Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

15 results about "Heat pipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A heat pipe is a heat-transfer device that combines the principles of both thermal conductivity and phase transition to effectively transfer heat between two solid interfaces. At the hot interface of a heat pipe a liquid in contact with a thermally conductive solid surface turns into a vapor by absorbing heat from that surface. The vapor then travels along the heat pipe to the cold interface and condenses back into a liquid – releasing the latent heat. The liquid then returns to the hot interface through either capillary action, centrifugal force, or gravity, and the cycle repeats. Due to the very high heat transfer coefficients for boiling and condensation, heat pipes are highly effective thermal conductors. The effective thermal conductivity varies with heat pipe length, and can approach 100 kW/(m⋅K) for long heat pipes, in comparison with approximately 0.4 kW/(m⋅K) for copper.

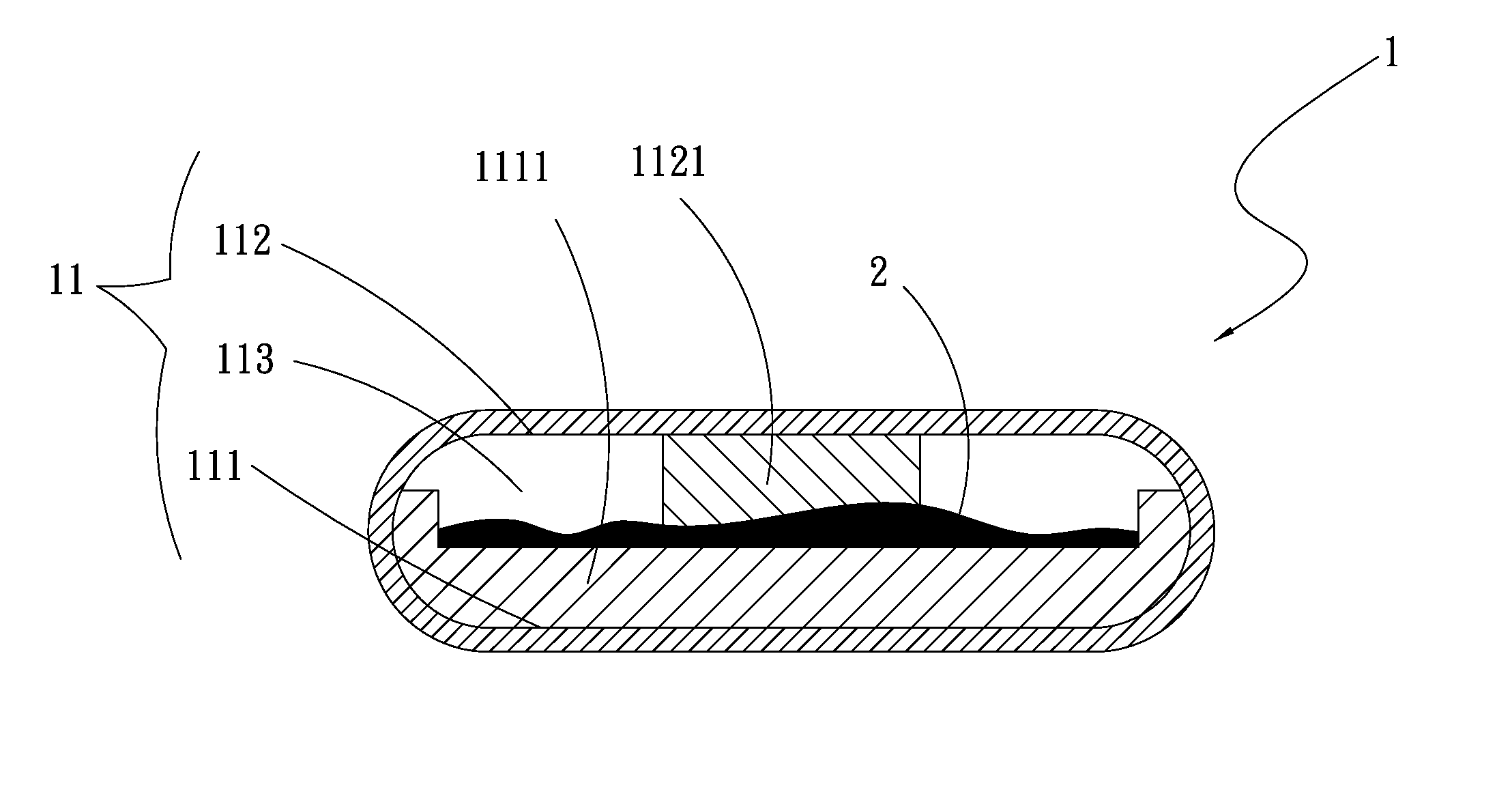

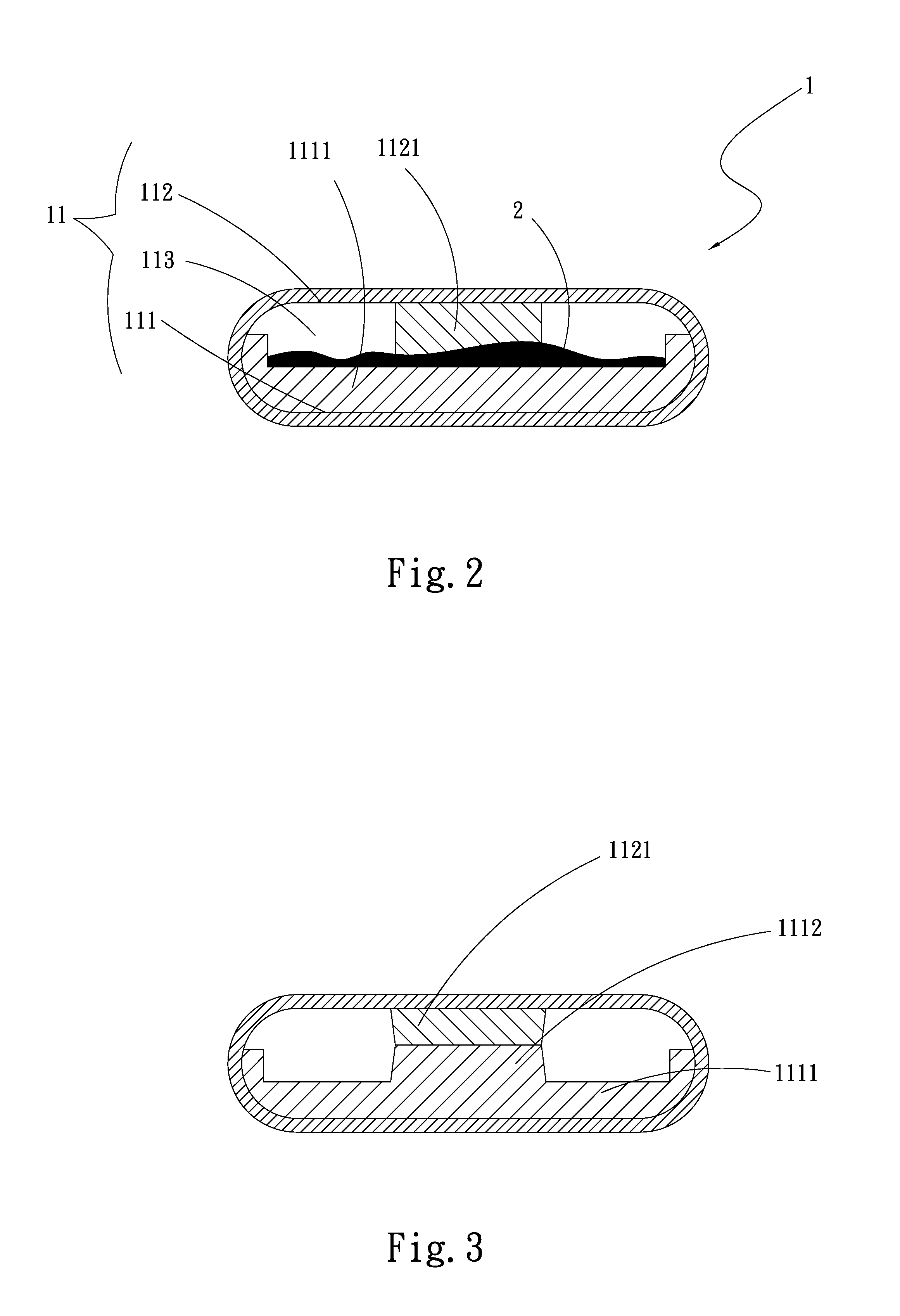

Heat pipe structure

ActiveUS20130213610A1Good heat conduction efficiencyImprove heat transfer efficiencySemiconductor/solid-state device detailsSolid-state devicesWorking fluidHeat transfer efficiency

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

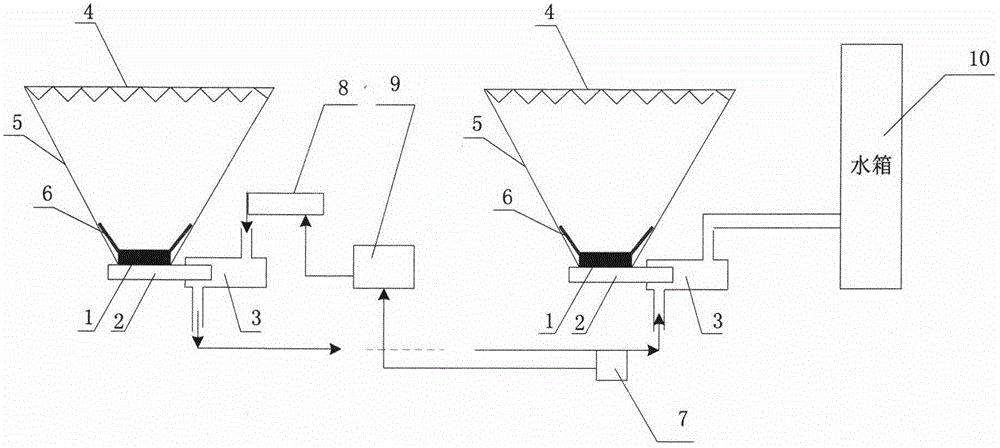

Composite type heat pipe radiator for heating

InactiveCN101373121AReduce useless energy consumptionWill not fail or even be scrappedIndirect heat exchangersVacuum pumpingHeat conducting

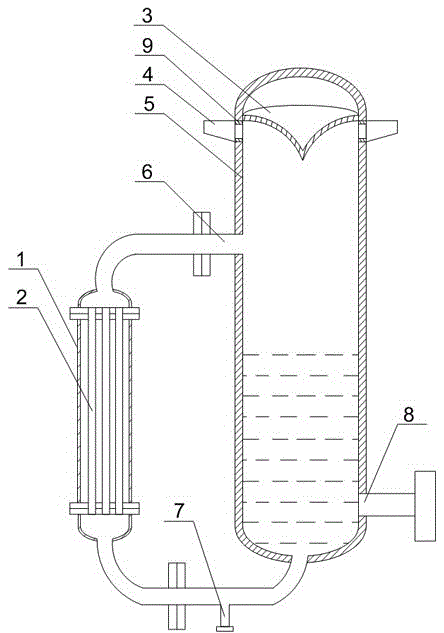

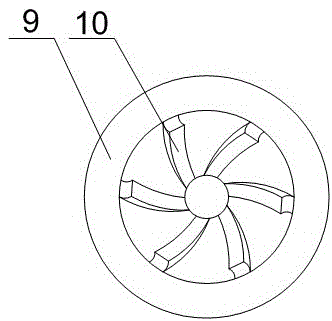

A composite type heat pipe radiator for heating relates to the heating ventilating field and comprises an upper header pipe (1), a lower header pipe (2), a radiating fin (3), a fin heating medium pipe (4), a vacuum pumping head (5), a vacuum regulating valve (6), a heat-conducting medium (7) and a heating medium (8). A cavity body formed by the upper header pipe (1), the lower header pipe (2), the radiating fin (3) and the heating medium pipe (4) with the vacuum pumping head (5) and the vacuum regulating valve (6) after a vacuum device extracts the air in the upper header pipe (1), the lower header pipe (2), the radiating fin (3) and the heating medium pipe (4) from the vacuum pumping head (5); and after the air in the cavity body is extracted, a vacuum hollow cavity is formed. The heat-conducting medium absorbs heat from a heat source and transfers the heat to the heating medium (8) through the fin heating medium pipe (4); the heating medium is heated and gasified and transfers the heat to the air so as to serve the heating function. The invention has the advantages of high efficiency, safety, water and energy conservation, beauty, duration, light weight, and high borne pressure. The invention can manufactured into composite type vacuum ultra heat conducting pipe energy-saving efficient radiators of various types and specifications, such as the plate type, the pipe type, the cylindrical type, various wing types, and the like.

Owner:肖建选

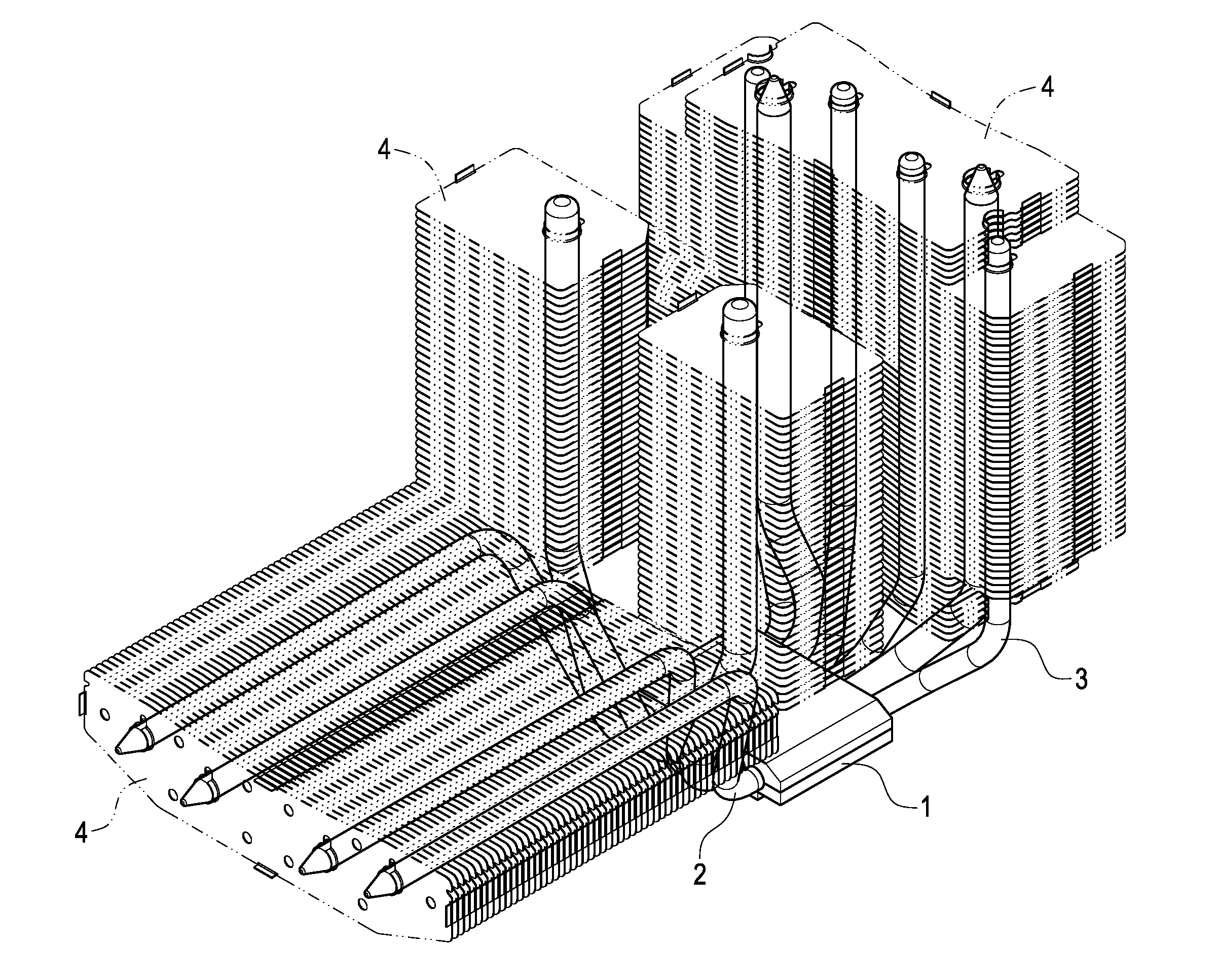

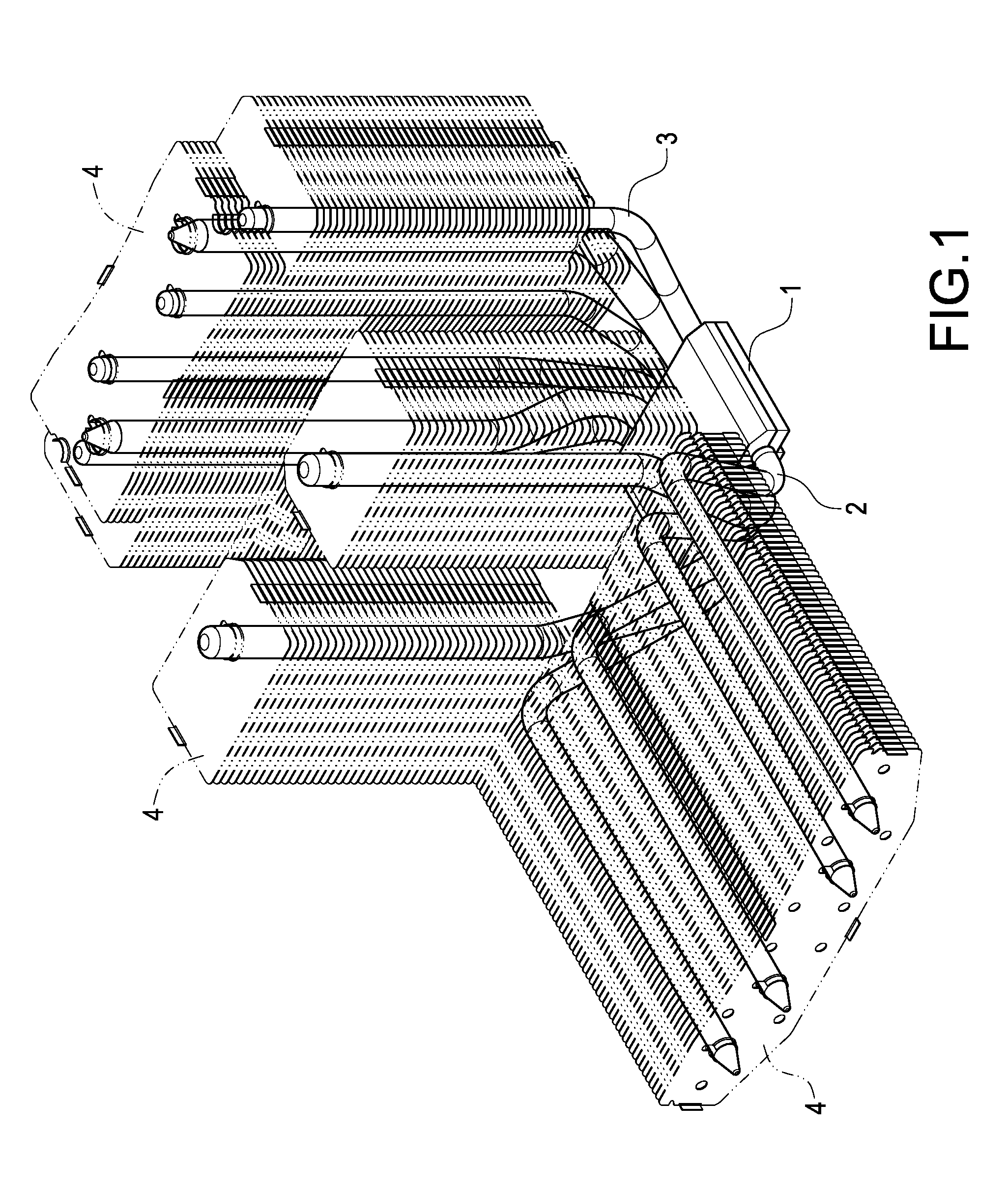

Heat dissipating apparatus extended laterally from heat pipe

ActiveUS20090173474A1Dissipation effectSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat pipe

Owner:CHEMTRON RES

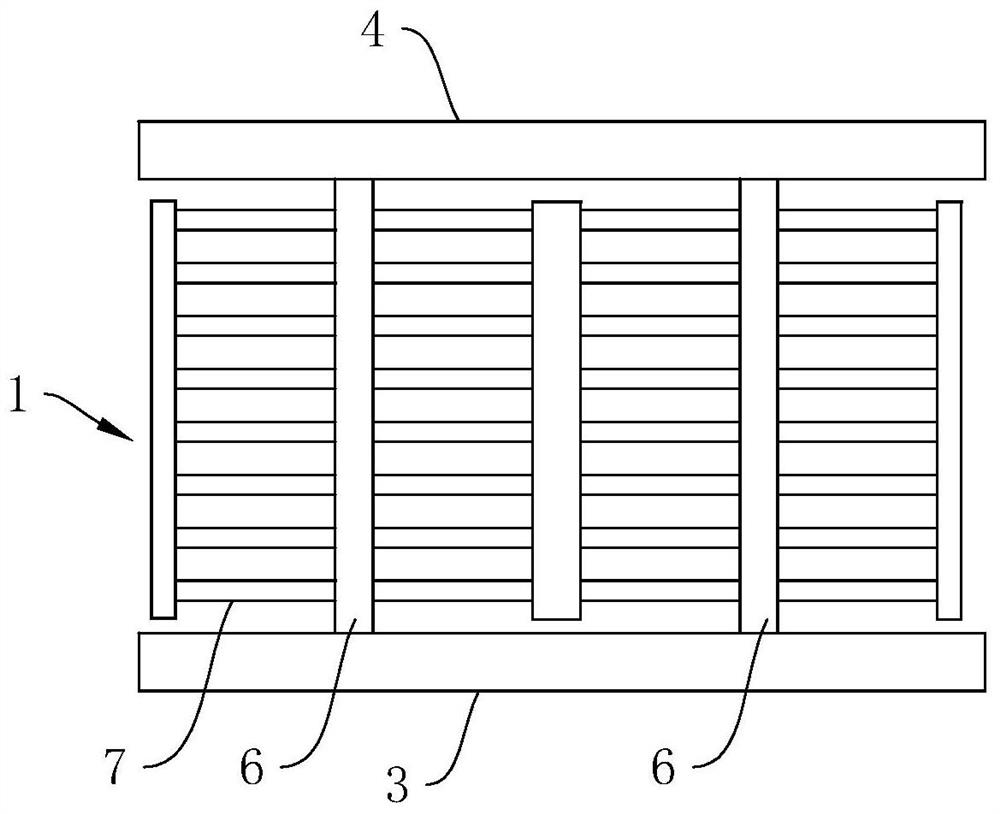

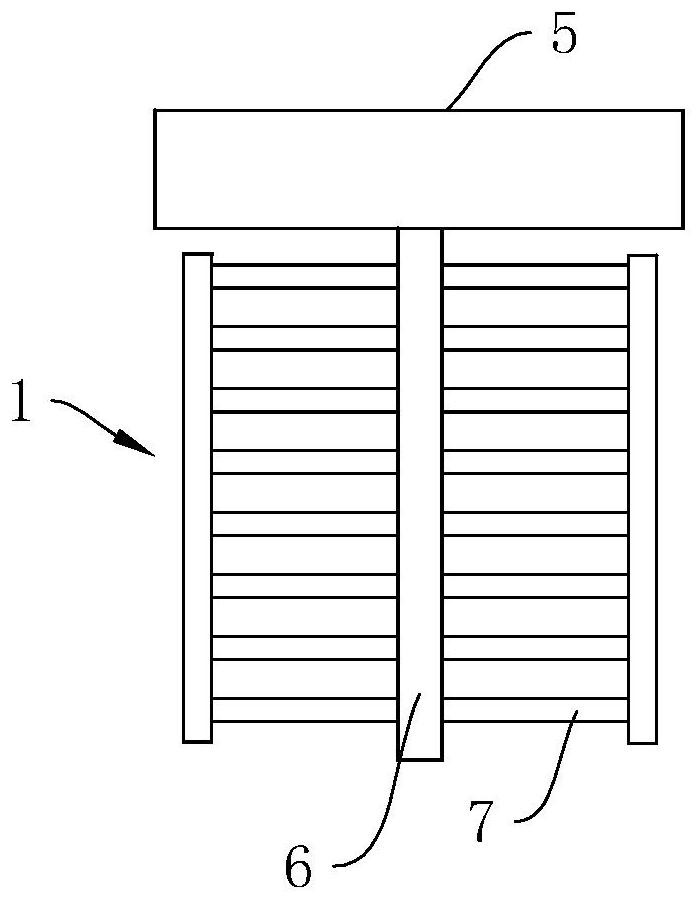

Microchannel-group integrated heat-pipe radiator

InactiveCN1851911ASimple preparation processSpeed up the flowDigital data processing detailsSemiconductor/solid-state device detailsWorking fluidMetal sheet

This invention relates to a micro-slot group integrated heat-pipe radiator including a closes shell made of metal thin plates, in which, the inside cavity of the shell is vacuum filled with working fluid, a core piled up closely by multiple metal thin plates are set in the closed shell, the outer surface of the core is welded to the internal surface of the shell, gaps generating capillary force to adsorb the working fluid is set between the metal thin plates, the surface of the plate is opened with through holes, multiple piled up through holes form through holes on said core to drive the boiled fluid to flow among the slots adjacent to said metal thin plates.

Owner:杨洪武

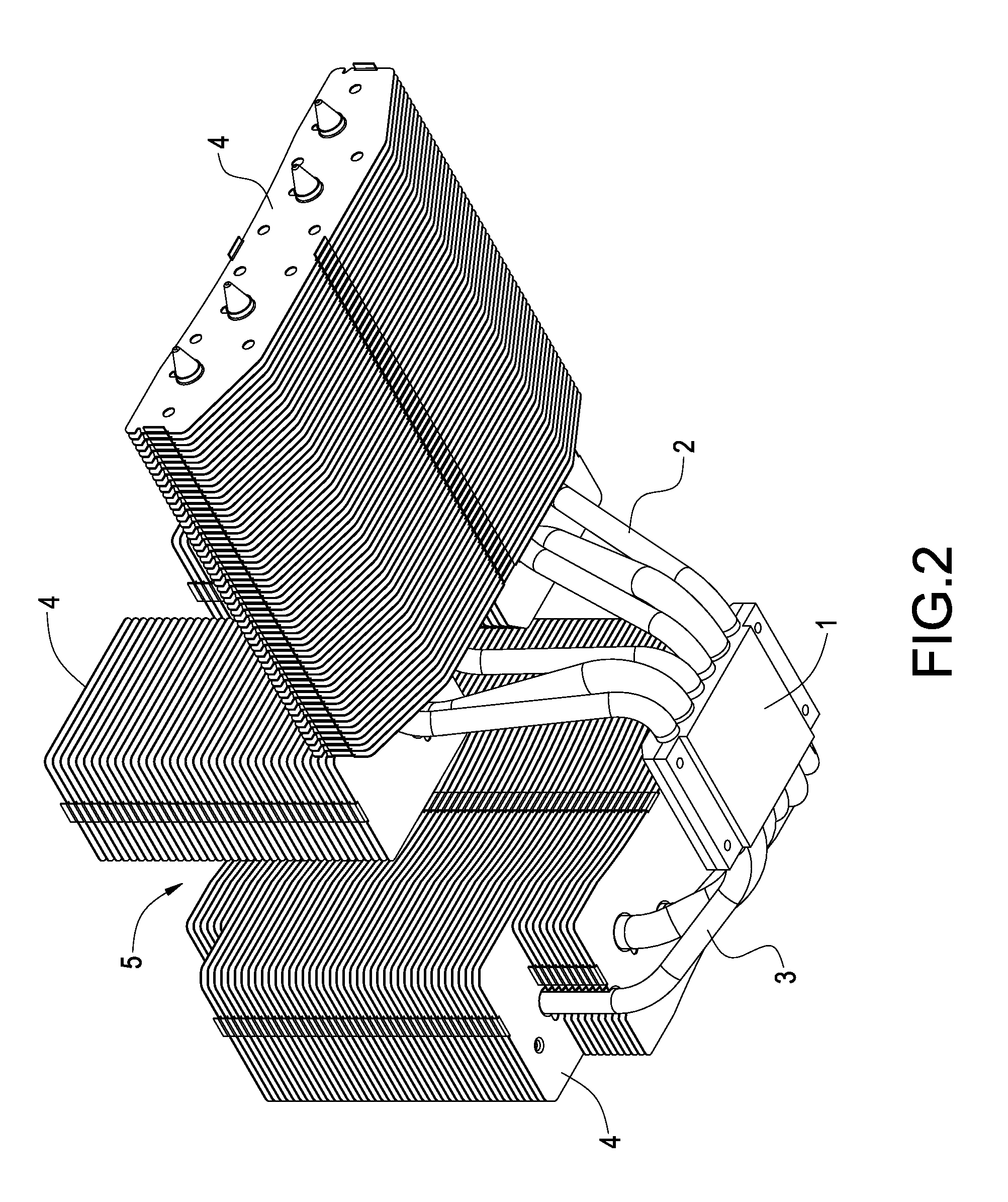

Heat dissipation device

InactiveUS20090277615A1Dissipate heat generatedSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat sink

A heat dissipation device includes a substrate, a fin assembly located on the substrate, a plurality of heat pipes connecting the substrate and the fin assembly, and a fan fixed on the substrate by a clip. The fin assembly includes a first fin unit, a second fin unit, and a third fin unit. The third fin unit is located on the substrate, the second fin unit is located on the third fin unit, and the first fin unit is located on the first fin unit. A receiving space is defined in the second and third fin unit. The fan is received in the receiving space and spaced apart from the fin assembly.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Heat pipe type concentrator-type photovoltaic/thermal integration-based combined heat and power generation apparatus

InactiveCN106160650AReduce the temperatureEfficient use ofPhotovoltaicsPhotovoltaic energy generationCogenerationEvaporation

Owner:NANJING JIAYE NEW ENERGY

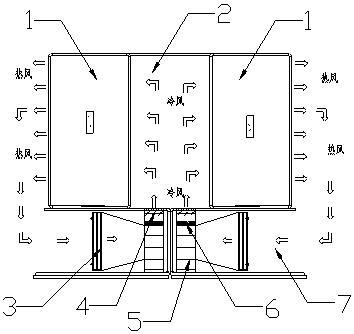

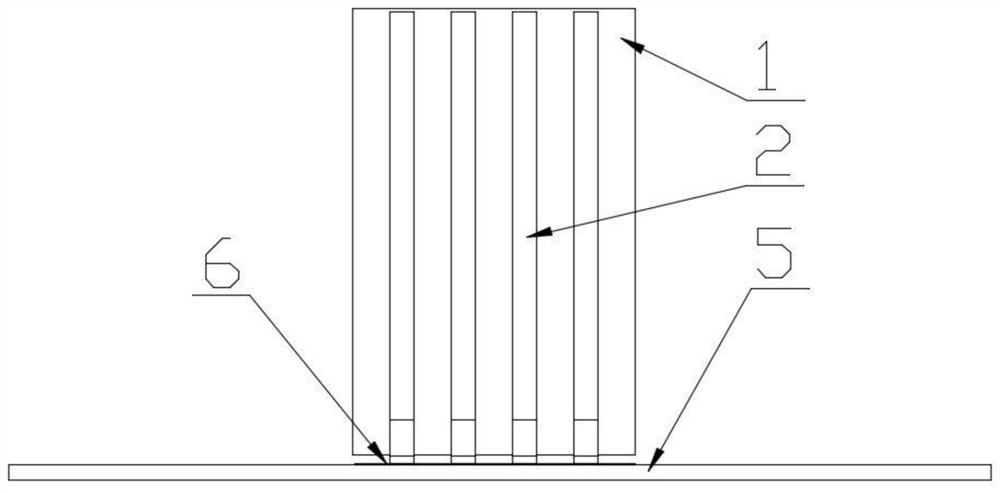

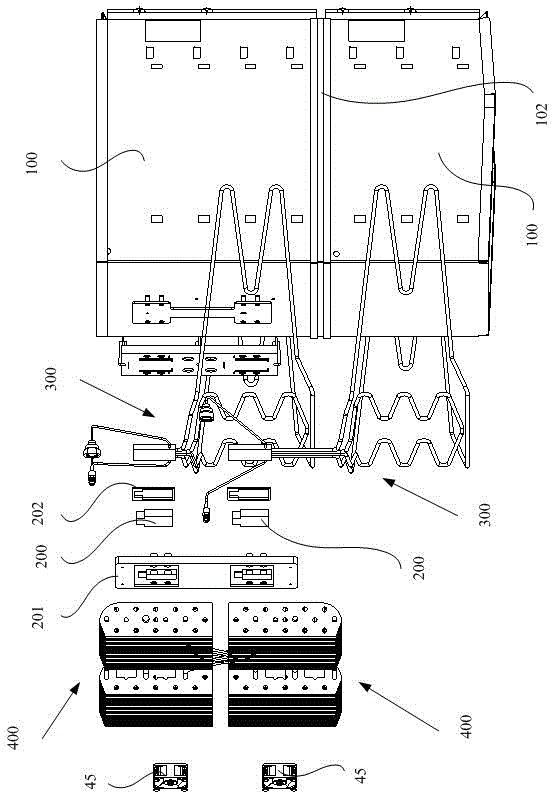

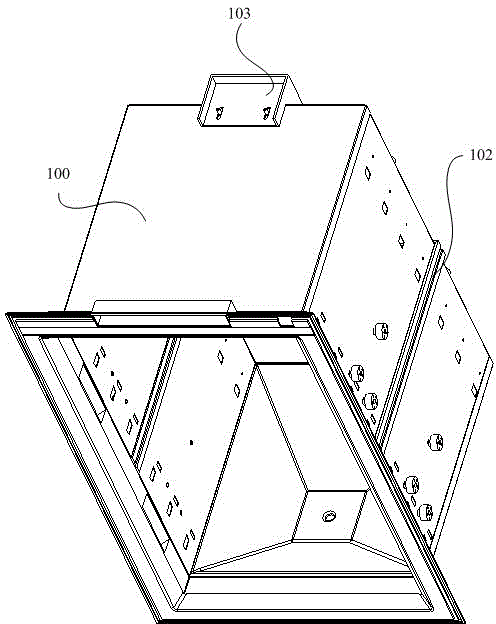

Multi-combined heat pipe cooling system with bottom type microchannel heat exchangers

InactiveCN109587998AReduce inhalationImprove efficiencyModifications for standard racks/cabinetsCold airEngineering

Owner:江苏天源太阳能发电有限公司

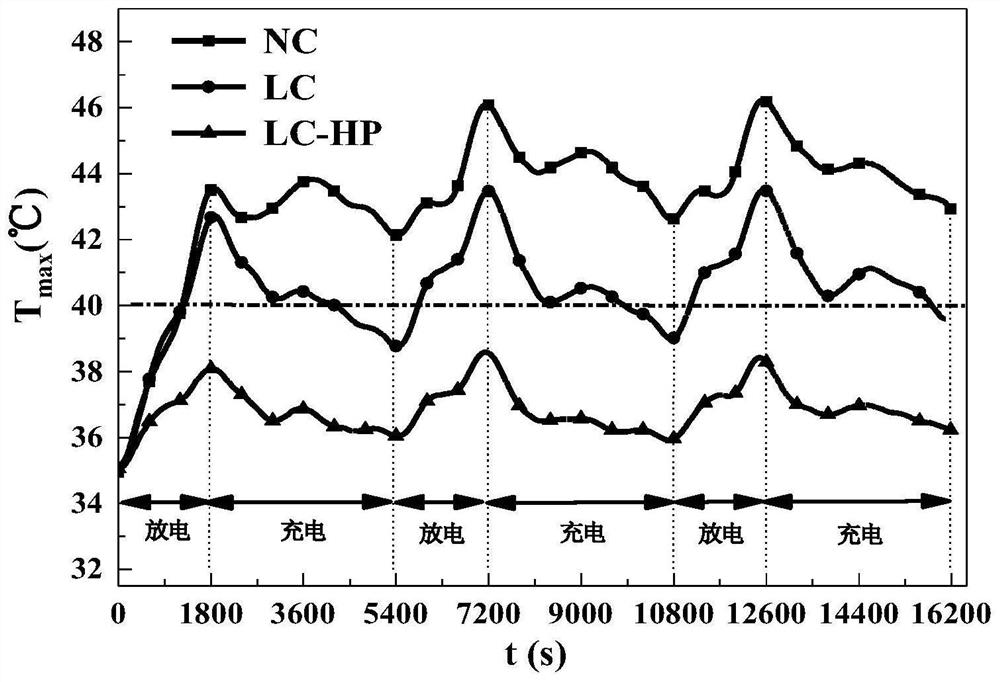

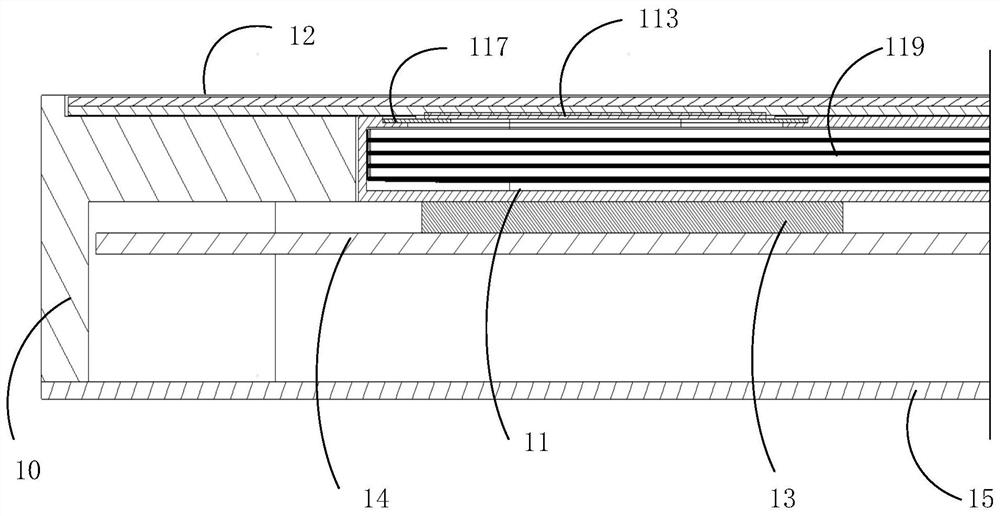

Novel battery cooling structure based on coupling of heat pipe and liquid cooling plate

ActiveCN112582703AReduce wall temperatureImprove charge and discharge performanceSecondary cellsVehicular energy storageThermodynamicsEngineering

Owner:JIANGSU UNIV

Cooling device and semiconductor refrigeration equipment

ActiveCN105716317AReduce energy consumptionMake full use of cooling capacityIndirect heat exchangersMachines using electric/magnetic effectsComputer moduleEngineering

Owner:QINGDAO HAIER SPECIAL ICEBOX

Heat pipe type photovoltaic generating thermal collection assembly

ActiveCN104913520AImprove cooling effectImprove power generation efficiencySolar heating energySolar heat devicesHeat conductingEvaporation

Owner:BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE

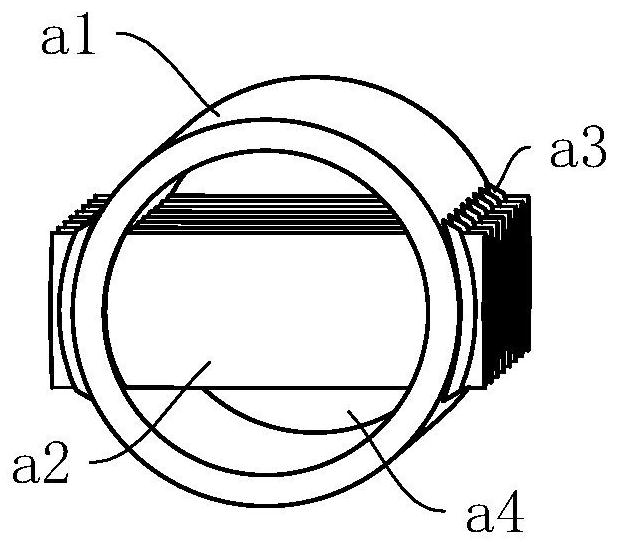

Solar straight-tube photoelectric converter

InactiveCN101902168AInto less packagingLow costLight radiation electric generatorPhotovoltaic energy generationThermal energyTemperature control

The invention aims to provide a solar through-tube photoelectric conversion device. A through-tube transparent material is sampled; solar photoelectric conversion materials are arranged on inner and outer surfaces of a through-tube device; the solar energy is converted into electric energy; and an opening end is sealed for direct use without packaging, so that the cost of the conventional photoelectric conversion material is reduced. Meanwhile, fluid or a heat pipe is arranged inside a cavity of a through-tube transparent device so as to control the temperature of the photoelectric conversion material. Therefore, high-efficiency conversion efficiency of the photoelectric conversion material is always kept, and the heat energy is transferred through the fluid or the heat pipe for comprehensive utilization. Therefore, the comprehensive integrated utilization of solar power generation, temperature control, improvement of solar conversion efficiency and solar heat utilization is realized.

Owner:CHENGDU AONENGPU TECH

A heat recovery system and method for communication equipment

ActiveCN104754920BSave energyNo noise pollutionIndirect heat exchangersSteam engine plantsComputer moduleEngineering

The invention discloses a thermal energy recovery system and a thermal energy recovery method of a communication device, and relates to the technical field of communication device. The thermal energy recovery system comprises a combined type heat pipe, and multiple groups of thermal energy recovery devices, wherein the combined type heat pipe is a closed circulation pipe network filled with heat exchange medium; the combined type heat pipe comprises a gathering pipeline and a plurality of branch pipelines respectively connected with the gathering pipeline in a parallel manner; each group of thermal energy recovery devices is corresponding to one branch pipeline; each thermal energy recovery device comprises a thermal energy collecting module and a plurality of thermal energy gathering plates respectively connected with the thermal energy collecting module; each thermal energy gathering plate is arranged on a single disc in a corresponding manner, and the thermal energy collecting module is arranged on the outer pipe wall of the branch pipeline in a corresponding manner. The thermal energy recovery system and the thermal energy recovery method of the communication device can save a lot of energy, do not produce noise pollution and do not affect normal life of people.

Owner:FENGHUO COMM SCI & TECH CO LTD

Steam generation tank for power station

InactiveCN106524102AEasy dischargeImprove efflux efficiencySolar heating energySteam generation heating methodsPower stationEngineering

Owner:付建军

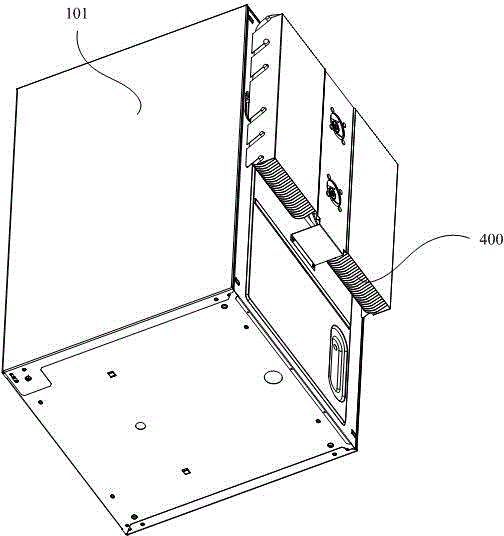

Electronic device

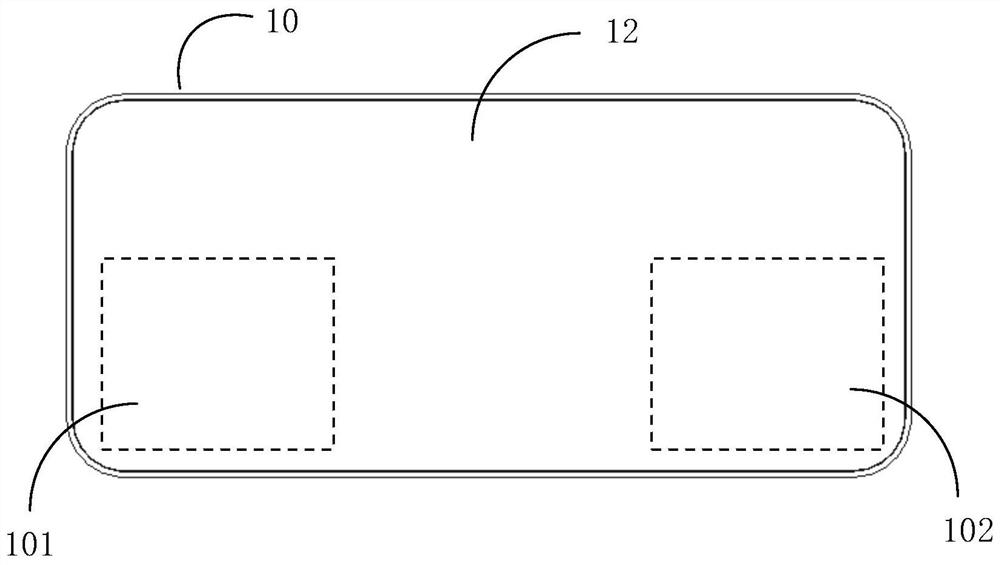

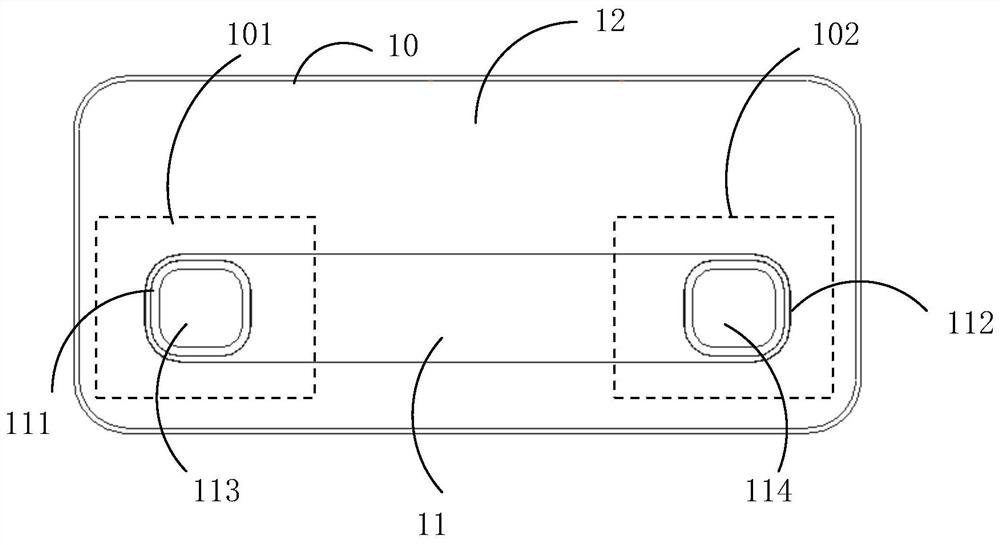

ActiveCN113141760AImprove cooling efficiencyImprove cooling effectModifications using liquid coolingEngineeringFlexible display

Owner:VIVO MOBILE COMM CO LTD

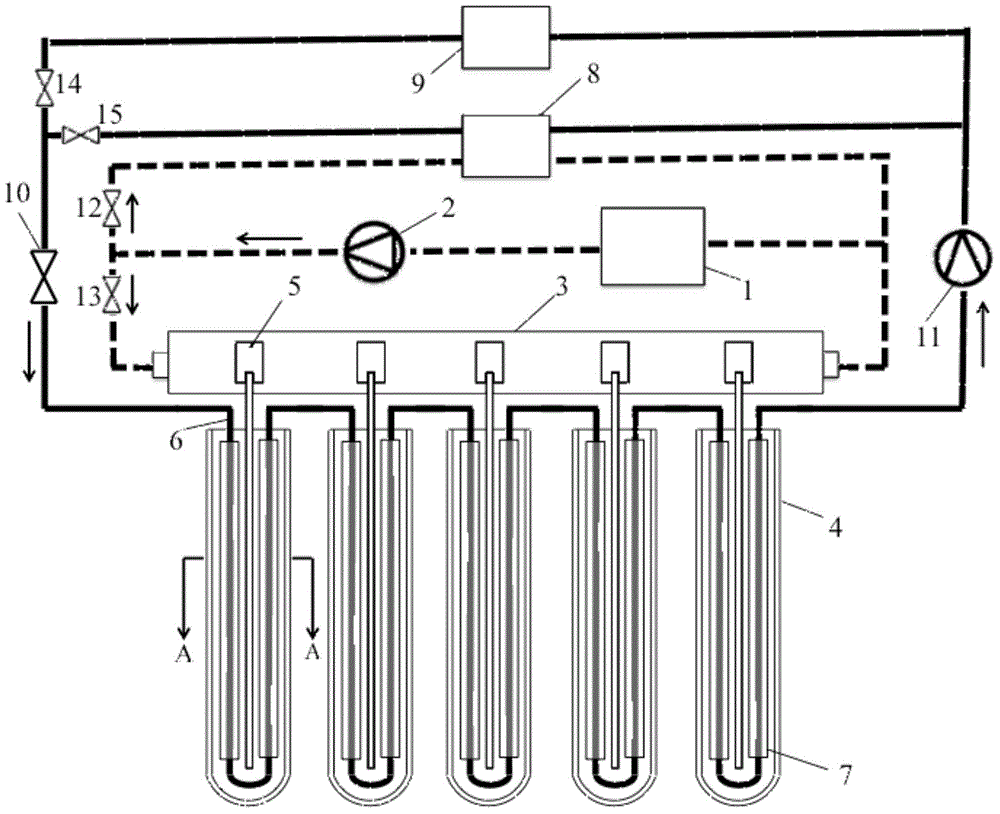

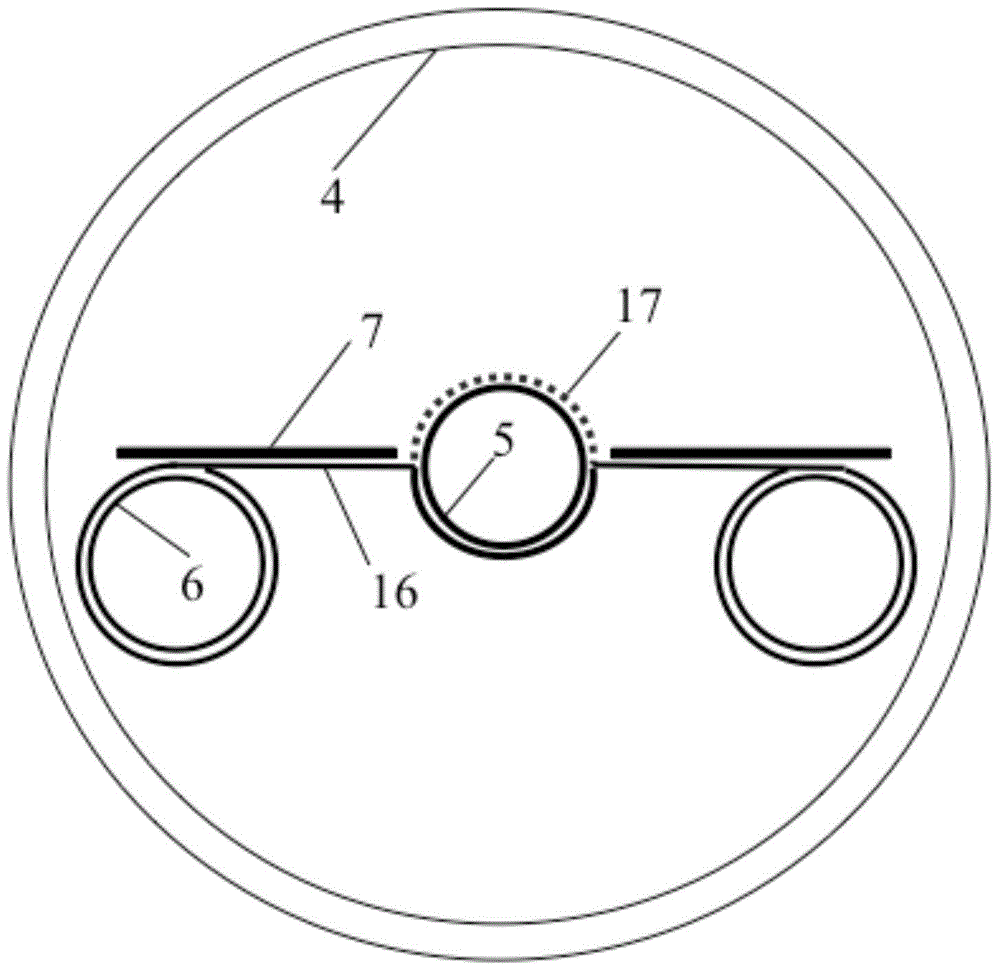

Superconducting heat pipe solar water heating system

PendingCN113251673AEnsuring light-to-heat conversion efficiencyIncrease usageSolar heating energySolar heat collectors with working fluidsThermodynamicsHeat transmission

Owner:山东阳光博士太阳能工程有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap