Cavity lining device for improving PECVD (plasma enhanced chemical vapor deposition) cleaning efficiency

A technology of cleaning efficiency and lining, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of incomplete cleaning, deposition on the bottom of the cavity and the inner wall of the cavity, etc., to ensure the quality of the deposited film , Reduce film deposition and prevent glow discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

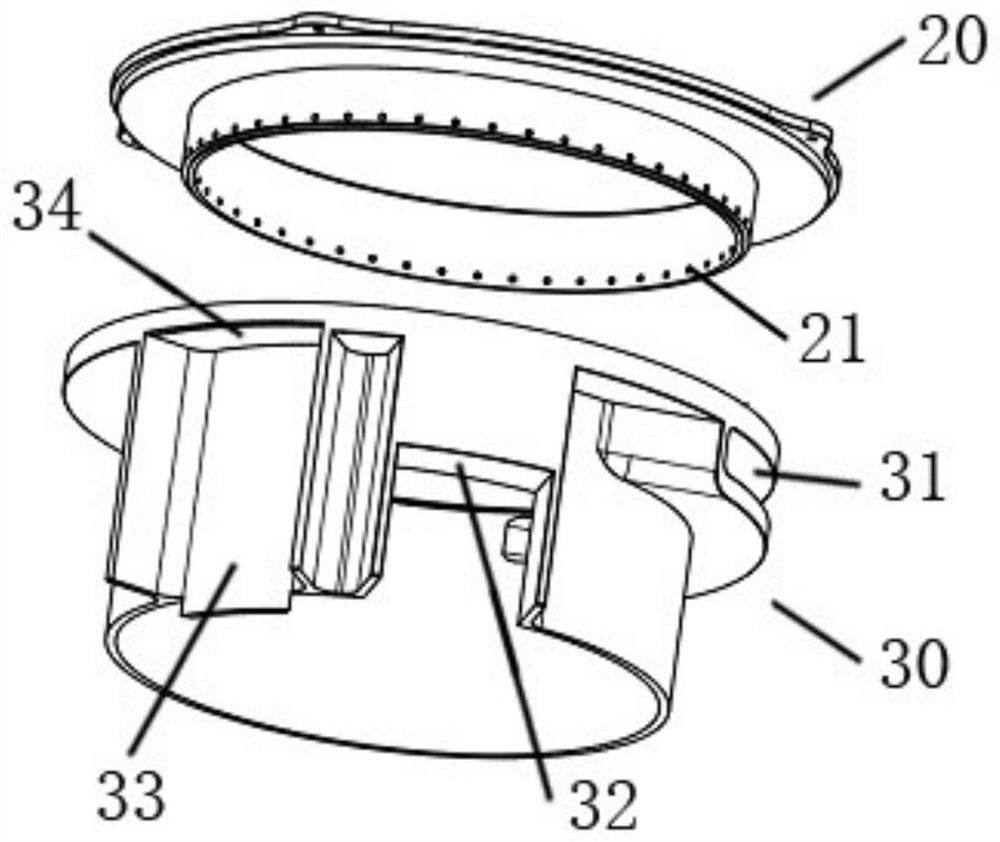

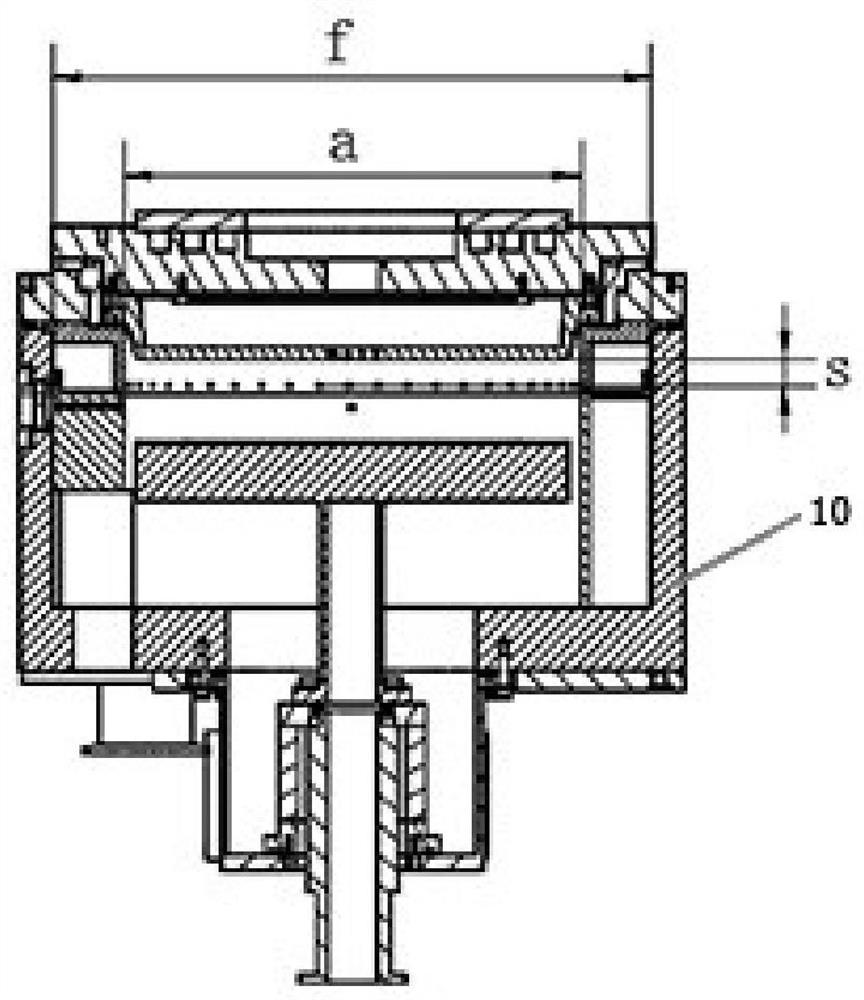

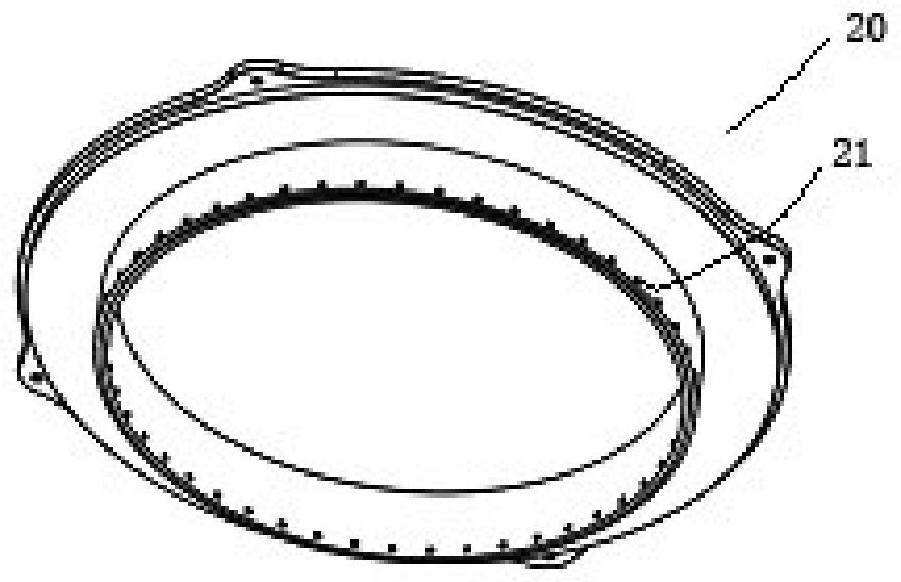

[0034] The optimal implementation scheme proposed in this embodiment is specifically as follows, a chamber lining device for improving PECVD cleaning efficiency, the basic structure of which is as described above. like figure 2 As shown, “a” in the figure is the diameter of the inner ring of the lining 30, “f” is the diameter of the inner ring of the cavity 10, and “s” is the distance between the gas uniform disk and the air extraction small hole 21. In this scheme, the diameter of the inner ring of the lining 30 (such as figure 2 The diameter of "a" shown in "a" and the inner ring of the ceramic ring 20 are both 240 mm, and the inner ring of the lining 30 extends axially downward to a height of 250 mm. The inner lining 30 is made of aluminum alloy, which has the advantages of easy processing, high yield, and low cost. The ceramic ring 20 is made of ceramics, which can prevent glow discharge from occurring in the gas distribution plate and the cavity 10. The ceramic ring 20 i

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap