Web-fed rotary press

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

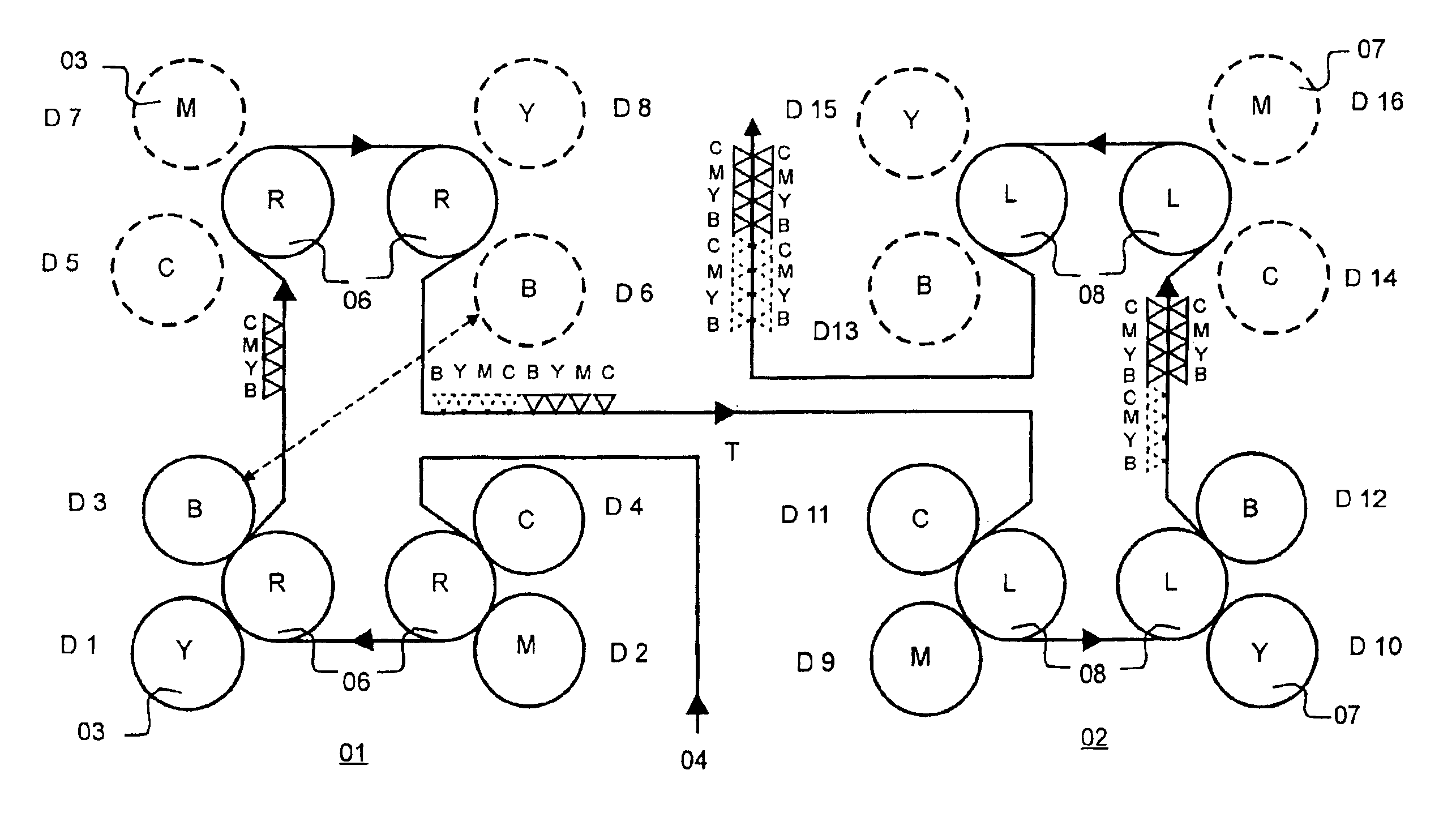

first embodiment

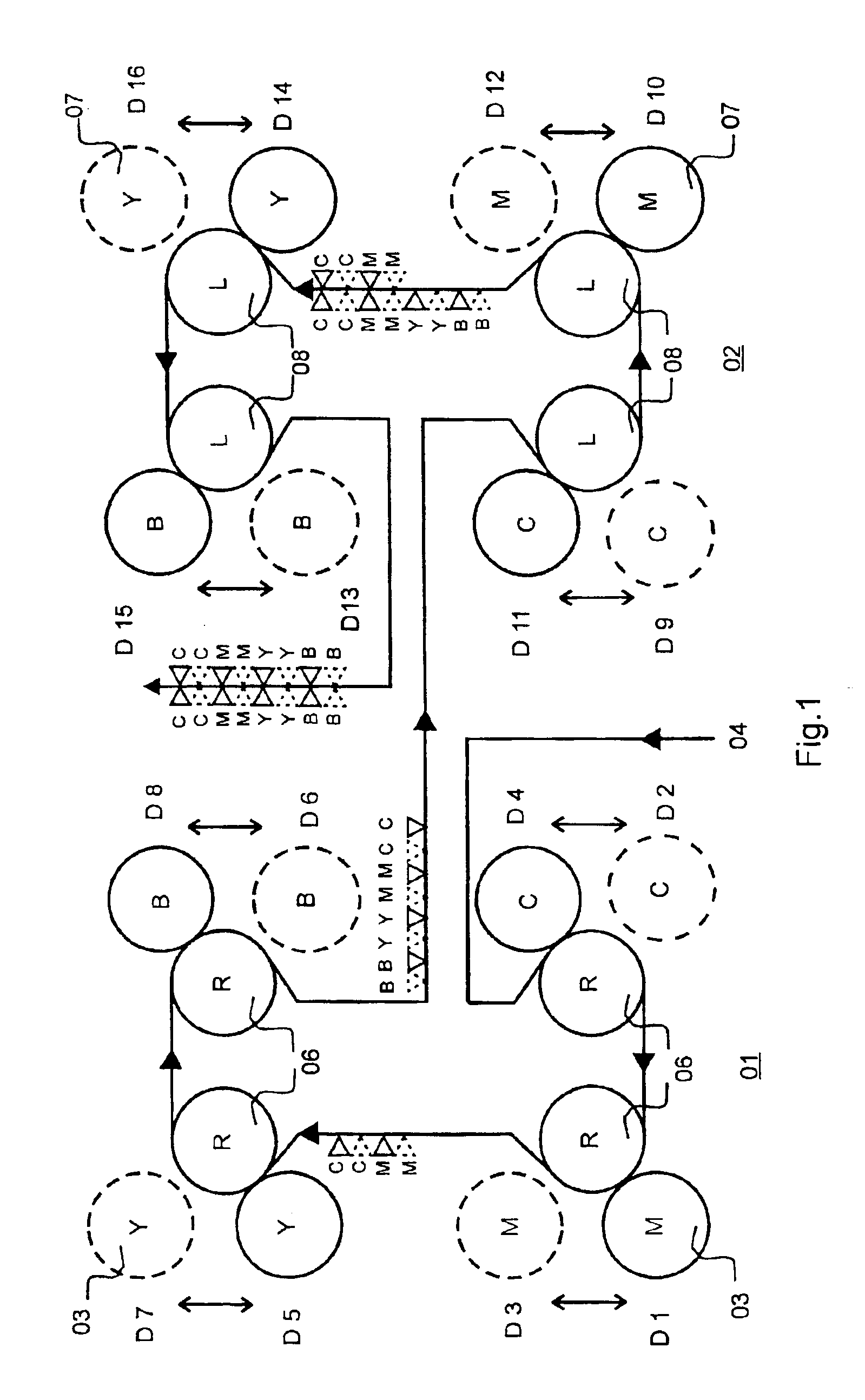

[0036]However, in this second preferred embodiment the two print positions D1, D2, D3, D4, D5, D6, D7, D8, D9, D10, D11, D12, D13, D14, D15, D16, respectively which are provided with the same colored ink in each printing tower 01, 02, and which can be alternatingly placed into and out of operation, are not arranged directly adjoining and working together with the same satellite cylinder 06, 08 as was the case in the Instead, they are arranged, within their respective printing tower 01 or 02, in a diagonally mirror-like way which is indicated in FIG. 2 by the use of a dashed arrow, as seen in the first printing unit unit 01. In the depicted second preferred embodiment, the print positions D1 and D8 in the first printing tower 01, and the print positions D10 and D15 in the second printing tower 02 contain the color yellow Y. The print positions D2 and D7 in the first printing tower 01 and the print positions D9 and D16 in the second printing tower 02 contain the color magenta M. The pri

third embodiment

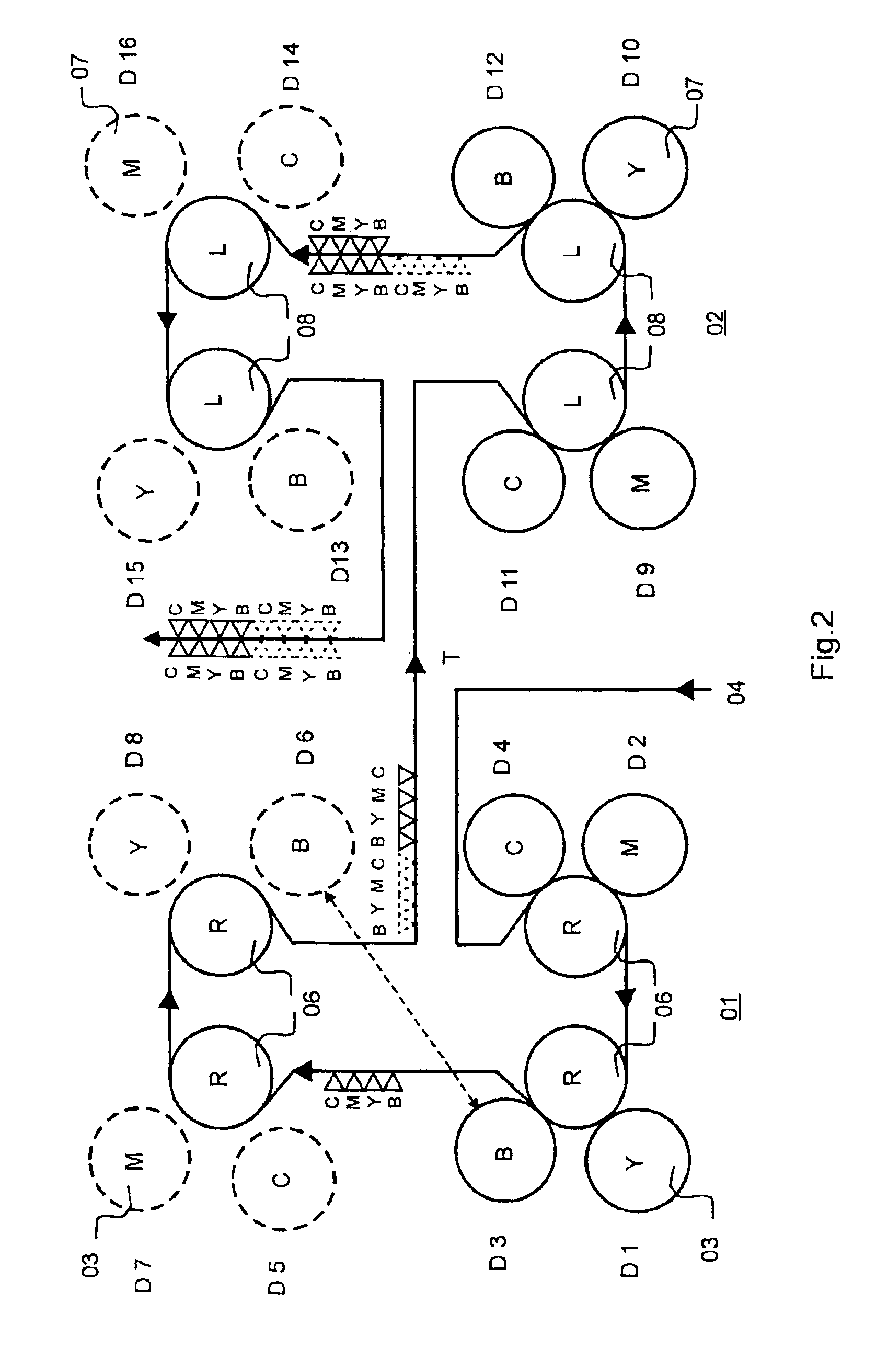

[0042]In this preferred embodiment, the printing groups D1, D2, D3, D4, D5, D6, D7, D8, D9, D10, D11, D12, D13, D14, D15, D16, each with one colored ink, and which alternatingly work together with the same side of the paper web 04, are respectively located within a unit 01 or 02. The maximum distance between these two printing groups D1, D2, D3, D4, D5, D6, D7, D8, D9, D10, D11, D12, D13, D14, D15, D16 is less than half the length of the paper web 04 from the first to the last print position D4, D2, D1, D3, D5, D7, D8, D6, D11, D9, D10, D12, D14, D16, D15, D13. The local distribution of moisture is uniform for both modes of operation. Also in the third embodiment, the distance between the first and the last of the printing groups, for example D4 and D16, or D1 and D13, which are in the contacted position, is greater in both modes of operation of the imprinter operation than half the distance between the first and the last printing groups D4, D2, D1, D3, D5, D7, D8, D6, D11, D9, D10, D1

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap