High-pressure dust-catching spraying device capable of moving and lifting

A spray device, high-pressure technology, applied in safety devices, dust-proof, mining equipment and other directions, can solve the problems of unfavorable safety application, can not cover the whole section of the dust-catching net well, complicated moving, installation and use, etc., to achieve great application prospects , The effect of protecting the health of workers and being easy to move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

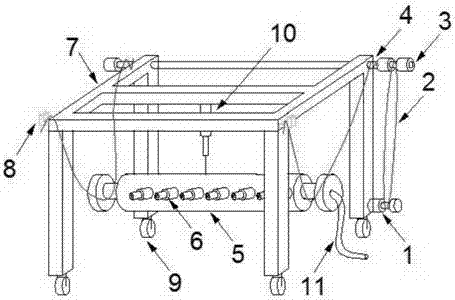

[0016] The technical solution of a movable and liftable high-pressure dust-catching spray device of the present invention will be described in detail below with reference to the accompanying drawings.

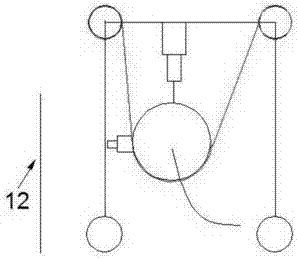

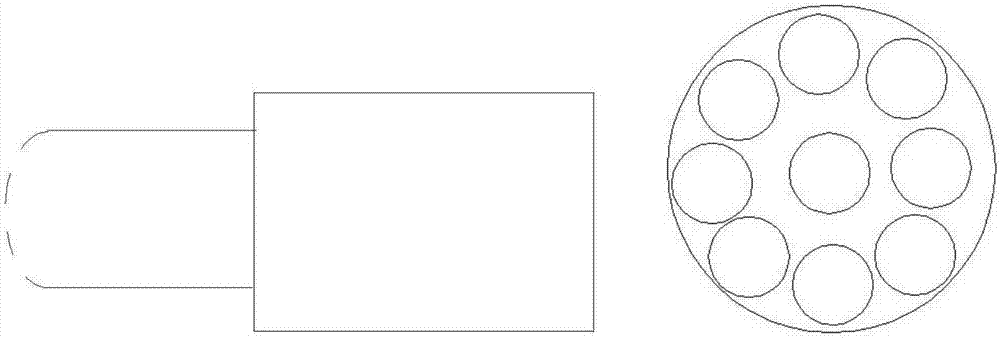

[0017] Such as figure 1 with image 3 As shown, after the water inlet switch is turned on, water will enter the horizontal hollow water pipe 5 from the water inlet pipe 11, and the water flow will be sprayed from the spray head 6 to the dust net 12 through the horizontal hollow water pipe 5.

[0018] The whole device can be moved to the working surface by the pulley 9 and the distance between the device and the dust net 12 can be adjusted.

[0019] When the motor 1 rotates backwards after power-on, the belt 2 drives the cylindrical horizontal shaft 3 to rotate. The cylindrical horizontal shaft 3 rotates to wind the rope 4, and the rope 4 lifts the horizontal hollow water pipe 5. When the motor 1 rotates forward after power on, the belt 2 drives the cylindrical horizontal axis 3 to rotat

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap