Oil gas purification recycling device and tail gas purification recycling device and method thereof

A recovery device and tail gas purification technology, which is applied in the direction of distribution device, special distribution device, liquid distribution, transportation or transfer device, etc., can solve the problems of high cost and poor recovery effect, and achieve the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

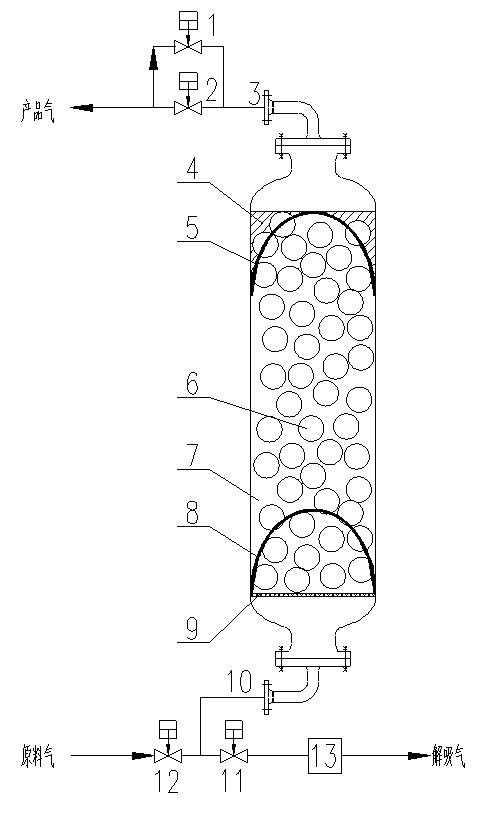

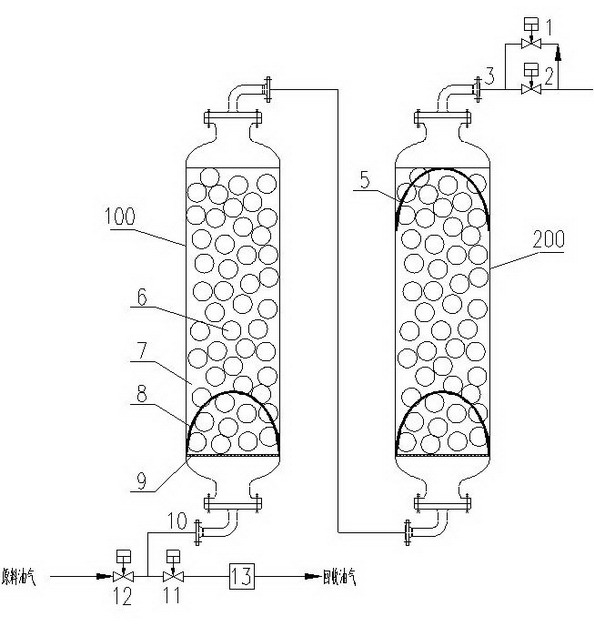

[0055] figure 2 A schematic diagram of the structure of the pressure swing adsorption tower is shown.

[0056] Such as figure 2 As shown, 1 is a program-controlled valve (switched by a preset program); 2 is a program-controlled valve; 3 is the product gas outlet of the adsorption tower, which can also be used as the inlet of the adsorption tower pressurized gas; The part used is called "dead space"; 5 is the adsorption front curve at the end of the adsorption process of the adsorption tower; 6 is the adsorbent; 7 is the adsorption saturation zone; 8 is the adsorption front curve at the beginning of adsorption; Adsorbent tray; 10 is the feed gas inlet / desorption gas outlet of the adsorption tower; 11 is a program-controlled valve; 12 is a program-controlled valve; 13 is a vacuum pump.

[0057] Its working principle is: when the feed gas has just ente

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap