NMR MAS inflow bernoulli bearing

a technology of bernoulli bearing and nmr mas, which is applied in the direction of magnetic circuit rotating parts, magnetic circuit shapes/forms/construction, instruments, etc., can solve the problem that the axial pressure over the conical rotor end may then exceed the atmospheric pressure by a substantial amount, and achieve the effect of improving stability and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

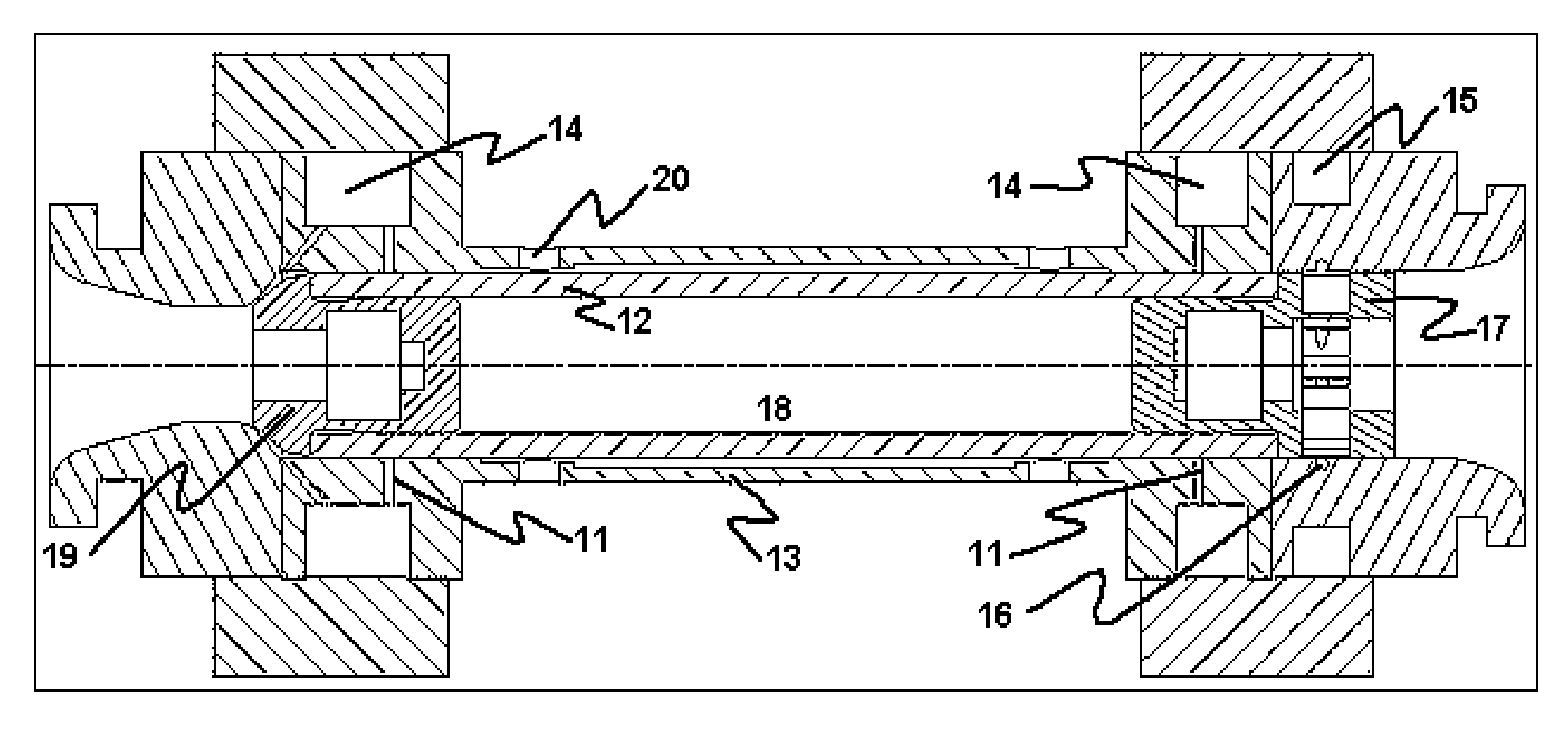

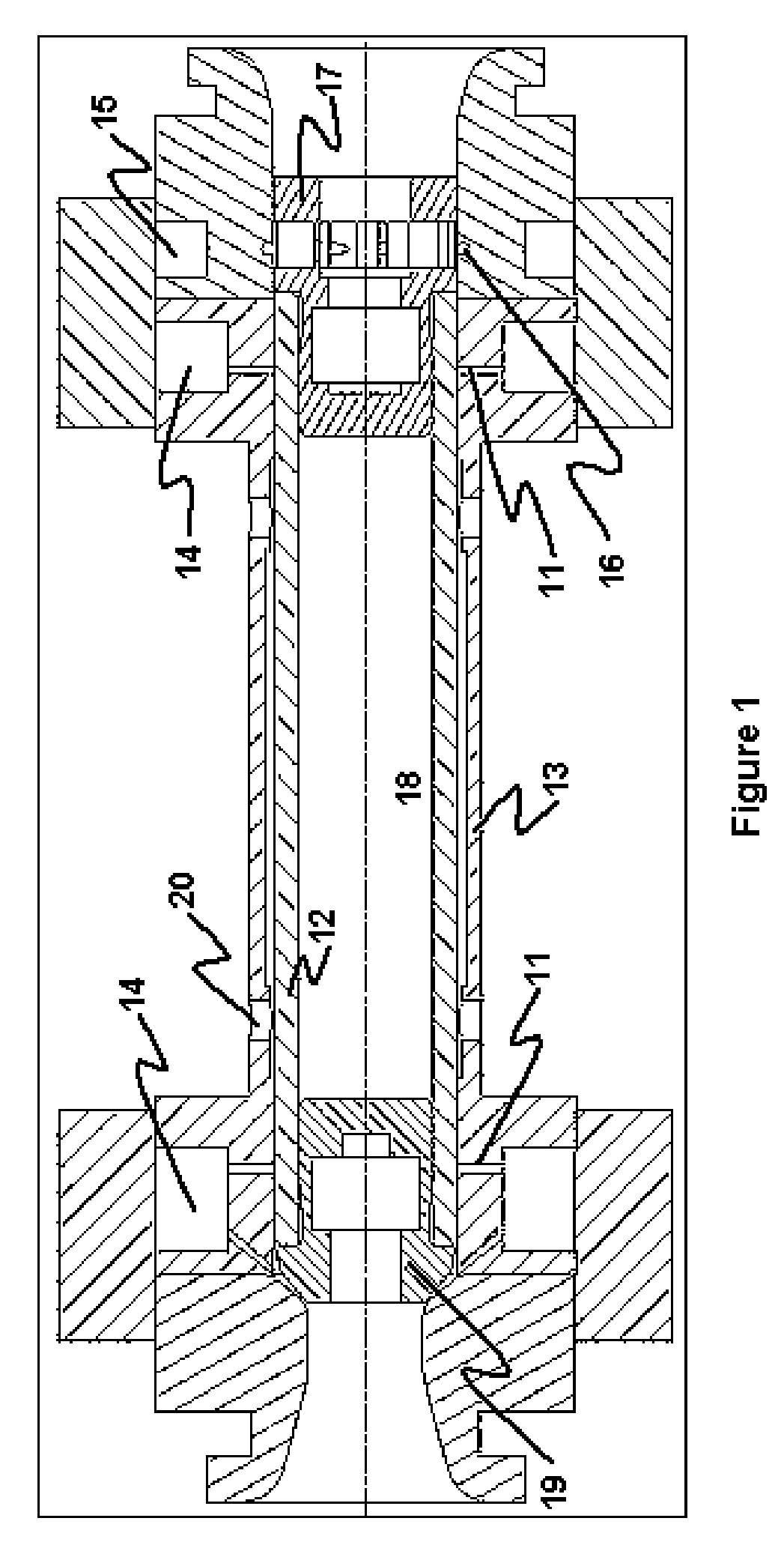

[0031] The high-speed NMR sample spinner shown in FIG. 1 has hydrostatic air radial bearing orifices 11 introducing pressurized gas radially to support the ceramic rotor 12 near both ends inside the ceramic cylindrical stator 13, according to the prior art. Note that these orifices are referred to as radial for convenience, as they establish radial support, but in practice they are typically offset from a purely radial direction. Bearing manifolds 14 are provided for distribution of air to the radial bearing orifices of throat diameter d1, and a drive manifold 15 is provided for distribution of air to the tangentially directed drive nozzles 16, which enable the microturbine 17 at the “top” or “front” of the rotor to spin the rotor 12 and its NMR sample 18. The axial bearing tip 19 is pressed into the “bottom” or “rear” of the rotor. The preferred radial bearing orifice throat diameter d1 is typically about 0.1 mm for a rotor of 2 mm outside diameter, and it is about 0.25 mm for a 14 mm

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap