Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41 results about "Vacuum pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A vacuum pump is a device that removes gas molecules from a sealed volume in order to leave behind a partial vacuum. The first vacuum pump was invented in 1650 by Otto von Guericke, and was preceded by the suction pump, which dates to antiquity.

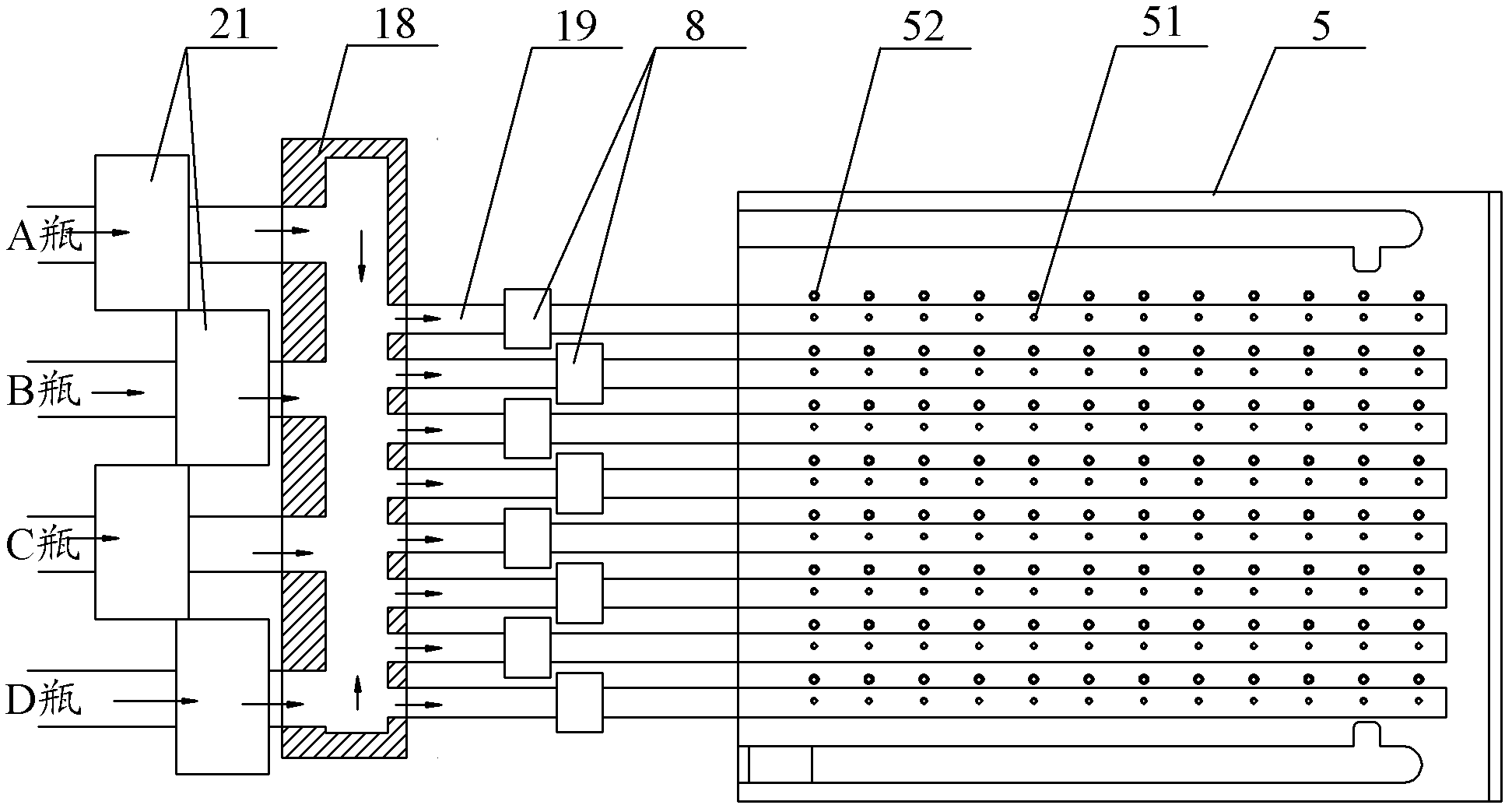

Pressure balance system of automatic ELISA (Enzyme-Linked Immunosorbent Assay) plate washer and automatic ELISA plate washer

Owner:SHENZHEN PERWIN BIO TECH

Dense core permeability measuring device and method

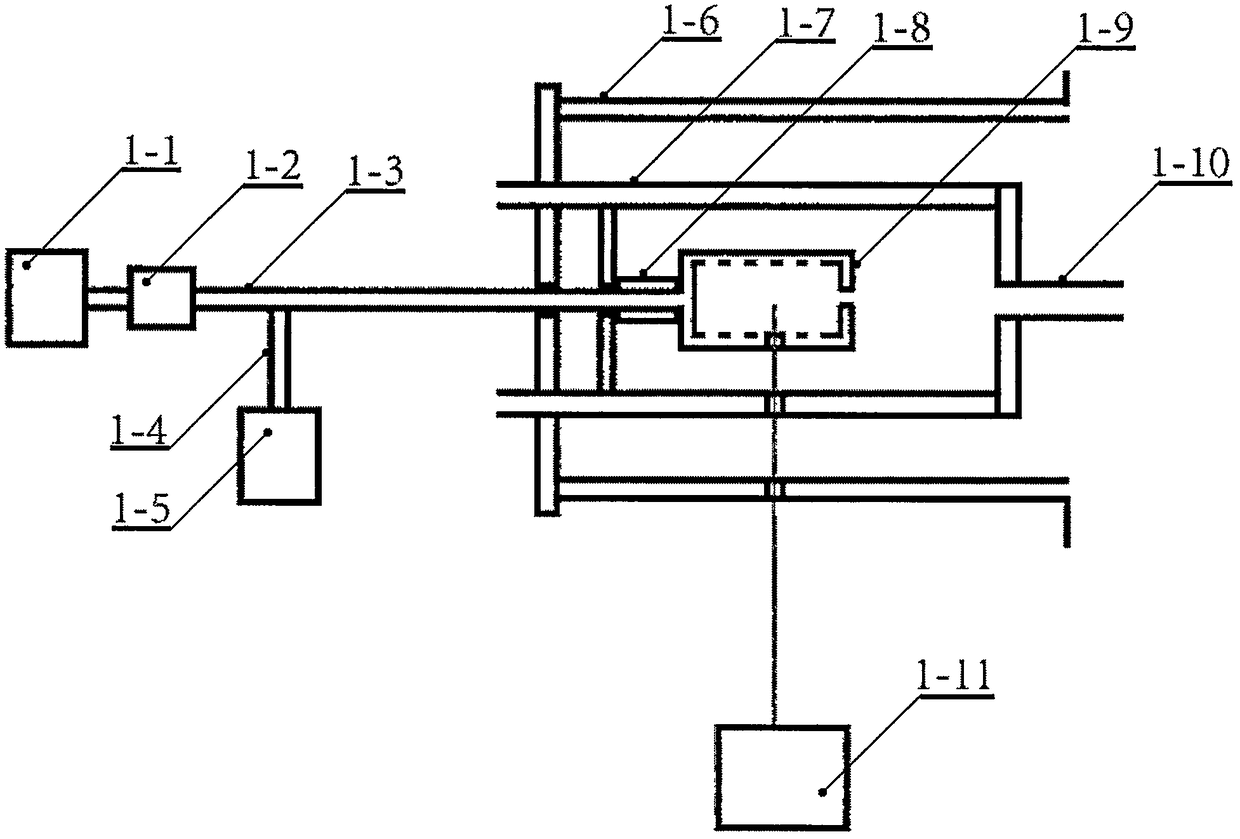

ActiveCN110208164AEasy to operateAvoid the problem of inaccurate flow meteringComponent separationPermeability/surface area analysisVacuum pumpingLine tubing

The invention discloses a dense core permeability measuring device and method. The dense core permeability measuring device comprises a core holder, a standard gas mixture supply system, a confining pressure pump, a vacuum pump, a gas chromatograph and a thermostat, wherein an air inlet end of the core holder is connected with the standard gas mixture supply system through a pipeline. The method for measuring the dense core permeability of the dense core permeability measuring device comprises the following steps: S1, placing a rock sample to be measured with a length L into a rock sample cavity, and performing vacuum pumping on the rock sample and gas in the device by using the vacuum pump; and S2, starting the confining pressure pump, increasing the confining pressure of a confining pressure cavity to a required confining pressure value, and keeping the pressure constant. Through adoption of the dense core permeability measuring device and method, the problems of difficulty in measuring flow and no consideration of dispersion and slip in the process of measuring the permeability with the existing steady state method are solved.

Owner:SOUTHWEST PETROLEUM UNIV

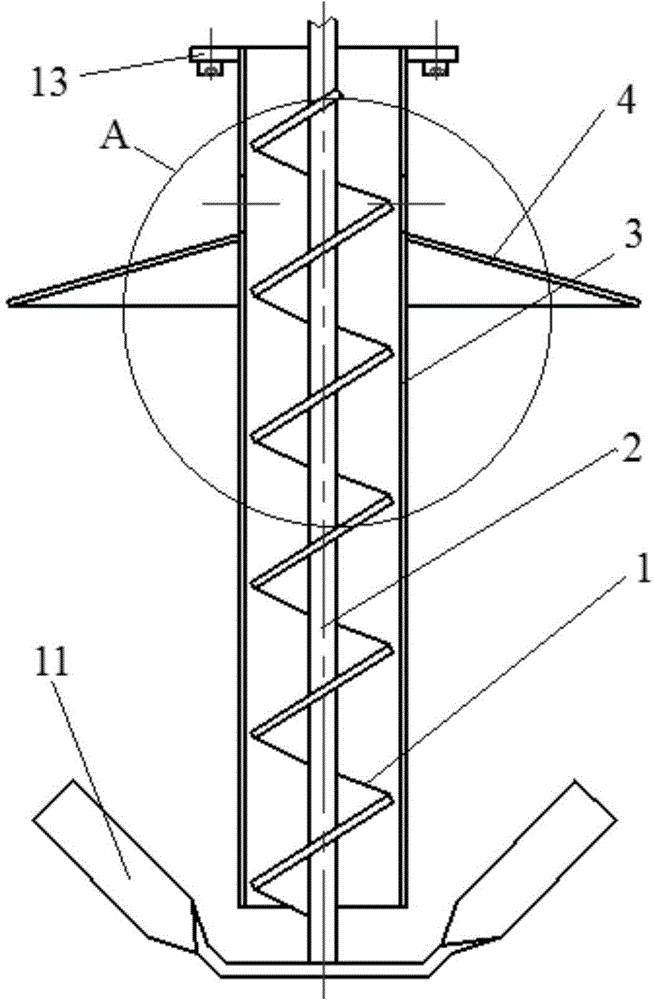

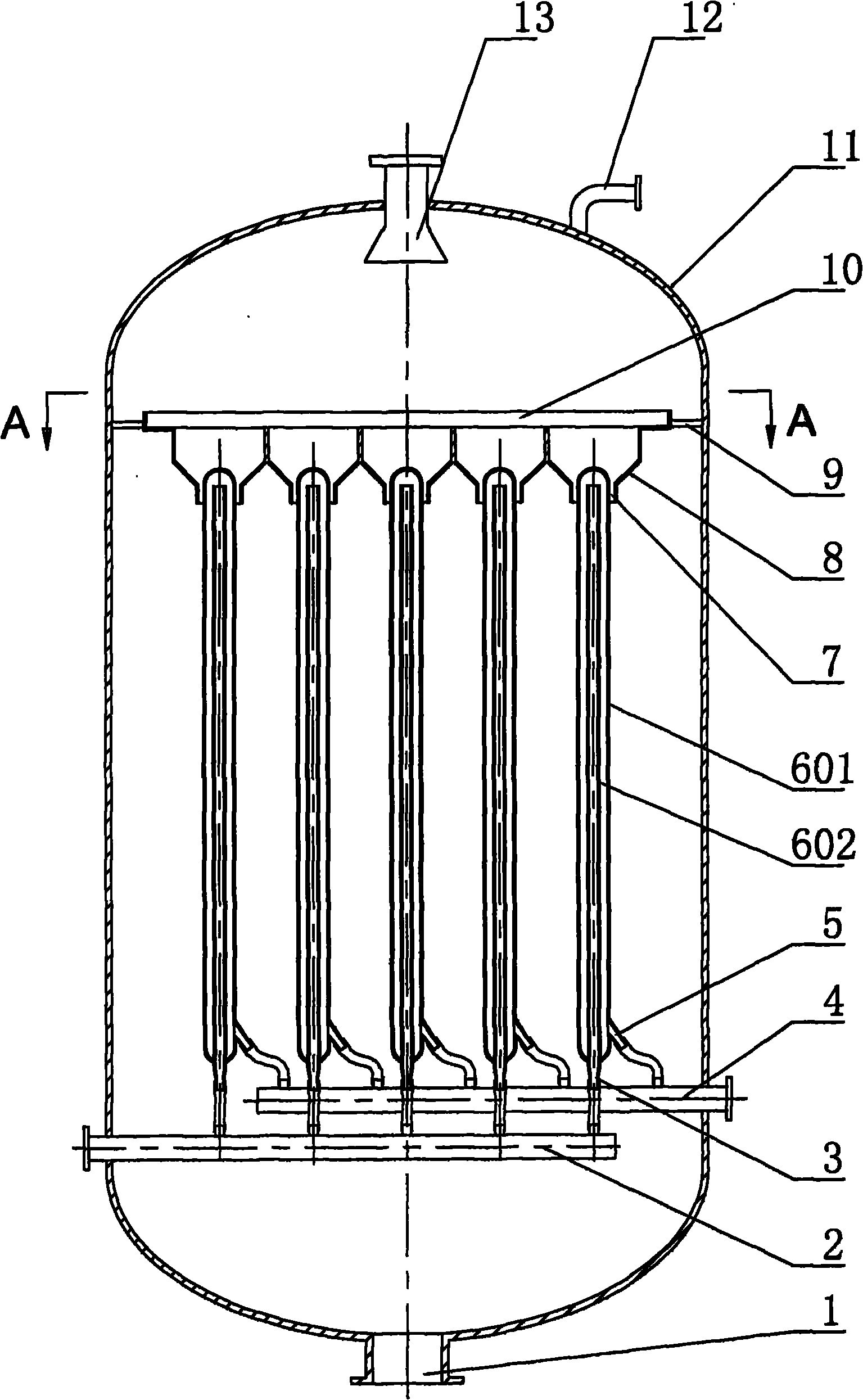

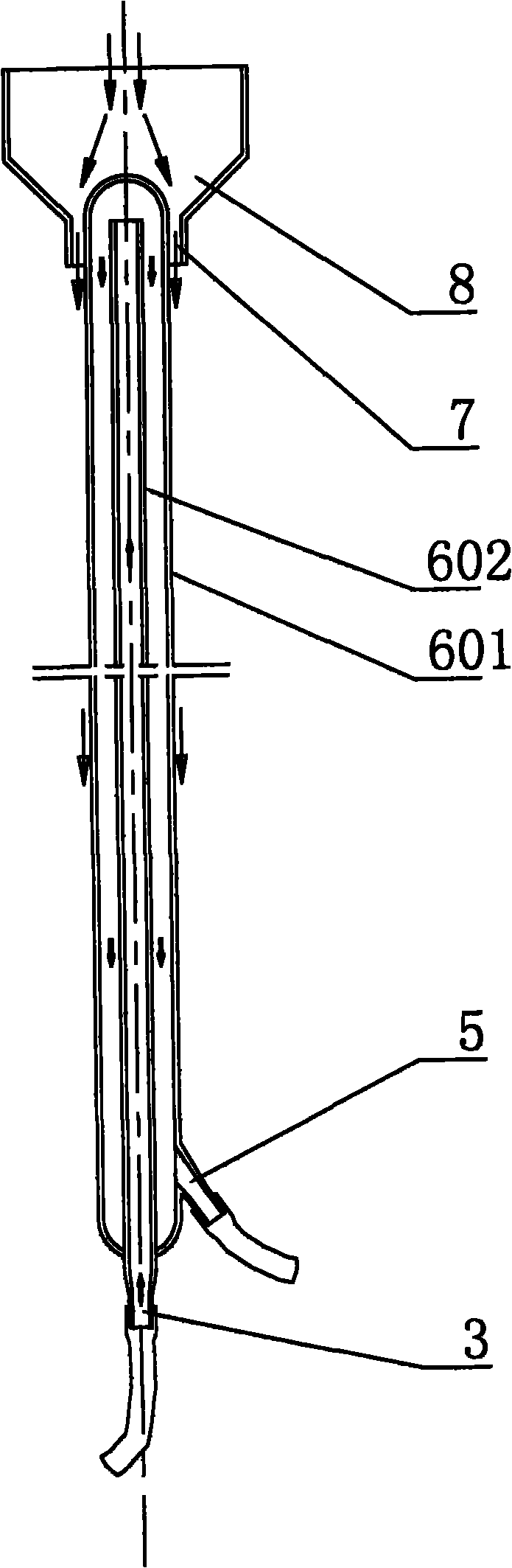

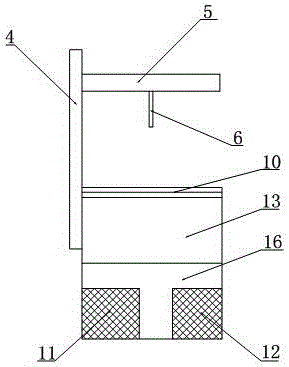

Composite type heat pipe radiator for heating

InactiveCN101373121AReduce useless energy consumptionWill not fail or even be scrappedIndirect heat exchangersVacuum pumpingHeat conducting

A composite type heat pipe radiator for heating relates to the heating ventilating field and comprises an upper header pipe (1), a lower header pipe (2), a radiating fin (3), a fin heating medium pipe (4), a vacuum pumping head (5), a vacuum regulating valve (6), a heat-conducting medium (7) and a heating medium (8). A cavity body formed by the upper header pipe (1), the lower header pipe (2), the radiating fin (3) and the heating medium pipe (4) with the vacuum pumping head (5) and the vacuum regulating valve (6) after a vacuum device extracts the air in the upper header pipe (1), the lower header pipe (2), the radiating fin (3) and the heating medium pipe (4) from the vacuum pumping head (5); and after the air in the cavity body is extracted, a vacuum hollow cavity is formed. The heat-conducting medium absorbs heat from a heat source and transfers the heat to the heating medium (8) through the fin heating medium pipe (4); the heating medium is heated and gasified and transfers the heat to the air so as to serve the heating function. The invention has the advantages of high efficiency, safety, water and energy conservation, beauty, duration, light weight, and high borne pressure. The invention can manufactured into composite type vacuum ultra heat conducting pipe energy-saving efficient radiators of various types and specifications, such as the plate type, the pipe type, the cylindrical type, various wing types, and the like.

Owner:肖建选

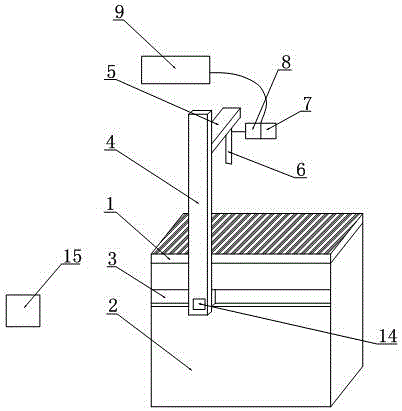

Vacuum chuck type insert fixing device for injection mold

The invention discloses a vacuum chuck type insert fixing device for an injection mold. The vacuum chuck type insert fixing device comprises a fixed mold and a movable mold, wherein a vacuum chuck isarranged at the bottom of the fixed mold, the bottom of the vacuum chuck communicates with an L-shaped pipeline, a vacuum pump is fixedly installed on the outer side wall of the fixed mold, the otherend of the L-shaped pipeline is connected with the vacuum pump, a hollow rod is vertically connected to the interior of the L-shaped pipeline in a penetrating and sliding mode, a vertical through holeused in cooperation with the lower end of the hollow rod is further formed in the bottom of the fixed mold, an electric push rod is fixedly installed at the inner bottom of the hollow rod, the outputend of the electric push rod is vertically upward, and a vertically-arranged transmission rod is fixedly connected to the top end of the electric push rod. According to the vacuum chuck type insert fixing device for the injection mold, by arranging the hollow rod capable of stretching and retracting freely to be used in cooperation with a vertical pipe-shaped insert, two adjustable arc-shaped abutting blocks arranged on the outer side wall of the upper end of the hollow rod are used for abutting against the inner wall of the vertical pipe-shaped insert, and therefore the vertical pipe-shapedinsert can be fixed, and the application range is wider.

Owner:许芳林

Efficient defoaming solvent-free composite mixing unit cylinder

InactiveCN104941493AGuaranteed defoaming efficiencyQuality assuranceMixersFoam dispersion/preventionVacuum pumpingCoupling

Owner:XIAN UNIV OF TECH

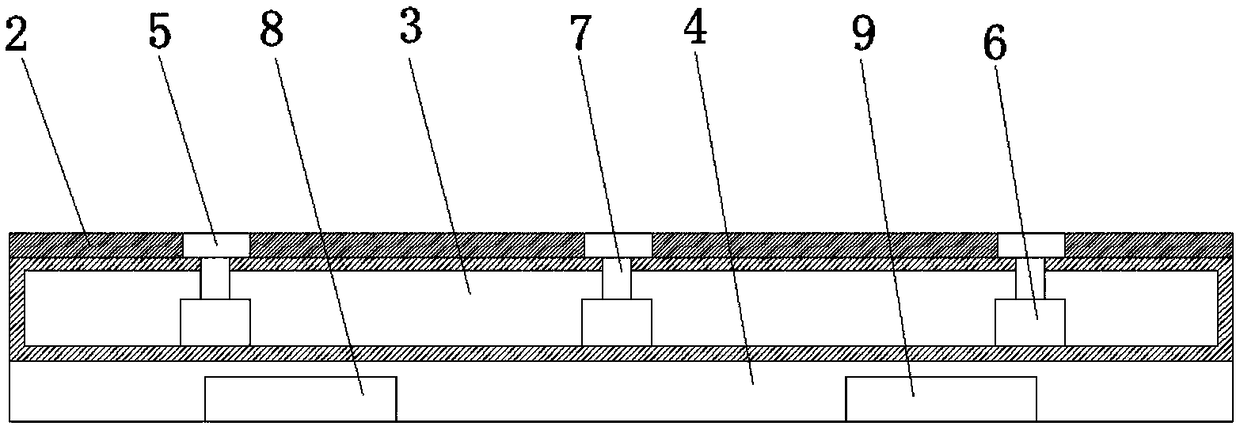

Manufacturing method for thin type heat conduction device

InactiveCN106225538AEnsure assembly flatnessImprove cooling effectIndirect heat exchangersVacuum pumpingEngineering

A manufacturing method for a thin type heat conduction device comprises the steps that a bottom plate and a cover plate which are combined in a face-shaped overlaid form are prepared, the bottom plate is provided with a flat heat dissipation face, a press-fit edge is arranged on the periphery of the part between the bottom plate and the cover plate, a vacuum cavity is formed within the surrounding range of the press-fit edge, a vacuum pumping liquid injection opening is formed in one position of the press-fit edge and sealed through a press-fit edge part, and the outer end of the press-fit edge part is sealed to be in a sealed state through a welding technology; the position, corresponding to the vacuum pumping liquid injection opening, of the press-fit edge is further provided with an upward inwards-concave face, and the upward inwards-concave face is in a face-shaped inwards-concave form in the direction from the flat heat dissipation face of the bottom plate to the cover plate; and accordingly, the outer end of the press-fit edge part forming the vacuum pumping liquid injection opening is in an upwards inwards-concave state relative to the flat heat dissipation face of the bottom plate, so that a space where welding flux used for sealing can protrude downwards is achieved, the welding flux is prevented from protruding out of the flat heat dissipation face of the bottom plate, and accordingly the assembling flatness degree and the optimal heat dissipation efficiency of the flat heat dissipation face of the bottom plate are ensured.

Owner:SUZHOU FORCECON ELECTRIC

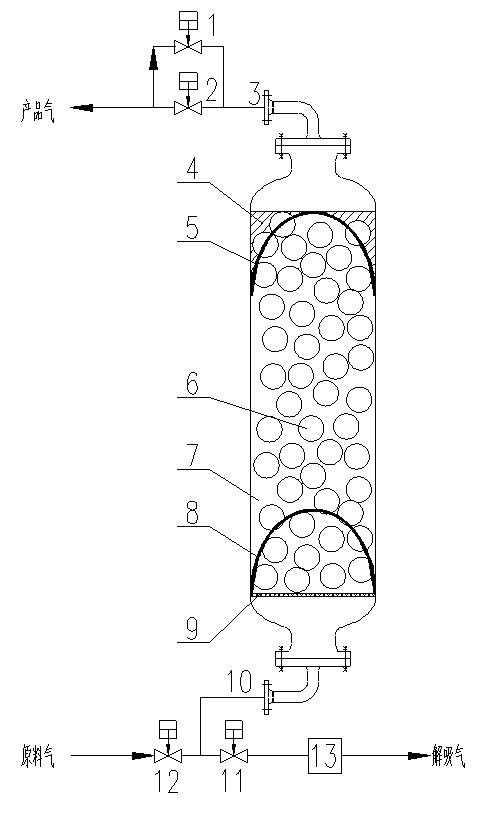

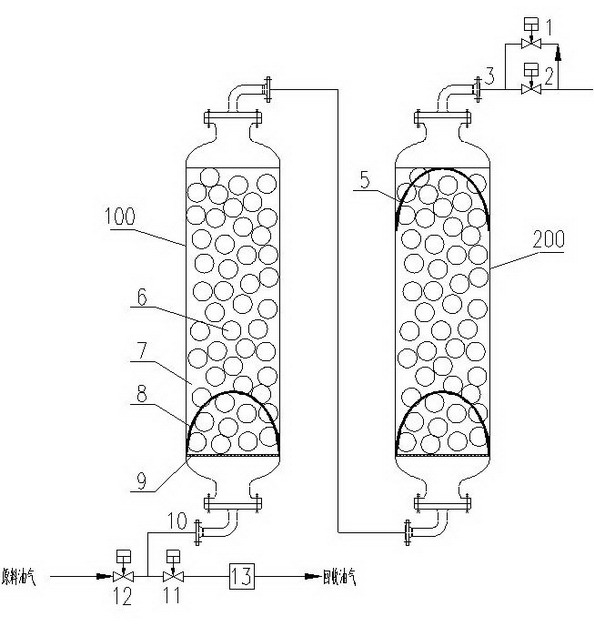

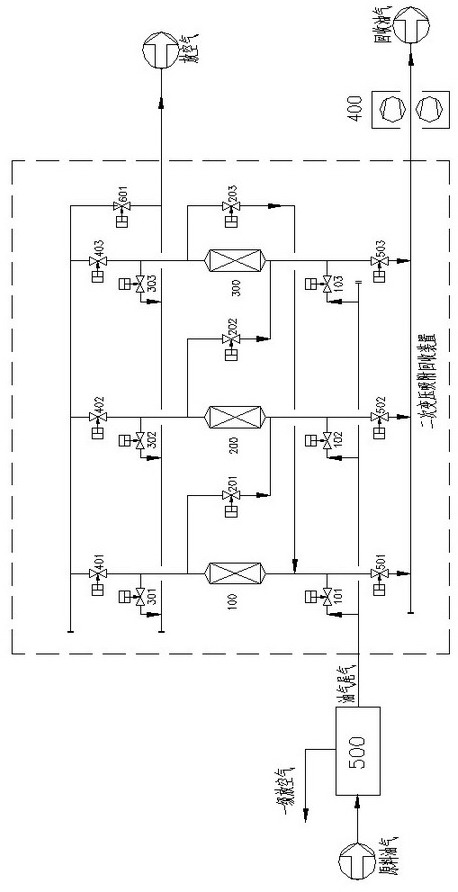

Oil gas purification recycling device and tail gas purification recycling device and method thereof

ActiveCN101830423AIncrease profitMeet the requirements of industrializationLiquid transferring devicesProcess engineeringProduct gas

Owner:ALLY HI TECH CO LTD

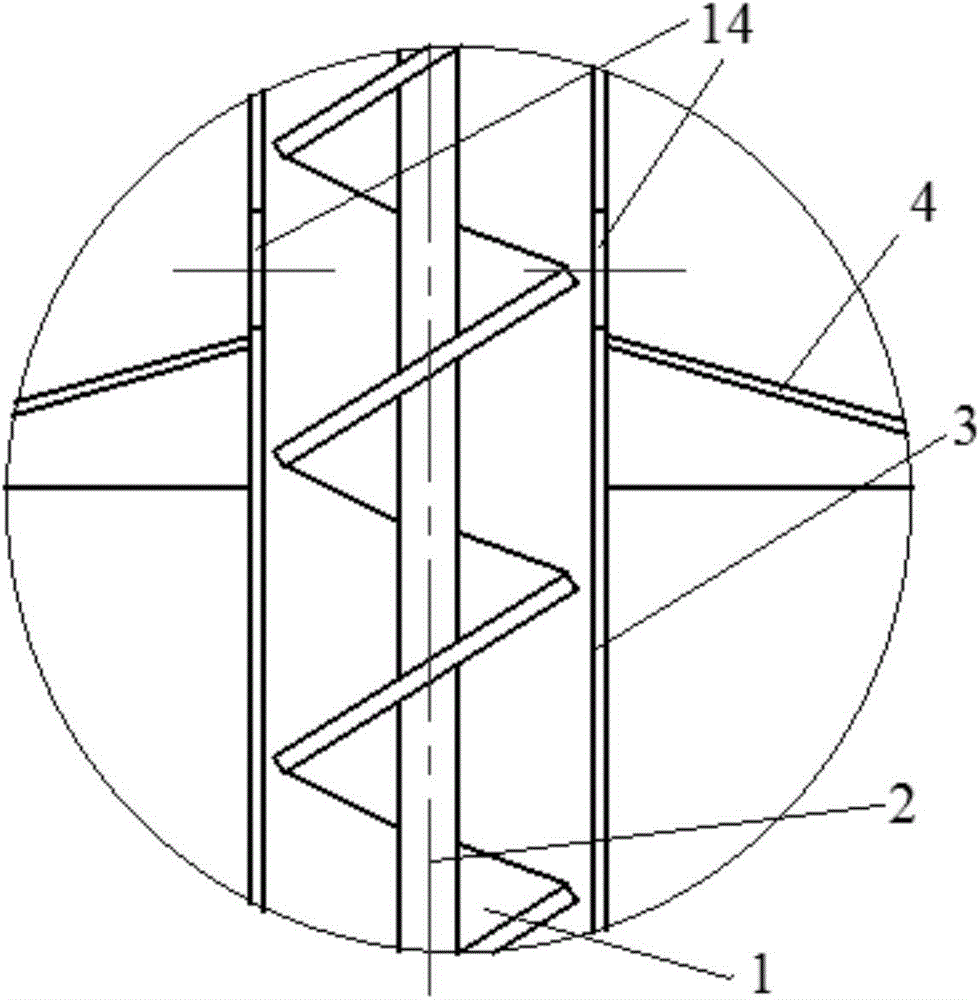

Embedded microwave cyclic adsorption-desorption column and operation method thereof

InactiveCN110090527AAchieve recyclingEvenly heatedGas treatmentOther chemical processesMicrowaveEngineering

Owner:CHANGZHOU UNIV

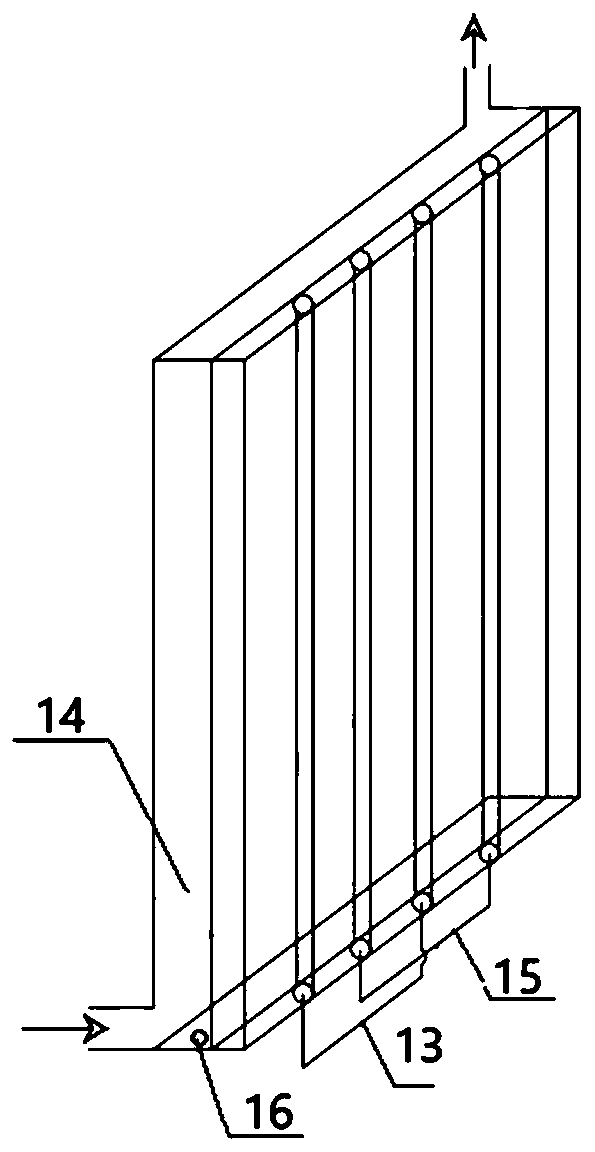

Tubular film evaporator

ActiveCN101785930ANo cloggingGood film formingEvaporators with vertical tubesPolyesterVacuum pumping

Owner:YANGZHOU HUITONG CHEM ENG TECHN

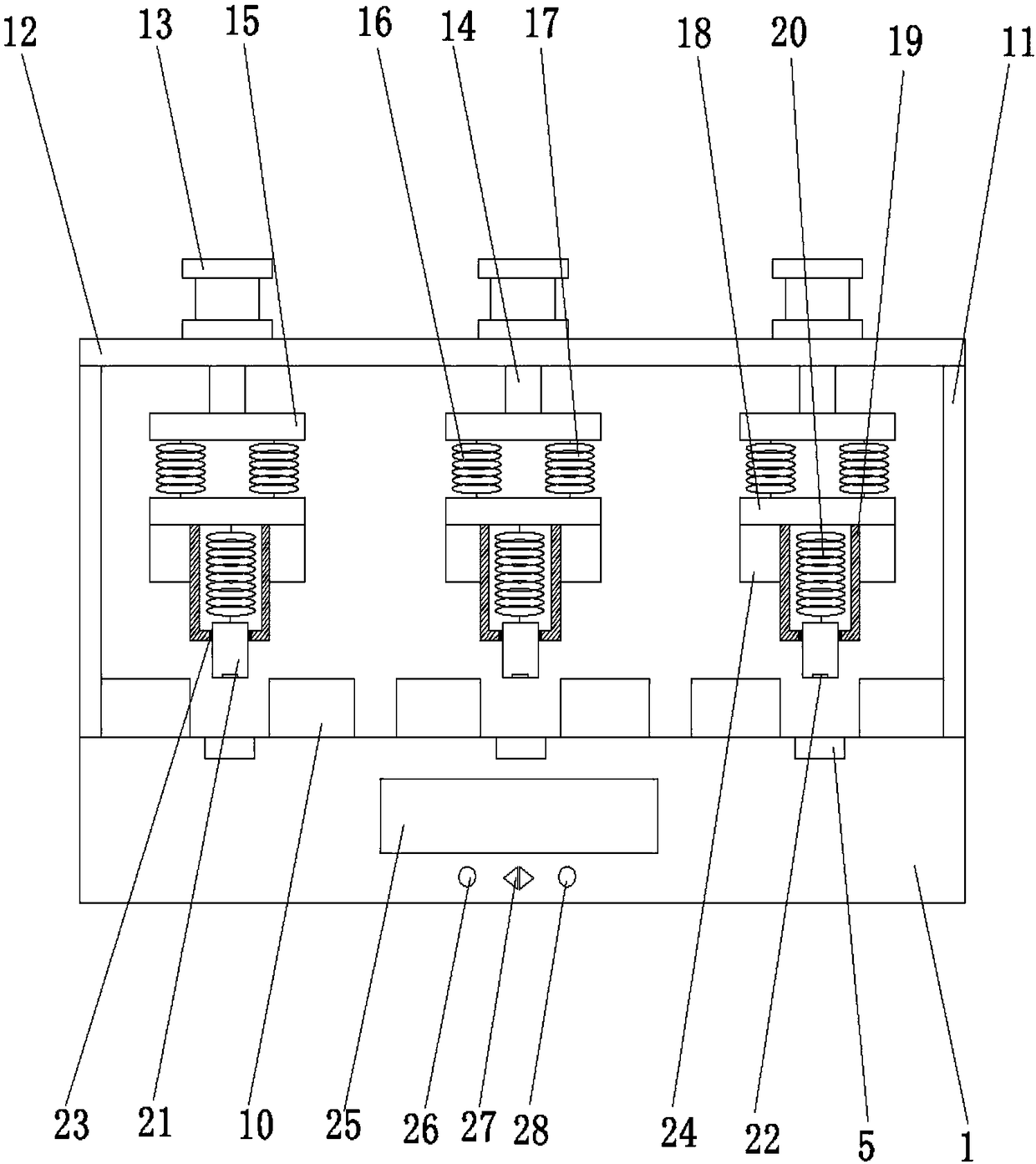

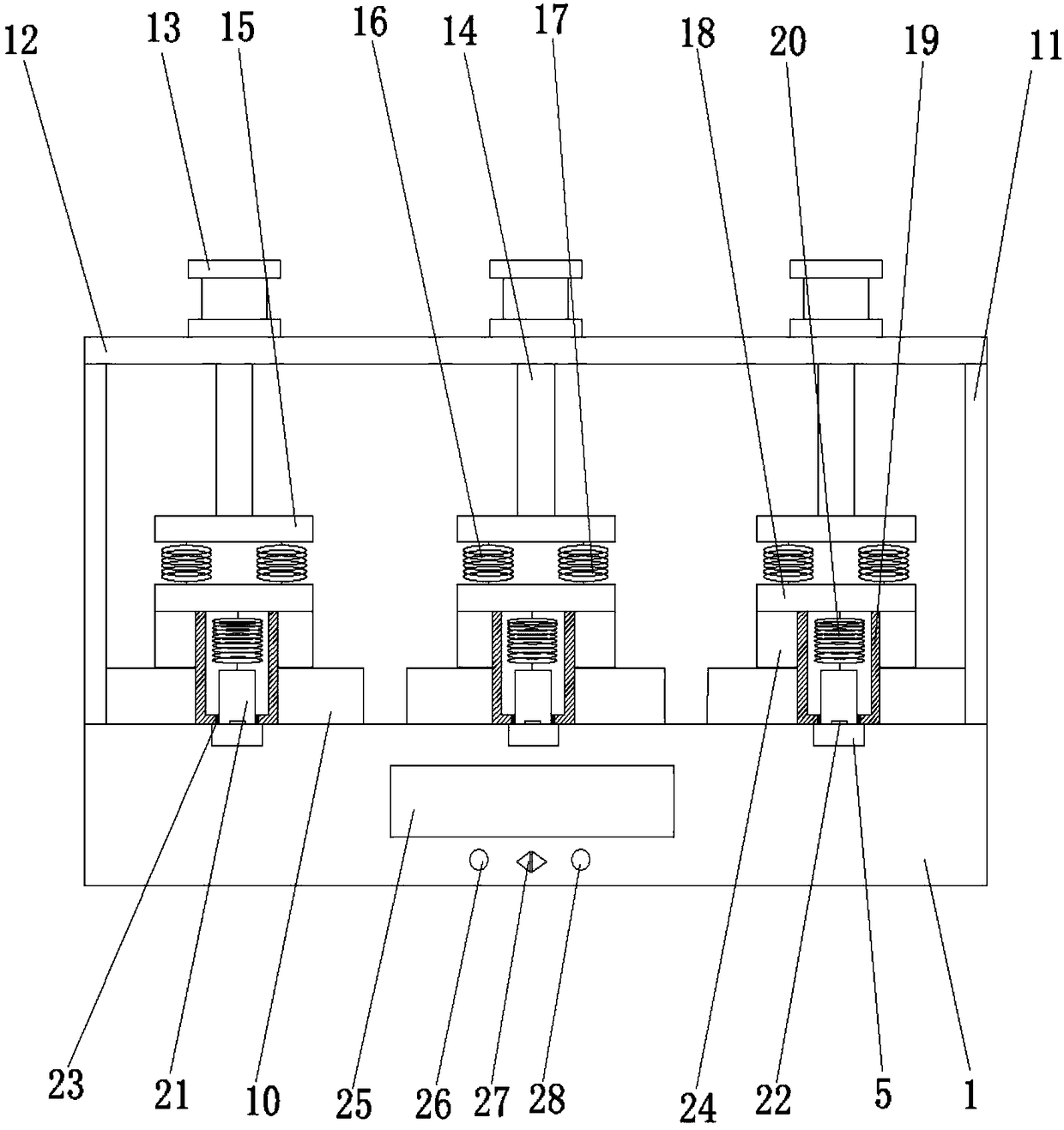

On-batch pressing testing device for touch control chip

InactiveCN108362565AGuaranteed accuracyDoes not affect accuracyMaterial strength using tensile/compressive forcesTest efficiencyControl layer

Owner:HUZHOU HUINENG ELECTROMECHANICAL TECH CO LTD

Laminated glass forming device

Owner:黄山市歙县凯旋工贸有限公司

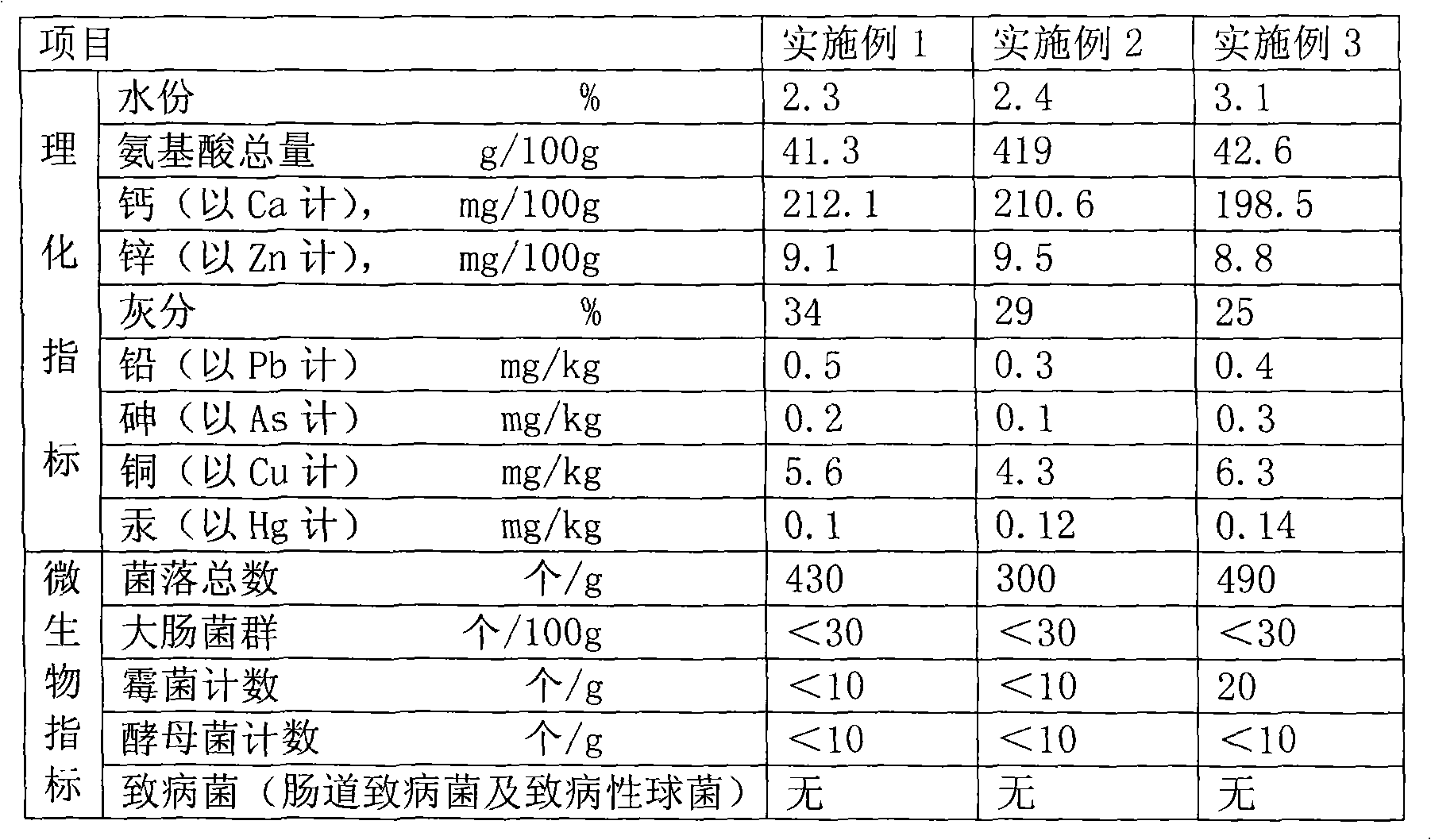

Active pure snake powder capsule and preparation technique thereof

ActiveCN101647820AGood for healthExpelling wind and dampness is beneficialMetabolism disorderAntinoxious agentsMedicineFreeze-drying

Owner:BENXI LONGBAO GROUP GINSENG & VELVET

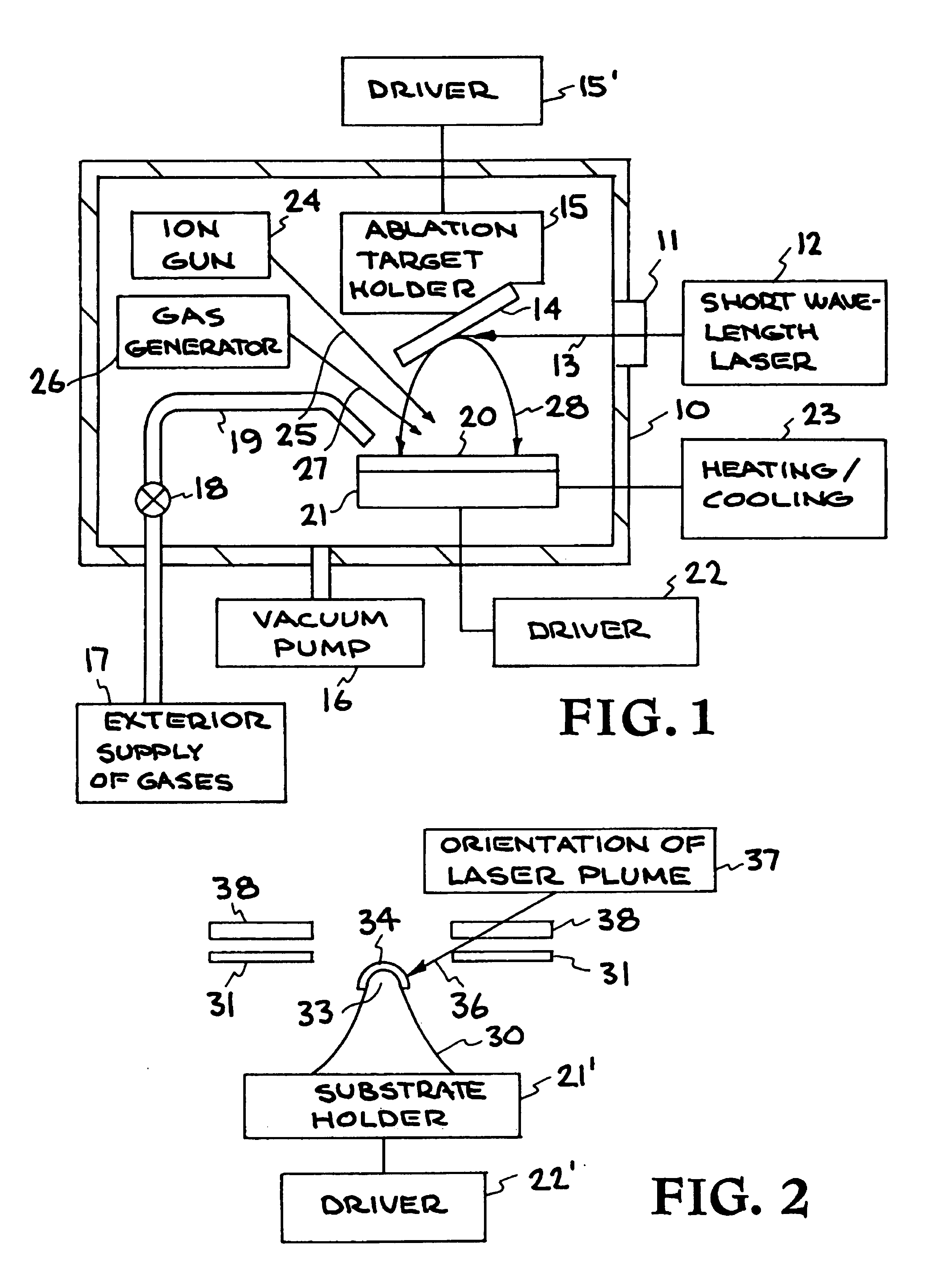

Apparatus for depositing a low work function material

InactiveUS7118630B1Low work function materialElectric discharge heatingVacuum evaporation coatingElemental compositionVacuum pump

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

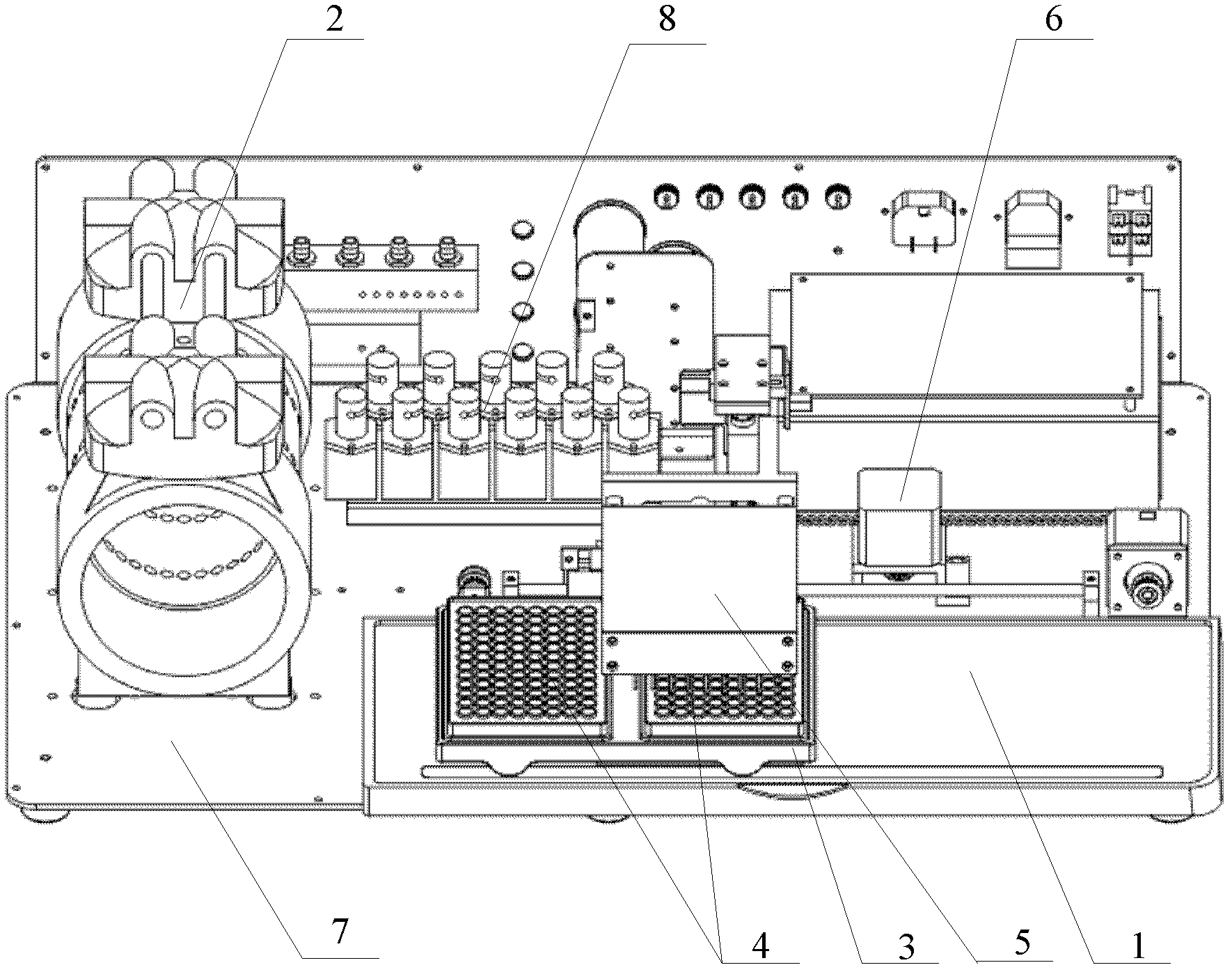

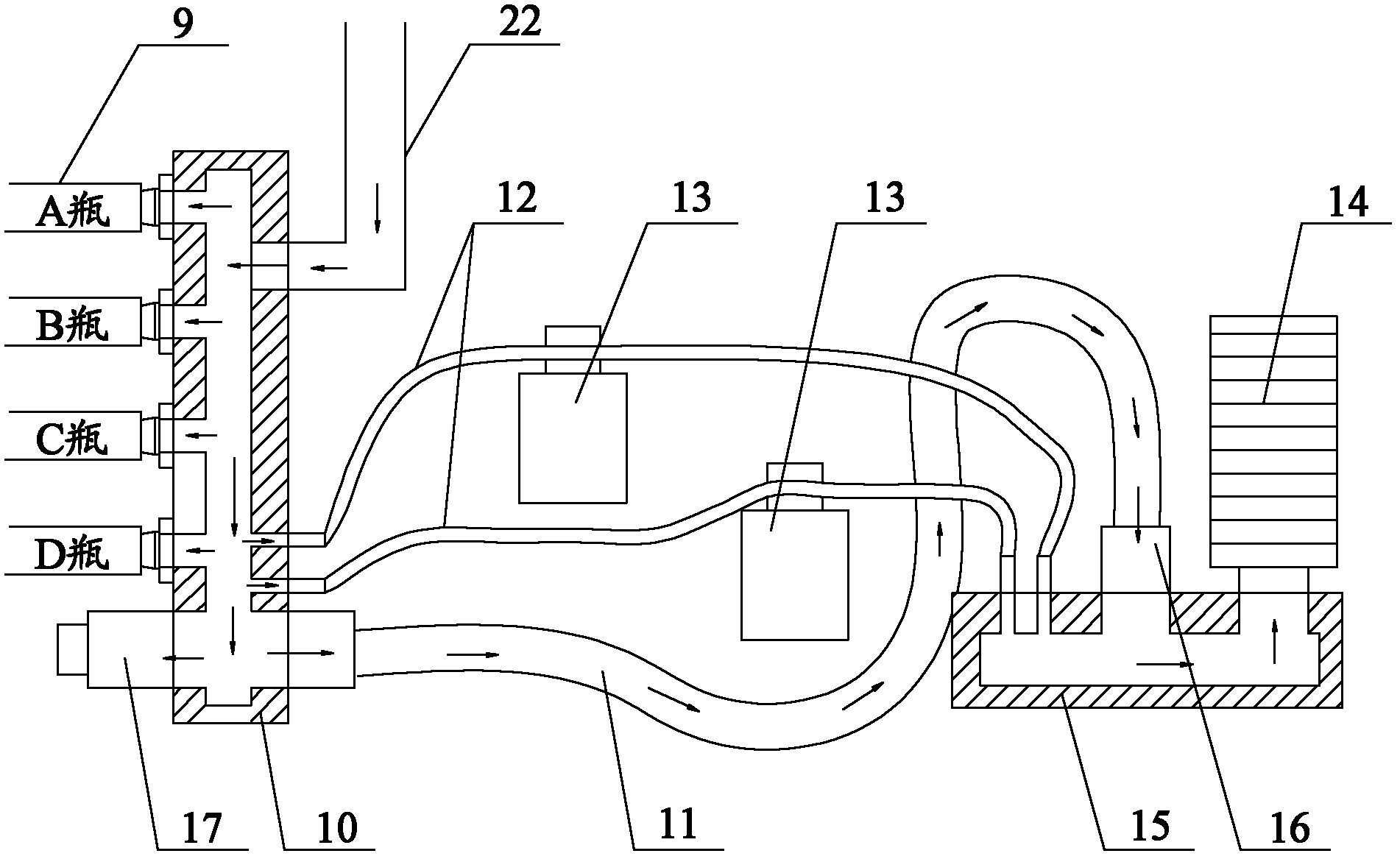

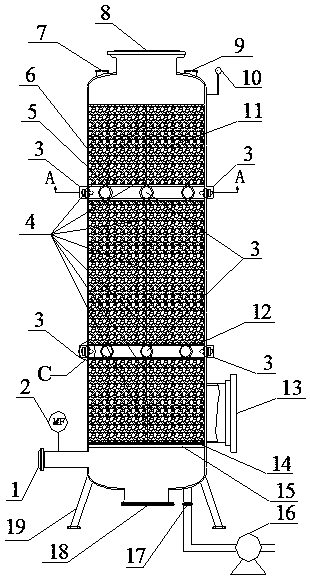

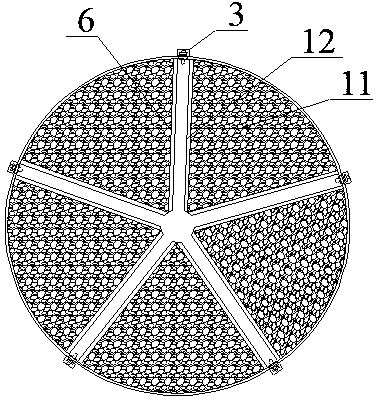

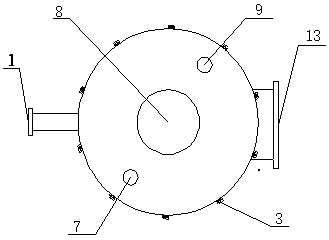

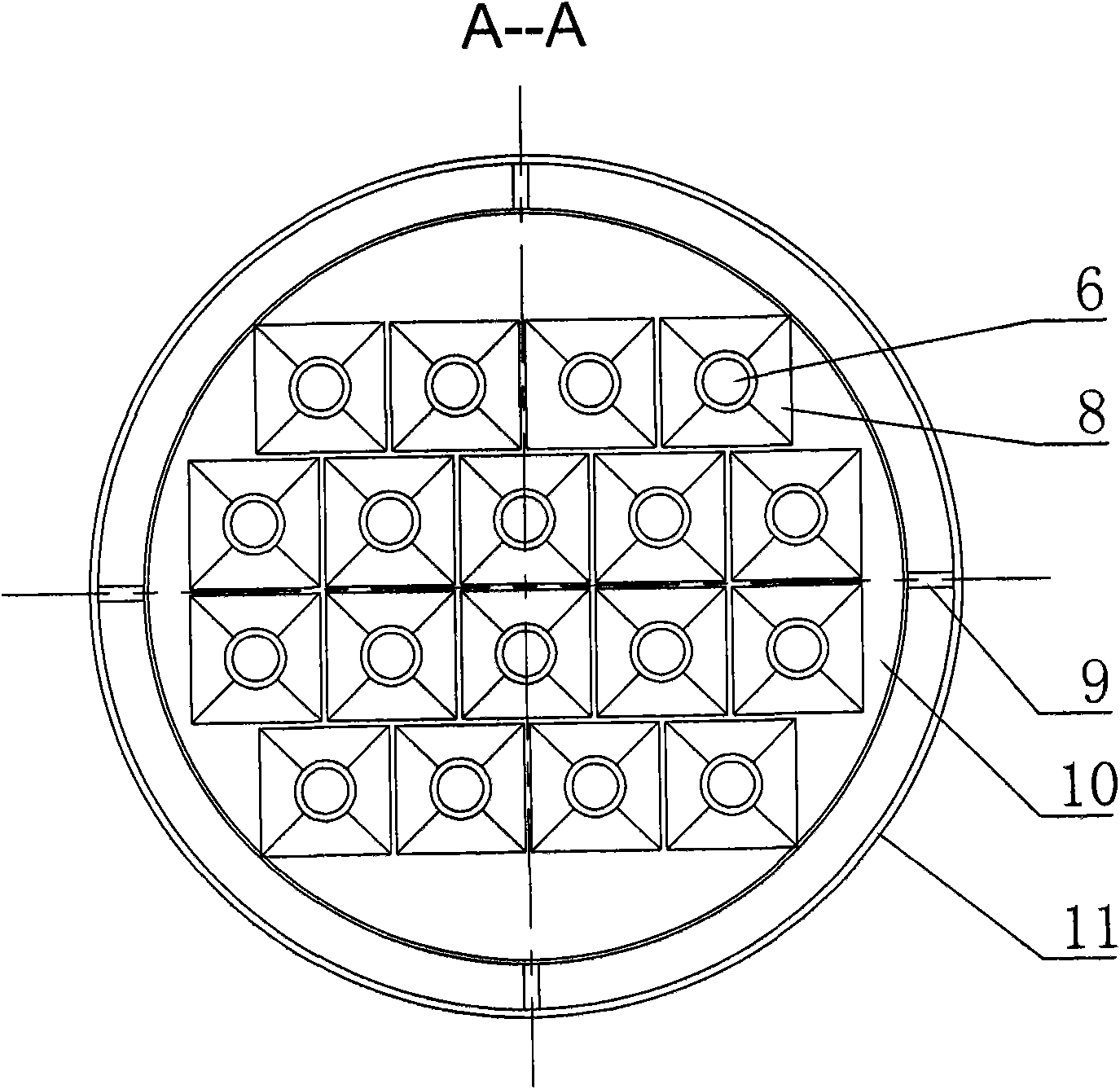

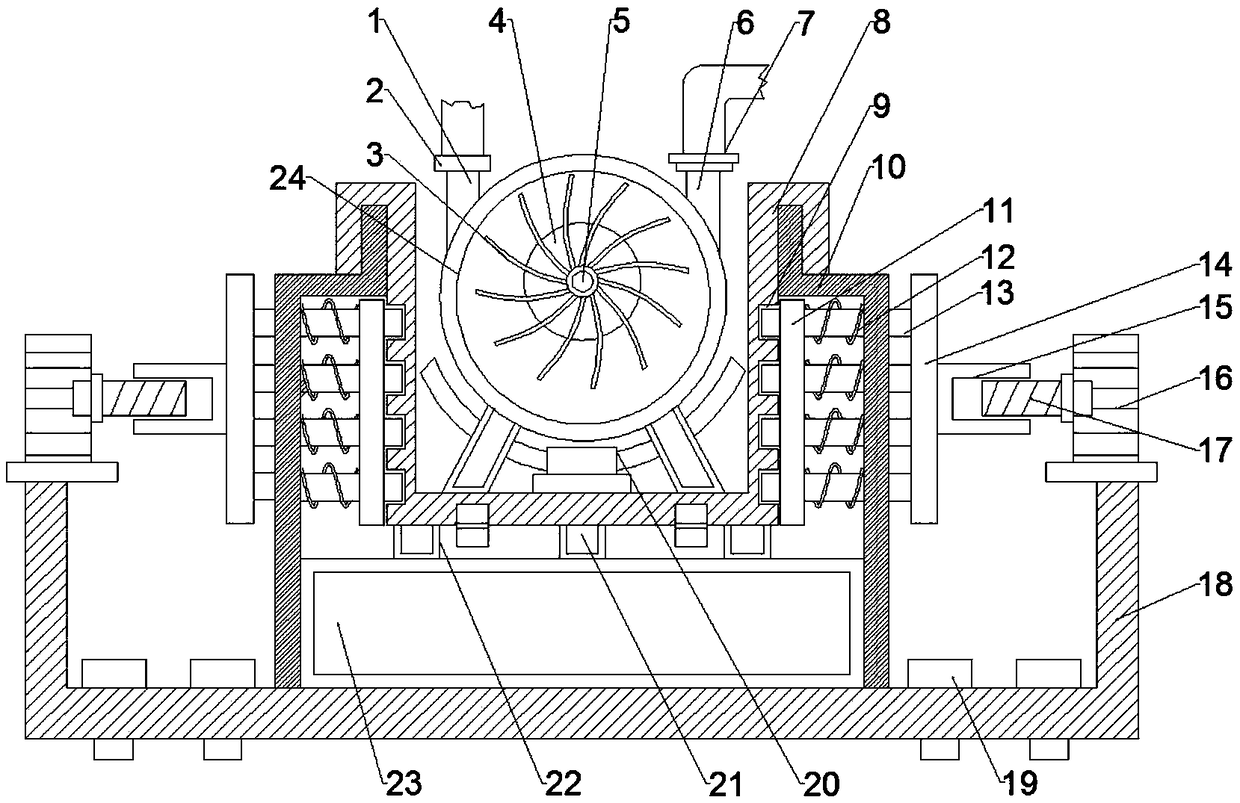

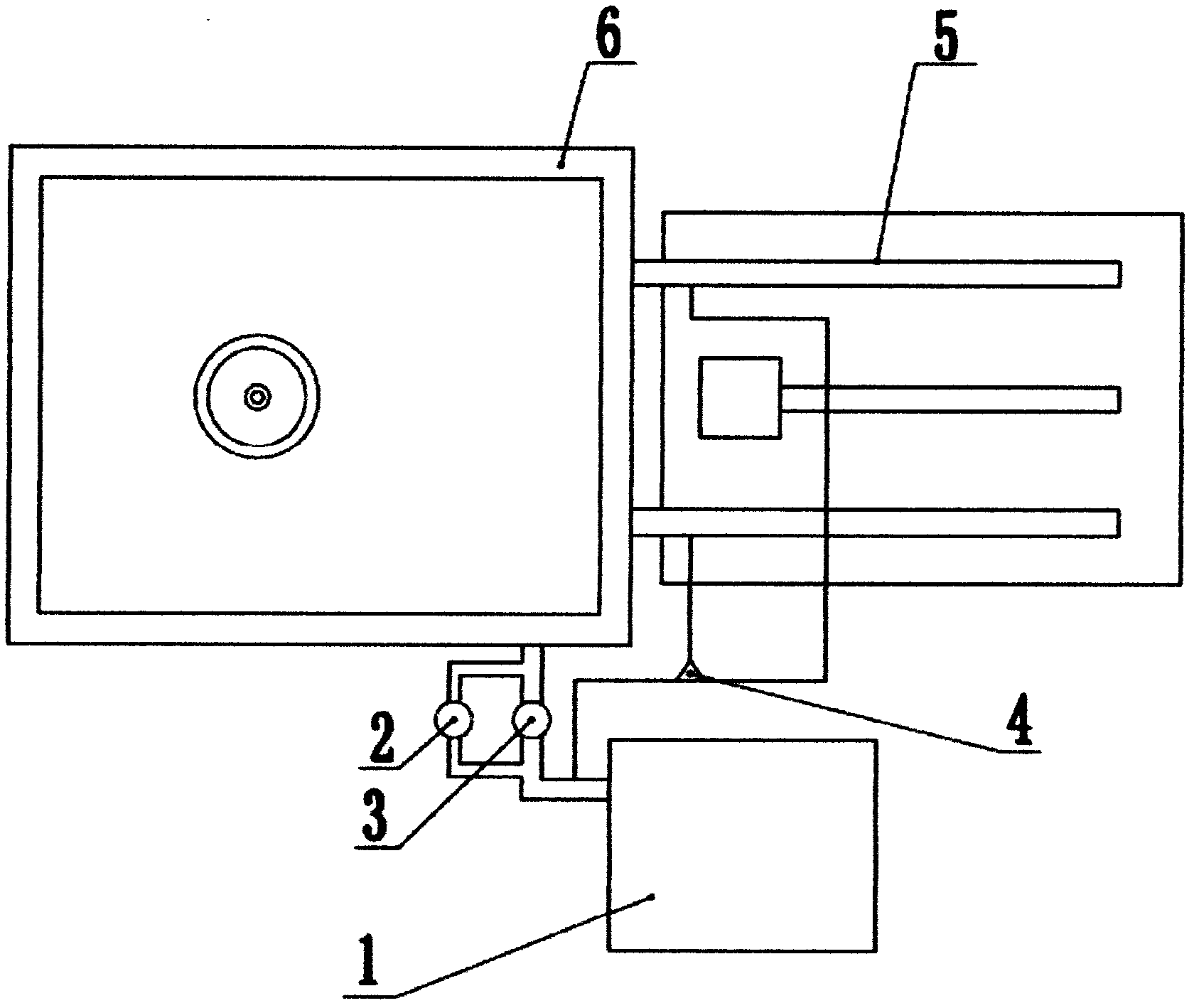

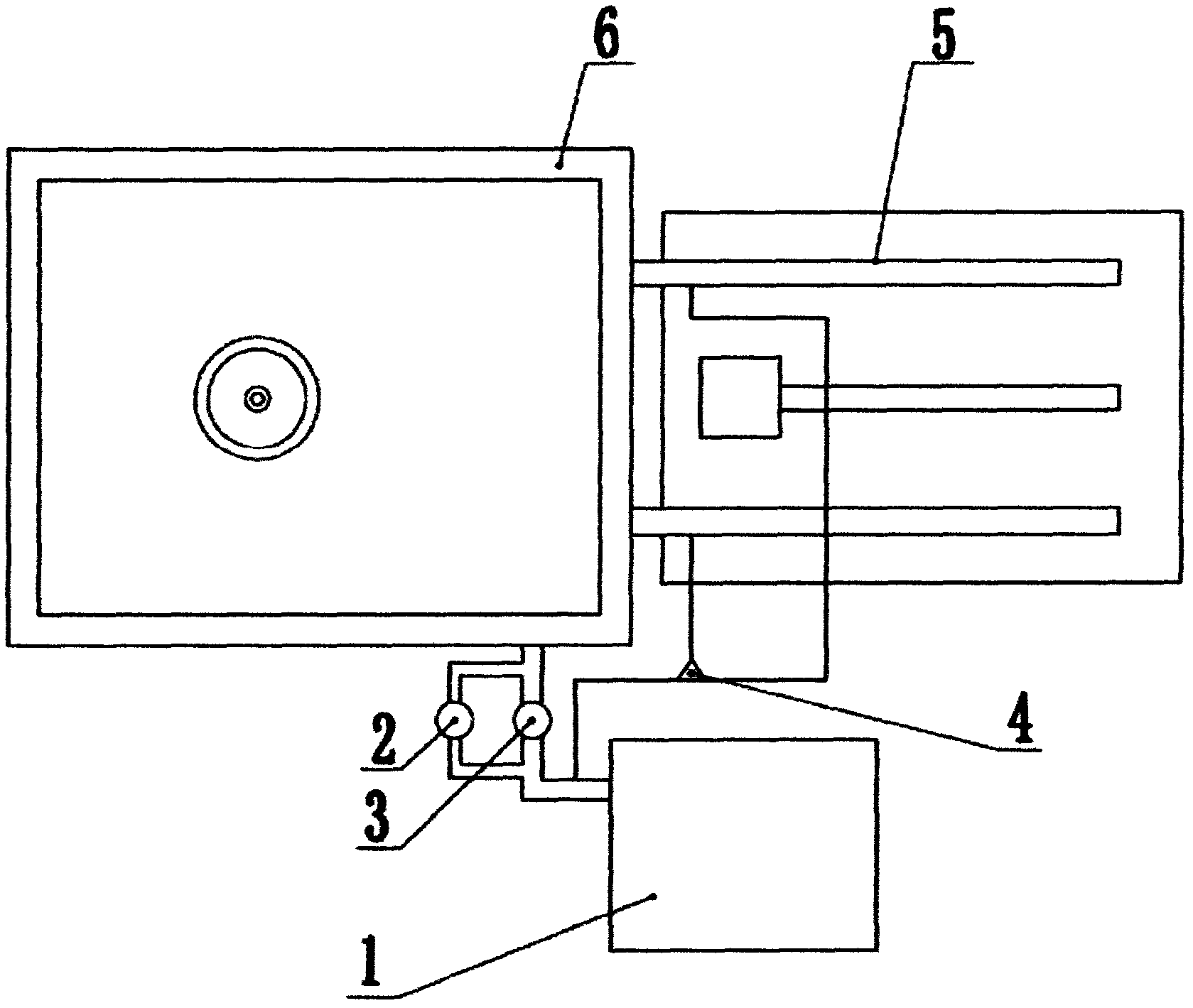

Central vacuum cooling apparatus of EPS foam molding machine

The invention discloses a central vacuum cooling apparatus of an EPS foam molding machine. The central vacuum cooling apparatus comprises a primary separation barrel (1), a secondary separation barrel (2), a condensation barrel (3), vacuum pumps (4), nozzles (5) and a water tank (6), the primary separation barrel (1) is connected with the condensation barrel (3) through a pipeline, the secondary separation barrel (2) is connected with the condensation barrel (3) through a pipeline, the bottom of the primary separation barrel (1), the secondary separation barrel (2) and the condensation barrel (3) is connected with the water tank (6) through a butterfly valve and a pipeline, the vacuum pumps (4) are connected with the secondary separation barrel (2) through a pipeline, and a group of nozzles (5) is arranged in the condensation barrel (3). The apparatus has the advantages of simple structure, intensive arrangement of the vacuum pumps, energy consumption reduction, noise reduction and maintenance cost reduction.

Owner:JIANGSU CHEN ZHAN FOAM TECH

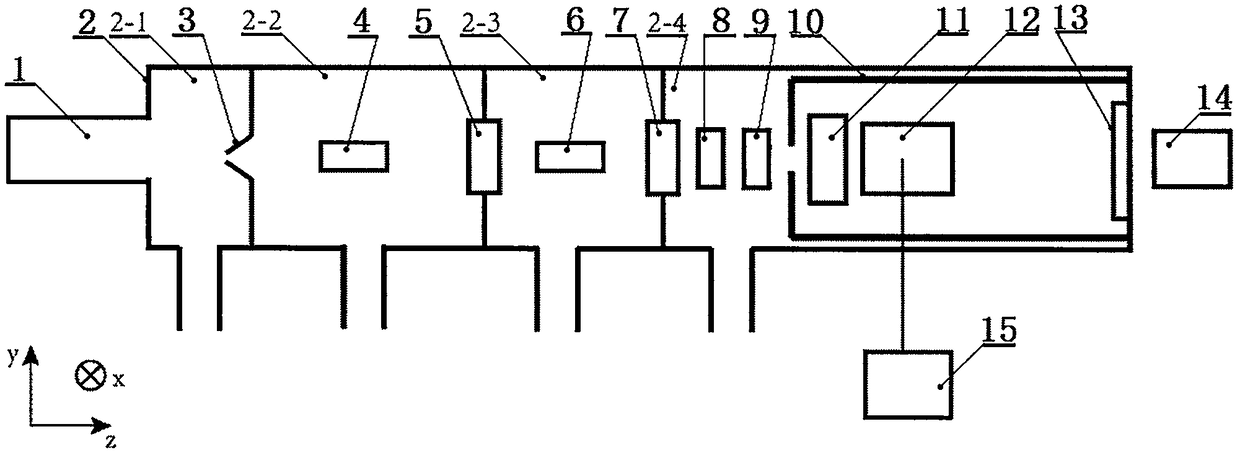

Full-automatic equipment and method for testing helium diffusion coefficient of reactor material

ActiveCN103616317AEasy to measureRapid determinationSurface/boundary effectData acquisitionLow vacuum

Owner:NANJING UNIV OF TECH +1

Particle imaging method

PendingCN109115660AShort cooldownEffective aggregationMaterial analysisLiquid storage tankCombined method

Owner:JINHUA VOCATIONAL TECH COLLEGE

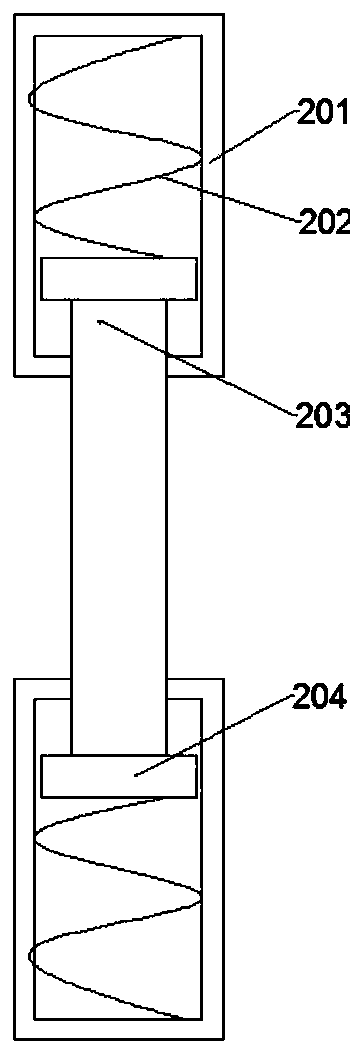

Gas-liquid separation device for high-vacuum system

The invention discloses a gas-liquid separation device for a high-vacuum system. The gas-liquid separation device comprises a vacuum pump, a front separator, a self-sucking pump and a material storage tank. The gas-liquid separation device is characterized in that a balancing pipe connector is designed in the lower side of a gas inlet of the front separator, the other end of the balancing pipe connector is connected with a connector of the side wall of an outlet pipe of the self-sucking pump, an inlet of the self-sucking pump is connected with the bottom of the front separator, an outlet of the self-sucking pump and the gas inlet of the front separator are connected with the material storage tank, and a gas outlet of the front separator is connected with the vacuum pump. As the front separator is additionally arranged and a balancing pipe is additionally arranged between the separator and the self-sucking pump, gas and liquid in the front separator can be separated, and the self-sucking pump pumps the liquid back into the original material storage tank. The gas-liquid separation device works circularly until substrates in the material storage tank are dried. Loss of the substrates in system materials is small, and the drying effect is good.

Owner:HUBEI SHENLONG PUMP

A system for detecting the adsorption capacity of a molecular sieve under high-pressure conditions and a detecting method thereof

ActiveCN107340214AFlexible detectionEvenly dispersedPermeability/surface area analysisMolecular sieveLiquid storage tank

The invention relates to a system for detecting the adsorption capacity of a molecular sieve under high-pressure conditions and a detecting method thereof. The system includes an impurity injecting unit, a molecular sieve adsorption tank and a detection instrument which are communicated with an outlet of a high-pressure liquid storage tank in order, and the high-pressure liquid storage tank. The inlet of the high-pressure liquid storage tank is communicated with an external high-pressure medium conveying pipeline. A first flux control valve and a second flux control valve are respectively disposed between the high-pressure liquid storage tank and the impurity injecting unit as well as between the impurity injecting unit and the molecular sieve adsorption tank. A pressure reducing valve is disposed between the molecular sieve adsorption tank and the detection instrument. The molecular sieve adsorption tank is connected to an external vacuum pump. The impurity injecting unit includes at least one impurity tank. Compared with the prior art, the adsorption capacity of a molecular sieve material for different impurities under high-pressure conditions can be tested by the system and the method, adsorption temperatures, impurity species and impurity concentrations can be easily adjusted in the testing method, and tests on the co-adsorption capacity of a plurality of impurities can be achieved.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

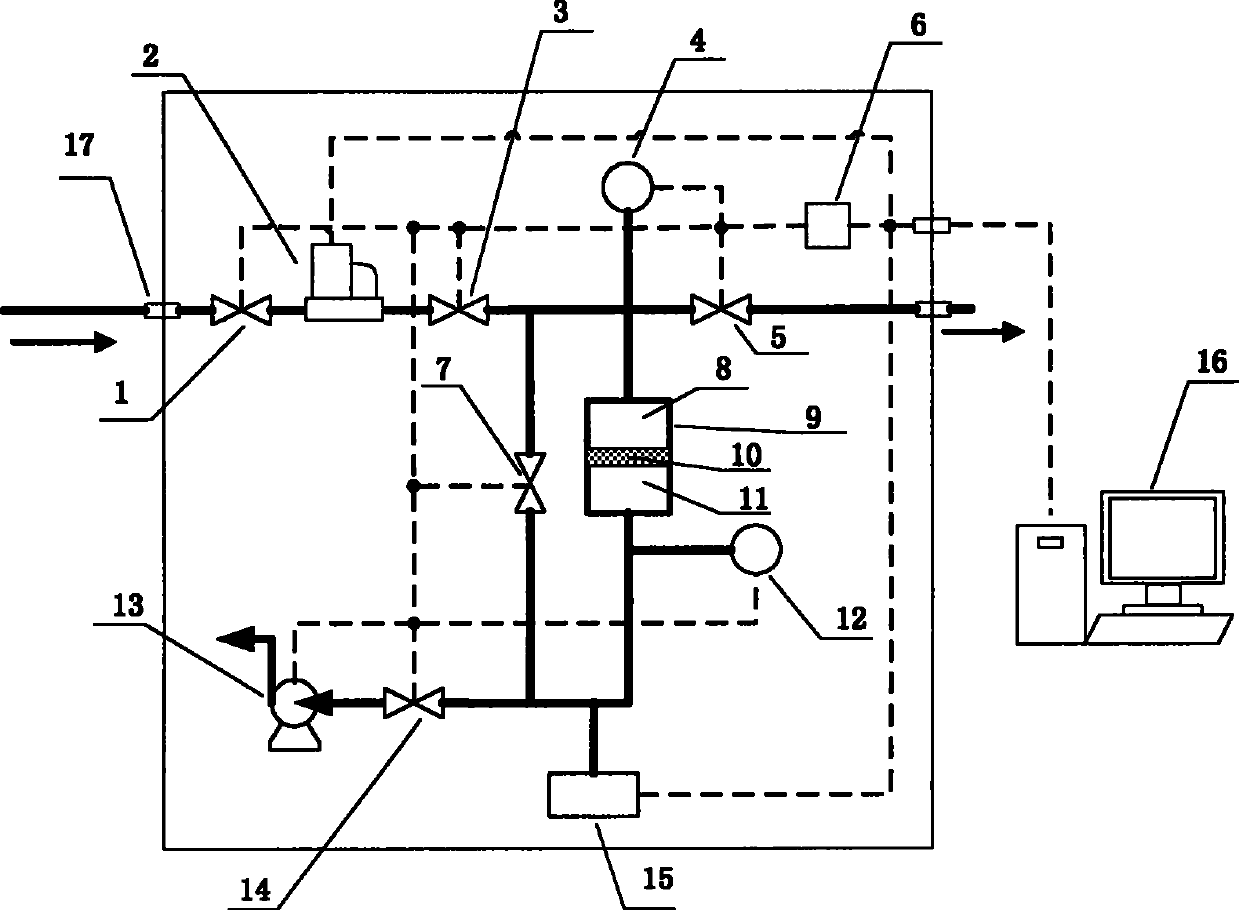

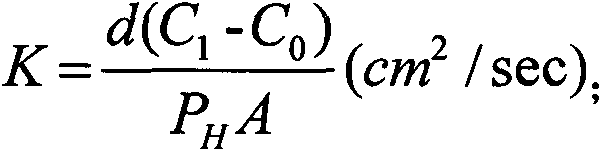

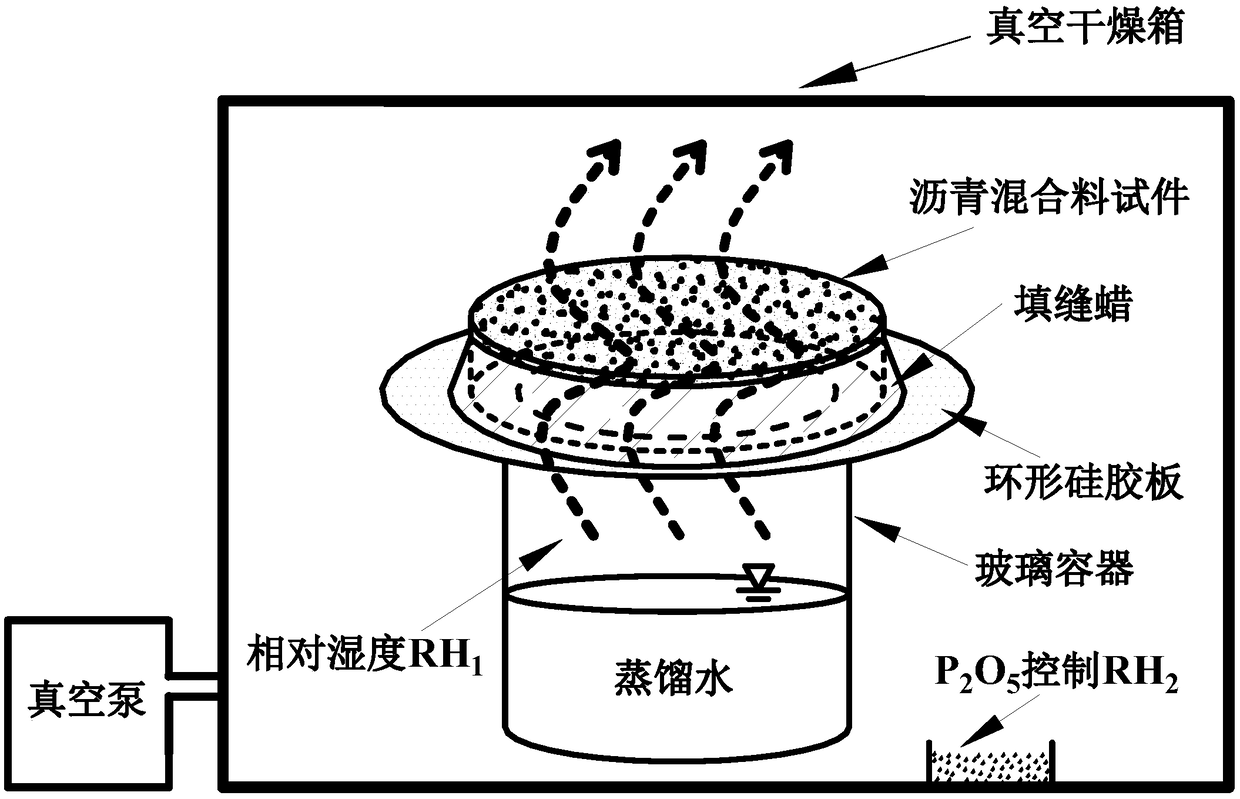

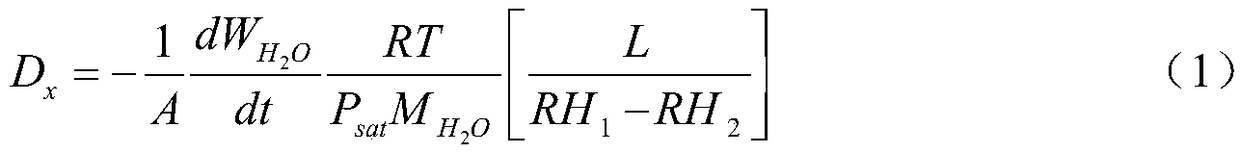

A method for detecting the penetration type water vapor diffusion coefficient of a large-thickness low-porosity asphalt mixture

ActiveCN108776084ARealize humidity gradient driveIncrease humiditySurface/boundary effectPorosityWater vapor

Owner:WUHAN UNIV OF TECH

Core heat setting process method

Owner:南通海美电子有限公司

Preparation method for earthworm extract solution

InactiveCN106619729ATroubleshoot technical issues with extractionOvercome the technical problem of incomplete removal of precipitationCosmetic preparationsToilet preparationsCold airMicrowave

Owner:陈雨

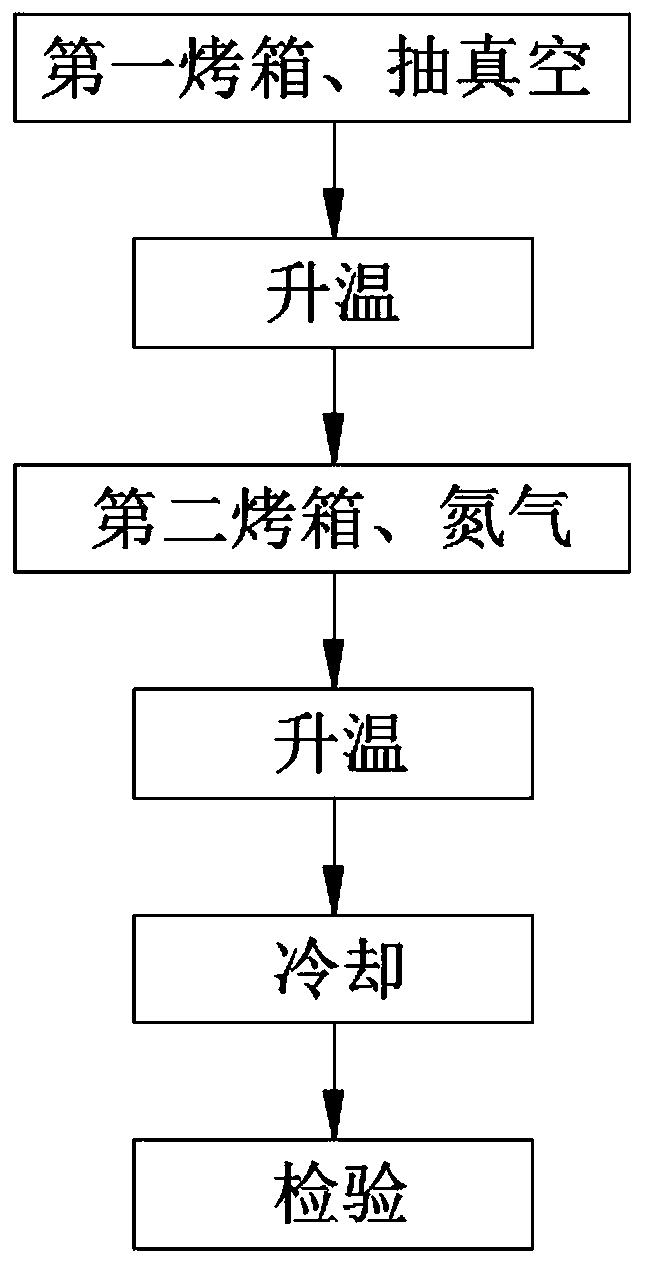

Medium and low temperature oil bath tempering equipment

The invention provides medium and low temperature oil bath tempering equipment. The medium and low temperature oil bath tempering equipment comprises a furnace body, a vacuumizing protective atmosphere system, a hot oil circulation system and a cold oil circulation system. The vacuumizing protective atmosphere system comprises a tee joint gas pipe, a vacuum pump communicating with an inner cavityof the furnace body through the tee joint gas pipe, and a steel cylinder for storing inert gas, and the steel cylinder is connected with the tee joint gas pipe. The hot oil circulation system comprises a hot oil tank, a first hot oil pump, a heater and a hot oil circulation pipeline with the two ends communicating with the furnace body, and the hot oil tank, the first hot oil pump and the heater are sequentially connected with the hot oil circulation pipeline. The cold oil circulation system comprises a second hot oil pump, a cold oil tank and a cold oil circulation pipeline with the two endscommunicating with the furnace body, and the second hot oil pump and the cold oil tank are both connected with the cold oil circulation pipeline. Tempering oil is heated and subjected to heat preservation under a completely sealed condition, and aging caused by oxidation when the tempering oil makes contact with air is eliminated. Meanwhile, oil fumes are eliminated, and the higher tempering temperature is obtained. After tempering is finished, the hot oil circulation pipeline is closed, the cold oil circulation pipeline is opened, cold oil is injected into the furnace body, a workpiece is cooled through the cold oil, and the recycled cold oil flows back to the cold oil tank.

Owner:HAINING XINYI MACHINERY & ELECTRICAL

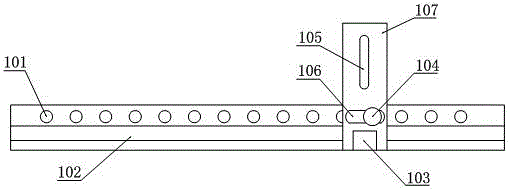

Automatic spraying device applied to SPE film and achieving method of automatic spraying device

ActiveCN105772252AImprove permeabilityAvoid deformationSpray nozzlesTemperature controlControl system

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

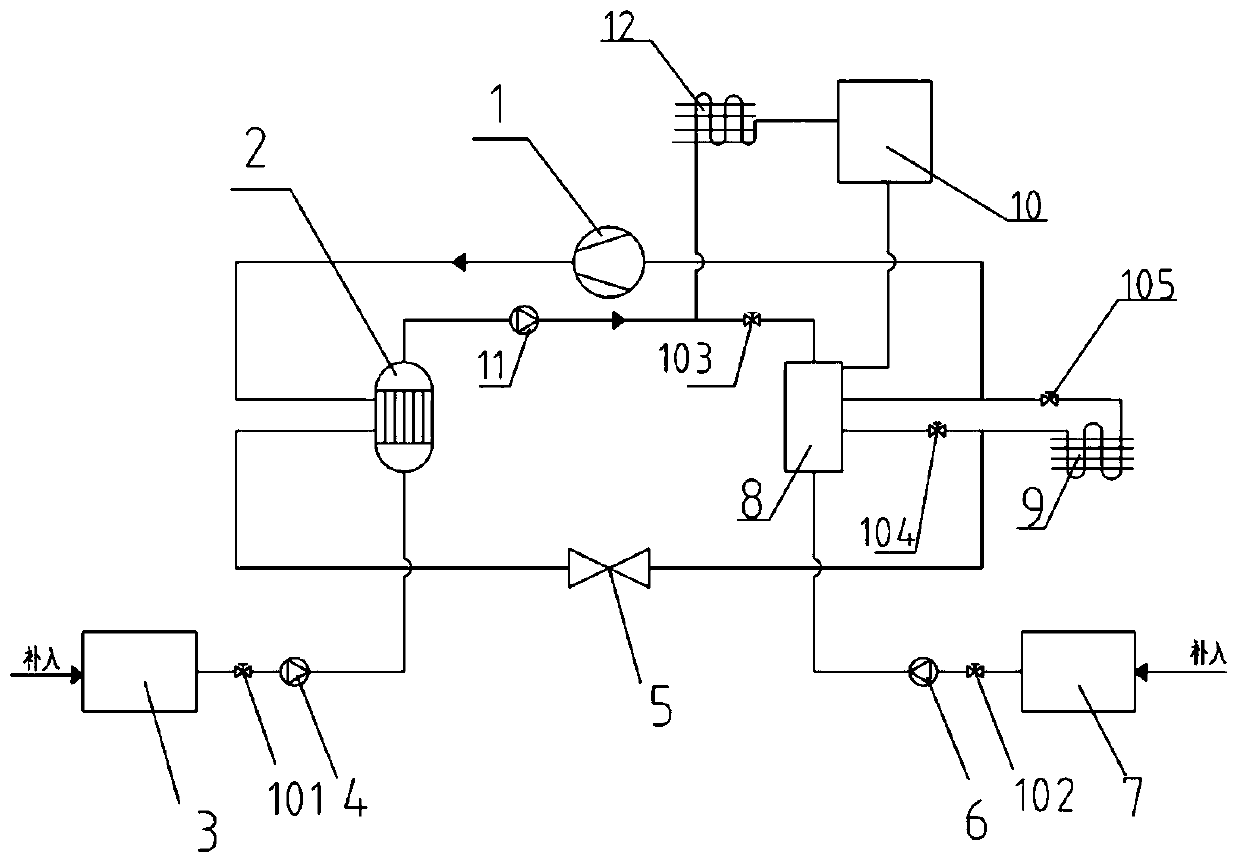

Heat pump seawater desalination device utilizing evaporator and condenser

PendingCN111018026AIncrease fade speedLower desalination costsSeawater treatmentGeneral water supply conservationWater vaporEnvironmental engineering

Owner:ZHEJIANG UNIV OF TECH

Production equipment for pesticide aqueous suspension

InactiveCN105360112ATransparent appearanceGood dispersionBiocideAnimal repellantsEmulsionPulp and paper industry

Owner:NANJING GAOZHENG AGROCHEM

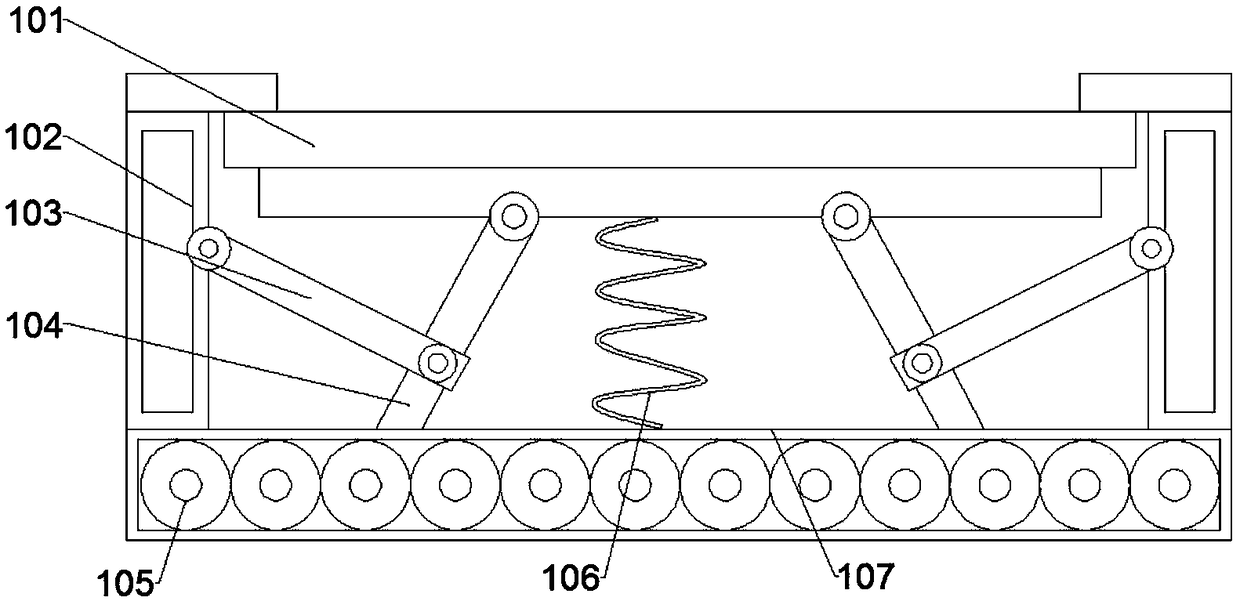

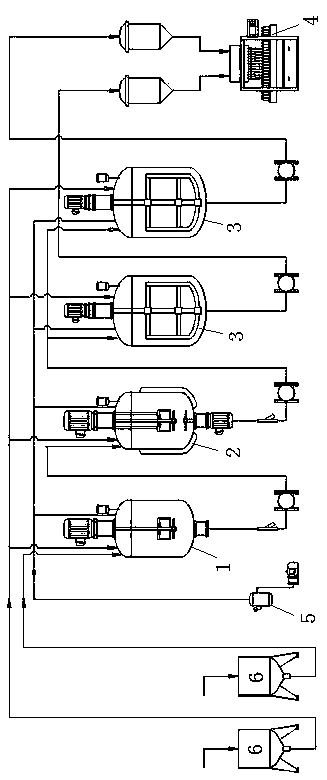

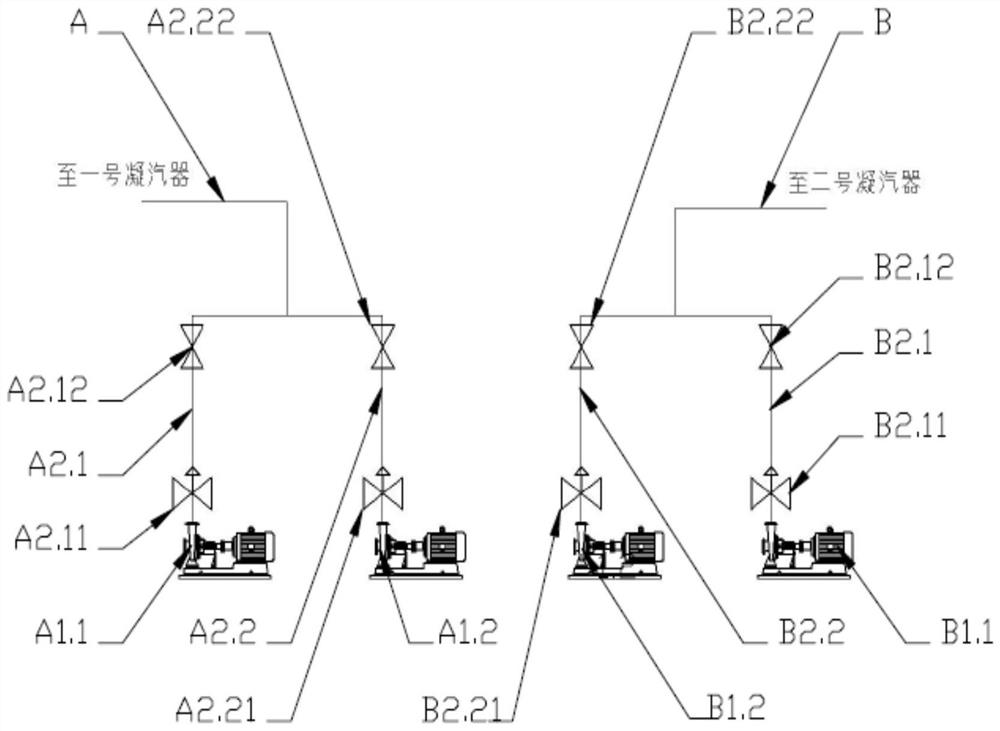

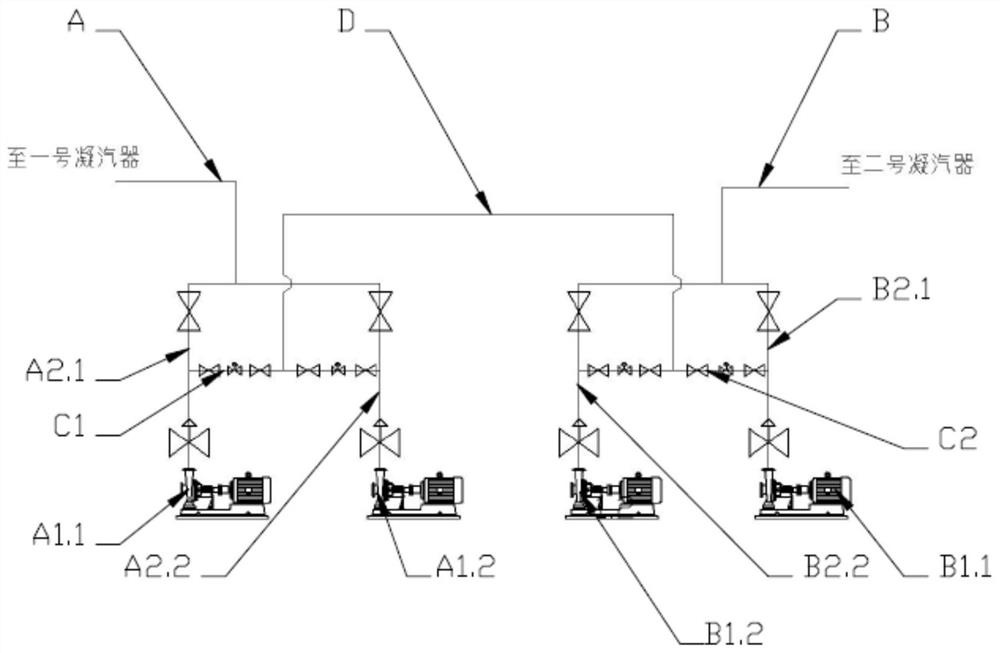

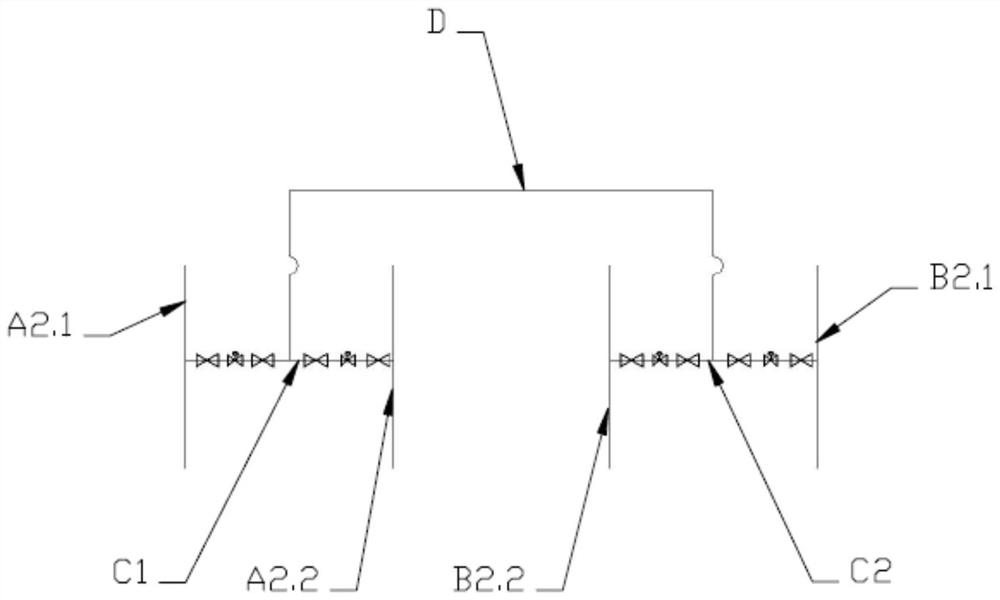

Pipeline system of vacuum pump unit of waste incineration power plant

PendingCN113833630AReduce downtime incidentsMake sure the connection works securelyPositive displacement pump componentsPump installationsPower stationProcess engineering

Owner:CHAOZHOU SHENZHEN ENERGY ENVIRONMENT CO LTD +5

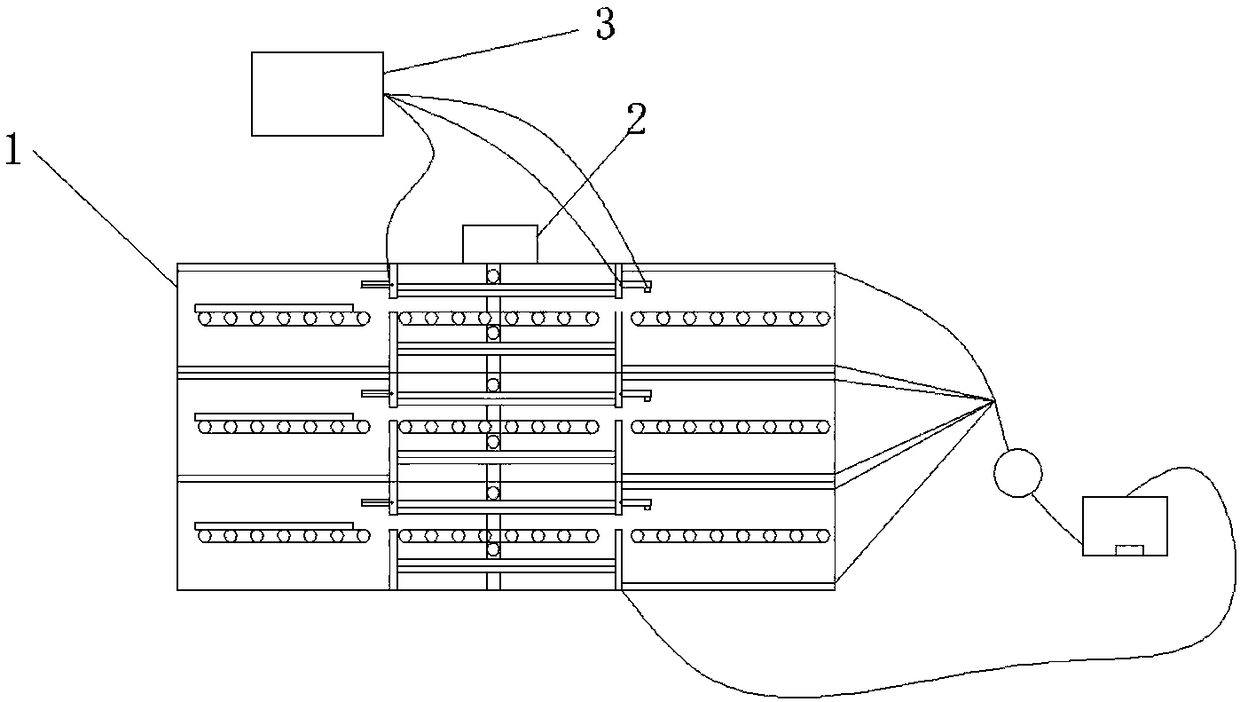

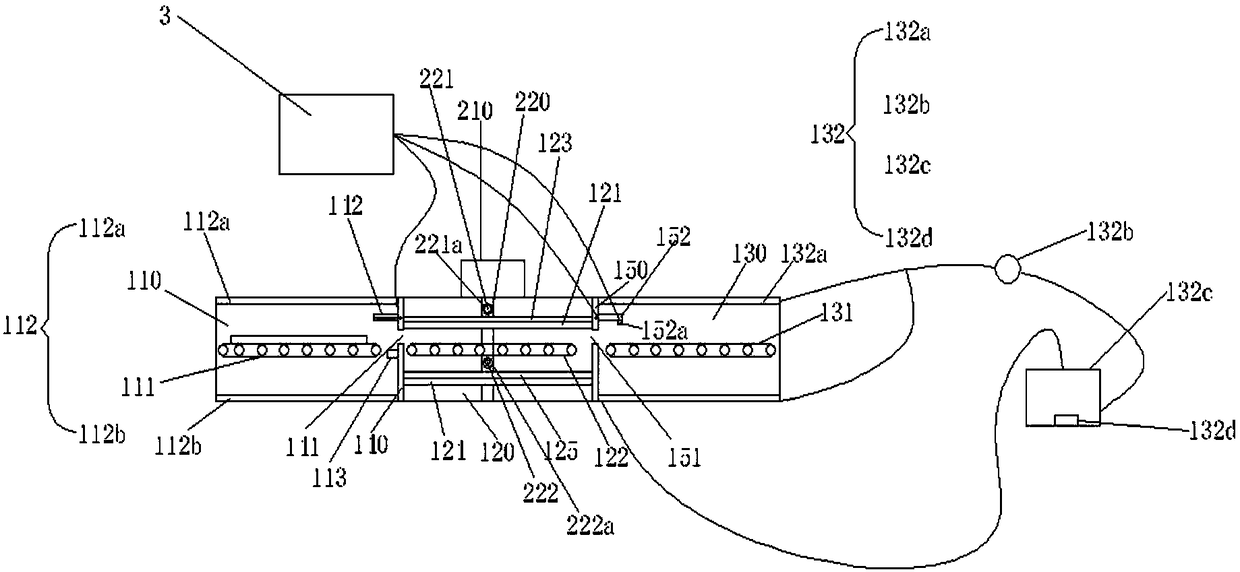

Conveying device for stamping surface leather of ball sports goods

InactiveCN114750241AGuaranteed stabilityRealize automatic separation operationMetal working apparatusPunchingPumping vacuum

The invention discloses a conveying device for surface leather stamping of ball sports goods and belongs to the field of ball leather conveying, the conveying device for surface leather stamping of the ball sports goods can achieve rapid separation of stamped leather blocks, and a sleeve arranged on the outer side of a fixed roller in a sleeving mode is arranged on the right side of a first guide roller; a plurality of first through holes communicating with the interiors of the fixed rollers are formed in the outer sides of the sleeves, air flow is pumped by means of work of a vacuumizing pump in the main machine body, leather blocks formed in the leather materials in a punching mode can be adsorbed, the leather blocks are automatically separated in cooperation with movement of the leather materials, and automatic separation operation in the conveying process is achieved; and the working efficiency of the device is improved.

Owner:NANTONG YUEYANG SPORTS EQUIP CO LTD

Target molecule detection method based on molecularly imprinted polymer

The invention discloses a molecularly imprinted polymer-based target molecule detection method, which comprises the following steps of: firstly, loading a specific molecularly imprinted polymer into a solid-phase extraction column by taking the specific molecularly imprinted polymer as a recognition unit; connecting the upper part of the solid-phase extraction column with a container filled with water, and loading the lower part of the solid-phase extraction column on a solid-phase extraction instrument; connecting the solid-phase extraction column with a vacuum pump for vacuumizing so that water at the upper part quickly flows; and recording the time when the water completely passes through the solid-phase extraction column by using a timer, and converting molecular detection into time detection to realize the detection of specific target molecules. The method can realize the detection of different target molecules, is simple and convenient, does not need expensive instruments and professional operation, and can be applied to the rapid detection of trace hydroxyl polychlorinated biphenyl in a water sample.

Owner:INST OF QUALITY STANDARD & TESTING TECH FOR AGRO PROD OF CAAS

Leak-proof protection system

InactiveCN102560639ASealed double insuranceGuarantee product qualityPolycrystalline material growthSingle crystal growth detailsEngineeringProtection system

Owner:ZHEJIANG HONGYE NEW ENERGY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap