Gigging fuse wire structure

A fused filament structure and raising technology, applied in filament/thread forming, textile and papermaking, fiber processing, etc., can solve the problems of chemical fiber insulation performance is not good, excellent, chemical fiber does not have natural fiber uneven texture, etc., to prevent Air flow, the effect of improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

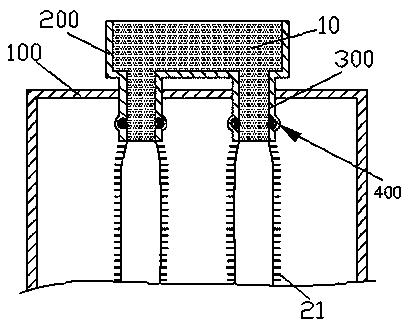

[0018] refer to figure 1 , in this embodiment, the fleece fuse structure includes a melt extrusion device 200 filled with melt 10 and a fuse nozzle 300 arranged on the melt extrusion device 200, and the fuse nozzle 300 nozzle It is arranged downward on the top of a closed box 100, and the inner surface of the fuse nozzle 300 is provided with a heat conduction layer, and the heat conduction layer is thermally connected with a cooling device, and the inner surface of the fuse nozzle 300 is evenly distributed along the circumferential direction. There is a perforating member 400 for perforating the melt 10 .

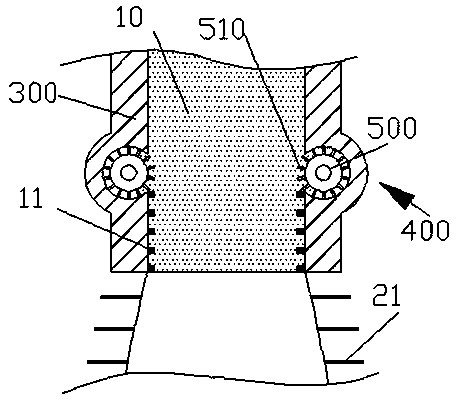

[0019] refer to figure 2 , the perforating member 400 is a pulley 500 ring-distributed in the inner wall of the fuse nozzle 300, the wheel surface side of the pulley 500 is tangent to the melt 10, the wheel surface of the pulley 500 is uniform A thin column 510 with a cooling layer on the top is arranged, and the pulley 500 rotates synchronously with the movement of the mel

Embodiment 2

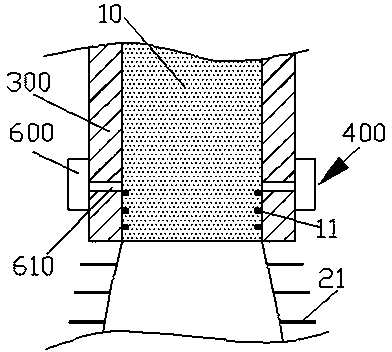

[0025] refer to figure 1 with image 3 , in this embodiment, only the perforating member 400 of the first embodiment is transformed into a nozzle 610 distributed on the inner wall of the fuse nozzle 300, and the nozzle 610 is connected with an intermittent pumping device 600 connected.

[0026] The working principle and method of the above-mentioned fleece fuse structure:

[0027] refer to figure 1 with image 3 , the melt 10 forms a small hole 11 due to the intermittent gas ejected from the spout 610, and the melt 10 forms a solidified layer with the small hole 11 due to the cooling of the heat conduction layer, and the melt 10 The expansion phenomenon, the melt 10 bound by the solidified layer expands, and flows out from the small hole 11 to form fluff 21 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap