Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Dry density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dry Density. It refers to the density of the soil, when it is taken in the dry state. The soil mass is commonly a mixture of air, water and soil solids. The dry density refers to the soil solids. It is otherwise called as dry unit weight of soil. Here, γd is dry density, Ms is mass of the soil solids and VT is total soil solid volume.

Low-density foaming cement and preparation method thereof

The invention discloses a low-density foaming cement, which comprises the following components in parts by weight: 60 to 120 parts of cement, 0.3 to 1.0 part of coagulant, 0.4 to 1.0 part of foam stabilizer, 0.5 to 1.2 parts of water reducer, 9 to 14 parts of foaming agent, 0.2 to 0.5 part of fiber, and 25 to 50 parts of water. The invention also discloses a preparation method of the low-density foaming cement. The low-density foaming cement is prepared through the following steps: evenly stirring dry powder, adding water to prepare cement slurry, adding a foaming agent under rapid stirring, casting to mould, and carrying out natural maintenance; and has the advantages of low dry density and low thermal conduction coefficient.

Owner:GUANGDONG JIANKE CONSTR CONSULTING CO LTD

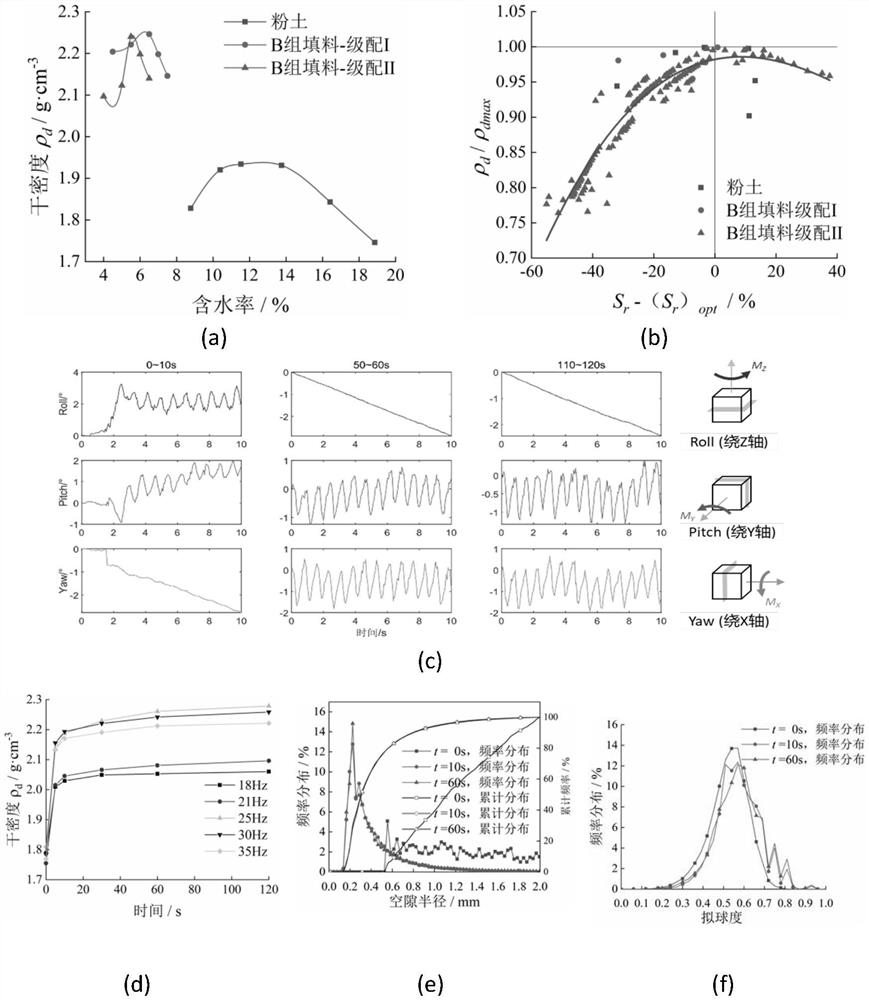

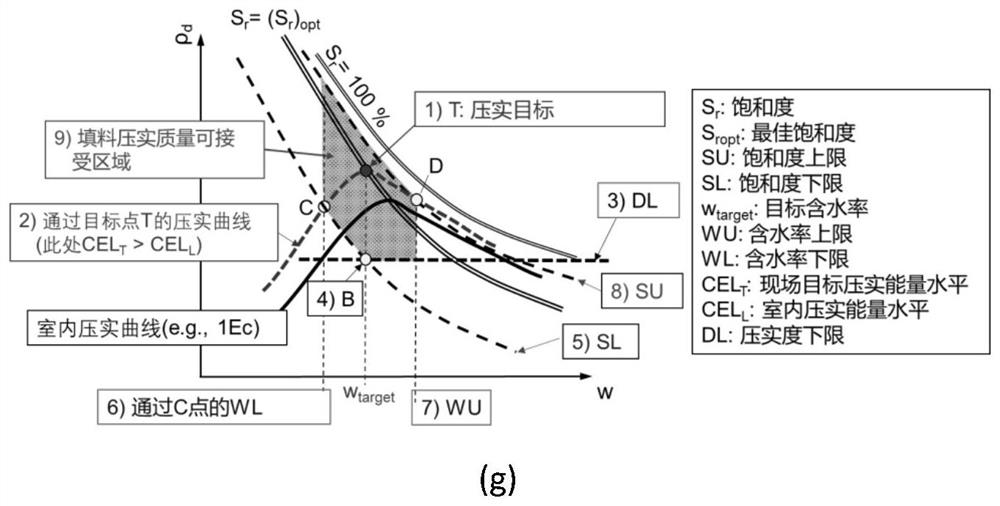

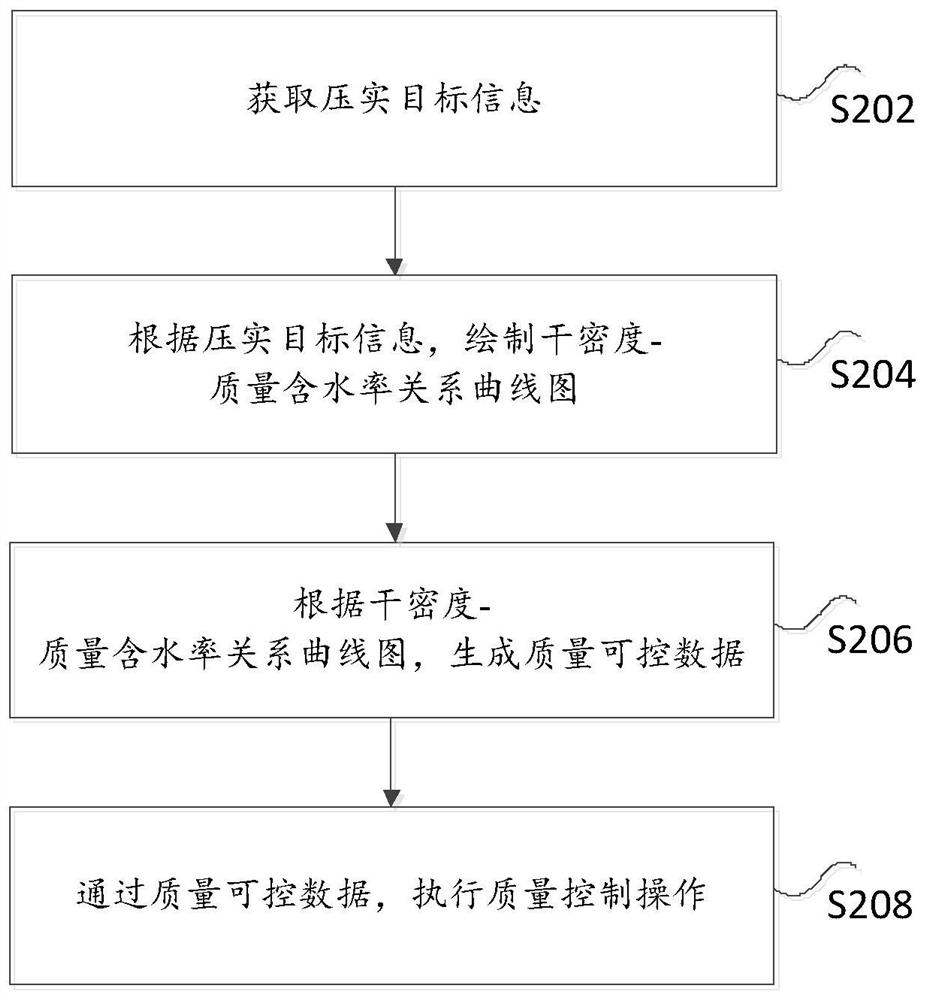

Roadbed filler compaction quality control method and system

ActiveCN113215894AAccurate evaluationPrecise regulationGeometric CADRoadwaysSoil scienceQuality control

Owner:CENT SOUTH UNIV

Gypsum-based thermal insulation material for interior walls and preparation method thereof

The invention discloses a gypsum-based thermal insulation material for interior walls. The gypsum-based thermal insulation material is composed of the following ingredients, by weight, 50-70 parts of water, 18-25 parts of meerschaum, 5-10 parts of glazed hollow bead, 3-8 parts of aluminum silicate wool, 2-5 parts of gypsum and 0.2-0.8 part of cellulose ether. A preparation method of the gypsum-based thermal insulation material comprises the following steps: the above ingredients are weighed according to the above weight ratio; carrying out dry mixing on meerschaum, glazed hollow bead, aluminum silicate wool and cellulose ether in advance to an uniform state; adding weighed water and mixing; and stirring for later use. Before construction, weighed gypsum is added and uniformly stirred for use. The material provided by the invention has advantages of fire prevention and flame retardation, low dry density, high strength, good thermal insulation effect and low dry shrinkage, is convenient to operate during construction, has good adaptation to base walls, and has a wide market prospect.

Owner:HUNAN YINGSHUO BUILDING ENERGY SAVING MATERIALS

Cleaning method of breeding farm

Owner:张诗敏

Faced rock-fill dam rolling density and humidity rapid detection method

InactiveCN103076261AMeet the requirements of high-strength construction quality inspectionQuick checkMaterial analysis using wave/particle radiationEarth-fill damsSmall holeDry density

The invention discloses a faced rock-fill dam rolling density and humidity rapid detection method. According to the invention, a faced rock-fill dam detection point position is determined; detection point coordinate is recorded; a detection hole is drilled right at the detection point, until a detection layer depth is reached; and a nucleon density gauge probe is placed into the detection hole, such that rolling density and humidity are detected. According to the invention, from respects such as auxiliary tool design, field detection method, and detection processes, problems such as accurate drilling and detection depth are solved, such that a nucleon density / humidity detection method can be used in detection of faced rock-fill dam rolling density and humidity. A detection depth can reach 100cm. The method can also be used for detecting parameters such as dry density, compaction degree, and the like, such that high-intensity construction quality detection requirement of dam construction can be satisfied. According to the invention, an indirect geophysical detection technology is adopted. Only 1 or 2 small holes with depths reaching the rolling thickness are needed to be drilled on a detection surface, and density and humidity detections can be rapidly completed without digging. The method provided by the invention belongs to a non-destructive detection technology.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap