Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

23 results about "Dry powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

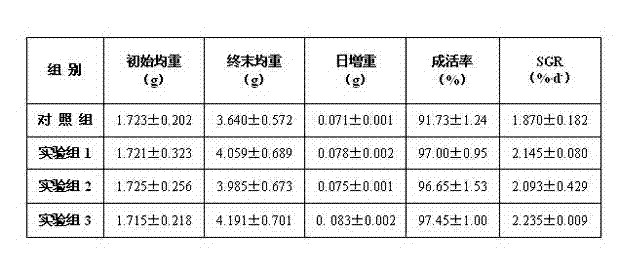

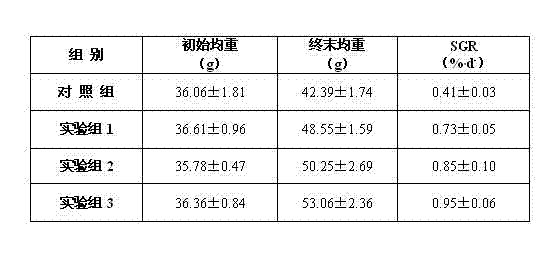

Stichopus japonicus powder feed and processing method thereof

ActiveCN102232492AFast growthIncrease growth rateAnimal feeding stuffAccessory food factorsAdditive ingredientPollution

Owner:安源生物科技(大连)有限公司

Method for preparing positive pole material for ferrous phosphate lithium battery from low-valence oxygen-containing acid of phosphorus

InactiveCN101332984ALow costWide variety of sourcesCell electrodesPhosphorus compoundsPhosphateFerrous salts

Owner:FUJIAN NORMAL UNIV

Method for preparing raw material pellets in production of vanadium-nitrogen alloy

Owner:ANYANG YUQIANXIN METALLURGY REFRACTORY

Low-density foaming cement and preparation method thereof

The invention discloses a low-density foaming cement, which comprises the following components in parts by weight: 60 to 120 parts of cement, 0.3 to 1.0 part of coagulant, 0.4 to 1.0 part of foam stabilizer, 0.5 to 1.2 parts of water reducer, 9 to 14 parts of foaming agent, 0.2 to 0.5 part of fiber, and 25 to 50 parts of water. The invention also discloses a preparation method of the low-density foaming cement. The low-density foaming cement is prepared through the following steps: evenly stirring dry powder, adding water to prepare cement slurry, adding a foaming agent under rapid stirring, casting to mould, and carrying out natural maintenance; and has the advantages of low dry density and low thermal conduction coefficient.

Owner:GUANGDONG JIANKE CONSTR CONSULTING CO LTD

Efficient environmentally friendly ecological insecticide for garden and preparation method thereof

InactiveCN107136126AReach driveDigestive system malfunctionBiocideDead animal preservationSpodoptera lituraArge pagana

Owner:HEFEI SHENWO HORTICULTURE CO LTD

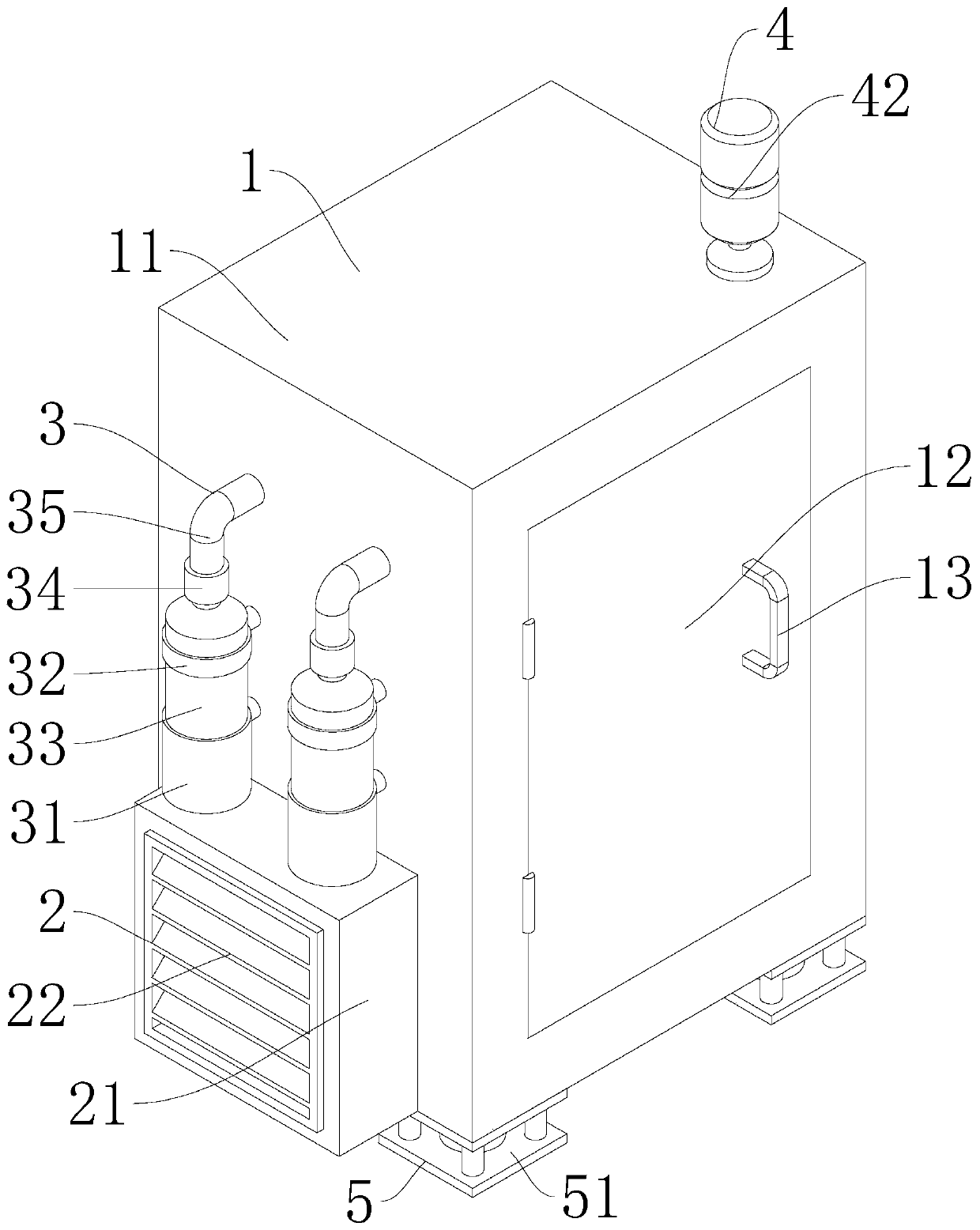

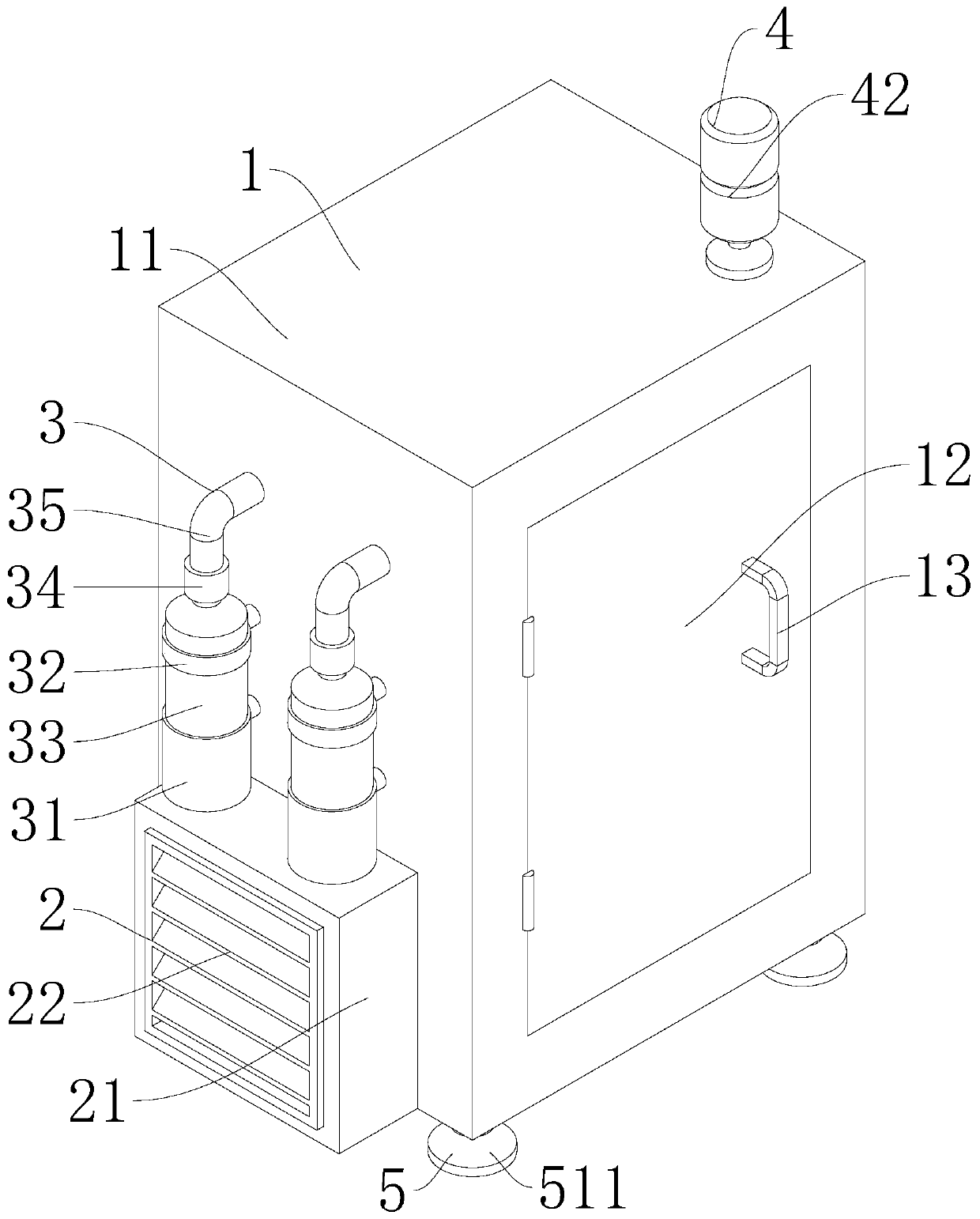

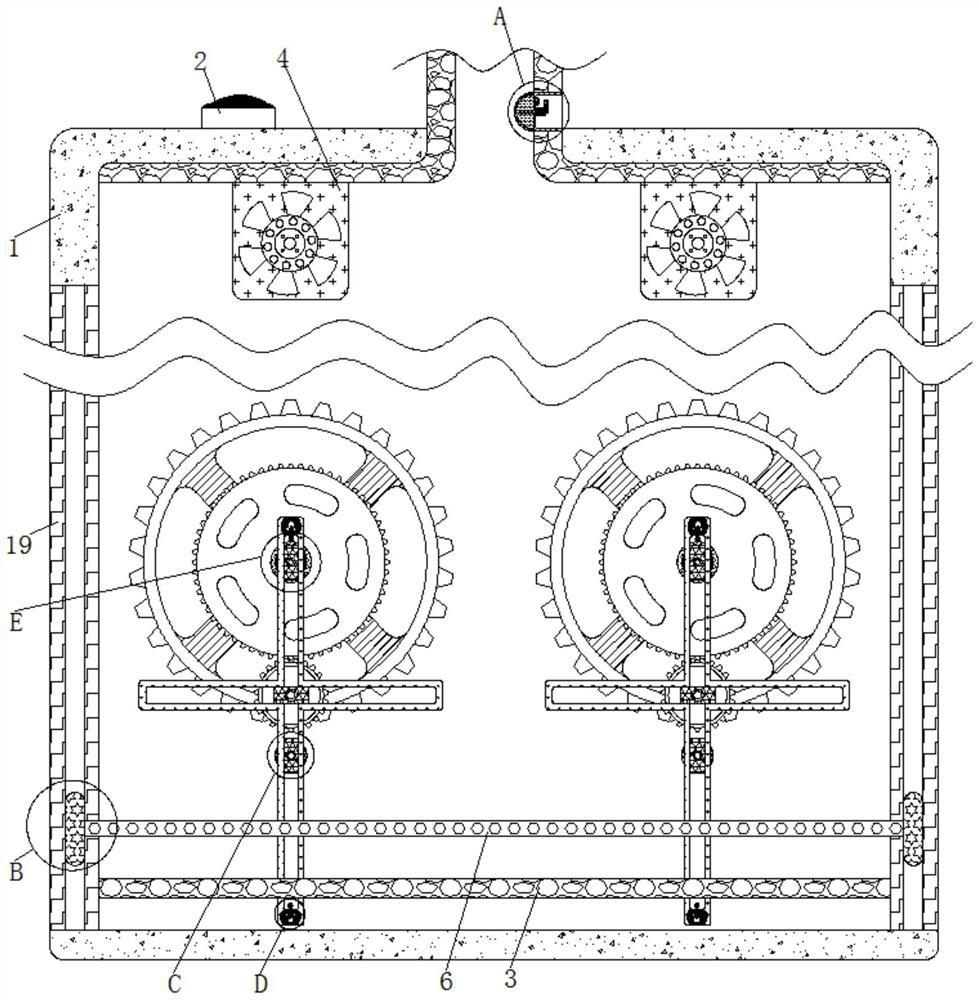

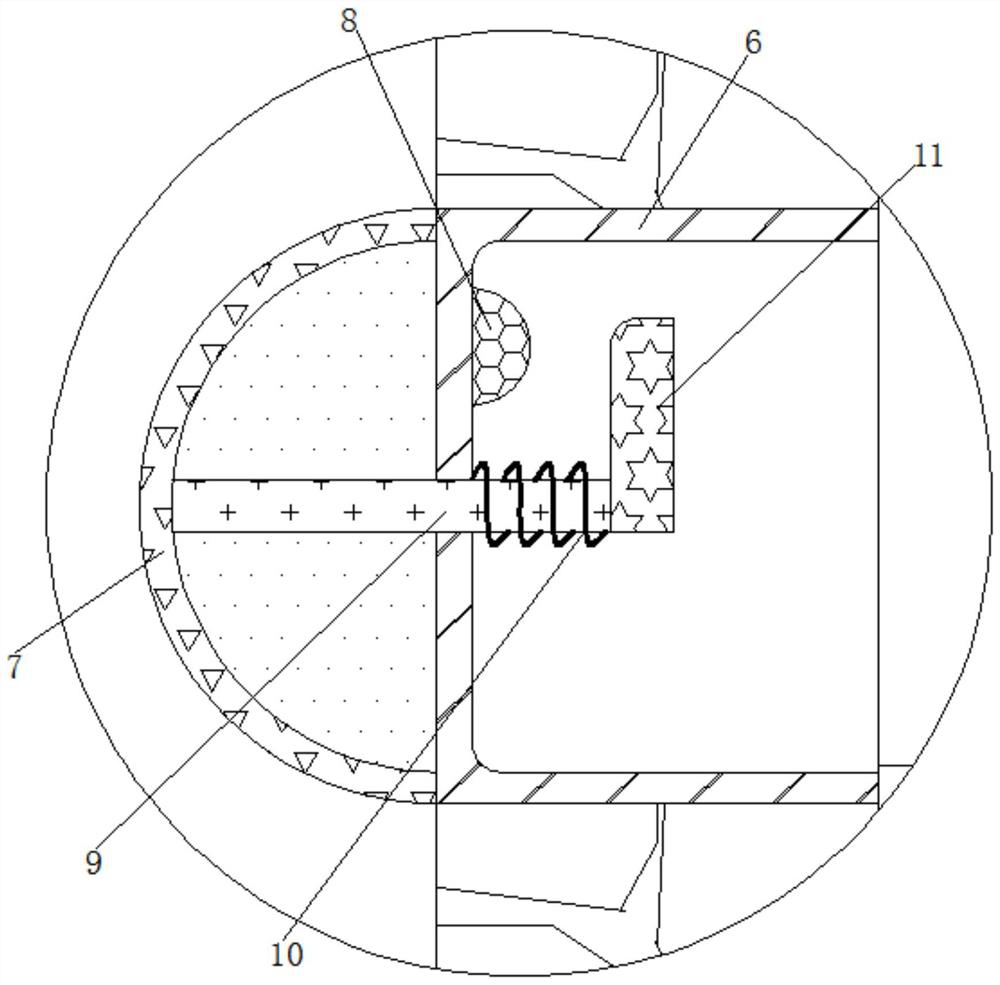

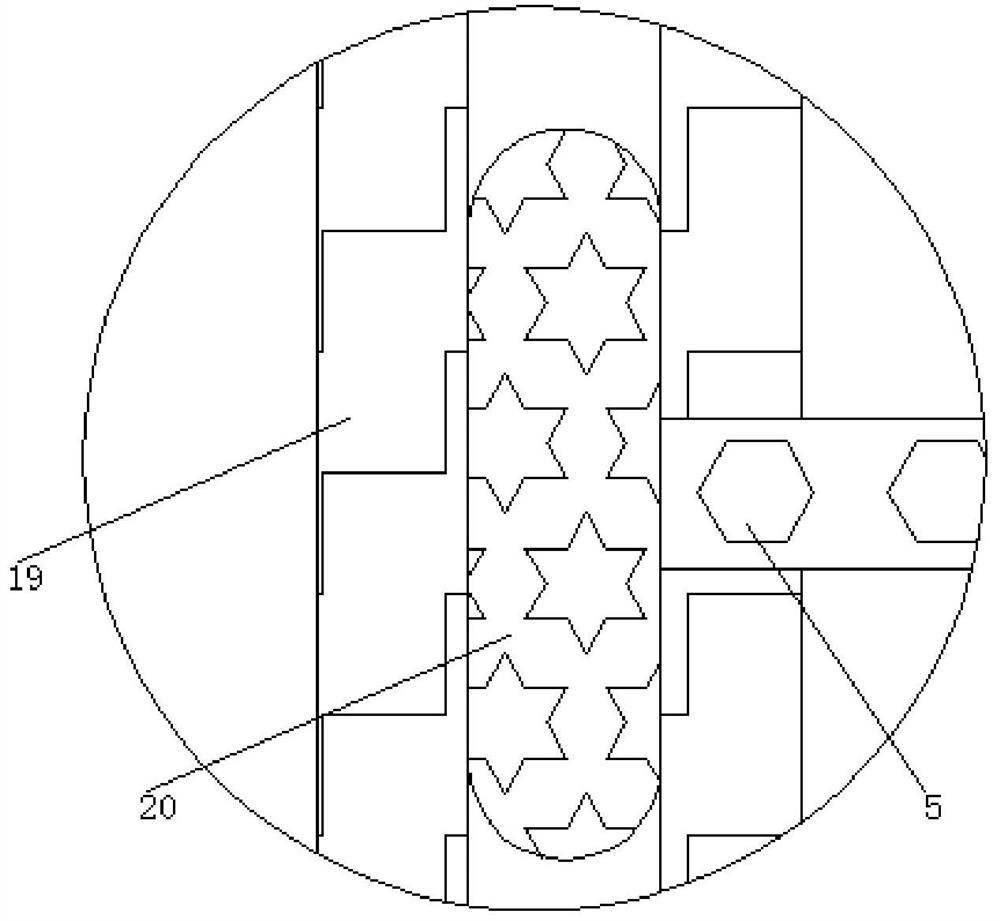

Fire extinguishing mechanism of power distribution cabinet

Owner:广州市顺承电气设备有限公司

Composite quality control product of liver function, and preparation method and application thereof

ActiveCN112063686AAvoid inactivationHigh purityMicrobiological testing/measurementDisease diagnosisNucleotidaseUltrafiltration

The invention relates to a composite quality control product of a liver function, and a preparation method and application thereof, wherein the composite quality control product comprises alpha-L-fucosidase, adenosine deaminase and 5'-nucleotidase; and the preparation method comprises the following steps of: taking a fresh pork liver as a raw material, and obtaining the composite quality control product of the liver function simultaneously containing three kinds of enzymes through processes of grinding, homogenizing, crushing, centrifuging, salting-out, purifying, ultrafiltration, freeze-drying and the like. By optimizing preparation process parameters, enzyme inactivation in the preparation process is avoided; meanwhile, impurities in the finished product are reduced; therefore, the purity of the target enzyme is improved; furthermore, the freeze-dried powder of the composite quality control product with better stability is obtained through a freeze-drying process; furthermore, a protective agent of enzyme solution is optimized, so that the thermal stability and long-term stability of the freeze-dried powder of the composite quality control product are enhanced; and thus, the composite quality control product of the liver function, which is simple and rapid in preparation method, low in cost and high in enzyme activity, uniformity and stability, is obtained.

Owner:WUHAN LIFE ORIGIN BIOTECH LTD

Preparation method and formula of aquatic feed

InactiveCN112753893AIncrease elasticityIncrease sweetnessFood processingClimate change adaptationHordeum vulgareHermetia illucens

The invention discloses a preparation method and a formula of an aquatic feed. The preparation method of the aquatic feed comprises the following steps of: S1, selecting the following raw materials in a weight ratio: dry flour of yellow mealworms, dry flour of barley pests, dry flour of black soldier flies, puffed soybean meal, pregelatinized starch, high-gluten flour, spirulina powder, blood worm powder, shrimp shell powder, beer yeast powder, bentonite powder, multivitamin for eels, glycerol monolaurate, choline chloride and calcium dihydrogen phosphate; S2, uniformly stirring the raw materials to form a mixed raw material; S3, adding water into the mixed raw material, continuing stirring, and then puffing the mixed raw material, wherein the water content in the mixed raw material is 17-20% by mass; and S4, after the puffing is completed, cooling and drying the granulated feed formed by puffing. The preparation method and the formula of the aquatic feed are applied to the technical field of aquatic feeds.

Owner:GUANGDONG LUJIN BIOTECHNOLOGY CO LTD

Method for preparing 4-amino-2,6-dihydroxypyrimidine by virtue of dry frying process

InactiveCN107721938AReduce manufacturing costReduce preparation energy consumptionOrganic chemistrySodium methoxideChemical synthesis

Owner:王微

Dry powder extinguishing agent and preparation method thereof

InactiveCN107551444AReduce manufacturing costPrevent damp cakingFire extinguisherPotassium nitrateSodium bicarbonate

Owner:SUZHOU WUYUE SYNTHETIC FIRE SCI TECH

Hydrating molding process and raw material formula of concrete faux marble granite dry powder

ActiveCN103880345AHigh degree of simulationLow-carbon environmental protection and energy savingSolid waste managementBrickHigh pressure

The invention discloses a hydrating molding process and a raw material formula of concrete faux marble granite dry powder. The raw material formula comprises ceramic residue, mineral powder, cement and quartz sand; the molding process comprises the following steps: mixing color, agitating materials, storing materials, spraying powder by virtue of a computer, distributing by virtue of a plurality of pipelines, controlling a manipulator to adjust a pattern, spraying water at high pressure for hydrating, vibrating to mold, maintaining with steam, and polishing a surface. The raw material formula is on the basis of the ceramic residue and cement, and the molding process does not need any high-temperature firing, so that the advantages of low carbon, environmental friendliness and energy conservation are realized; in addition, a finished product molded through the process is high in simulation degree, the plate is 10 to 30mm in thickness, or a composite layer on the surface of a concrete faux marble granite composite plate is 3 to 8mm in thickness; all finished bricks are slightly different, have high sense of wholeness, and also show high naturalness while being applied to a specific scene; moreover, the problem of the current ceramic industry that a wall brick or a ceramic brick can only be molded by firing at a high temperature, which causes large energy consumption, serious pollution and treatment on lots of ceramic residues produced by the production of the wall brick or ceramic brick in the traditional ceramic industry, can be solved.

Owner:李庆洪

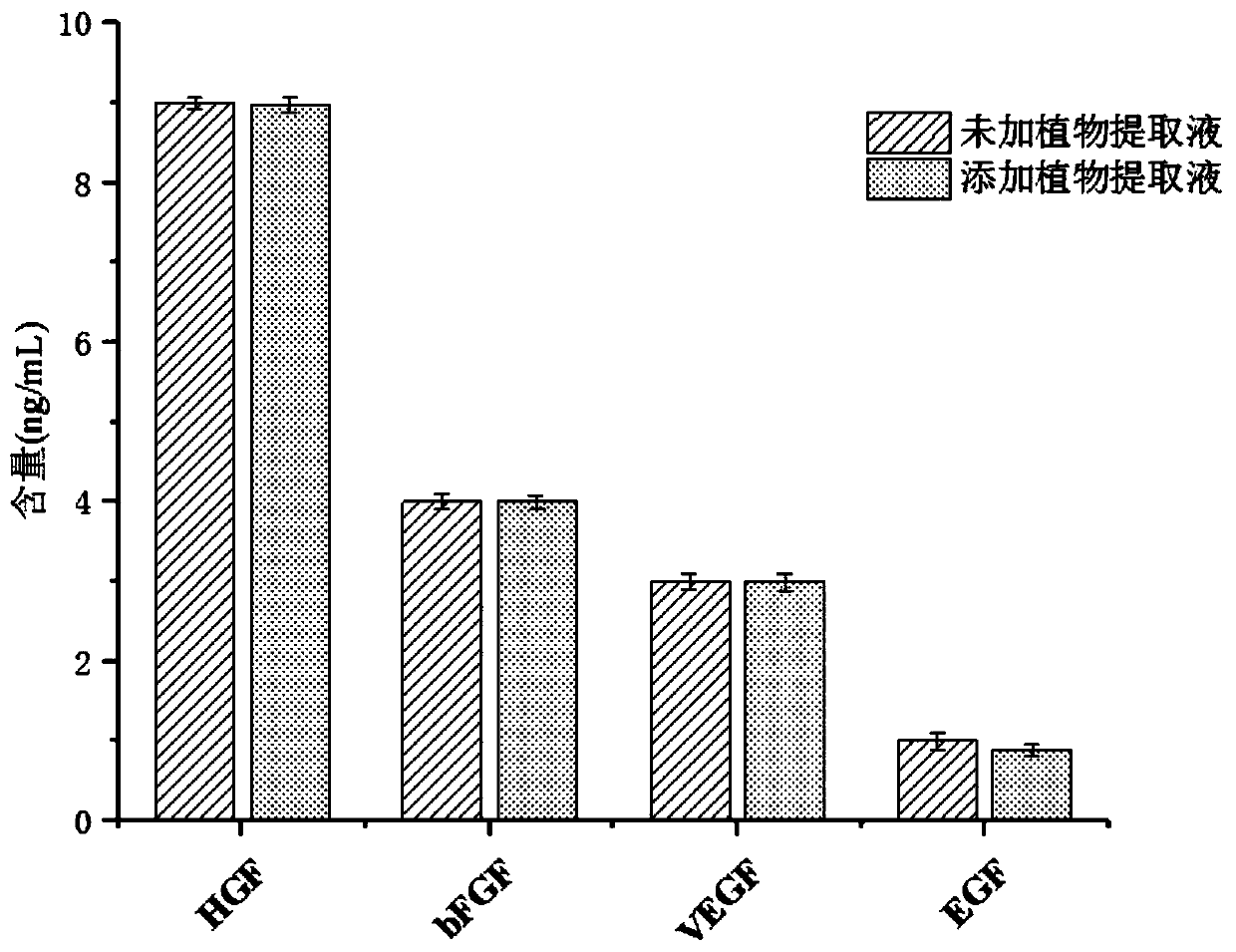

Preparation method and application of humanized skin fibroblast intracellular effective components

InactiveCN111518754AGuaranteed stabilityIncrease productionCell dissociation methodsPowder deliveryEnzymatic digestionLysis

Owner:潍坊峡山源宜医学科技有限责任公司

Insecticide-fertilizer for out-of-season fruit green radish and preparation method thereof

Owner:潍坊市绿旺达生物肥料科技有限公司

Rich aroma maltol sashimi and preparation method thereof

InactiveCN104905319AReduced nutritional valueShorten the timeFood ingredient functionsFood preparationBiotechnologySesbania gum

Owner:合肥市韩林家庭农场有限公司

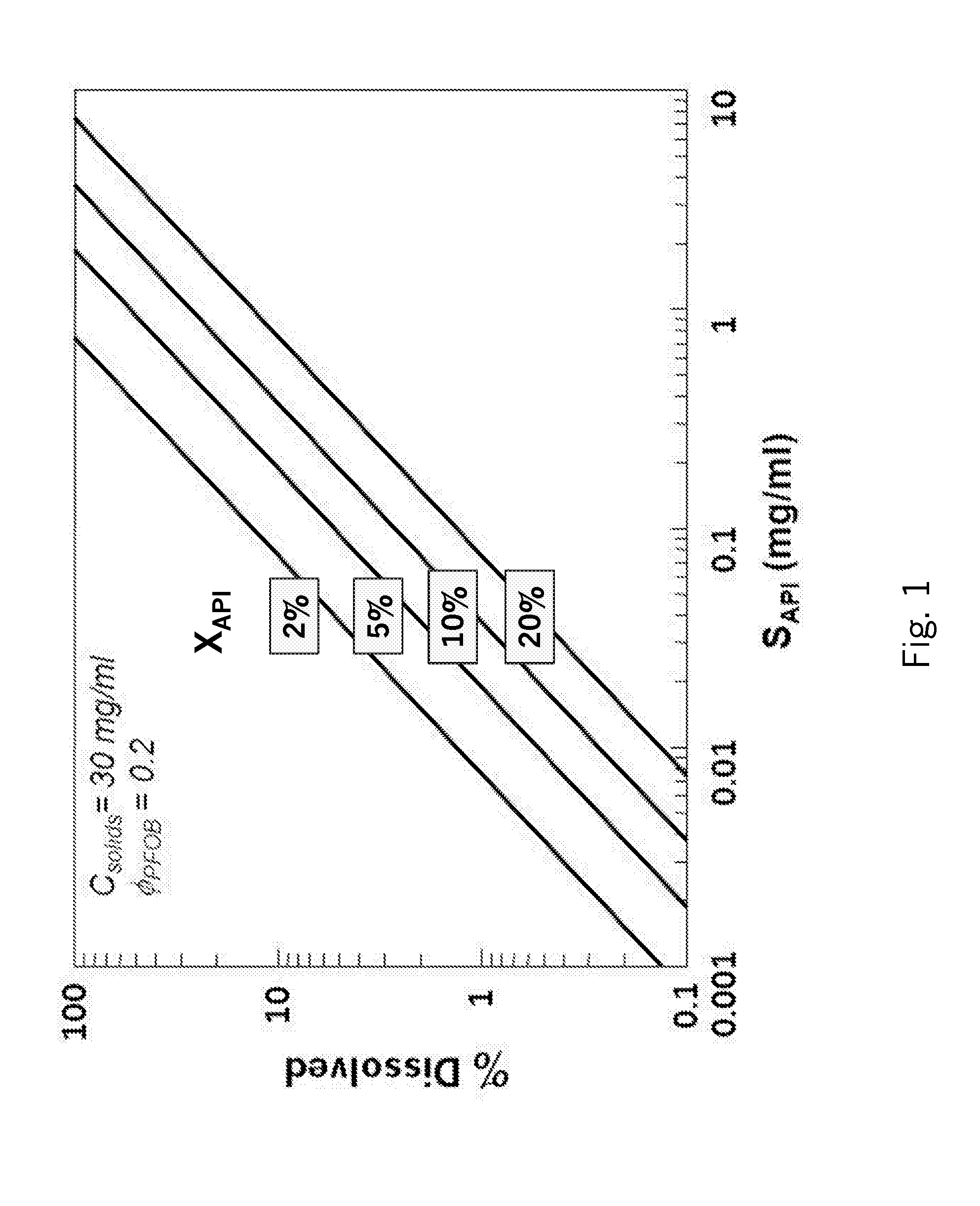

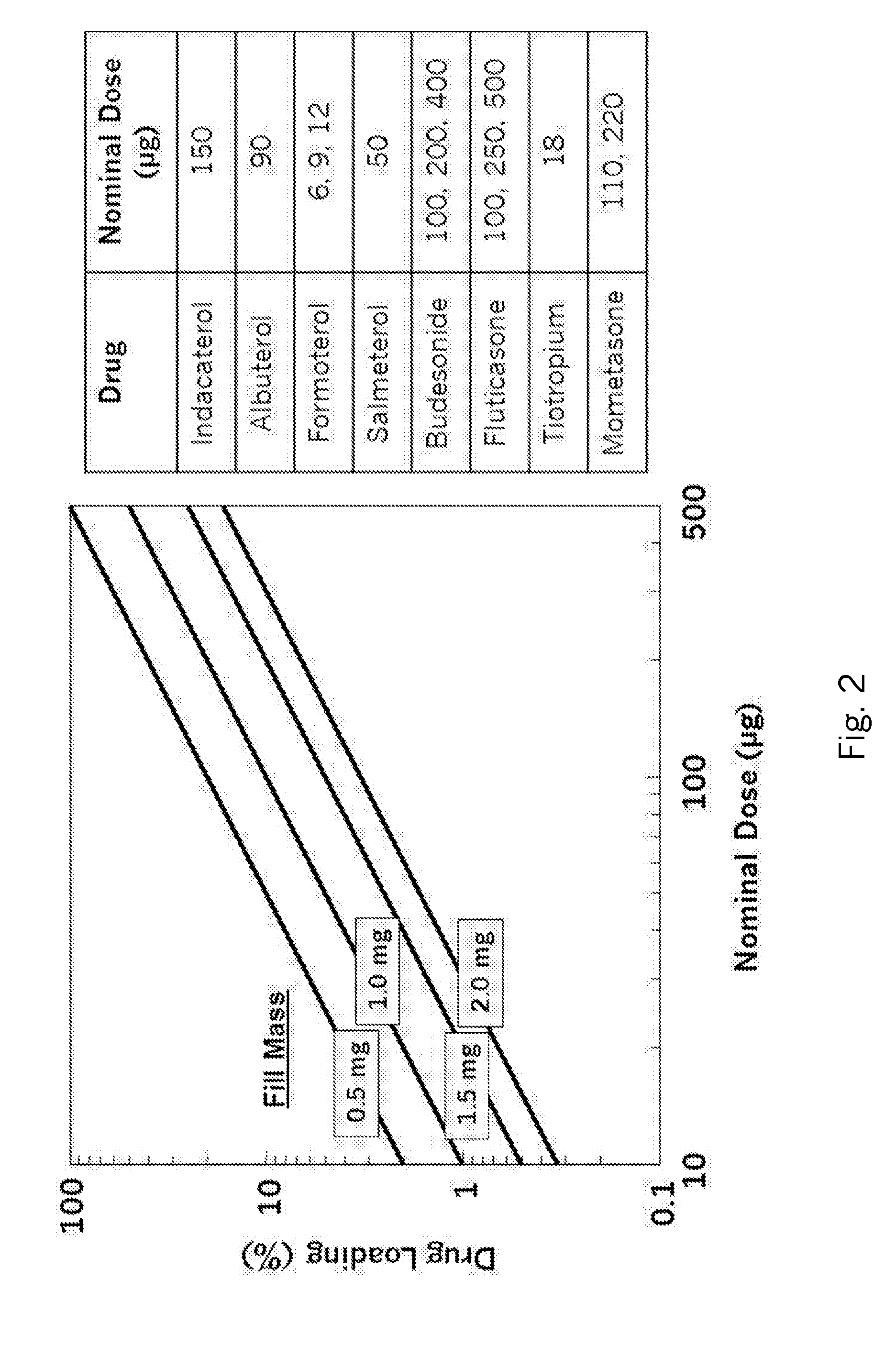

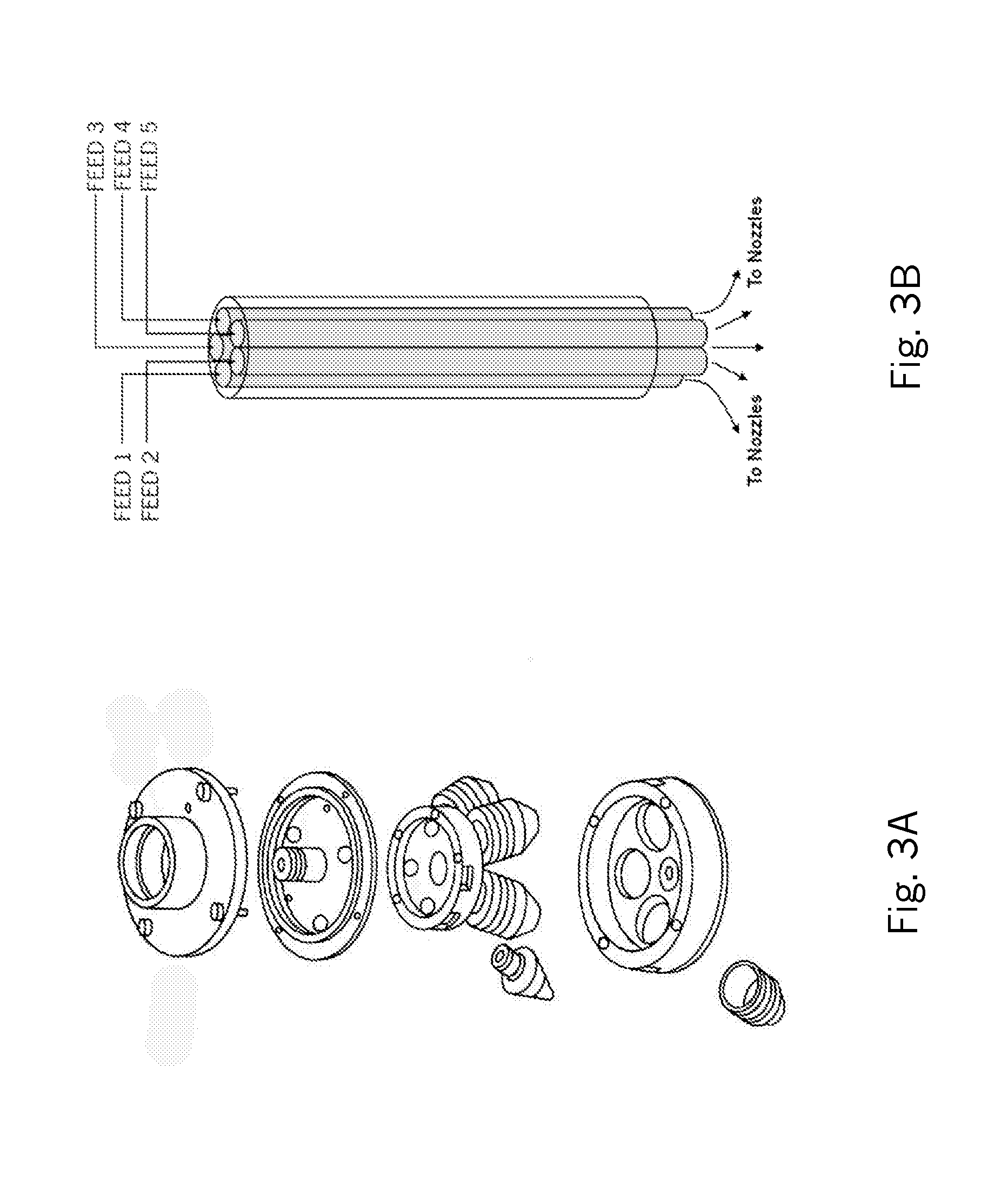

Deamorphization of spray-dried formulations via spray-blending

Owner:NOVARTIS AG

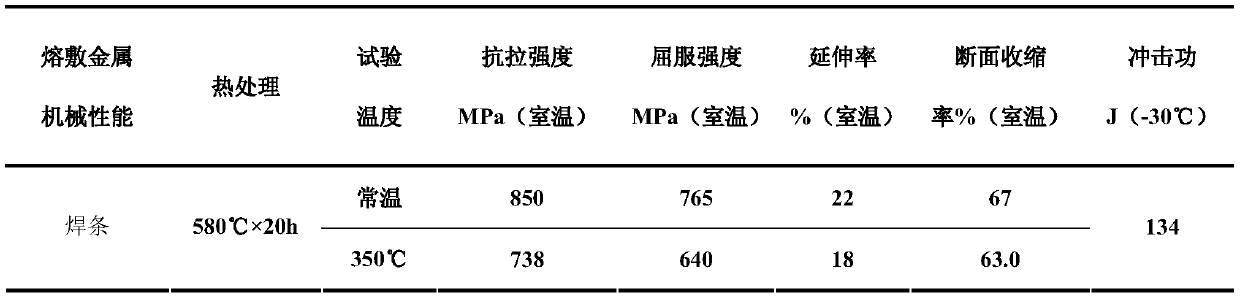

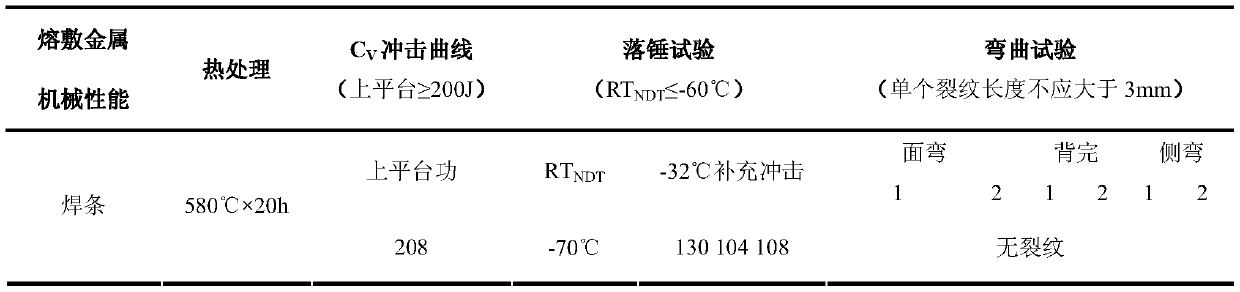

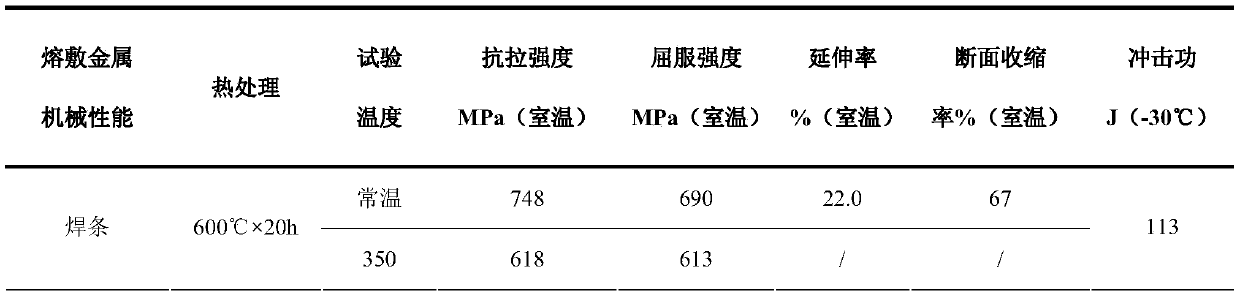

Welding rod matched with steel for 3Ni-1.6 Cr-0. 5Mo nuclear power equipment and preparation method of welding rod

ActiveCN111037152AGood welding adaptabilityGood workmanshipWelding/cutting media/materialsSoldering mediaMetal powderUltimate tensile strength

Owner:CFHI DALIAN HYDROGENANT REACTOR +1

Traditional Chinese medicine composition for treating skin ulcer and method for preparing traditional Chinese medicine composition

ActiveCN106975018AWith detoxification and swellingGood curative effectAnthropod material medical ingredientsFungi medical ingredientsSporePropolis

Owner:任建丰

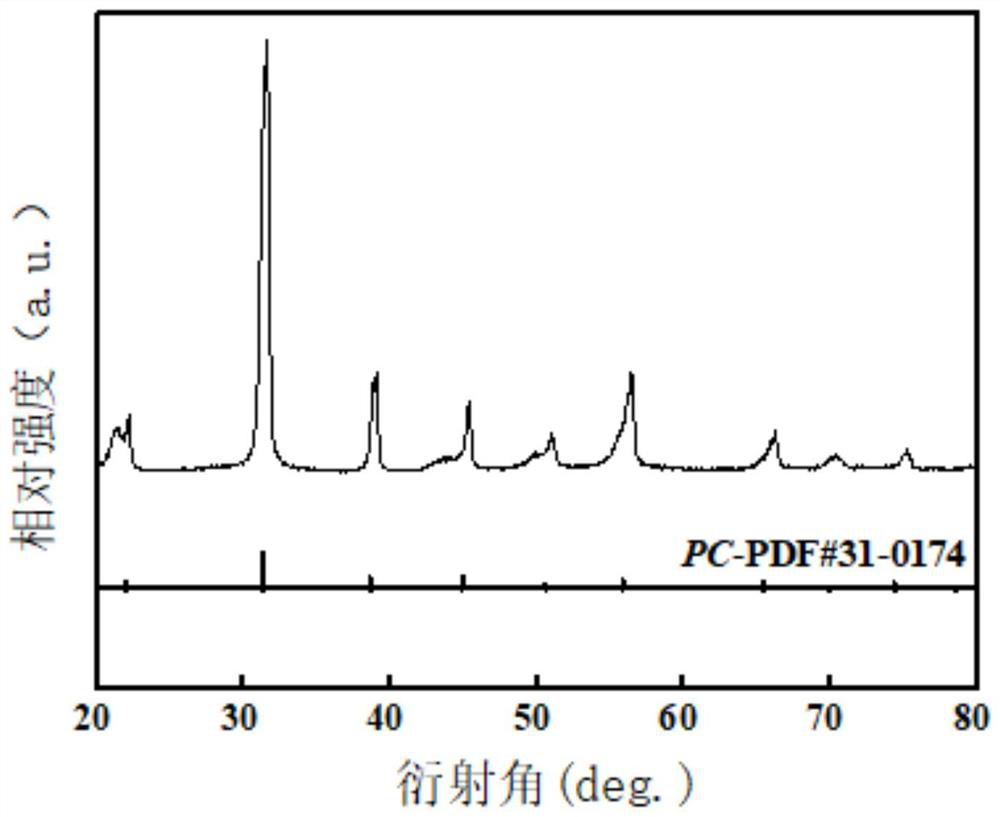

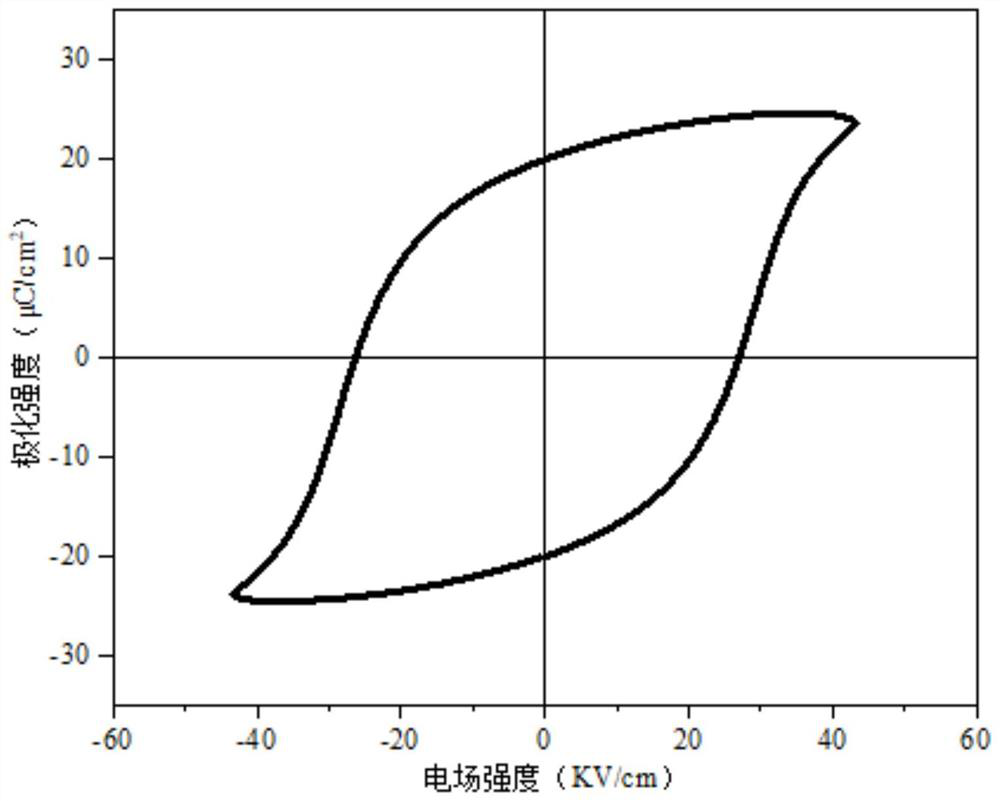

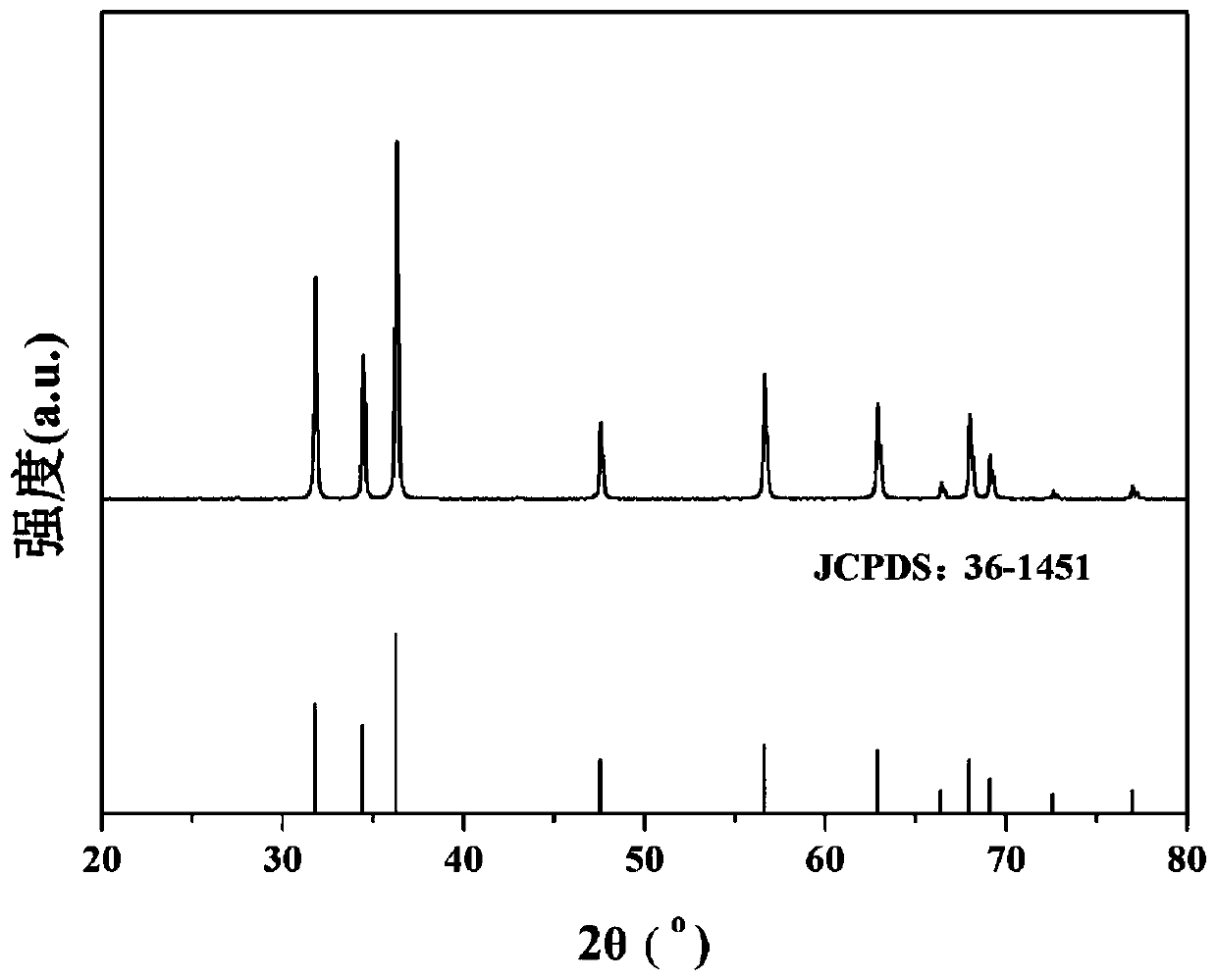

Preparation method of doped bismuth ferrite-barium titanate-based lead-free piezoelectric ceramic material

PendingCN114180952ASmall grain sizeHigh densityFixed capacitor dielectricAcceleration measurementBarium titanatePolyvinyl alcohol

Owner:UNIV OF SCI & TECH BEIJING

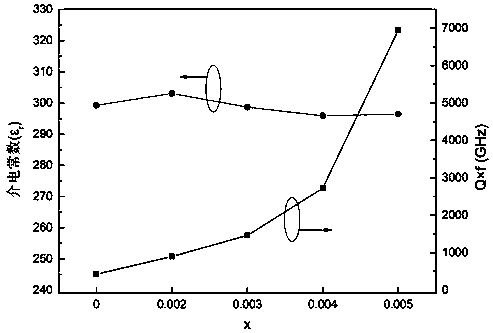

Strontium titanate ceramic with high dielectric constant and low dielectric loss

InactiveCN108129146AExcellent dielectric propertiesHigh utility valueStrontium titanium oxideDielectric loss

Owner:EAST CHINA UNIV OF SCI & TECH

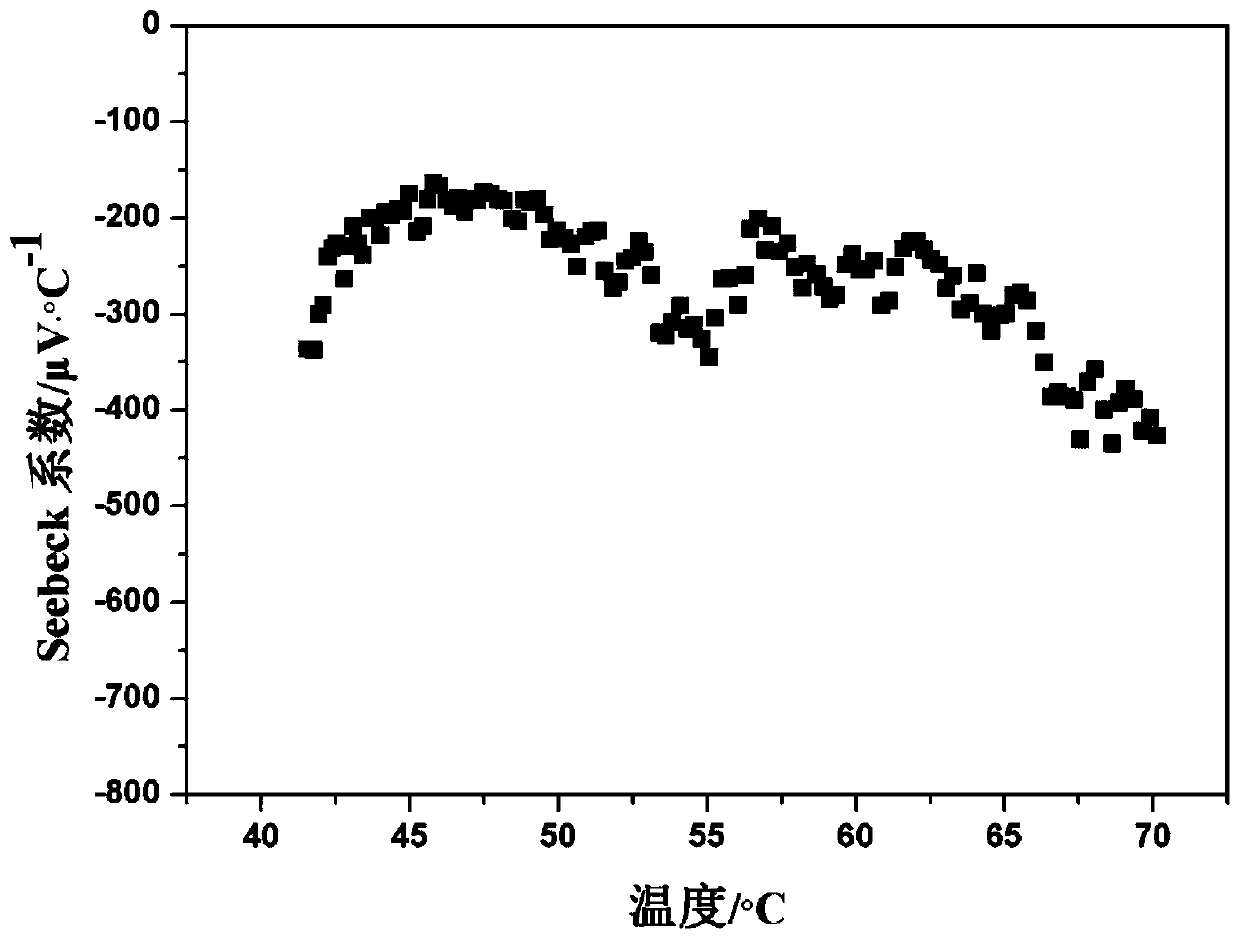

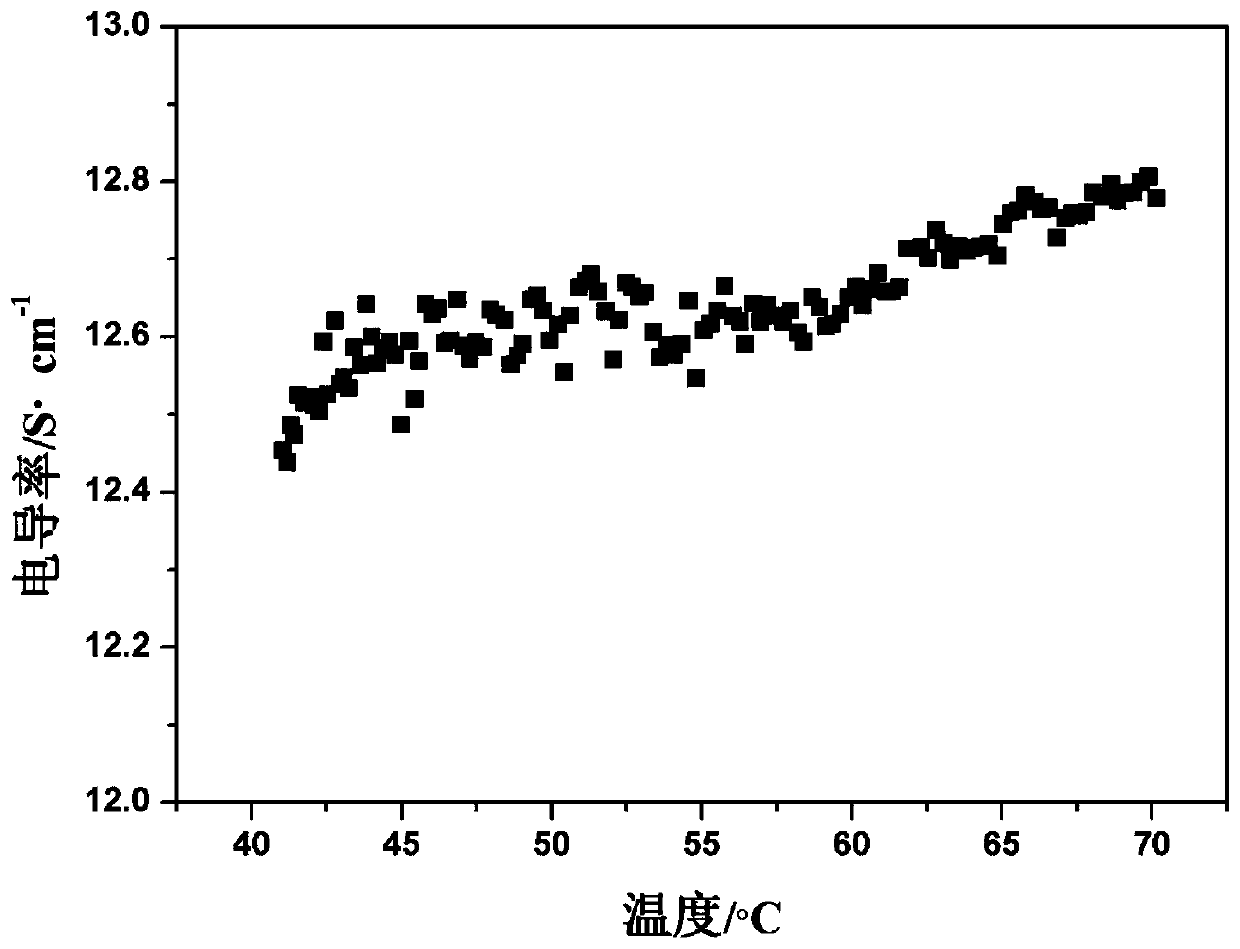

Method for improving power factor of cement-based composite material by pretreating zinc oxide

ActiveCN111302687AHigh thermoelectric power factorSuitable for application requirementsBall millHeat treated

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Health care green tea

InactiveCN109315529AEasy to get ingredientsEasy to drinkPre-extraction tea treatmentAdditive ingredientGinkgo biloba

Owner:湖北芈熙茶业股份有限公司

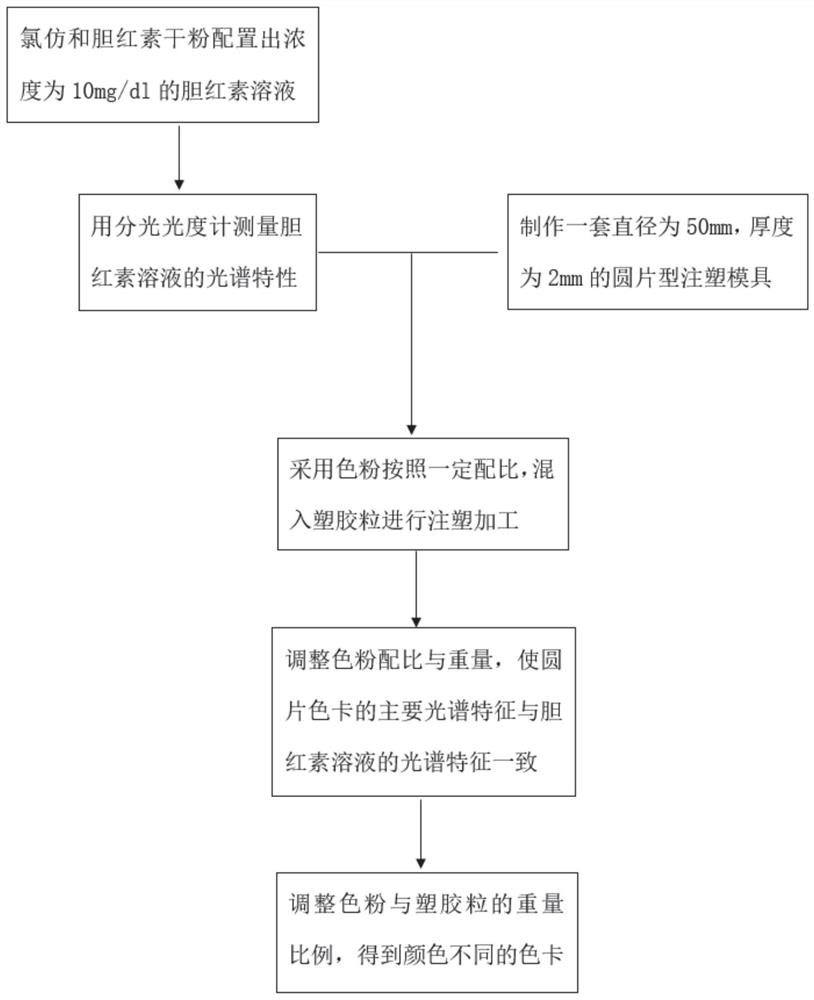

Method for manufacturing calibration color card of newborn percutaneous jaundice instrument

PendingCN114454416AAchieve traceabilityImprove consistencySensorsDiagnostic recording/measuringSpectrum analyzerInjection moulding

Owner:深圳丹娃科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap