Stable and controllable time delay switch

A time-delay switch and stable technology, applied in thyristors, circuits, semiconductor devices, etc., can solve problems such as the inability of time-delay switches to be adjusted, and achieve the effects of low manufacturing cost, long service life and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

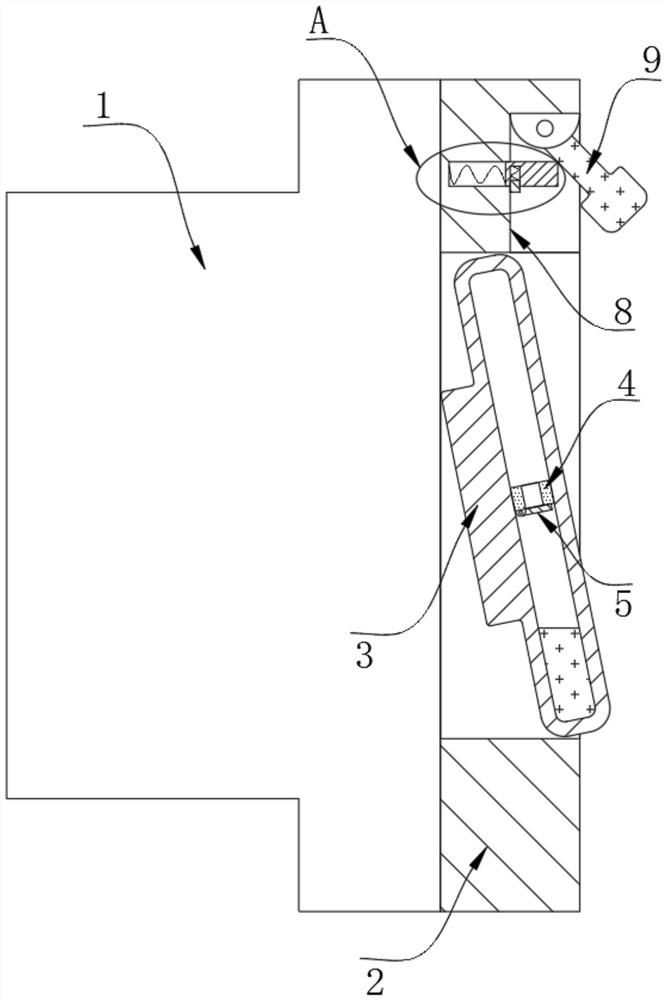

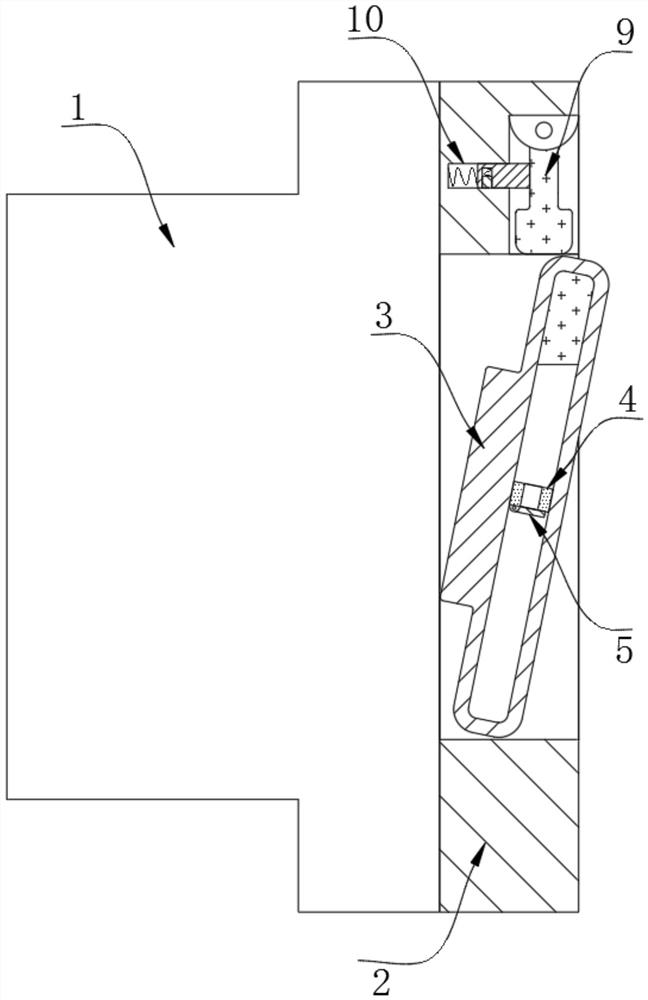

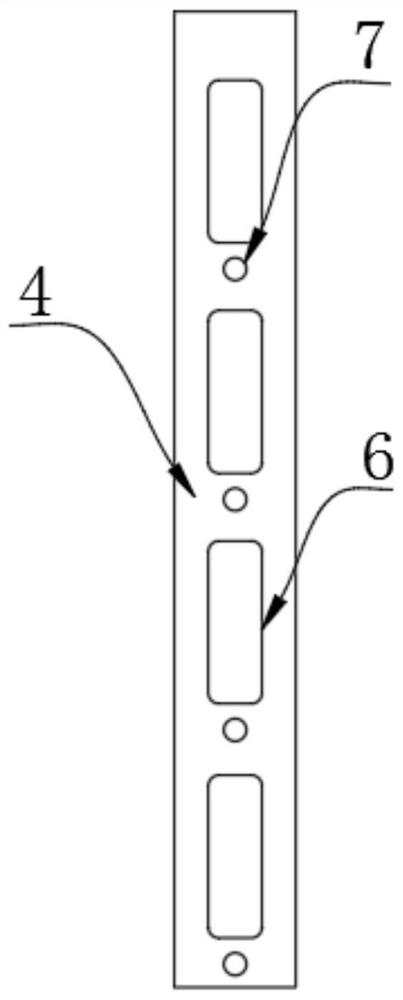

[0019] refer to Figure 1-4 , a stable and controllable time-delay switch, including a wiring body 1 and a panel 2 installed on it, the inner wall of the panel 2 is rotatably connected with a push cover 3, and the inner wall of the press cover 3 is fixed with a partition plate 4, the partition plate The upper end of 4 is provided with a plurality of fast-falling grooves 6 and slow-release holes 7, and the bottom of the partition plate 4 is connected with a plurality of baffle plates 5 corresponding to a plurality of fast-falling grooves 6 one by one through a torsion spring. The aperture of 6 is obviously larger than the slow-release hole 7, and the baffle plate 5 closes the lower part of the quick-falling groove 6, so that the quick-falling groove 6 can only pass through from top to bottom, and cannot flow in reverse. The upper wall of the panel 2 is provided with a conversion groove 8, The inner wall of the transfer tank 8 is rotatably connected with a rotary block 9 .

[0020

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap