Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Small hole" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

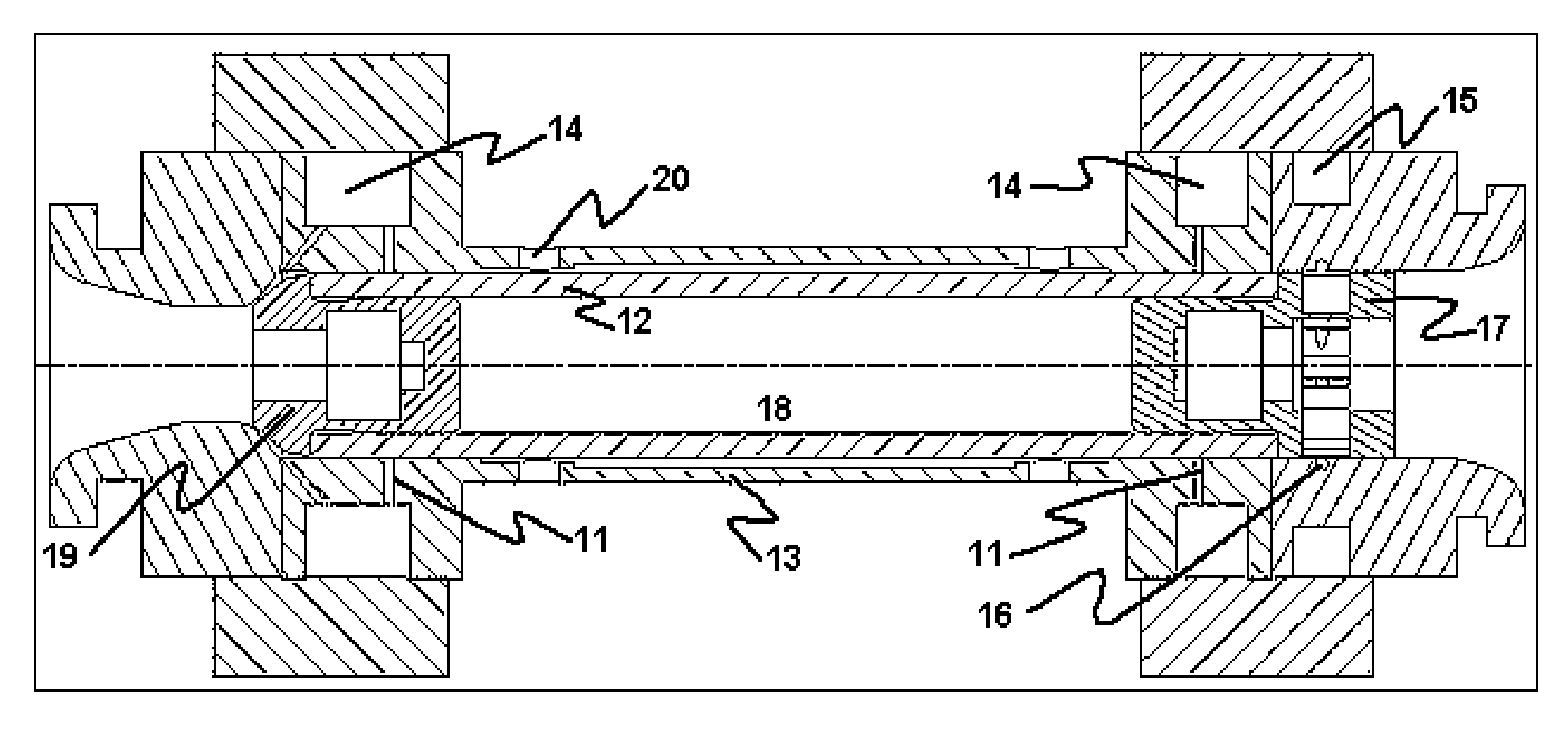

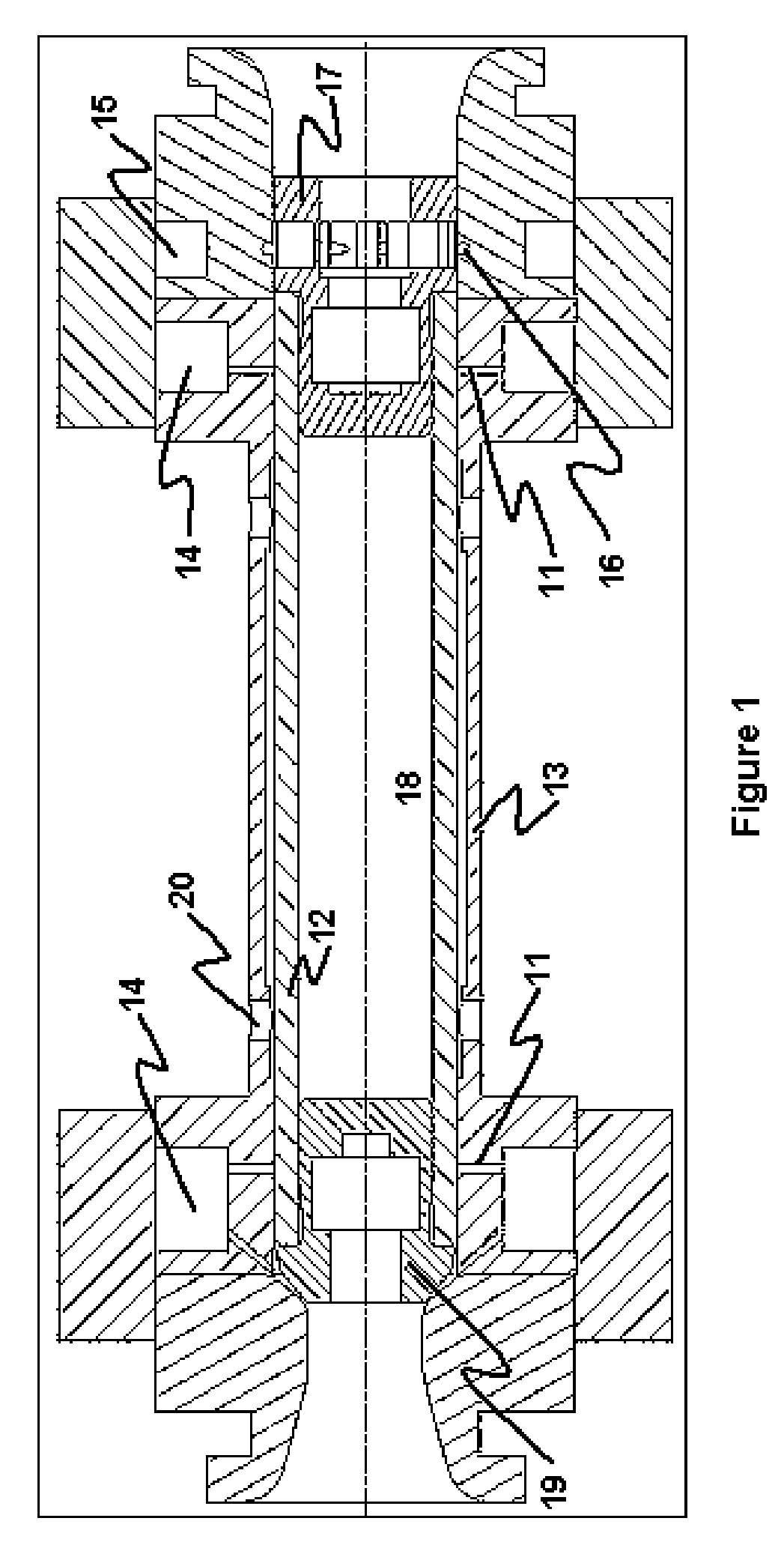

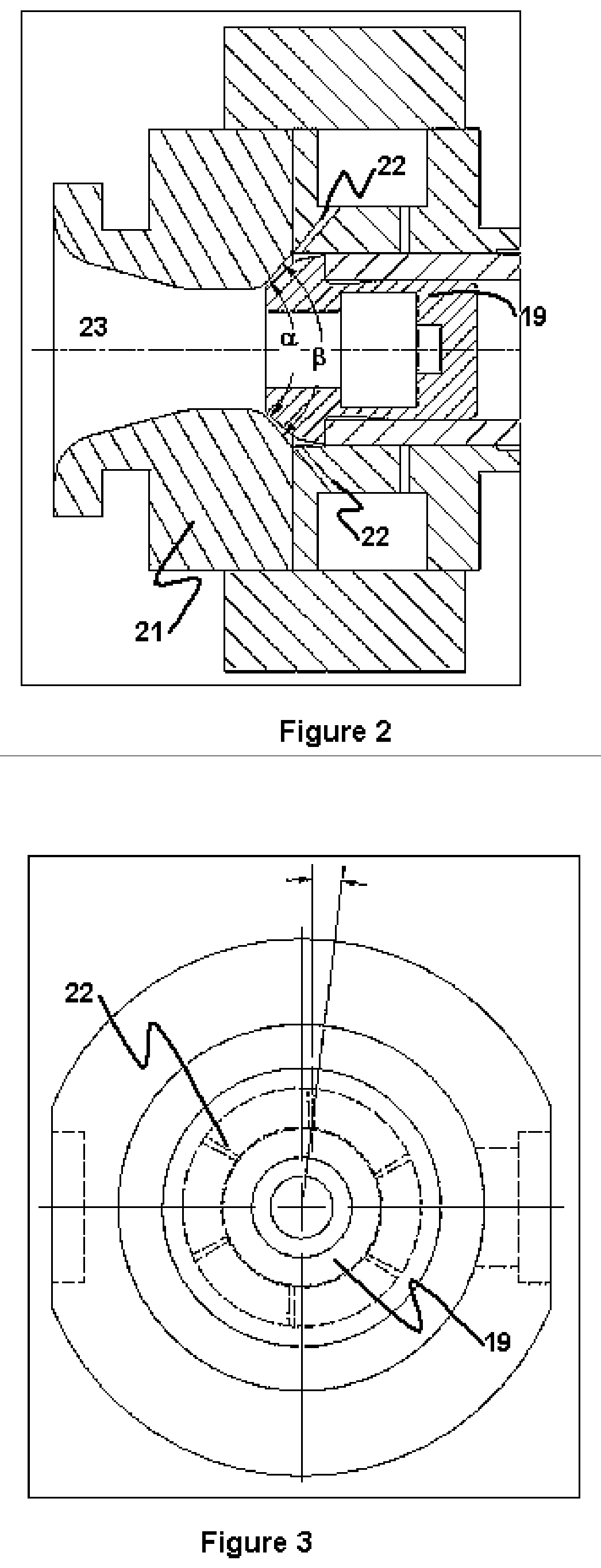

NMR MAS inflow bernoulli bearing

ActiveUS20060082371A1Improve stabilityIncrease stiffnessMagnetic circuit rotating partsMagnetic measurementsAxial pressureSurface velocity

Owner:DOTY SCI

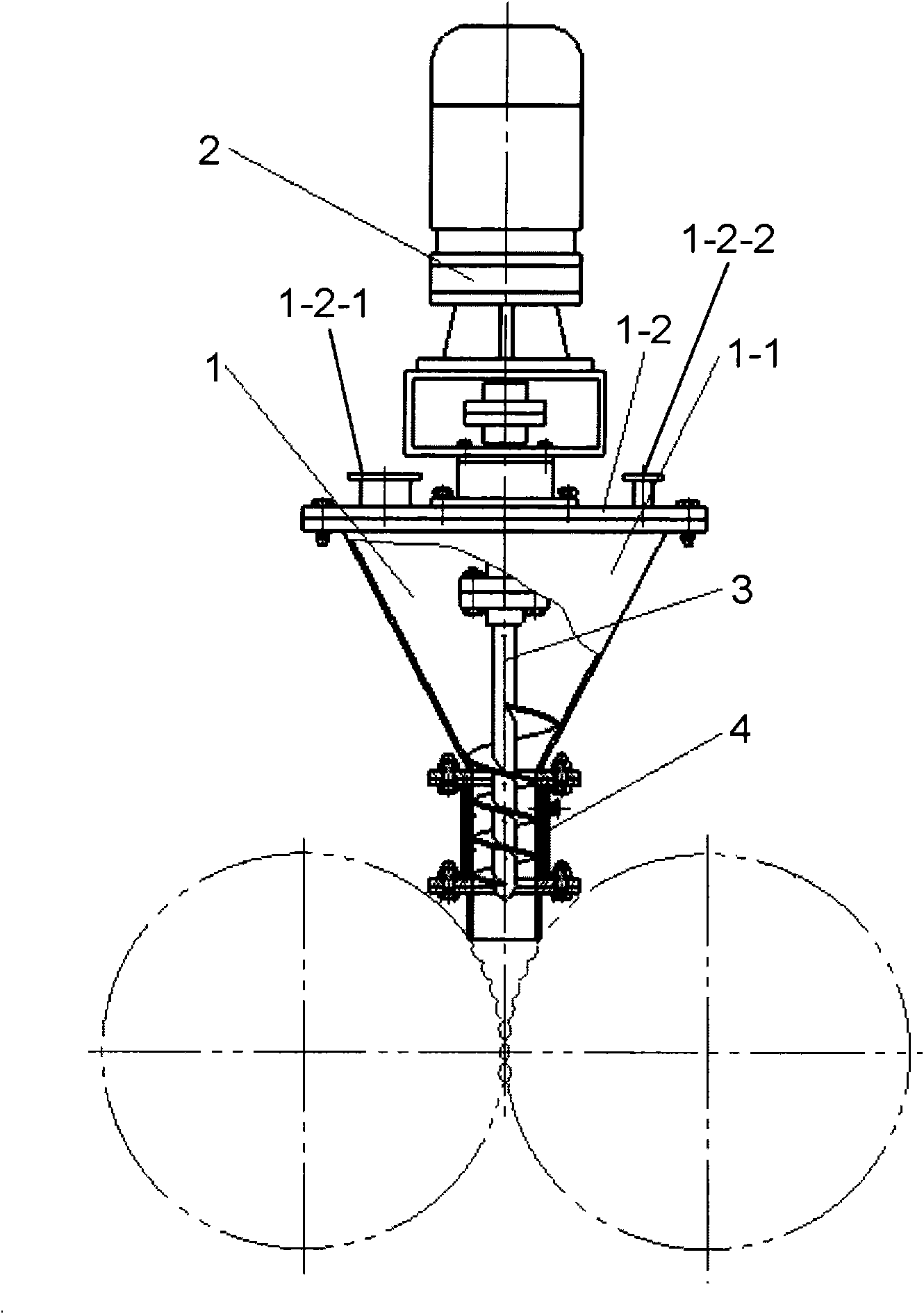

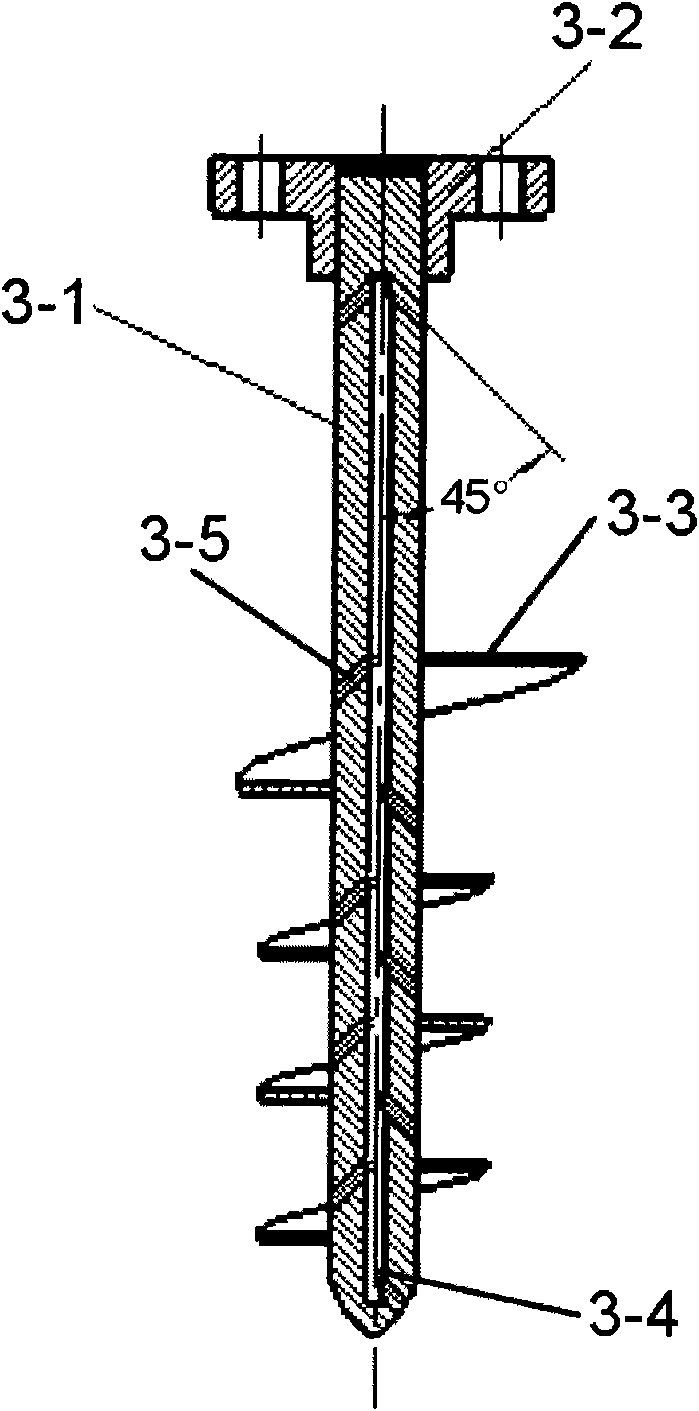

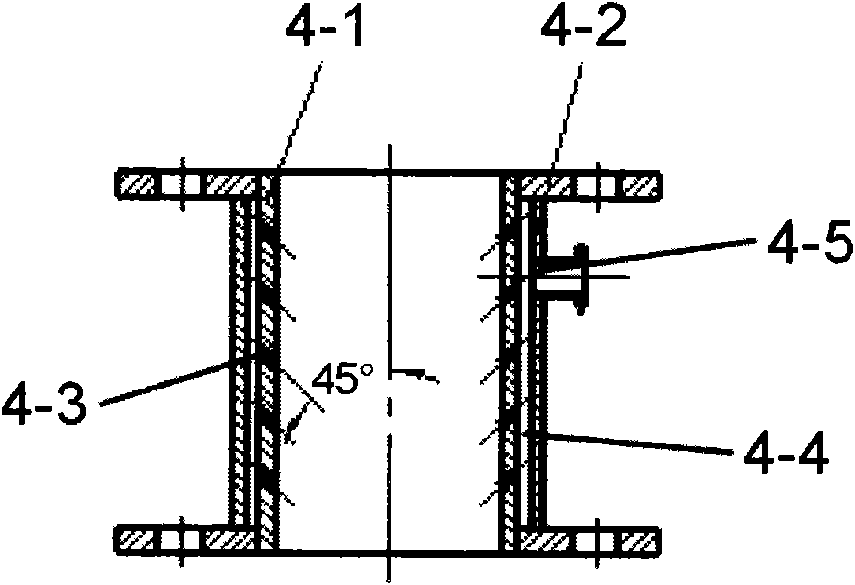

Spiral forced-feeding device, shaping system with same and degassing method

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

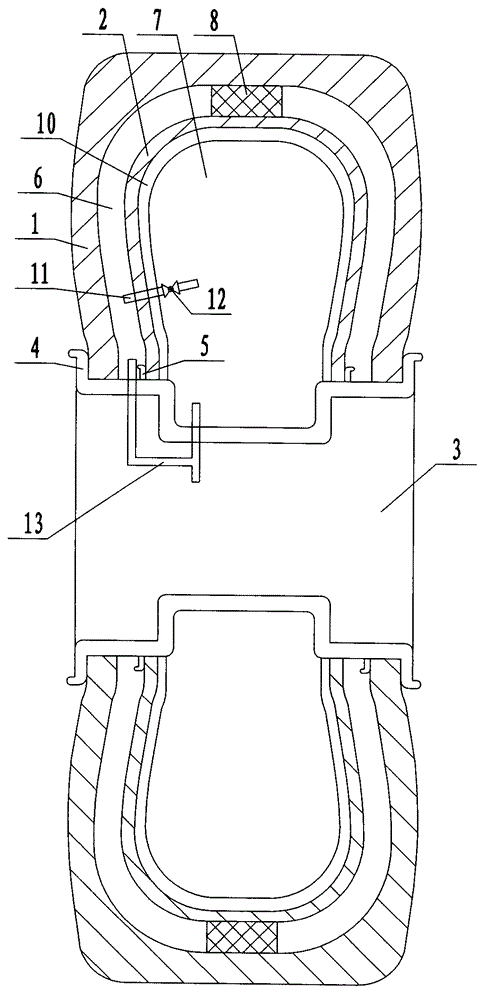

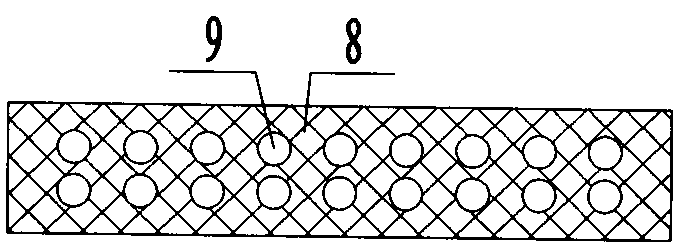

Blowout proof tire

InactiveCN104890452AAvoid loss of life and propertyImprove driving safetyTyre partsEngineeringCheck valve

Owner:卞婧

Non-contact diameter measuring instrument based on LED light source

The invention provides a measuring device for detecting the diameter, thickness and other information of an object in a non-contact manner based on an LED light source. A diameter measuring instrumentis composed of an LED light source parallel light tube, a linear array CCD sensor and an image processing system. A measured object is placed between the LED light source parallel light tube and thelinear array CCD sensor for non-contact measurement. An LED (Light Emitting Diode) produces parallel light after passing through a series of optical lenses and small holes, and the parallel light hitsthe measured object and is finally projected to the linear array CCD sensor. The linear array CCD sensor converts an optical signal into an electrical signal. The digital image processing system processes the electrical signal, and displays the processing result through a display system.

Owner:王威立

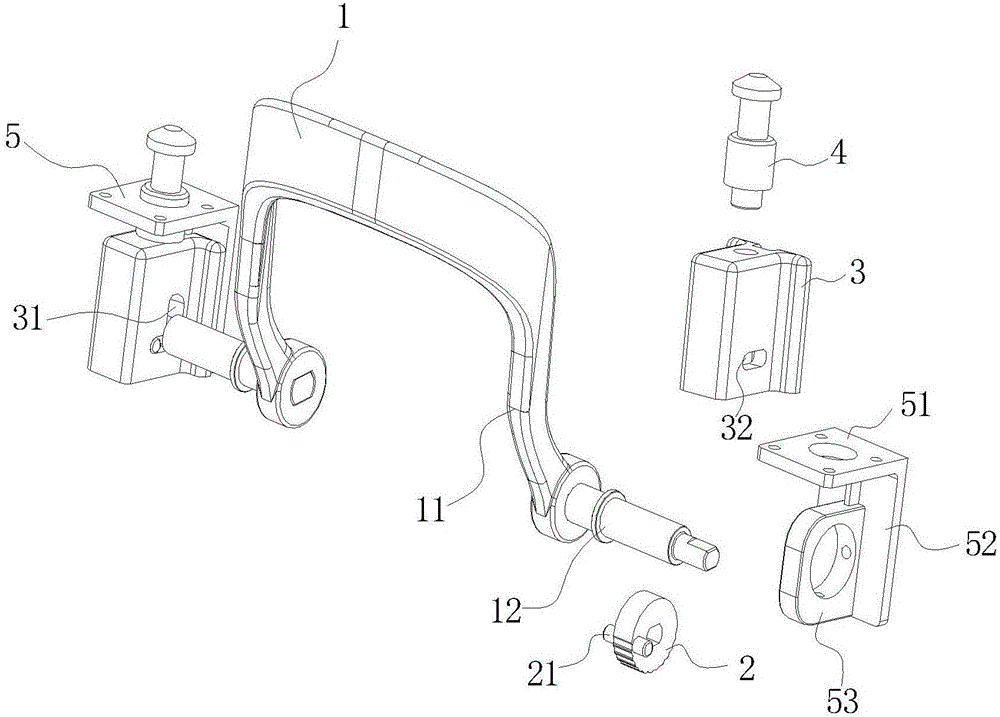

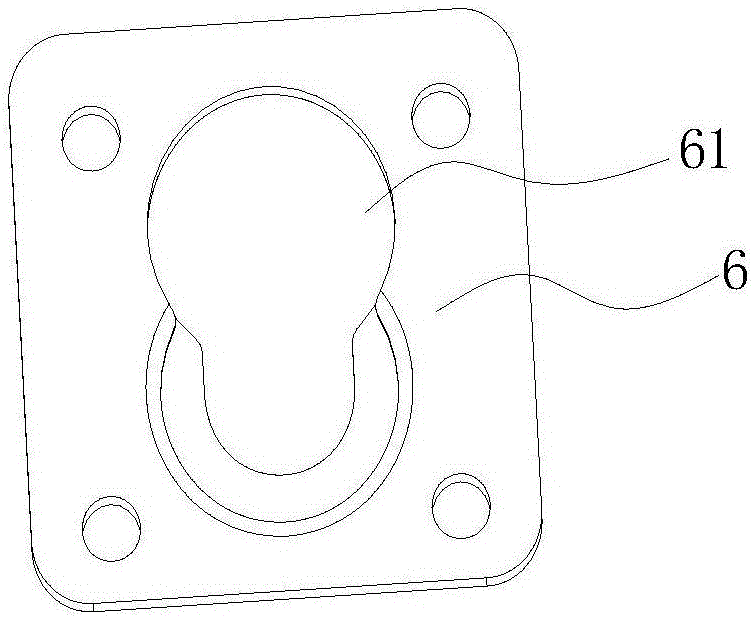

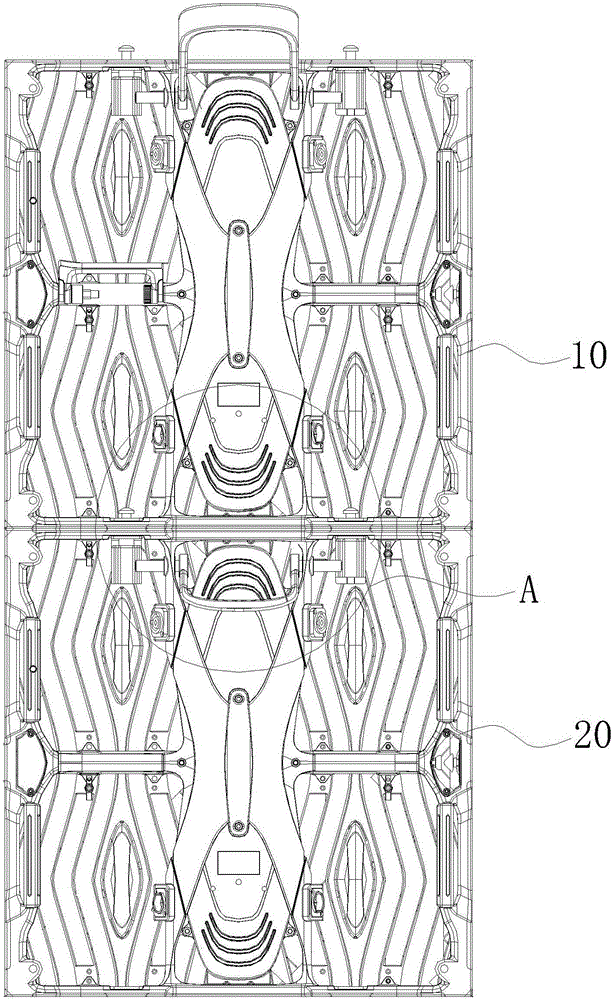

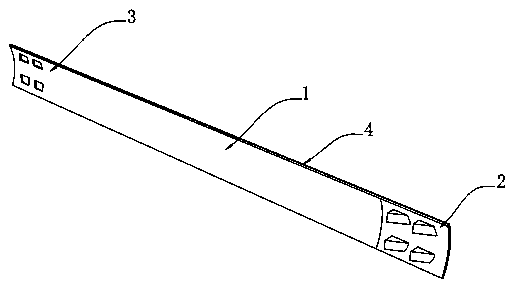

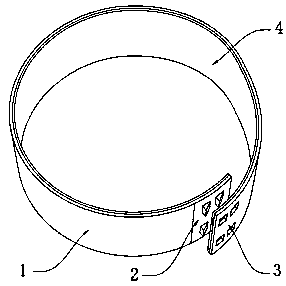

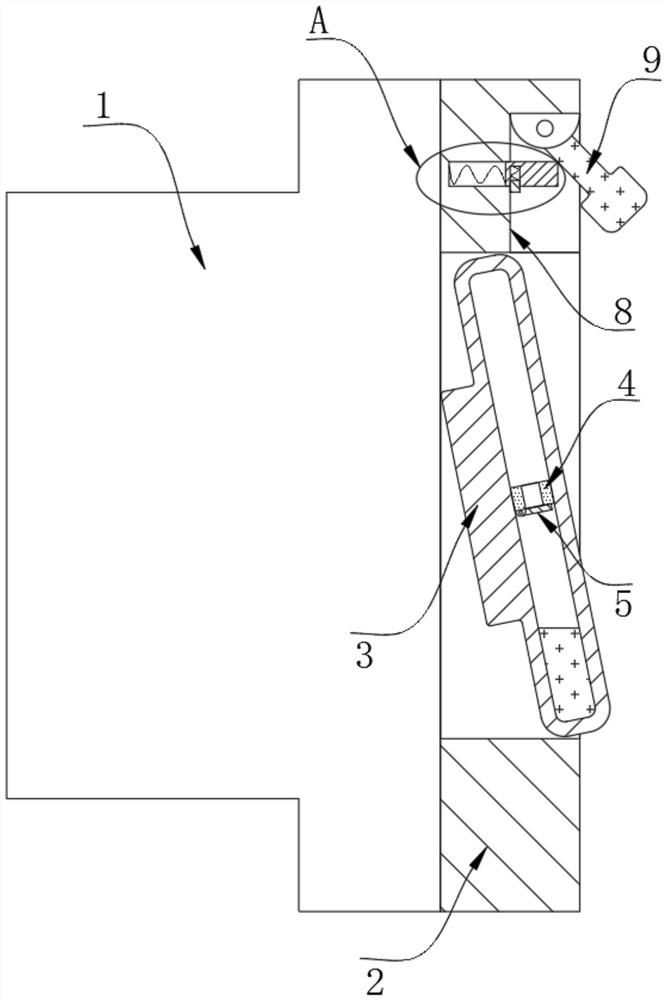

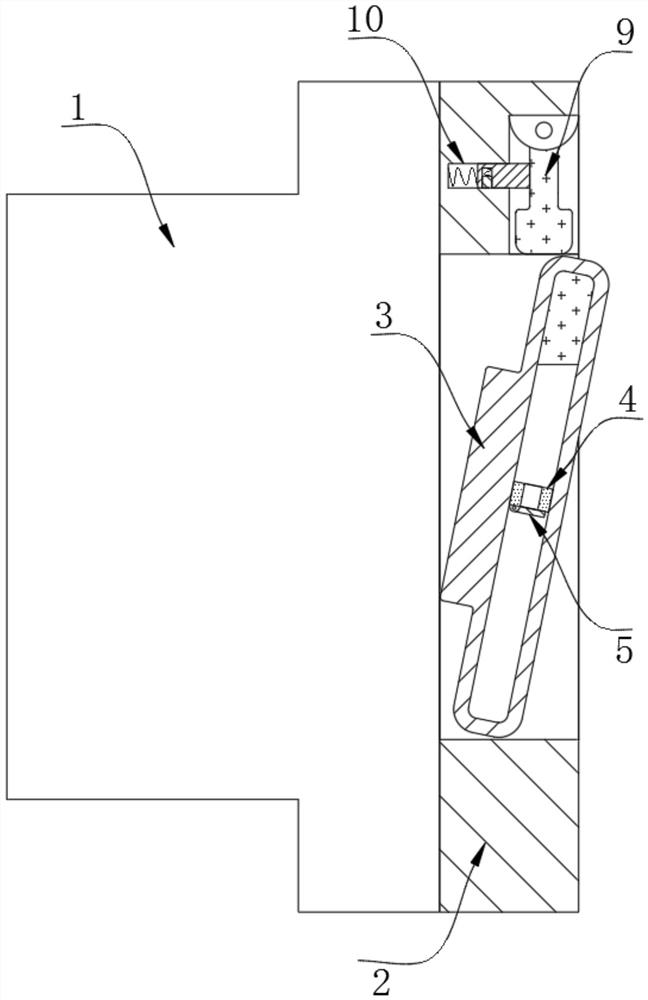

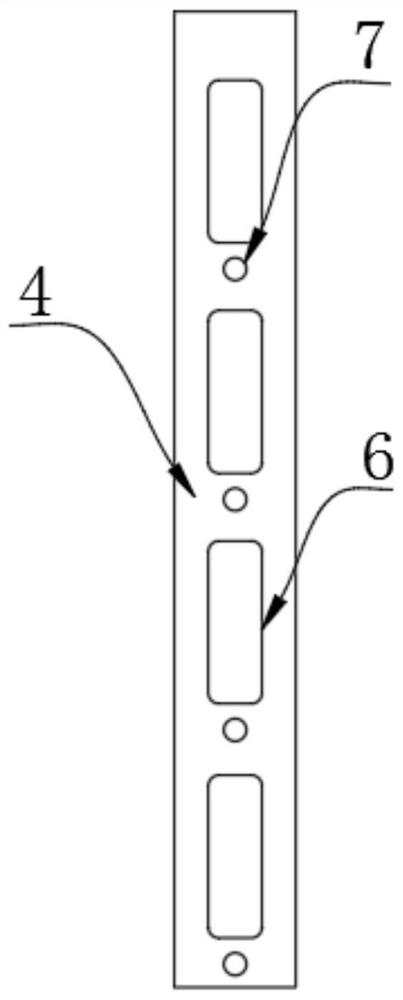

Locking device and LED display screen

Owner:SHENZHEN LIGHTLINK DISPLAY TECH

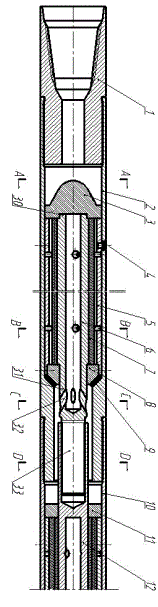

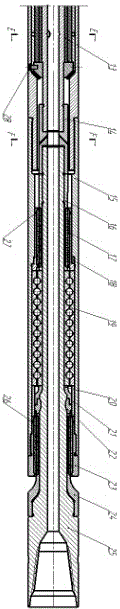

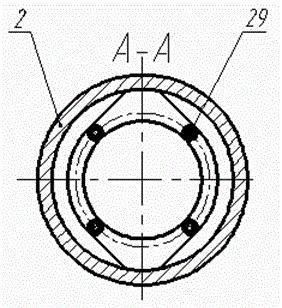

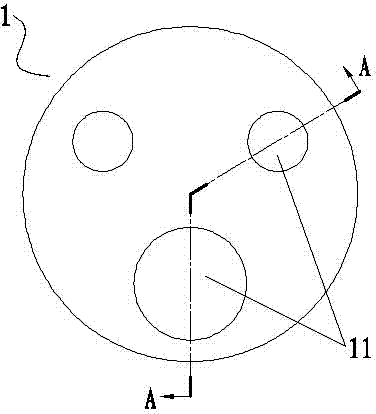

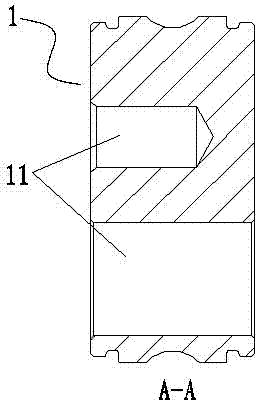

Coaxial all-metal cam stator and rotor underground dynamical drilling tool

Owner:XI'AN PETROLEUM UNIVERSITY

Combination gauge for abnormal bearing inner ring pore detection and detection method thereof

Owner:BH TECH GRP CO LTD

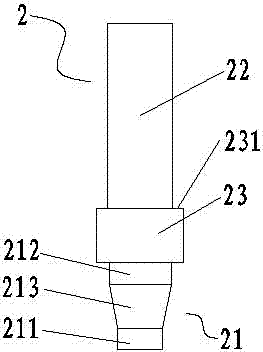

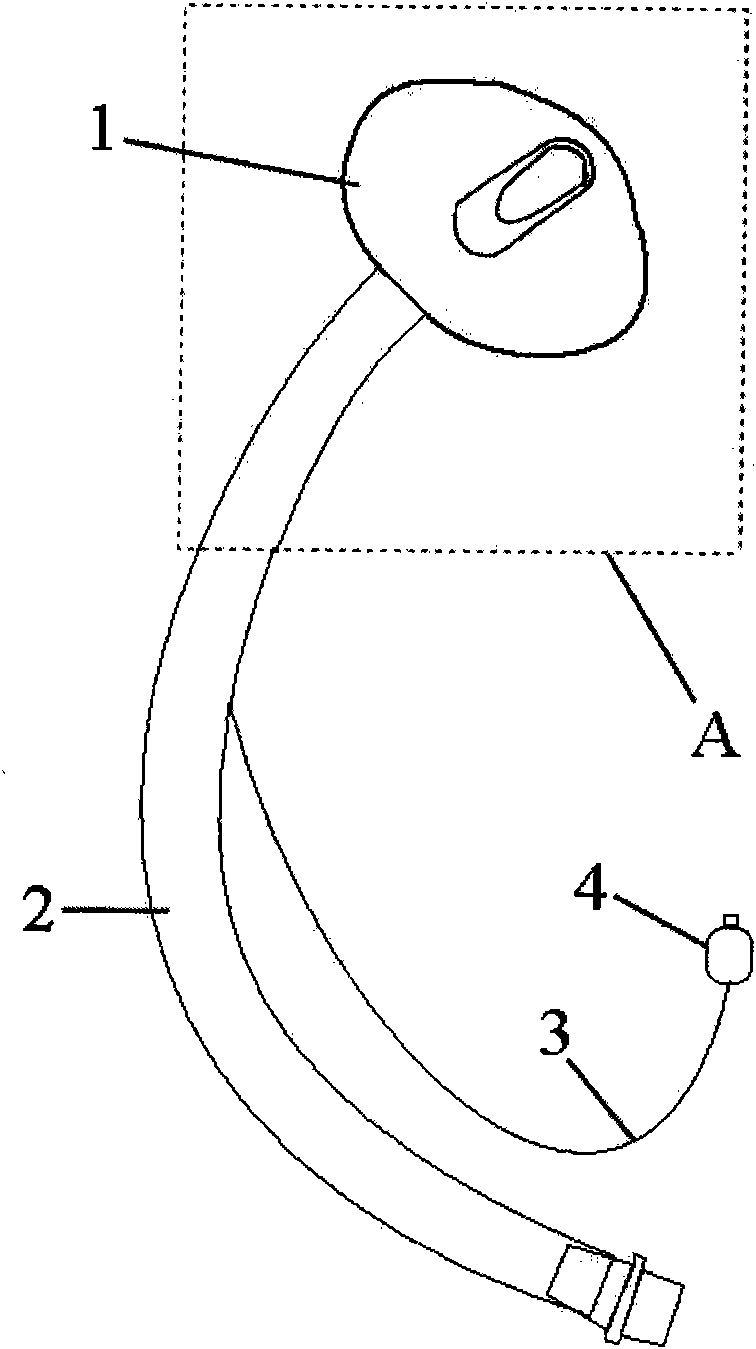

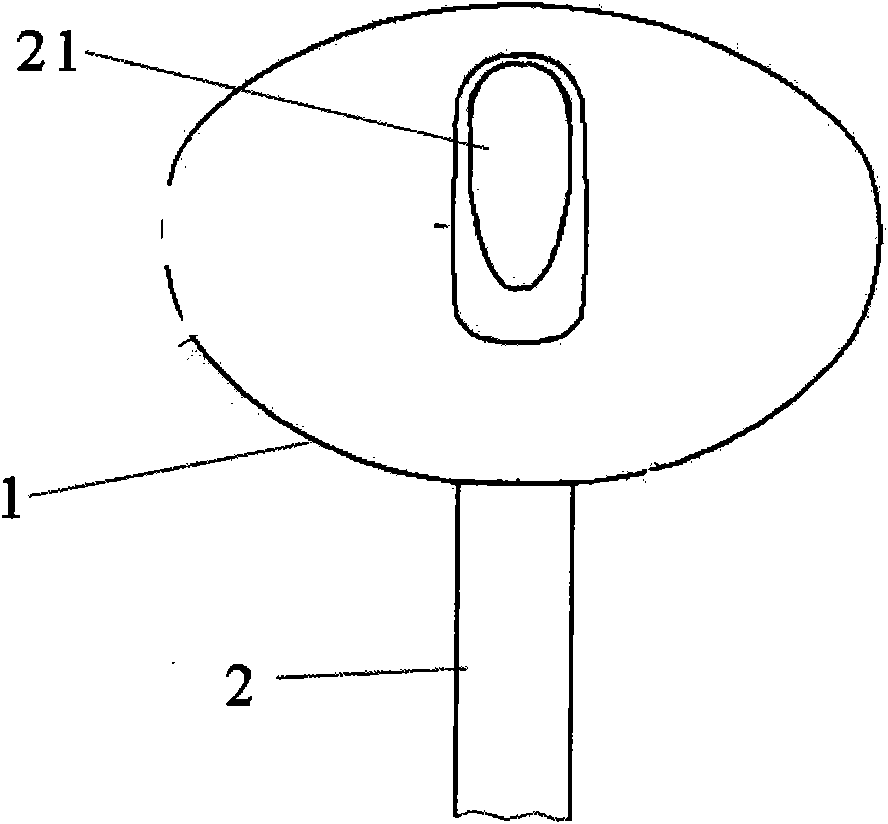

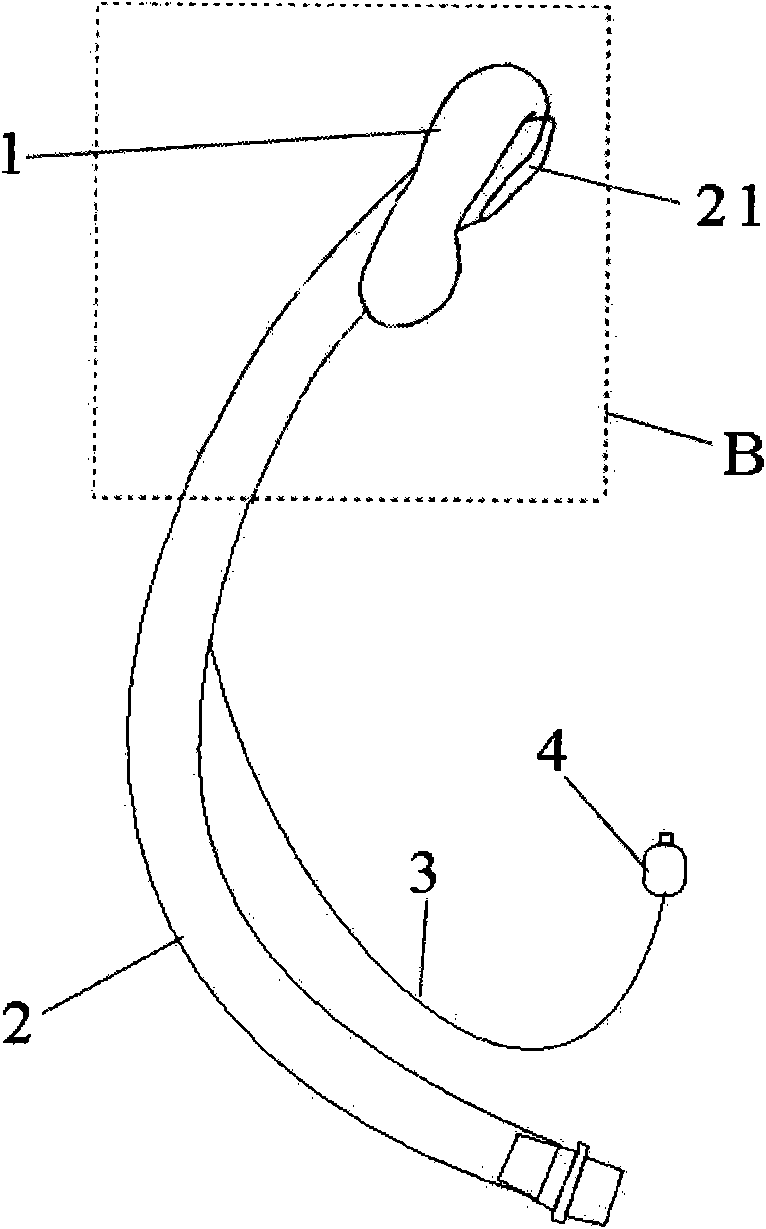

Transnasal laryngeal mask

Owner:同济大学附属同济医院

Pollination device for orchid

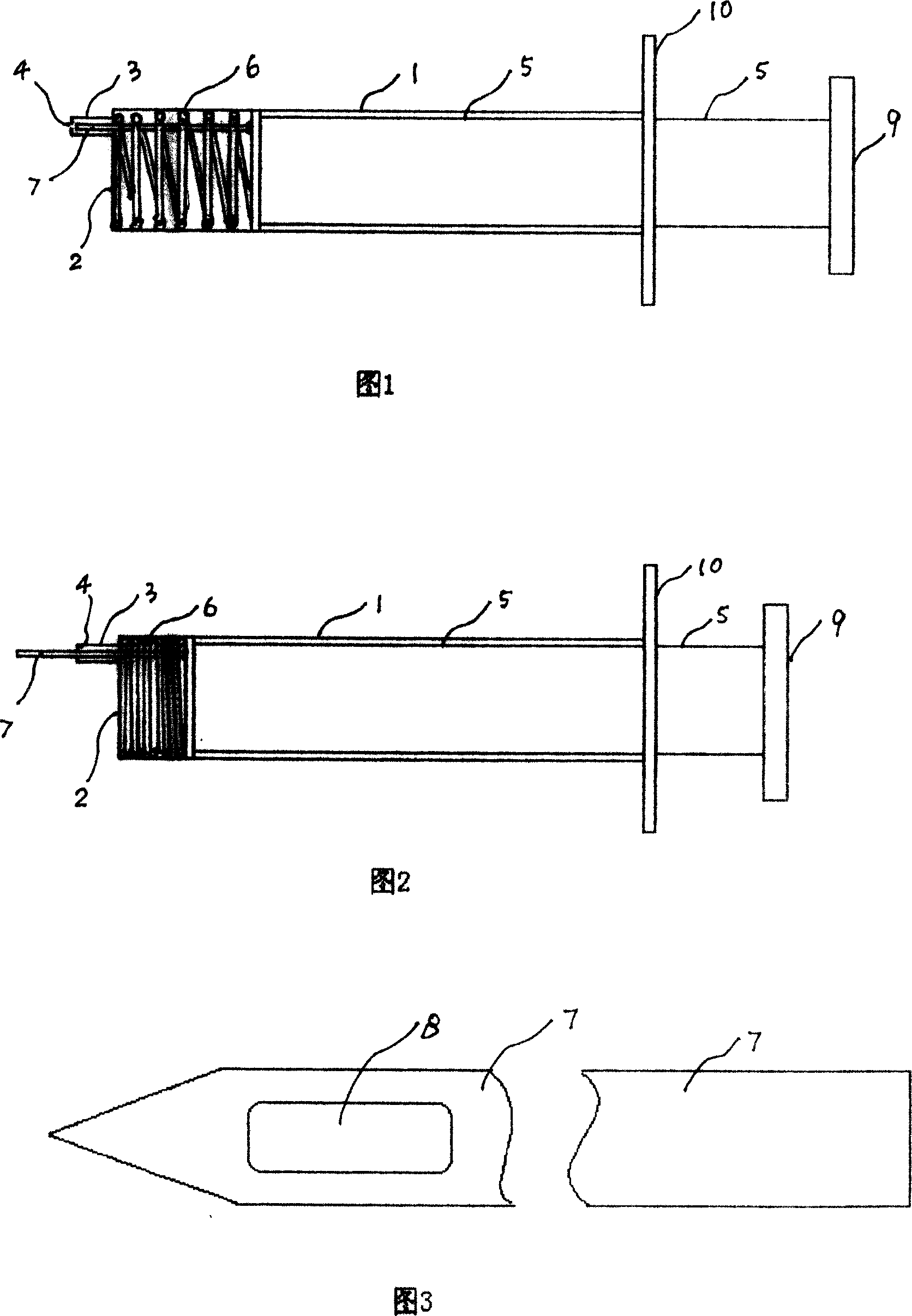

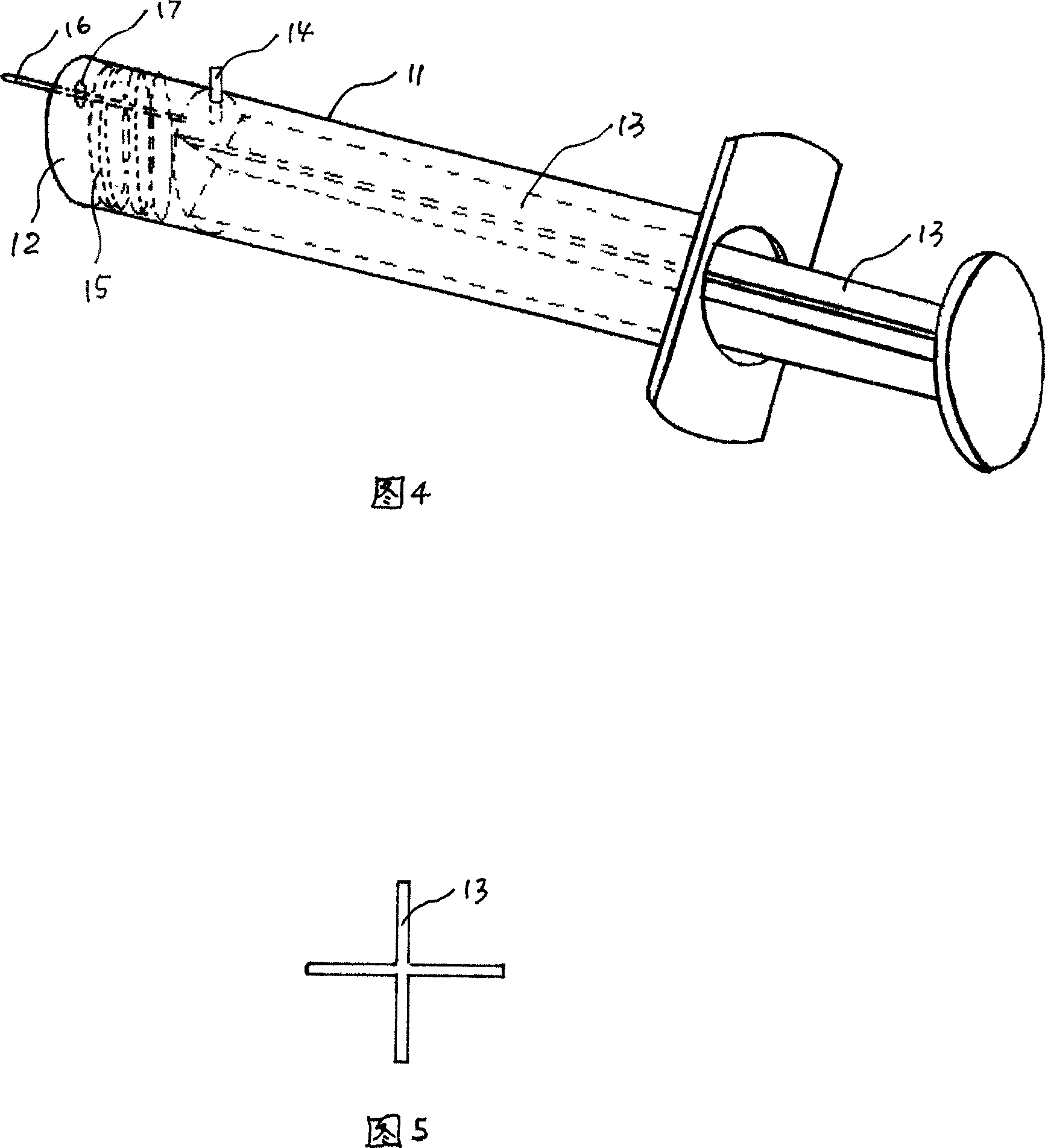

InactiveCN100998310ASolving the Problems of Sexual ReproductionSimple structurePlant genotype modificationPollenPollination

Owner:YUNNAN UNIV

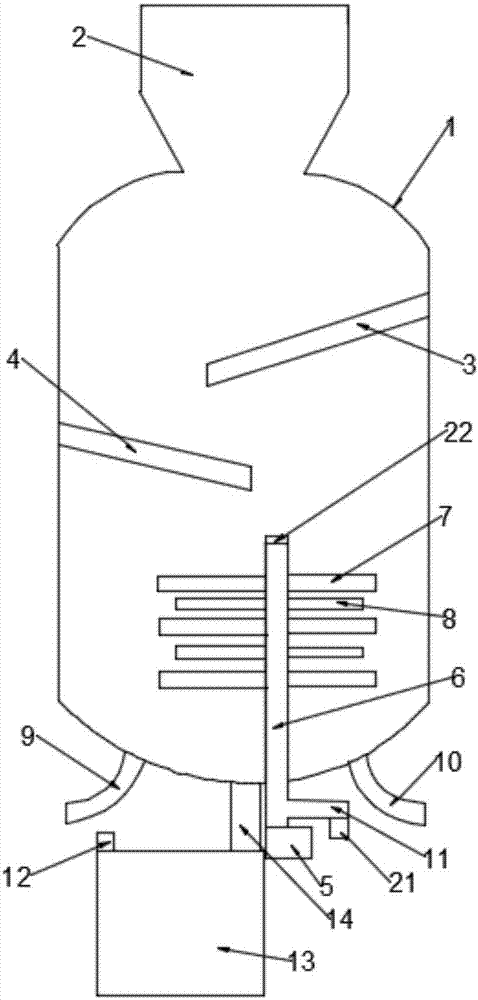

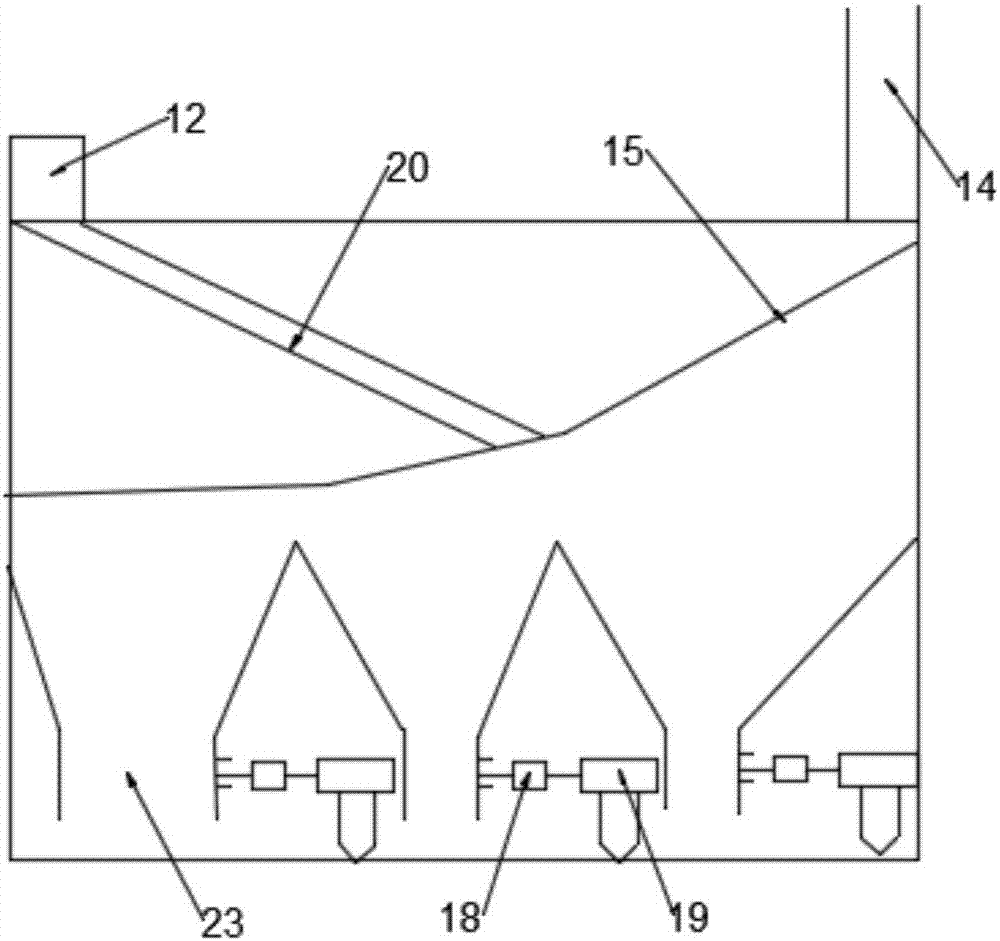

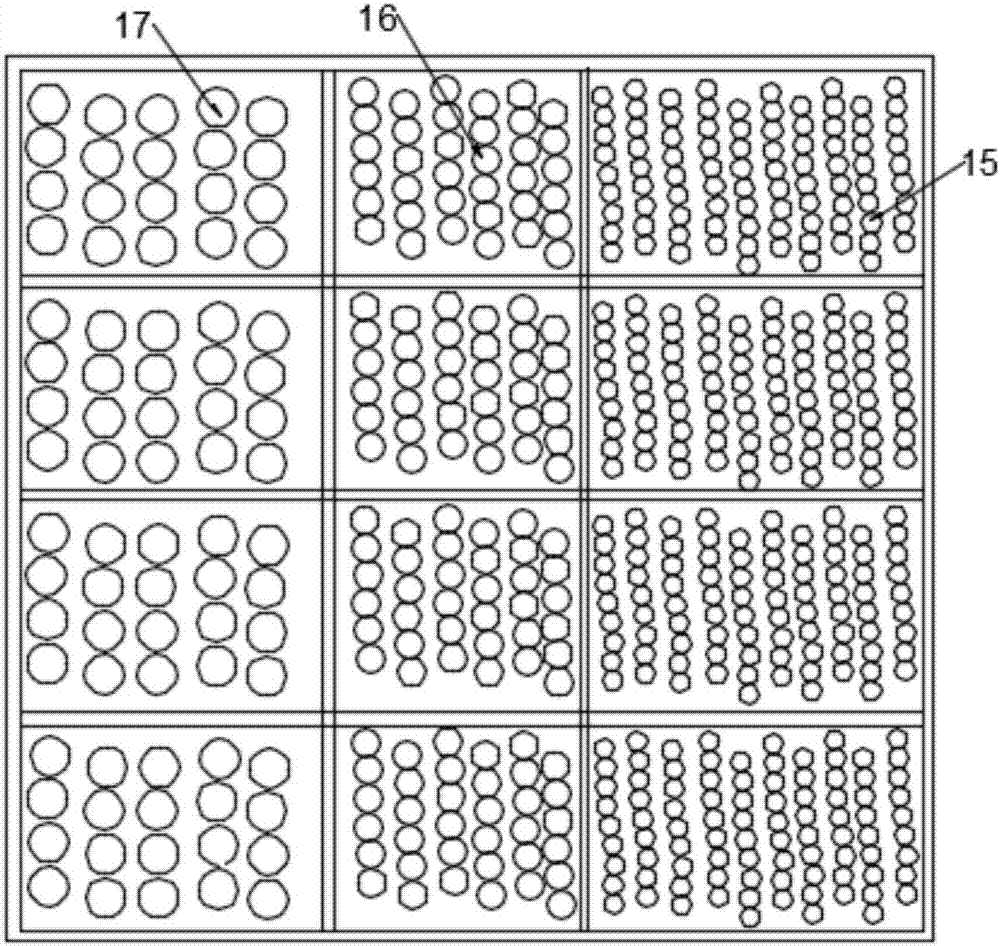

Wastewater treatment device

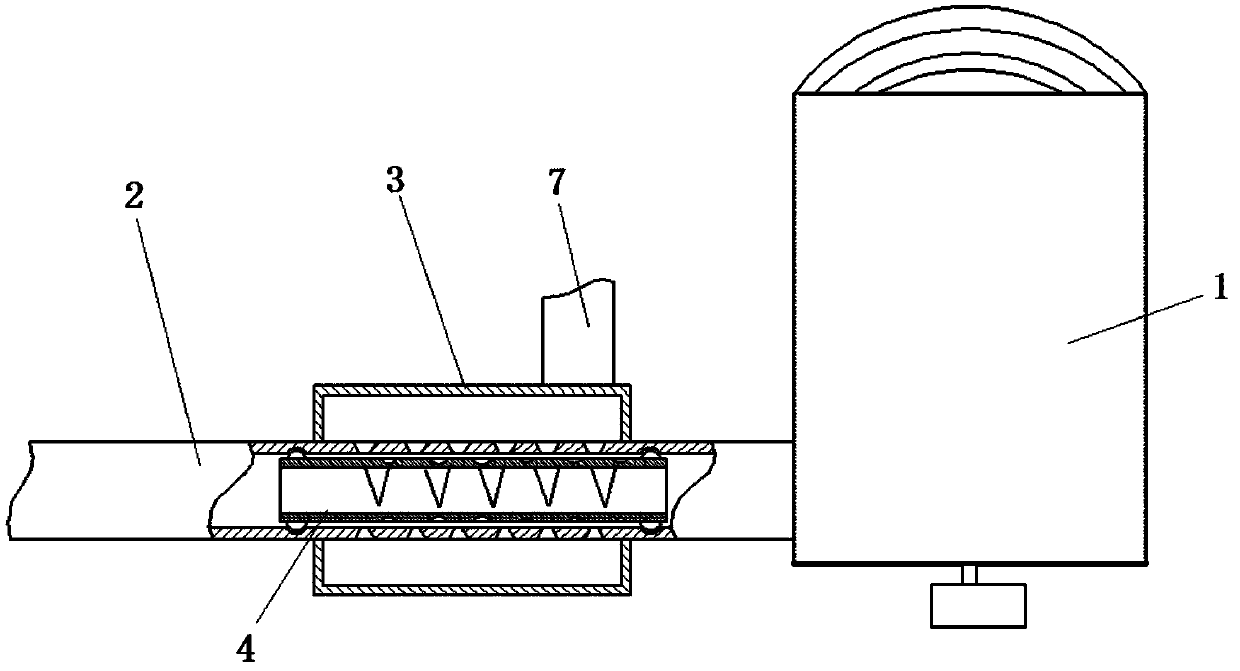

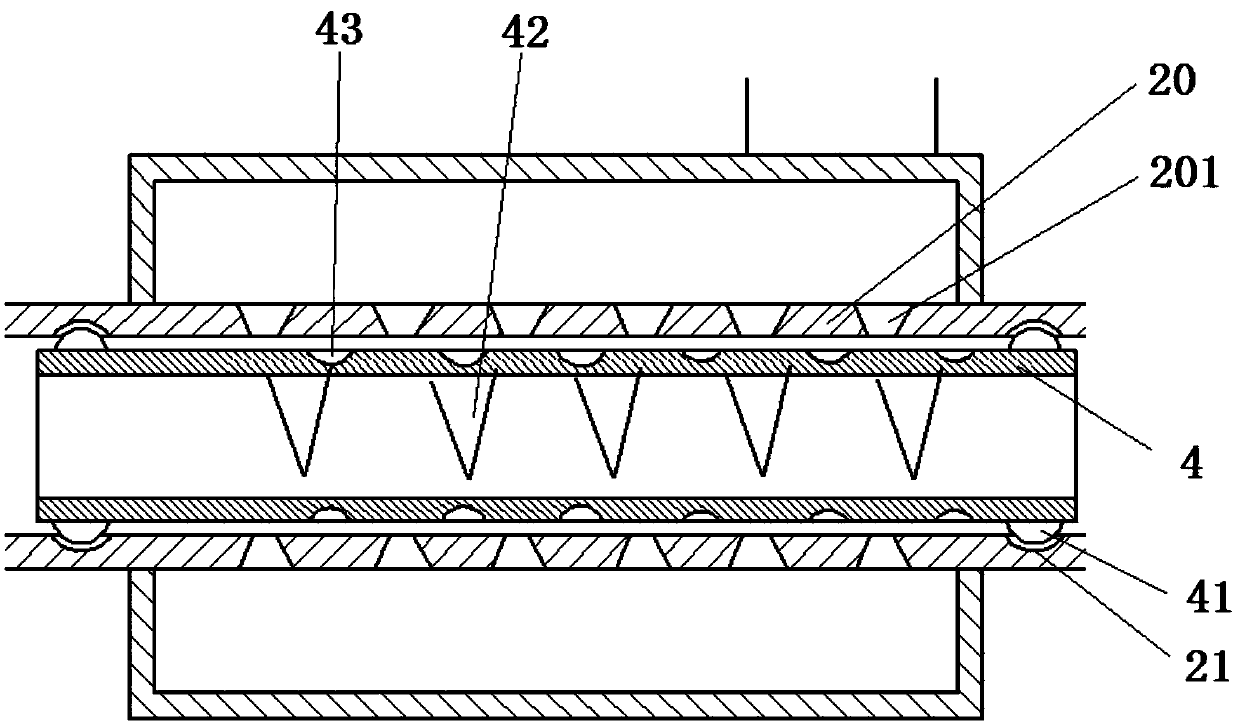

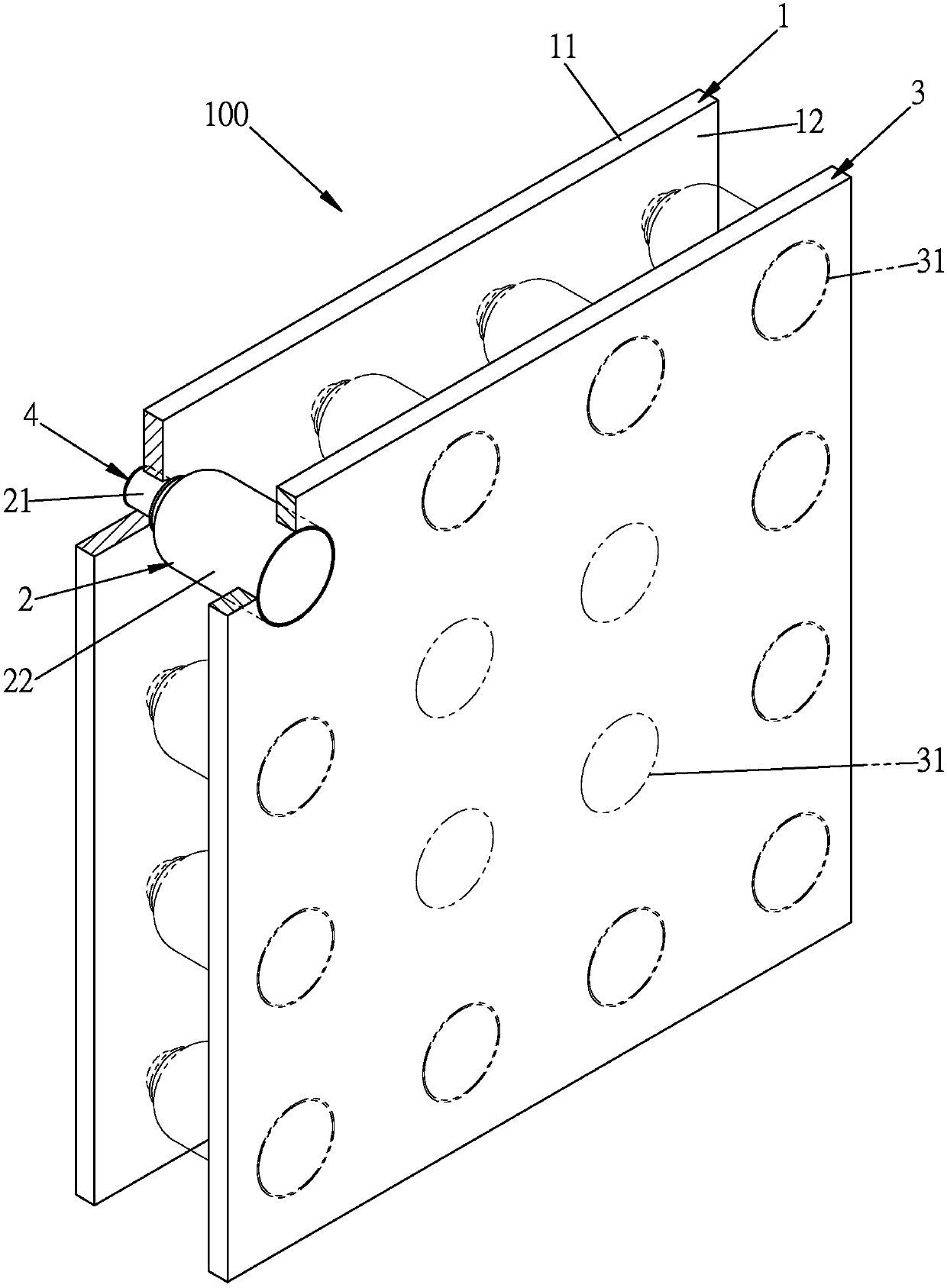

ActiveCN109621544AAvoid cloggingEffective placement of clogsFiltration circuitsKnife bladesSmall hole

The invention relates to the field of filtration, and discloses a wastewater treatment device. The wastewater treatment device comprises a filtering device (1) and a pipeline (2), an external pipeline(3) sleeves a liquid inlet end of the pipeline (2), the external pipeline (3) is connected with a water conveying pipe (7), a plurality of small holes (201) are formed in the wall surface of a dredging pipeline (20), the small holes (201) are uniformly distributed in the dredging pipeline (20), and the diameters of the small holes (201) are gradually increased in the radial direction of the dredging pipeline (20); the wastewater treatment device further comprises a rotary cylinder (4). According to the wastewater treatment device, through helical distribution of the small holes and gradual decline of the diameters of the small holes, the pressure of water injected into the dredging pipeline is increased, action force is applied to the rotary cylinder in the dredging pipeline, so that therotary cylinder rotates, residual impurities are subjected to secondary treatment through rotating knife blades, and the situation that the pipeline is blocked by wastewater which is treated by a filter device is prevented. Through the structure, the filtered wastewater is subjected to secondary treatment, blocking of the pipeline is effectively prevented, the structure is reasonable, and the practicability is high.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Toad deep disease trenchless repair method based on foam geopolymer

InactiveCN112358245AReduce accumulationReduce the burden onSolid waste managementCement productionArchitectural engineeringGeopolymer

The invention discloses a road deep disease trenchless repair method based on a foam geopolymer. The road deep disease trenchless repair method comprises a road deep disease trenchless repair construction process and a corresponding foam geopolymer repair material. The trenchless repair construction process for the deep road diseases comprises a large-hole and small-hole spaced grouting method, main diseases are repaired by compacting, splitting and grouting large holes from bottom to top, and fine diseases are repaired by permeating small holes from top to bottom. The situation that waste iscaused by excessive grouting during single grouting, and some small cracks and holes are not effectively filled can be effectively avoided. The invention also provides a foamed geopolymer grouting material for road grouting reinforcement, the grouting material is divided into a component A and a component B, and has the characteristics of low density, high strength, good durability and no shrinkage after being cured, the density can reach 600-700kg / m<3>, and the 7-day compressive strength can reach 10-12MPa.

Owner:HUNAN COMM RES INST CO LTD

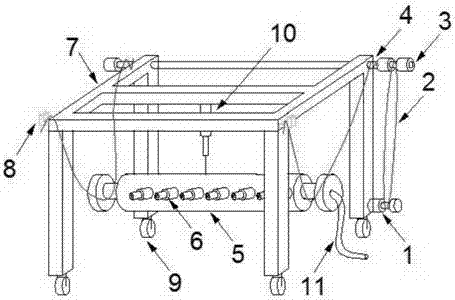

Cleaning type blackboard for teaching

InactiveCN107415548AQuick eraseEasy to removeBoard cleaning devicesWriting boardsEngineeringSmall hole

The invention relates to a blackboard, in particular to a cleaning type blackboard for teaching. According to the cleaning type blackboard for teaching, the blackboard can be cleanly and wholesomely wiped. The cleaning type blackboard for teaching comprises a fixed box and the like. An opening is formed in the front wall of the fixed box. Lower leaking holes are evenly formed in the bottom of the fixed box. A first blackboard is arranged on the inner top of the fixed box. A rotating moving device is arranged at the inner lower part of the fixed box. The rotating moving device is located on the lower portion of the blackboard. Fixing devices are connected with the left end and the right end of the rotating moving device. The top of the fixing device is connected with a supporting rod. A small hole is formed in the supporting rod. A blackboard eraser is arranged at the top end of the supporting rod. By means of the cleaning type blackboard for teaching, the effects of clean wiping and convenient cleaning are achieved, the first blackboard is wiped only needing to rotate a rotating rod, words on the blackboard can be quickly wiped off, and the fact that a user wipes the first blackboard more conveniently and fast is achieved.

Owner:江勇

Technology for producing paper pulp from biogas residues of fast anaerobic fermentation of straw

InactiveCN109505187AExpand the scope of useReduce utilizationWaste based fuelFermentationFiberPapermaking

Owner:黑龙江徐盛农业科技有限公司

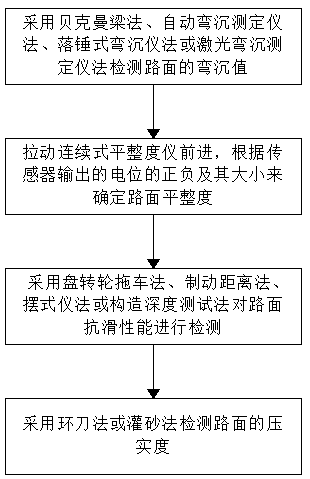

Method for detecting construction quality of crossing lane

InactiveCN110453577AResponsibilities are clearGuarantee the construction qualityRoads maintainenceData acquisitionRoad surface

Owner:广东茂冠达建设工程有限公司

Gigging fuse wire structure

InactiveCN103409831AStop the flowImprove insulation effectArtificial thread manufacturing machinesFilament/thread formingPunchingEngineering

Owner:SUZHOU HAOJIAN TEXTILE

Simple excrement drying and collecting device of toilet bowl

A simple excrement drying and collecting device of a toilet bowl is made from an aluminum product. Two barrels are manufactured into a drying device, one end of the first barrel is closed while the other end thereof is open, and the second barrel is of the same structure with one side open and the other side closed. An oval slot is formed on the outer periphery of each barrel transversely. The second barrel is inserted from an opening of the first barrel so that the two barrels are overlapped; a bell-mouth shaped object is designed at the opening of the two barrels and is connected to the oval slots of the barrels; an exhaust hole is formed in the middle of the bell-mouth shaped object. Small holes are drilled in the center of the barrels, a stirring rod penetrates the small holes and is provided with an excrement stirrer and an excrement scraper, bearings are arranged on two sides of the stirring rod and a mini motor is arranged on one side of the stirring rod; an excrement outlet is arranged on the lower side of the first barrel, a slide way is arranged below the excrement outlet; a handle is installed on the outer periphery of the second barrel, and the drying device is installed on the outer periphery of the toilet bowl.

Owner:胡纯翠

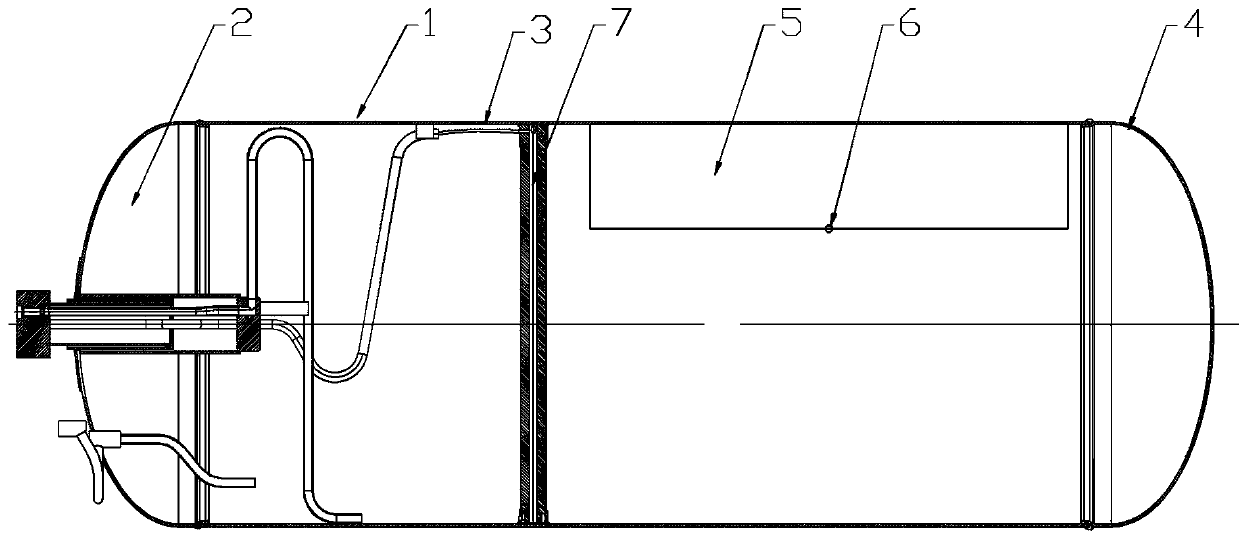

Excessive-filling preventing horizontal heat-insulating gas bottle

PendingCN107606477ARaise the water levelSolve the problem of prone to overfillingPressure vesselsGas cylinderEngineering

Owner:田锋

Fully automatic capsule hole puncher

Owner:绍兴易瑞普健康科技有限公司

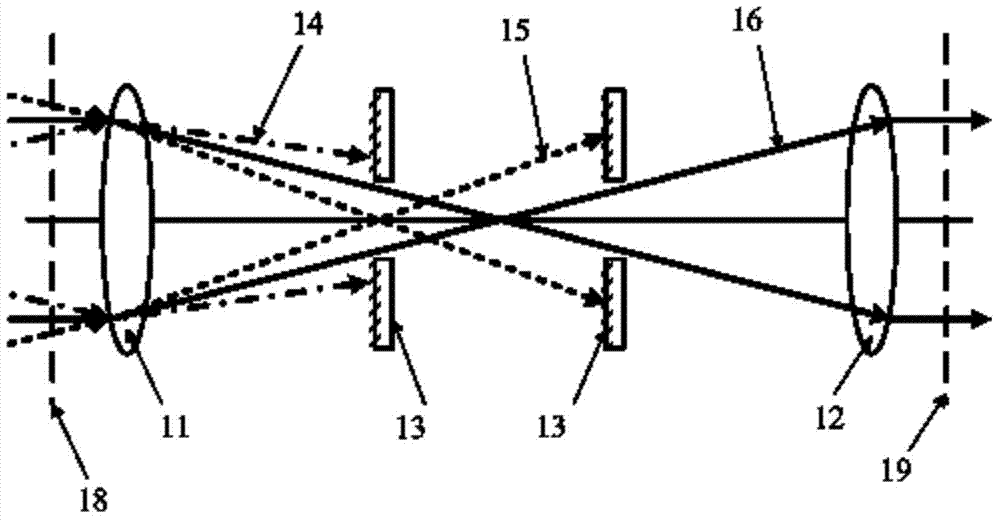

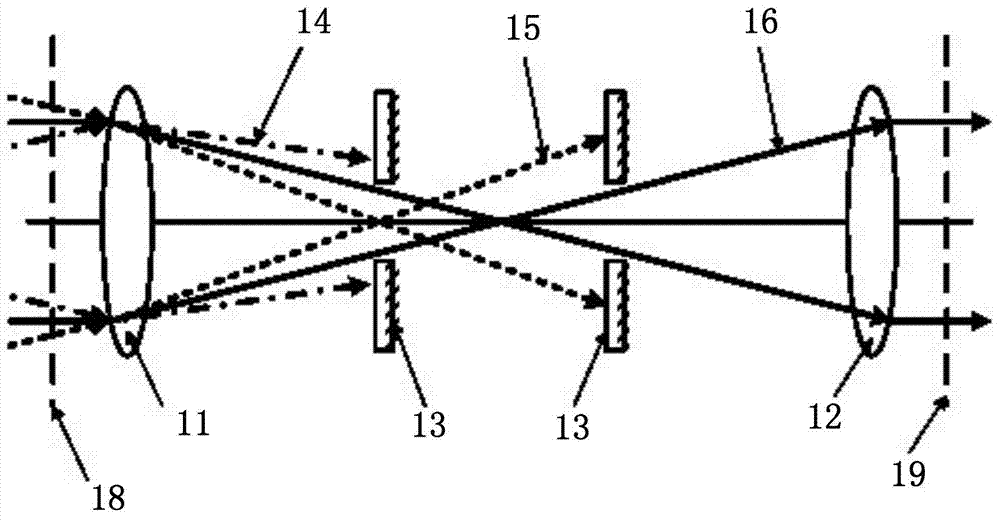

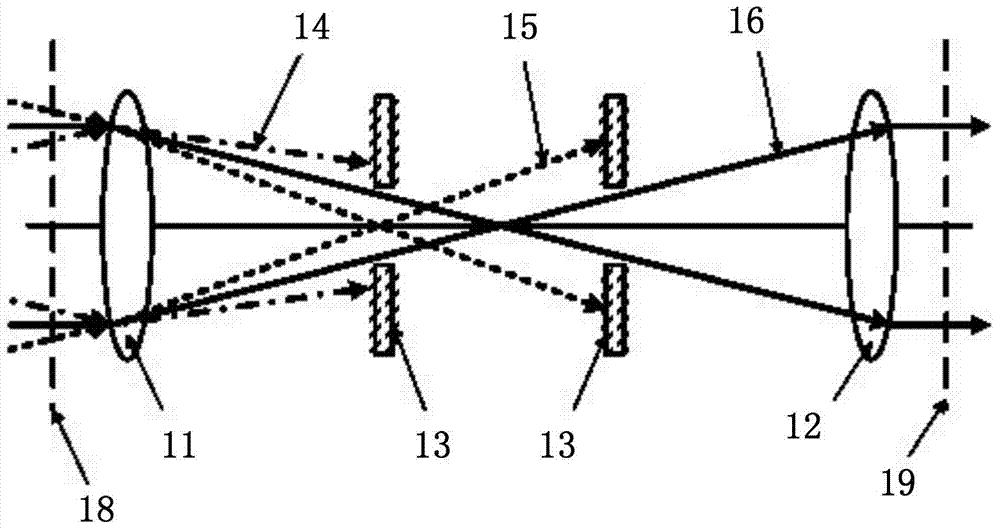

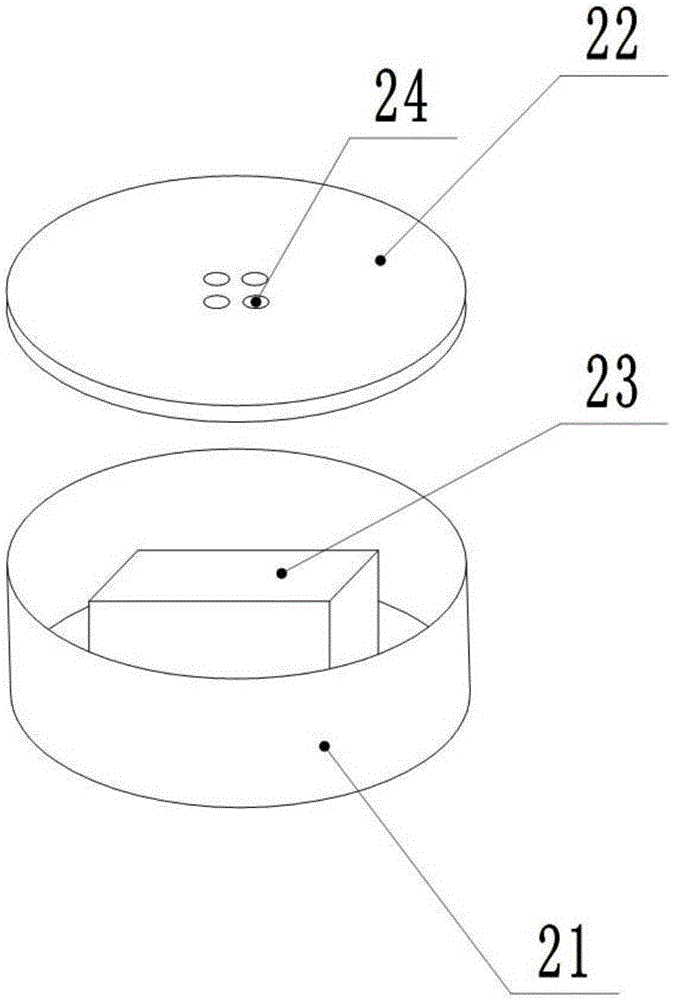

Spatial filtering device

ActiveCN104849873AIncreased misalignment toleranceReduce absorptionOptical elementsOptoelectronicsScattering effect

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

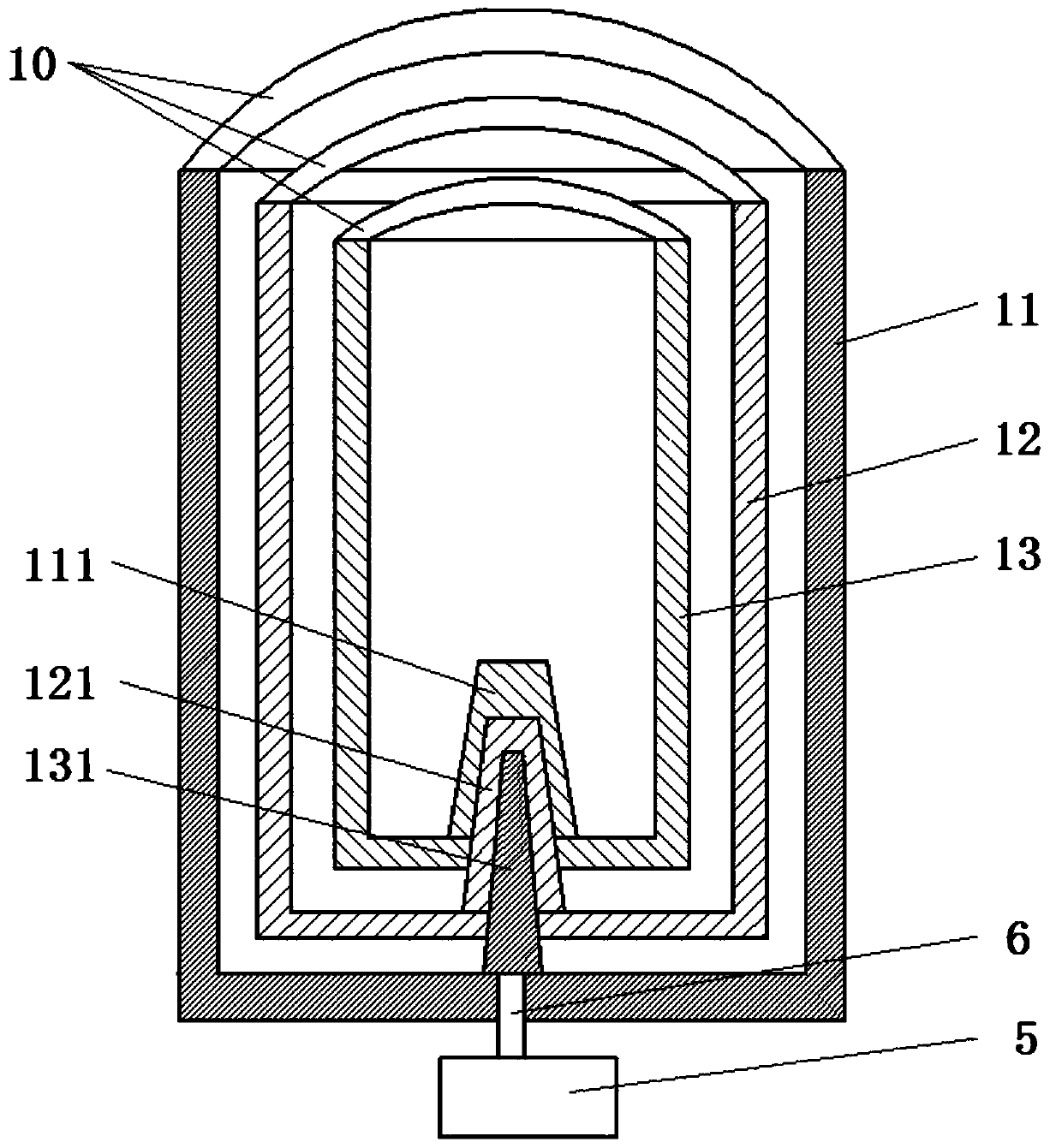

Cavity lining device for improving PECVD (plasma enhanced chemical vapor deposition) cleaning efficiency

ActiveCN113737155AReduce depositionGuaranteed cleaning effectFinal product manufactureChemical vapor deposition coatingThin membraneSmall hole

Owner:江苏鲁汶仪器股份有限公司

Leaf spring product and application of leaf spring

InactiveCN109805989AImprove efficiencyIncision instrumentsObstetrical instrumentsBiological bodyWound surface

Owner:武欣 +1

Method for machining face plate through cooperation of numerical control machine tool and punching

Owner:SUZHOU ANJIE TECH

High-pressure dust-catching spraying device capable of moving and lifting

Owner:ANHUI UNIV OF SCI & TECH

Indoor natural radiating device

InactiveCN107687685AAchieve heat dissipationAchieve coolingLighting and heating apparatusSpace heating and ventilation detailsEngineeringOutdoor temperature

Owner:张仲甫

Faced rock-fill dam rolling density and humidity rapid detection method

InactiveCN103076261AMeet the requirements of high-strength construction quality inspectionQuick checkMaterial analysis using wave/particle radiationEarth-fill damsSmall holeDry density

The invention discloses a faced rock-fill dam rolling density and humidity rapid detection method. According to the invention, a faced rock-fill dam detection point position is determined; detection point coordinate is recorded; a detection hole is drilled right at the detection point, until a detection layer depth is reached; and a nucleon density gauge probe is placed into the detection hole, such that rolling density and humidity are detected. According to the invention, from respects such as auxiliary tool design, field detection method, and detection processes, problems such as accurate drilling and detection depth are solved, such that a nucleon density / humidity detection method can be used in detection of faced rock-fill dam rolling density and humidity. A detection depth can reach 100cm. The method can also be used for detecting parameters such as dry density, compaction degree, and the like, such that high-intensity construction quality detection requirement of dam construction can be satisfied. According to the invention, an indirect geophysical detection technology is adopted. Only 1 or 2 small holes with depths reaching the rolling thickness are needed to be drilled on a detection surface, and density and humidity detections can be rapidly completed without digging. The method provided by the invention belongs to a non-destructive detection technology.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

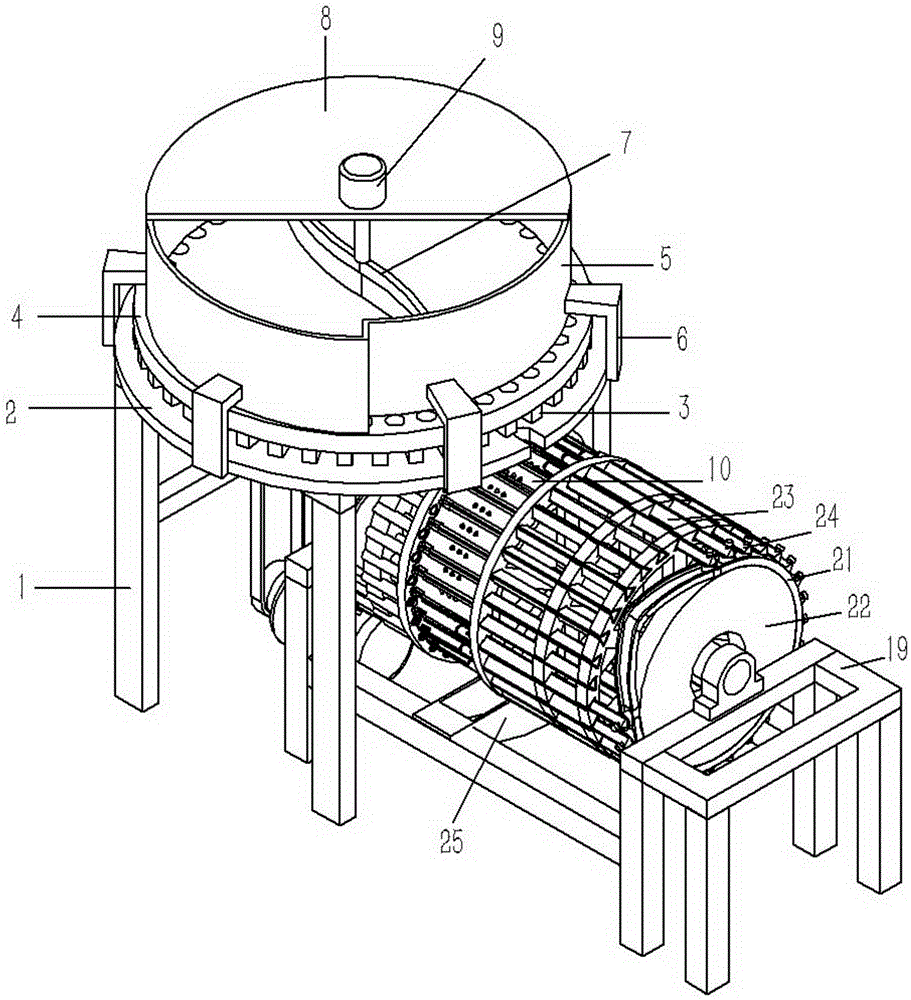

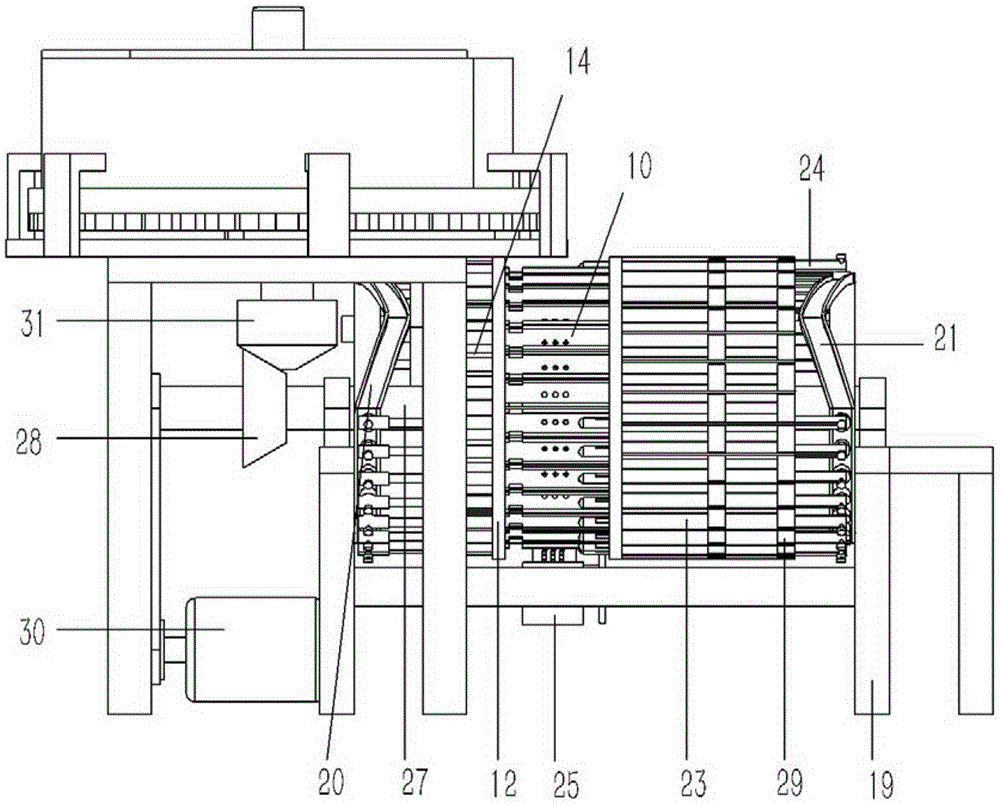

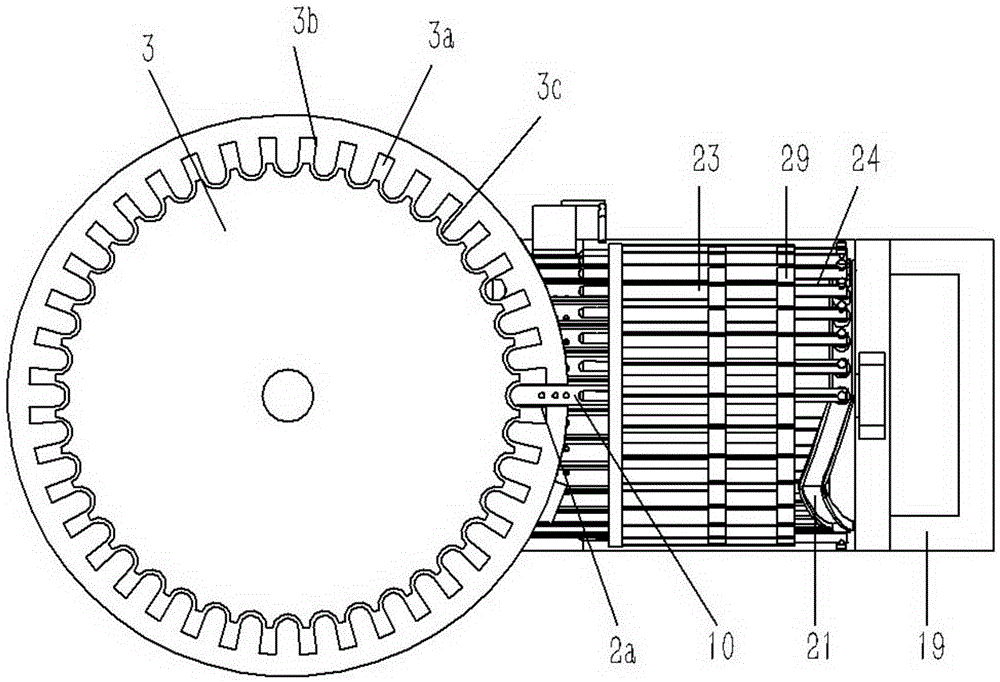

Continuous production device of carbon powder for printing machine

InactiveCN111550995AStir wellFast dryingDrying gas arrangementsDrying chambers/containersAgitatorPrinting press

The invention discloses a continuous production device of carbon powder for a printing machine. The continuous production device of the carbon powder for the printing machine structurally comprises amachine body, a feeding opening, a discharging opening, a stirrer and a conveyor, wherein the feeding opening is formed in the upper portion of the machine body, the discharging opening is formed in the front portion of the machine body, and the upper portion of the interior of the machine body is in sliding connection with the stirrer. According to the device, in the stirring process, air guns start to work, stop blocks around the air guns can surround and rotate, under the condition of rapid rotation, no gap exists around the air guns, objects to be treated such as wood chips cannot make contact with air openings of the air guns, the phenomenon of air opening blockage is avoided, at the moment, the air guns facing upwards can blow off to-be-treated objects attached to a stirring body anda rotating body through small holes in the front ends of the stop blocks, the air guns perpendicular to a connecting body can blow away the to-be-treated objects, gaps among the blown-away to-be-treated objects can be enlarged, and the drying speed of the to-be-treated objects can be increased through cooperation of wind power.

Owner:刘洋

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap