Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about "Indirect heat exchangers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

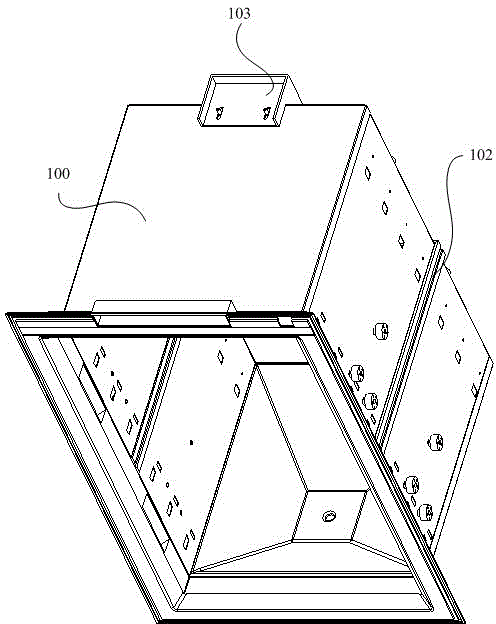

Noise-reducing attachment apparatus for heat exchanger door of an electronics rack of a data center

InactiveUS20090201640A1Facilitates egressReduce noiseShow cabinetsDigital data processing detailsUltrasound attenuationData center

Owner:IBM CORP

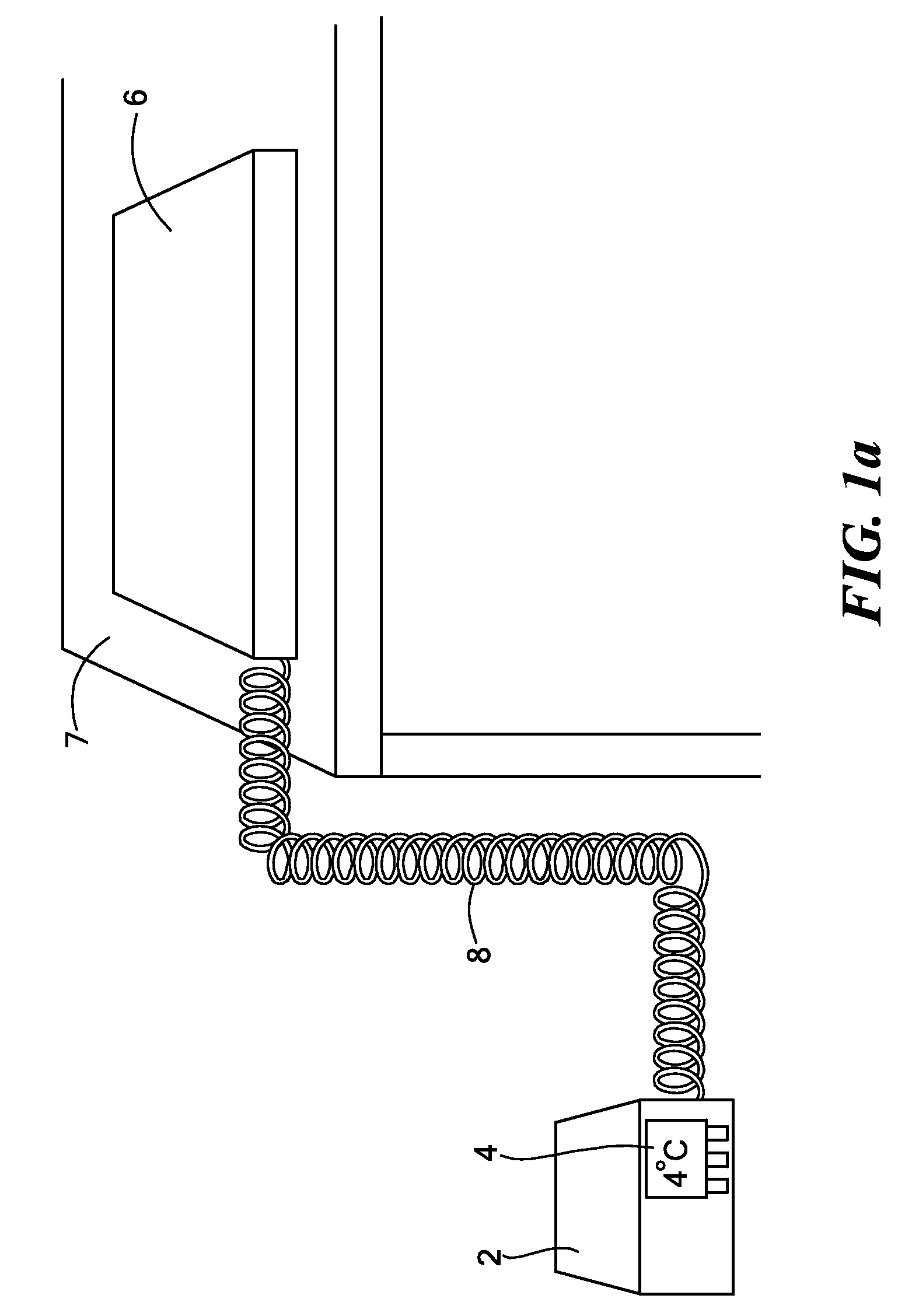

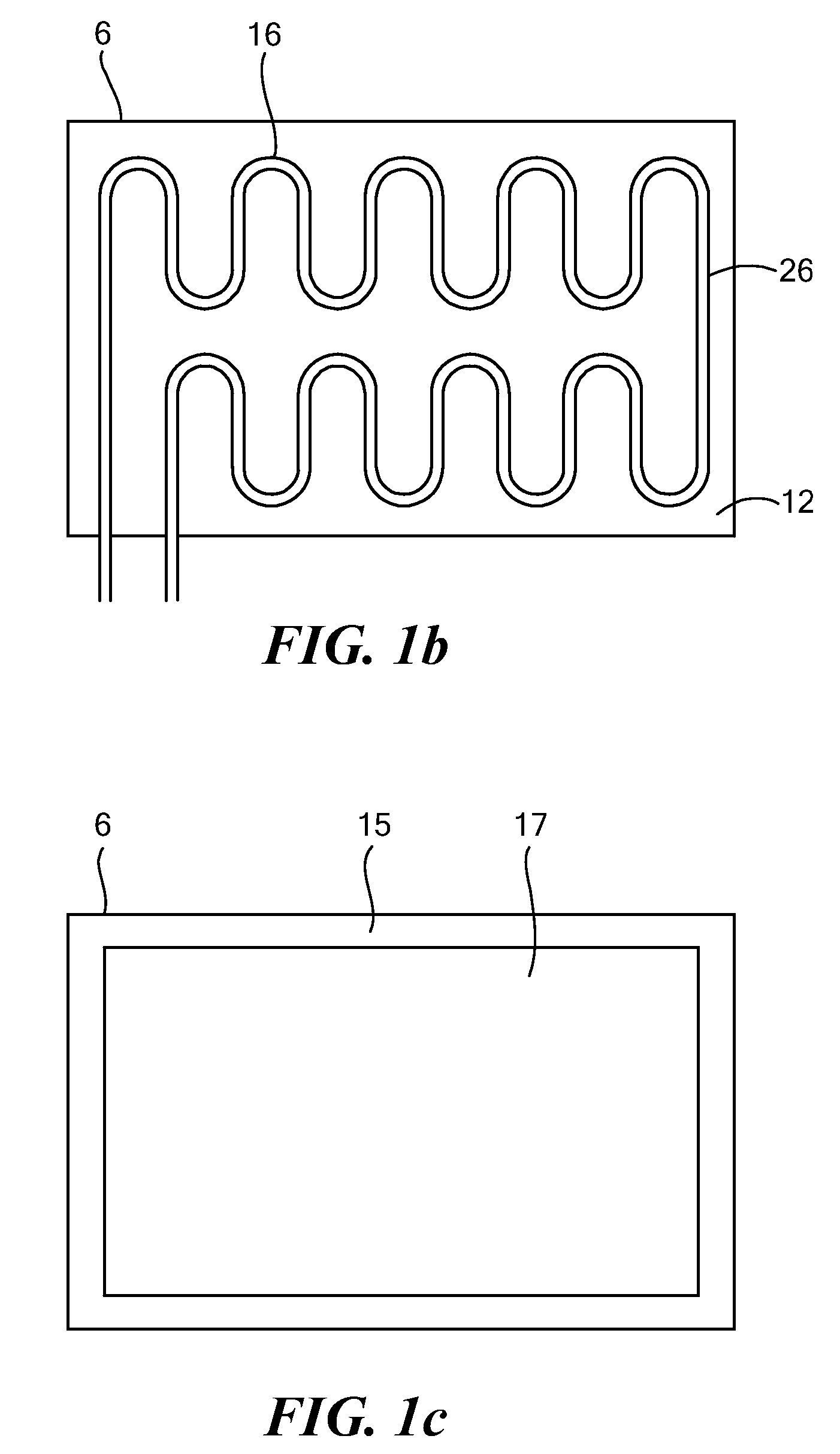

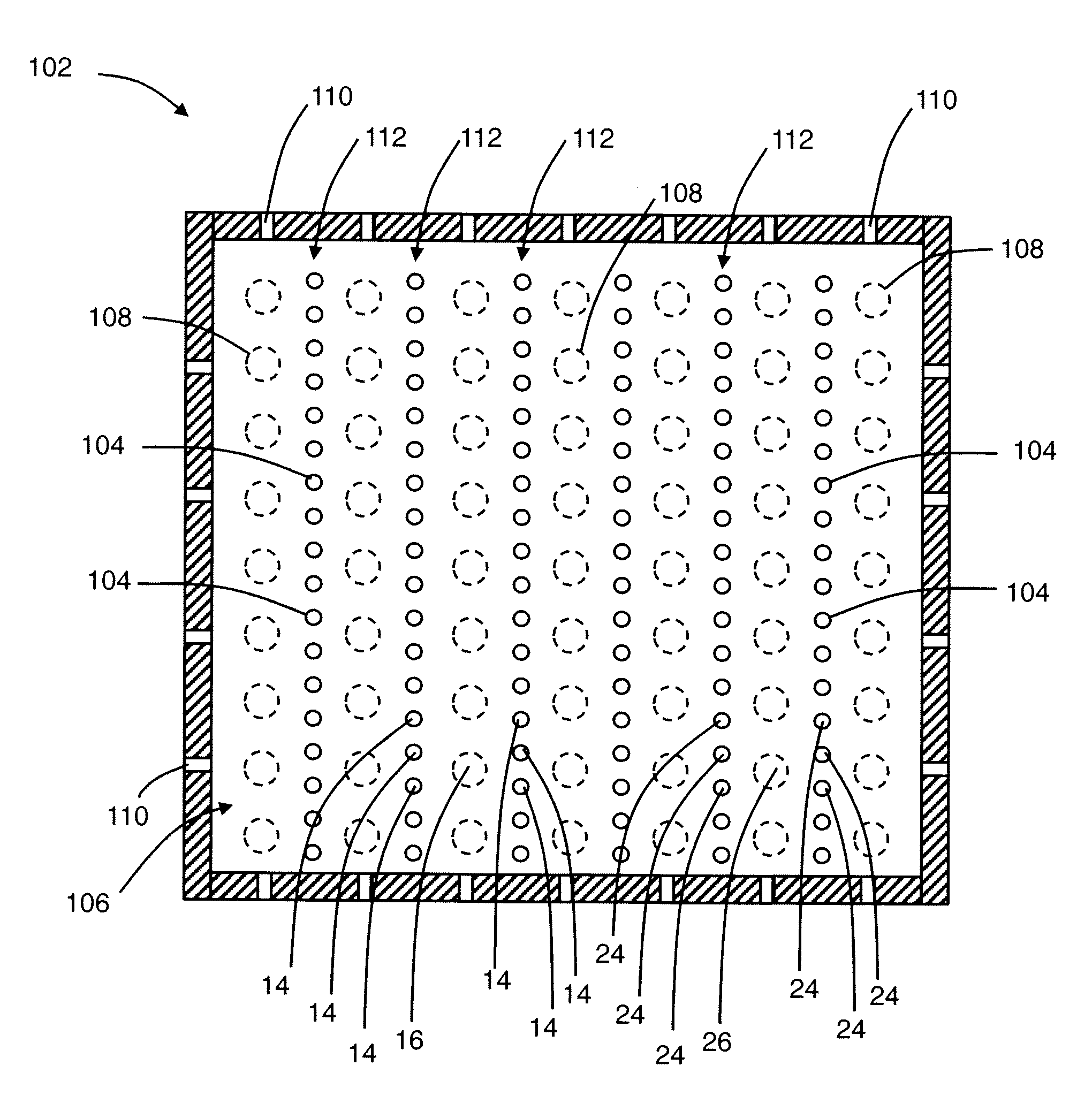

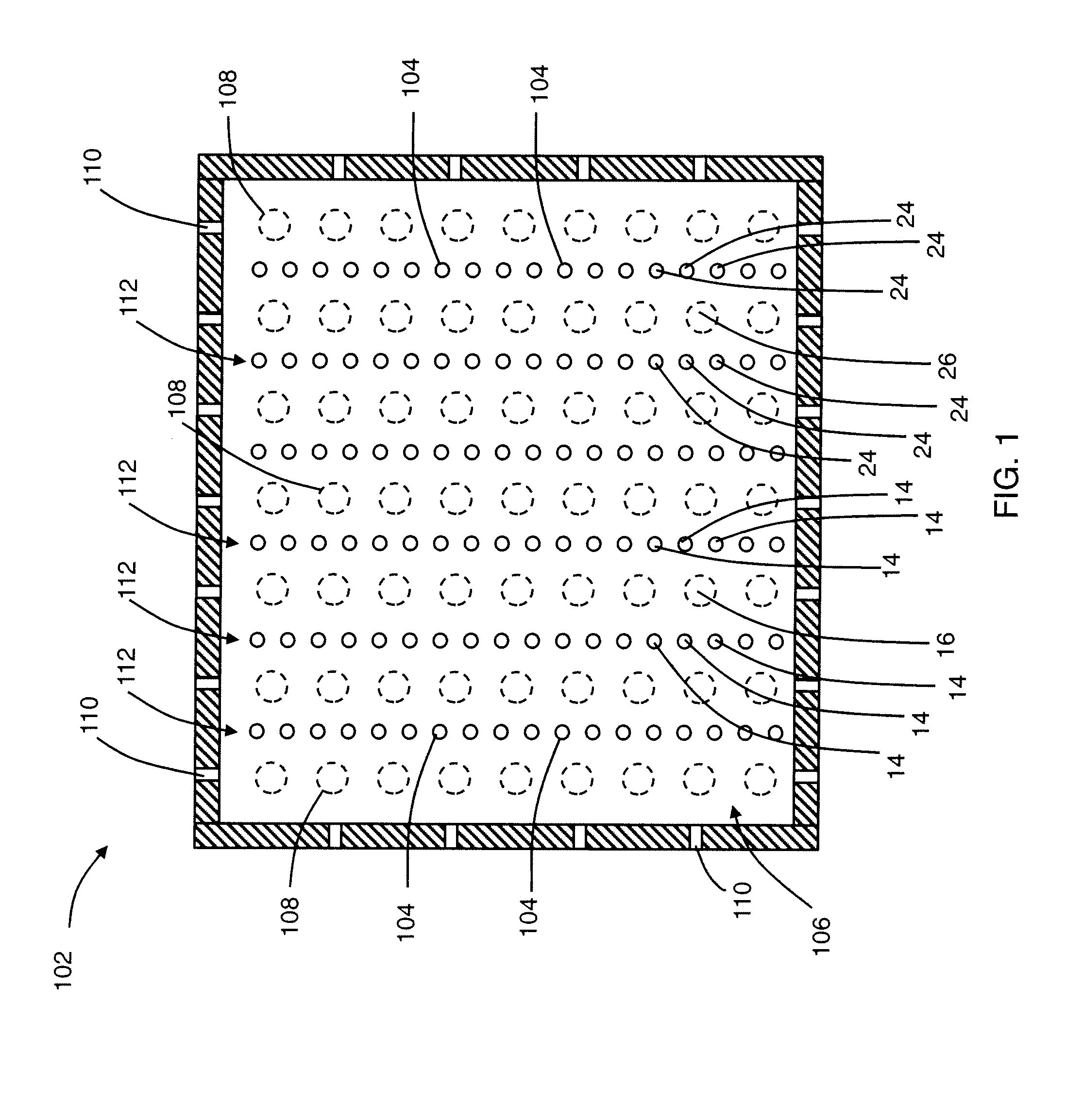

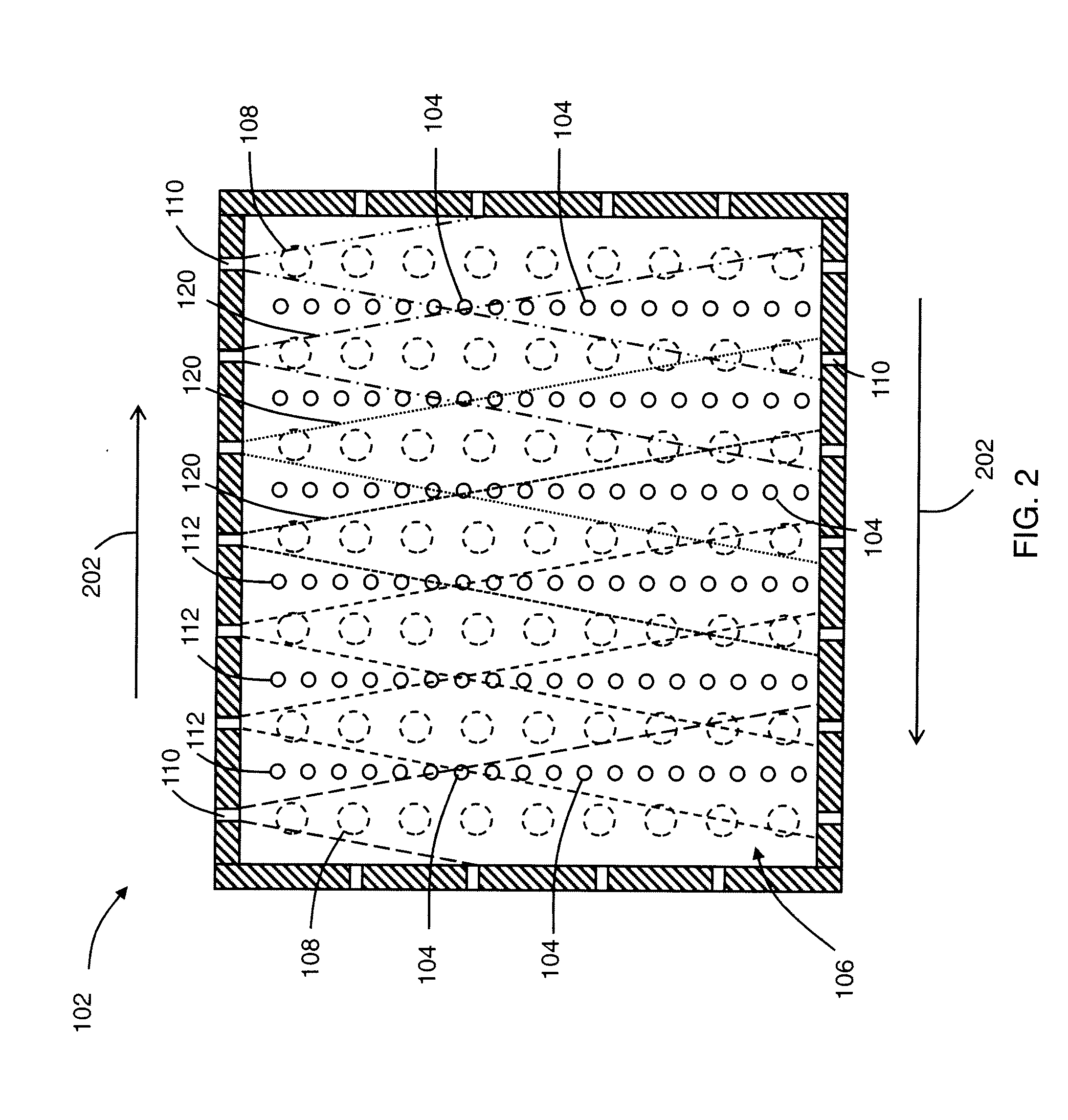

Laboratory Temperature Control With Ultra-Smooth Heat Transfer Surfaces

InactiveUS20080029248A1Decreased emissivitySludge treatmentHeating or cooling apparatusTemperature controlElectrical resistance and conductance

Owner:SAGE SCI

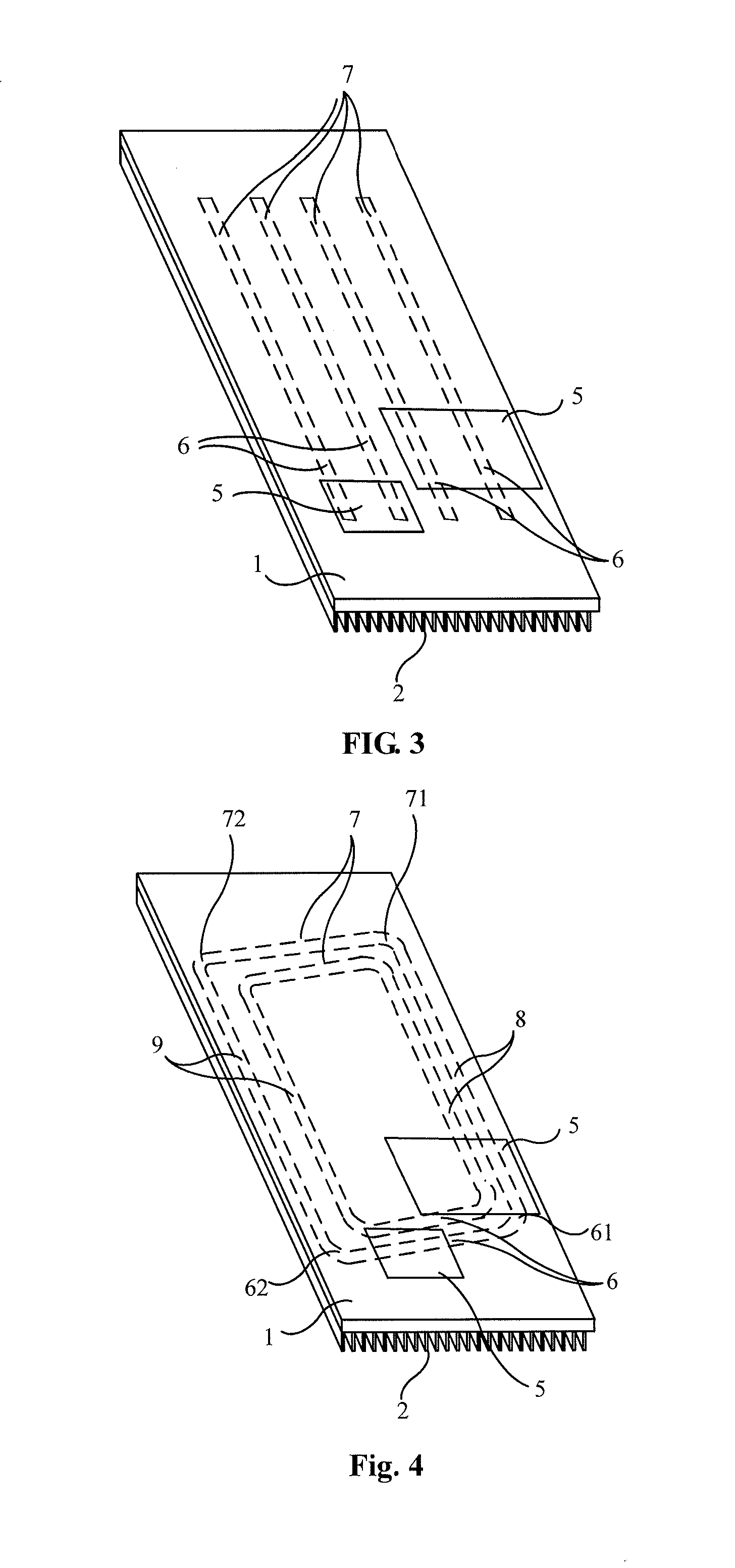

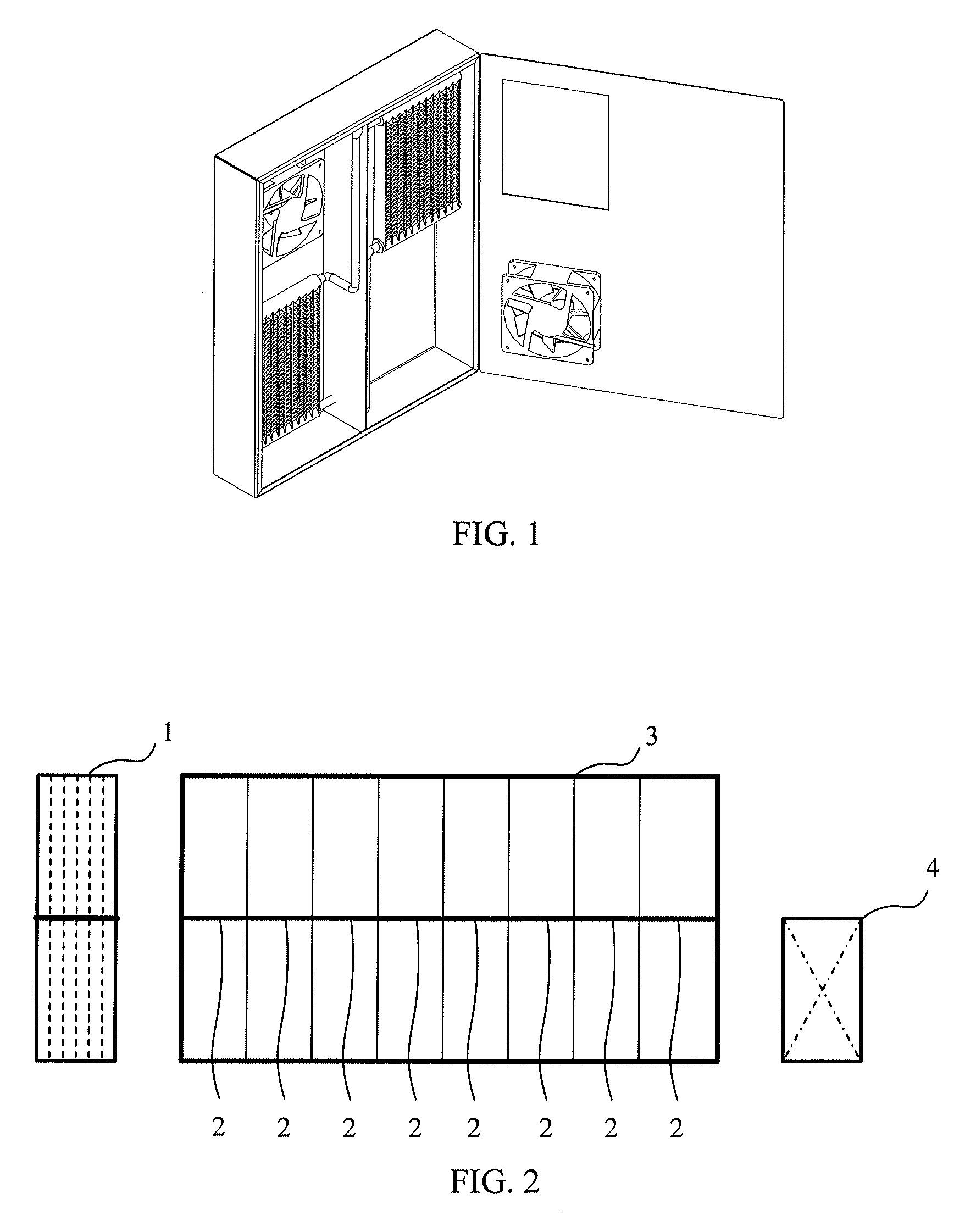

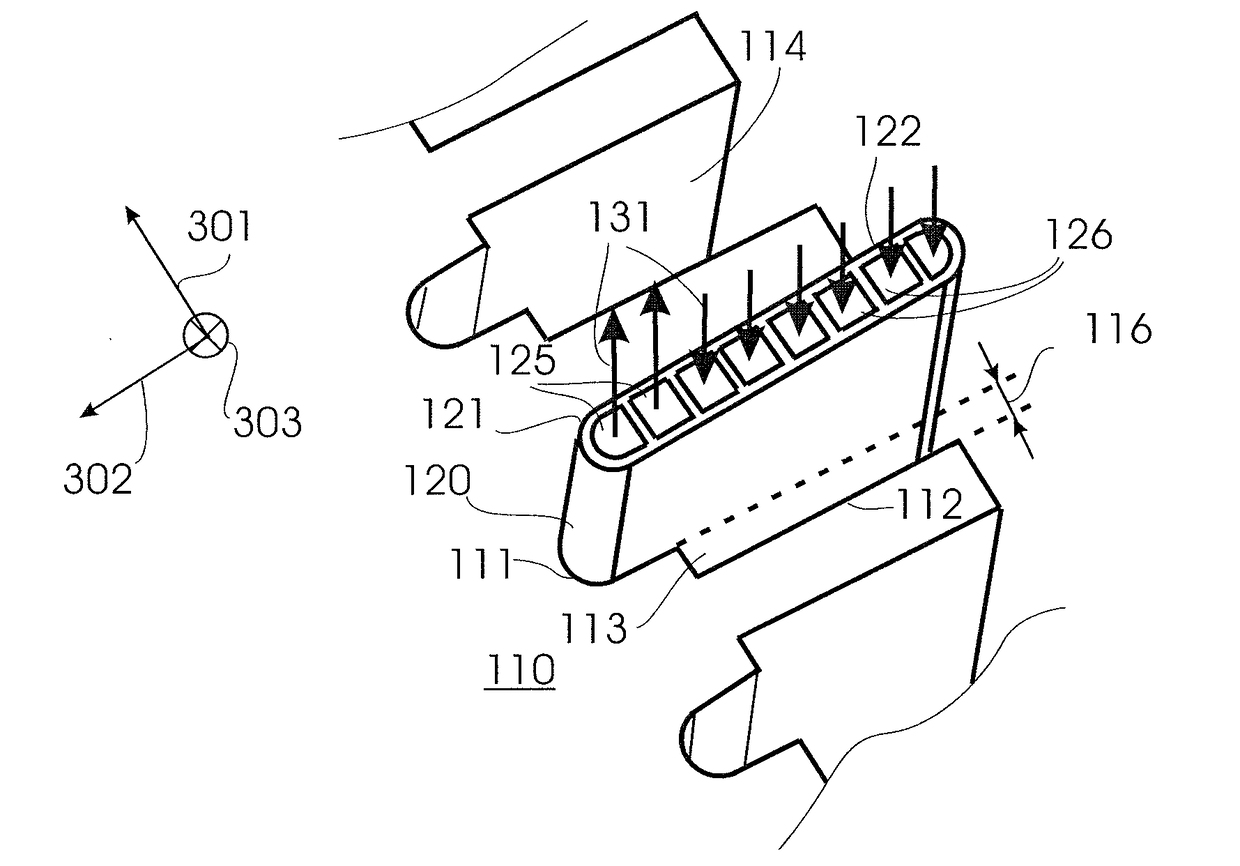

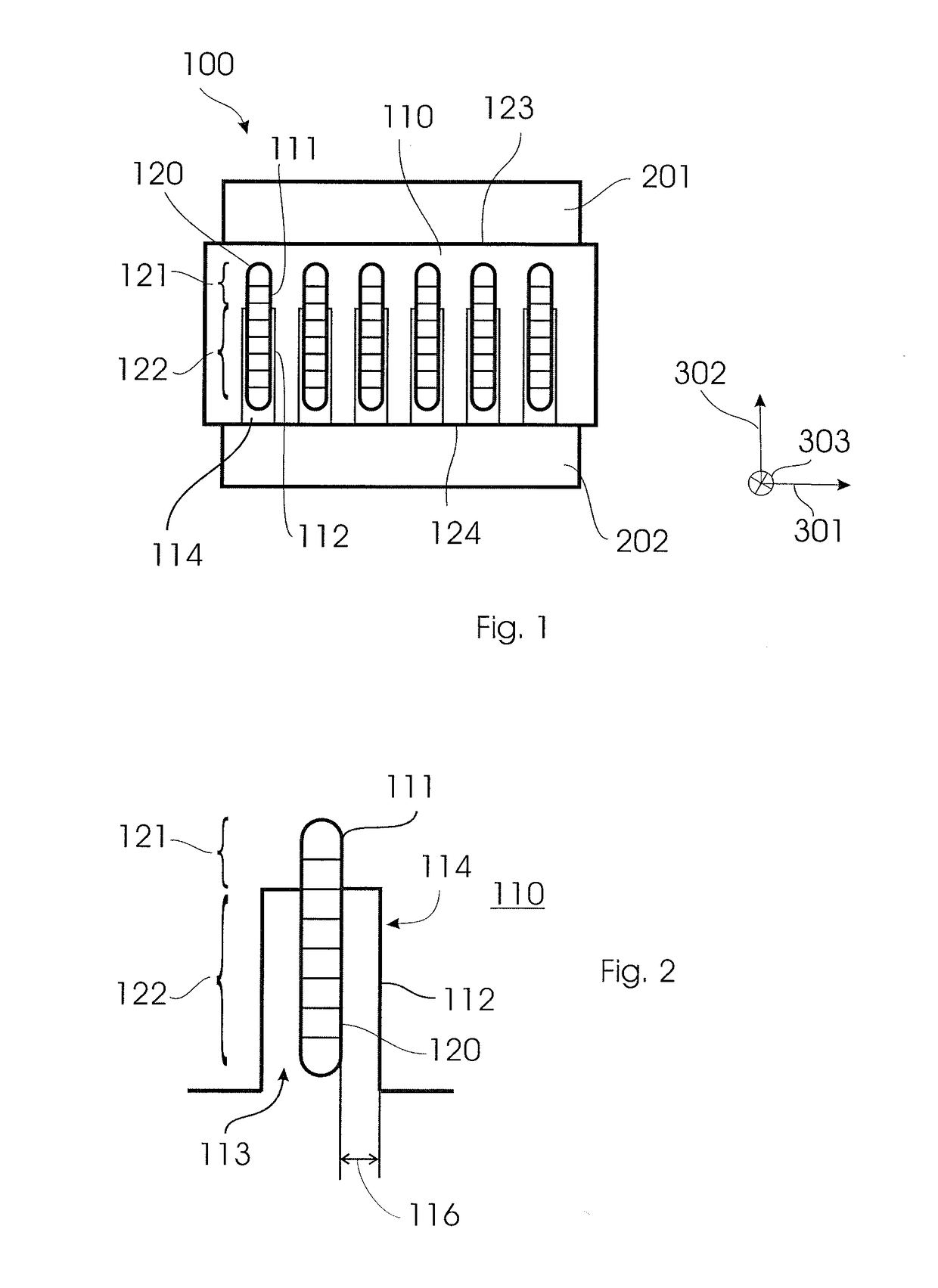

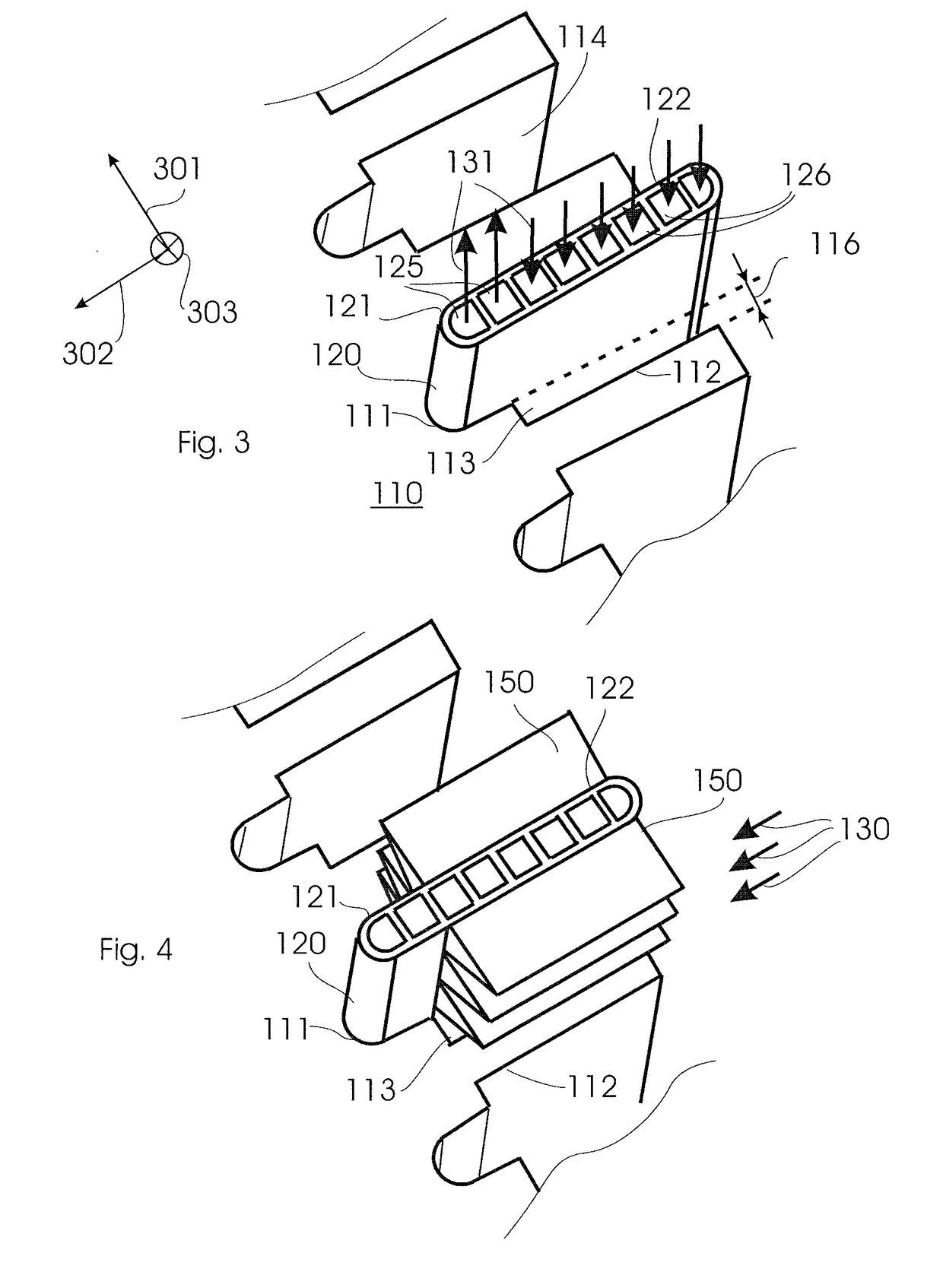

Heat dissipation device and radio frequency module with the same

ActiveUS20120087090A1Indirect heat exchangersCooling/ventilation/heating modificationsRadio frequencyEngineering

Owner:HUAWEI TECH CO LTD

Furnace coil fins

ActiveUS20120251407A1Thermal non-catalytic crackingChemical/physical/physico-chemical reactor detailsNaphthaGreenhouse

The present invention provides low profile, thick (“stubby”) longitudinal fins having a cross section which is a parallelogram, trapezoid or a triangle extending from 10% to 100% of a coil pass and comprising from 3 to 45 weight % of a coil in a radiant section of a furnace for thermally cracking one or more of paraffins and naphtha. The fins provide an additional surface through which heat may be transferred to the coil making the coil more efficient reducing greenhouse emissions.

Owner:NOVA CHEM (INT) SA

Method of Operating a Furnace

Owner:AIR PROD & CHEM INC

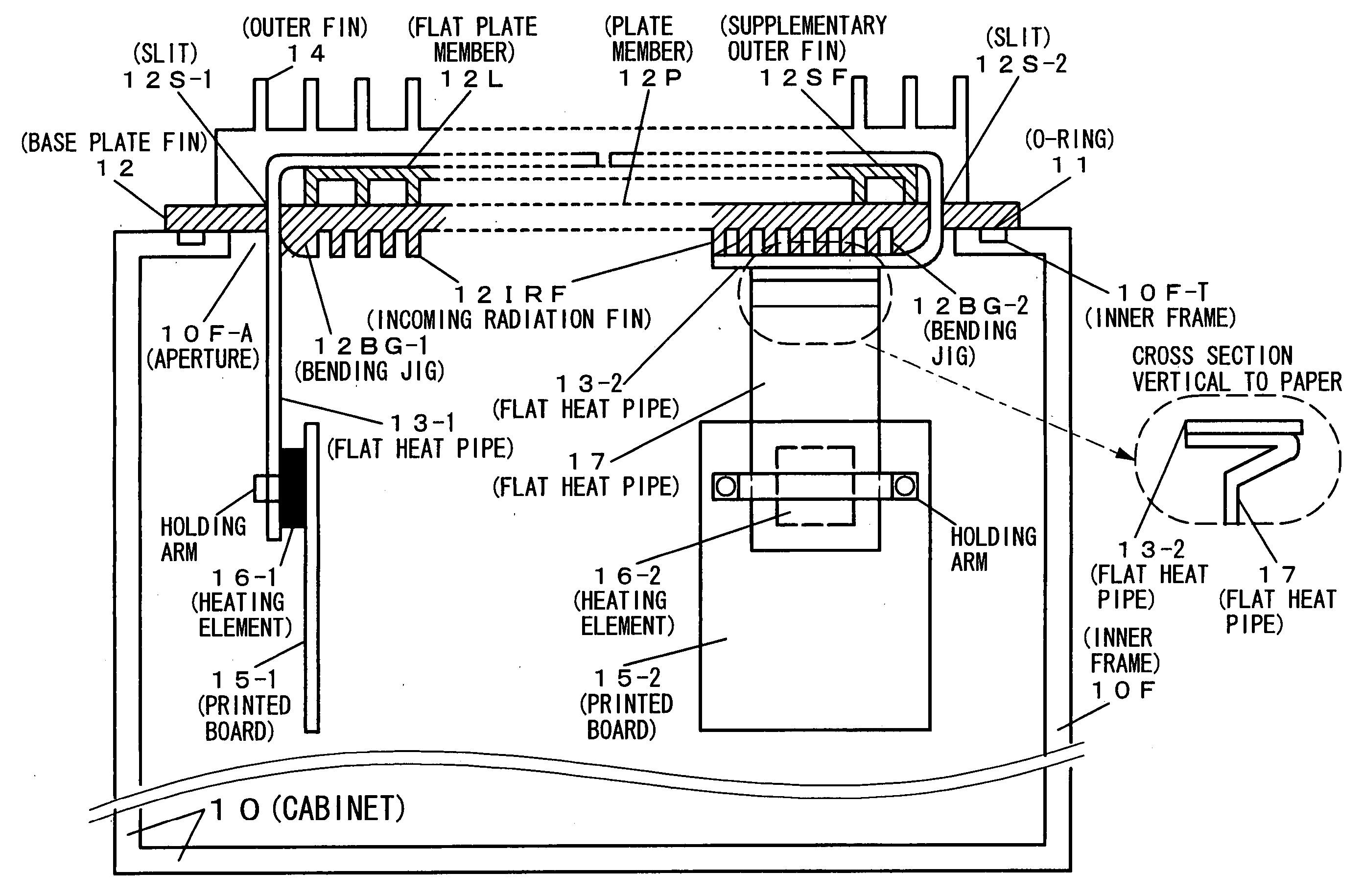

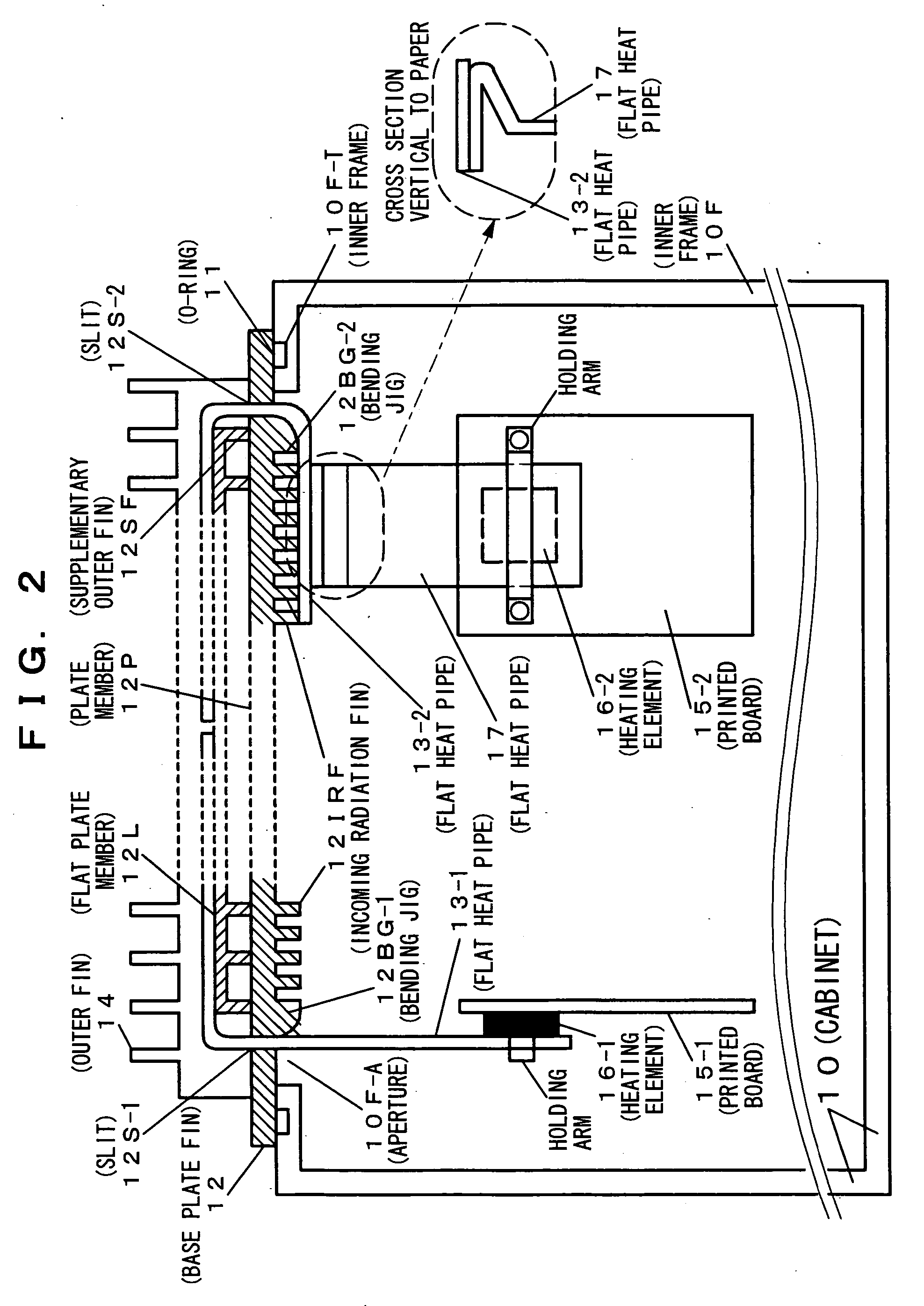

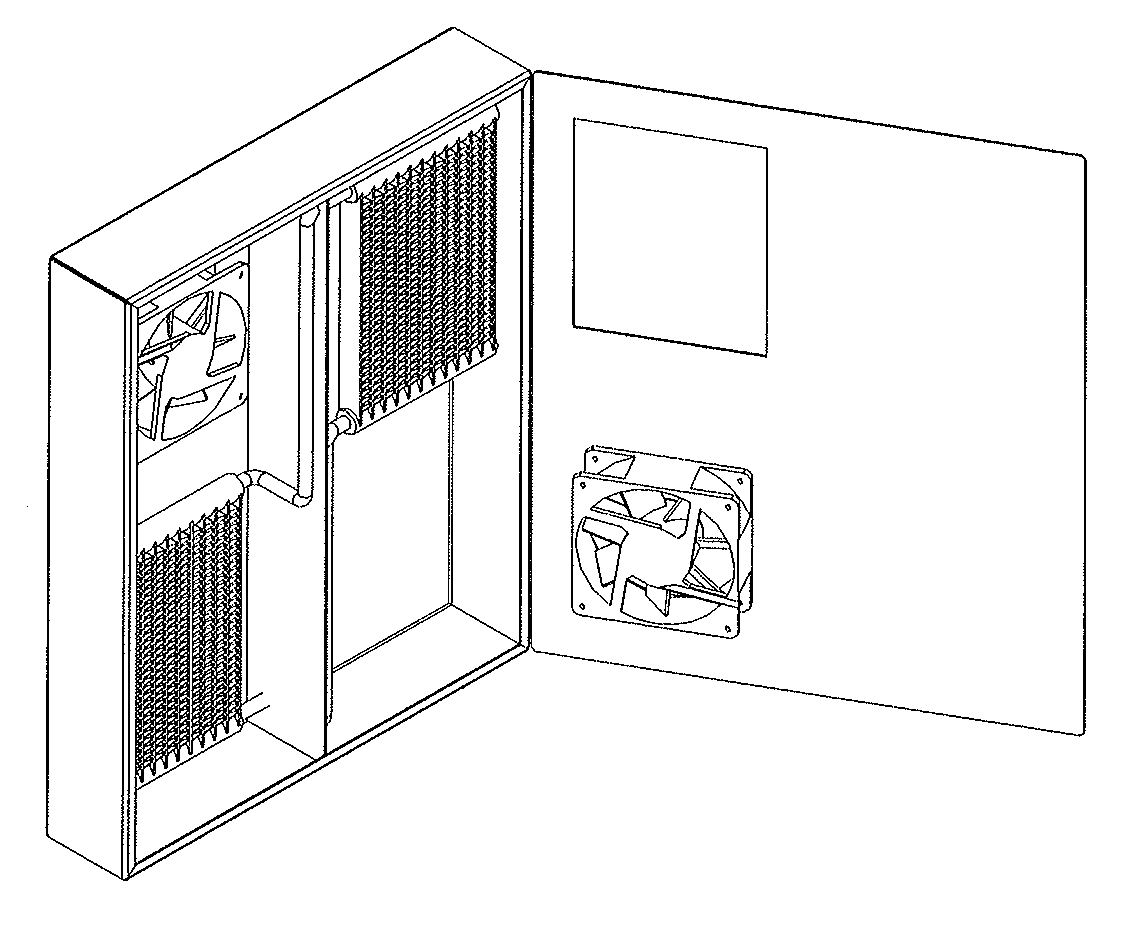

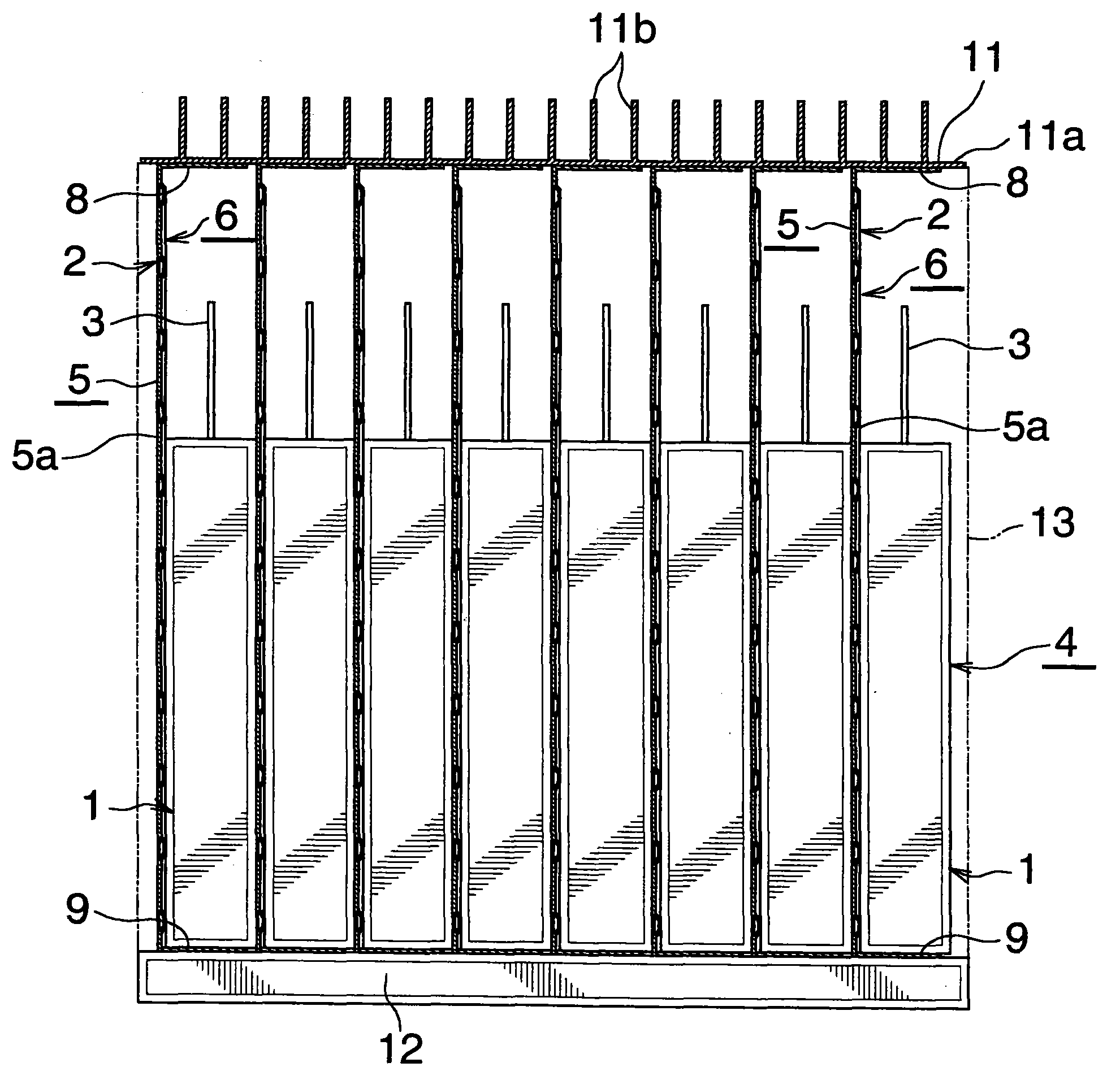

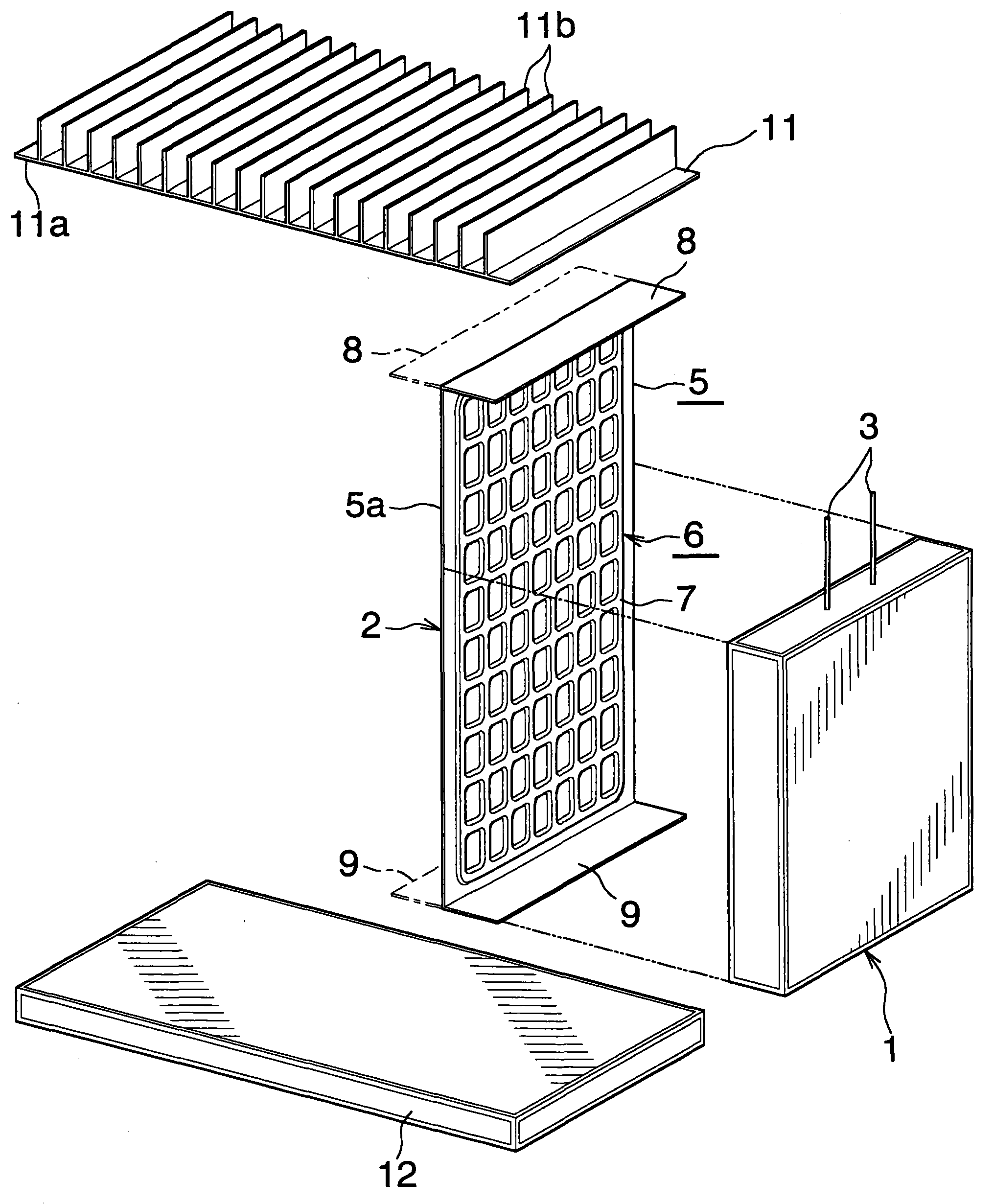

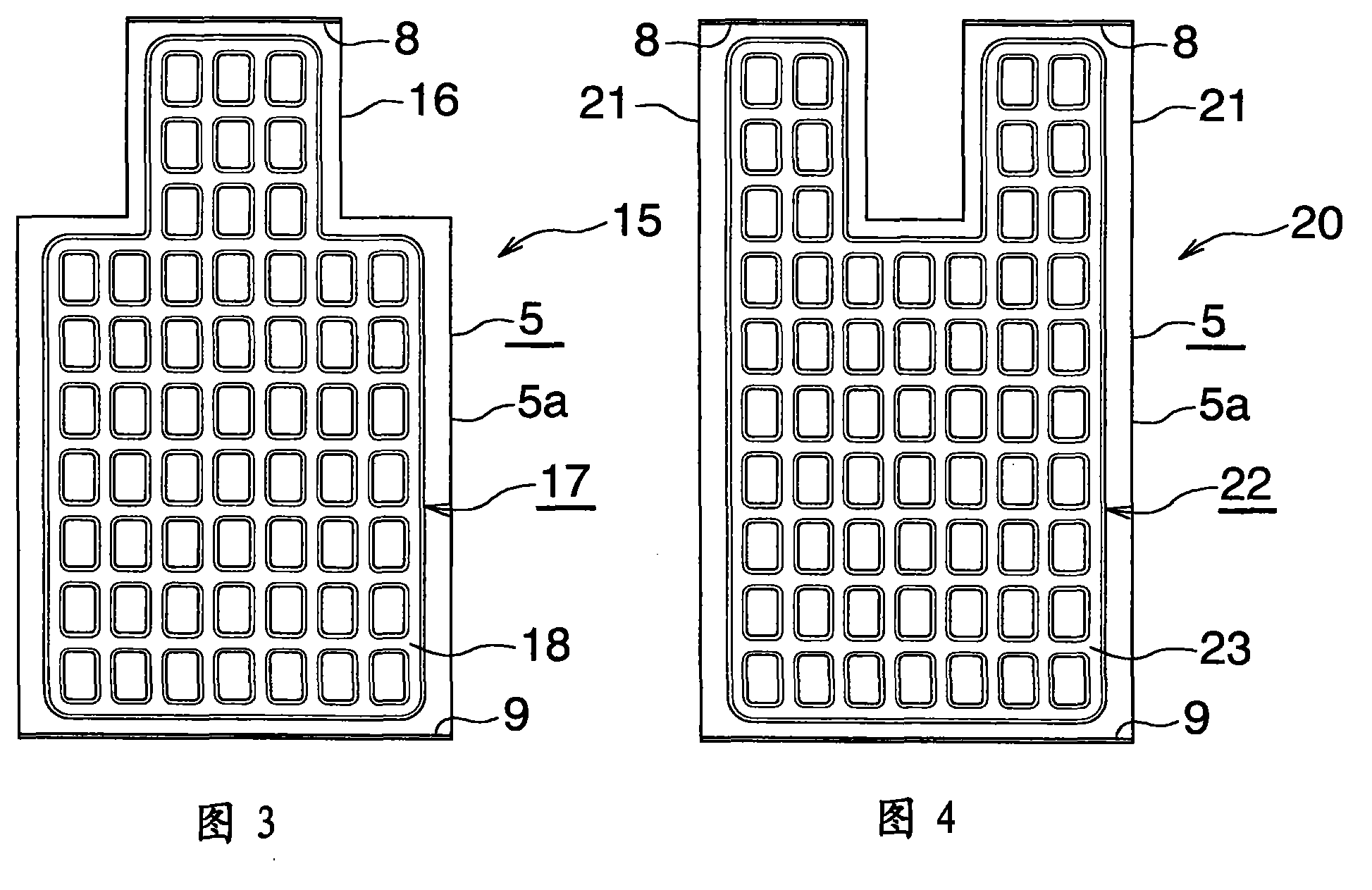

Cabinet having heat radiation function and heat radiation member

ActiveUS20050168951A1Improve serviceabilityAvoid it happening againIndirect heat exchangersCooling/ventilation/heating modificationsElectrical conductorEngineering

Owner:FUJITSU LTD

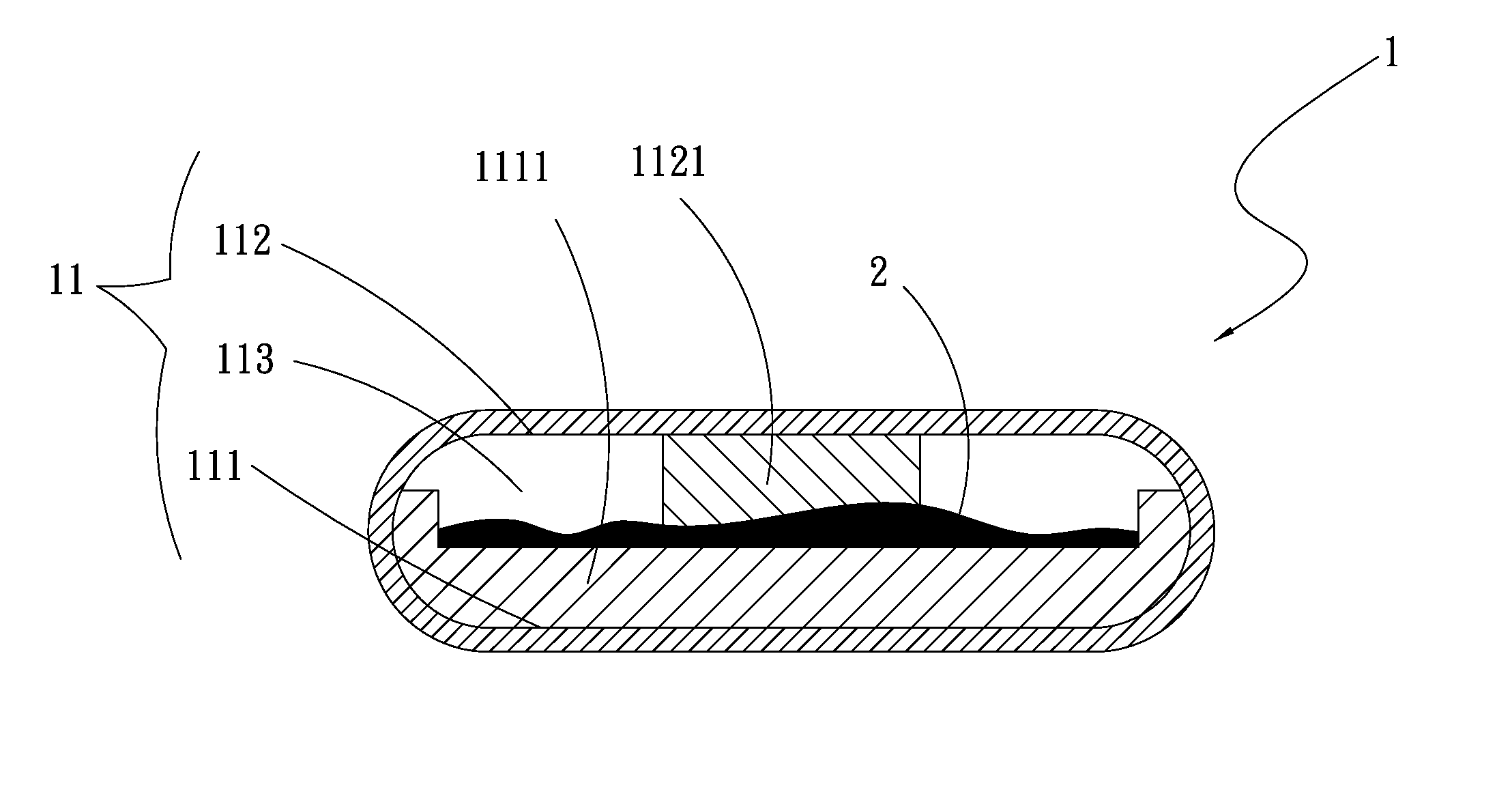

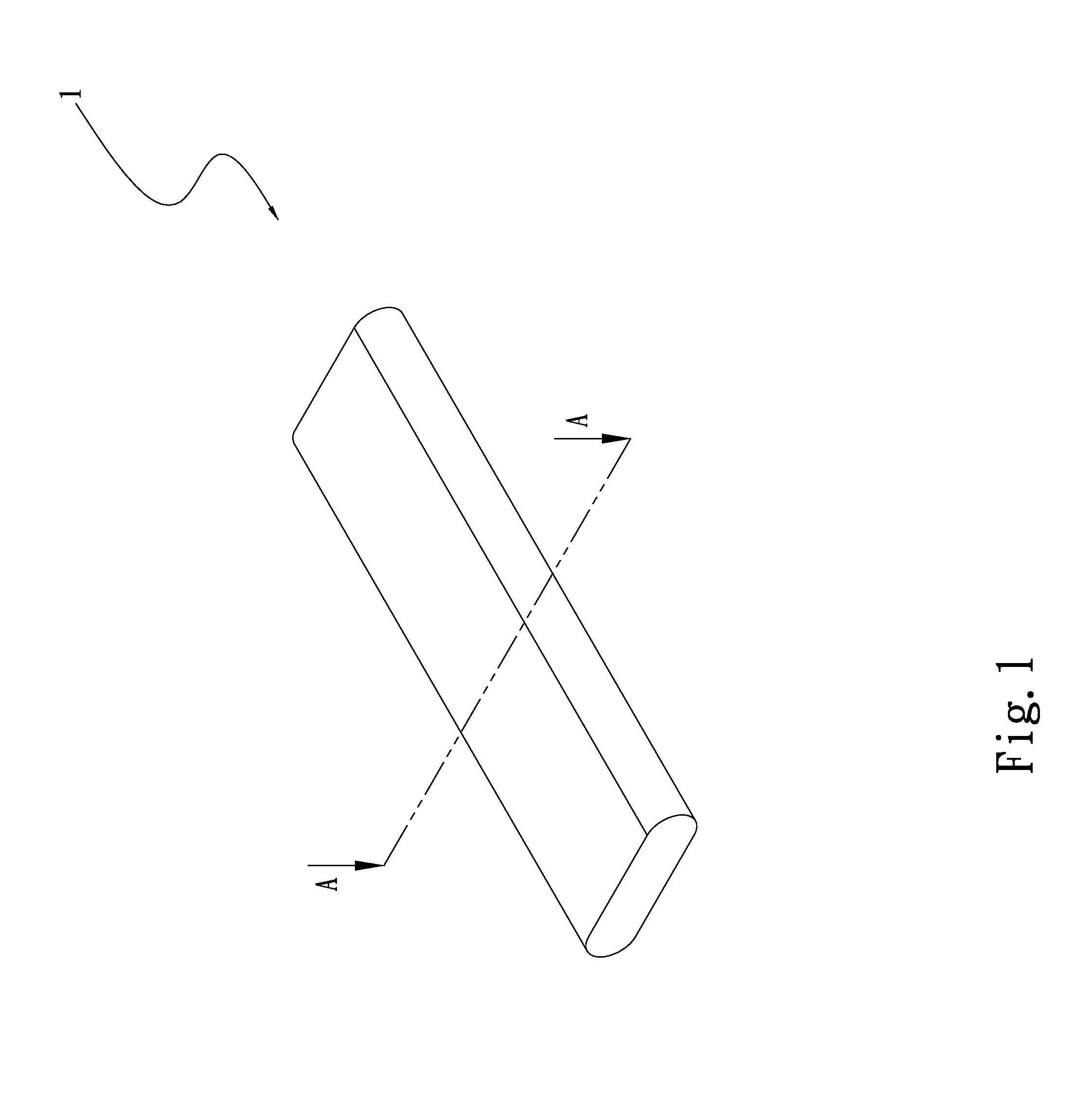

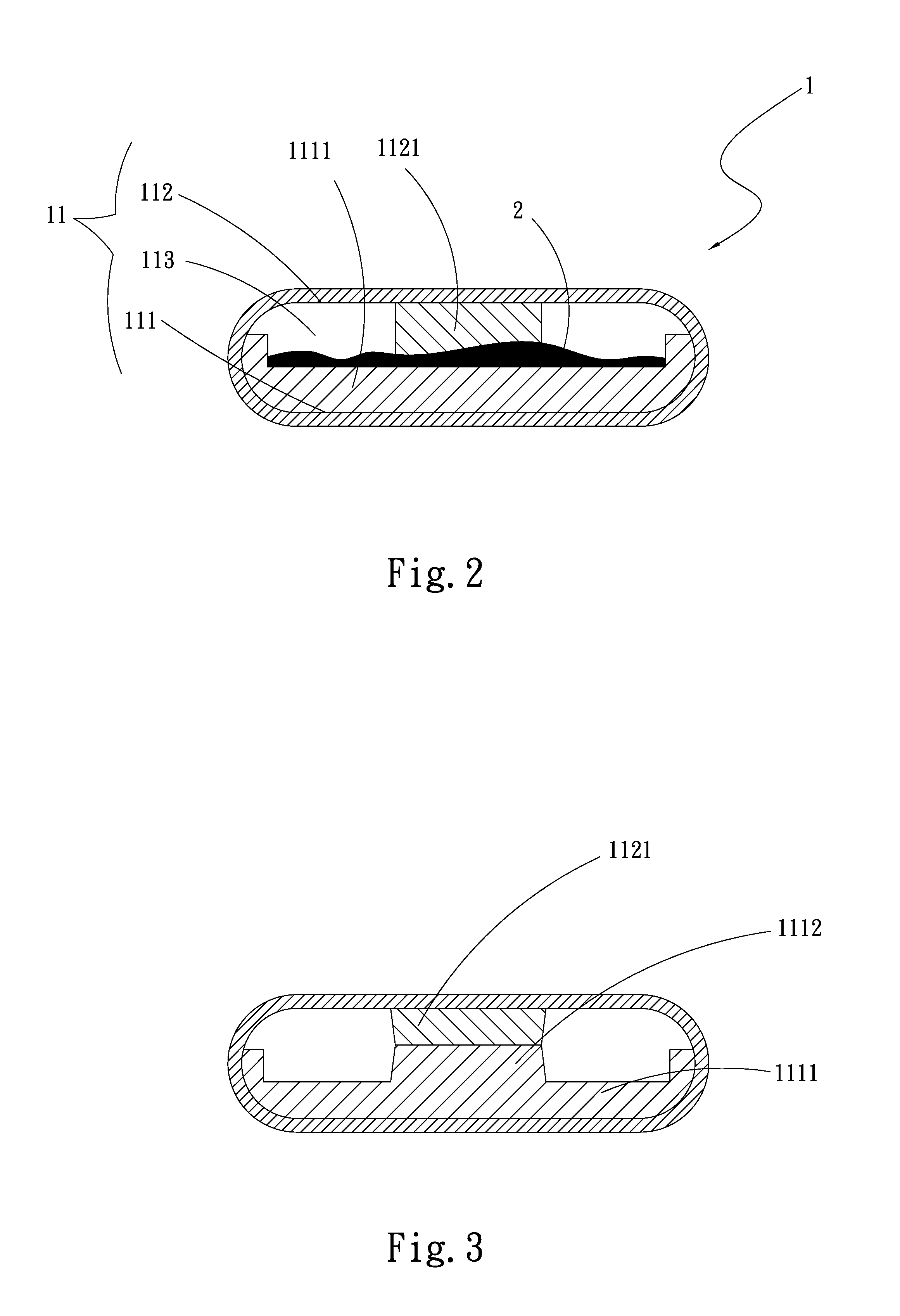

Heat pipe structure

ActiveUS20130213610A1Good heat conduction efficiencyImprove heat transfer efficiencySemiconductor/solid-state device detailsSolid-state devicesWorking fluidHeat transfer efficiency

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

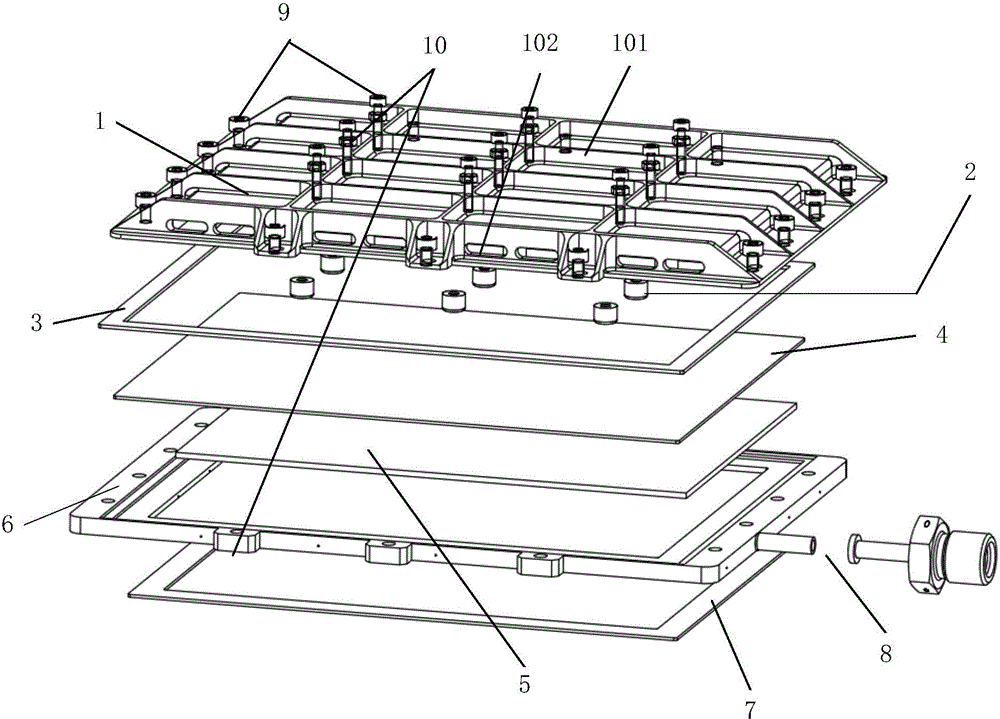

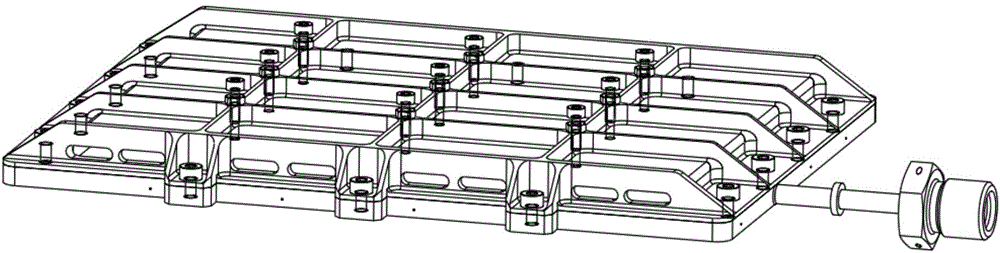

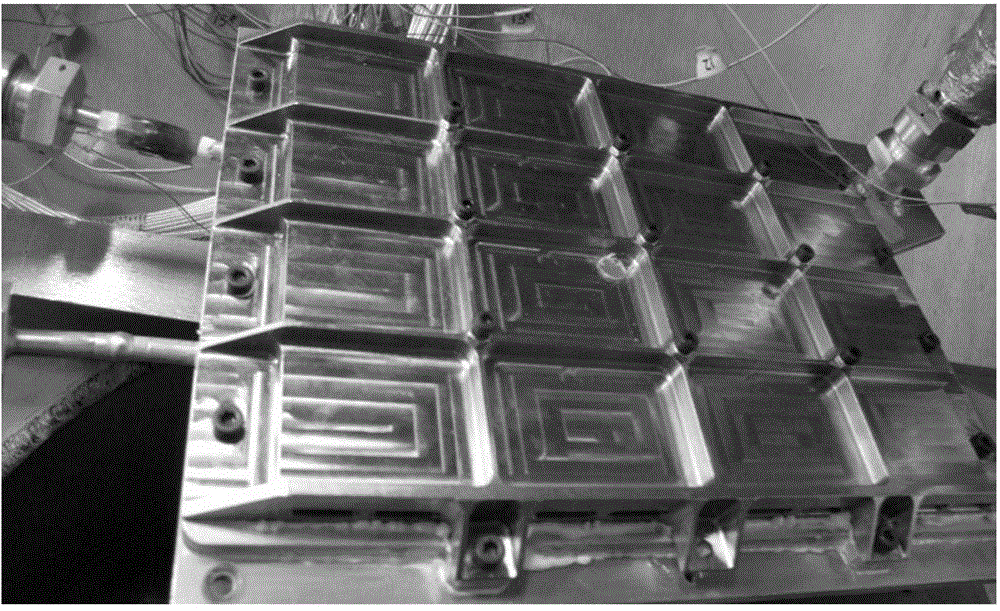

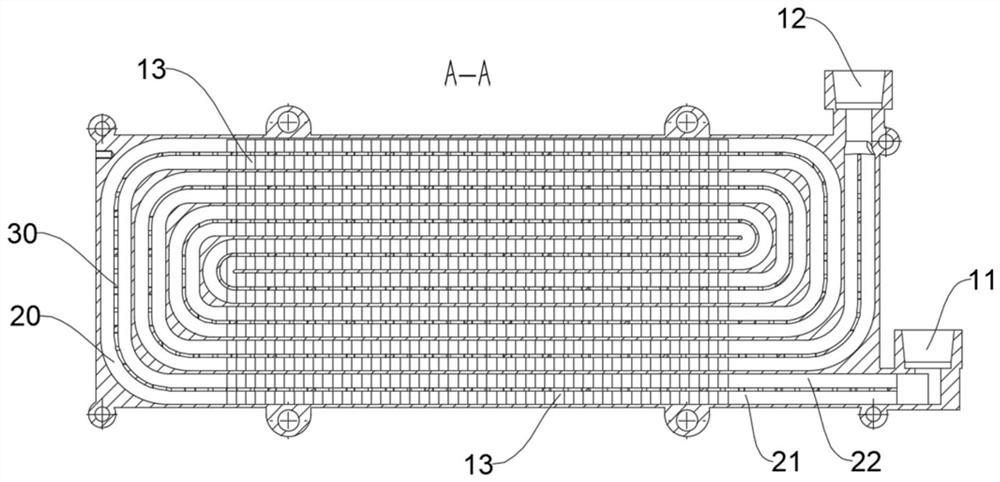

Flat-plate-type water sublimation cold plate for aerospace radiation

ActiveCN104019685AEnsure the uniformity of water supplyConvenience to workIndirect heat exchangersTriple pointEngineering

Owner:BEIJING INST OF SPACECRAFT SYST ENG

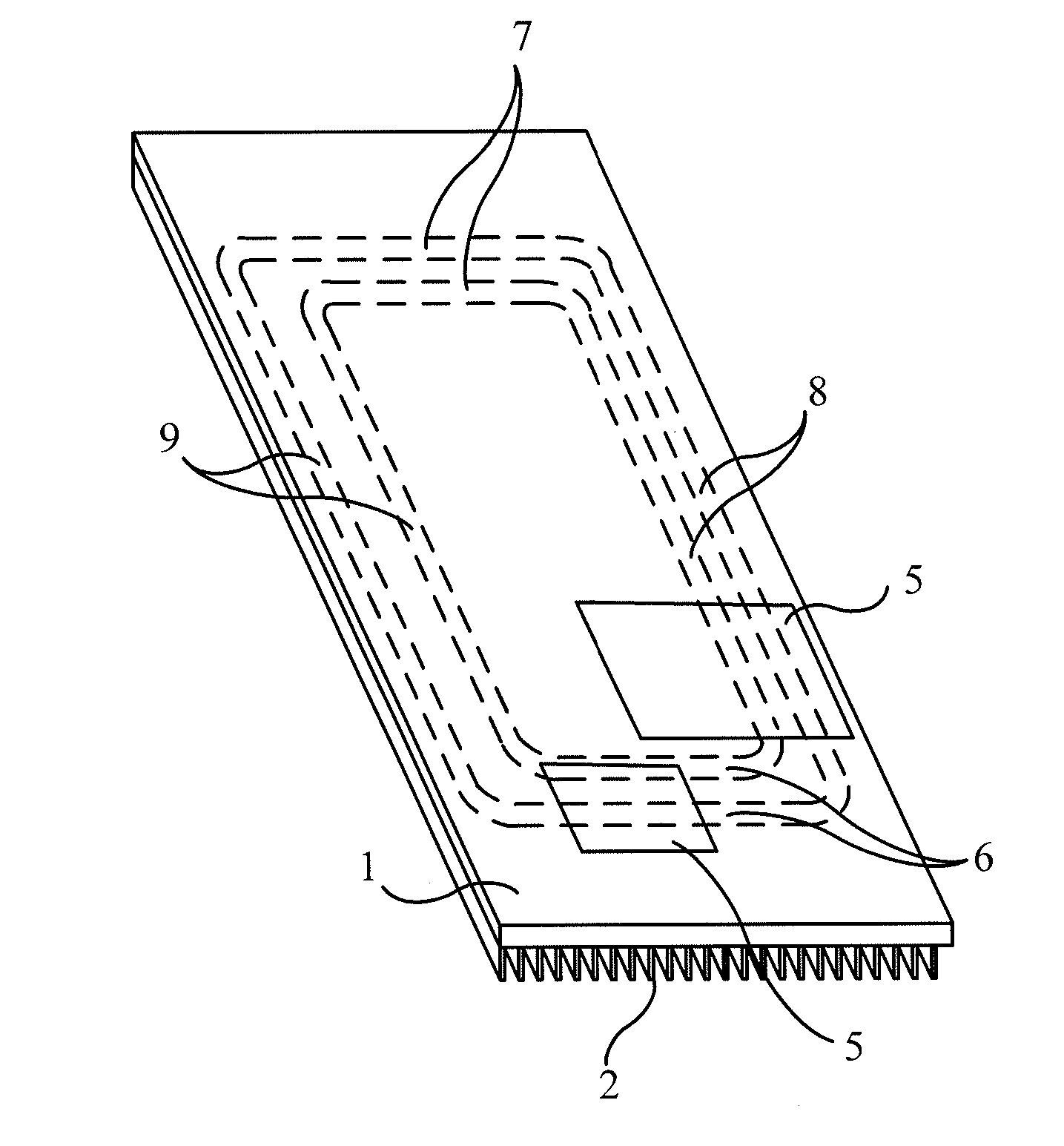

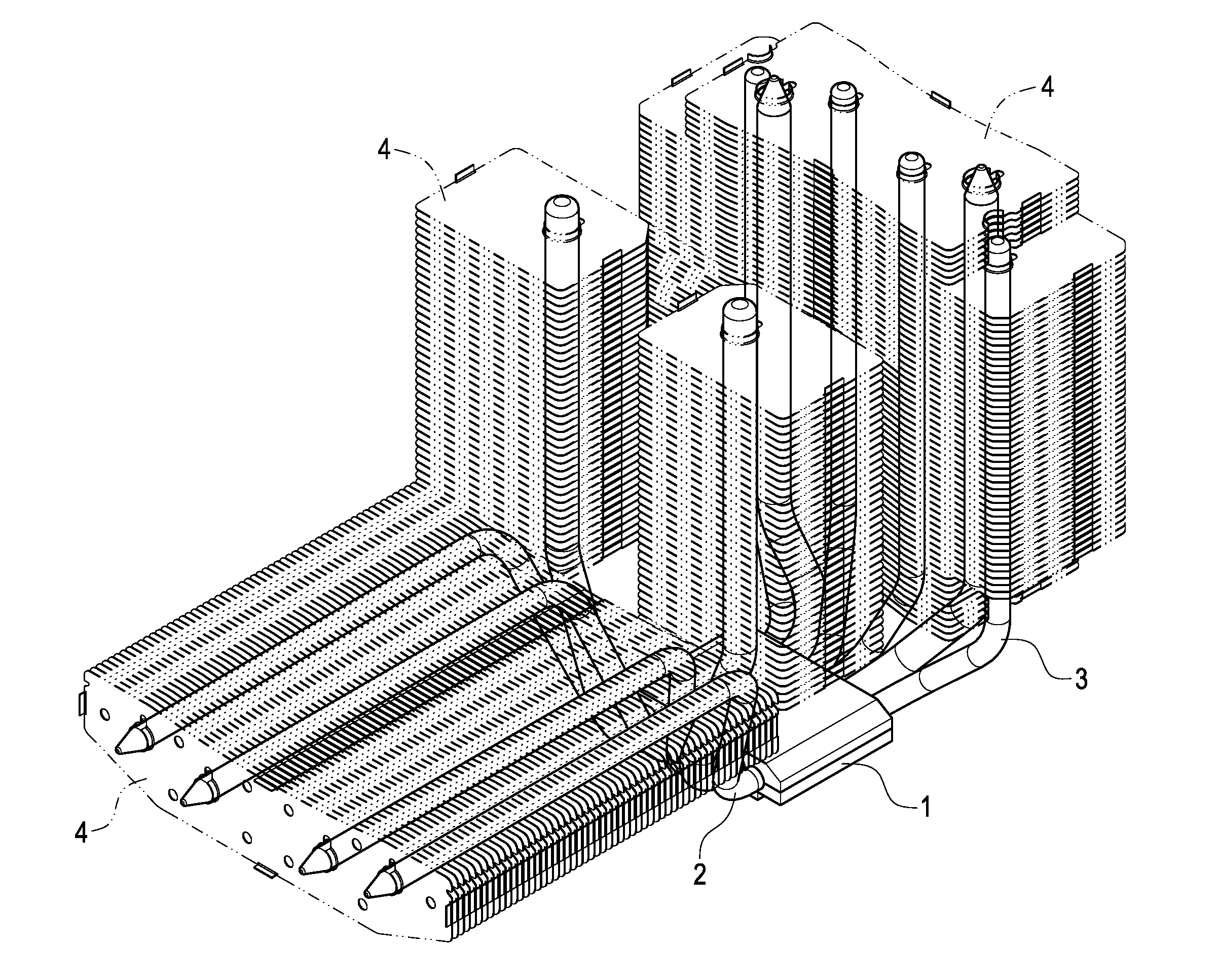

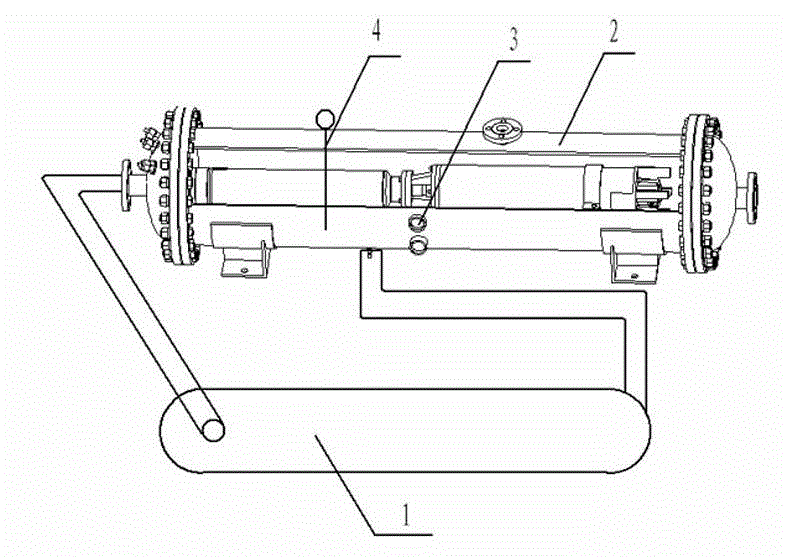

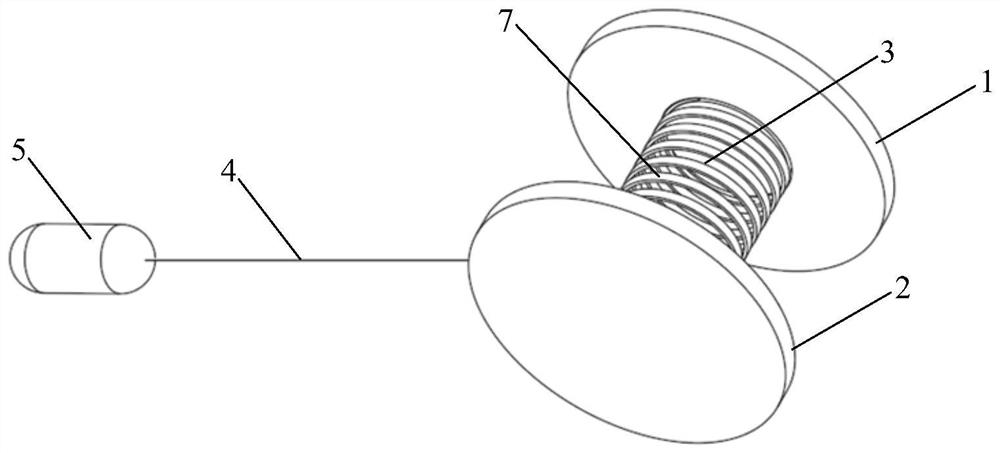

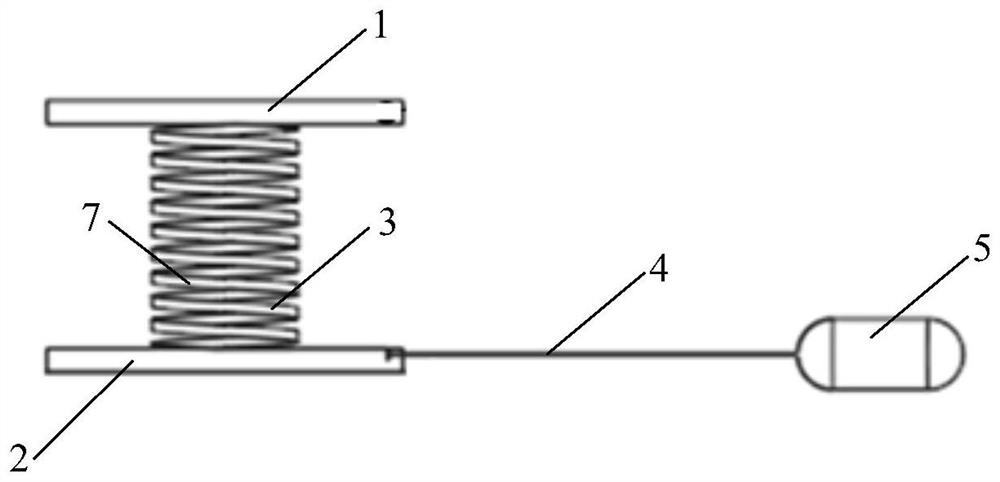

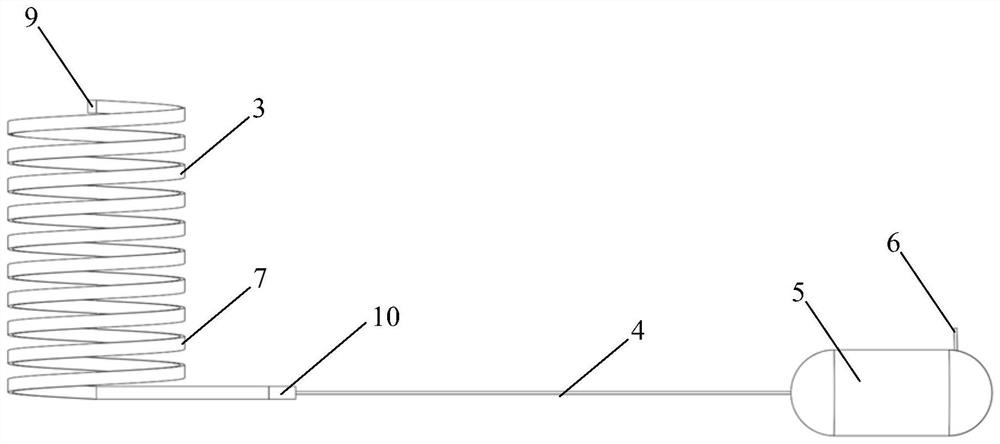

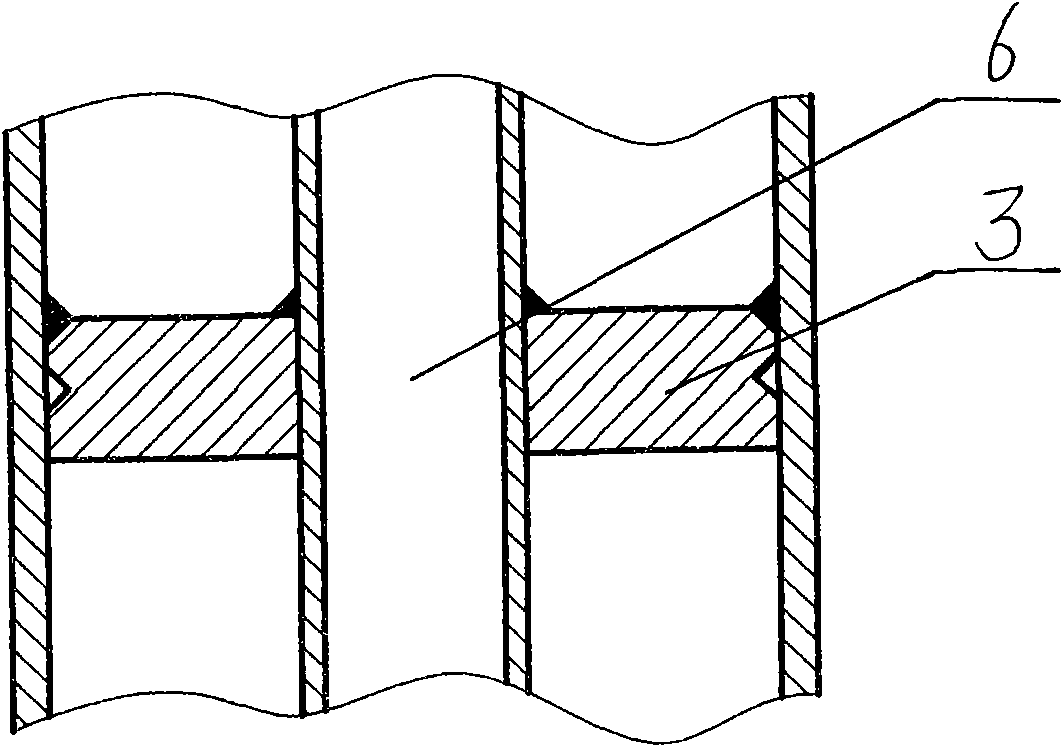

Composite type heat pipe radiator for heating

InactiveCN101373121AReduce useless energy consumptionWill not fail or even be scrappedIndirect heat exchangersVacuum pumpingHeat conducting

A composite type heat pipe radiator for heating relates to the heating ventilating field and comprises an upper header pipe (1), a lower header pipe (2), a radiating fin (3), a fin heating medium pipe (4), a vacuum pumping head (5), a vacuum regulating valve (6), a heat-conducting medium (7) and a heating medium (8). A cavity body formed by the upper header pipe (1), the lower header pipe (2), the radiating fin (3) and the heating medium pipe (4) with the vacuum pumping head (5) and the vacuum regulating valve (6) after a vacuum device extracts the air in the upper header pipe (1), the lower header pipe (2), the radiating fin (3) and the heating medium pipe (4) from the vacuum pumping head (5); and after the air in the cavity body is extracted, a vacuum hollow cavity is formed. The heat-conducting medium absorbs heat from a heat source and transfers the heat to the heating medium (8) through the fin heating medium pipe (4); the heating medium is heated and gasified and transfers the heat to the air so as to serve the heating function. The invention has the advantages of high efficiency, safety, water and energy conservation, beauty, duration, light weight, and high borne pressure. The invention can manufactured into composite type vacuum ultra heat conducting pipe energy-saving efficient radiators of various types and specifications, such as the plate type, the pipe type, the cylindrical type, various wing types, and the like.

Owner:肖建选

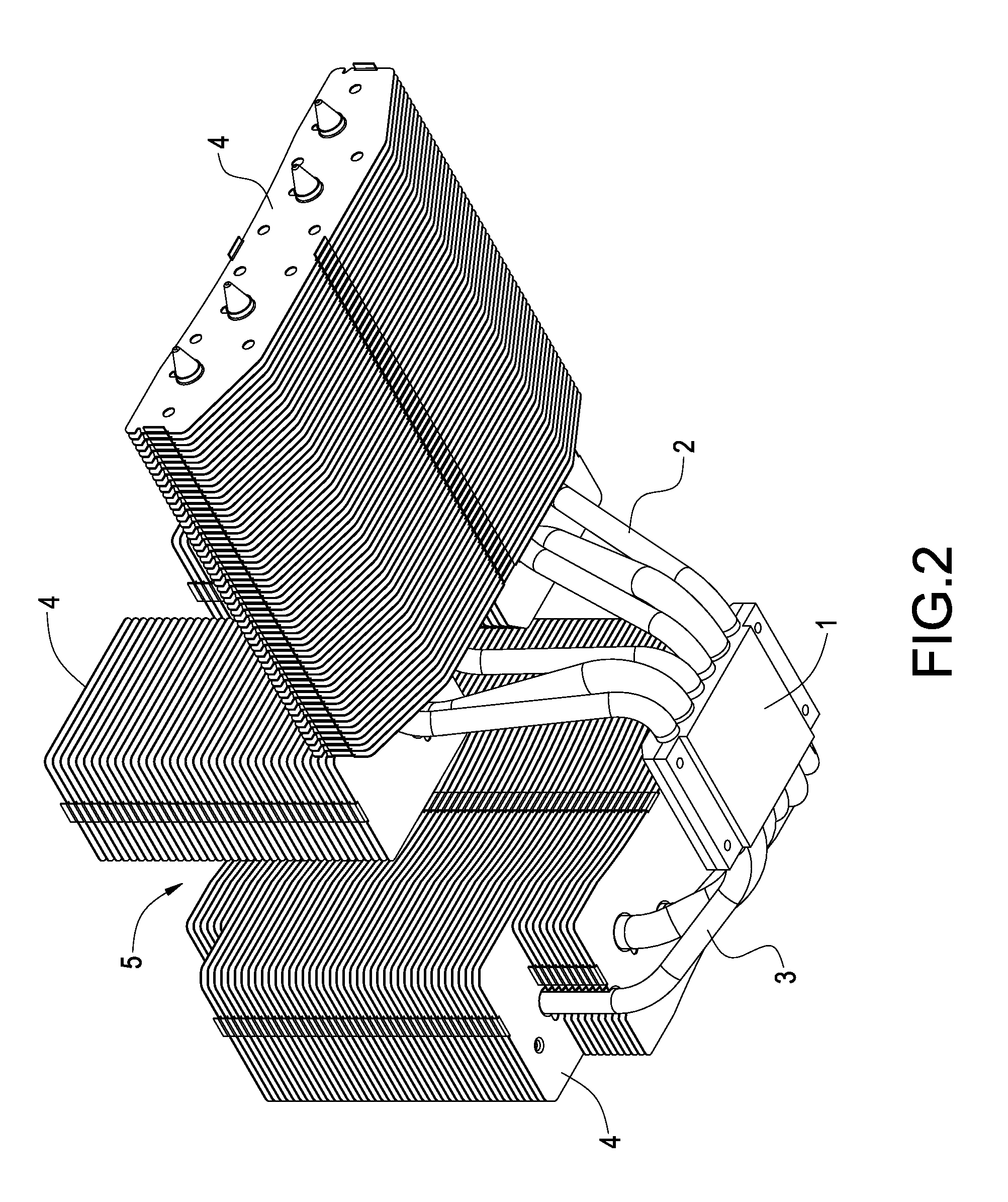

Heat dissipating apparatus extended laterally from heat pipe

ActiveUS20090173474A1Dissipation effectSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat pipe

Owner:CHEMTRON RES

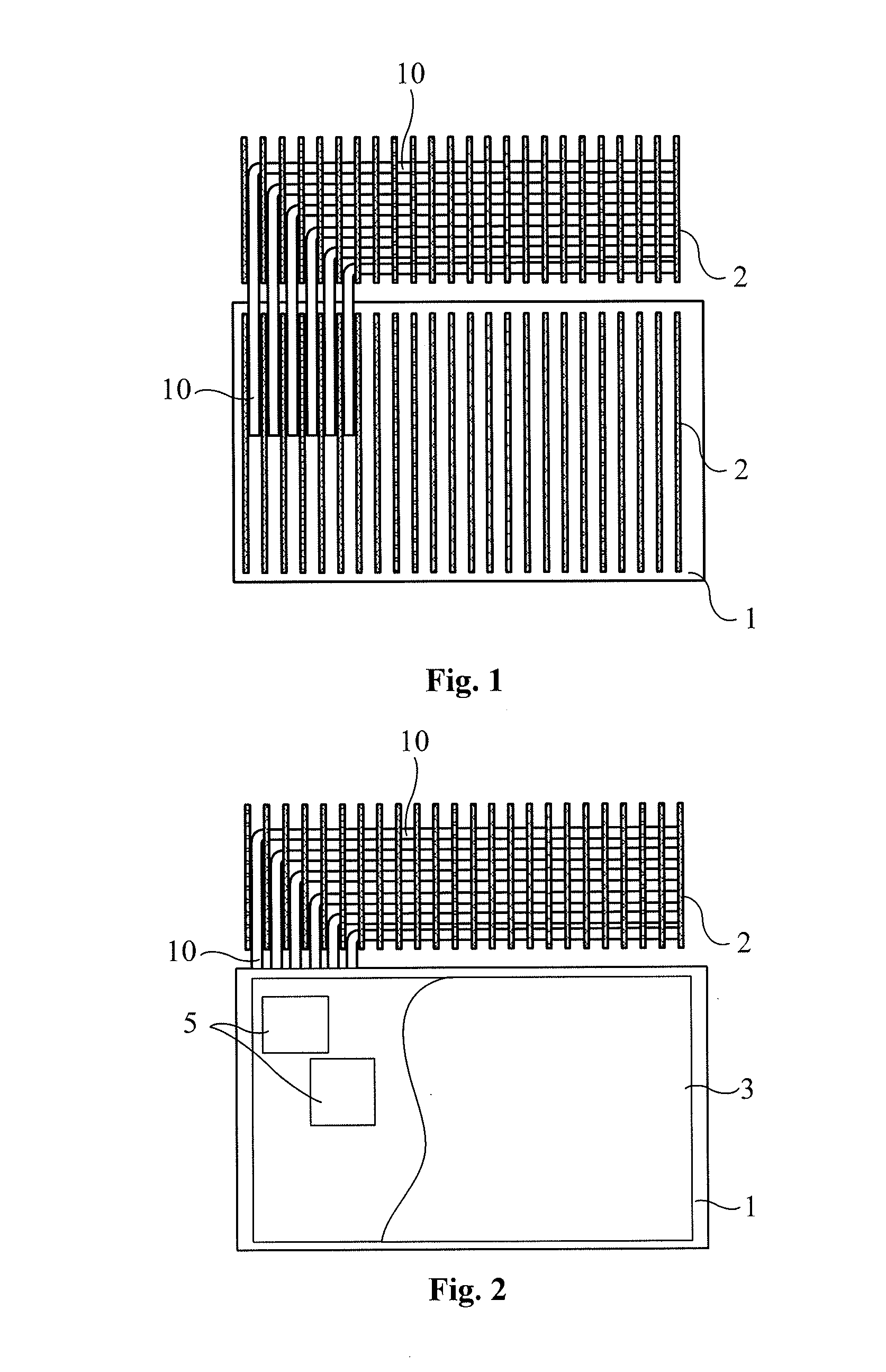

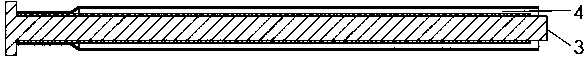

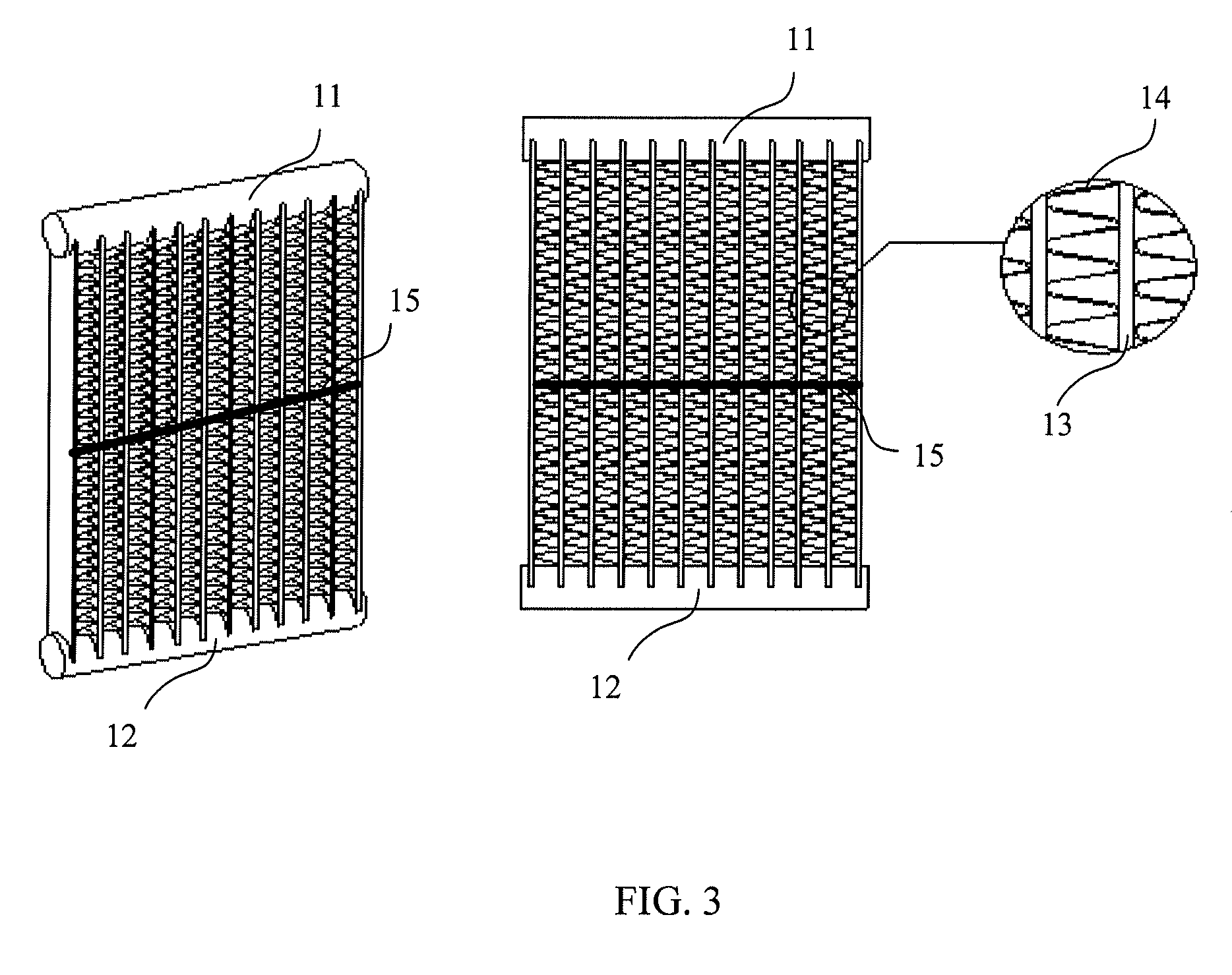

Microchannel-group integrated heat-pipe radiator

InactiveCN1851911ASimple preparation processSpeed up the flowDigital data processing detailsSemiconductor/solid-state device detailsWorking fluidMetal sheet

This invention relates to a micro-slot group integrated heat-pipe radiator including a closes shell made of metal thin plates, in which, the inside cavity of the shell is vacuum filled with working fluid, a core piled up closely by multiple metal thin plates are set in the closed shell, the outer surface of the core is welded to the internal surface of the shell, gaps generating capillary force to adsorb the working fluid is set between the metal thin plates, the surface of the plate is opened with through holes, multiple piled up through holes form through holes on said core to drive the boiled fluid to flow among the slots adjacent to said metal thin plates.

Owner:杨洪武

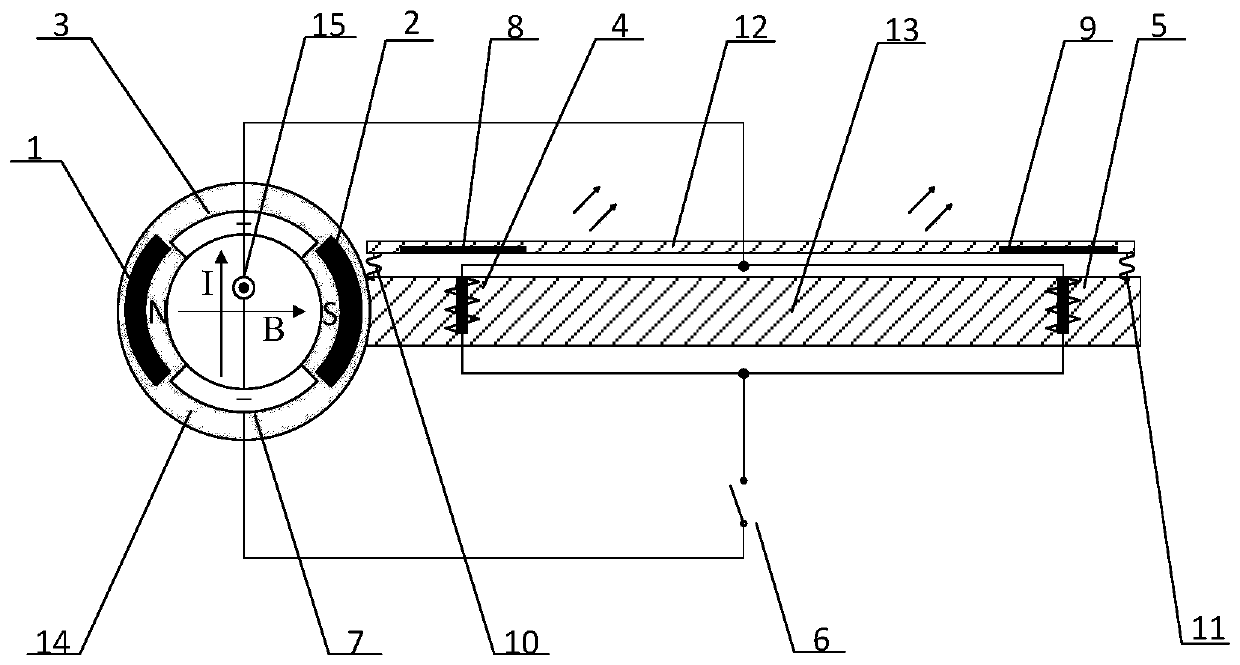

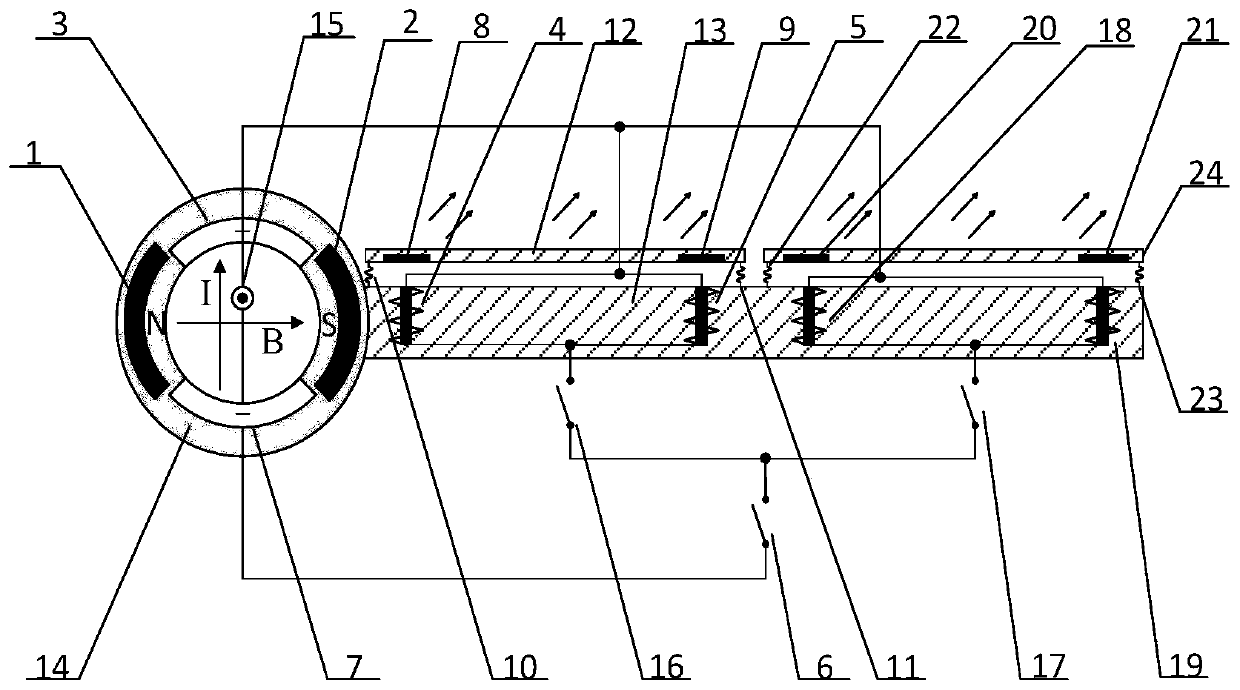

Heat dissipation apparatus and outdoor communication device

InactiveUS20120291990A1Easy to mountEasy maintenanceIndirect heat exchangersModifications for standard racks/cabinetsEngineeringTelecommunications equipment

Owner:HUAWEI TECH CO LTD

Heat exchanger for power-electronic components

ActiveUS20170202108A1Improve cooling effectReduce filter sizeThermal insulationIndirect heat exchangersEngineeringElectronic component

Owner:ABB (SCHWEIZ) AG

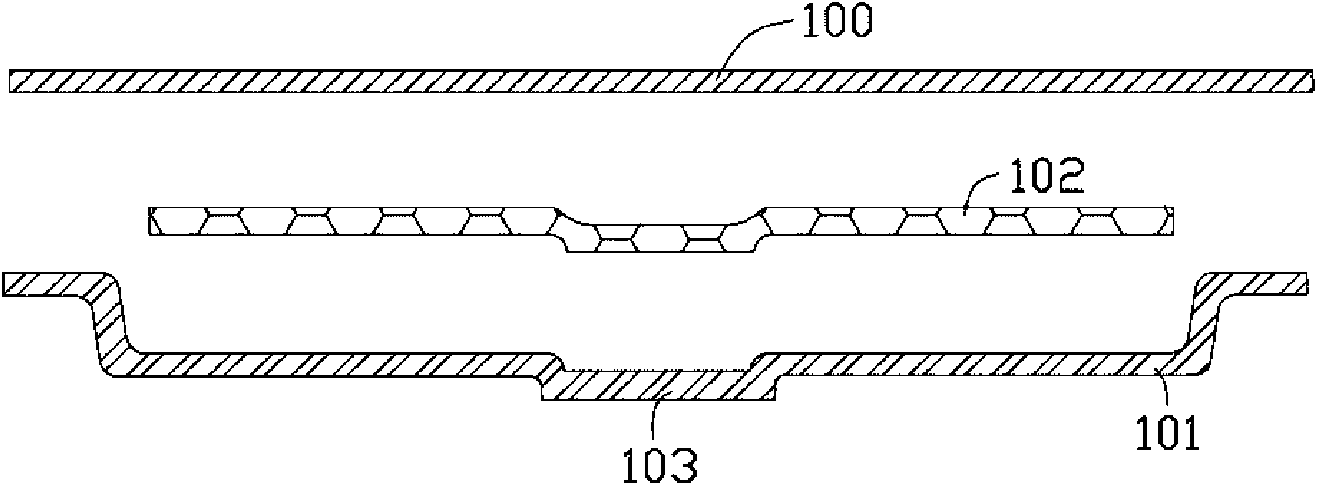

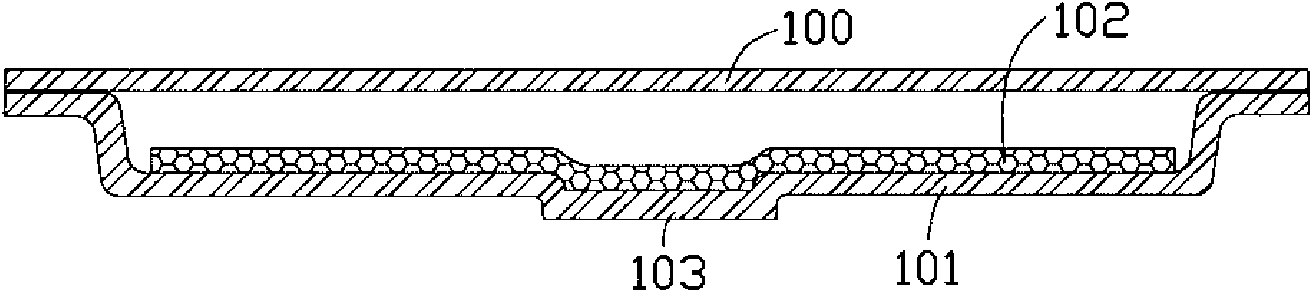

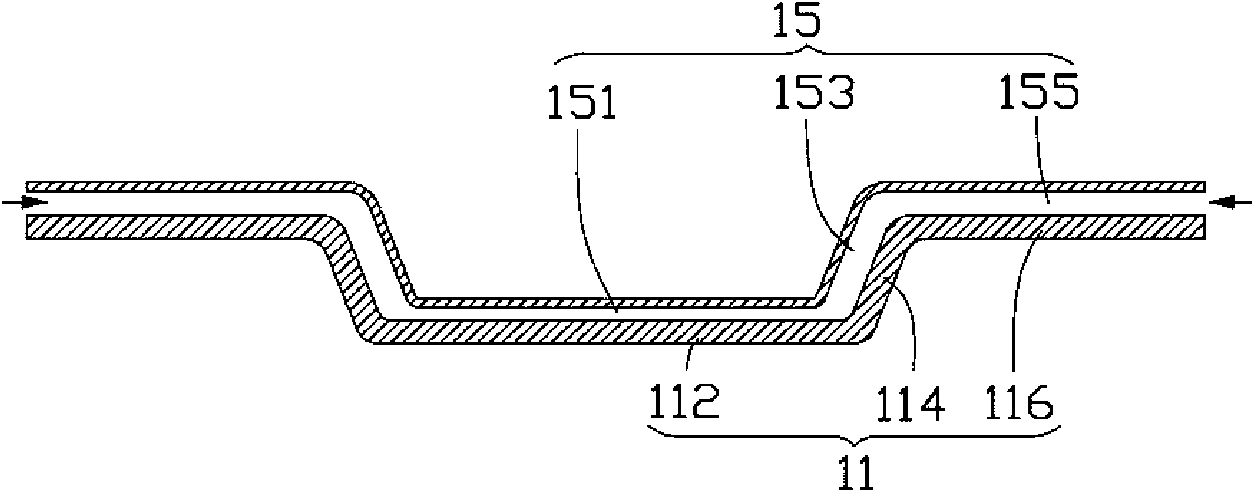

Manufacturing method for thin type heat conduction device

InactiveCN106225538AEnsure assembly flatnessImprove cooling effectIndirect heat exchangersVacuum pumpingEngineering

A manufacturing method for a thin type heat conduction device comprises the steps that a bottom plate and a cover plate which are combined in a face-shaped overlaid form are prepared, the bottom plate is provided with a flat heat dissipation face, a press-fit edge is arranged on the periphery of the part between the bottom plate and the cover plate, a vacuum cavity is formed within the surrounding range of the press-fit edge, a vacuum pumping liquid injection opening is formed in one position of the press-fit edge and sealed through a press-fit edge part, and the outer end of the press-fit edge part is sealed to be in a sealed state through a welding technology; the position, corresponding to the vacuum pumping liquid injection opening, of the press-fit edge is further provided with an upward inwards-concave face, and the upward inwards-concave face is in a face-shaped inwards-concave form in the direction from the flat heat dissipation face of the bottom plate to the cover plate; and accordingly, the outer end of the press-fit edge part forming the vacuum pumping liquid injection opening is in an upwards inwards-concave state relative to the flat heat dissipation face of the bottom plate, so that a space where welding flux used for sealing can protrude downwards is achieved, the welding flux is prevented from protruding out of the flat heat dissipation face of the bottom plate, and accordingly the assembling flatness degree and the optimal heat dissipation efficiency of the flat heat dissipation face of the bottom plate are ensured.

Owner:SUZHOU FORCECON ELECTRIC

Manufacturing method of capillary structure of flat-sheet heat pipe

Owner:FU ZHUN PRECISION IND SHENZHEN +1

A cooling and heating structure

InactiveCN103227354AImprove cooling effectEfficient heatingSecondary cellsIndirect heat exchangersEngineeringThermal contact

Owner:SHOWA DENKO KK

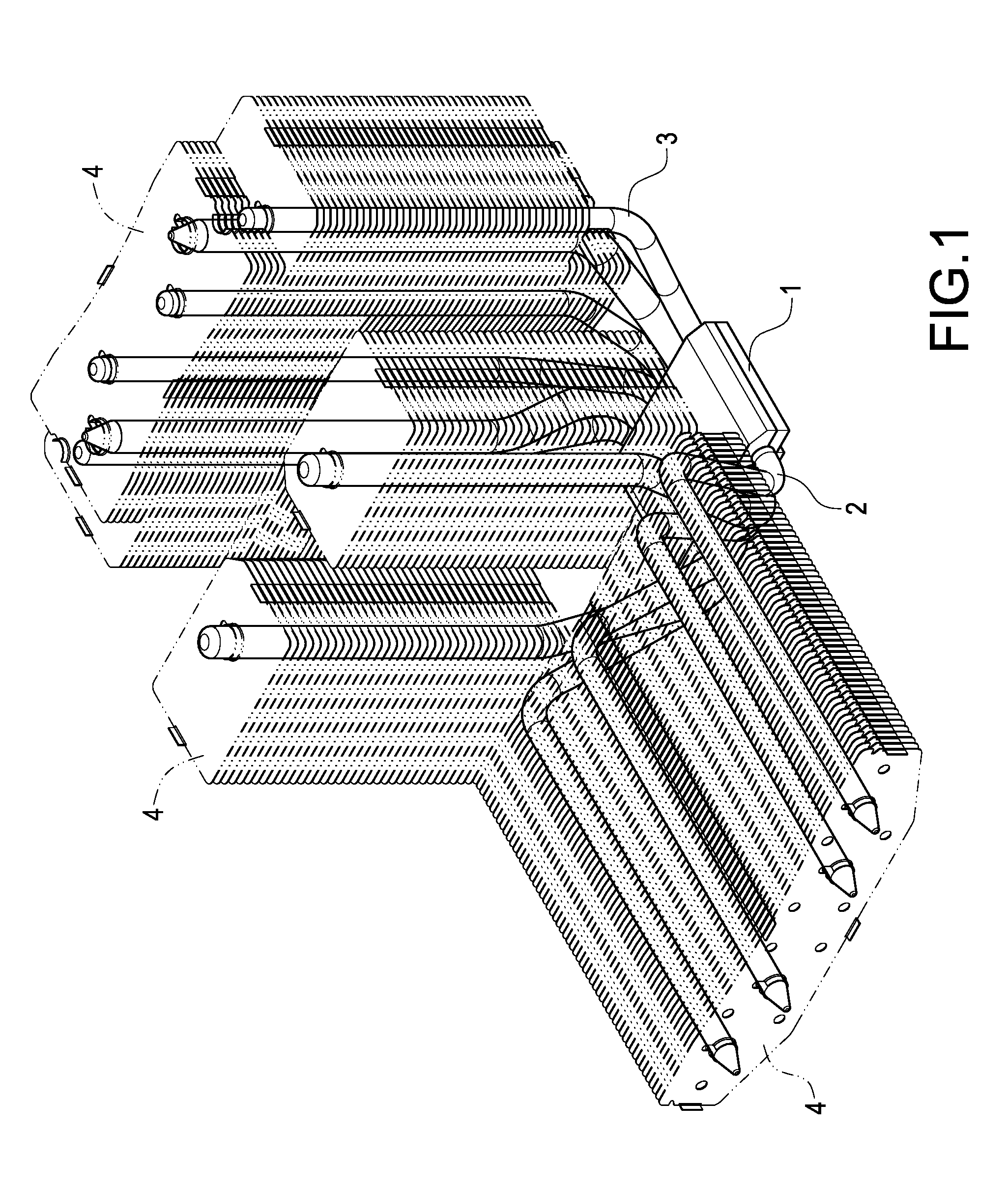

Heat dissipation device

InactiveUS20090277615A1Dissipate heat generatedSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat sink

A heat dissipation device includes a substrate, a fin assembly located on the substrate, a plurality of heat pipes connecting the substrate and the fin assembly, and a fan fixed on the substrate by a clip. The fin assembly includes a first fin unit, a second fin unit, and a third fin unit. The third fin unit is located on the substrate, the second fin unit is located on the third fin unit, and the first fin unit is located on the first fin unit. A receiving space is defined in the second and third fin unit. The fan is received in the receiving space and spaced apart from the fin assembly.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Low-temperature waste heat utilization system

Owner:SHENZHEN AUTO-UNION CONTROL SYST CO LTD

Cooling device and semiconductor refrigeration equipment

ActiveCN105716317AReduce energy consumptionMake full use of cooling capacityIndirect heat exchangersMachines using electric/magnetic effectsComputer moduleEngineering

Owner:QINGDAO HAIER SPECIAL ICEBOX

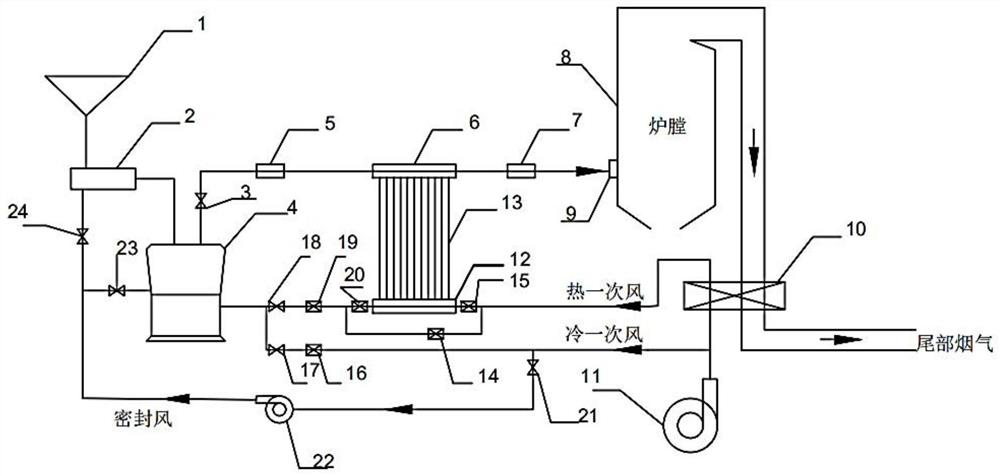

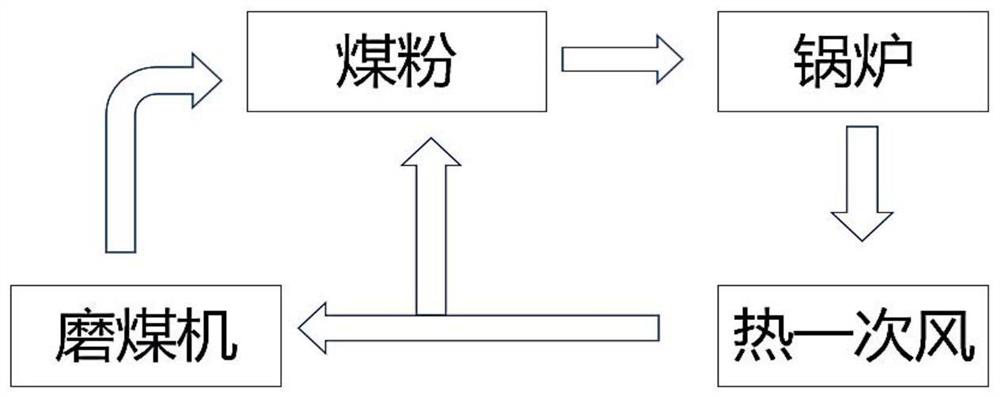

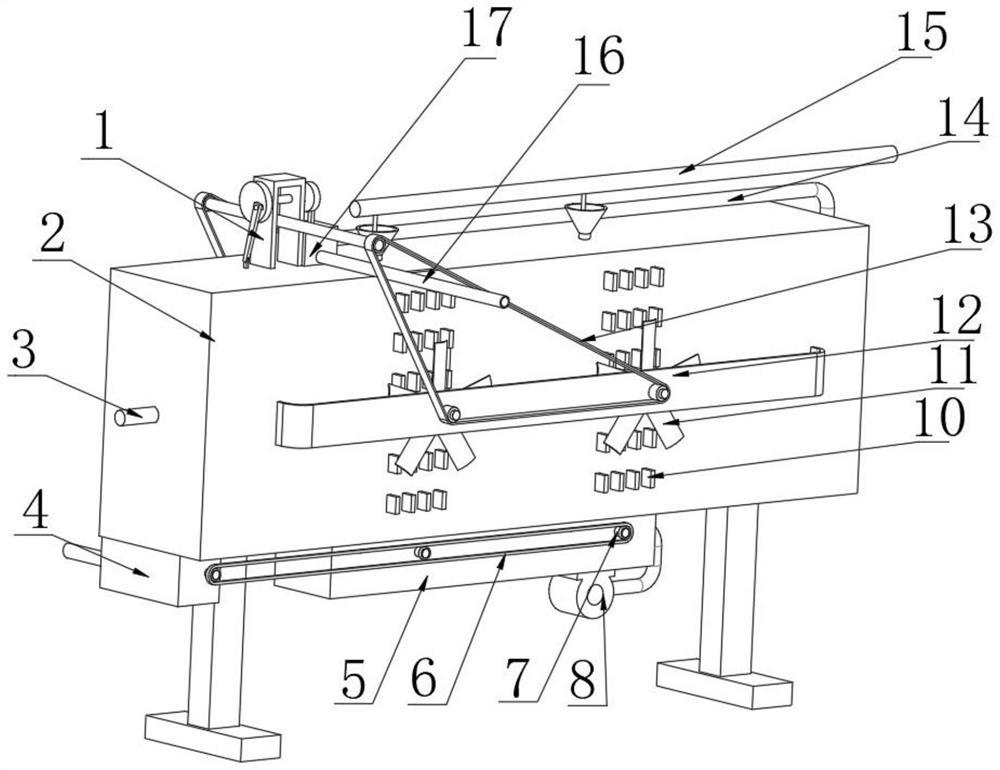

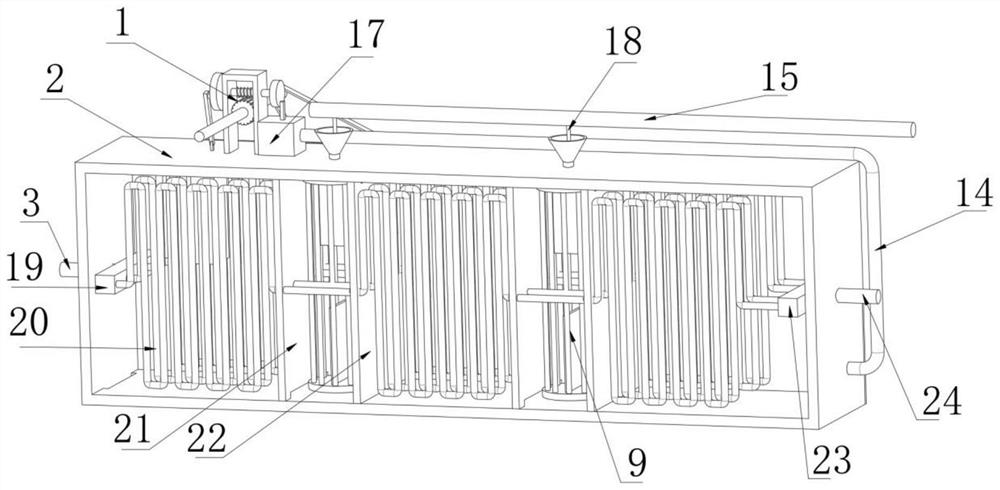

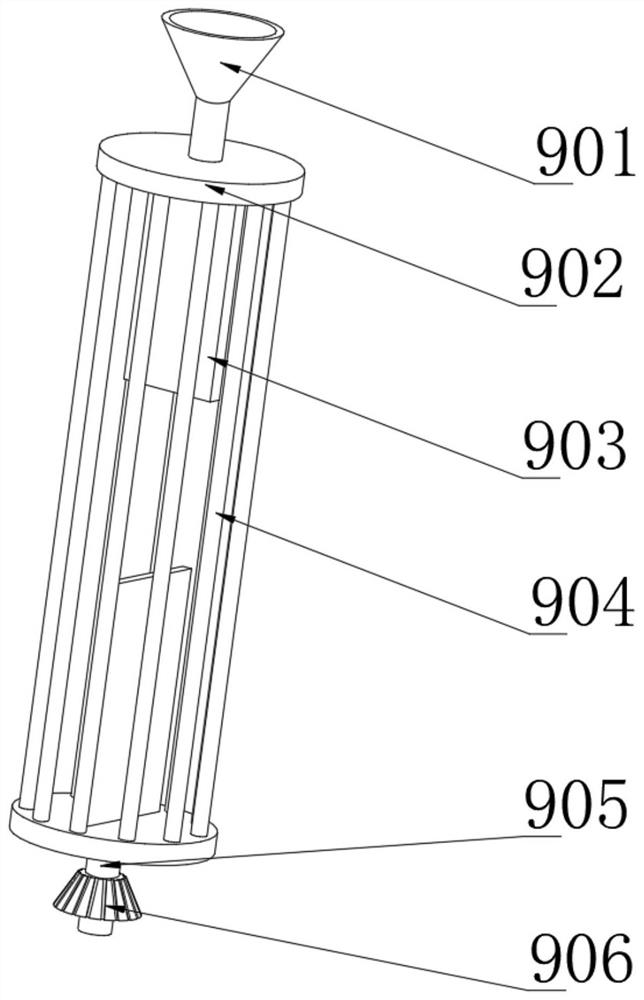

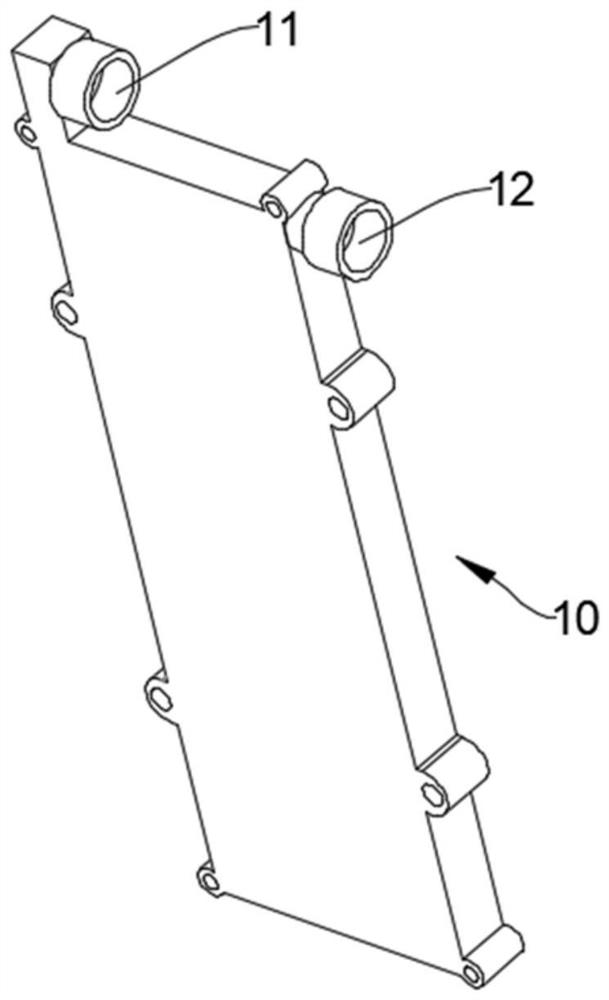

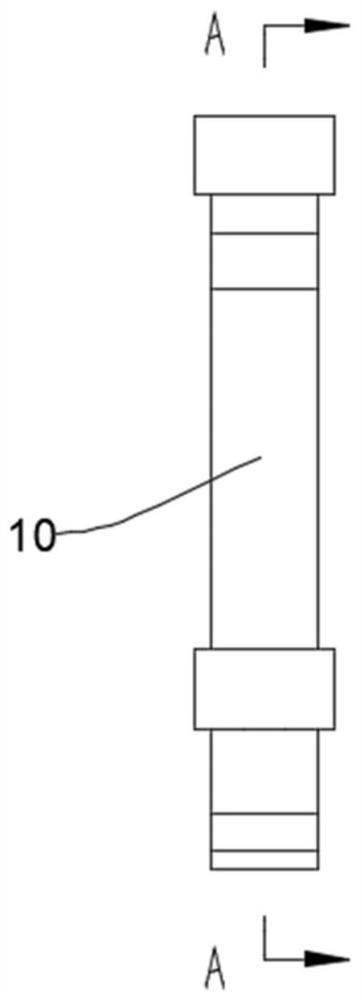

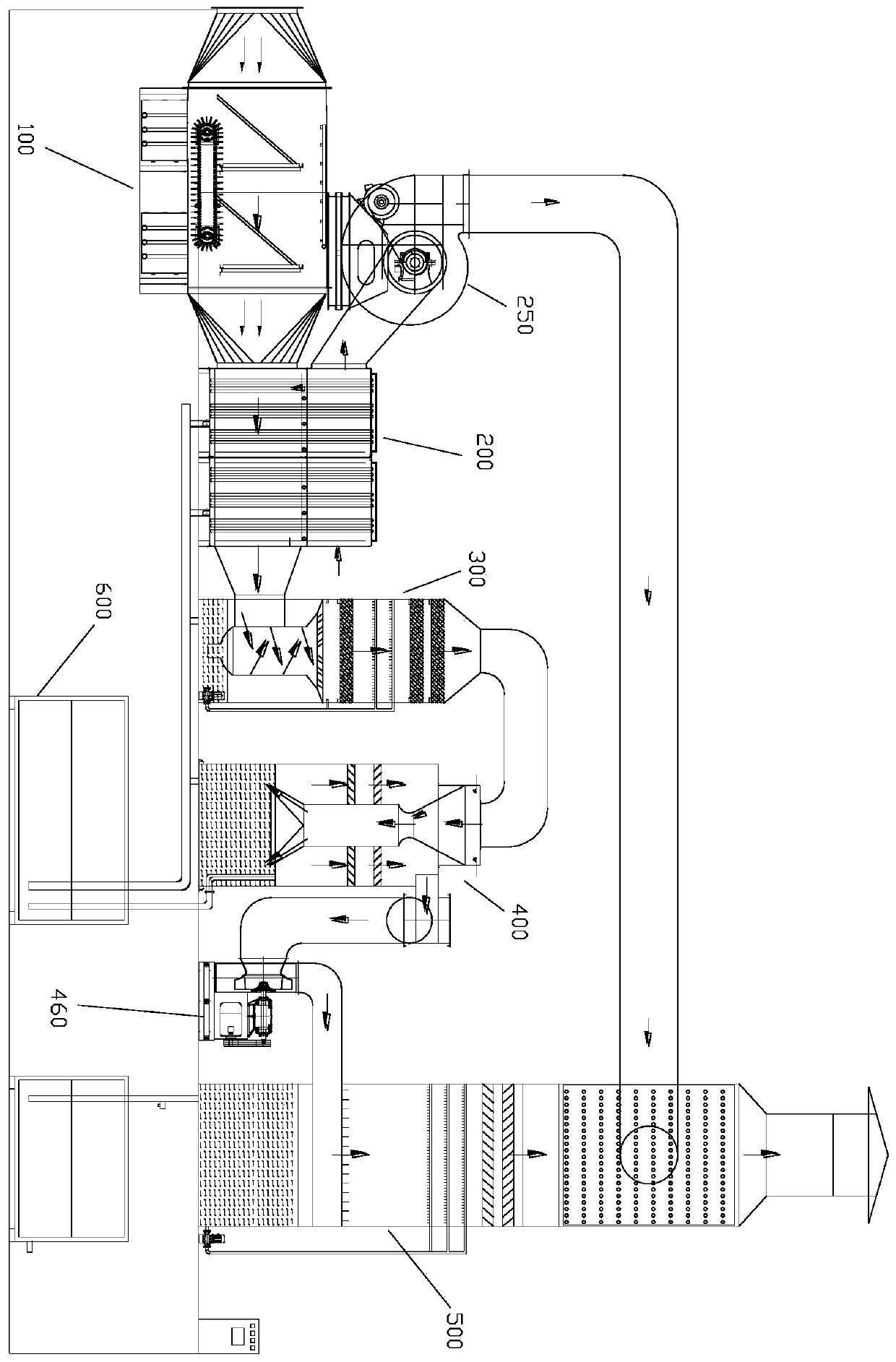

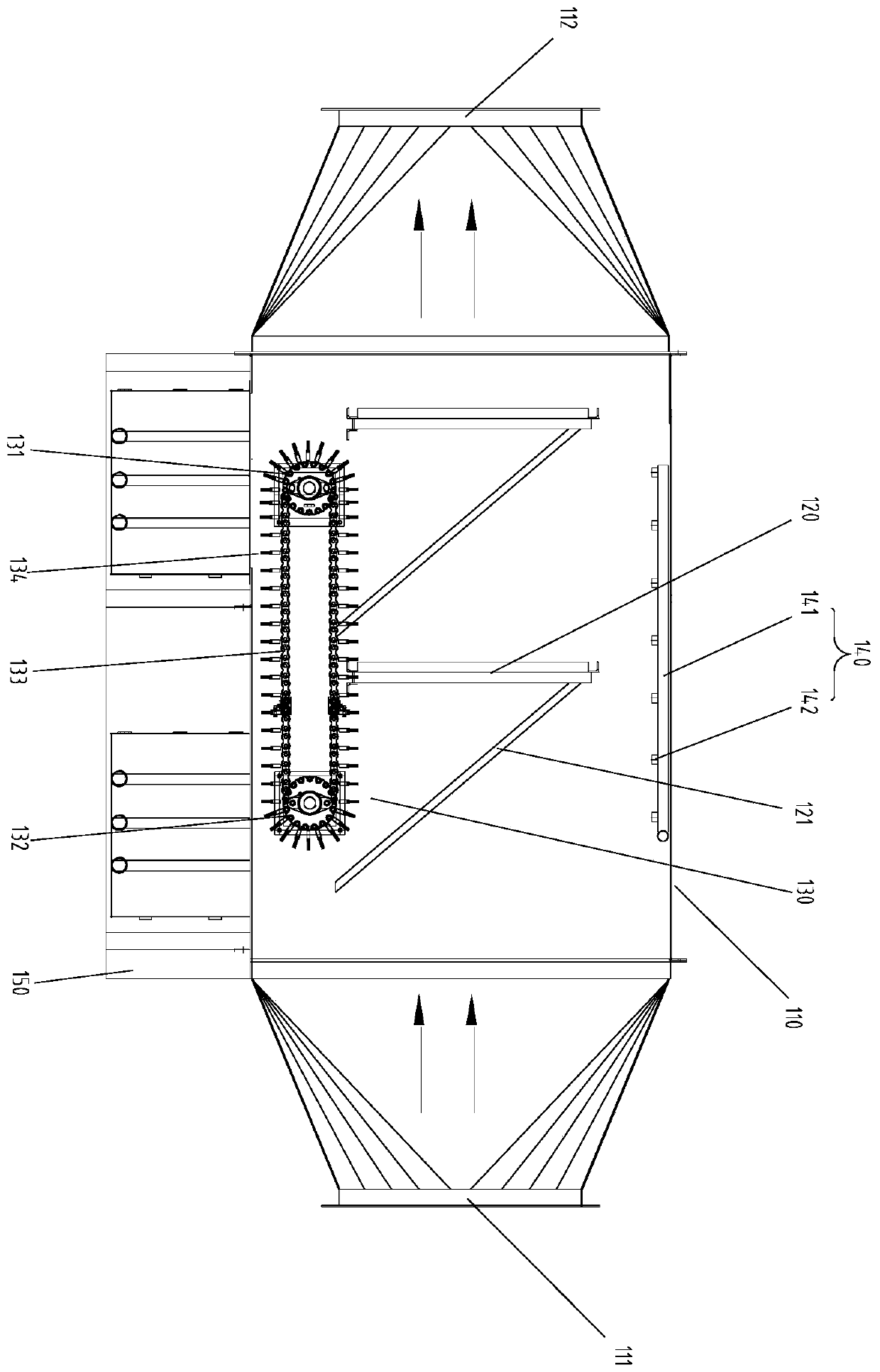

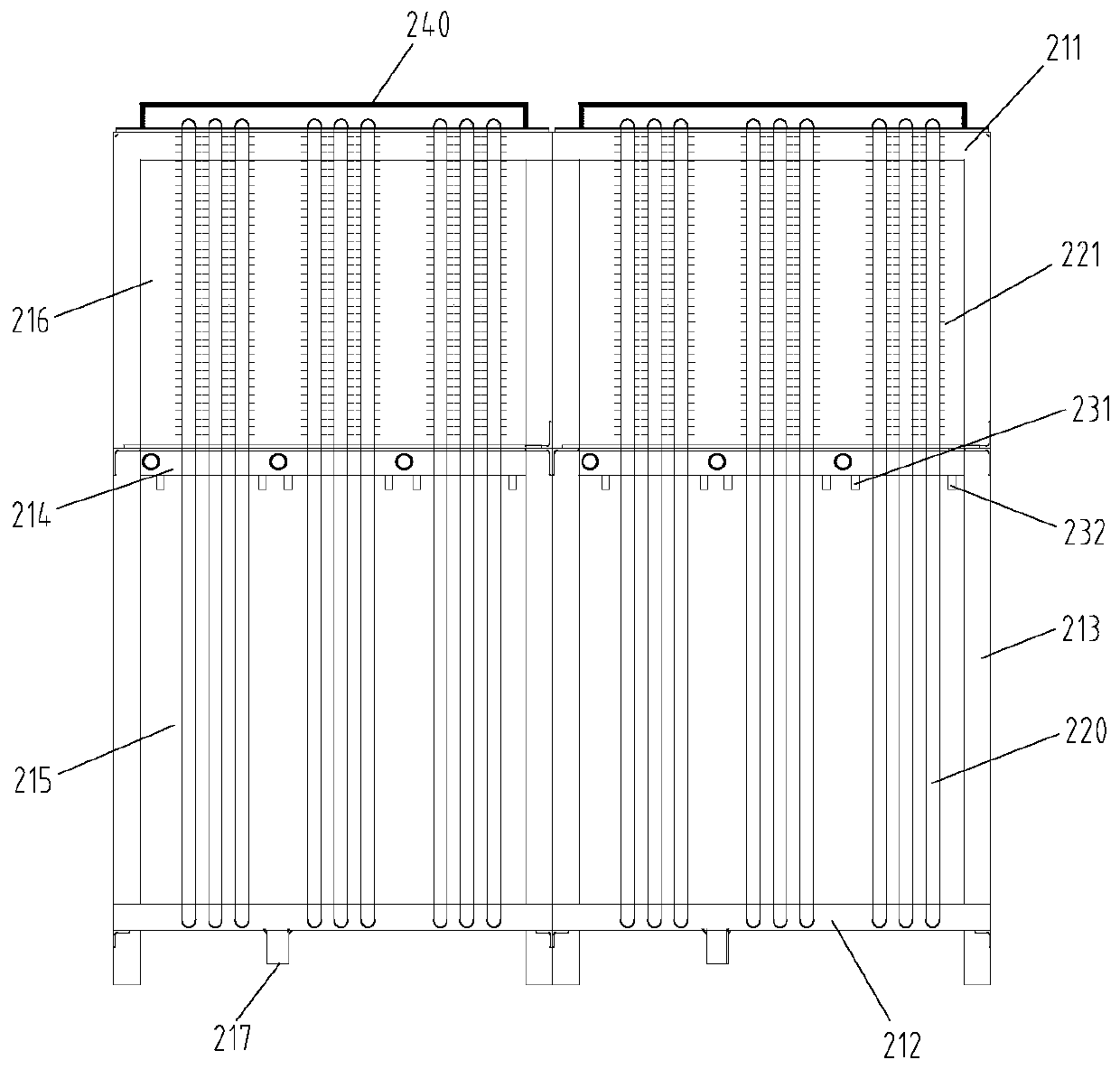

Graded heating pulverizing system based on heat pipe technology and control method thereof

PendingCN112024108AIndirect heat exchangersGrain treatmentsHeat pipe heat exchangerProcess engineering

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Heat exchange device for low-temperature afterheat generator set

Owner:SHANXI YITONG ENVIRONMENTAL ENERGY TECH GROUP

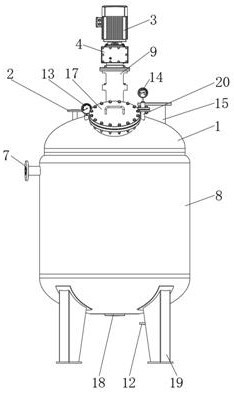

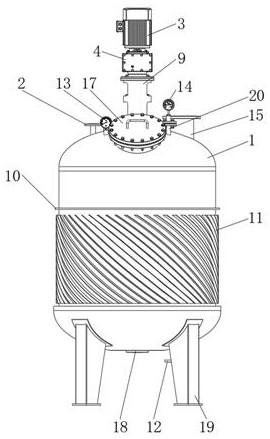

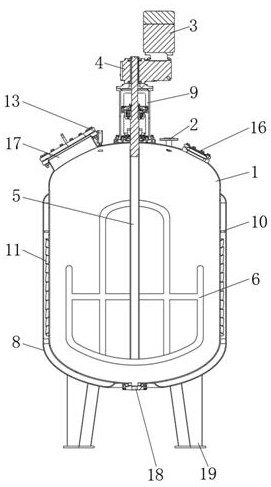

Novel fin vortex jacket reactor

PendingCN114225861AIndirect heat exchangersChemical/physical/physico-chemical processesElectric machineryEngineering

Owner:上海冰通实业有限公司

Oil-gas cooler

PendingCN114264183ASlow down the flowImprove cooling effectIndirect heat exchangersHeat exchanger casingsCooling effectEngineering

Owner:DONGYING LIANHE PETROCHEMICAL CO LTD

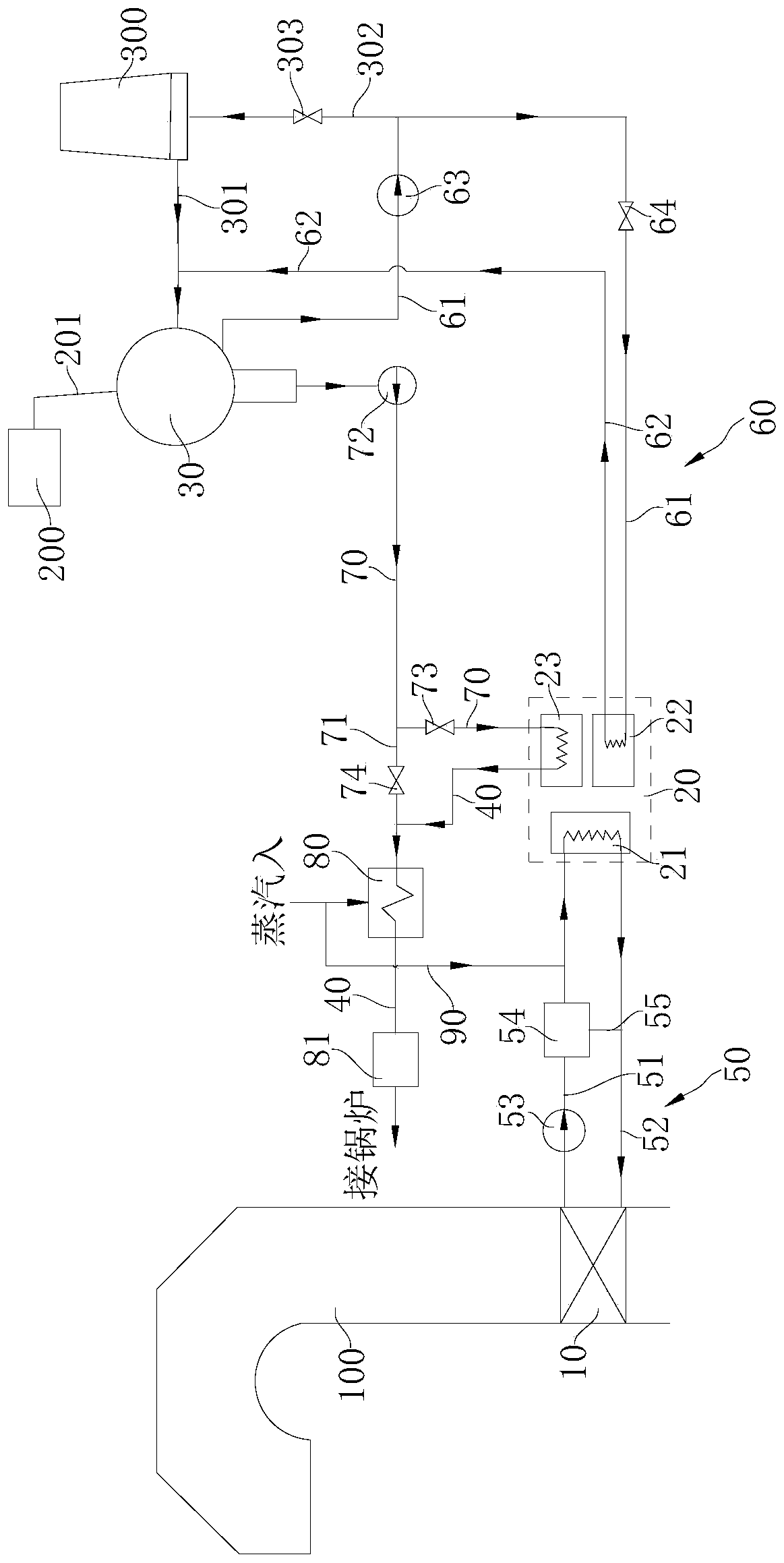

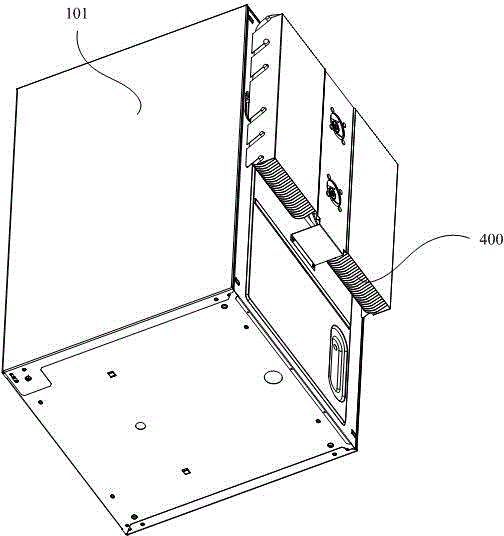

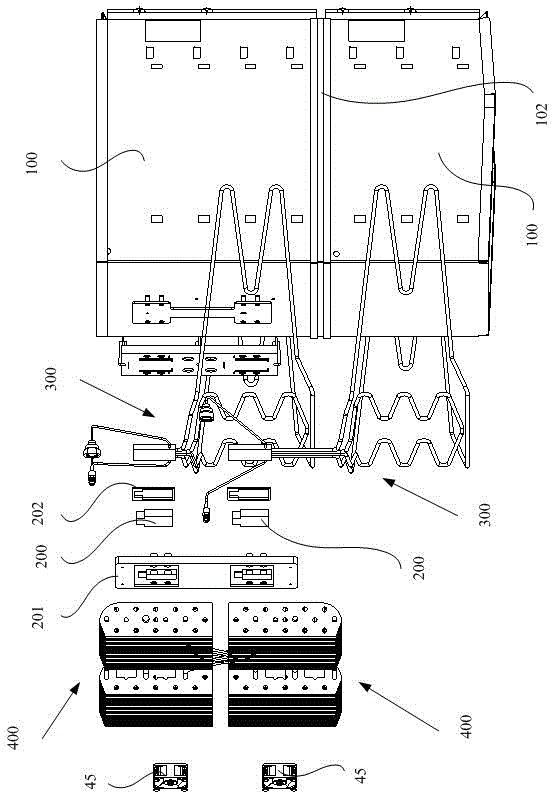

A heat recovery system and method for communication equipment

ActiveCN104754920BSave energyNo noise pollutionIndirect heat exchangersSteam engine plantsComputer moduleEngineering

The invention discloses a thermal energy recovery system and a thermal energy recovery method of a communication device, and relates to the technical field of communication device. The thermal energy recovery system comprises a combined type heat pipe, and multiple groups of thermal energy recovery devices, wherein the combined type heat pipe is a closed circulation pipe network filled with heat exchange medium; the combined type heat pipe comprises a gathering pipeline and a plurality of branch pipelines respectively connected with the gathering pipeline in a parallel manner; each group of thermal energy recovery devices is corresponding to one branch pipeline; each thermal energy recovery device comprises a thermal energy collecting module and a plurality of thermal energy gathering plates respectively connected with the thermal energy collecting module; each thermal energy gathering plate is arranged on a single disc in a corresponding manner, and the thermal energy collecting module is arranged on the outer pipe wall of the branch pipeline in a corresponding manner. The thermal energy recovery system and the thermal energy recovery method of the communication device can save a lot of energy, do not produce noise pollution and do not affect normal life of people.

Owner:FENGHUO COMM SCI & TECH CO LTD

Heat exchange structure and semiconductor heat exchange device

PendingCN112880454AImprove heat transfer performanceImprove heat transfer efficiencyIndirect heat exchangersMachines using electric/magnetic effectsThermodynamicsHeat flow

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

High-temperature printing and dyeing waste gas treatment equipment

PendingCN110270217AEmissions invisibleNo smellCombination devicesUsing liquid separation agentParticulatesMicrobubbles

Owner:SUZHOU BANGTIKE INTELLIGENT TECH CO LTD

Power-adjustable space radiation heat dissipation system and working method thereof

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Low-temperature cold superconducting vibration isolation device for space low-temperature refrigerator

PendingCN114087317AEffective isolation of mechanical vibrationAddress mechanical propertiesIndirect heat exchangersRefrigeration devicesVibration isolationMechanical engineering

Owner:上海亘满科技有限公司

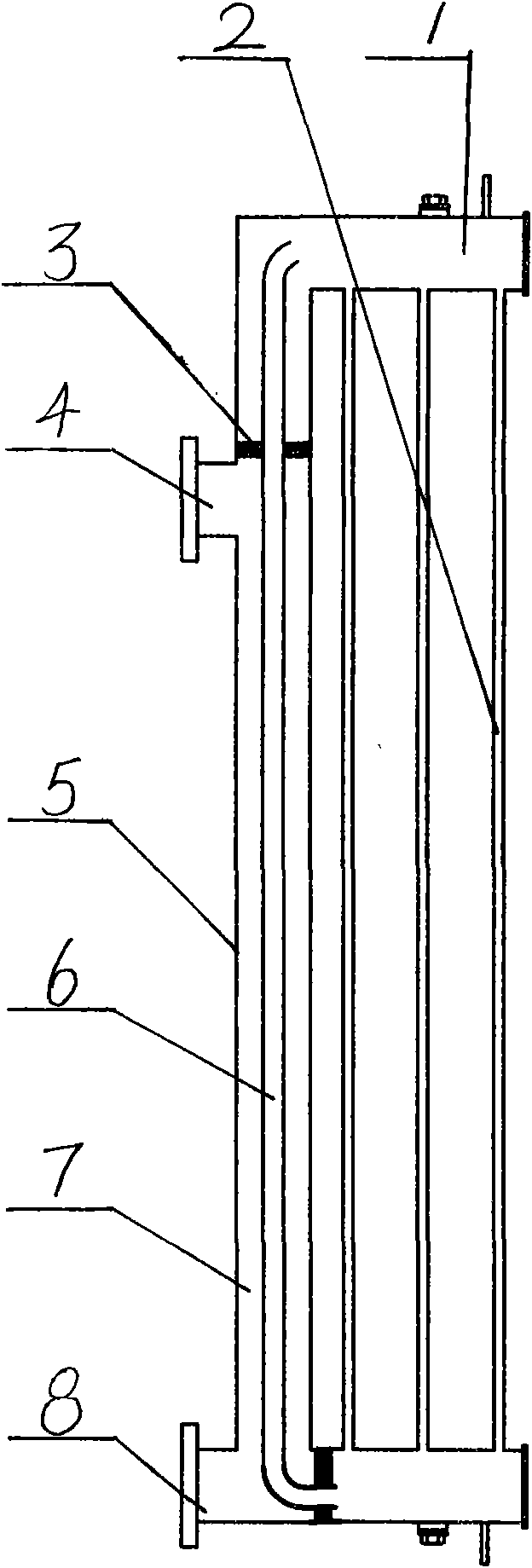

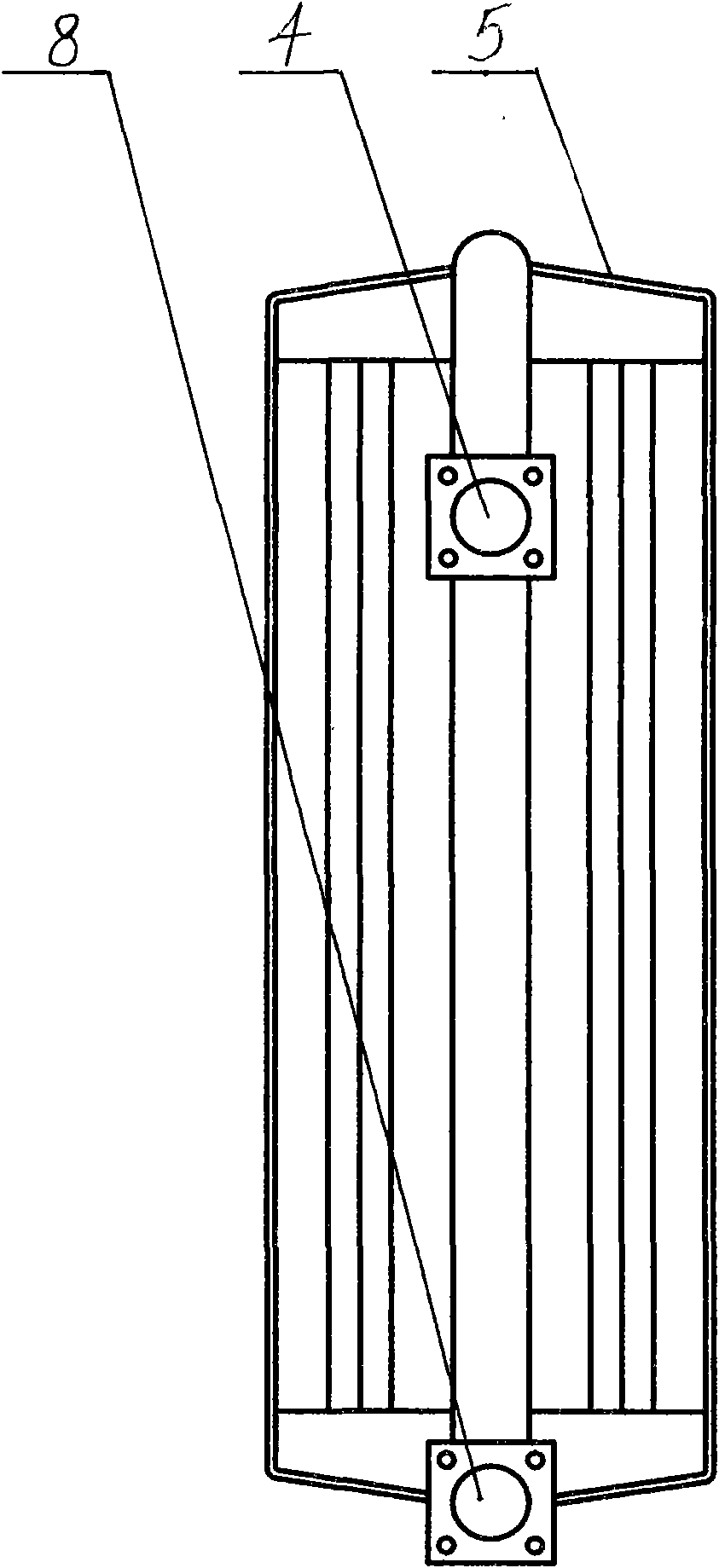

Heat tube plate type radiator

Owner:田亚东

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap