Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

17 results about "Vacuum pumping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

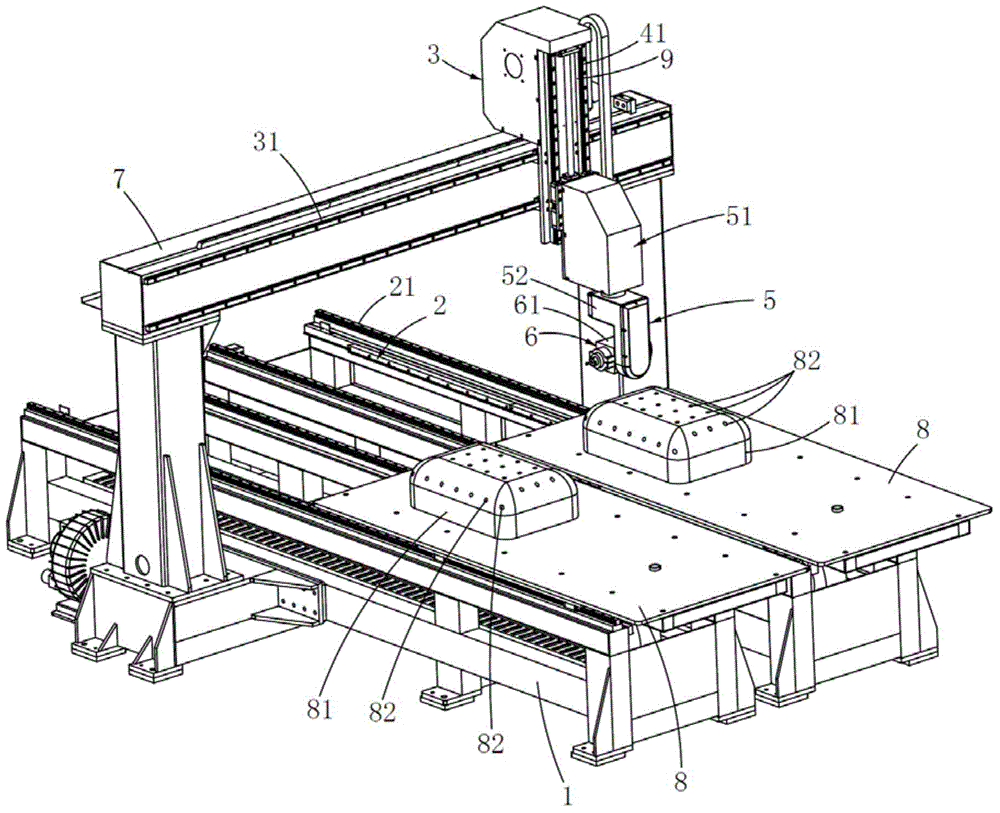

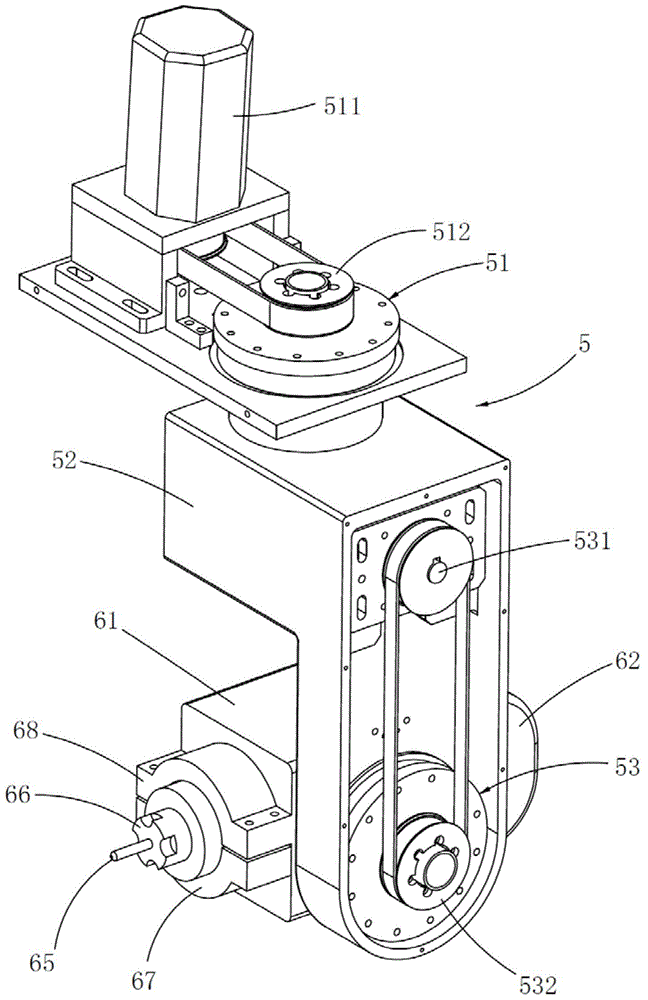

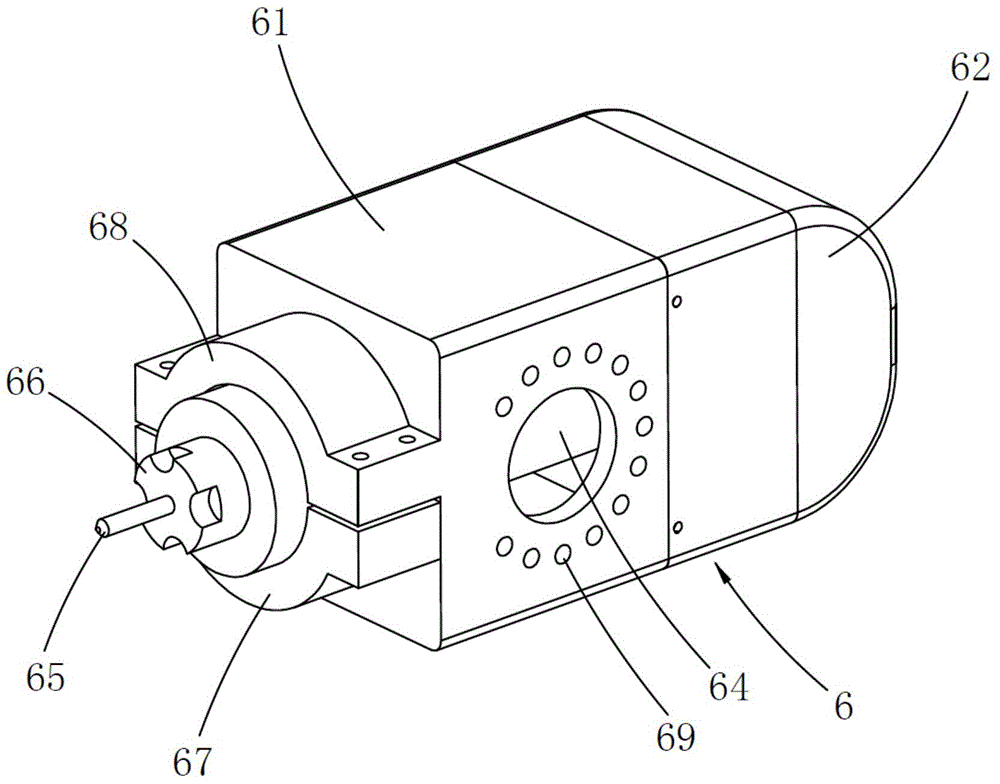

Hole drilling and edge cutting dual-purpose machine

Owner:DONGGUAN HONGFENG ROBOT TECH

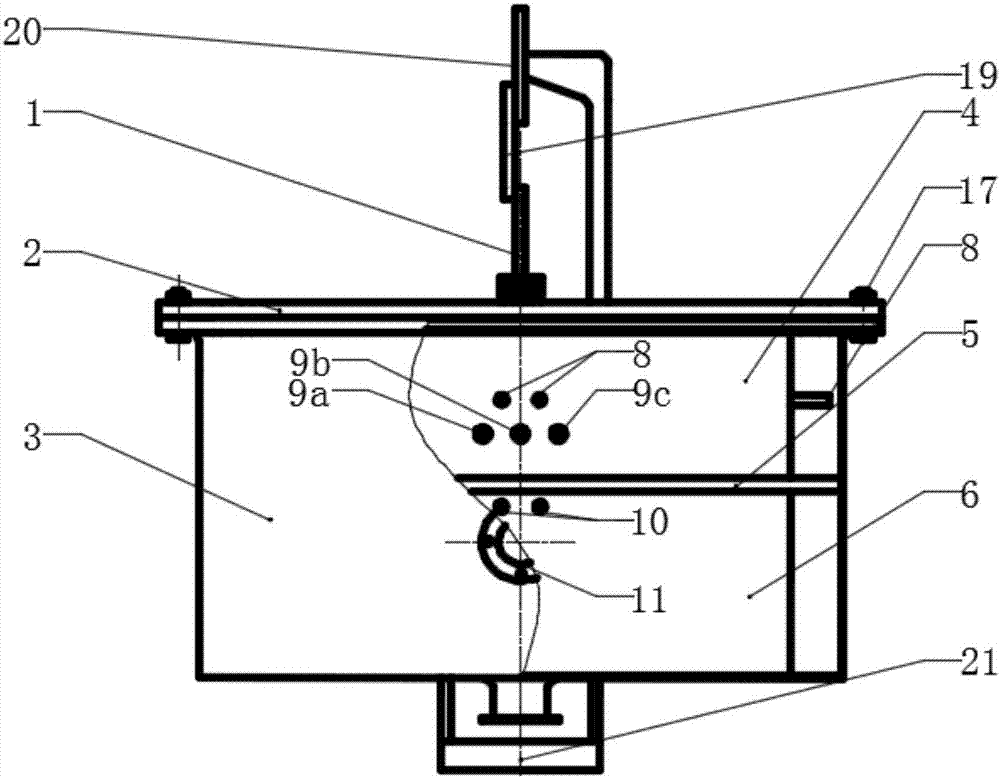

Dense core permeability measuring device and method

ActiveCN110208164AEasy to operateAvoid the problem of inaccurate flow meteringComponent separationPermeability/surface area analysisVacuum pumpingLine tubing

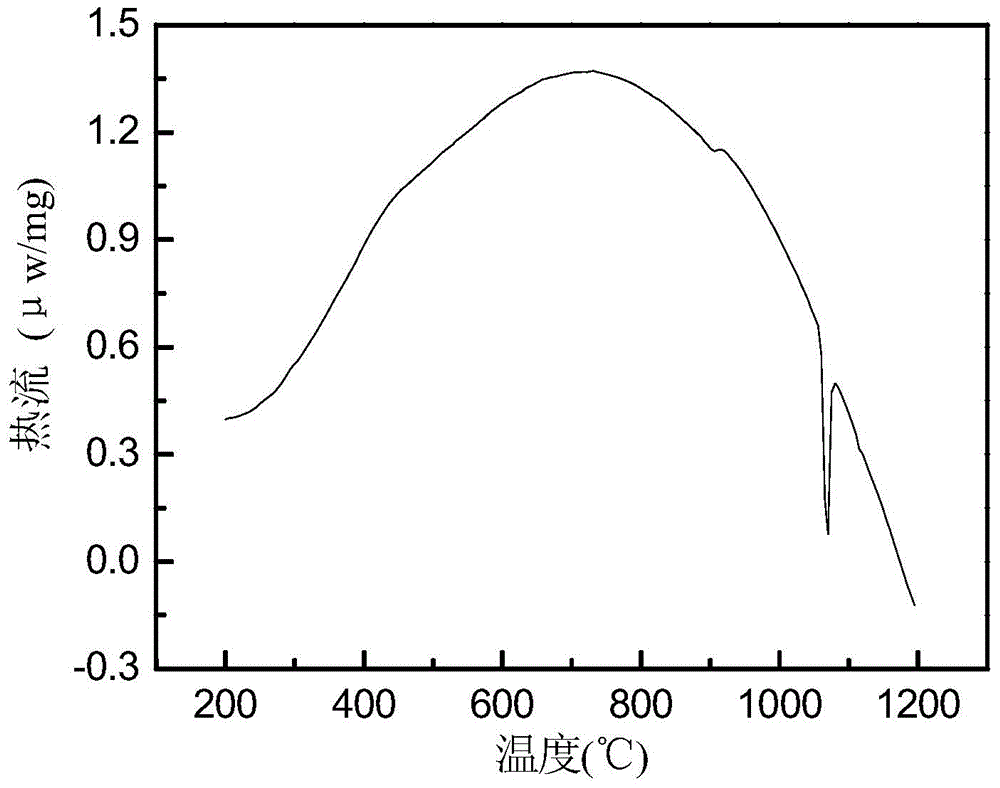

The invention discloses a dense core permeability measuring device and method. The dense core permeability measuring device comprises a core holder, a standard gas mixture supply system, a confining pressure pump, a vacuum pump, a gas chromatograph and a thermostat, wherein an air inlet end of the core holder is connected with the standard gas mixture supply system through a pipeline. The method for measuring the dense core permeability of the dense core permeability measuring device comprises the following steps: S1, placing a rock sample to be measured with a length L into a rock sample cavity, and performing vacuum pumping on the rock sample and gas in the device by using the vacuum pump; and S2, starting the confining pressure pump, increasing the confining pressure of a confining pressure cavity to a required confining pressure value, and keeping the pressure constant. Through adoption of the dense core permeability measuring device and method, the problems of difficulty in measuring flow and no consideration of dispersion and slip in the process of measuring the permeability with the existing steady state method are solved.

Owner:SOUTHWEST PETROLEUM UNIV

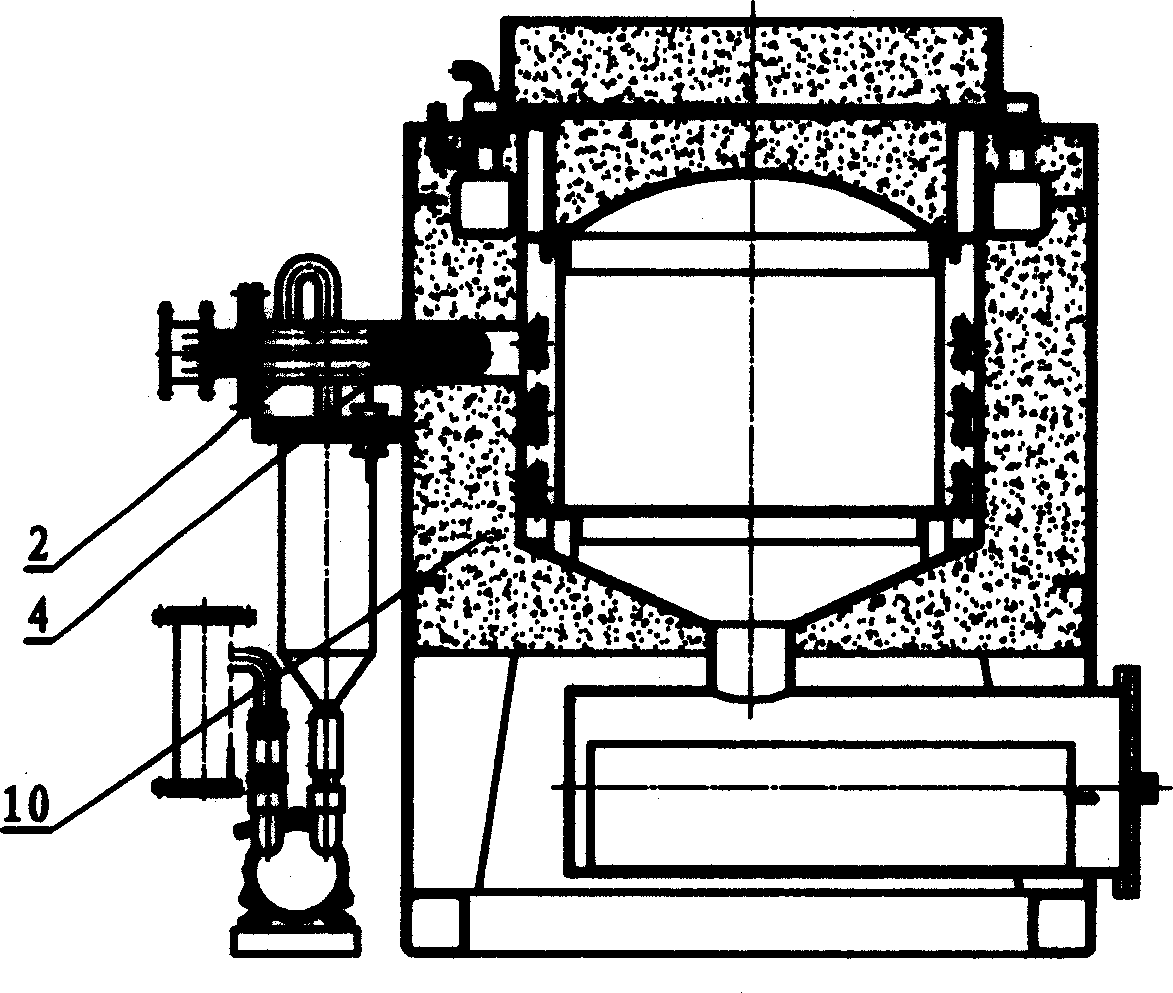

Composite type heat pipe radiator for heating

InactiveCN101373121AReduce useless energy consumptionWill not fail or even be scrappedIndirect heat exchangersVacuum pumpingHeat conducting

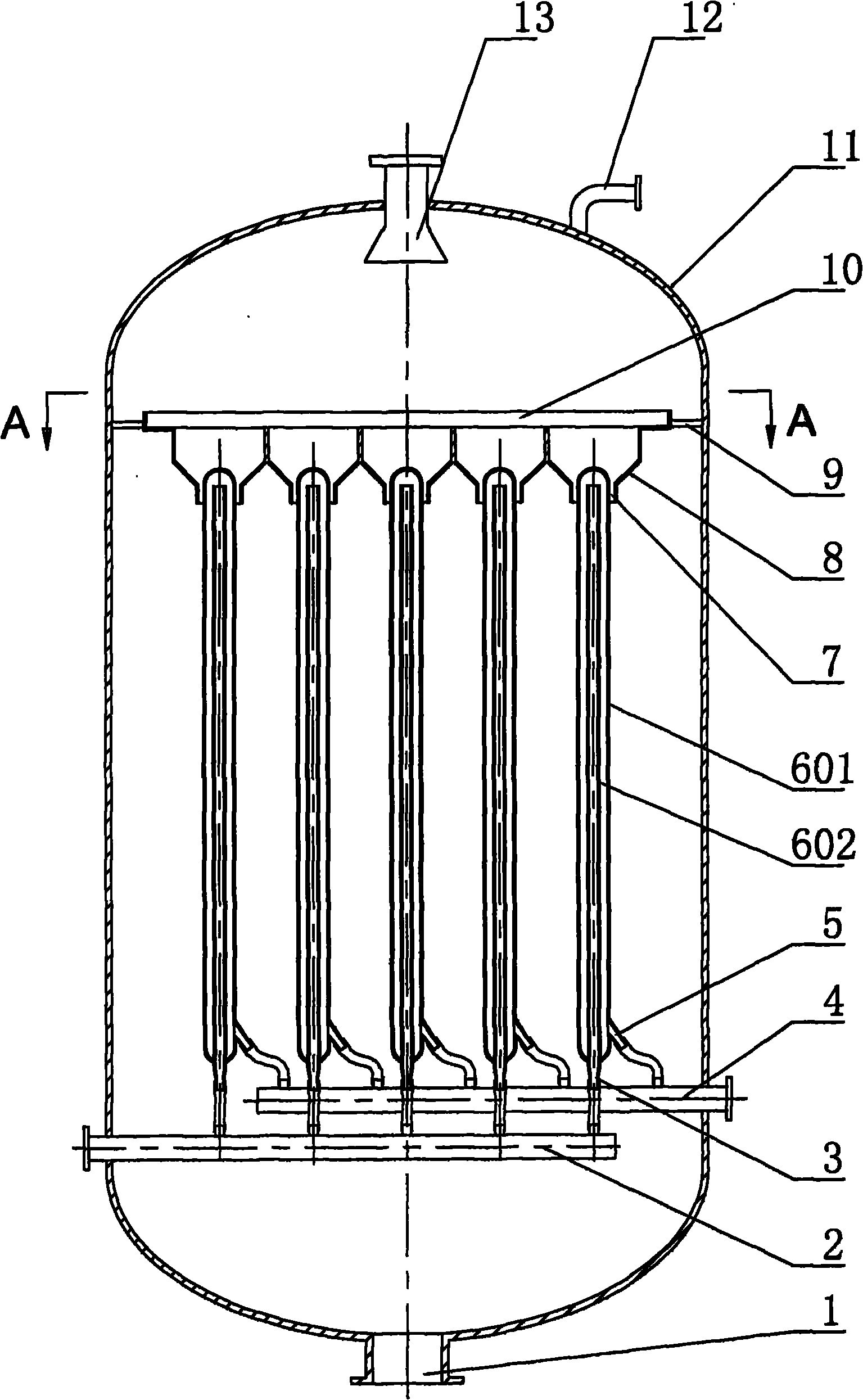

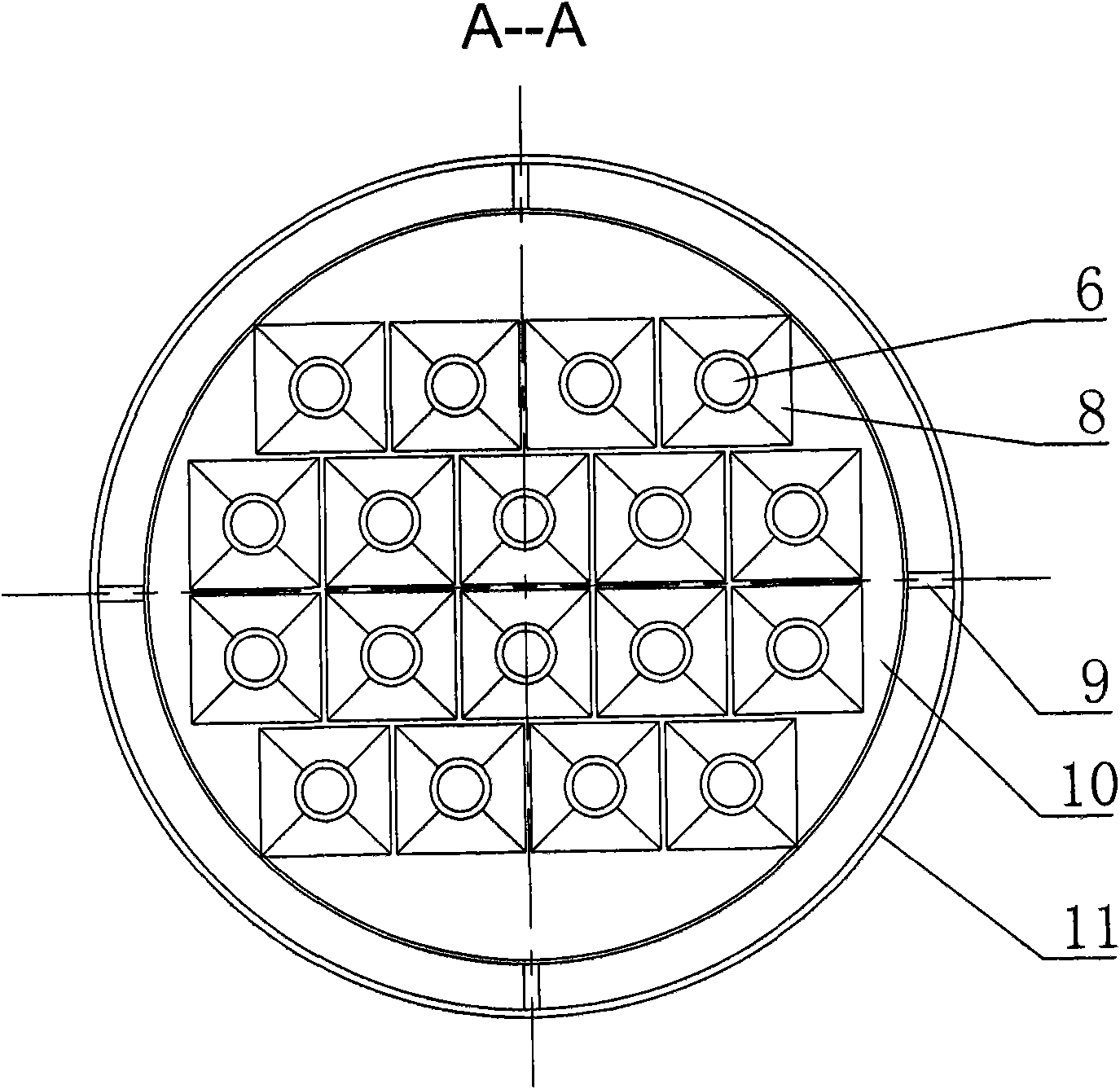

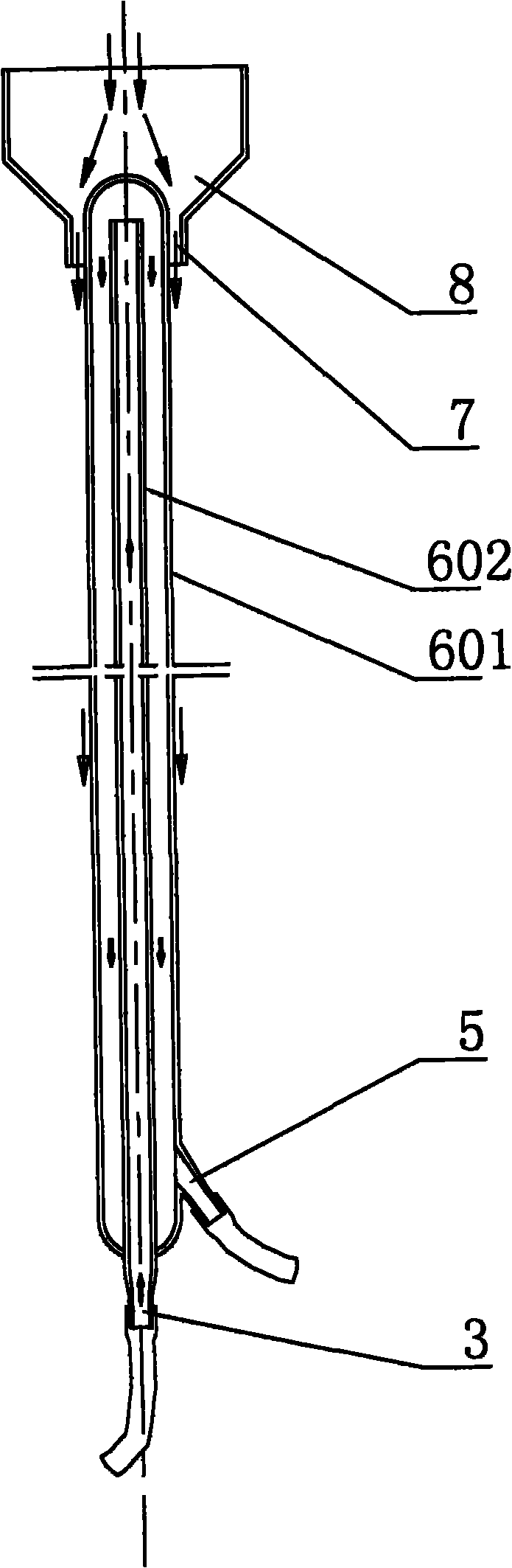

A composite type heat pipe radiator for heating relates to the heating ventilating field and comprises an upper header pipe (1), a lower header pipe (2), a radiating fin (3), a fin heating medium pipe (4), a vacuum pumping head (5), a vacuum regulating valve (6), a heat-conducting medium (7) and a heating medium (8). A cavity body formed by the upper header pipe (1), the lower header pipe (2), the radiating fin (3) and the heating medium pipe (4) with the vacuum pumping head (5) and the vacuum regulating valve (6) after a vacuum device extracts the air in the upper header pipe (1), the lower header pipe (2), the radiating fin (3) and the heating medium pipe (4) from the vacuum pumping head (5); and after the air in the cavity body is extracted, a vacuum hollow cavity is formed. The heat-conducting medium absorbs heat from a heat source and transfers the heat to the heating medium (8) through the fin heating medium pipe (4); the heating medium is heated and gasified and transfers the heat to the air so as to serve the heating function. The invention has the advantages of high efficiency, safety, water and energy conservation, beauty, duration, light weight, and high borne pressure. The invention can manufactured into composite type vacuum ultra heat conducting pipe energy-saving efficient radiators of various types and specifications, such as the plate type, the pipe type, the cylindrical type, various wing types, and the like.

Owner:肖建选

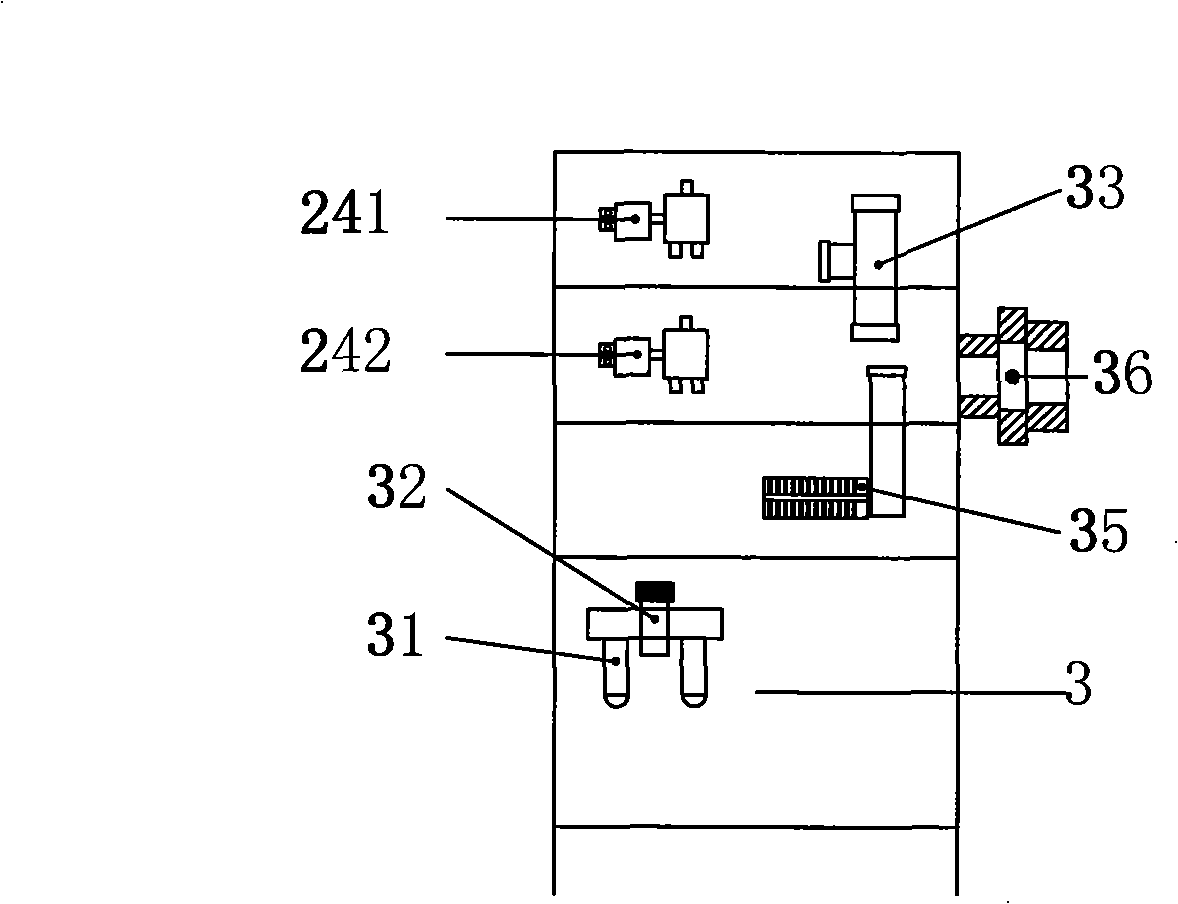

Efficient defoaming solvent-free composite mixing unit cylinder

InactiveCN104941493AGuaranteed defoaming efficiencyQuality assuranceMixersFoam dispersion/preventionVacuum pumpingCoupling

Owner:XIAN UNIV OF TECH

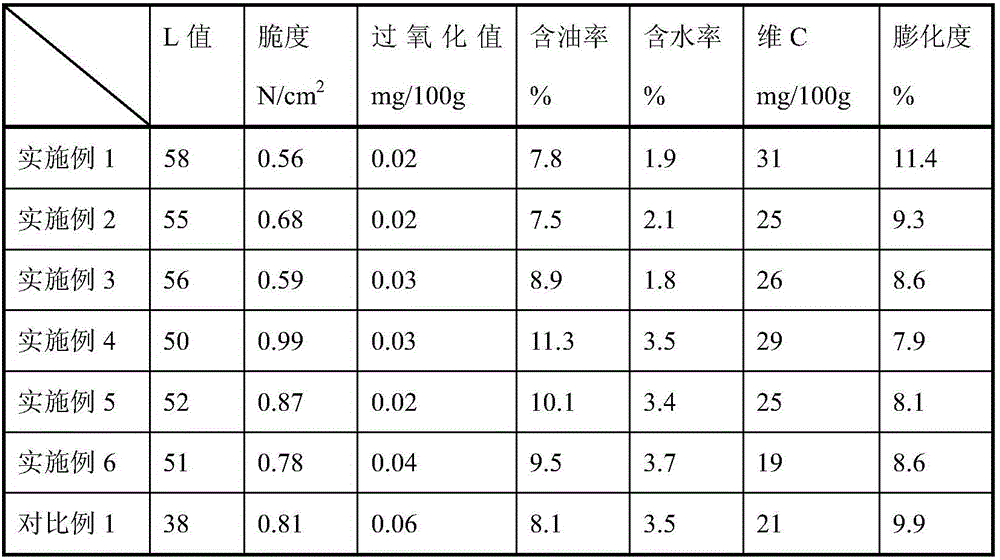

Preparation method of fruit and vegetable crisp slices

Owner:福建安兴食品有限公司

Manufacturing method for thin type heat conduction device

InactiveCN106225538AEnsure assembly flatnessImprove cooling effectIndirect heat exchangersVacuum pumpingEngineering

A manufacturing method for a thin type heat conduction device comprises the steps that a bottom plate and a cover plate which are combined in a face-shaped overlaid form are prepared, the bottom plate is provided with a flat heat dissipation face, a press-fit edge is arranged on the periphery of the part between the bottom plate and the cover plate, a vacuum cavity is formed within the surrounding range of the press-fit edge, a vacuum pumping liquid injection opening is formed in one position of the press-fit edge and sealed through a press-fit edge part, and the outer end of the press-fit edge part is sealed to be in a sealed state through a welding technology; the position, corresponding to the vacuum pumping liquid injection opening, of the press-fit edge is further provided with an upward inwards-concave face, and the upward inwards-concave face is in a face-shaped inwards-concave form in the direction from the flat heat dissipation face of the bottom plate to the cover plate; and accordingly, the outer end of the press-fit edge part forming the vacuum pumping liquid injection opening is in an upwards inwards-concave state relative to the flat heat dissipation face of the bottom plate, so that a space where welding flux used for sealing can protrude downwards is achieved, the welding flux is prevented from protruding out of the flat heat dissipation face of the bottom plate, and accordingly the assembling flatness degree and the optimal heat dissipation efficiency of the flat heat dissipation face of the bottom plate are ensured.

Owner:SUZHOU FORCECON ELECTRIC

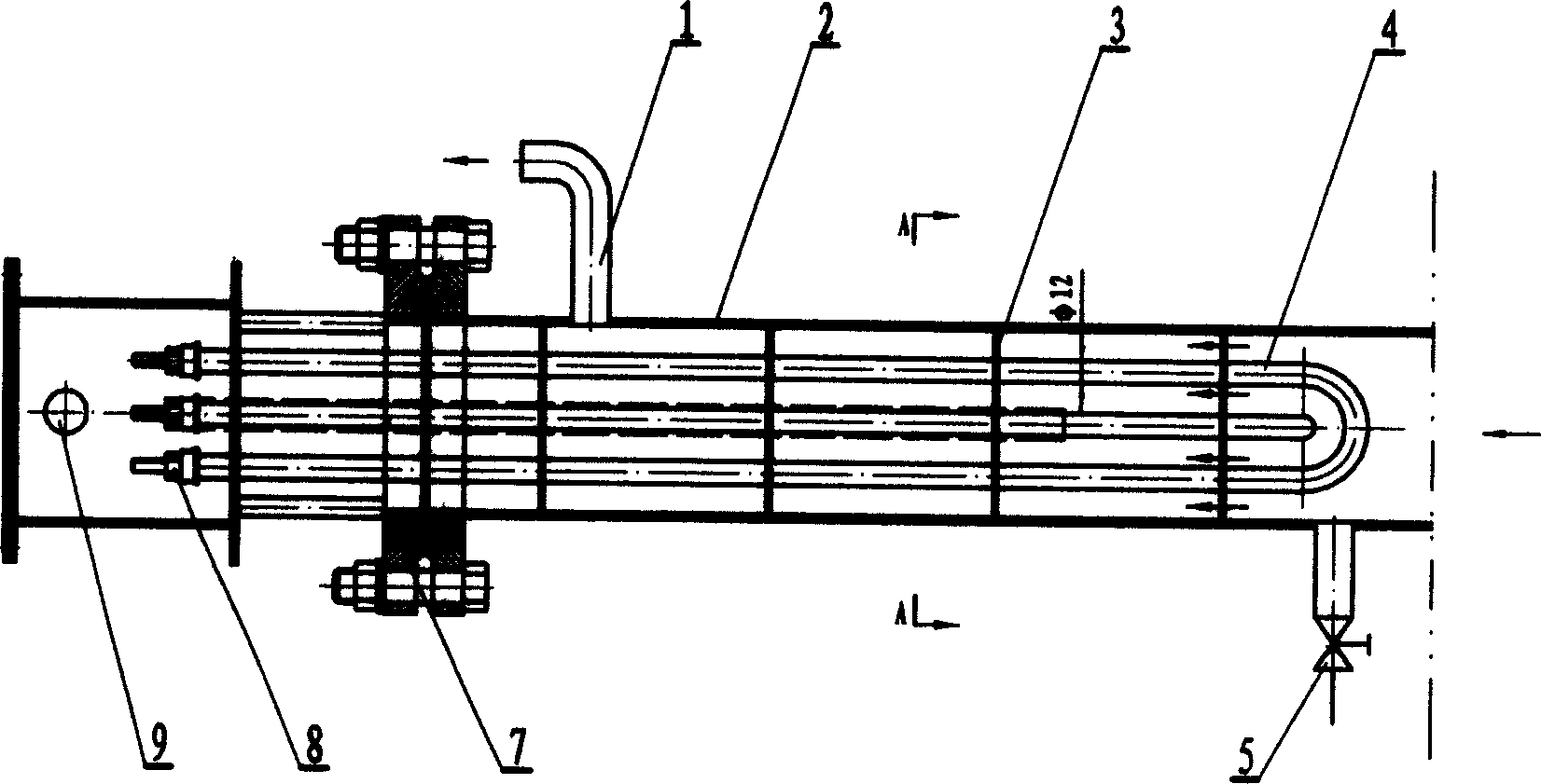

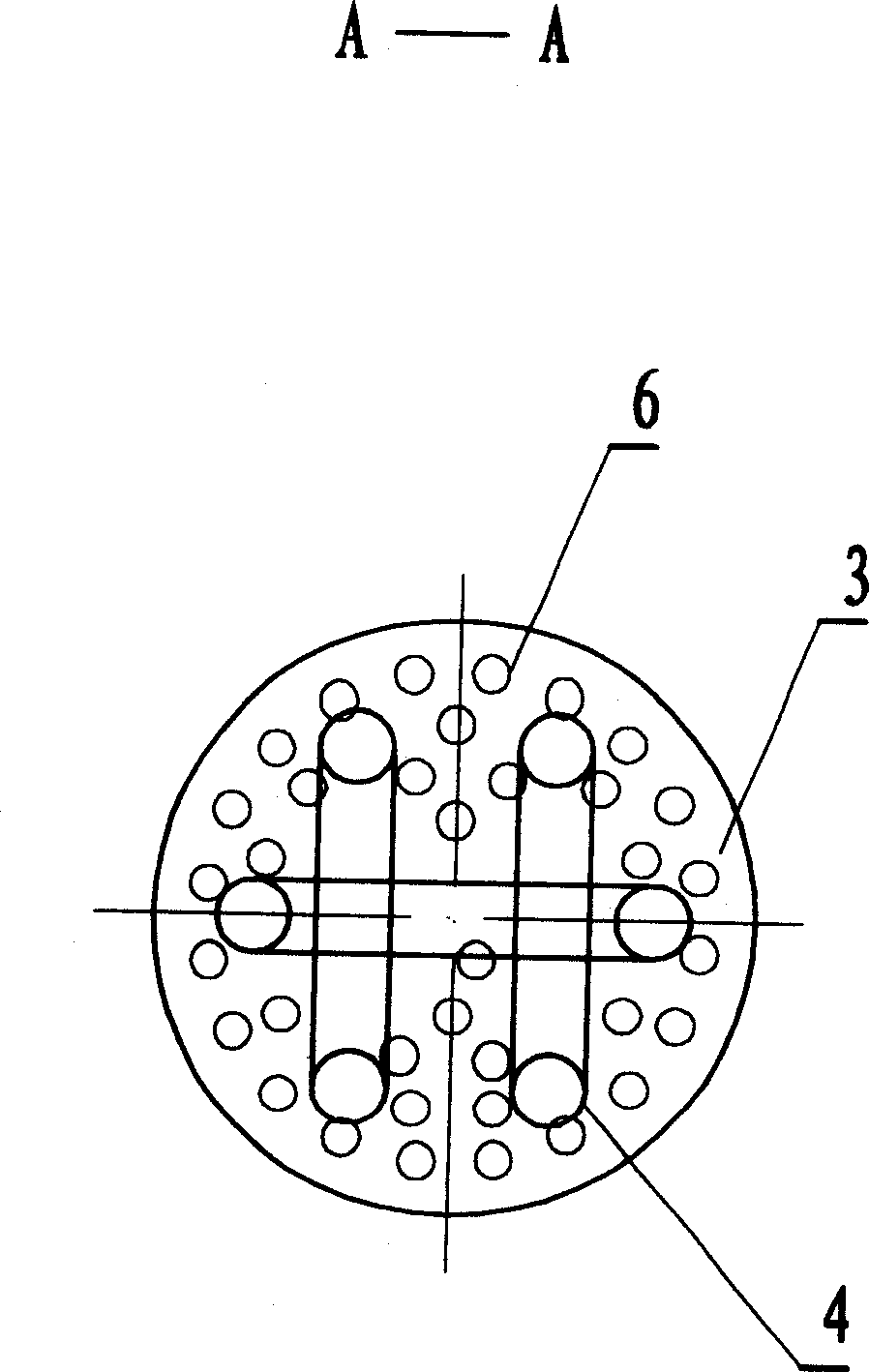

Tubular film evaporator

ActiveCN101785930ANo cloggingGood film formingEvaporators with vertical tubesPolyesterVacuum pumping

Owner:YANGZHOU HUITONG CHEM ENG TECHN

Method for welding magnesium target and copper back plate

InactiveCN112355461ASolve Oxidation ProblemsImprove bindingNon-electric welding apparatusVacuum pumpingArgon atmosphere

Owner:河南东微电子材料有限公司

Brazing filler metal for brazing of stainless steel and preparation method thereof

Owner:SHANGHAI UNIV OF ENG SCI

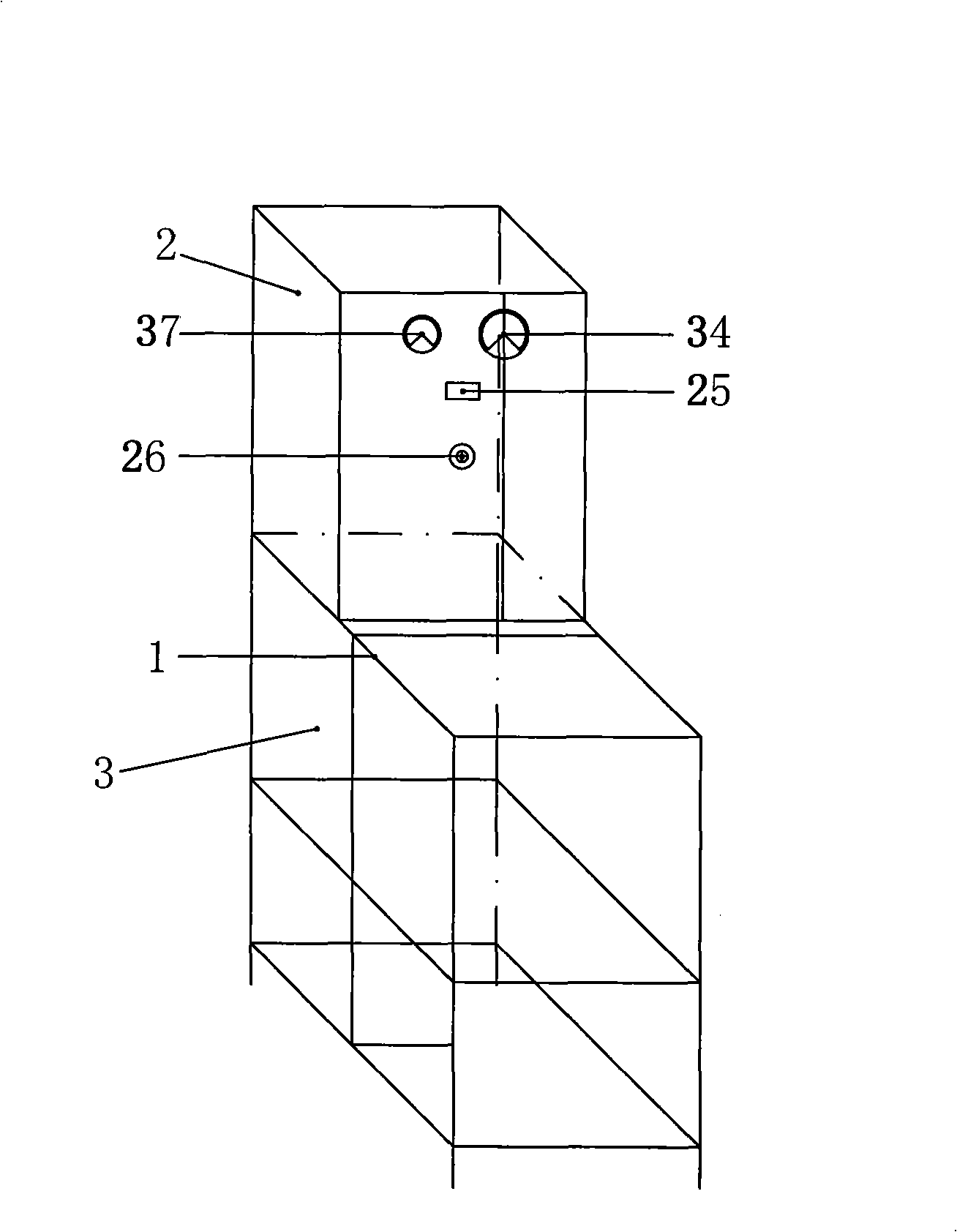

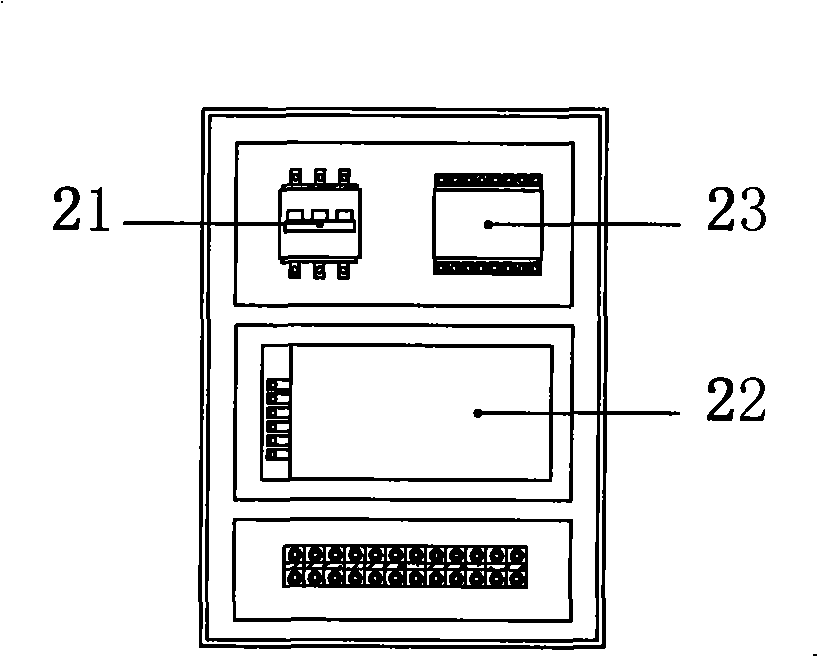

Multifunctional membrane testing device

ActiveCN101514949AIncrease vacuumEasy to operateWeather/light/corrosion resistanceProgramme control in sequence/logic controllersPositive pressureEngineering

Owner:ZHANJIANG DENI VEHICLE PARTS

Testing apparatus for plastic airtightness and method thereof

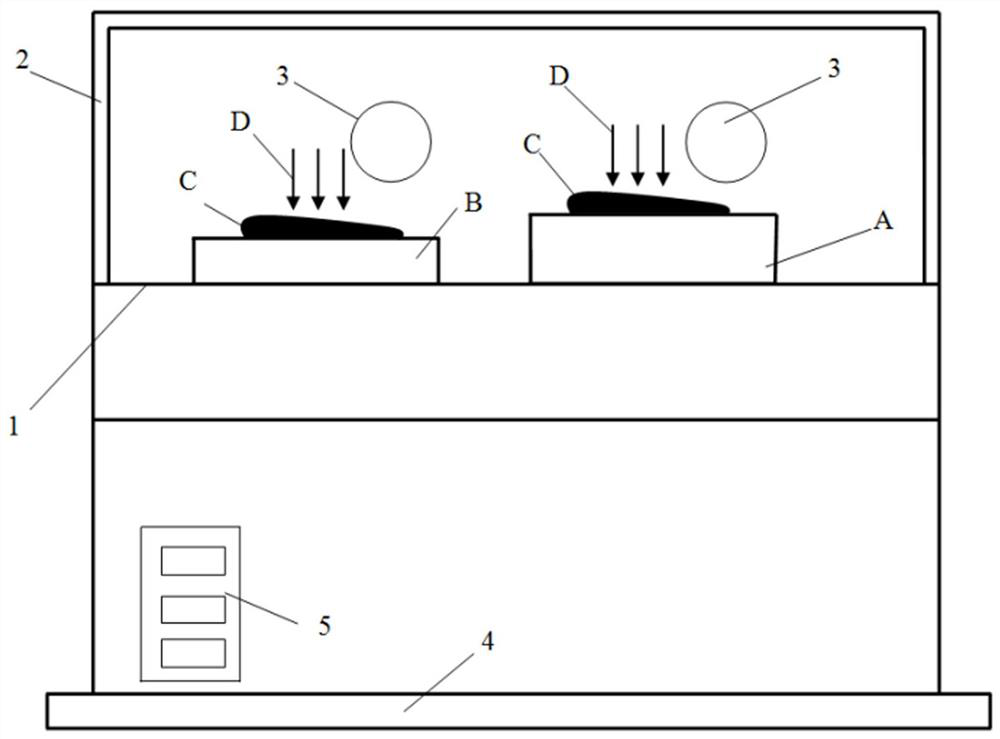

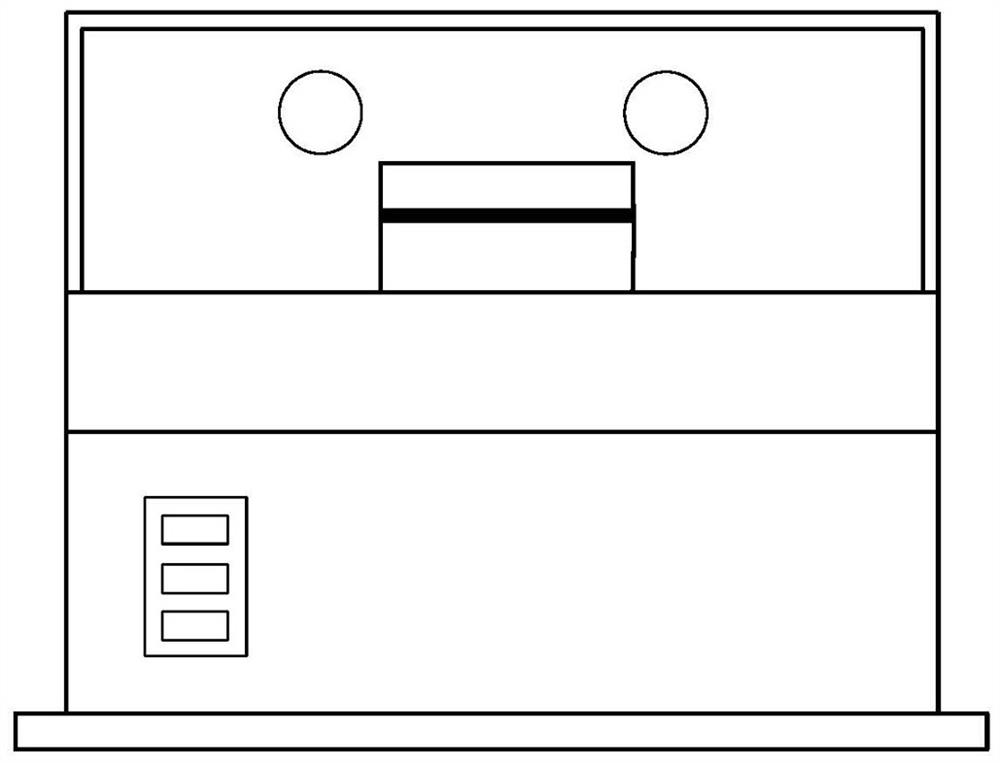

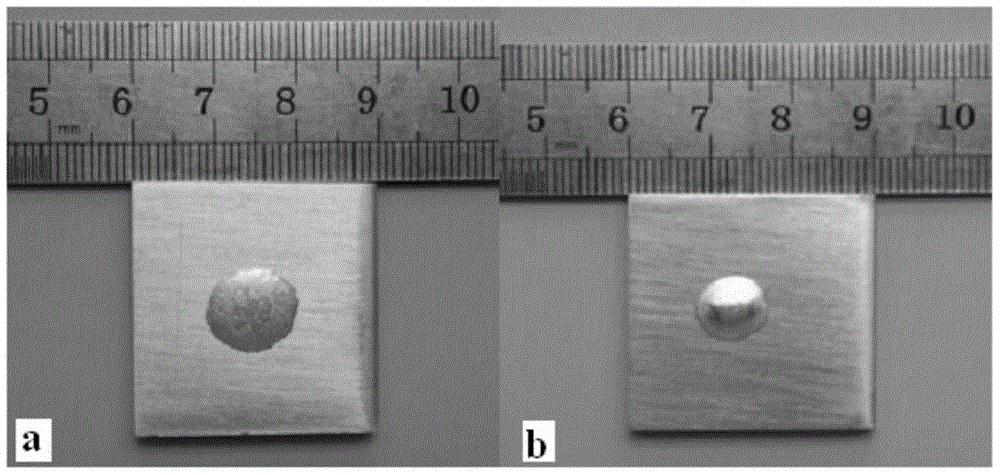

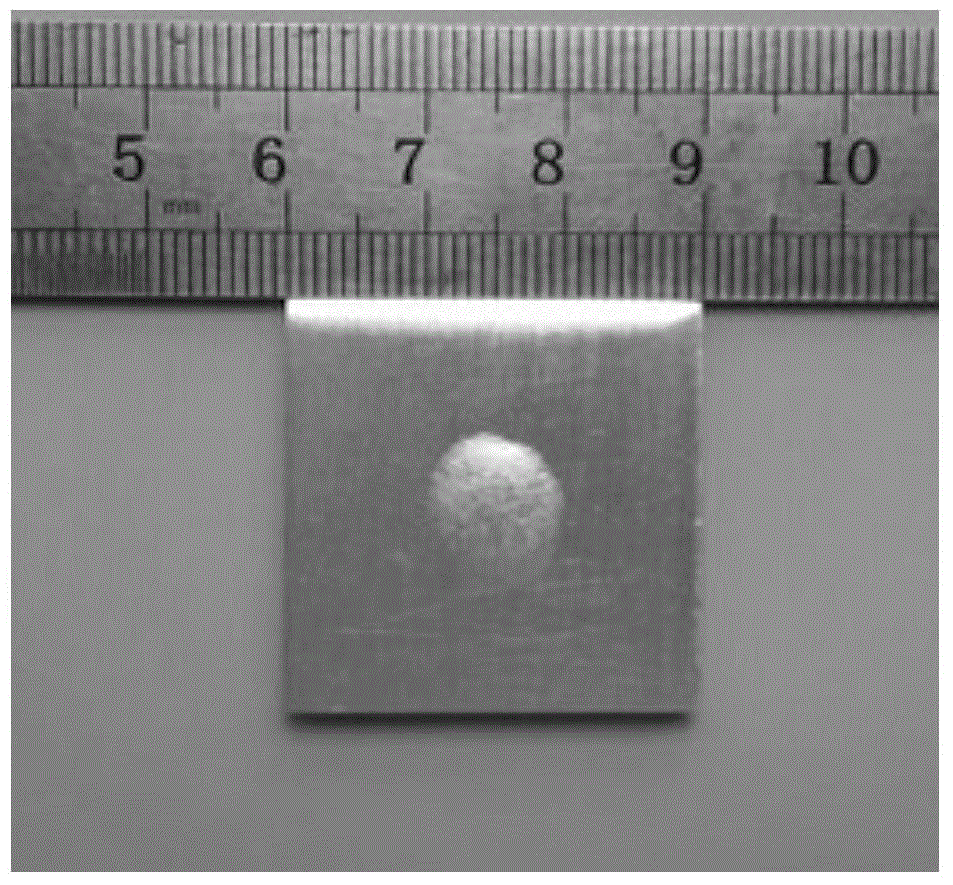

ActiveCN102445312BReduce leakageReduce mistakesMeasurement of fluid loss/gain rateMaterial analysisVacuum pumpingAir filter

The invention discloses a testing apparatus for plastic airtightness and a method thereof. The apparatus comprises an air pump, a pressure reducing valve, an air filter, an air inlet on-off valve, a high pressure element, a differential pressure measuring element, an air pipe, a testing chamber, a reference chamber and a three-way cutting sleeve ball valve. The testing chamber is composed of a high pressure chamber, a low pressure chamber, a sealing ring, and a plastic sample. The reference chamber consists of a high pressure chamber, a low pressure chamber, a sealing ring and a reference iron sheet sample. And the structural size of the testing chamber is identical with that of the reference chamber. According the above-mentioned technical scheme in the invention, the reference chamber is arranged and the size of the reference chamber is completely identical with that of the testing chamber, so that the two chambers can be contrasted and a system error can be reduced; besides, an initial testing pressure of the low pressure chamber is an atmospheric pressure, so that an occurrence of an air leakage phenomenon can be reduced; and there is no need for vacuum pumping, apparatus investment can be reduced, and energy can be saved.

Owner:BEIJING UNIV OF CHEM TECH

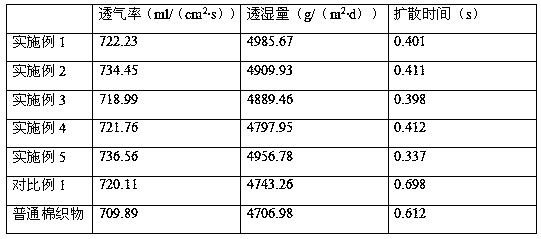

Sports outdoor clothing fabric for mass

InactiveCN108505336AAvoid discomfortLittle effect on material strengthFibre typesWoven fabricsPolyesterEpoxy

Owner:SUZHOU INST OF TRADE & COMMERCE

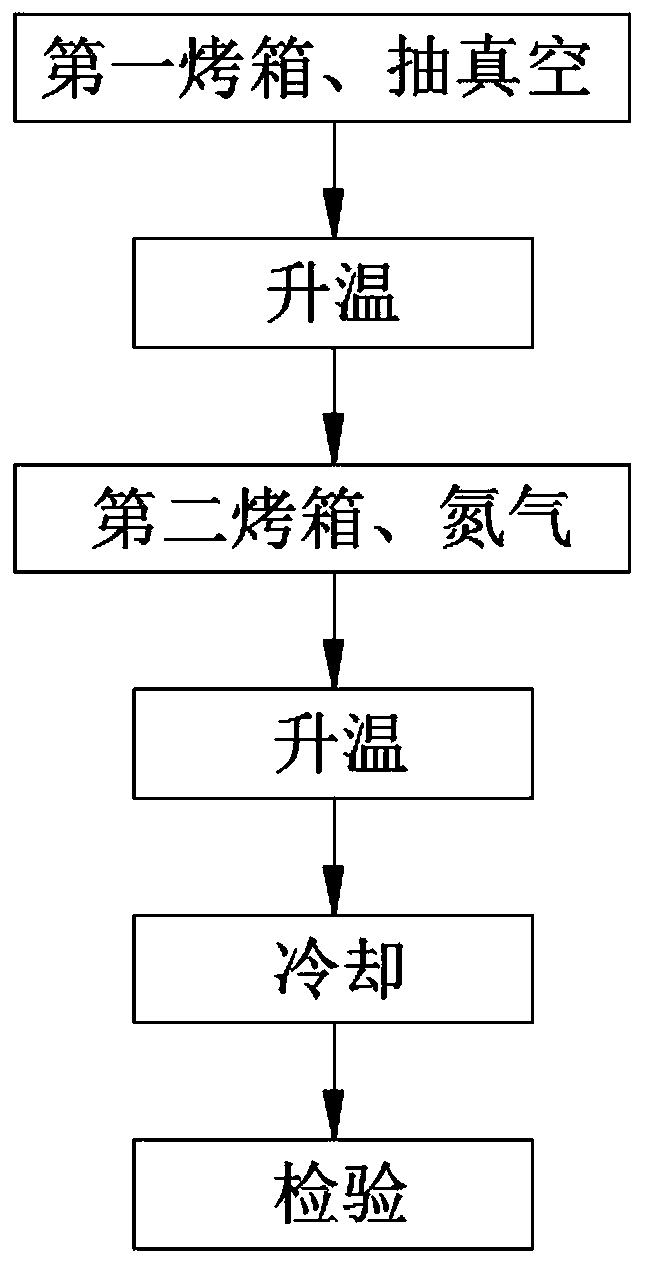

Core heat setting process method

Owner:南通海美电子有限公司

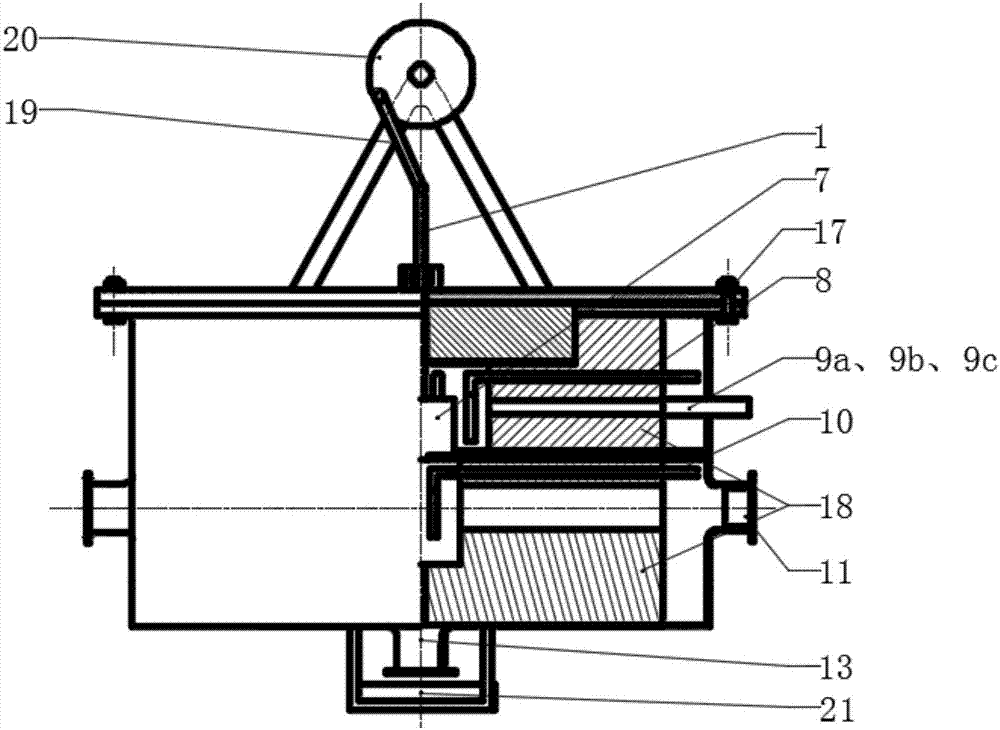

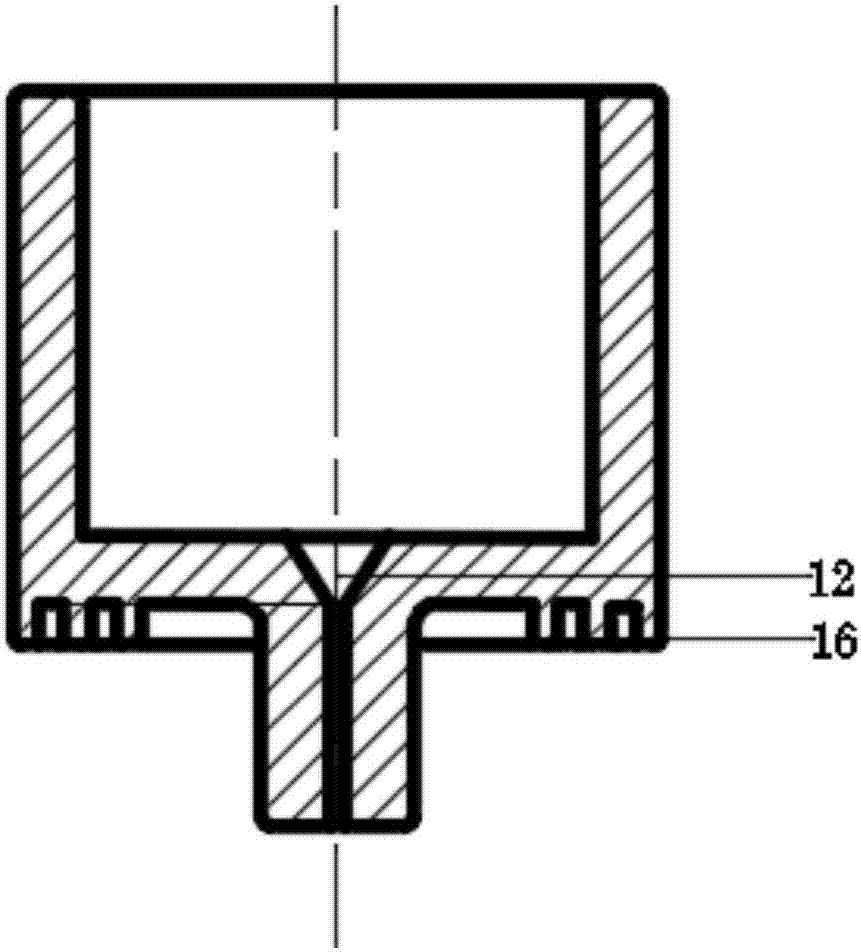

High-temperature melt granulation smelting furnace

ActiveCN107300324AMaintainance of heating chambersCrucible furnacesChemical industryVacuum pumping

Owner:CHONGQING UNIV

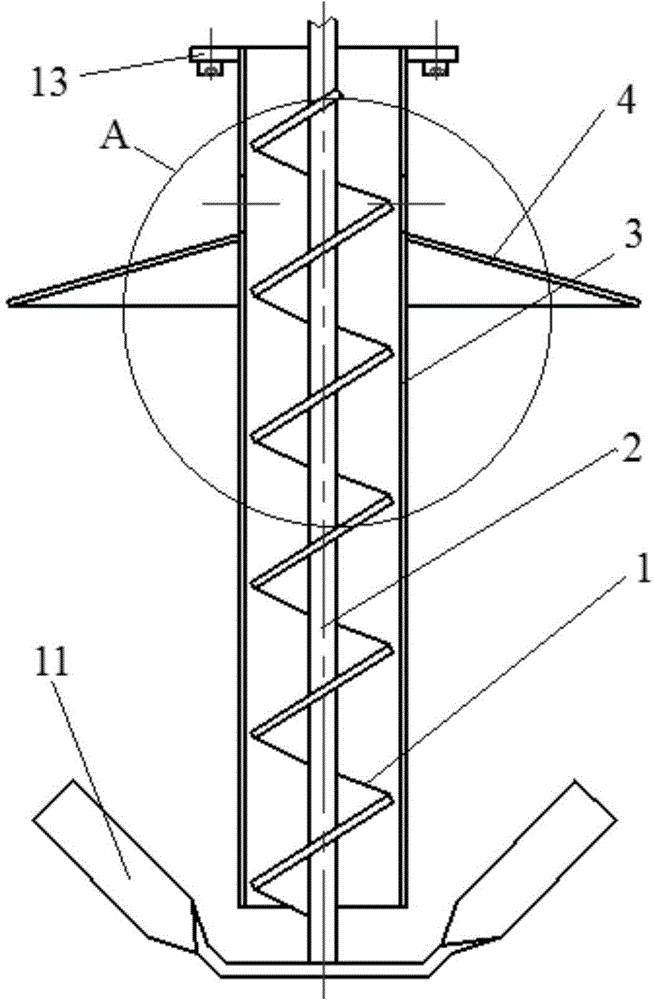

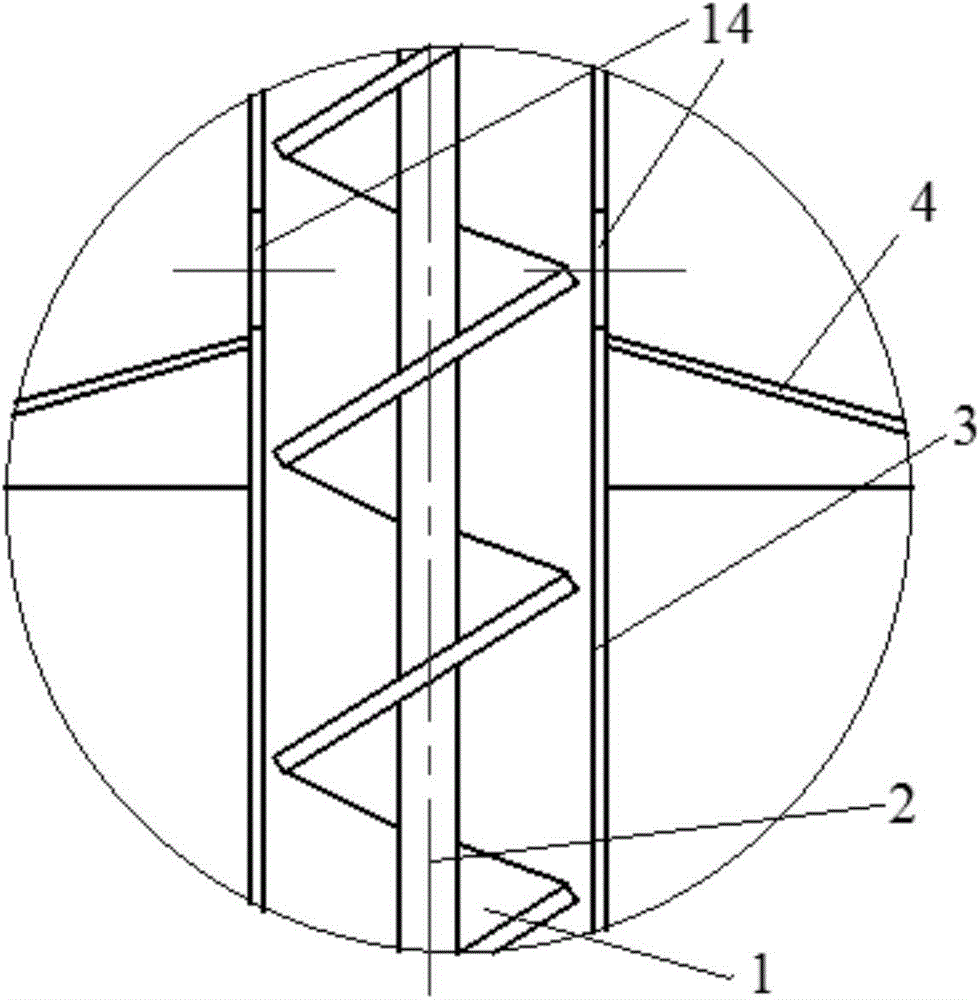

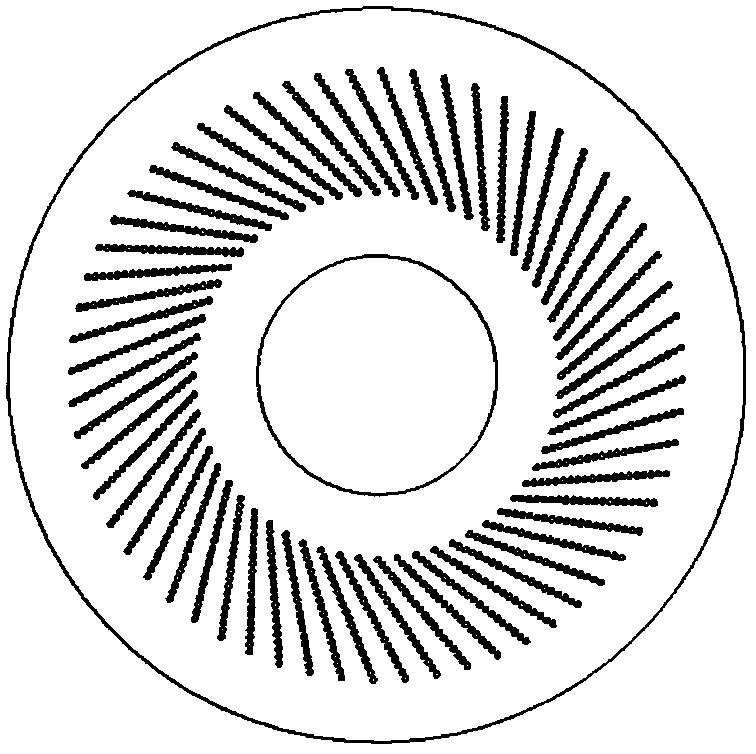

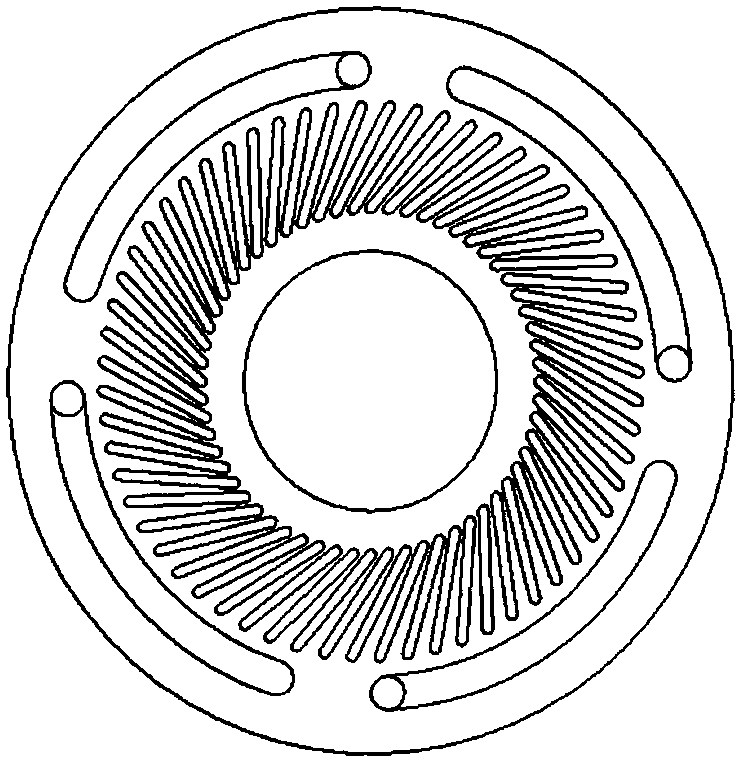

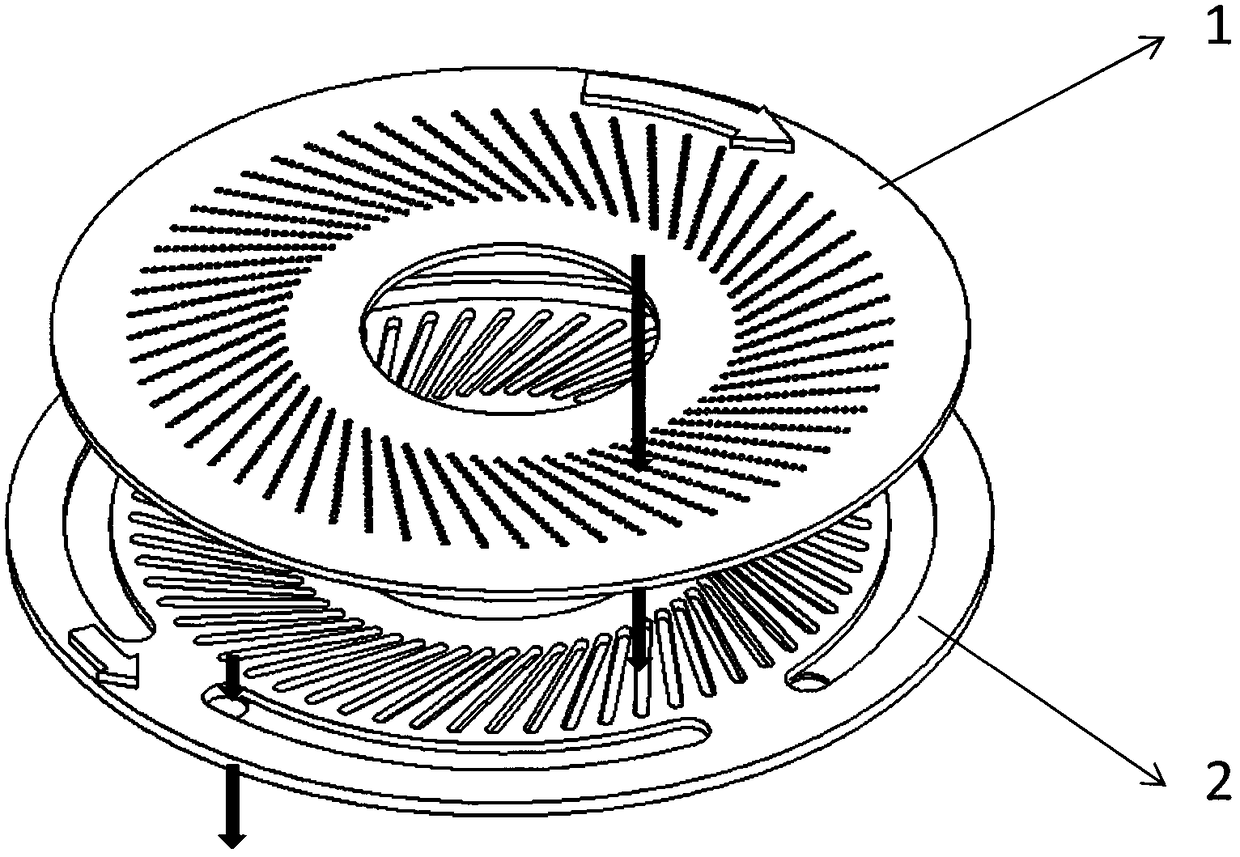

Set of molecular pump blade discs

The invention relates to a set of molecular pump blade discs, and belongs to the technical field of design methods of vacuum pump blades. Blades of a traditional molecular pump are similar to blades of an electric fan, the longer the blades are arranged, the better the air exhaust effect is, meanwhile, the strength of the blades is poor, and the blades are prone to breakage. According to the set of molecular pump blade discs, a movable disc provided with holes and a fixed disc provided with grooves are used for replacing the blades. According to the design, the machining cost is reduced, the heat deformation of the blades is reduced, the structural strength is enhanced, and the air pumping effect is improved. The set of molecular pump blade disc solves the technical problems that for the design problems, technical key points and application of an ultra-large-diameter molecular pump, both the holes in the movable disc and the grooves in the fixed disc have requirements for the size, thenumber and the position. The vacuum pumping effect can be achieved only by using the movable disc and the fixed disc in a cooperative mode. Based on the design, a molecular pump with a larger caliberand a larger pumping speed can be manufactured.

Owner:杨建康

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap