Fire extinguishing mechanism of power distribution cabinet

A technology for fire extinguishing mechanism and power distribution cabinet, which is applied in fire rescue and other directions, can solve the problems of disaster, inconvenience, and high cost, and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

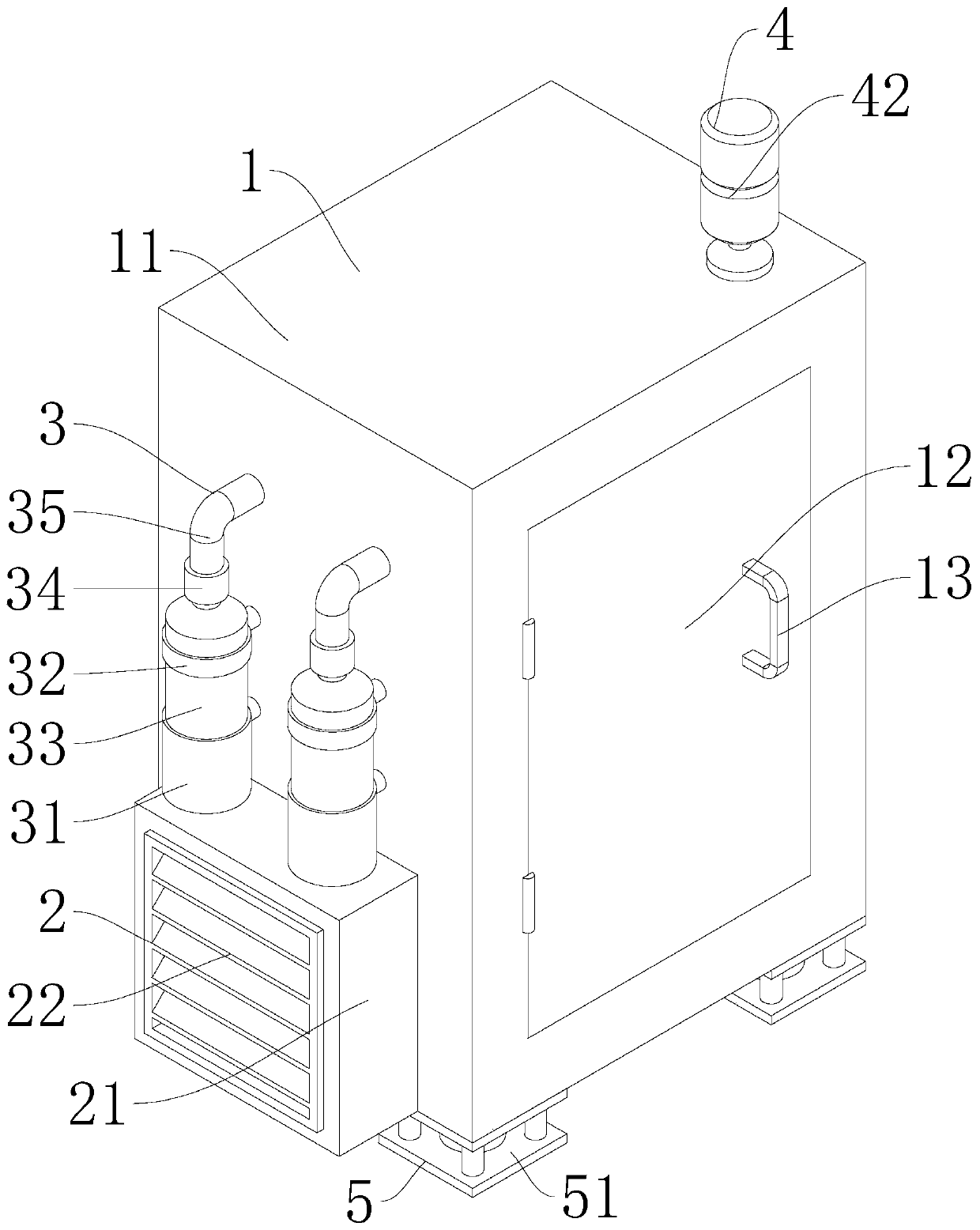

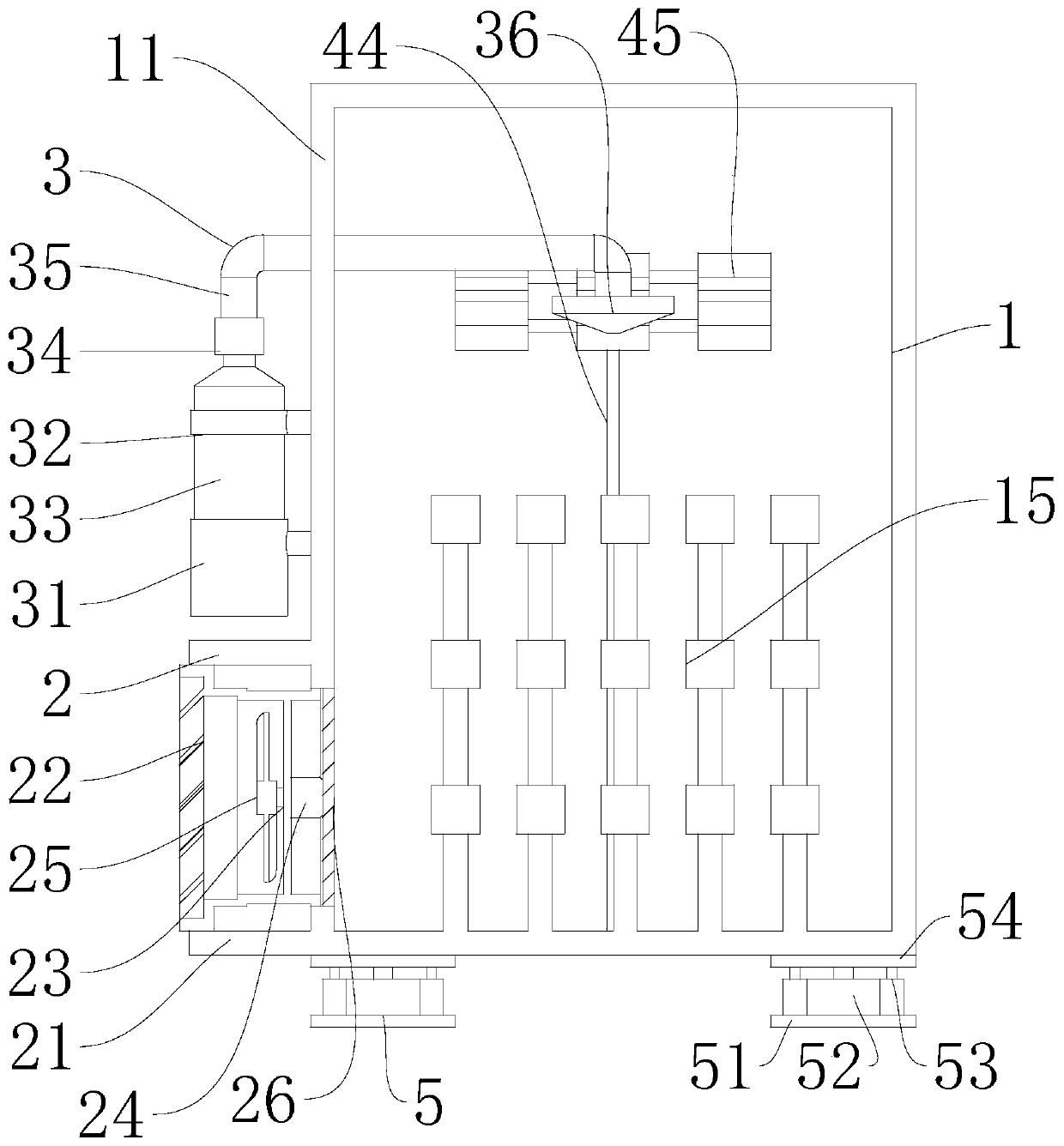

[0031] like figure 1 , image 3 , Figure 5 As shown, the damping mechanism 5 includes a base plate 51, a damping cylinder 52, a telescopic rod 53, and a support plate 54. The base plate 51 is provided with a damping cylinder 52, and the top of the damping cylinder 52 is connected with a telescopic rod 53. There is a support plate 54, and the support plate 54 is connected to the power distribution cabinet 1 through bolts. The power distribution cabinet 1 includes an electric box 11, an inspection door 12, a door handle 13, a socket port 14, and electrical components 15. The front side of the electric box 11 is connected by a hinge. There is an inspection door 12, a door handle 13 is arranged on the inspection door 12, a socket port 14 is arranged on the rear side of the electric box 11, a plug 45 is embedded in the socket port 14, electrical components 15 are arranged inside the electric box 11, and the cooling mechanism 2 includes a cooling box 21. Louver 22, mounting plate 23

Embodiment 2

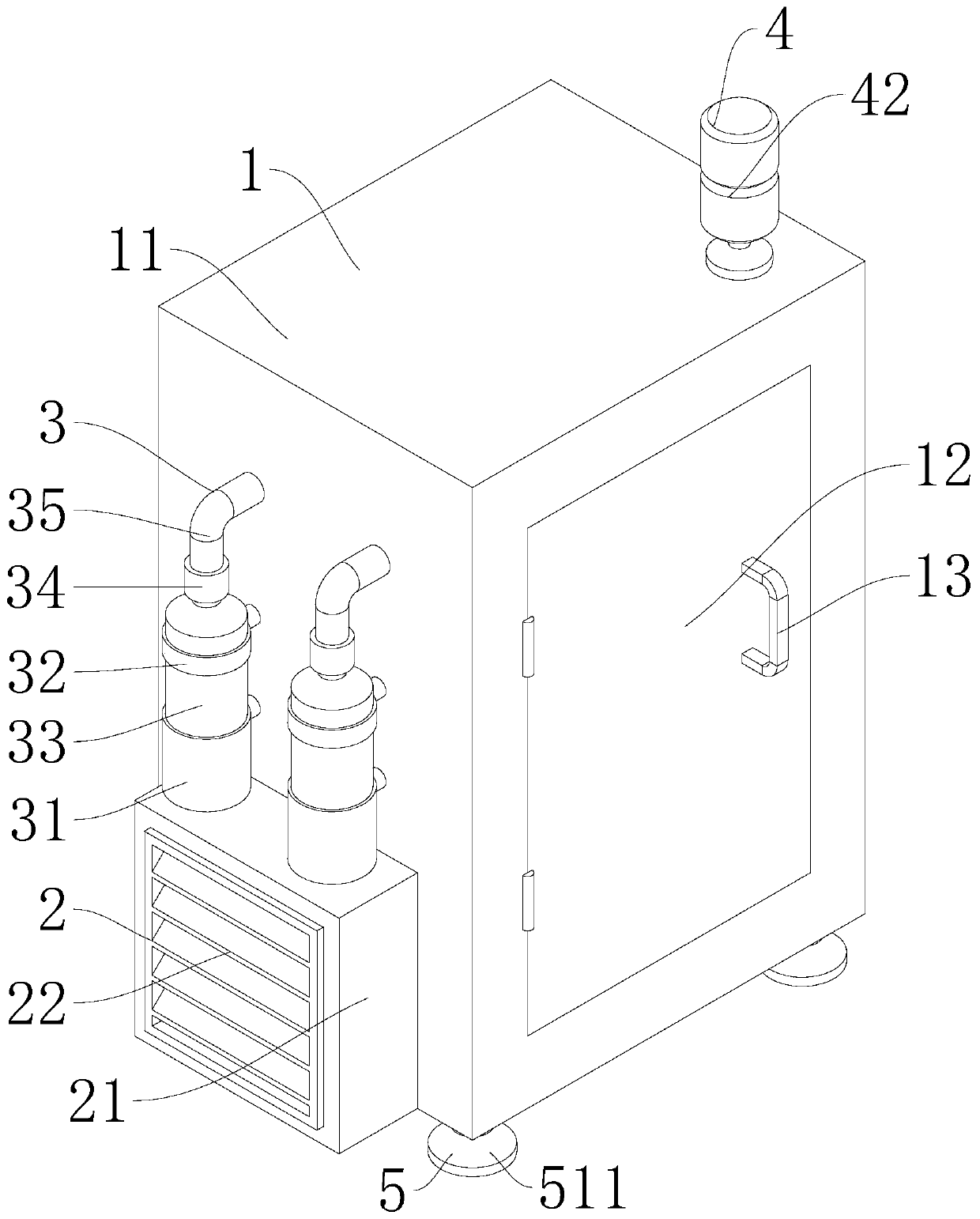

[0034] like figure 2 , Figure 4 , Figure 6As shown, the difference between Embodiment 2 and Embodiment 1 is that the bottom plate 51, shock-absorbing cylinder 52, telescopic rod 53, and support plate 54 are replaced with foot cups 511, shock-absorbing springs 512, and support rods 513, and the power distribution cabinet 1 uses At this time, the foot cup 511 effectively grips the ground, and the vibration generated by the power distribution cabinet 1 is transmitted to the support rod 513, and the support rod 513 transmits the vibration to the damping spring 512, and the vibration is removed by the damping spring 512.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap