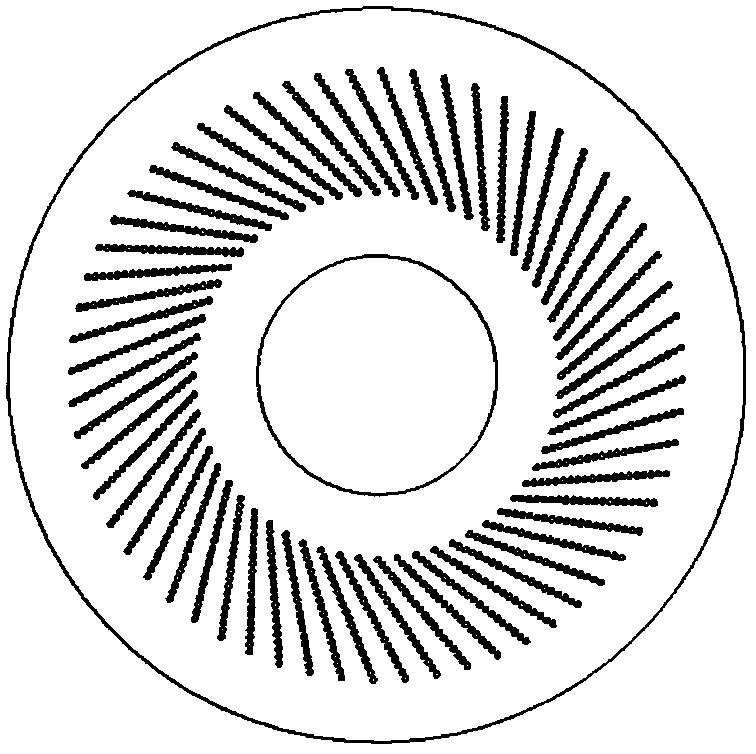

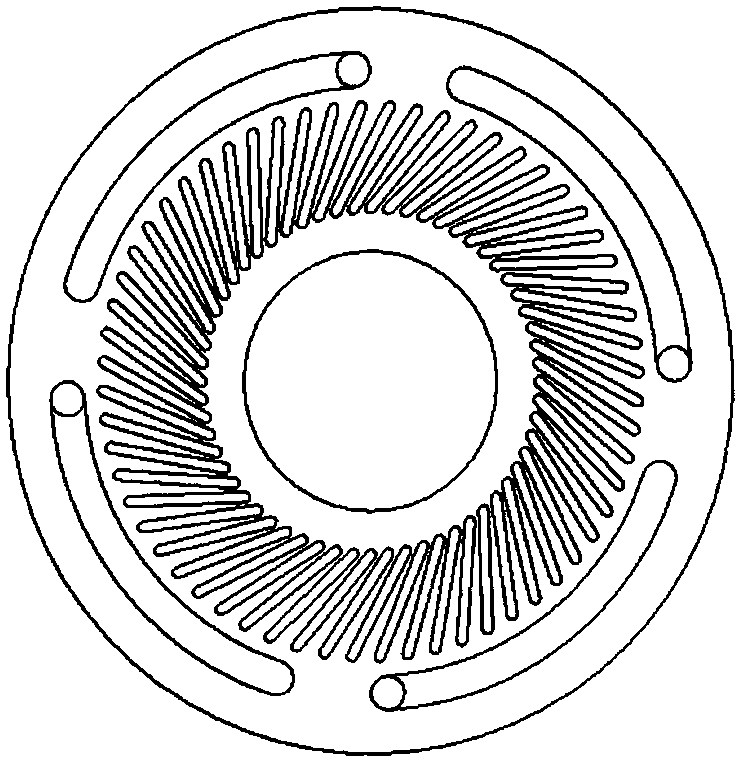

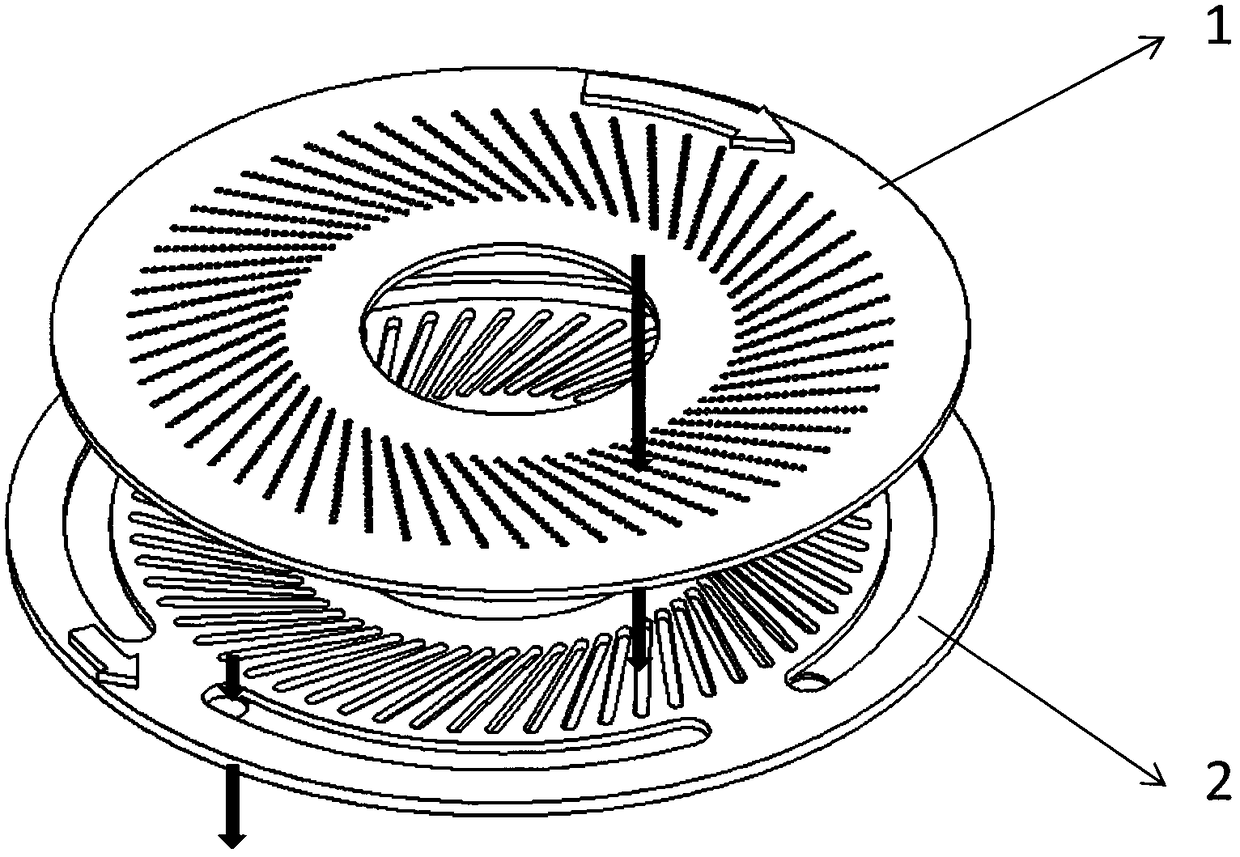

Set of molecular pump blade discs

A molecular pump and moving disc technology, applied in the field of vacuum pump blade design, can solve problems such as low structural strength, broken pump accidents, and easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The dynamic and static disks move relative to each other within a distance of less than one millimeter, and the speed is as high as tens of thousands of revolutions. The air molecules sandwiched between the moving and static disks collide and rub against the surface of the moving and static disks, and the leaf disks transmit their kinetic energy to the air molecules. The air molecules that have received kinetic energy scatter outward, and the gas pressure between the moving and static disks becomes lower. The gas pressure in the space on the upper surface of the moving disk is higher than the gas pressure between the moving disk and the static disk, and the gas in the space above the moving disk will move downward through the through holes on the surface of the moving disk. In this way, the extracted gas movement route is sucked from the vacuum chamber to the upper surface of the moving plate, and then passes through the through hole on the moving plate into the gap bet...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap