Plastic welding device and laser welding method thereof

A technology of plastic welding and laser welding, which is applied in the field of laser welding to reduce the heat-affected zone and increase water resistance and air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The plastic laser welding method of the present invention is mainly for welding thermosetting plastics, and is used to expand the application of laser welding on thermosetting plastics.

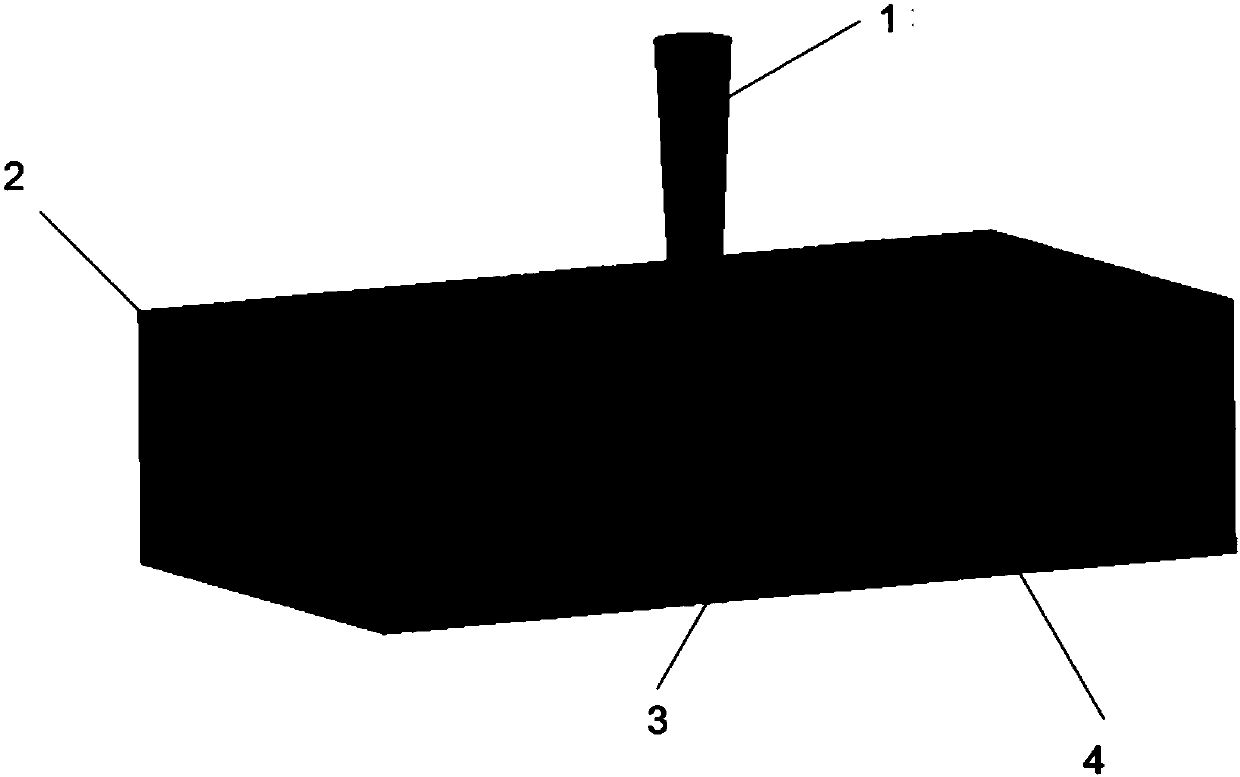

[0022] Such as figure 2 Shown is the schematic diagram of the present invention, the plastic welding device includes materials to be welded, and the materials to be welded include an upper layer of material 2 made of a light-transmitting material, a lower layer of material 4 made of an opaque material, and a layer of material located between the upper layer of material 2 and the lower layer The hot-melt tape 3 between the materials 4, the hot-melt tape is located at the position to be welded of the lower layer material 4, and the hot-melt tape 3 connects the upper layer material 2 and the lower layer material 4. The laser beam 1 acts on the upper material 2 to be welded.

[0023] The adhesive tape 3 can also be a thermosetting adhesive tape.

[0024] After the laser beam 1 passes throu

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap