Blowout proof tire

A technology of explosion-proof tires and inner tubes, which is applied to tire parts, transportation and packaging, and vehicle components, etc. It can solve the problems of loss of control of vehicle driving direction, affecting driving safety, and car crashes, so as to avoid sideslip and spin, improve Safe driving and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

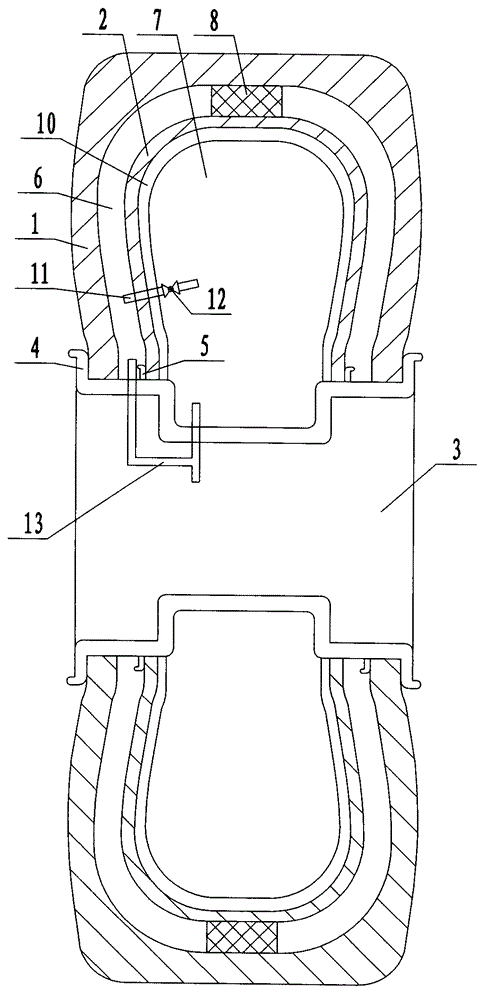

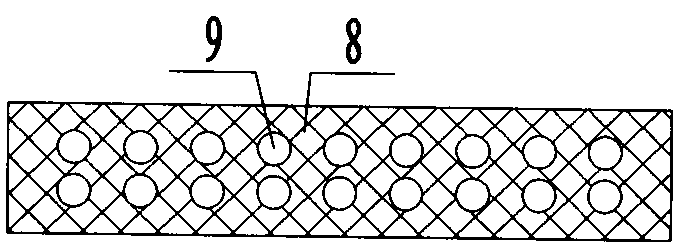

[0010] Such as figure 1 , figure 2 As shown, the explosion-proof tire includes: a cover tire 1, an inner tube 2 and a hub 3, on which the hub 3 is provided with an outer fixed steel ring 4 and an inner fixed steel ring 5, and the said cover tire 1 is clamped in the outer fixed steel ring 4, Described inner tube of a tire 2 is clamped in the inner fixed steel ring 5, is provided with outer cavity 6 between described cover tire 4 and inner tube of a tube 5, is provided with inner chamber 7 in described inner tube of a tube of a tire 5, in the inner side of described cover tire 1 and A gel block 8 is arranged between the outer sides of the inner tire 2, and a number of ventilating small holes 9 are arranged on the gel block 8, and a mesh steel wire skeleton 10 is embedded in the inner side of the inner tire 2, and the inne

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap