Heat exchanger for power-electronic components

a technology of heat exchanger and power-electronic components, which is applied in the direction of cooling/ventilation/heating modification, tubular elements, lighting and heating apparatus, etc., can solve the problems of limited cooling performance compared to water cooling, restrict the application of two-phase cooling systems in power-electronic systems, etc., to increase the current rating of power-electronic systems, increase the efficiency of heat exchangers, and increase the effect of losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]In the following, various aspects and embodiments of the invention are described. It is intended that each of the aspects, whether described in the context of a particular embodiment or of other features or not, can be combined with any other aspect.

[0027]In the figures and the following description, the same reference numbers are used for analogous elements, and the description of any embodiment relating to the same reference sign is applicable to any other embodiment unless mentioned otherwise and / or unless the description would be inconsistent with that embodiment.

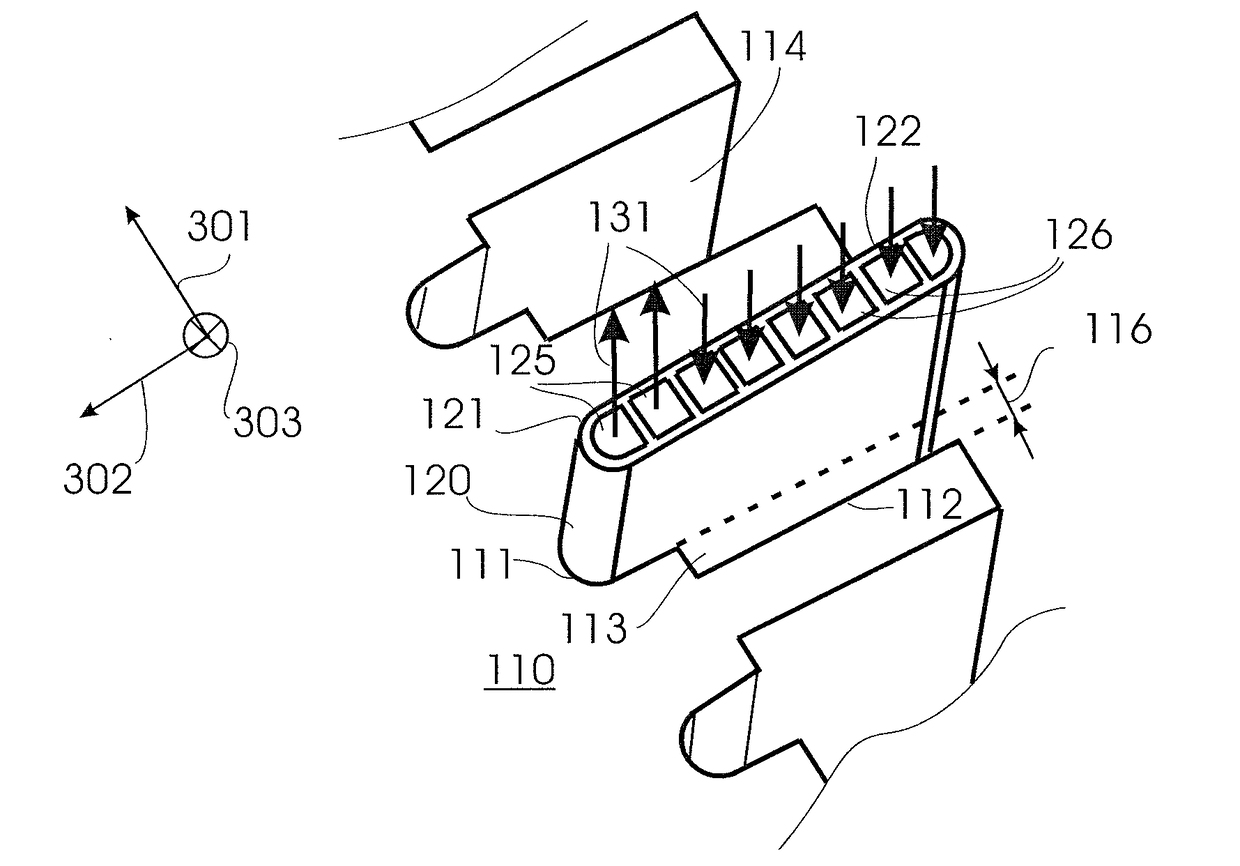

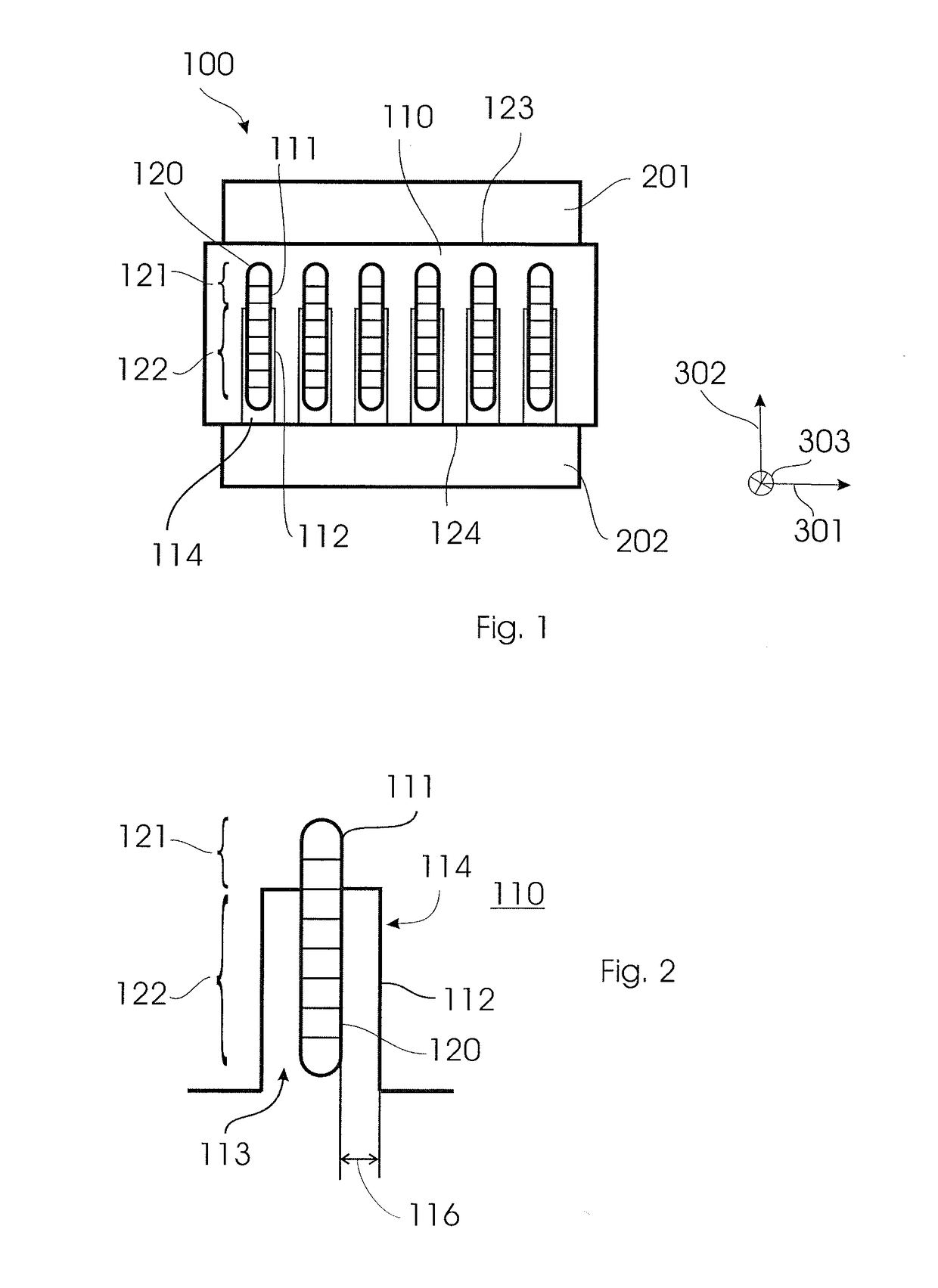

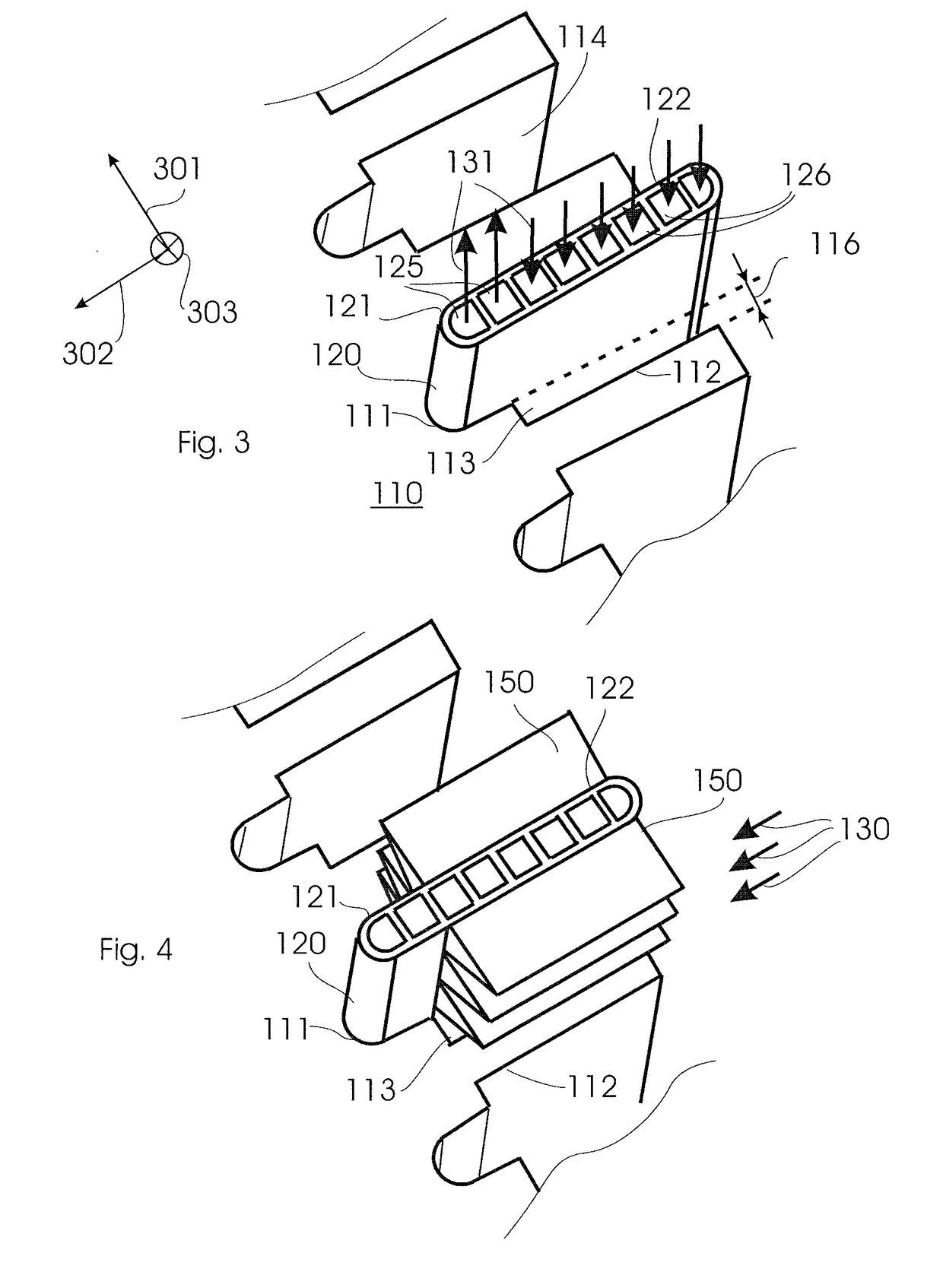

[0028]FIG. 1 shows a two-phase heat exchanger device 100 according to embodiments described herein. The heat exchanger device 100 is exemplarily shown in FIG. 1 as being stacked between two semiconductor modules 201 and 202. Typically, the heat exchanger device 100 and the two semiconductor modules 201, 202 are stacked in a stacking direction 302 as can be seen in the coordinate system in FIG. 1. According to some

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap