Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7 results about "Naphtha" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Naphtha (/ˈnæpθə/ or /ˈnæfθə/) is a flammable liquid hydrocarbon mixture. Mixtures labelled naphtha have been produced from natural gas condensates, petroleum distillates, and the distillation of coal tar and peat.

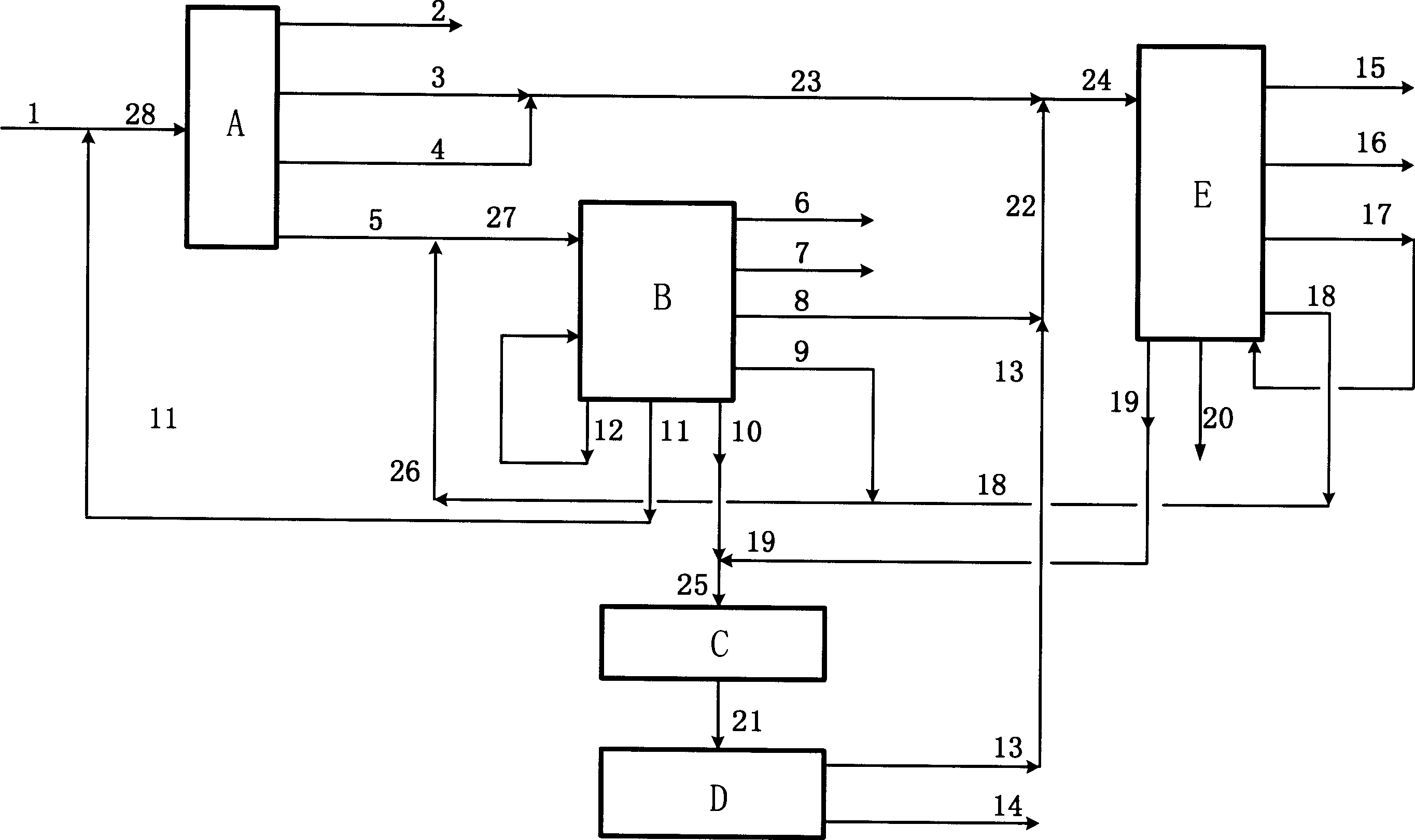

Method and device for preparing low carbon olefine and arene

Owner:CHINA PETROLEUM & CHEM CORP +1

Furnace coil fins

ActiveUS20120251407A1Thermal non-catalytic crackingChemical/physical/physico-chemical reactor detailsNaphthaGreenhouse

The present invention provides low profile, thick (“stubby”) longitudinal fins having a cross section which is a parallelogram, trapezoid or a triangle extending from 10% to 100% of a coil pass and comprising from 3 to 45 weight % of a coil in a radiant section of a furnace for thermally cracking one or more of paraffins and naphtha. The fins provide an additional surface through which heat may be transferred to the coil making the coil more efficient reducing greenhouse emissions.

Owner:NOVA CHEM (INT) SA

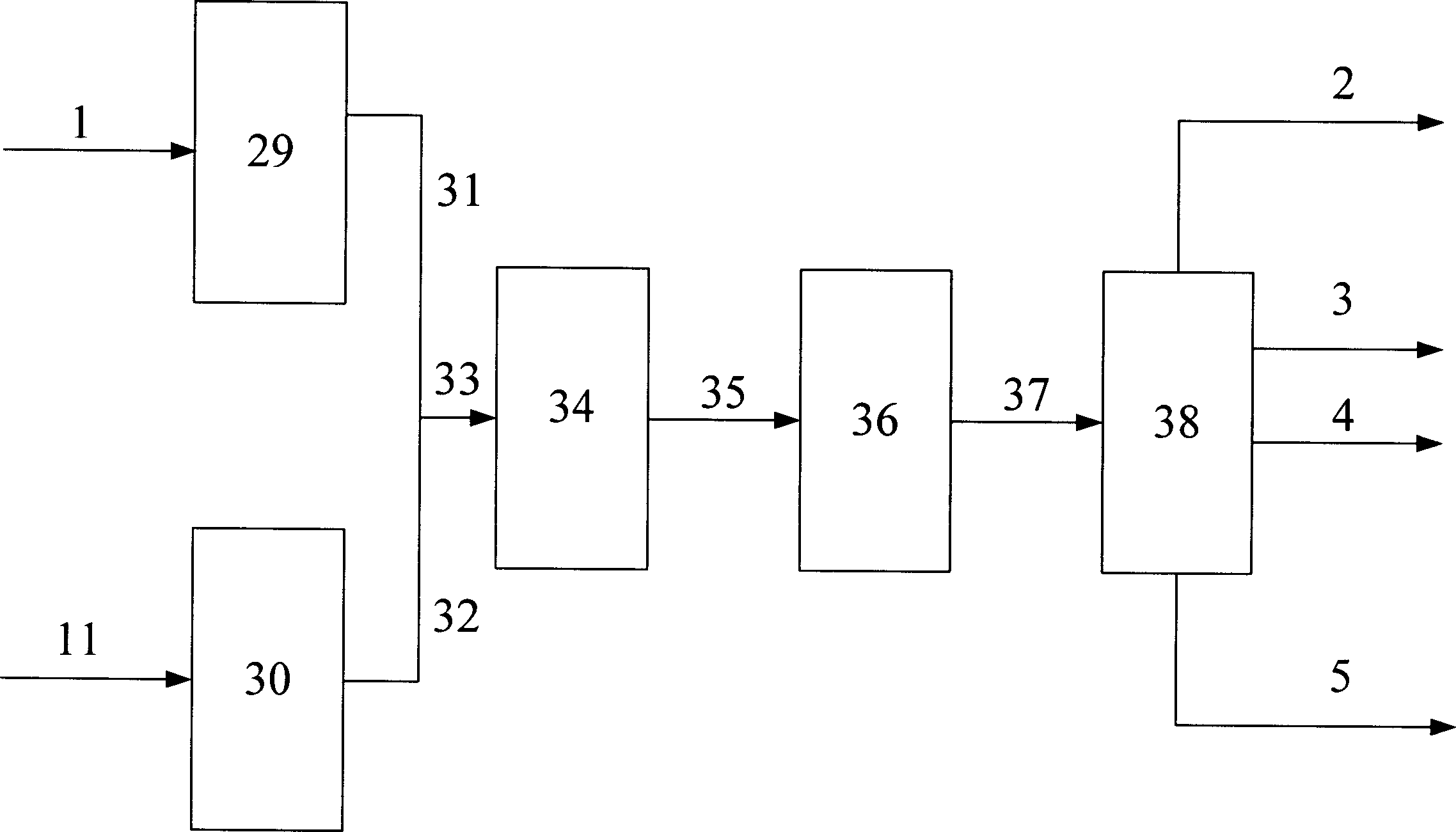

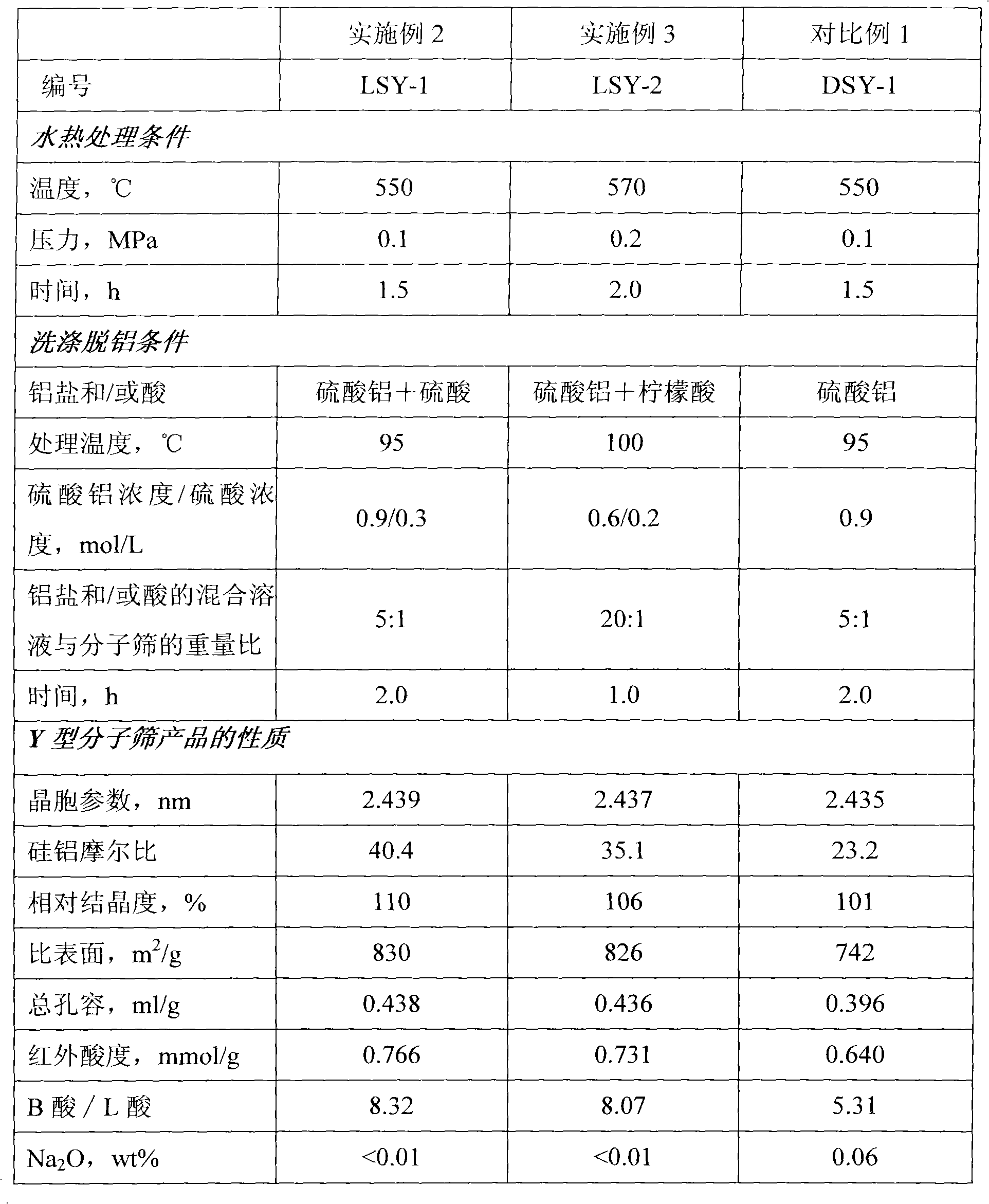

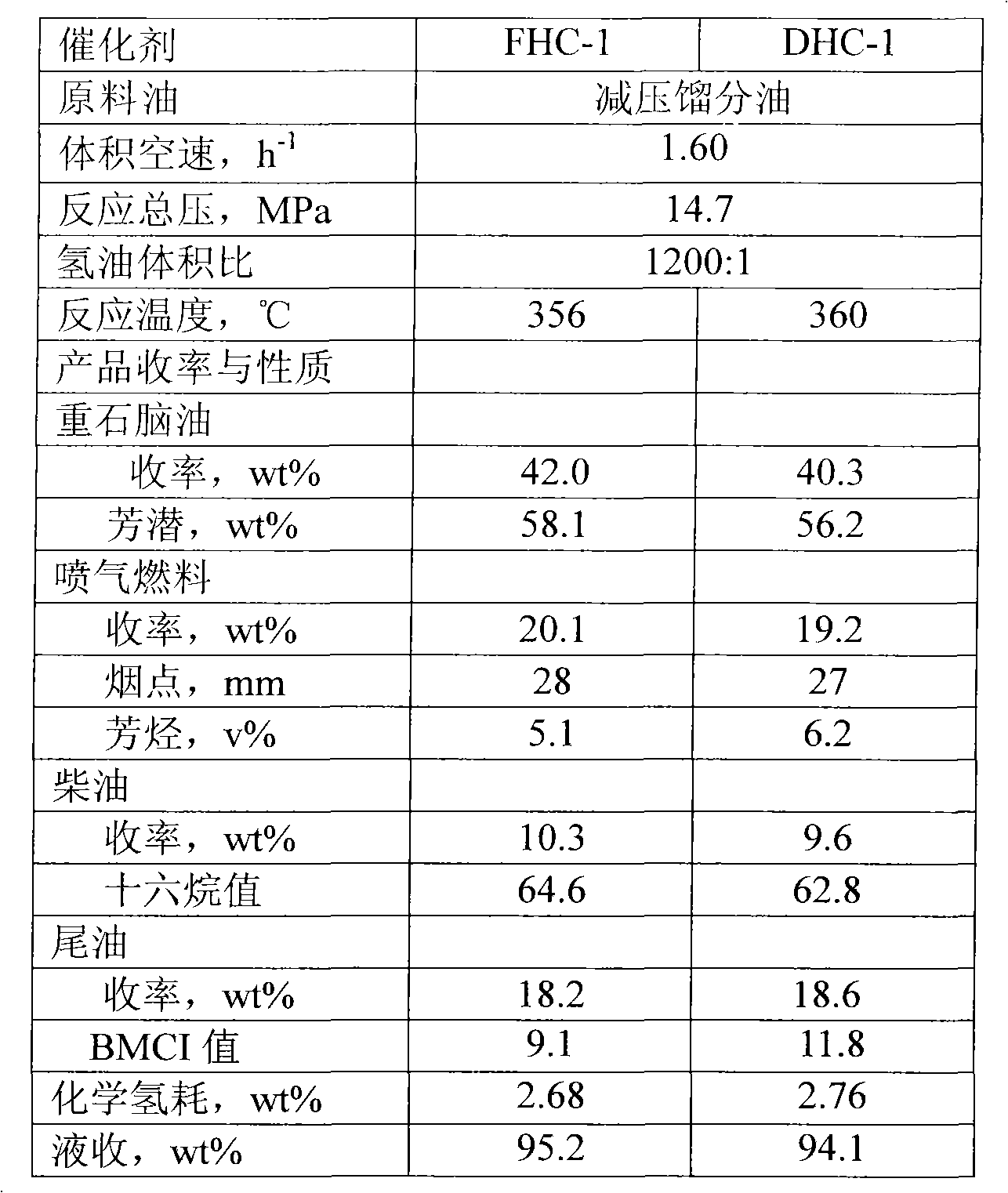

Y-type molecular sieve-containing hydrocracking catalyst carrier and preparation method thereof

ActiveCN101618347AHigh ratio of silicon to aluminumLarger than surfaceCatalyst carriersMolecular sieve catalystsCrystallinityCell parameter

Owner:CHINA PETROLEUM & CHEM CORP +1

Naphtha Reforming Catalyst and Preparation Method Thereof

ActiveUS20160051969A1High aromatization activityRaw materials are cheapCatalytic naphtha reformingCatalyst activation/preparationHalogenNaphtha

Owner:CHINA PETROCHEMICAL CORP +1

Environment-friendly ceramic coating material for water faucet

InactiveCN106189561ACorrosion resistantWear-resistantAnti-corrosive paintsCarbon fibersPolybutylene terephthalate

Owner:朱燕华

Methanol gasoline

InactiveCN106957697ALow costImprove performanceLiquid carbonaceous fuelsFuel additivesGasoline fuelAntioxidant

Owner:泸州清大能源股份有限公司

Walling glue prepared by adopting waste materials and preparation method thereof

InactiveCN101580696ASave dataImprove adhesionNatural rubber adhesivesNon-macromolecular adhesive additivesPolymer sciencePolystyrene

Owner:北京道顺国际技术开发有限责任公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap