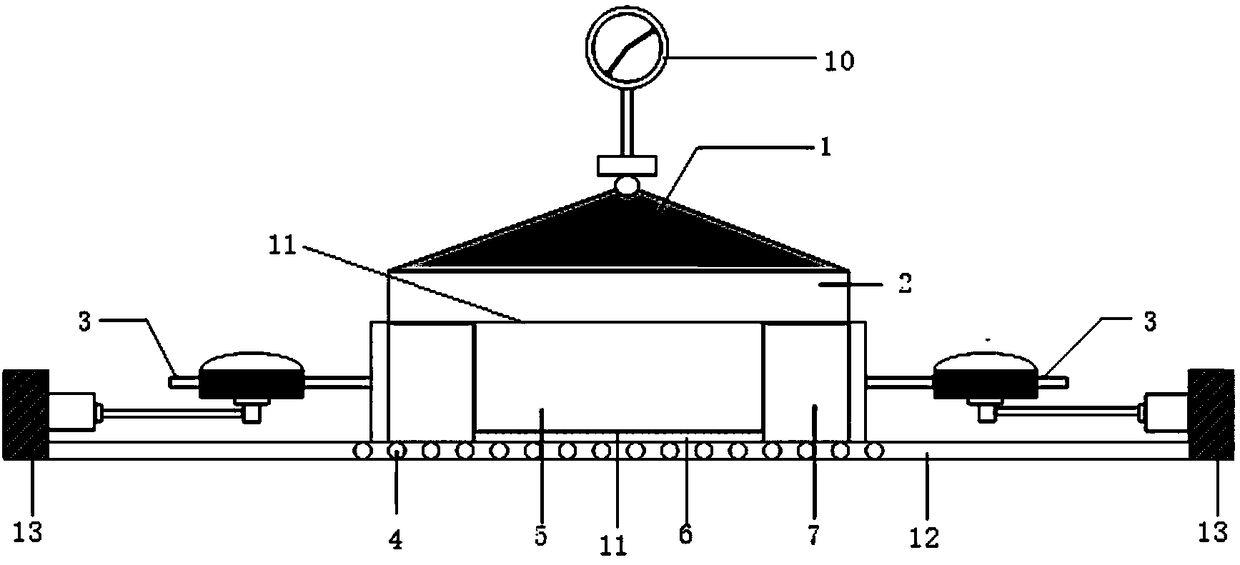

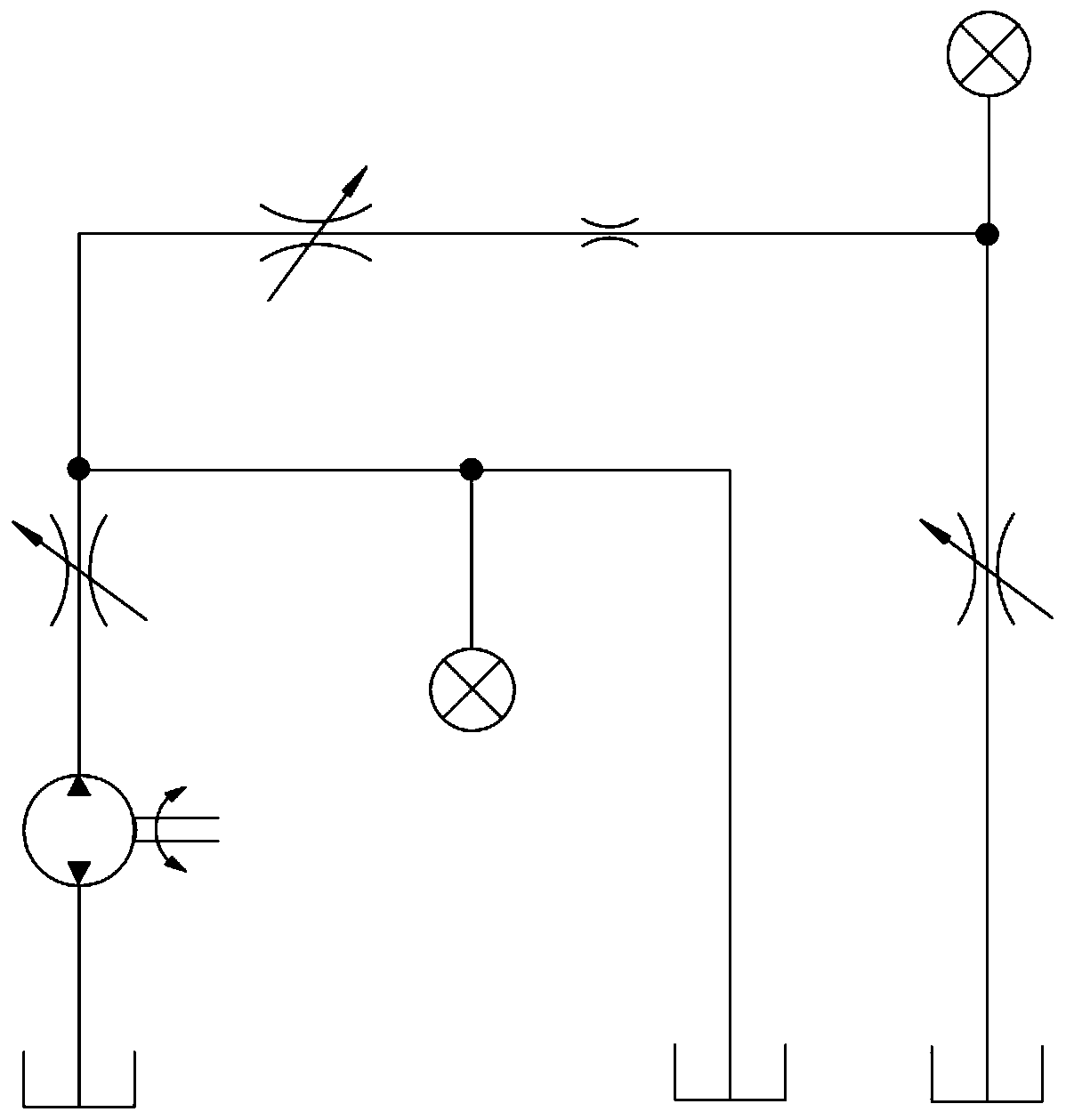

Creepage experiment system automatically controlling times of disturbance

InactiveCN109238851AControl Disturbance Loading TimeImprove test accuracyMaterial strength using tensile/compressive forcesAutomatic controlDigital recording

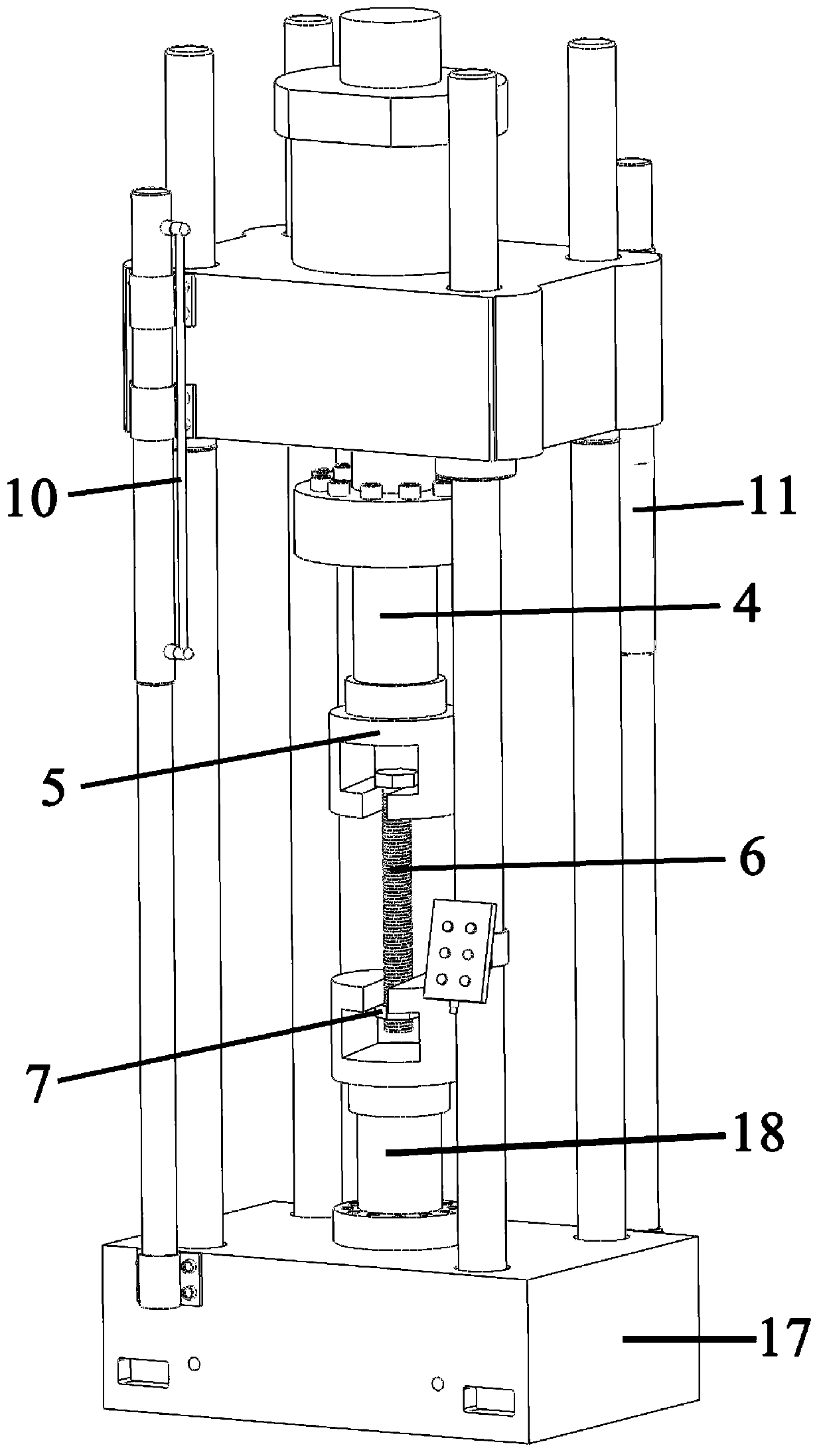

The invention relates to a creepage experiment system automatically controlling times of disturbance. The system comprises a rheometer bracket, wherein the middle upper part of the left end of a vertical part of the rheometer bracket is connected with fixed ends of a pressure rod and a turn-back lever; the turn-back lever is located at the lower end of the pressure rod; a disturbance loading system is arranged at the top of the pressure rod; a support point is arranged between the bottom end of the pressure rod and the turn-back lever; a triaxial pressure chamber is arranged at the bottom endof the pressure sensor and arranged at the top of a horizontal part of the rheometer bracket; and a free end of the pressure rod is connected with a scale pan through a connecting rod. According to the creepage experiment system, the disturbance time can be precisely controlled by a time relay in an experimental process; the disturbance loading system can automatically apply a disturbance load; and the experimental precision is greatly improved.

Owner:LIAONING TECHNICAL UNIVERSITY

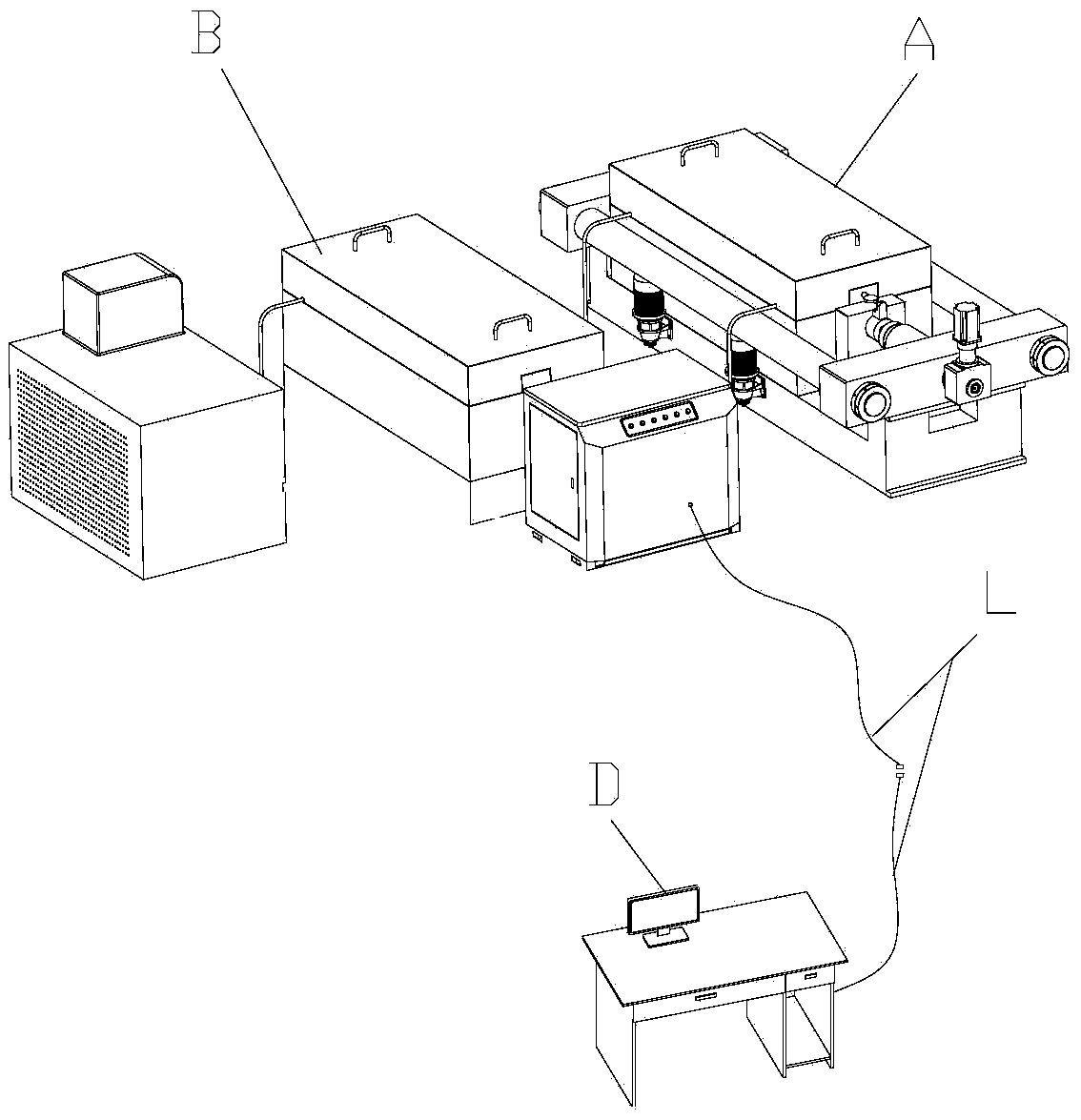

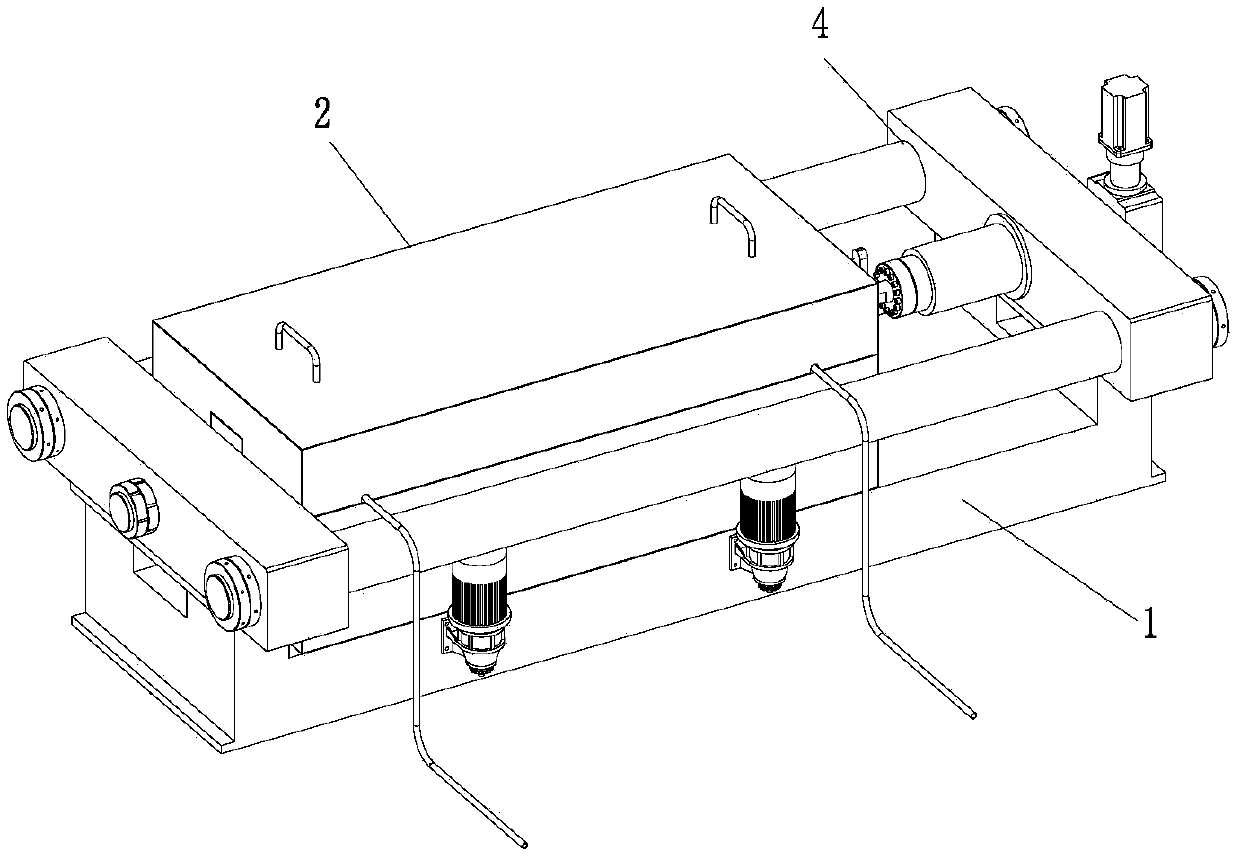

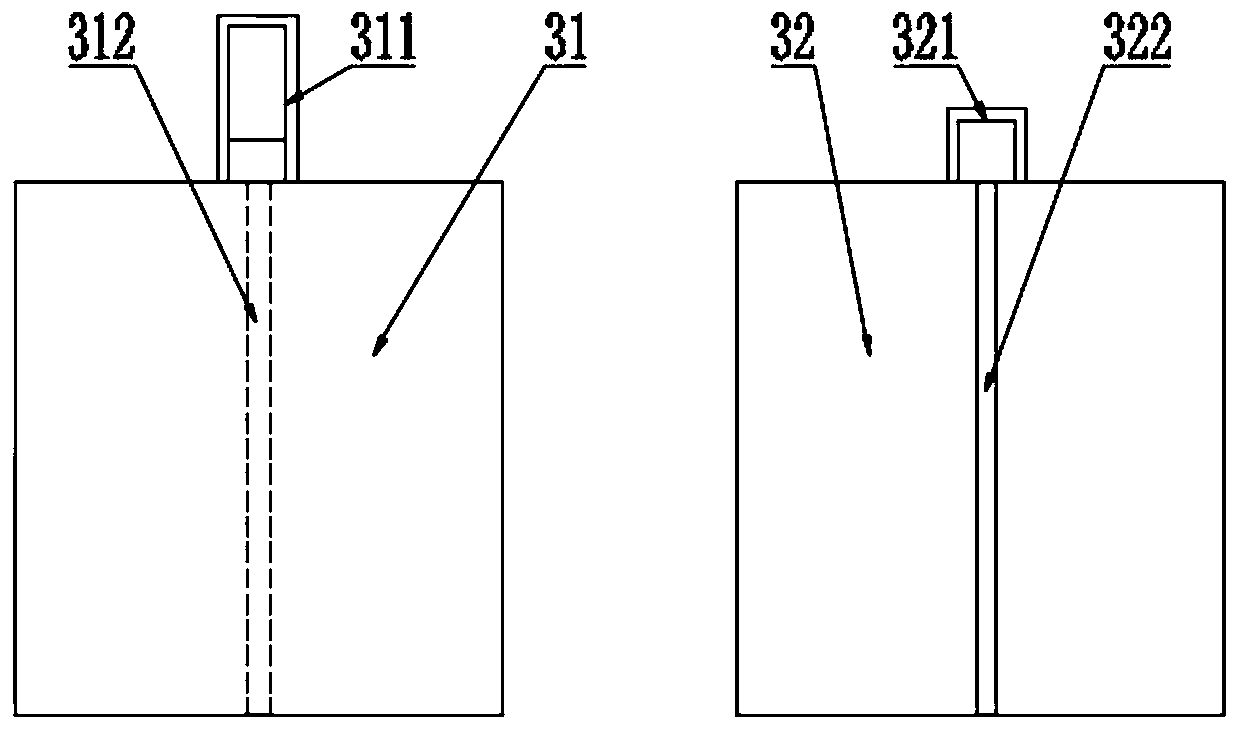

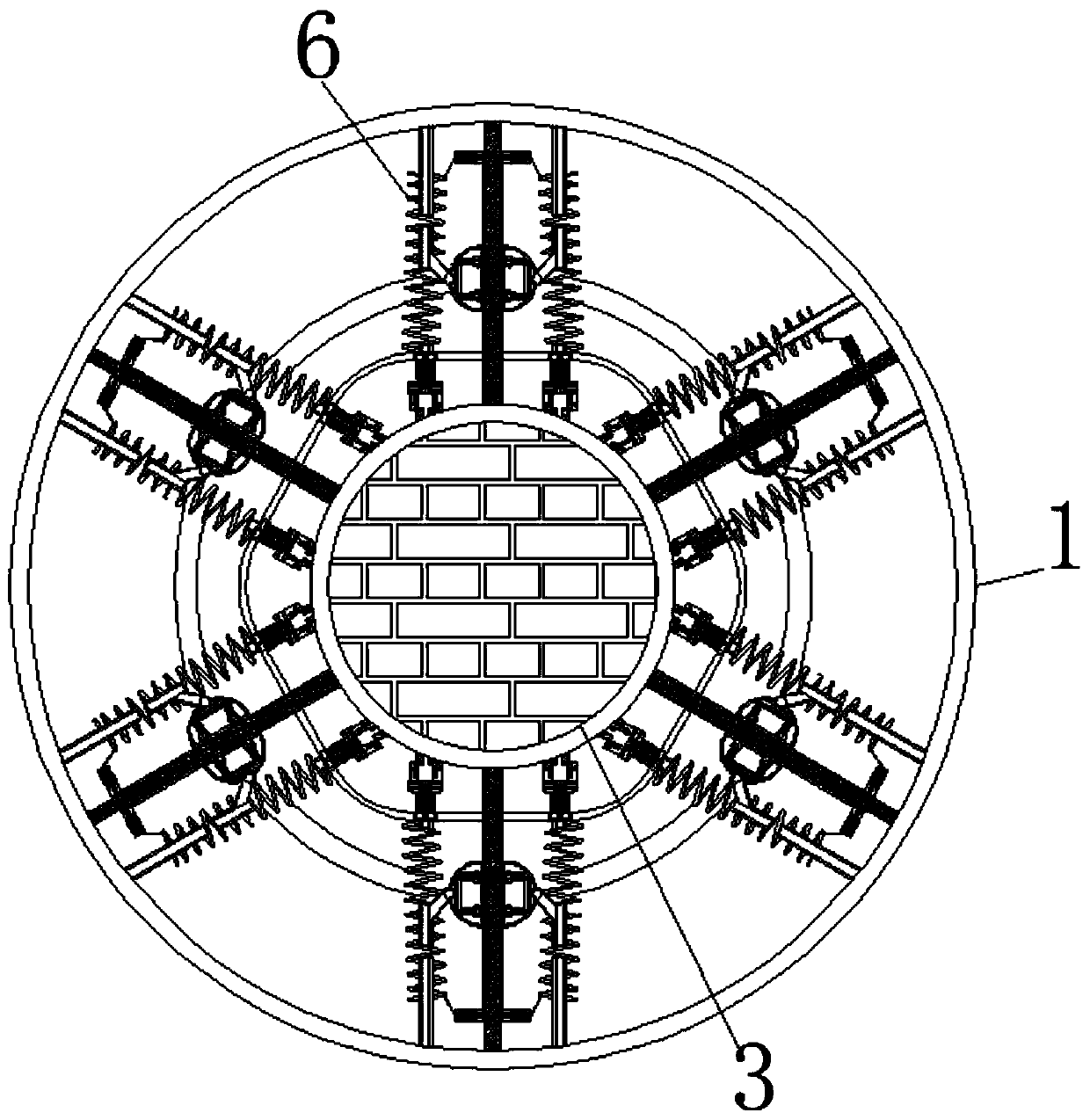

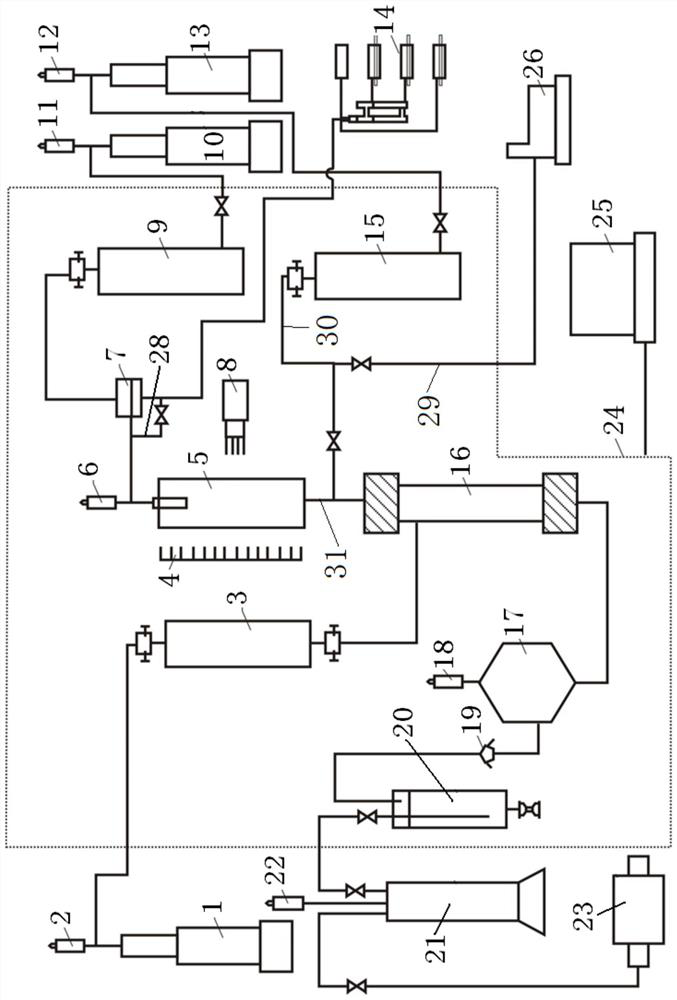

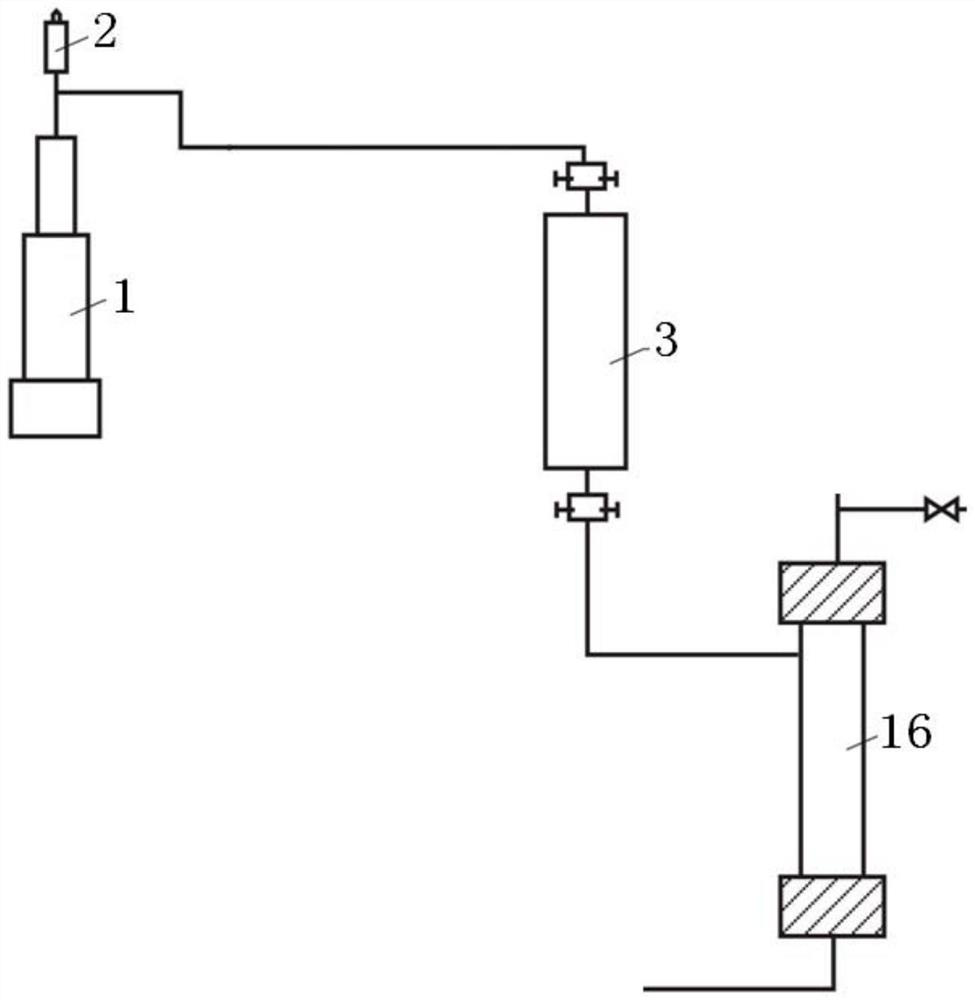

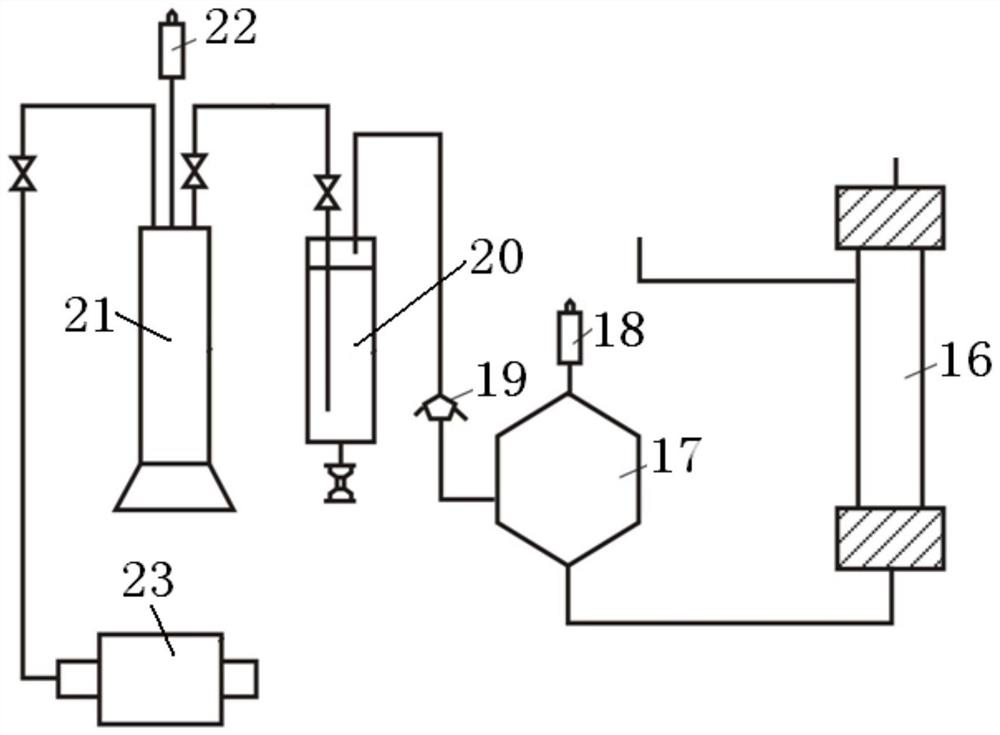

Underground cavern similarity simulation testing system

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Tester for lateral expansibility of soft rock

ActiveCN108663270AFit the actual engineeringAccurate measurementMaterial strength using tensile/compressive forcesDynamometerFilter paper

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Low-rigidity pull pressure pad structure for realizing uniform loading of radome

InactiveCN110567803ASolve the problem of local reinforcementDoes not change the local stiffnessMaterial gluingMaterial strength using tensile/compressive forcesRadarEngineering

The invention belongs to the field of experimental mechanics, and particularly relates to a low-rigidity pull pressure pad structure for realizing uniform loading of a radome. The structure is composed of a plurality of symbol-shaped polyurethane blocks, a transition steel plate and a pull ring; the polyurethane blocks and the pull ring are respectively connected to both surfaces of the transitionsteel plate; and the pull ring is arranged at a resultant force point of a loading subarea, and the resultant force point is overlapped with the gravity center of the steel plate. The structure proposed by the invention can solve the problems that the stress of the radome is too concentrated when a canvas belt applies a load, and that the load is locally strengthened when a wooden block / steel structure applies the load, the uniform application of the load of the radome can be guaranteed, and the local rigidity of the radome is not changed; and in addition, since the pull pressure pad structure designed by the patent is composed of the plurality of polyurethane blocks with small bonding areas, and a certain gap is reserved between each polyurethane block, compared with an entire large polyurethane block, the air permeability is good, and the bonding quality is ensured.

Owner:THE RES INST FOR SPECIAL STRUCTURES OF AERONAUTICAL COMPOSITE AVIC

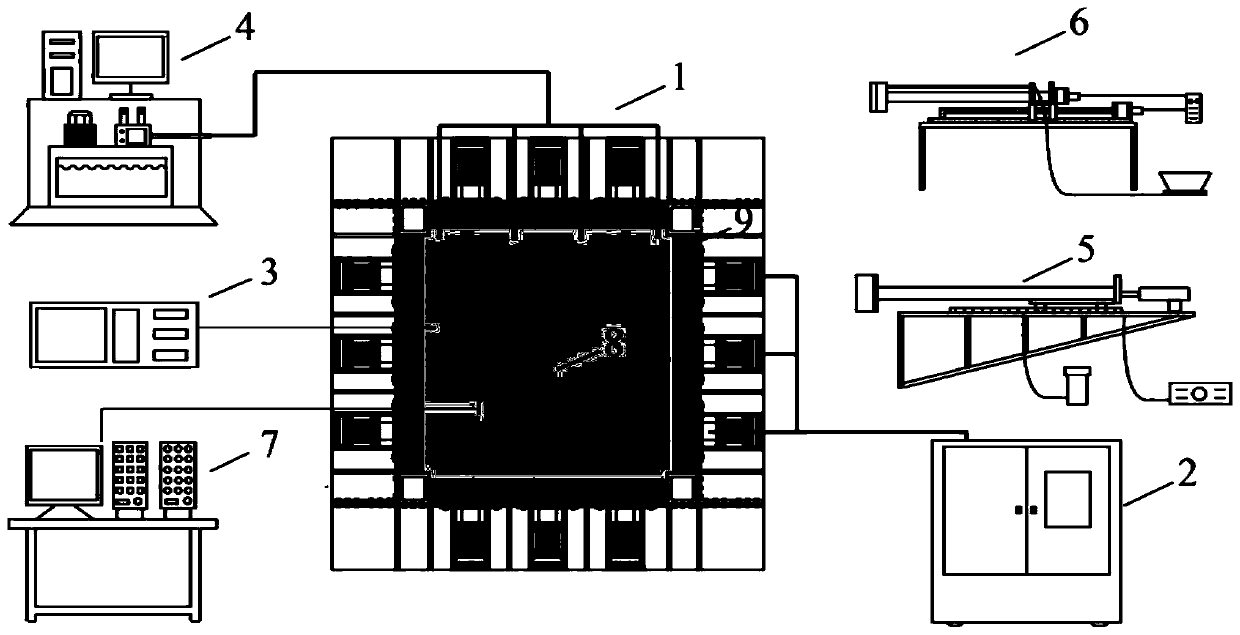

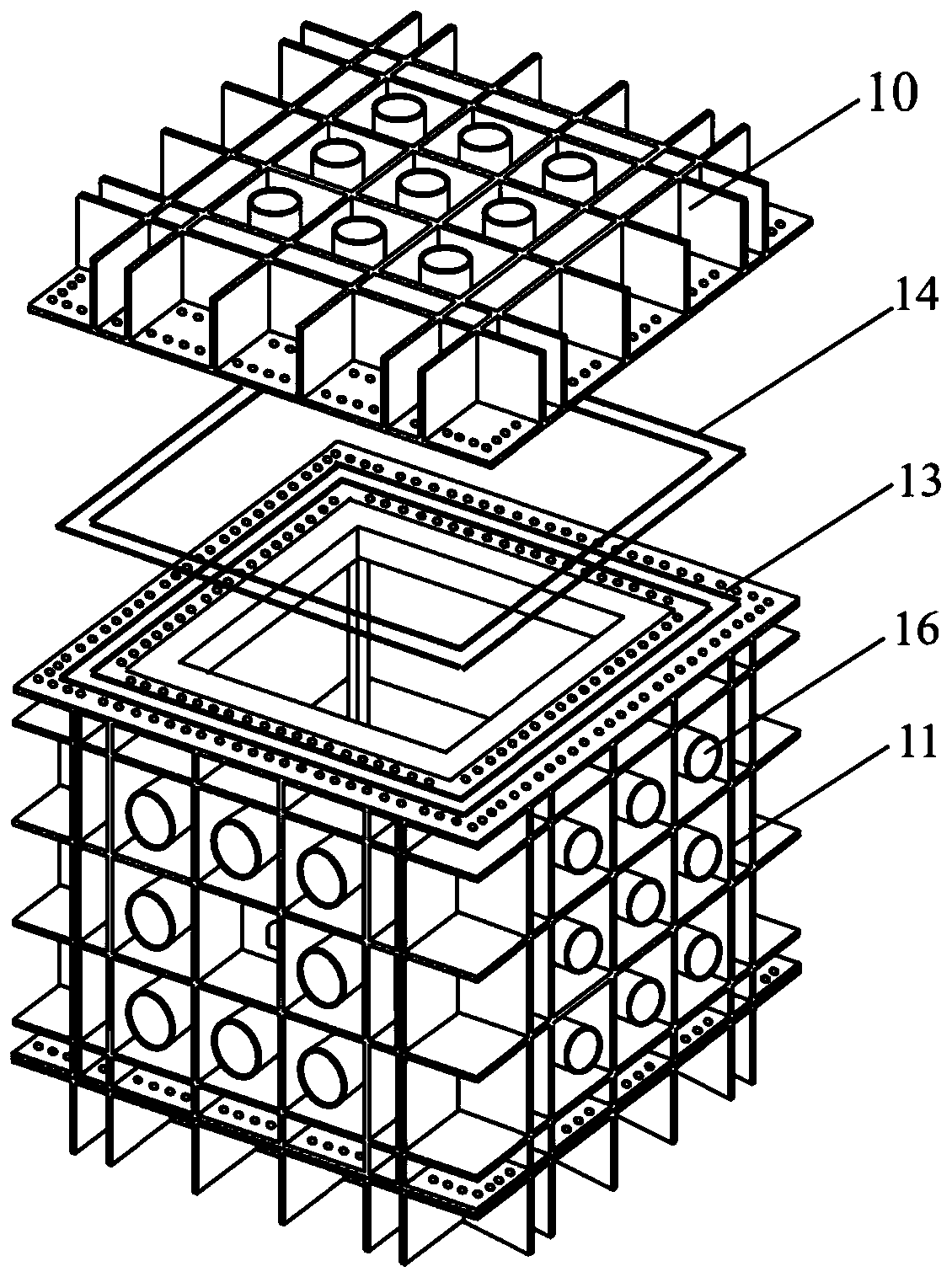

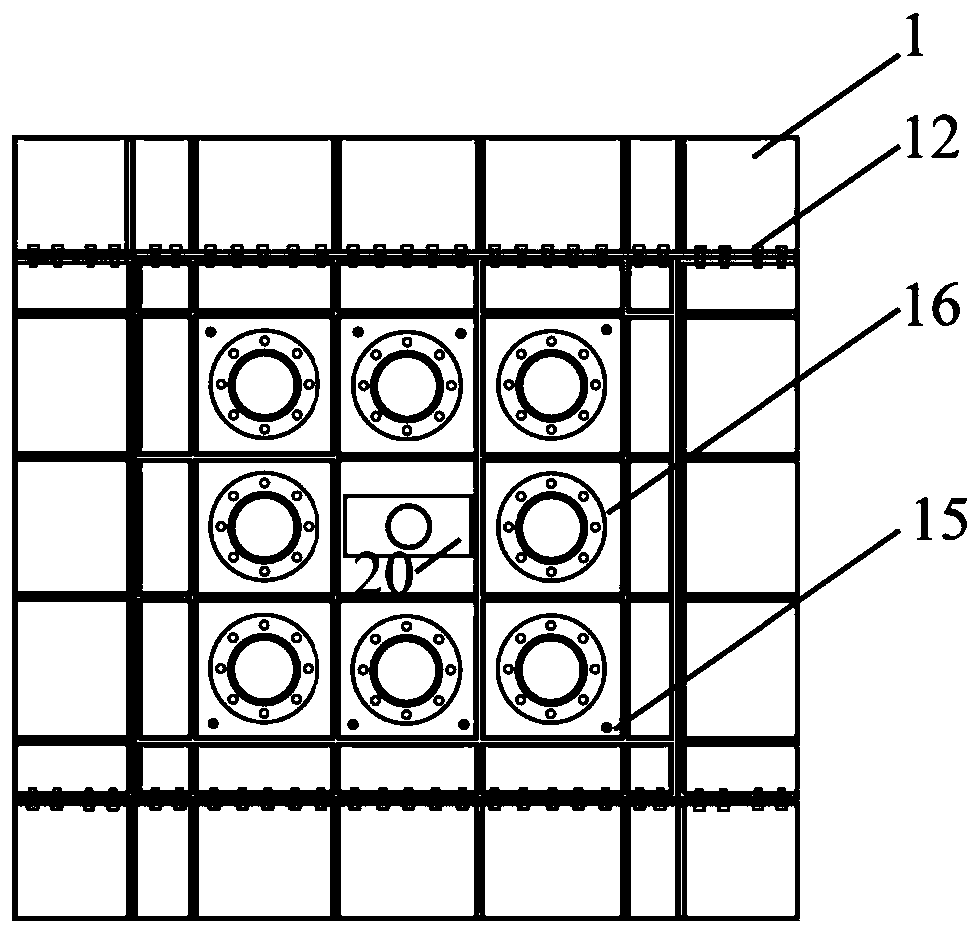

Large-burial-depth tunnel surrounding rock stabilization and support model test system under complex conditions

ActiveCN111208015AMaterial strength using tensile/compressive forcesStructural/machines measurementServoCrustal stress

Owner:SHANDONG UNIV

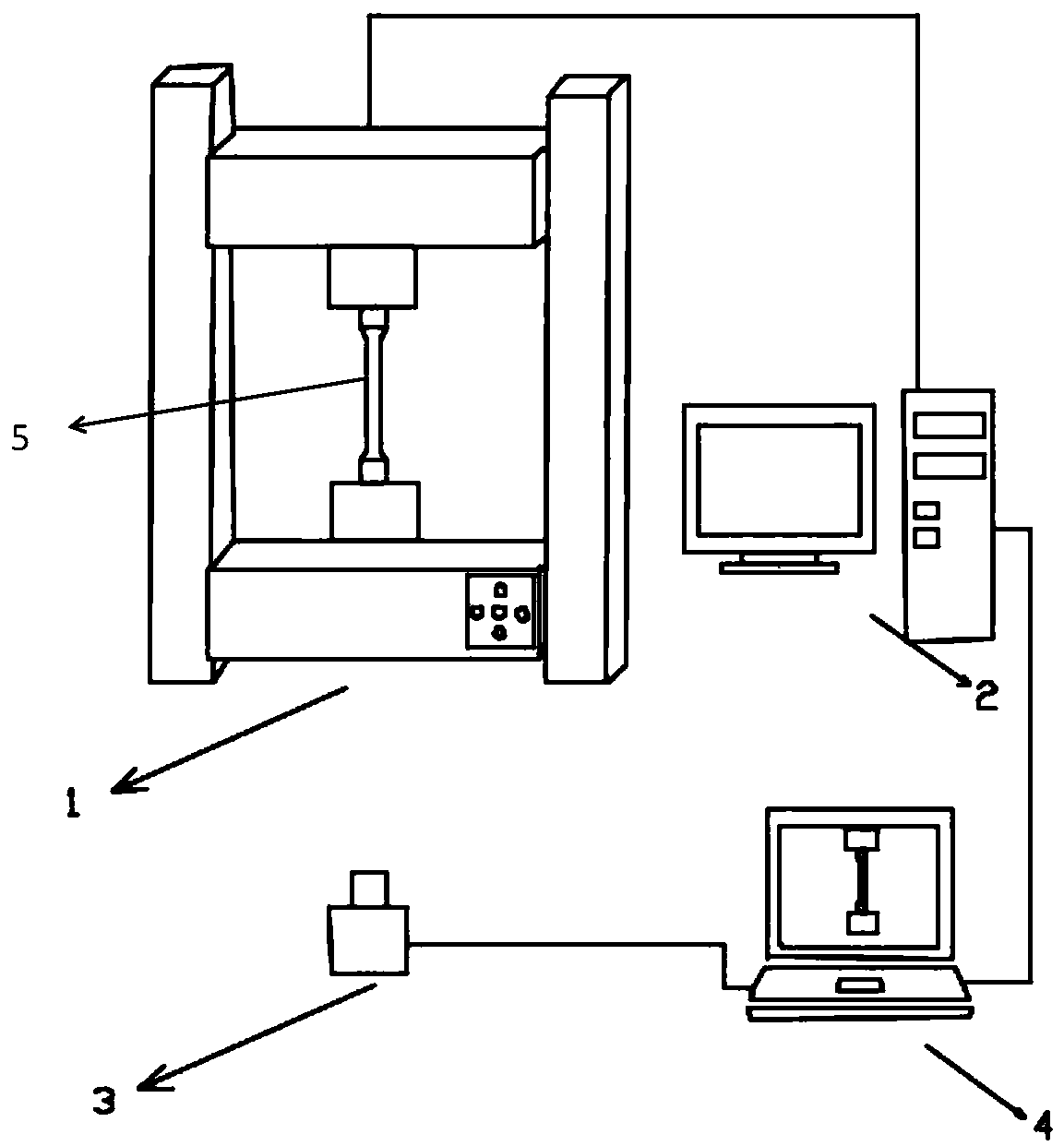

Soft matter mechanical property measurement method and system

InactiveCN105865923AImprove test accuracyImprove test efficiencyMaterial strength using tensile/compressive forcesComputer control systemAcoustics

The invention discloses a soft matter mechanical property measurement method and system. The measurement system comprises a piezoelectric bimorph beam, an electric hoisting platform, an impedance analyzer, a strain gauge and a computer control system. The measurement of a characterization method of a plurality of types of mechanical properties can be finished through one-time loading, and different mechanical properties of a sample to be detected are obtained, so that the testing accuracy and the testing efficiency can be improved; a change rule that the mechanical properties of the sample to be detected can be changed along pressing depth can be obtained, and influences on a measurement result, caused by factors including the end part abrasion of a pressed needle tip and the surface effect of the sample to be detected and the like are eliminated, so that a relatively accurate result is provided; a beam type loading system is adopted, is a flexible loading system and is applicable to measurement of soft matters; and the piezoelectric bimorph beam is used for amplifying a pressing signal by utilizing bending deformation in a pressing process, so that the sensitivity of a testing process is relatively high when amplification is carried out.

Owner:PEKING UNIV

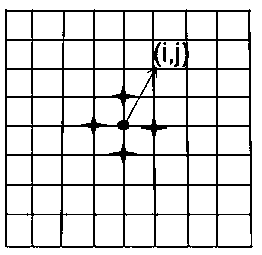

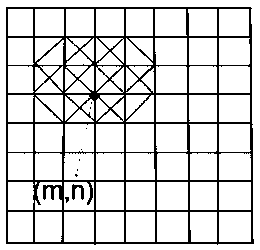

Out-of-surface strain measuring method based on digital image correlation

ActiveCN110207606ACause inaccuracyImprove measurement efficiencyImage enhancementImage analysisDigital imageComputer science

Owner:AEROSPACE SHENZHOU AIRCRAFT

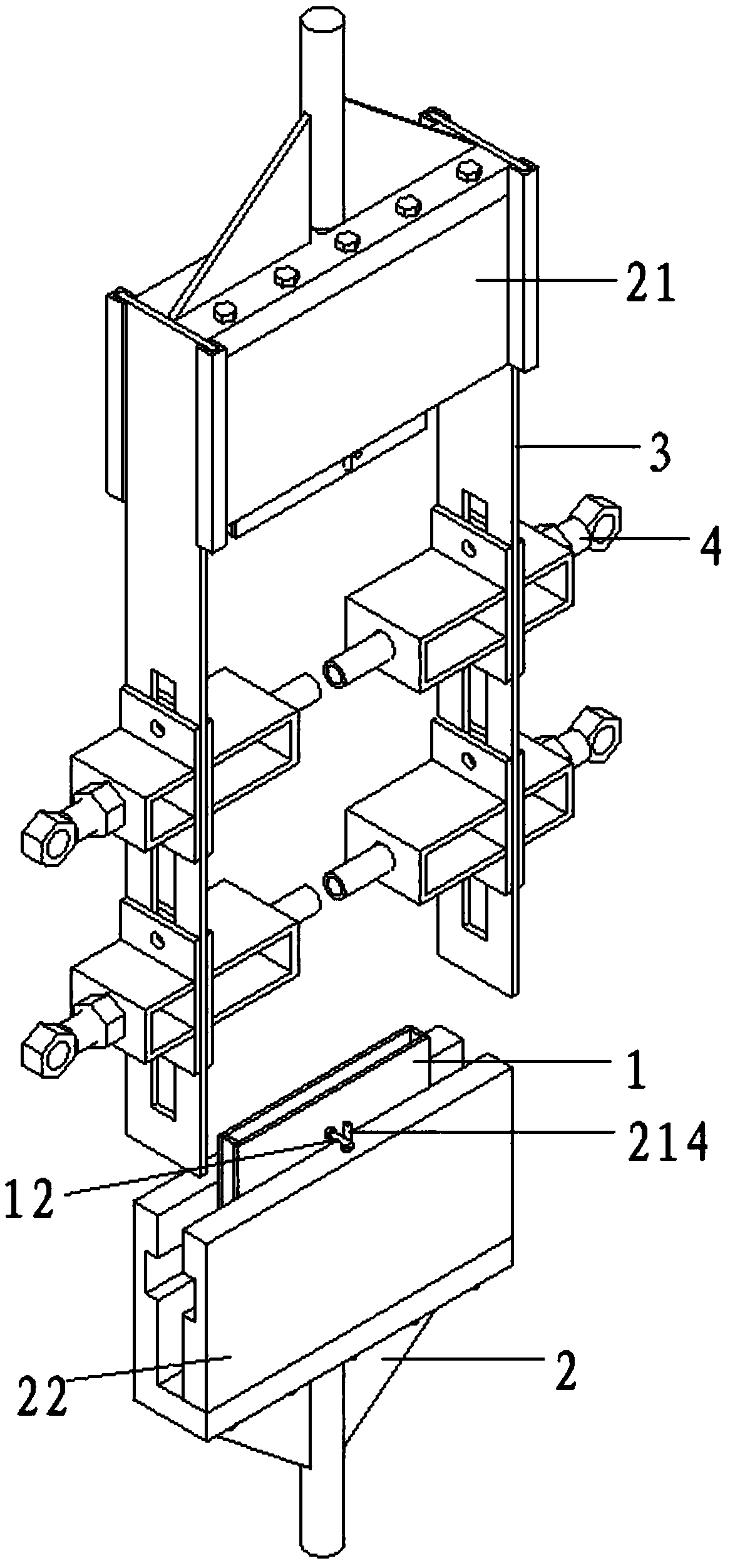

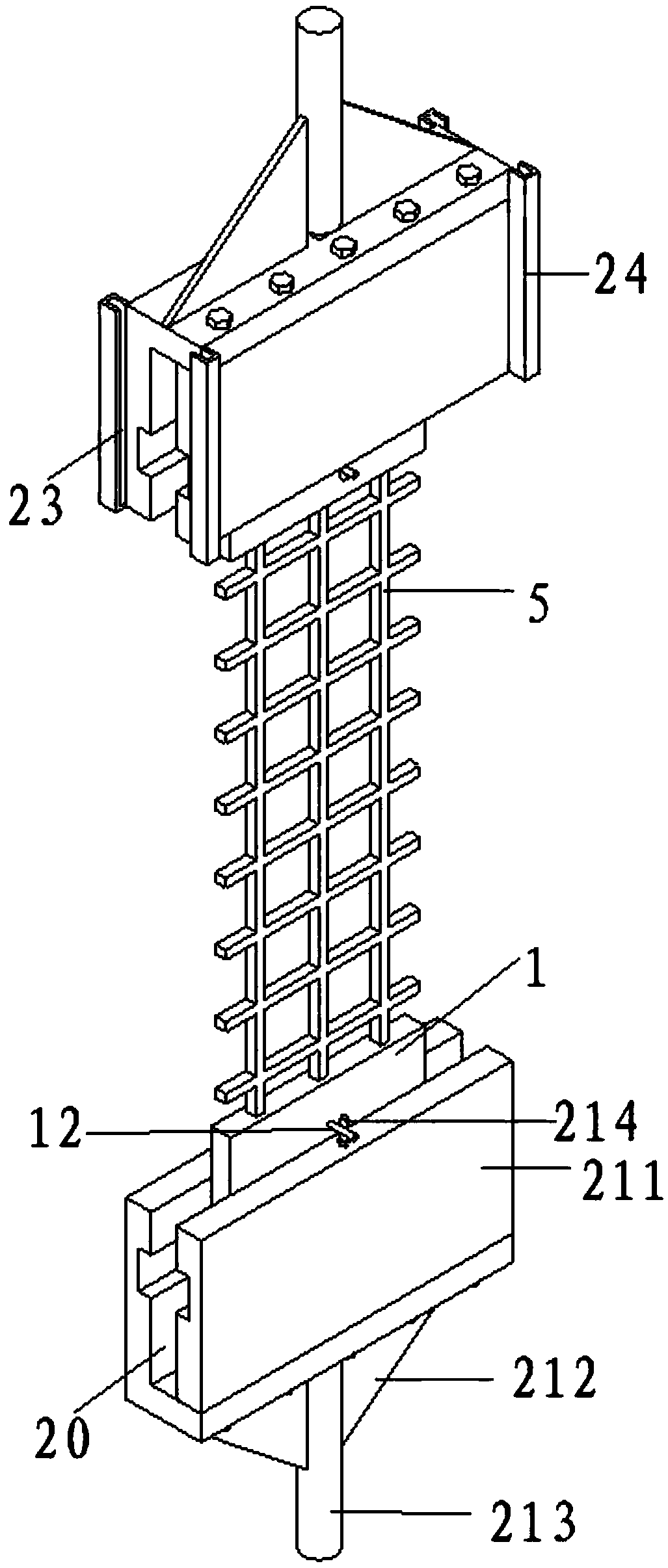

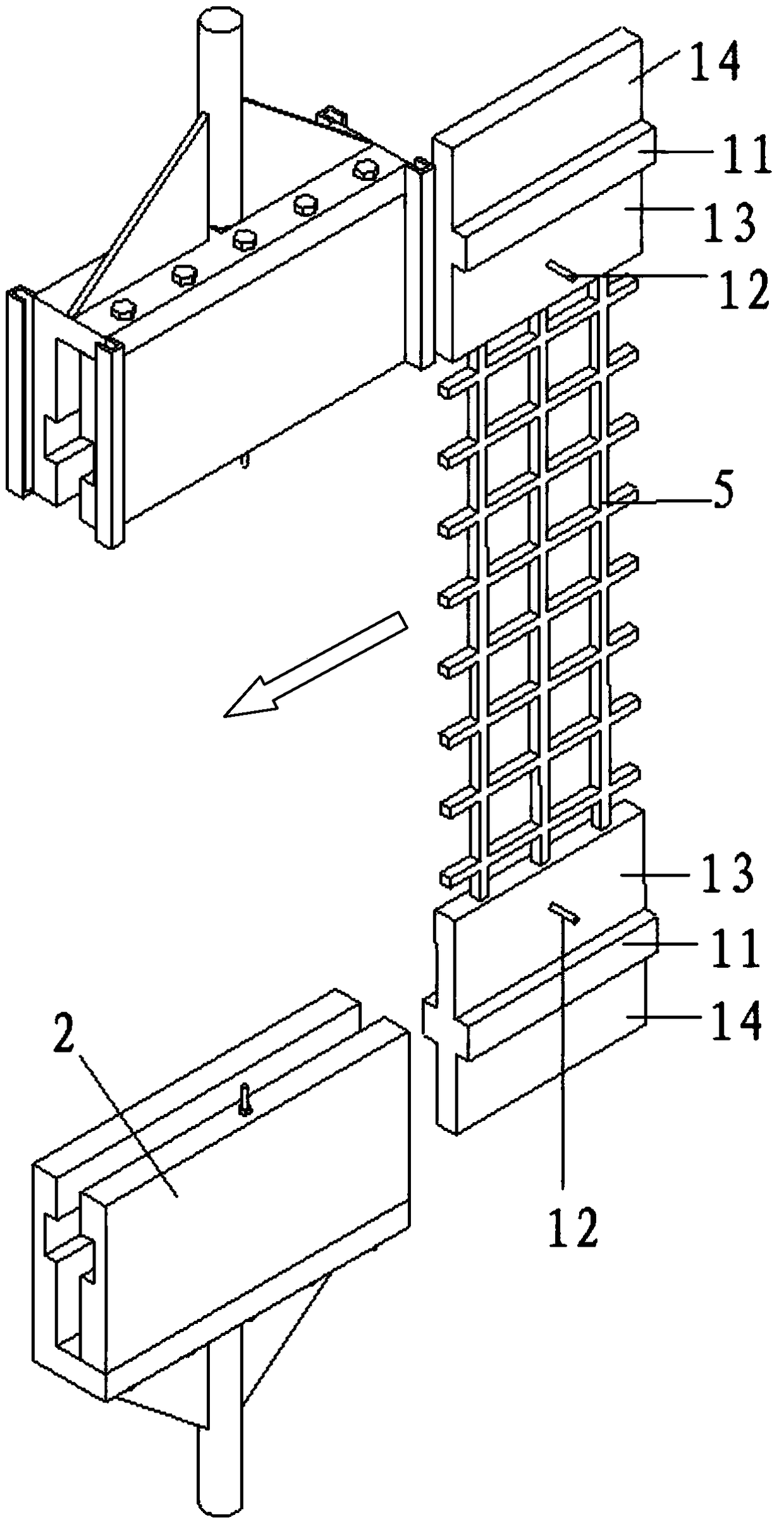

Test device and test method for testing performance of fiber composite grid material

PendingCN108801779APreparing sample for investigationMaterial strength using tensile/compressive forcesSteel platesComposite grid

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Tensile strength and break elongation test method of PVC paste resin glove material

ActiveCN106289900APreparing sample for investigationMaterial strength using tensile/compressive forcesInstruction dataRaw material

Owner:INNER MONGOLIA CHENHONGLI CHEM GRP CO LTD

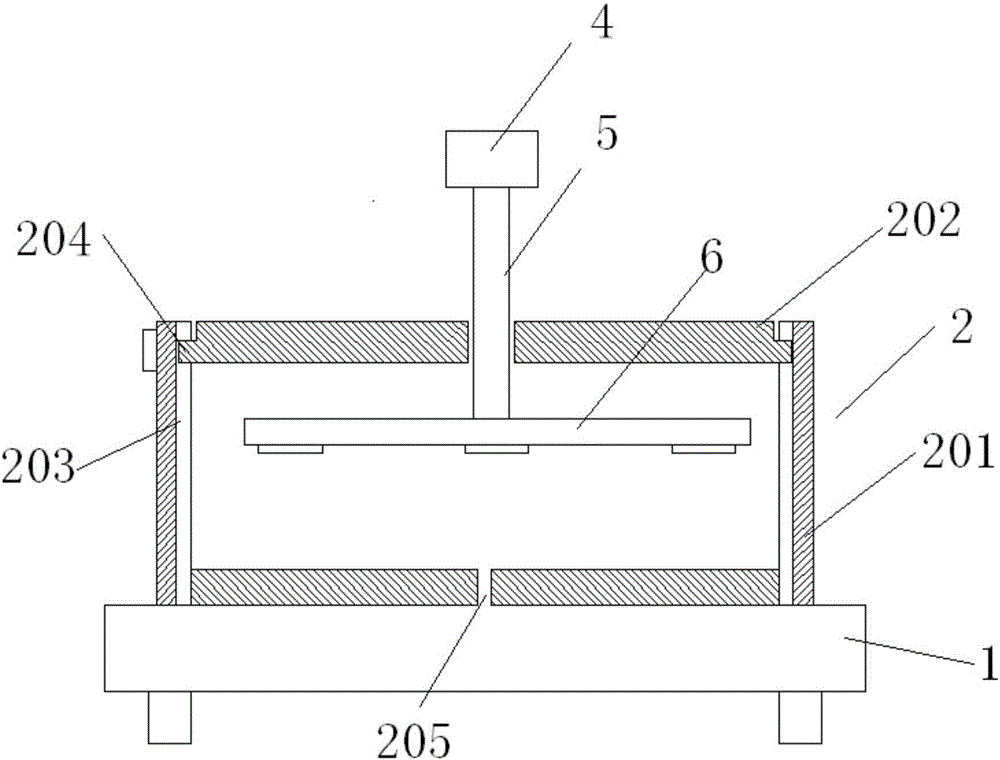

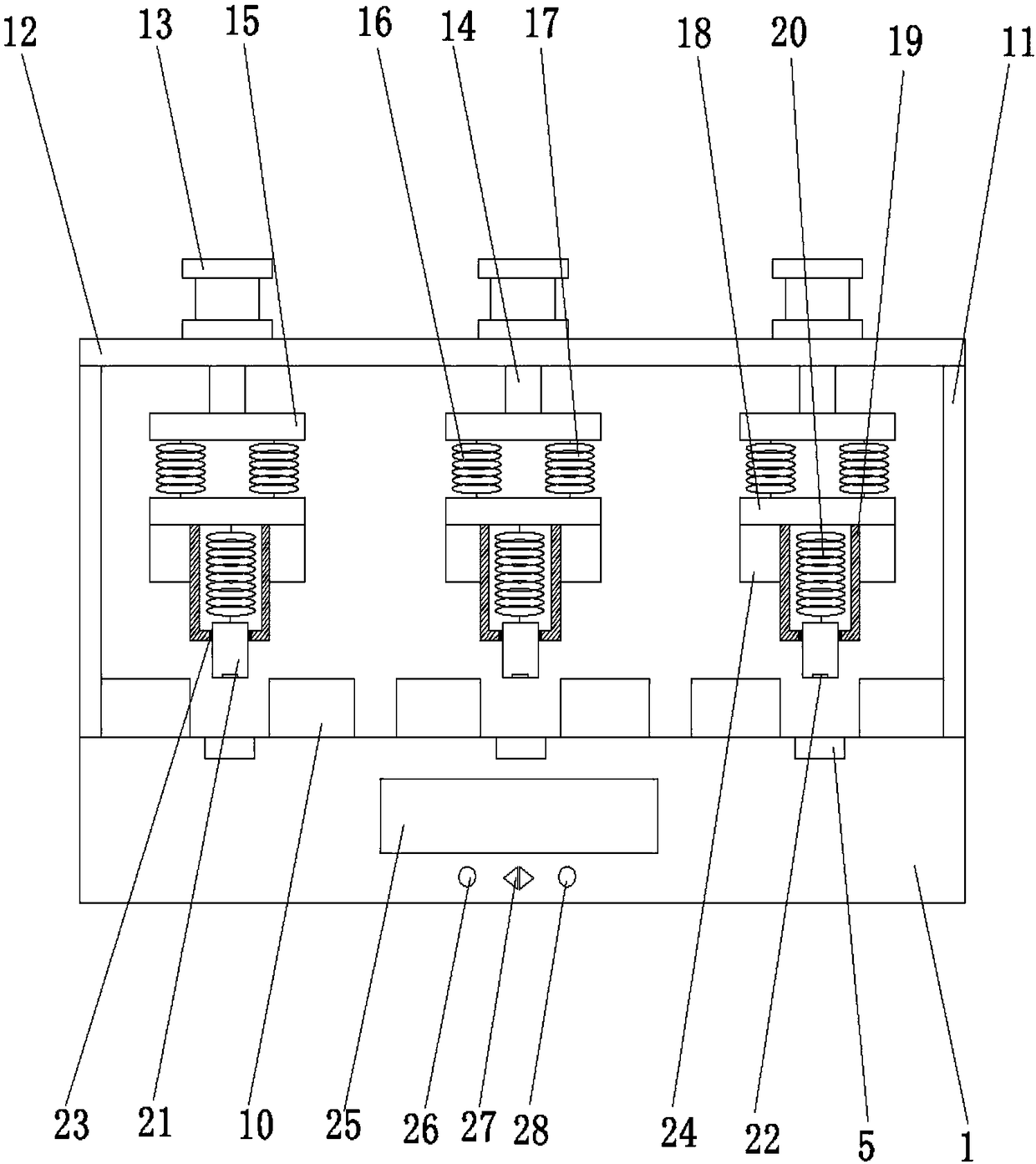

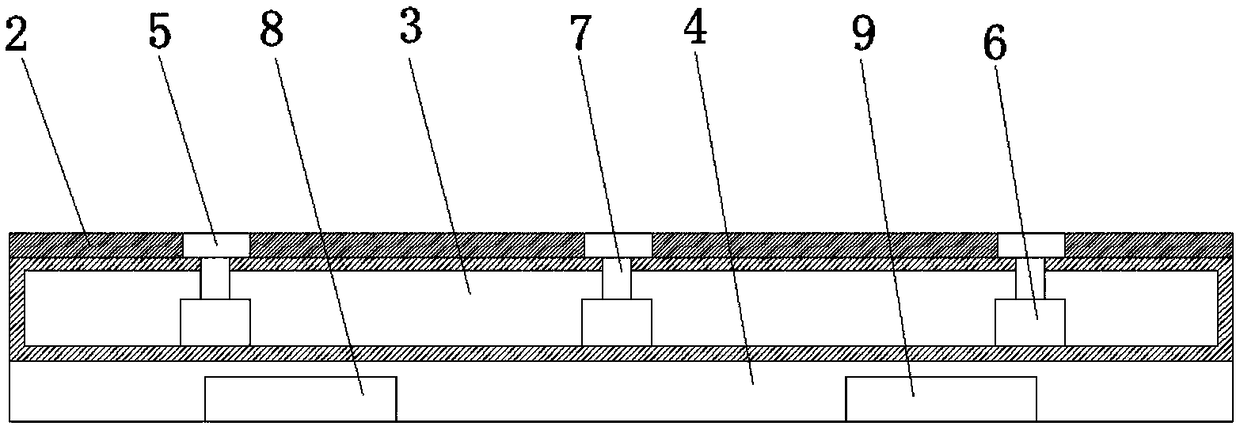

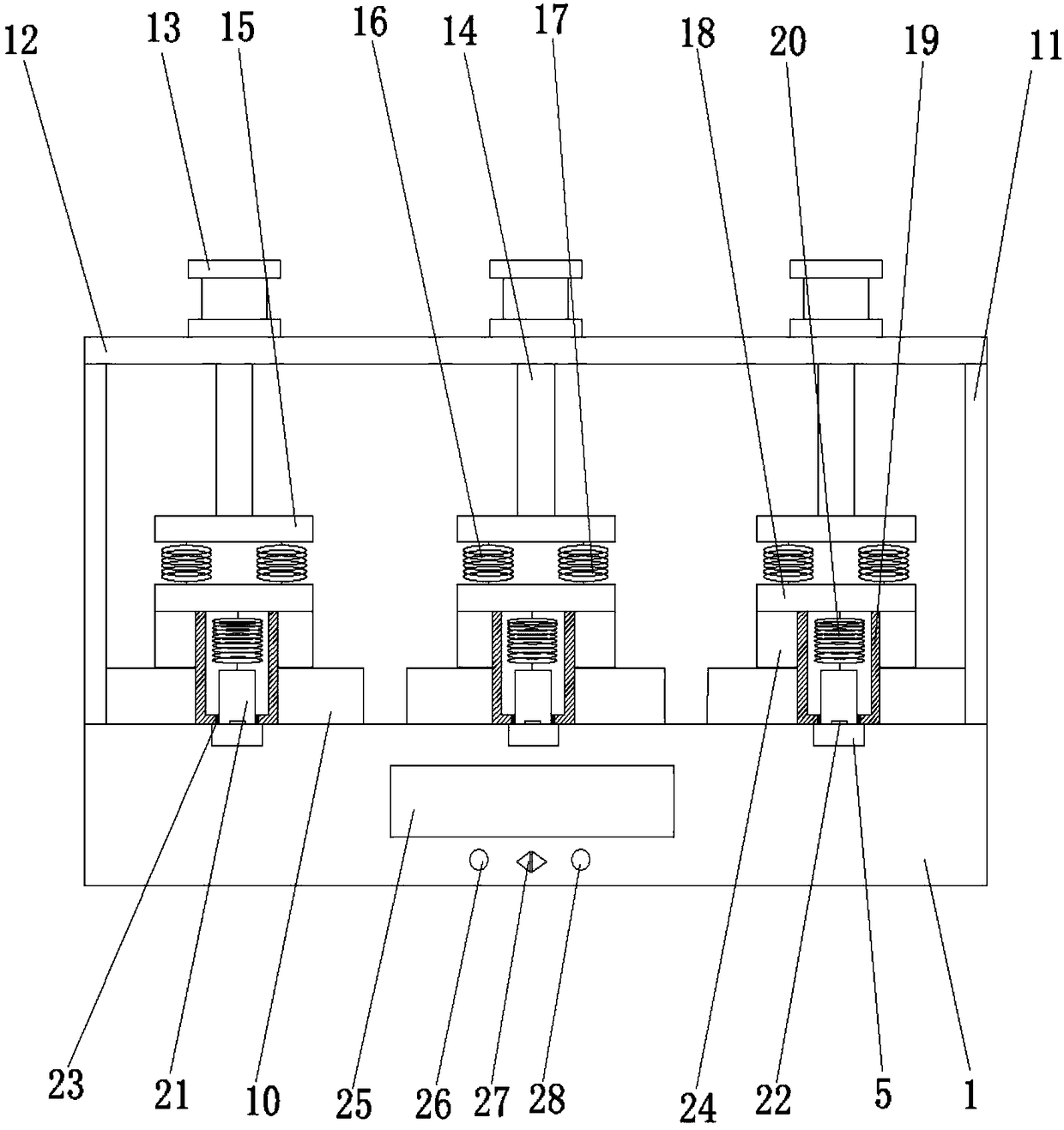

On-batch pressing testing device for touch control chip

InactiveCN108362565AGuaranteed accuracyDoes not affect accuracyMaterial strength using tensile/compressive forcesTest efficiencyControl layer

Owner:HUZHOU HUINENG ELECTROMECHANICAL TECH CO LTD

Tensile fixture

InactiveCN109142043AClamp firmlyPrevent slippageMaterial strength using tensile/compressive forcesButt jointRebar

Owner:LIUZHOU RAILWAY VOCATIONAL TECHN COLLEGE

Low-temperature stretching testing system and testing method

Owner:SOUTHWESTERN INST OF PHYSICS

Test device with convenient installation and unloading for testing dynamic characteristics of seismic isolation building structure

PendingCN110376071AEasy to installReturn quicklyMaterial strength using tensile/compressive forcesProtective buildings/sheltersOperabilityEngineering

Owner:SICHUAN INSITITUTE OF BUILDING RES

Equipment for detecting tensile property of thermistor by utilizing polishing characteristics

InactiveCN111272556AReduce the impactLittle elasticityMaterial strength using tensile/compressive forcesPhysicsThermistor

The invention relates to the technical field of thermistor pin detection, and further discloses equipment for detecting the tensile property of the thermistor by utilizing the polishing characteristics. The equipment comprises a shell, and an adsorption tank is fixedly connected to the interior of the shell; the bottom of the adsorption tank is movably connected with a millstone; a limiting bag isfixedly connected into the adsorption tank; the surface of the adsorption groove is movably connected with a spring rod; an extension spring is movably connected to the top of the adsorption groove,a supporting plate is movably connected to the interior of the extension spring, an extrusion rod is slidably connected to the surface of the supporting plate, a detection cover is movably connected to the end, away from the supporting plate, of the extrusion rod, rollers are movably connected to the interior of the detection cover, and buffer springs are movably connected to the surfaces of the rollers. The extension springs located on the lower portion move downwards, so that the symmetrical rollers get close to each other and clamp the pins to move downwards, the surfaces of the pins are unqualified if the pins are snapped at the moment, otherwise the surfaces of the pins are qualified, and therefore the effect of gradually detecting the anti-stretching capacity of the pins through thepin grinding working characteristics is achieved.

Owner:义乌招娣贸易有限公司

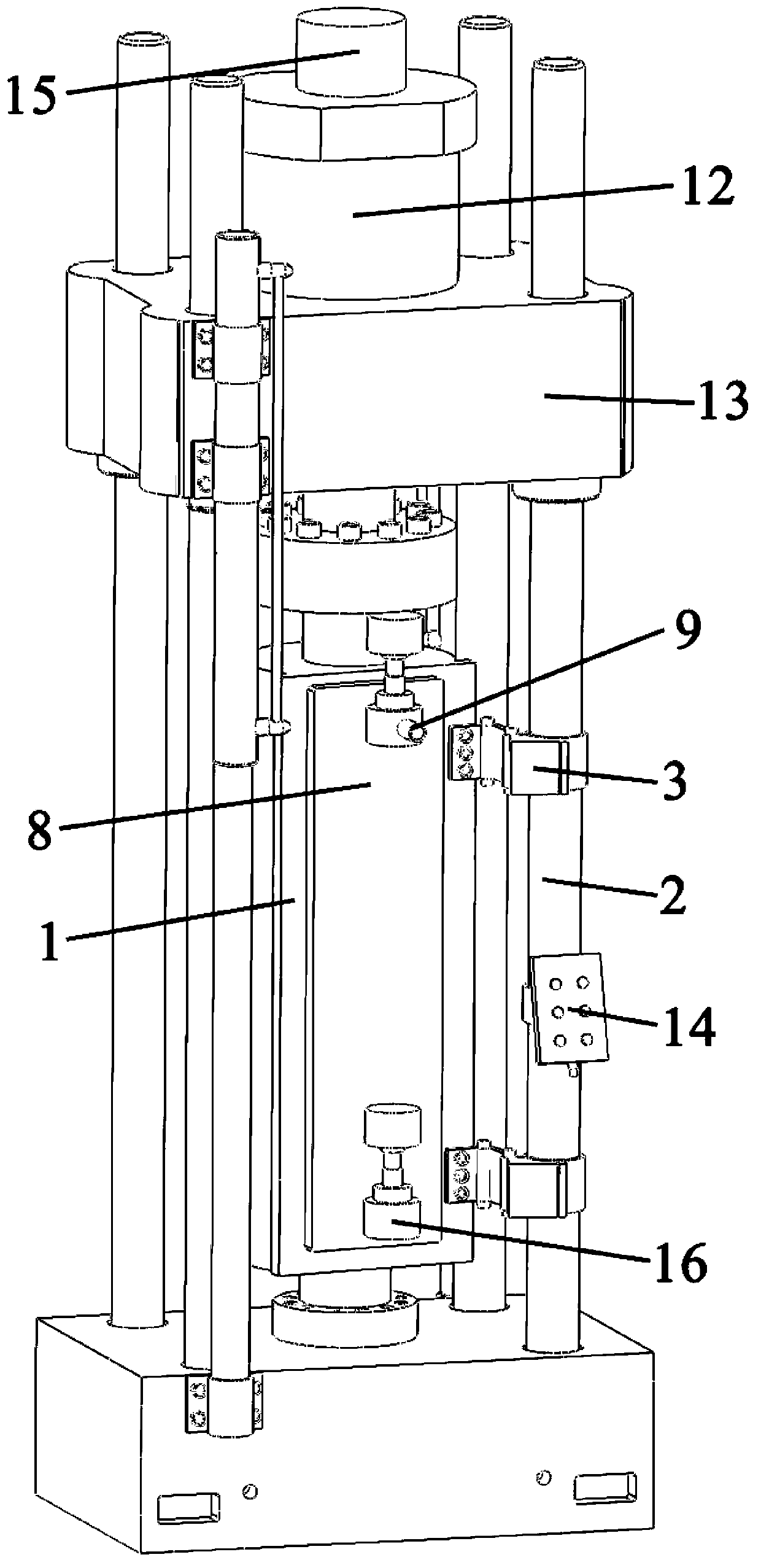

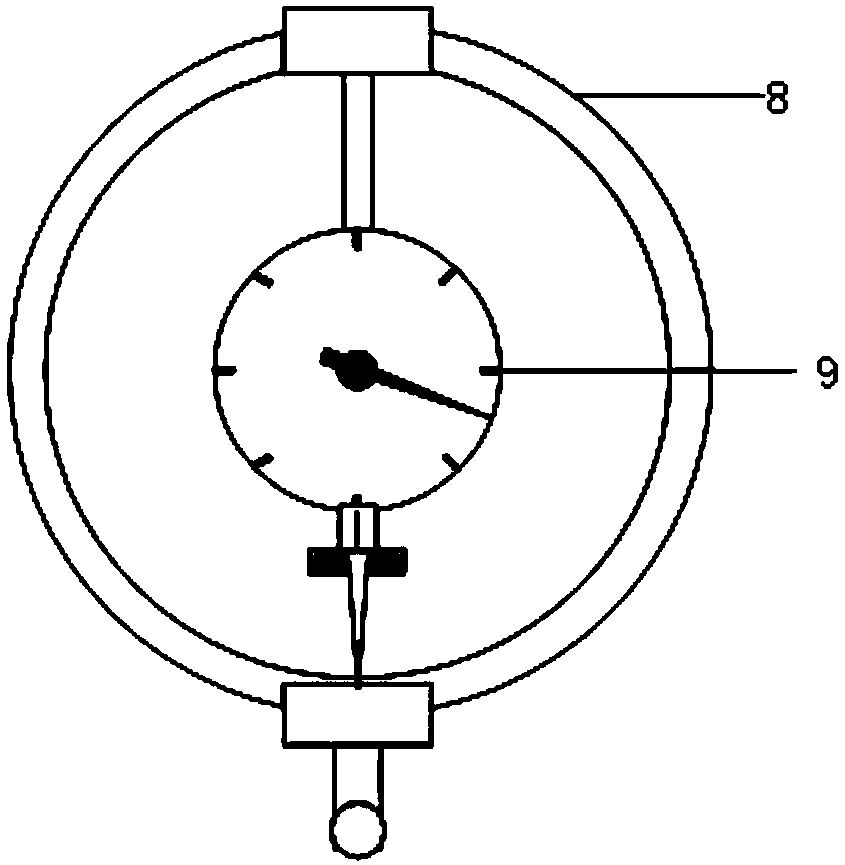

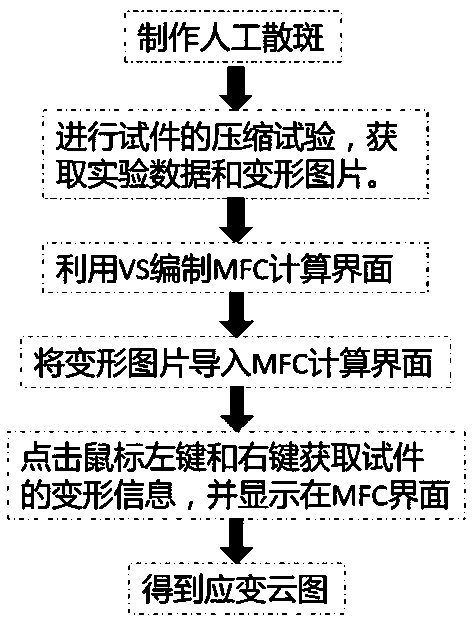

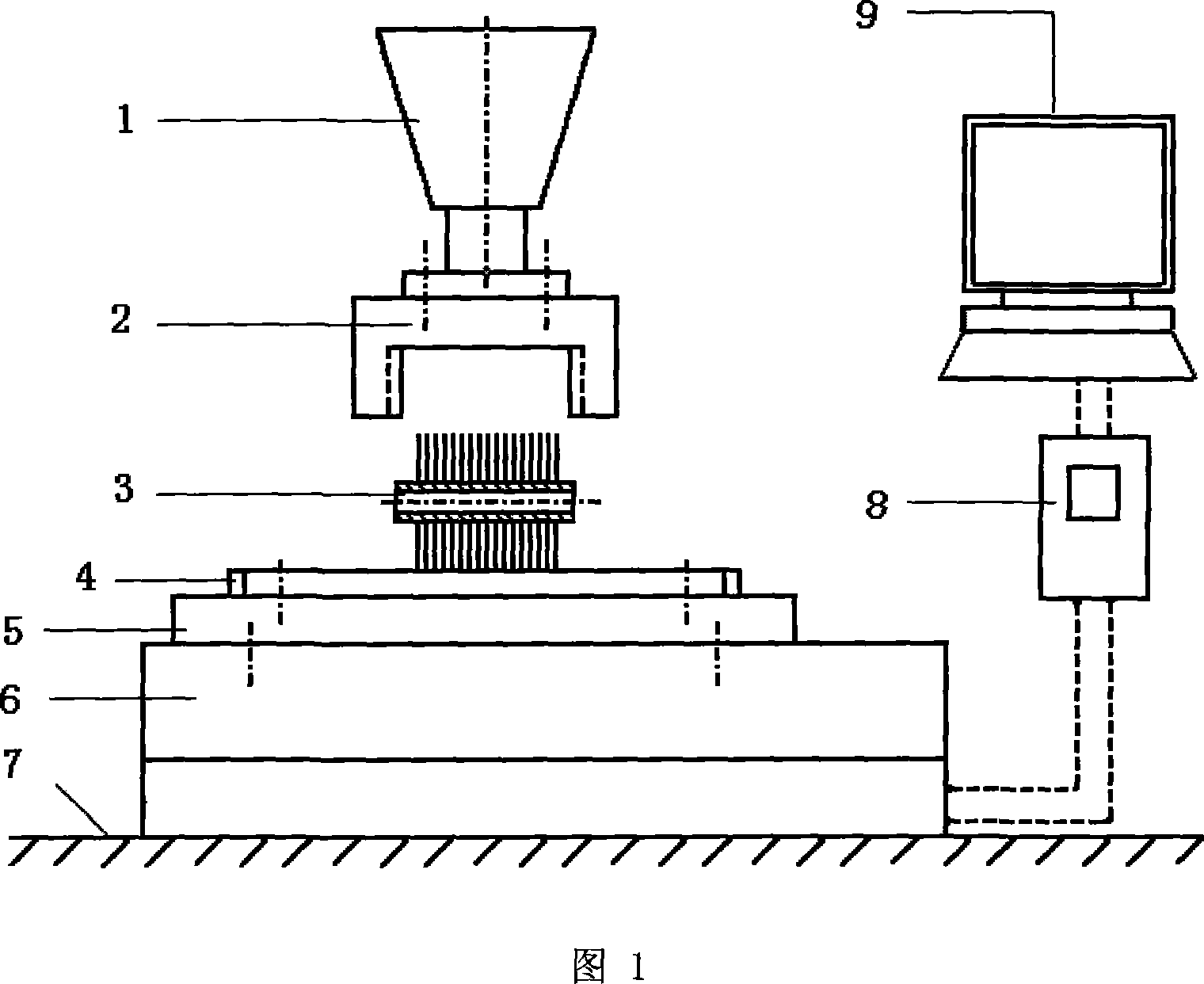

Testing method for determining stress and damage mechanism of columnar jointed rock mass

InactiveCN107271276ASolving Research Questions for StabilityAvoid cumbersomenessPreparing sample for investigationMaterial strength using tensile/compressive forcesTest sampleAxial pressure

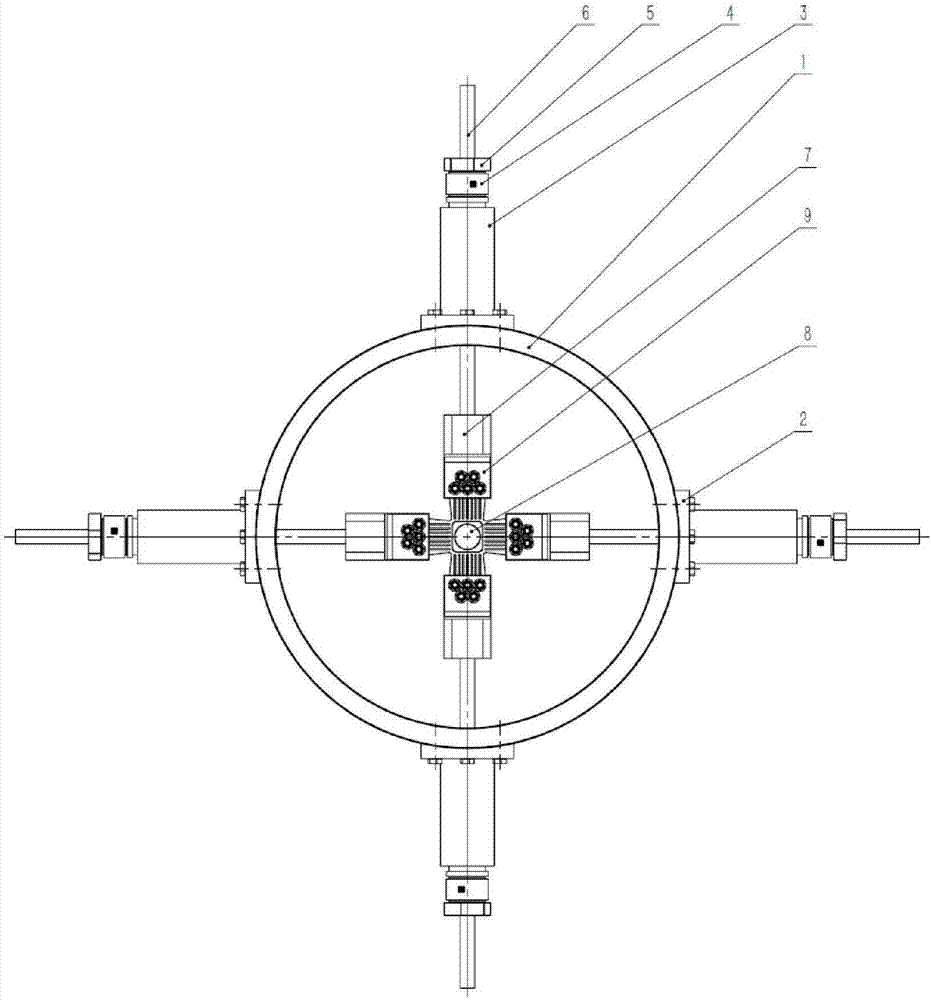

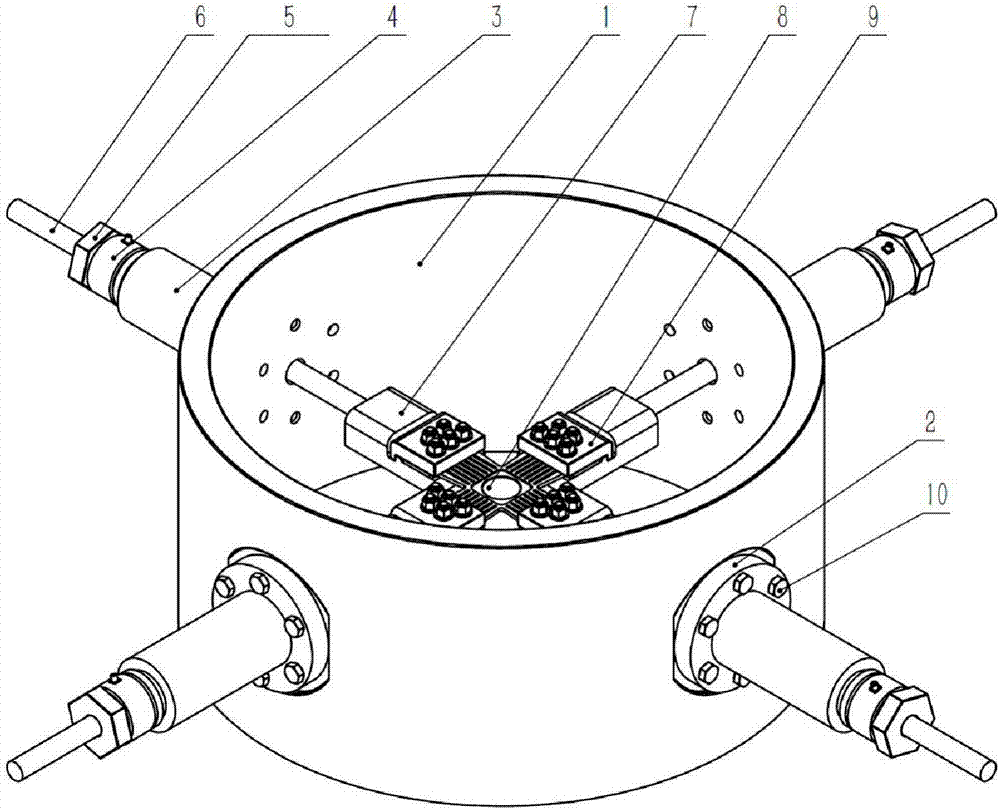

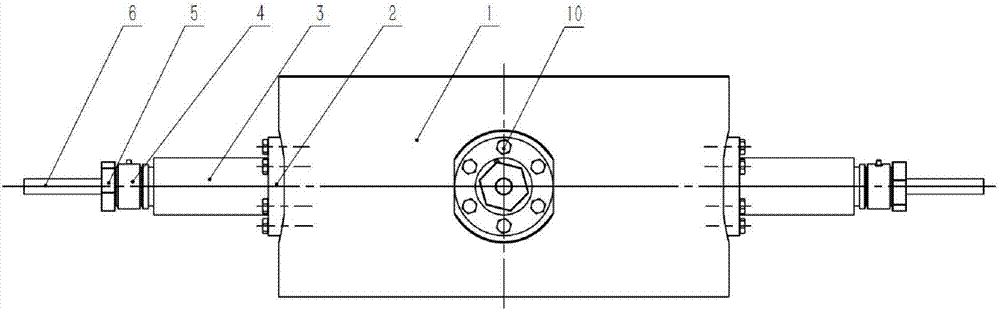

The invention discloses a testing method for determining a stress and damage mechanism of a columnar jointed rock mass. The testing method comprises the following steps: 1) preparing cement mortar according to mechanical characteristics of an actual rock mass to prepare a regular hexagonal prism-shaped test sample; 2) splicing the regular hexagonal prism-shaped test samples to form a cuboid-shaped columnar jointed rock mass test sample model; curing, cutting and polishing to prepare cube-shaped columnar jointed rock mass test pieces with different inclined angles; 3) putting the columnar jointed rock mass test pieces into a rock rheometer; fixing the rock rheometer in the horizontal direction and slowly applying axial pressure until the test pieces are damaged; recording stress and strain data in a testing process; 4) processing recorded testing data to obtain a stress-strain relation of the columnar jointed rock mass, wherein the stress-strain relation reflects the stress and damage mechanism of the rock mass. According to the testing method disclosed by the invention, stress and damage conditions of the columnar jointed rock mass are demonstrated by a model testing method; the testing method has the advantages of low construction price, high simulation degree, simplicity in operation and the like.

Owner:HOHAI UNIV

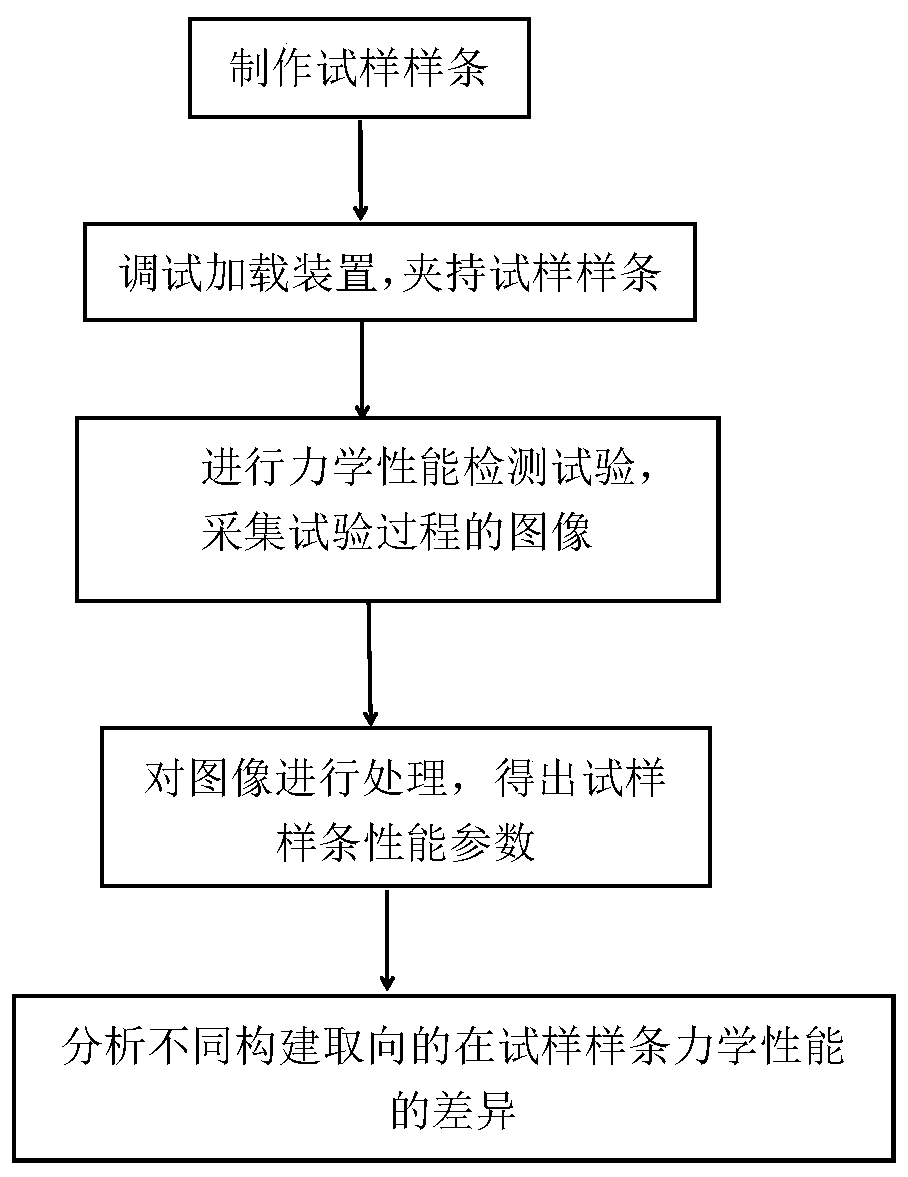

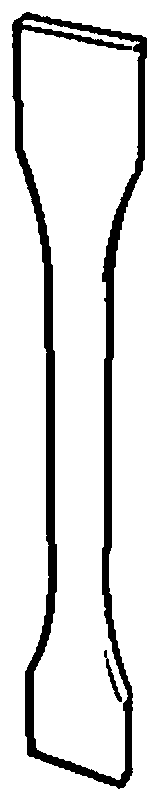

Method for analyzing mechanical properties of 3D printing samples with different construction orientations

InactiveCN111426552AAccurately obtain tensile propertiesAccurately get strengthMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesTest sampleStructural engineering

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

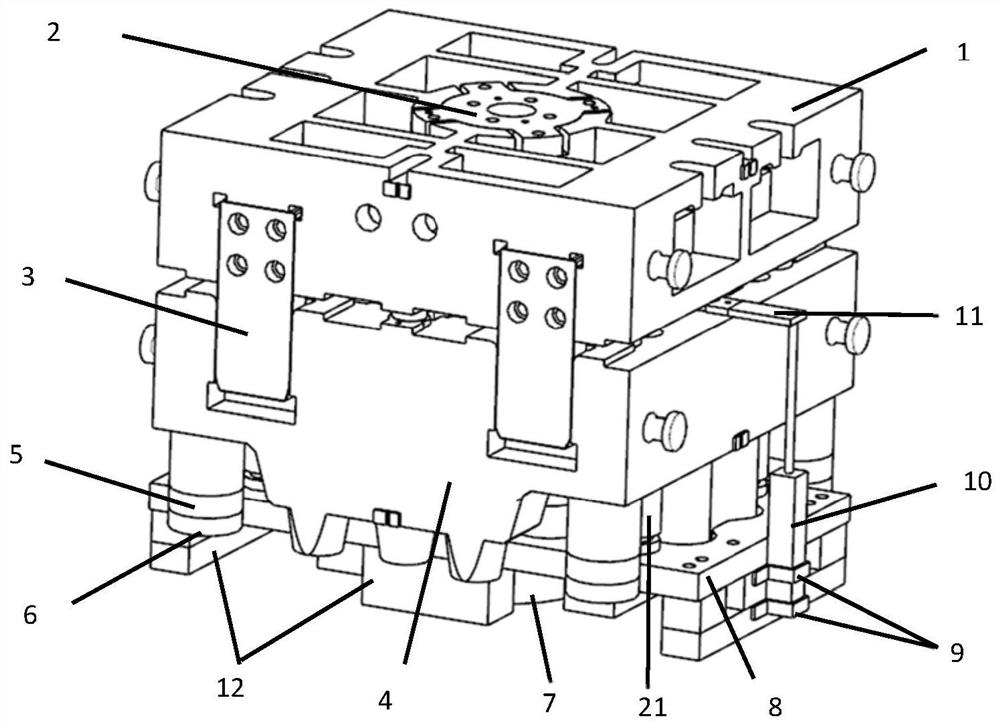

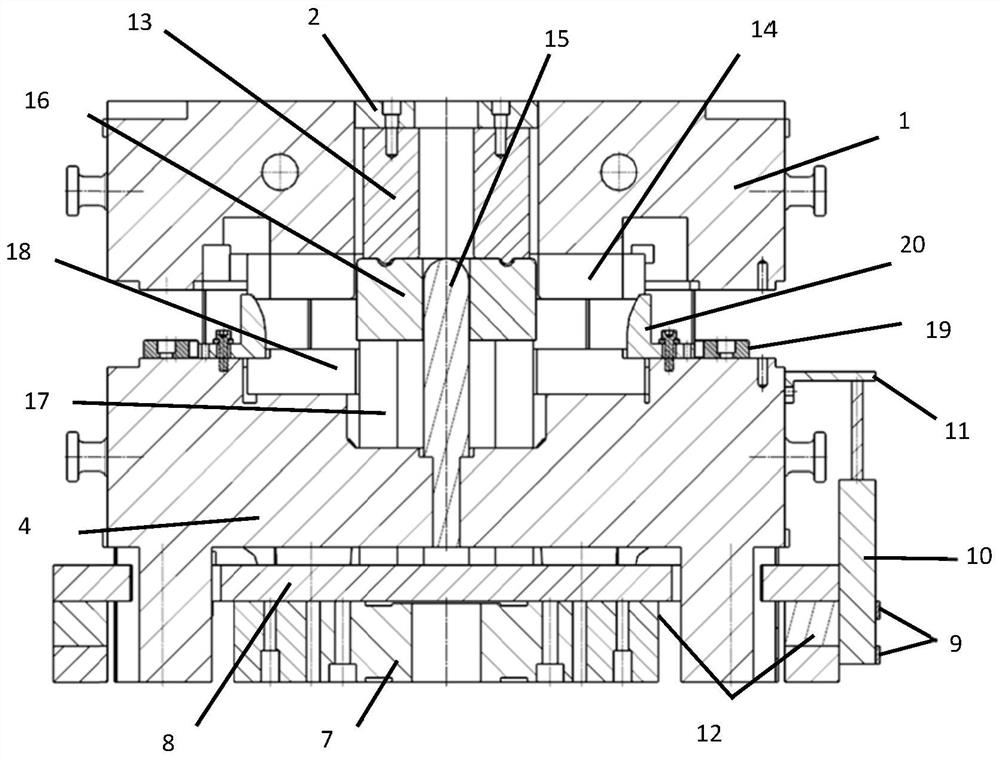

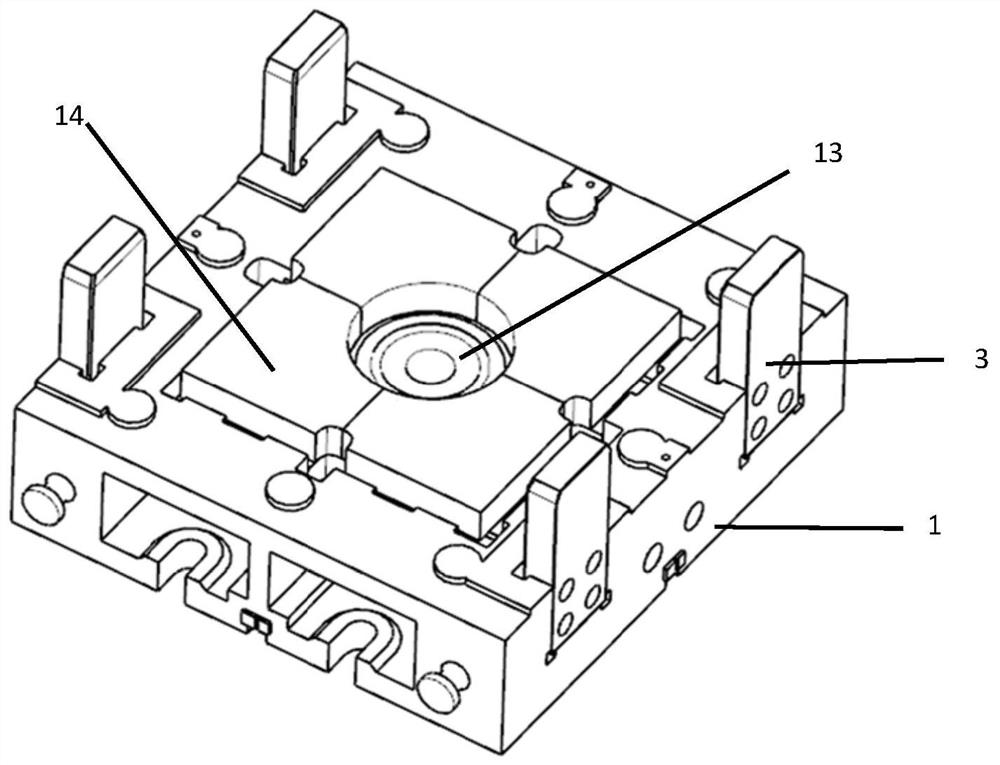

Die structure for plate drawing and bulging performance experiments

ActiveCN112045052AAvoid wastingGuaranteed accuracyShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

Owner:HUNAN UNIV +1

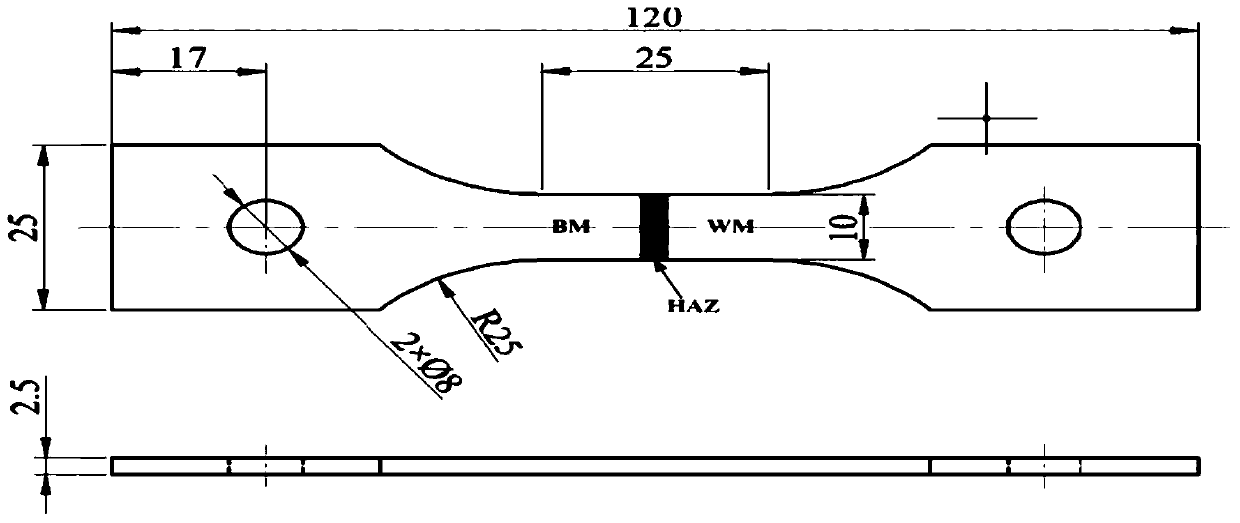

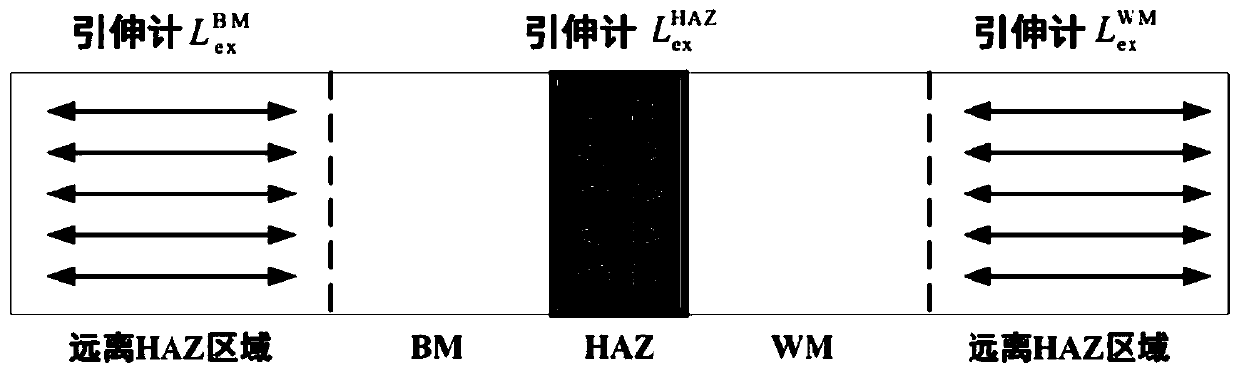

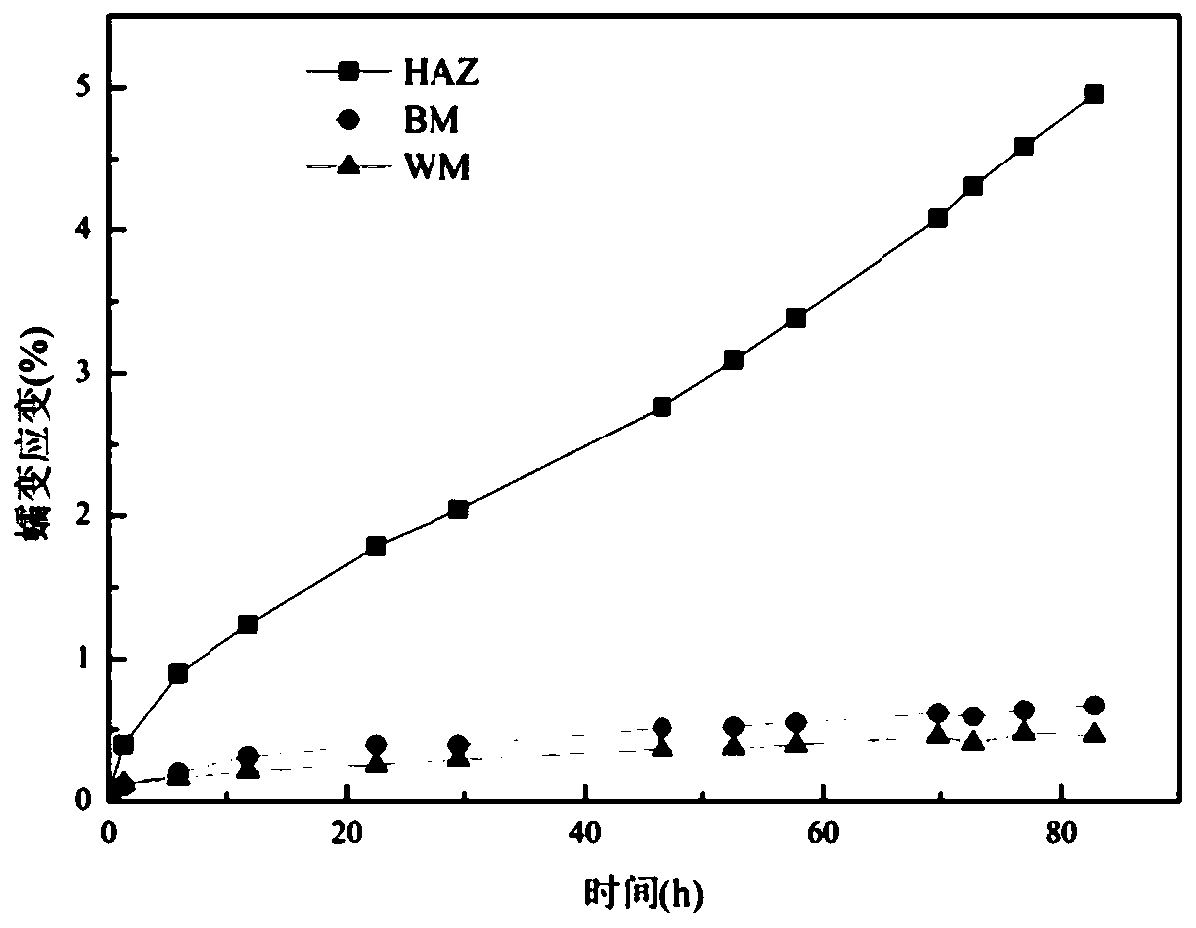

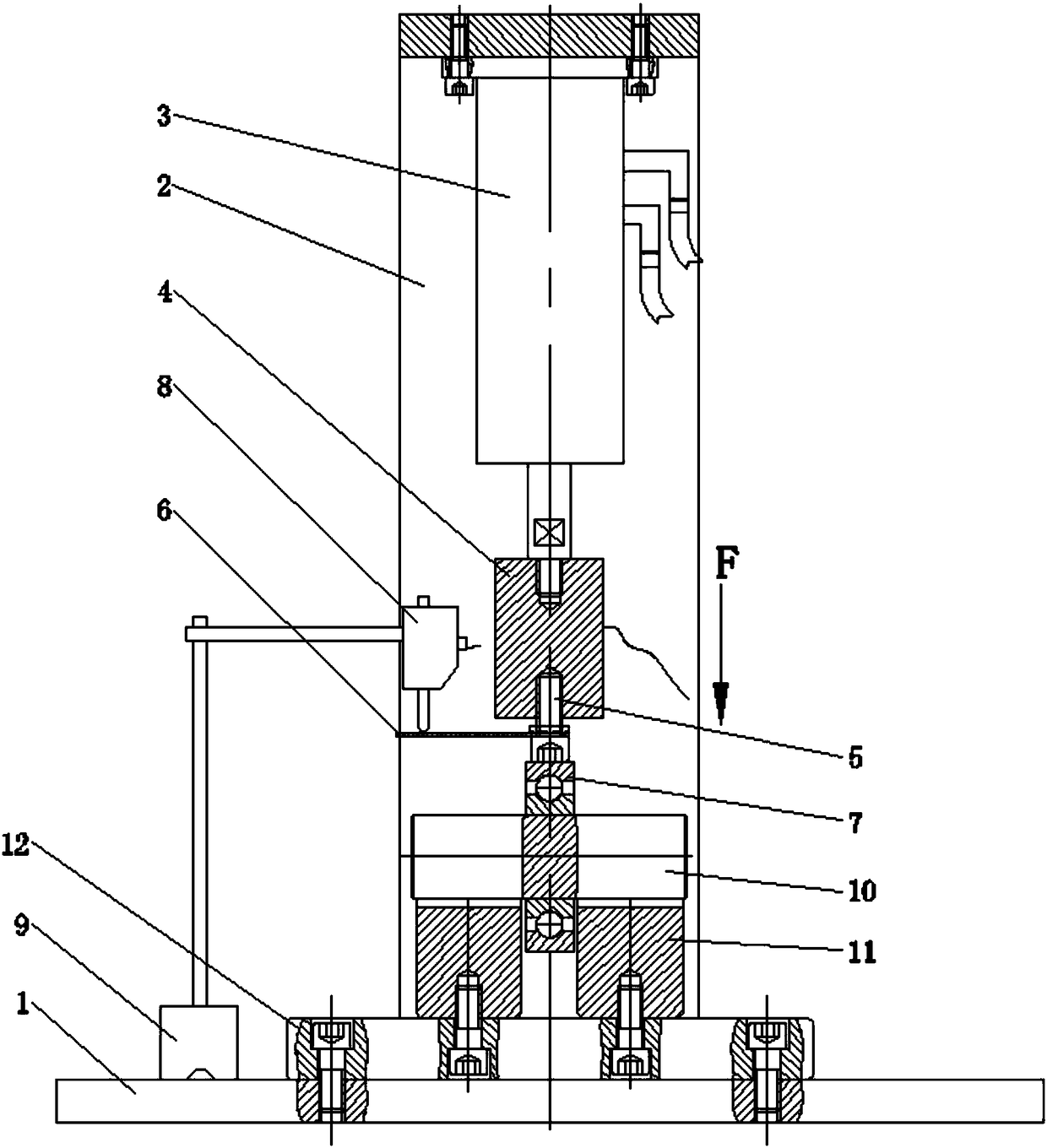

Welded joint creep deformation prediction method based on DIC technology

ActiveCN111044351ASolve the problem of creep deformation characterizationReduce measurement noisePreparing sample for investigationMaterial strength using tensile/compressive forcesHeat-affected zoneStress level

Owner:HEFEI GENERAL MACHINERY RES INST +1

Deep groove ball bearing rigiditystiffness testing device

Owner:CHONGQING CHANGJIANG BEARING

The device is suitable for rock gas breakthrough pressure measurement under high-temperature and high-pressure conditions

Owner:PETROCHINA CO LTD

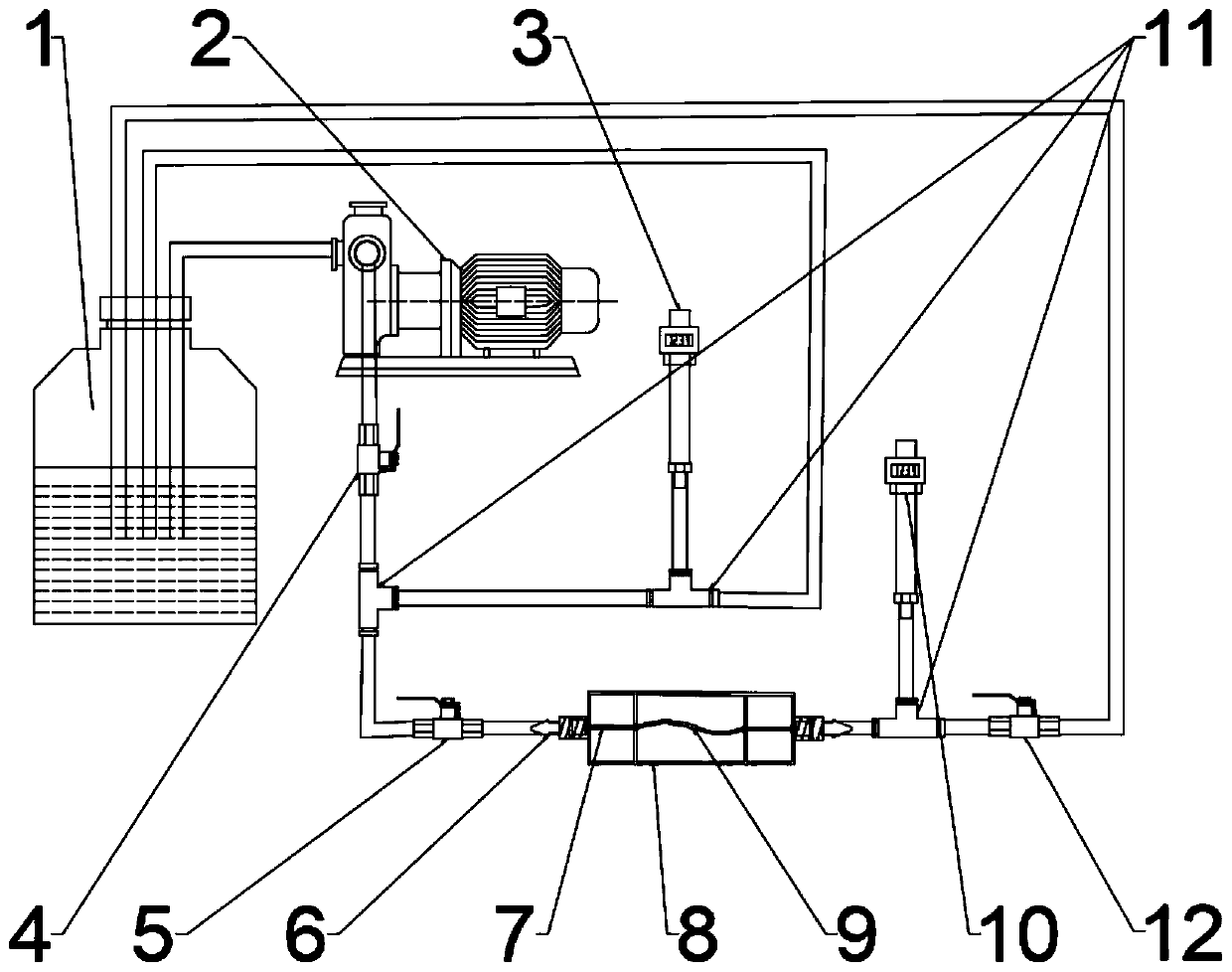

Small artificial bionic blood vessel perfusion fluid pressure testing system and method

ActiveCN110487638AMaterial strength using tensile/compressive forcesBall valveFluid Pressure Testing

Owner:XI AN JIAOTONG UNIV

Heating tensile test device for numerically-controlled machine tool spindle environment reliability test

ActiveCN112485105AEasy to replaceNo lossMaterial strength using tensile/compressive forcesNumerical controlElectric machinery

Owner:JILIN UNIV

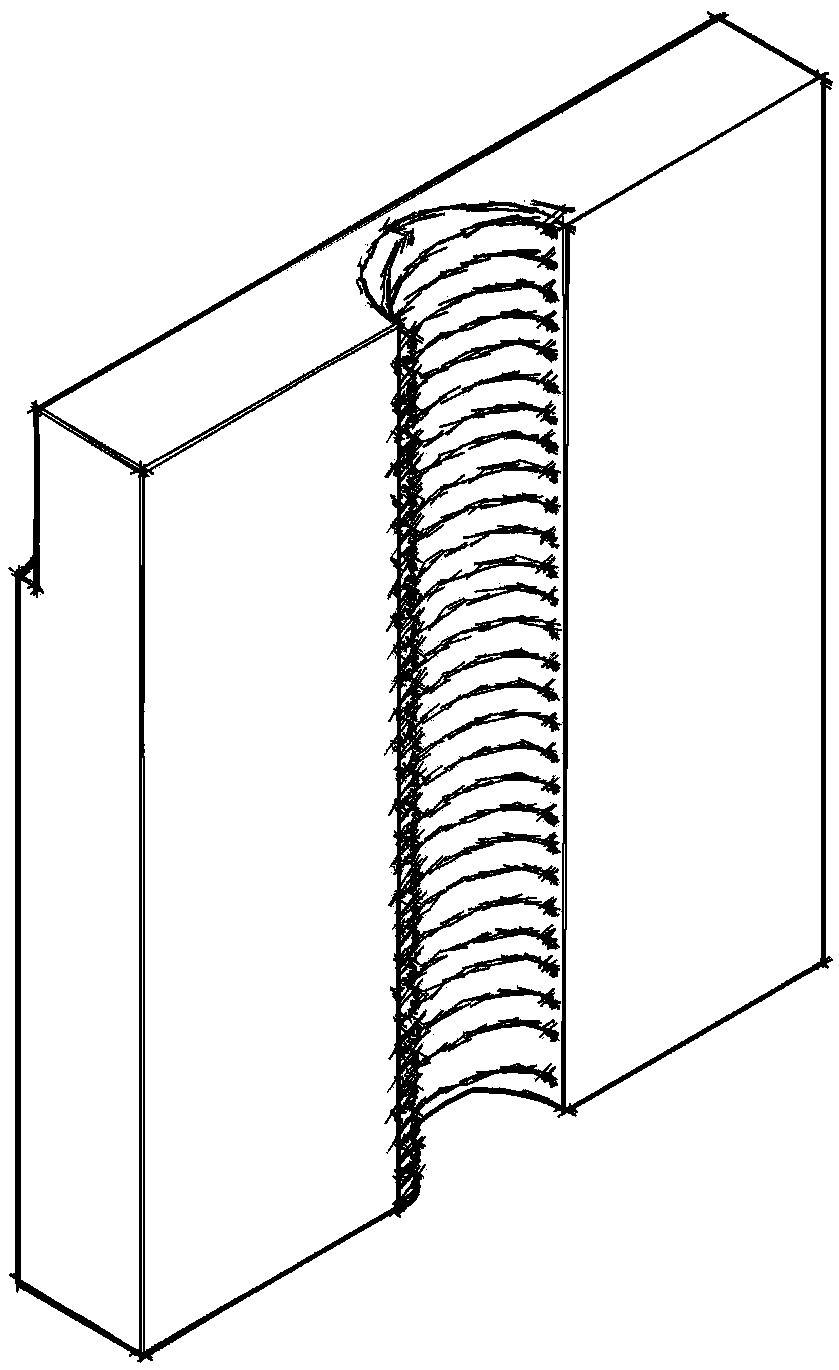

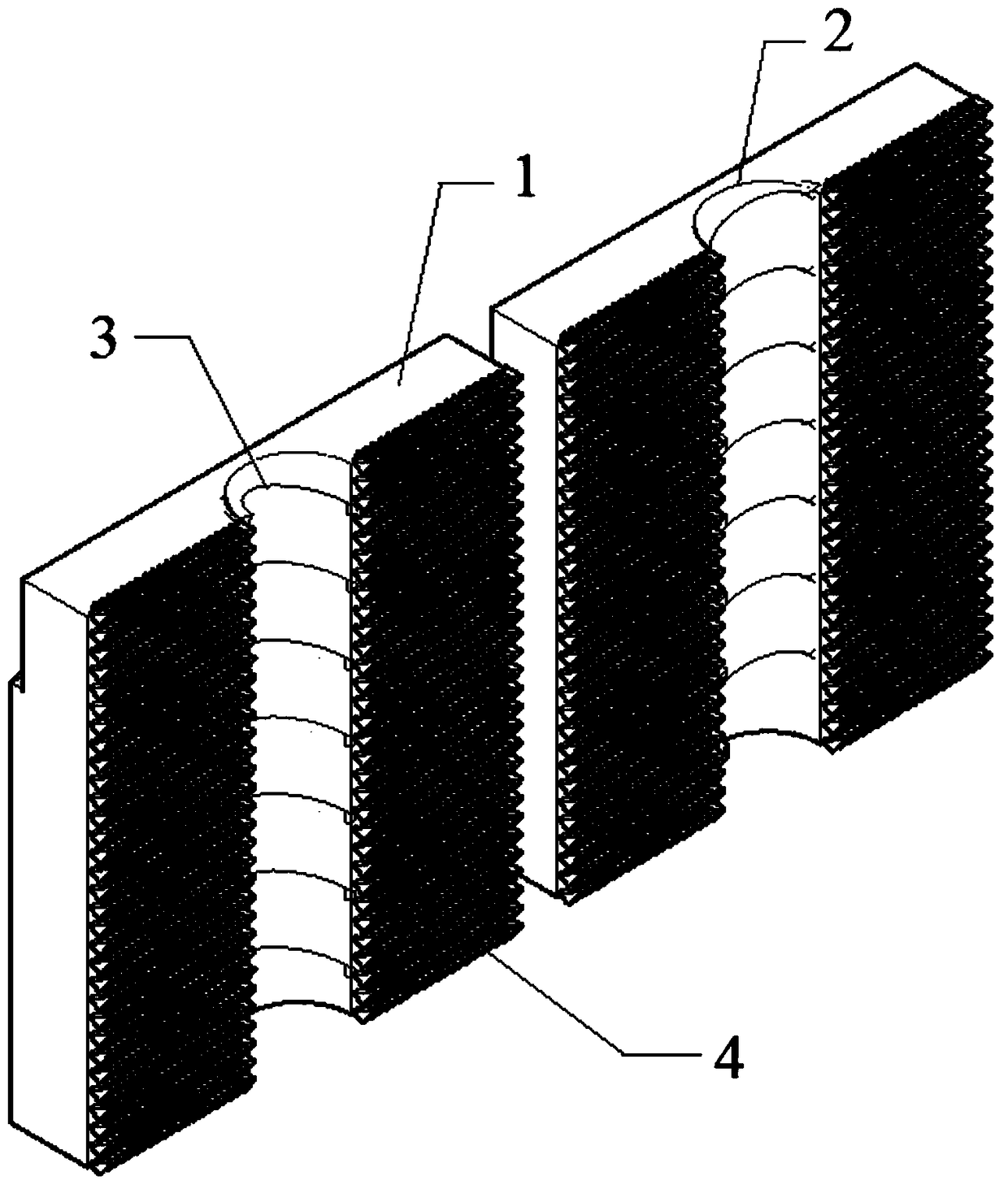

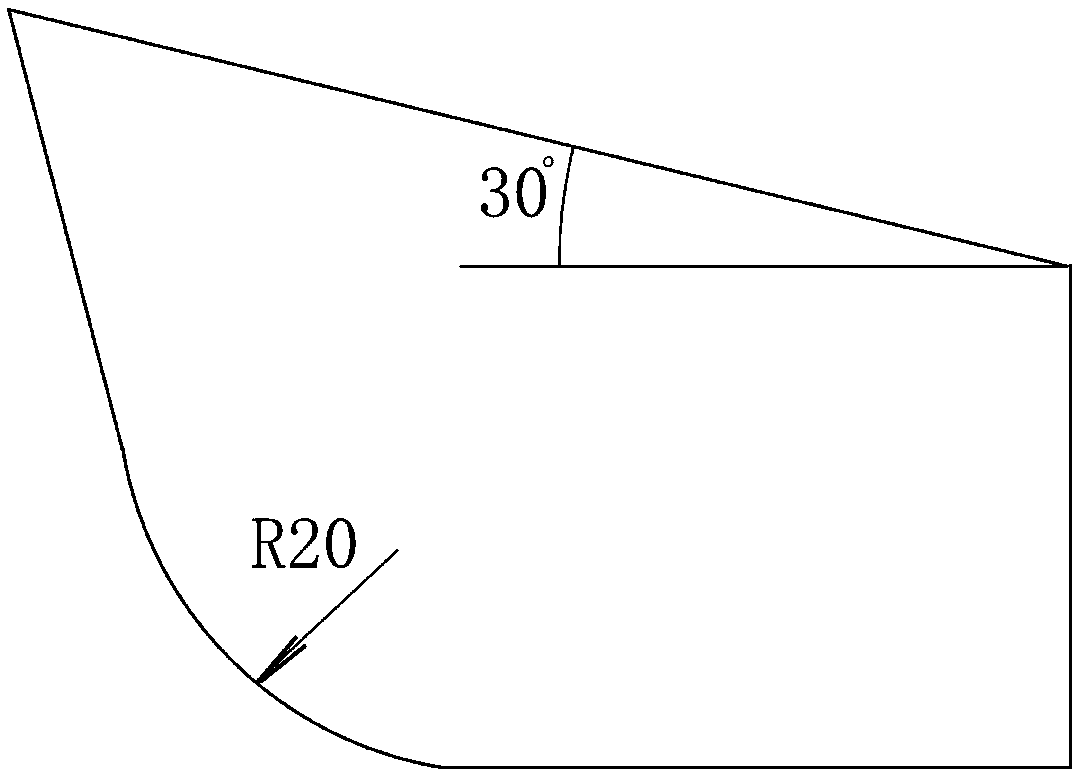

Device for measuring heat-exchanger ripple fin vertical strength under transverse loading

InactiveCN101074898AMaterial strength using tensile/compressive forcesElasticity measurementMeasurement deviceSurface plate

Owner:无锡凯博易机电科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap