High-temperature printing and dyeing waste gas treatment equipment

A waste gas treatment equipment and high-temperature technology, applied in lighting and heating equipment, air quality improvement, liquid separation agent, etc., can solve problems such as bad smell, thick smoke, material consumption, pollution, etc., to improve treatment efficiency and increase Effect of contact area, ability to raise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

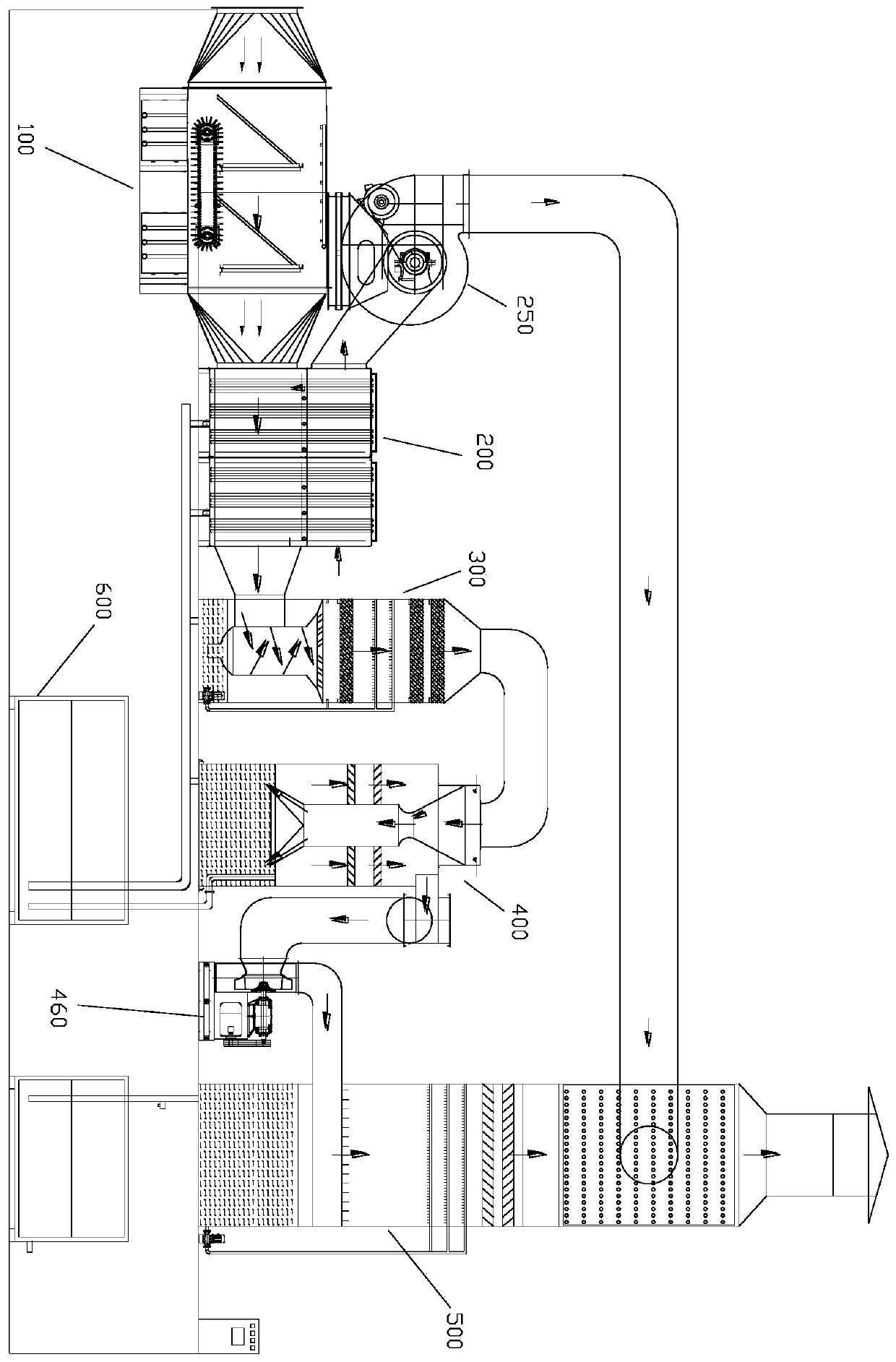

[0043] In the process of textile printing and dyeing, waste gas containing fluff, particulate matter, lampblack, wax, VOCs and other mixtures will be discharged, and it has the characteristics of high temperature, high humidity and strong adhesion, which is difficult to deal with. Aiming at this technical problem, the present invention discloses a high-temperature printing and dyeing waste gas treatment equipment, which includes a multi-stage filter device 100, a gas-gas heat exchange device 200, a swirl tower 300, a Venturi scrubber 400, and an active mud scrubber 500, and an oil dust collection pool 600.

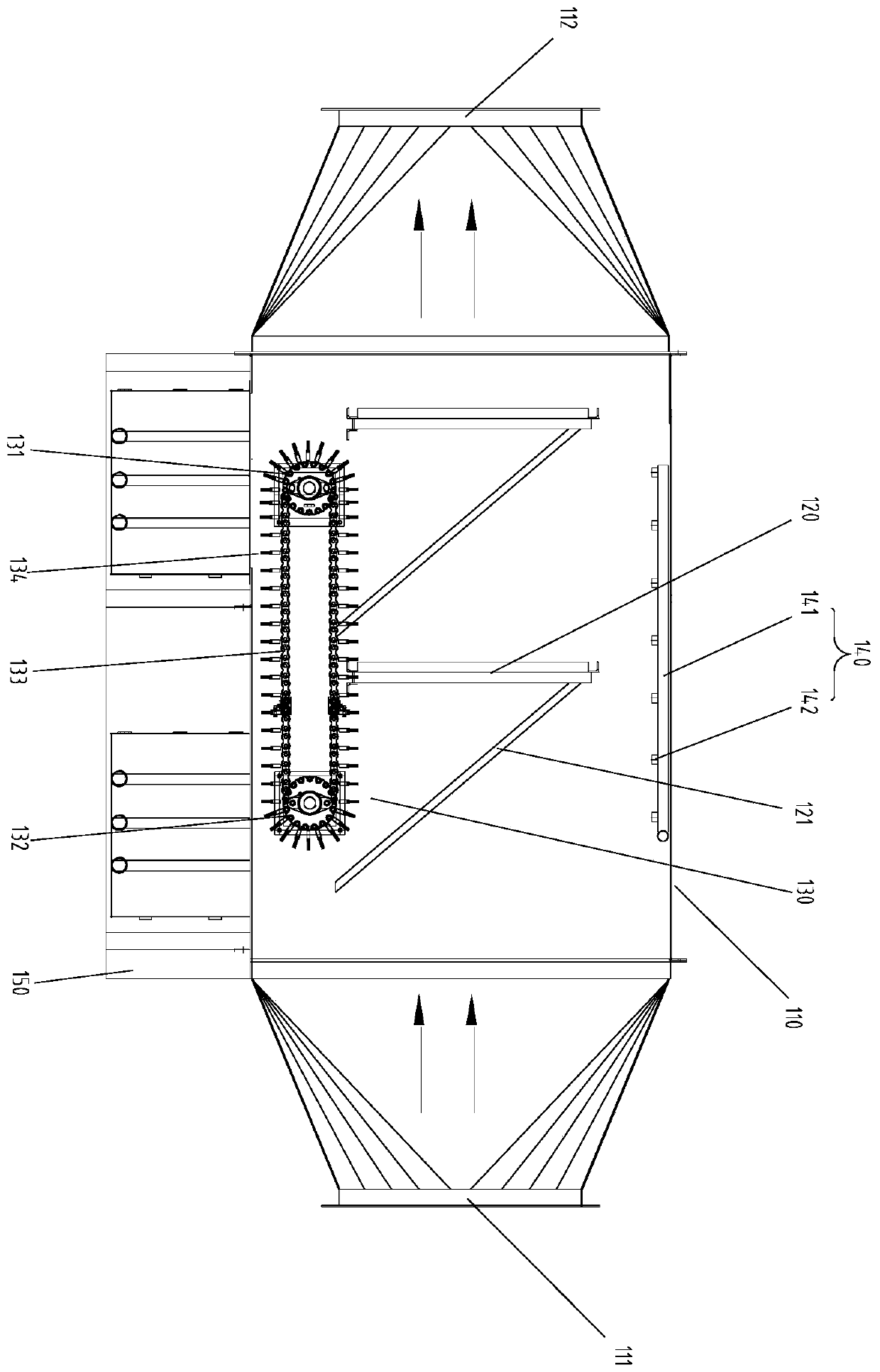

[0044] The multi-stage filter device 100 is the first equipment through which exhaust gas passes. see Figure 1-2 , which includes a filter housing 110, one end of the filter housing 110 is provided with an exhaust gas inlet 111, and the other end is provided with an exhaust gas inlet 112, and the filter housing 110 has an air duct for exhaust gas to pass through. A deconta

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap