Method for detecting construction quality of crossing lane

A technology of construction quality and detection method, which is applied in the field of construction quality detection of meeting lanes, and can solve problems such as inability to effectively guarantee construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

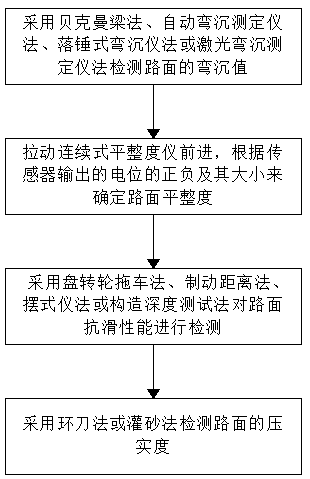

[0023] First, detect the deflection value of the pavement: use the Beckman beam method, the automatic deflection tester method, the drop weight deflection tester method or the laser deflection tester method to detect the deflection value of the road surface, and the automatic deflection tester method is composed of The test vehicle, the measurement mechanism, and the data acquisition and processing system are composed of three parts. The measurement mechanism is installed under the chassis of the test vehicle; then the road surface roughness inspection is carried out: when measuring, the continuous flatness instrument is pulled forward by a person or a vehicle, and the measurement is small due to the unevenness of the road surface. The wheel swings up and down, and drives the measuring rod of the displacement sensor to slide up and down in the small hole groove of the sensor, so as to determine the smoothness of the road surface according to the positive and negative potential outp

Embodiment 2

[0025] In embodiment one, add following operation:

[0026] The Beckman beam method is used to measure the deflection value on site in step (1), and the drop weight deflection meter is divided into trailer type and built-in type.

[0027] First, detect the deflection value of the pavement: use the Beckman beam method, the automatic deflection tester method, the drop weight deflection tester method or the laser deflection tester method to detect the deflection value of the road surface, and the automatic deflection tester method is composed of The test vehicle, the measurement mechanism, and the data acquisition and processing system are composed of three parts. The measurement mechanism is installed under the chassis of the test vehicle, and the deflection value is measured on-site using the Beckman beam method. The drop weight deflection meter is divided into trailer type and built-in type; then Carry out road surface roughness detection: when measuring, the continuous flatness

Embodiment 3

[0029] In embodiment two, add following operation:

[0030] In step (1), when using the laser deflection tester method for measurement, fix the tester in the rear wheel gap of the car on the road surface, and use the rebound of the road surface when the car drives away from the measured point to drive the silicon deflection that was originally fixed on the ground. The photocell measuring head rises upwards, so that the laser beam emitted by the laser passes through the incoming light and hits the silicon photocell to generate a photocurrent, and the value of the rebound deformation of the road surface is calculated according to the magnitude of the photocurrent, that is, the rebound deflection value of the road surface.

[0031] First, detect the deflection value of the pavement: use the Beckman beam method, the automatic deflection tester method, the drop weight deflection tester method or the laser deflection tester method to detect the deflection value of the road surface, and

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap