On-batch pressing testing device for touch control chip

A technology of touch chip and testing device, which is applied in the direction of measuring device, using stable tension/pressure testing material strength, instruments, etc., to achieve the effect of ensuring test accuracy, test safety and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments involved in the present invention will be described in further detail below in conjunction with the accompanying drawings.

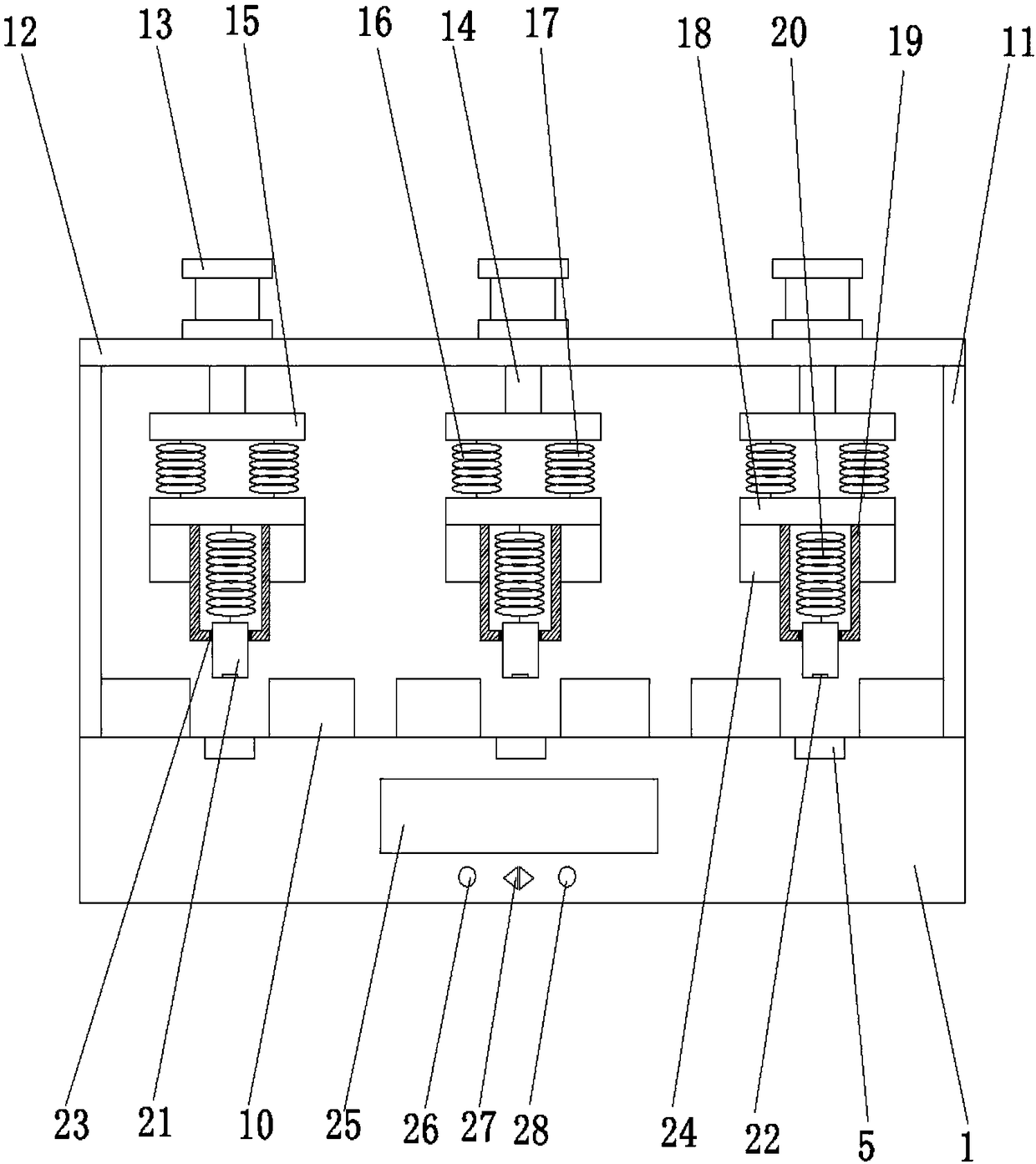

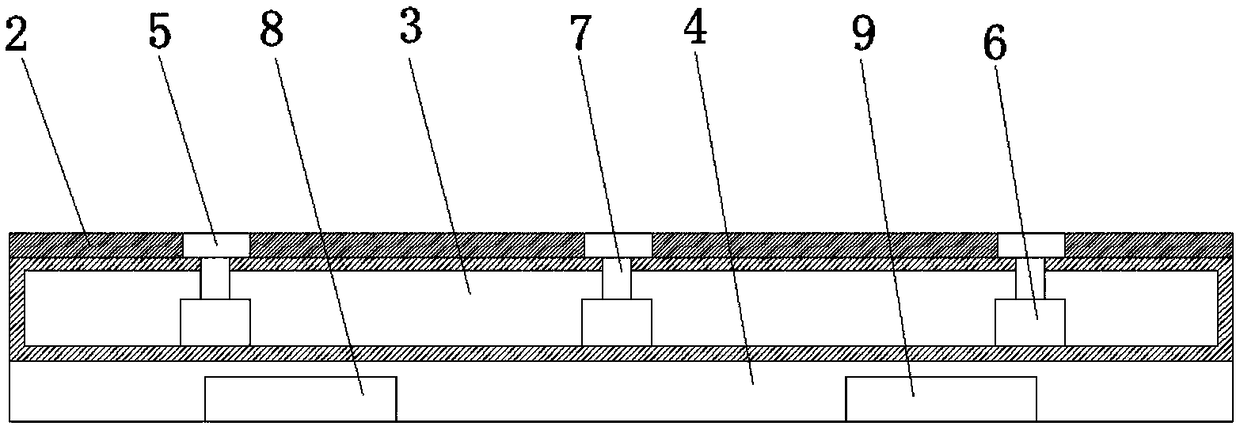

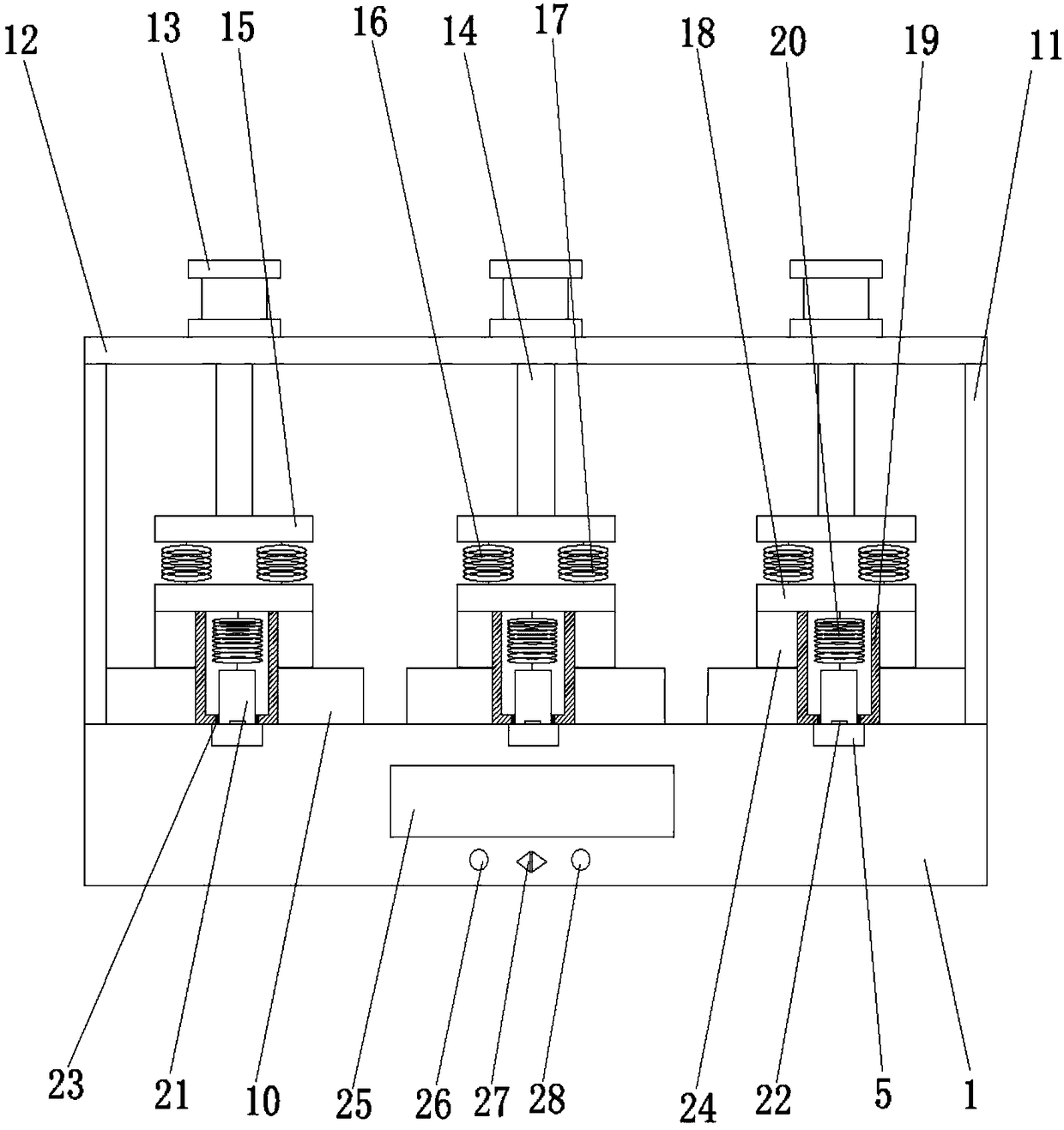

[0021] to combine Figure 1 ~ Figure 4 , a batch press test device for touch chips, including a device body, the device body includes a base 1, the base 1 is divided into a positioning layer 2, an adsorption layer 3 and a control layer 4, and the positioning layer 2, the adsorption layer 3 and the control layer 4 are composed of Arranged in order from top to bottom, the positioning layer 2 is provided with a number of positioning grooves 5, the depth of the positioning grooves 5 is equivalent to the thickness of the chip to be tested, and the bottom of the adsorption layer 3 is provided with a number of vacuum pumps 6, the number and position of the vacuum pumps 6 are consistent with the positioning Corresponding to the groove 5, the vacuum tube 7 of the vacuum pump 6 runs through the top of the adsorption layer 3 and communicates wit

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap