Excessive-filling preventing horizontal heat-insulating gas bottle

A thermal insulation and gas cylinder technology, which is applied to fixed-capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc., can solve the problem of not filling enough, and achieve the effect of good stress and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

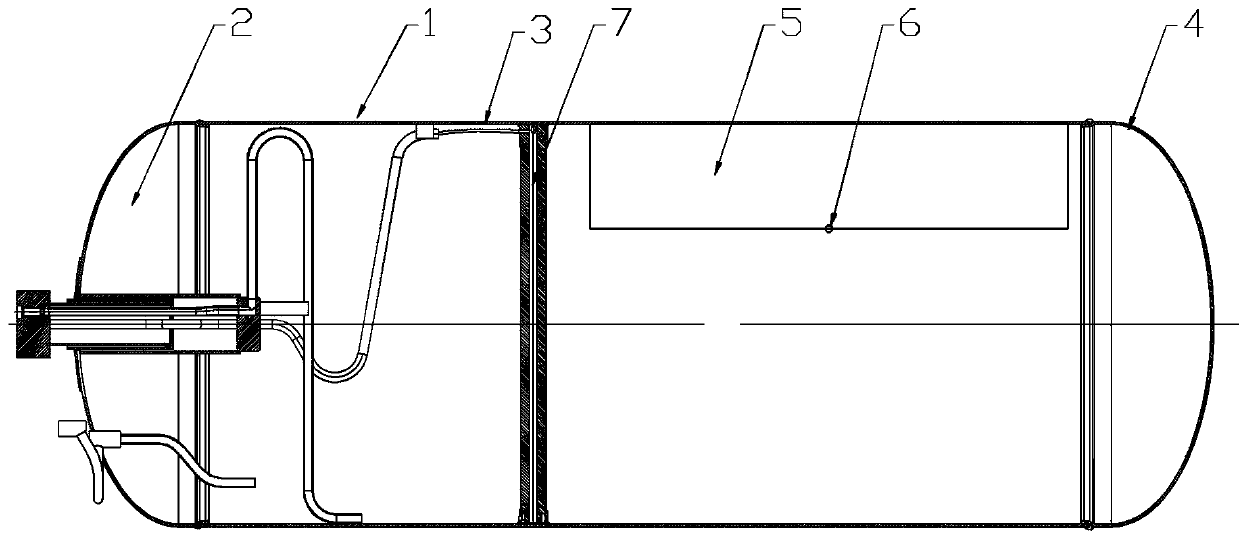

[0022] Such as figure 1 Shown: a horizontal thermally insulated gas cylinder for preventing overfilling, including a front head assembly 2, an inner cylinder body 3 and a rear head 4 constituting an inner tank 1, and a compartment is arranged on the upper part of the inner cavity of the inner tank 1 5. A small hole 6 is provided at the bottom of the compartment 5, and the small hole 6 is located on the upper side of the horizontal plane where the horizontal central axis of the liner 1 is located. In the above design, the compartment 5 is directly welded to the top of the inner tank 1 or the compartment 5 is suspended in the inner cavity of the inner tank 1 and fixed with a corresponding structure; The inner wall of the inner container 1 is composed of components and the corresponding inner wall of the inner container 1 . In addition, it should be noted t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap