Welded joint creep deformation prediction method based on DIC technology

A technology of welded joints and creep deformation, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, and preparation of test samples, which can solve the problems of lack of extraction of creep deformation data, etc., to solve the problem of creep deformation Deformation characterization problem, effect of reducing measurement noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A method for predicting creep deformation of welded joints based on DIC technology, comprising the following steps:

[0023] S1. Process the welded joint sample; specifically, first spray a layer of white high-temperature paint on the sample as a primer, and then spray diffuse and randomly distributed black high-temperature paint on the primer. In order to ensure the stability of the prepared high-temperature speckle, the sample was baked in a muffle furnace at a temperature of 230°C for 30 minutes. It should be noted that it is necessary to ensure that the welding heat-affected zone is located in the center of the sample, and the weld and base metal are located on both sides of the welding heat-affected zone.

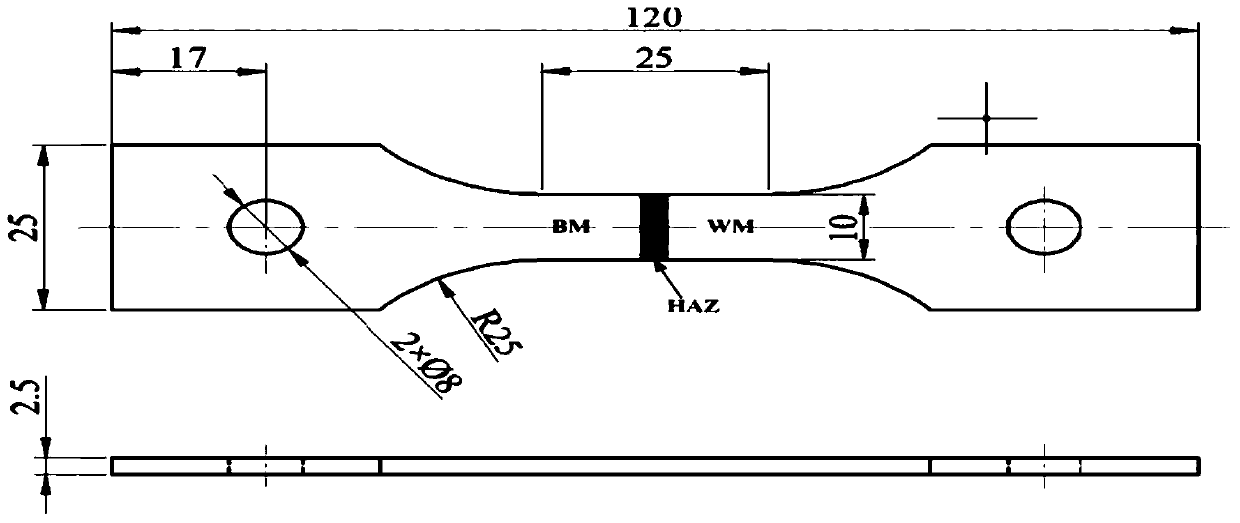

[0024] In this embodiment, the sample material of the welded joint is low-alloy ferritic steel 2.25Cr1Mo0.25V, the length and width of the gauge section are 25mm and 10mm respectively, and the thickness of the sample is 2.5mm. The schematic diagram of the sample g

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap