Fully automatic capsule hole puncher

A punching machine, fully automatic technology, applied in the direction of capsule delivery, drug delivery, pharmaceutical formulations, etc., can solve the problems of harmful health and low production efficiency, and achieve the effects of improving production efficiency, saving personnel costs, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

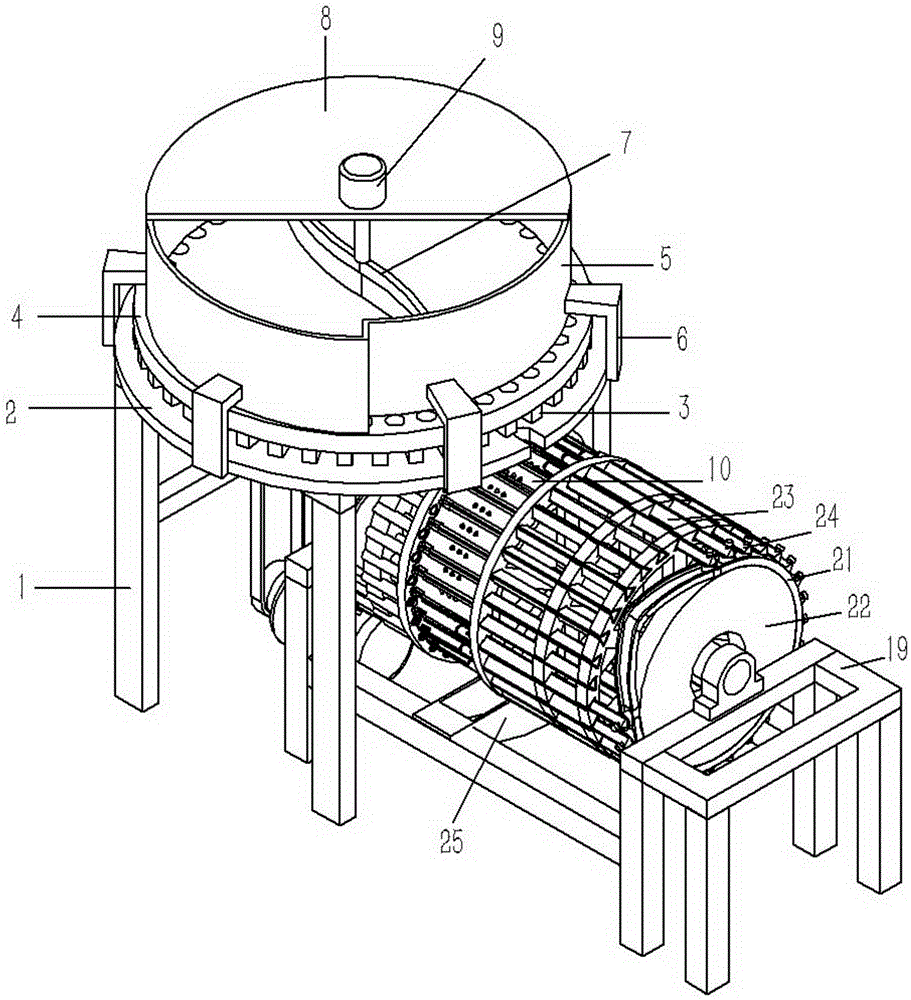

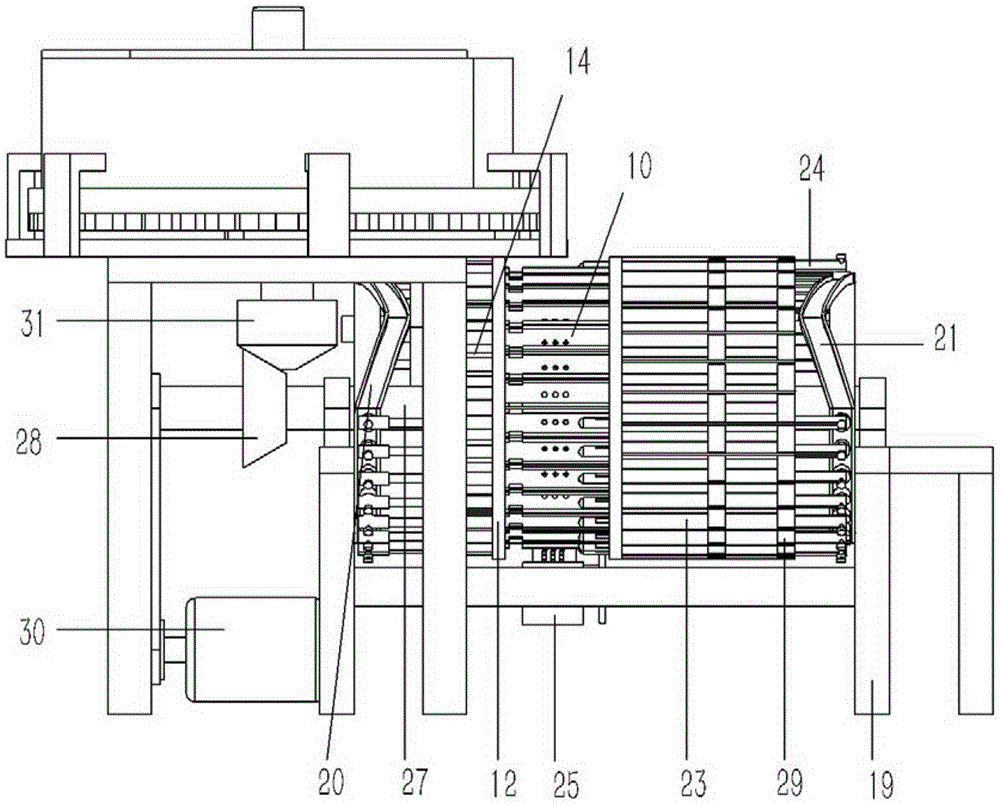

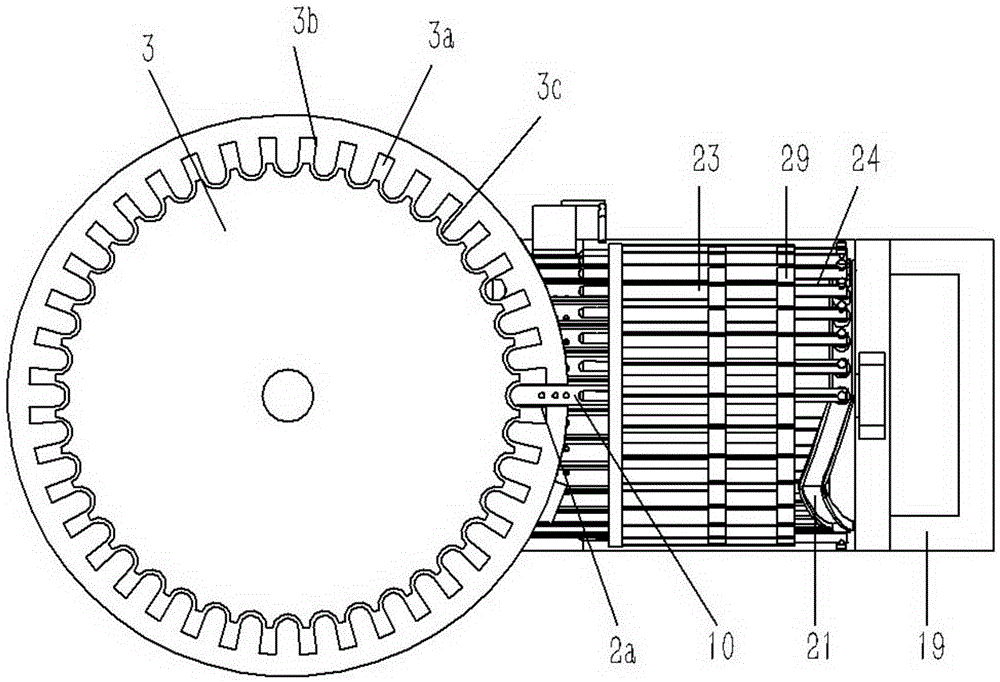

[0028] Example: see Figures 1 to 9 As shown, a fully automatic capsule punching machine includes a main frame 1, a chassis 2 is fixed on the main frame 1, a distribution tray 3 is hinged on the chassis 2, and a tray 4 and a storage box 5 are arranged on the distribution tray 3 , the tray 4 and the material storage box 5 are fixed on the chassis 2 through the connecting bracket 6, the material storage box 5 is provided with a feeding brush 7, the feeding brush 7 is fixed on the rotating shaft of the feeding brush motor 9, and the feeding brush motor 9 is fixed on the cover plate 8, the cover plate 8 is fixed on the top of the material storage box 5, the edge of the material distribution tray 3 is formed with stepped teeth 3a, and a strip-shaped hole 3b is formed between adjacent stepped teeth 3a, and the strip-shaped hole 3b The rear portion is a tapered hole 3c, and the chassis 2 below the bar-shaped hole 3b outside the material storage box 5 is formed with a feed port 2a, and s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap