Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60 results about "Knife blades" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

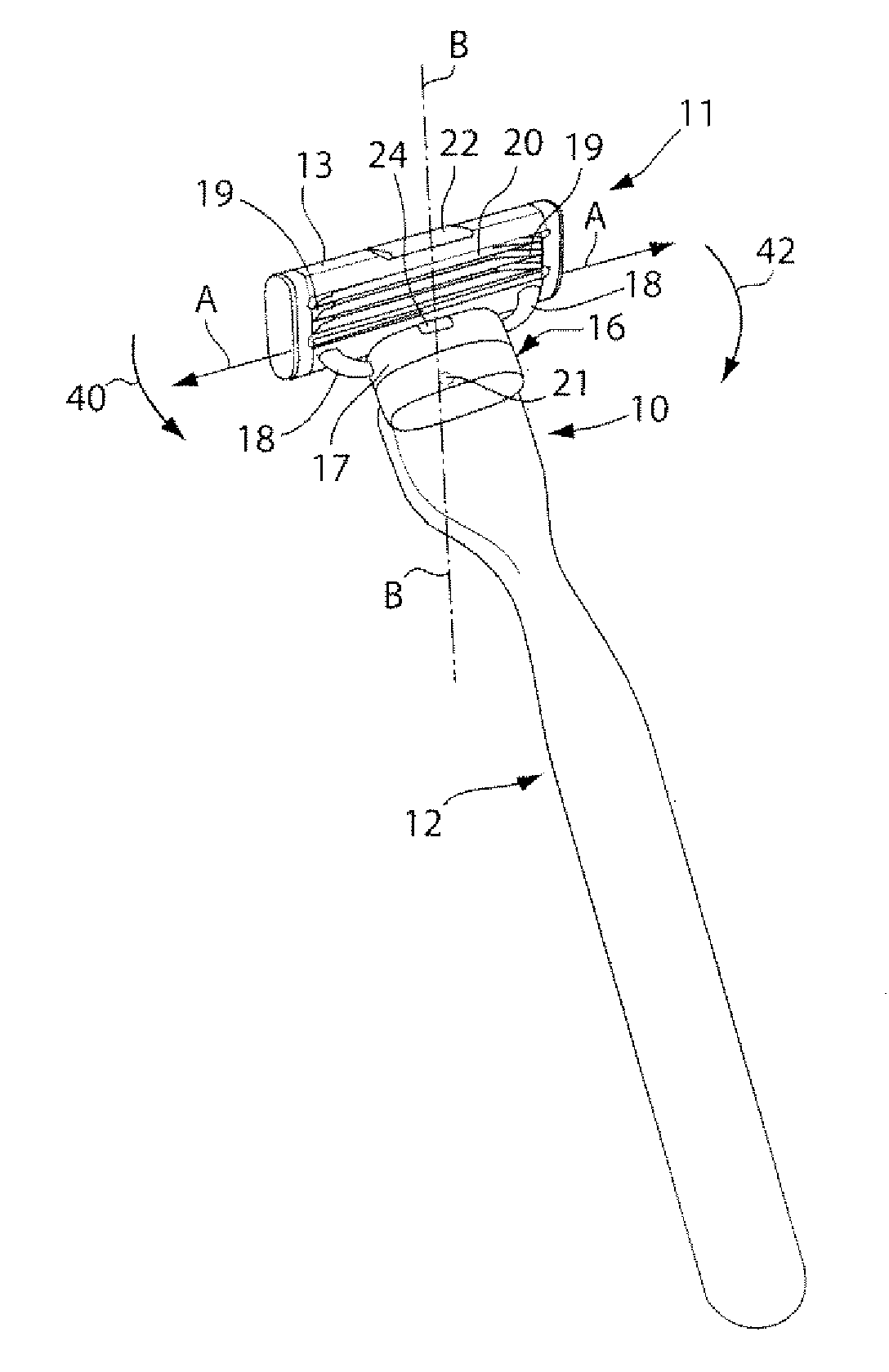

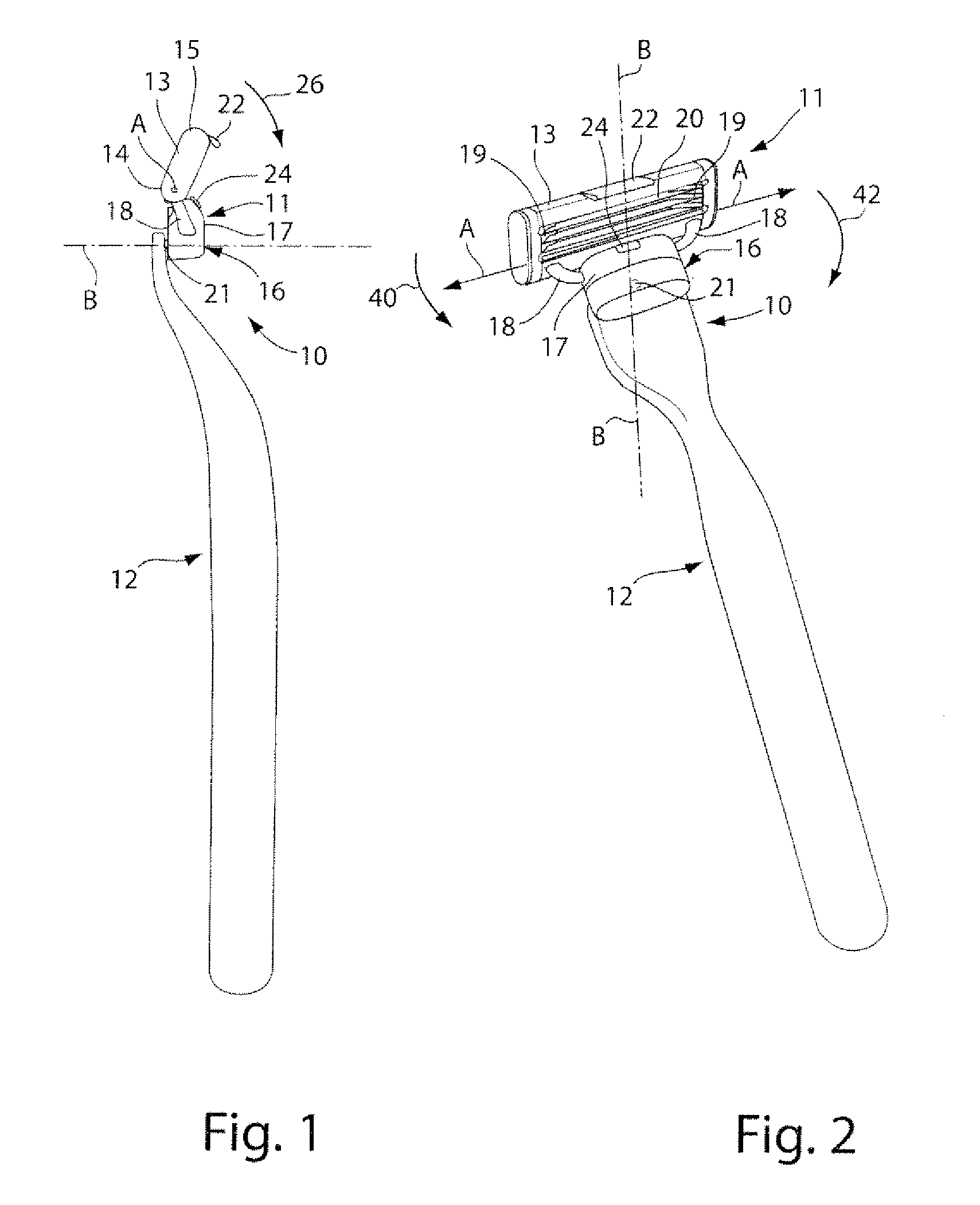

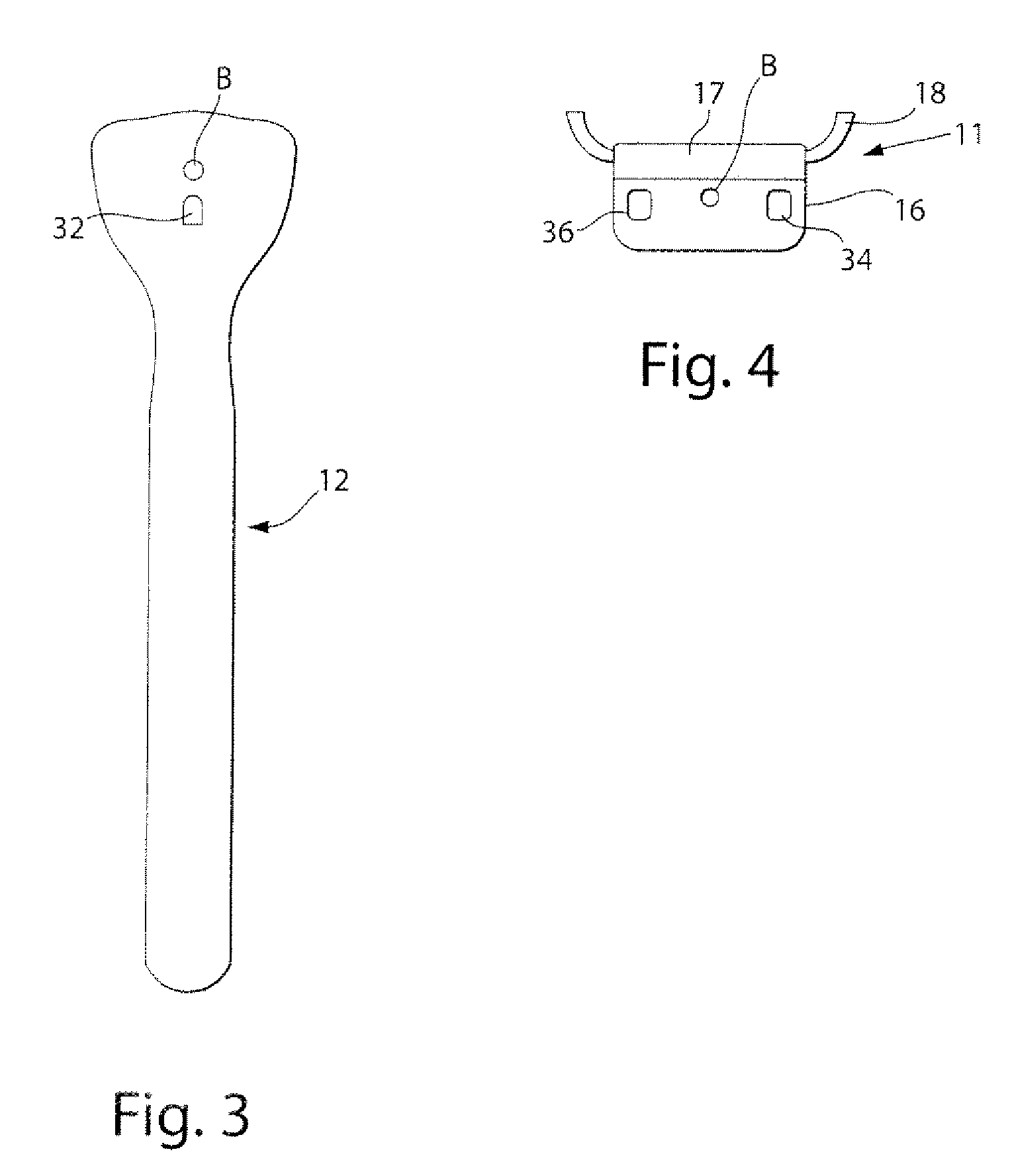

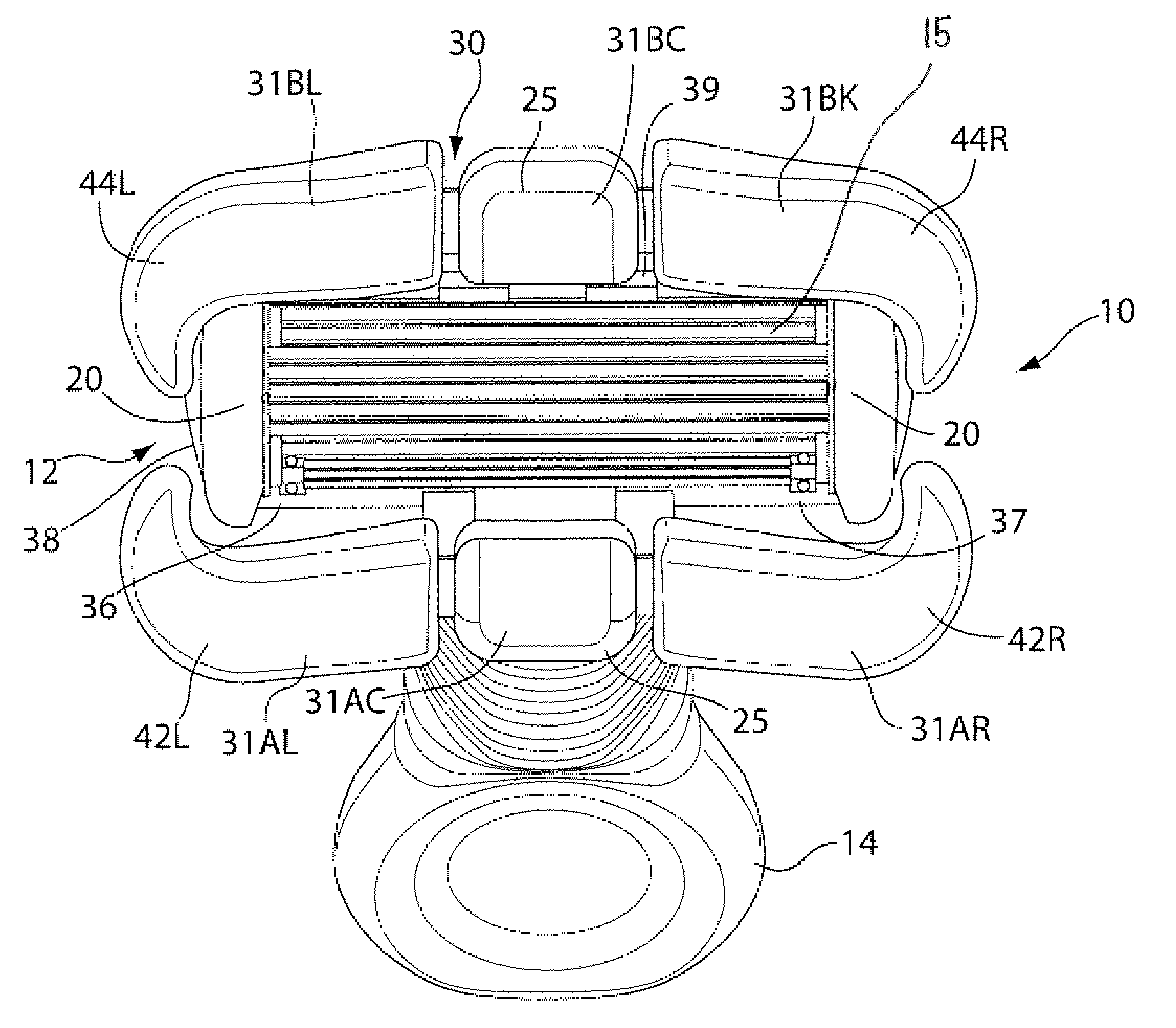

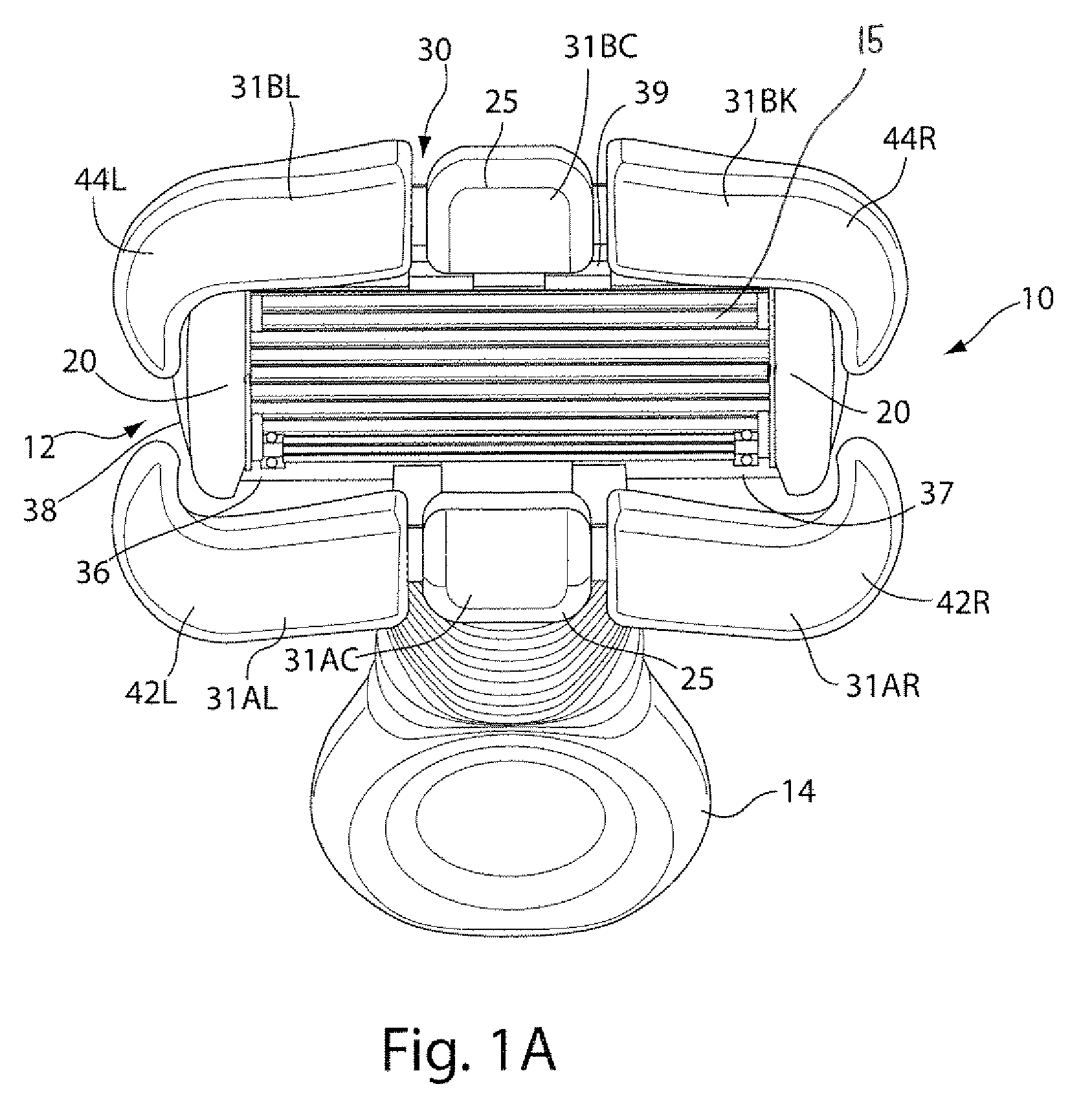

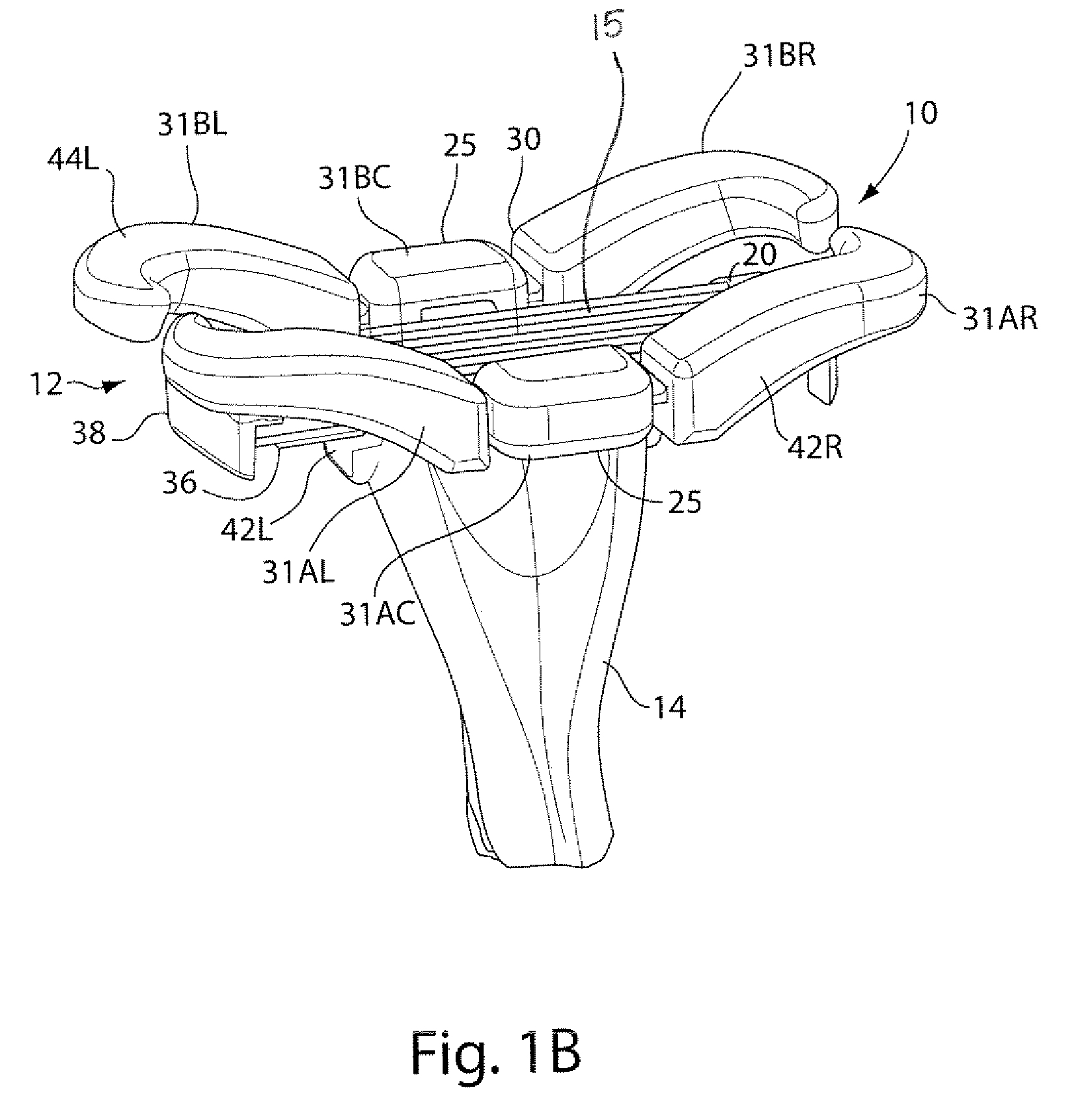

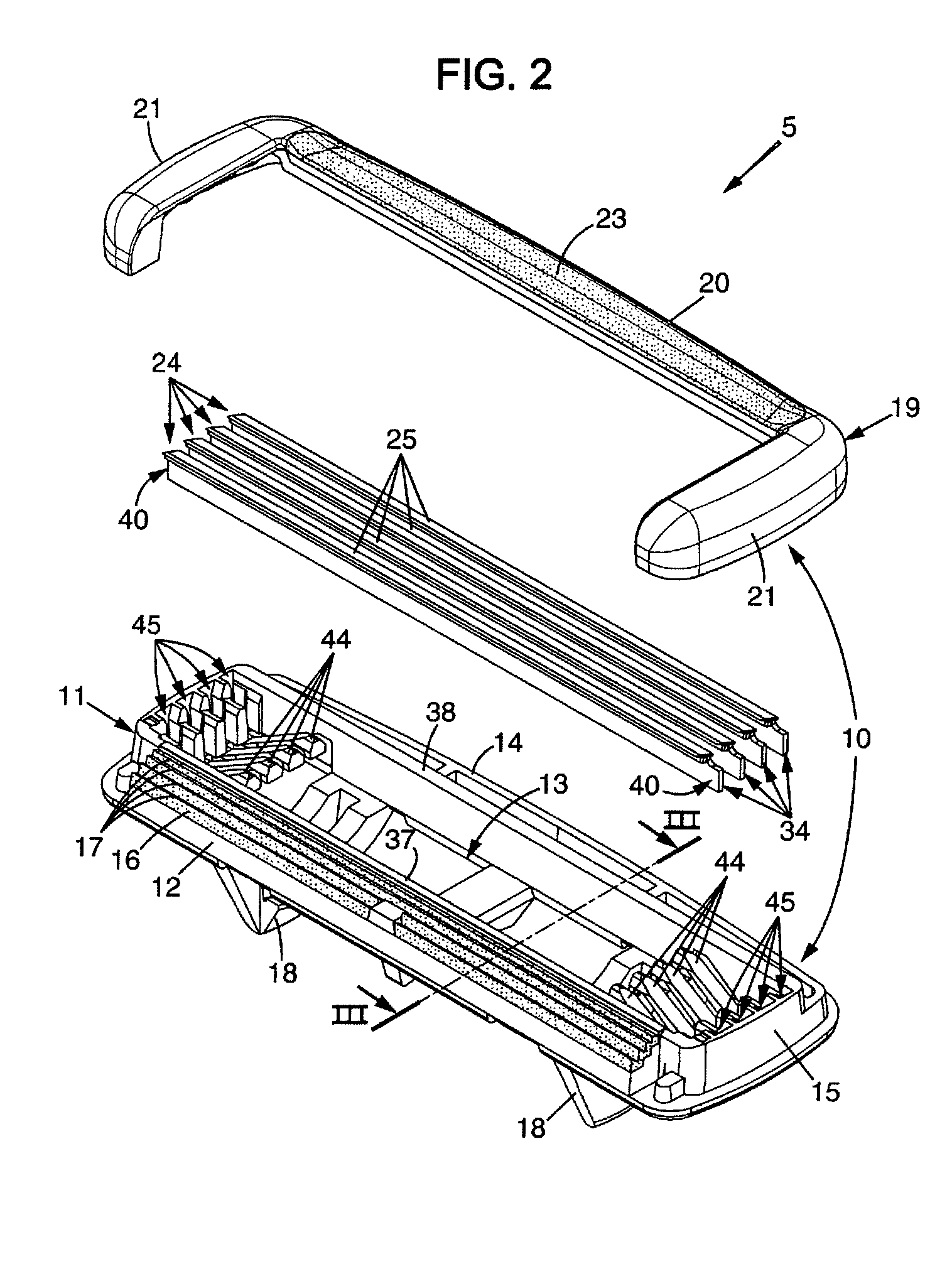

Safety razor with multi-pivot blade unit

Owner:THE GILLETTE CO

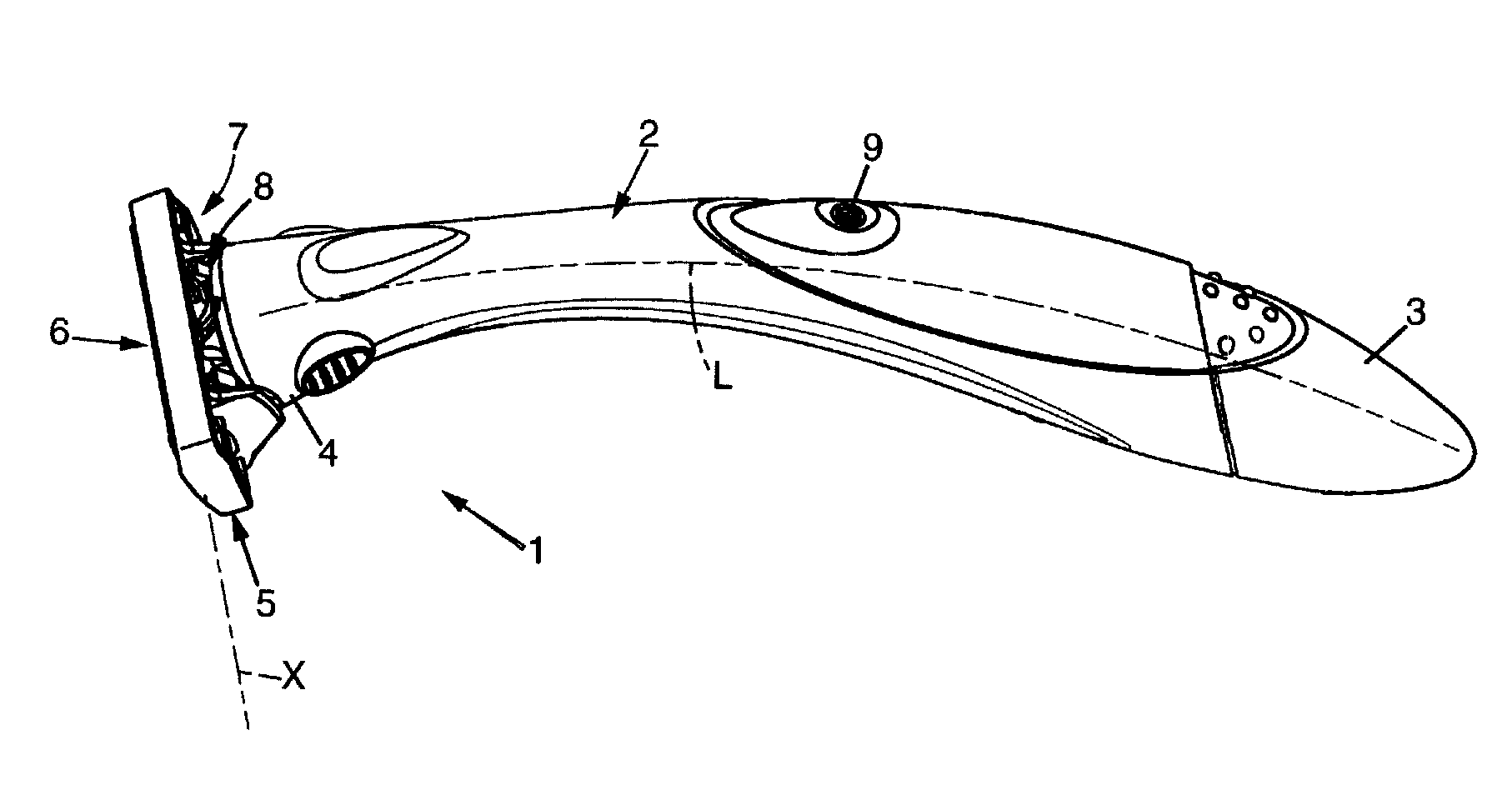

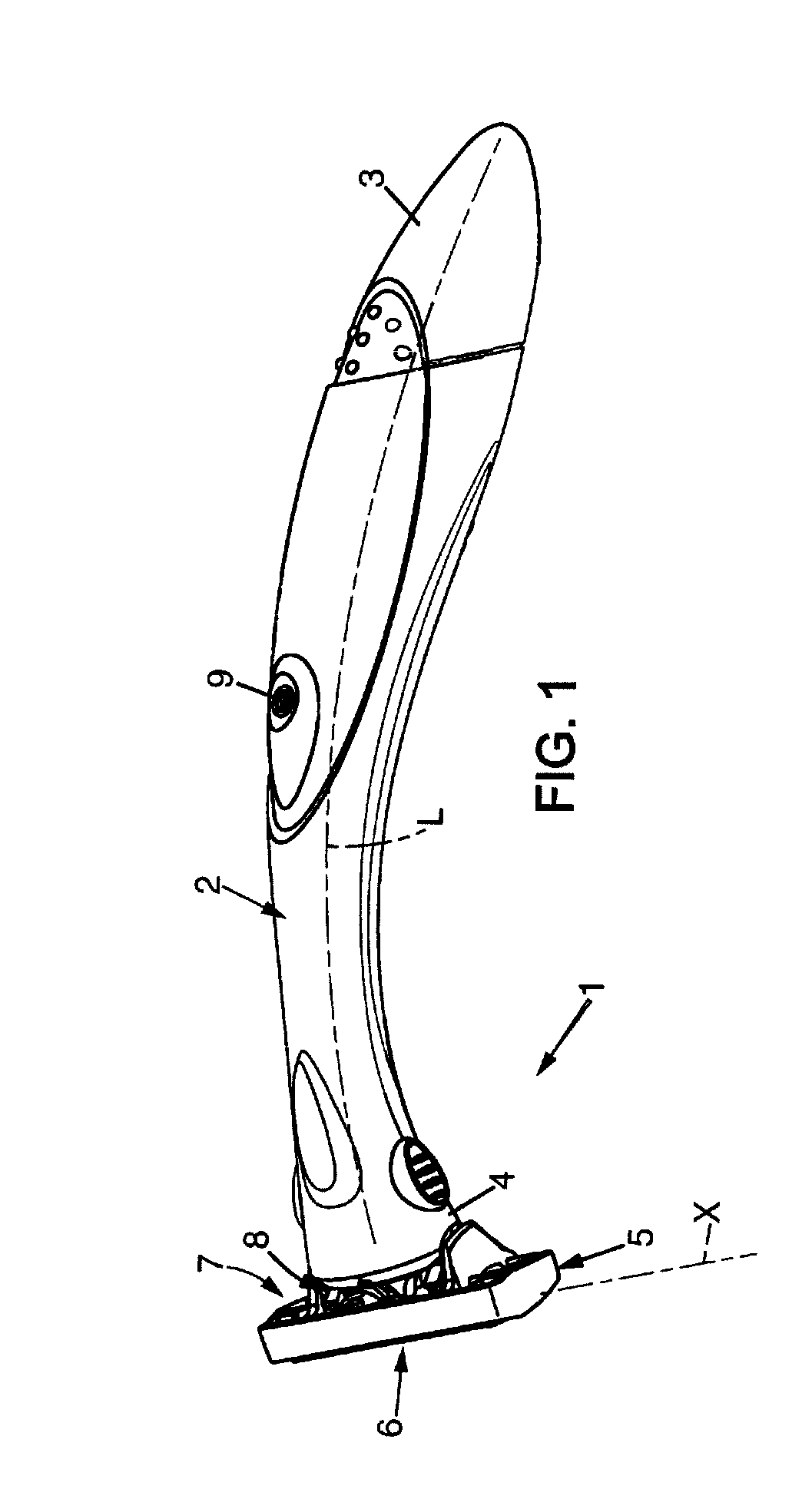

Razor Having A Wing Shaped Contouring Shaving Aid

Owner:THE GILLETTE CO

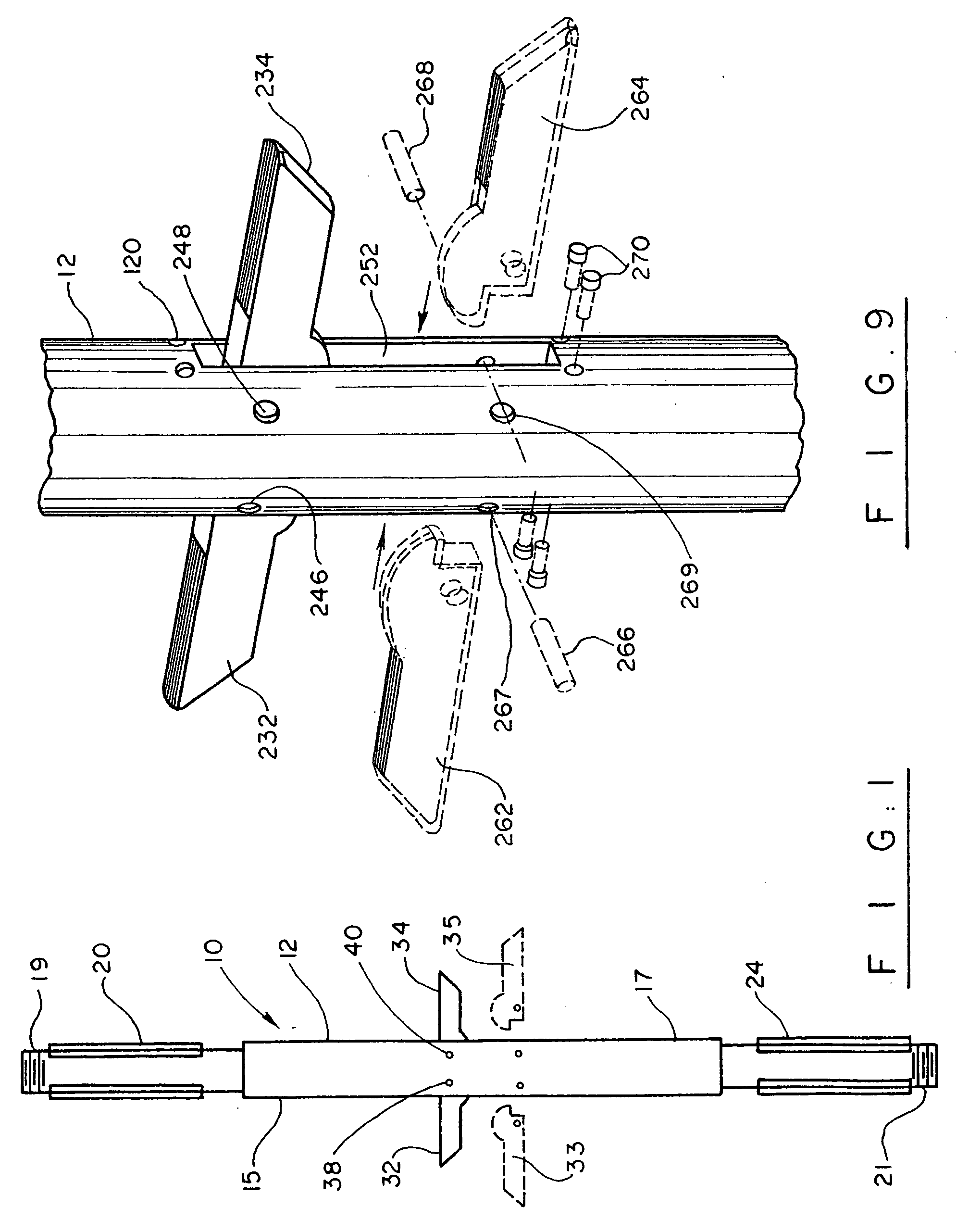

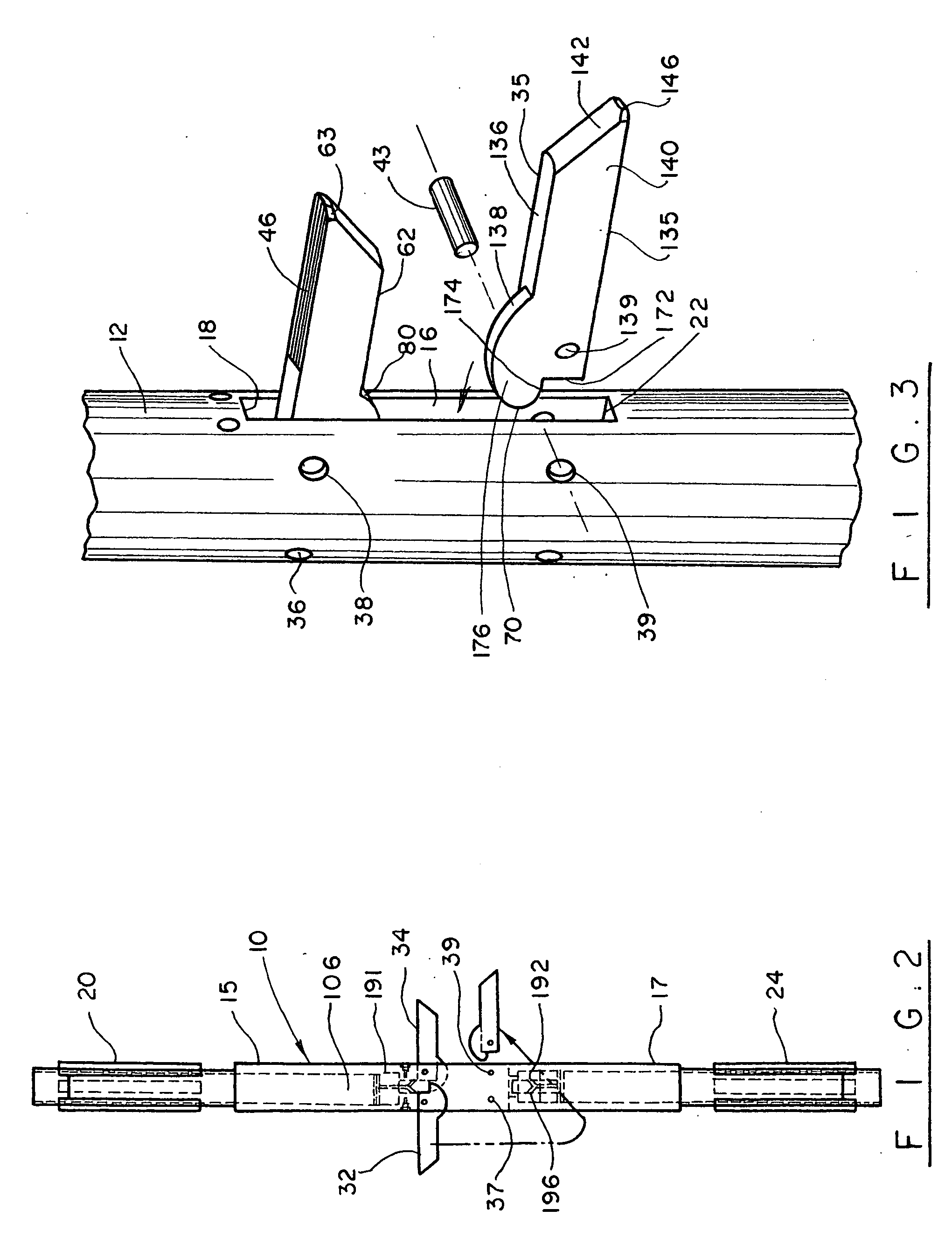

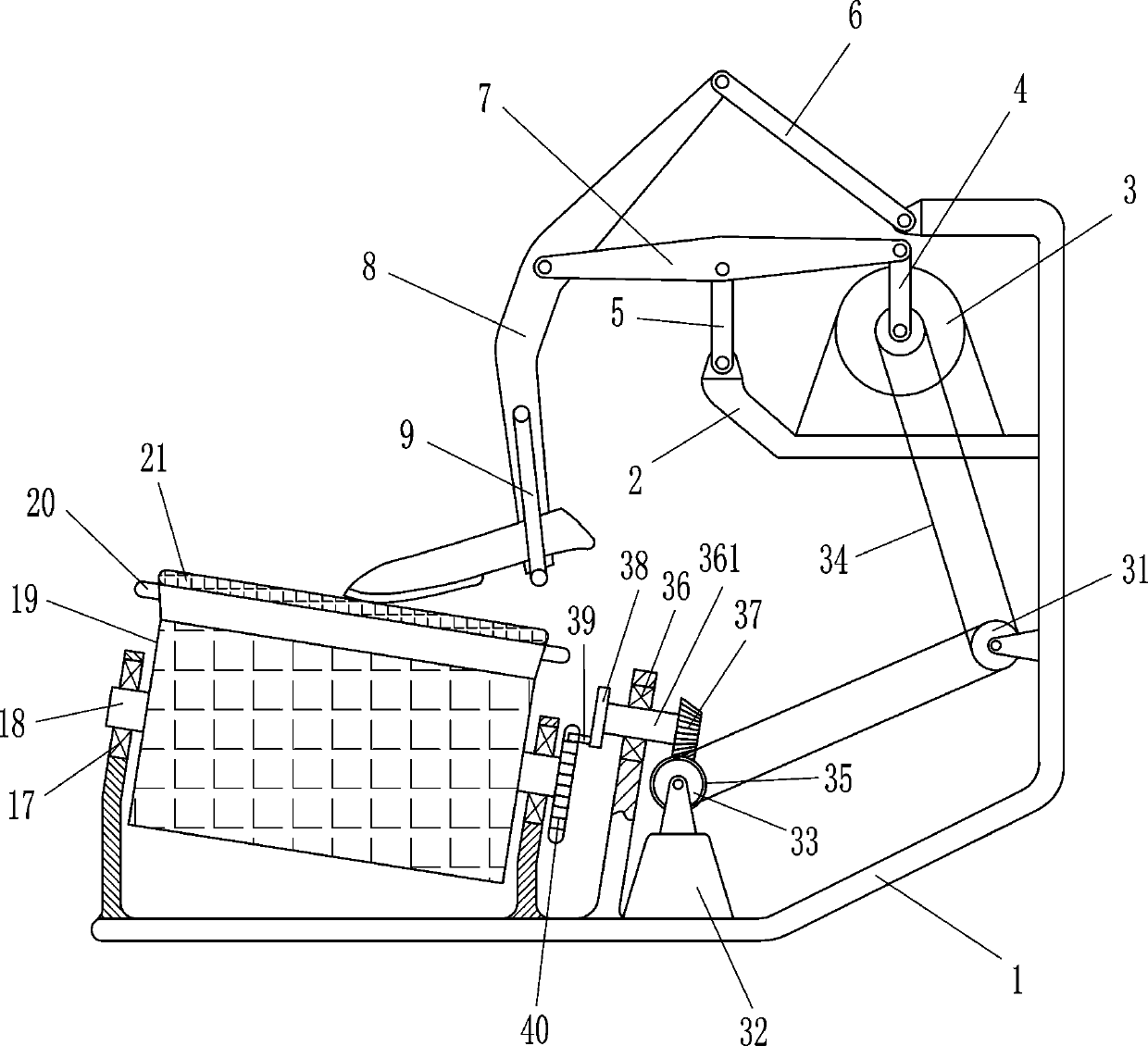

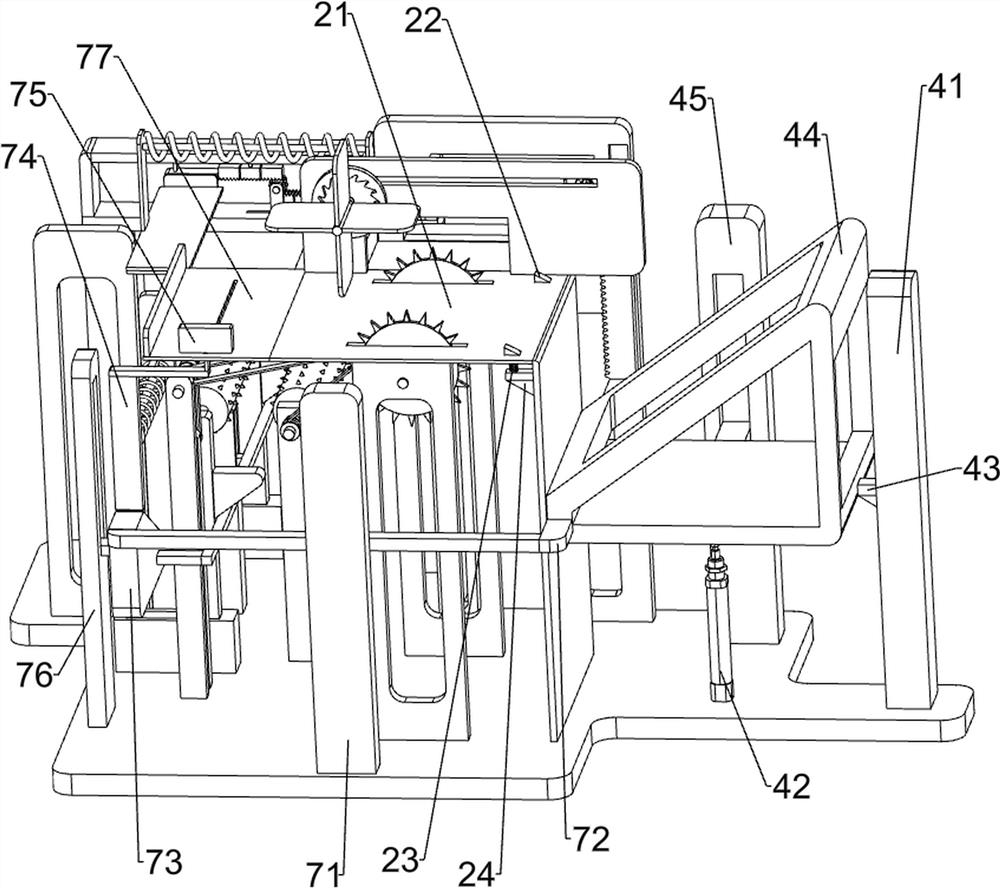

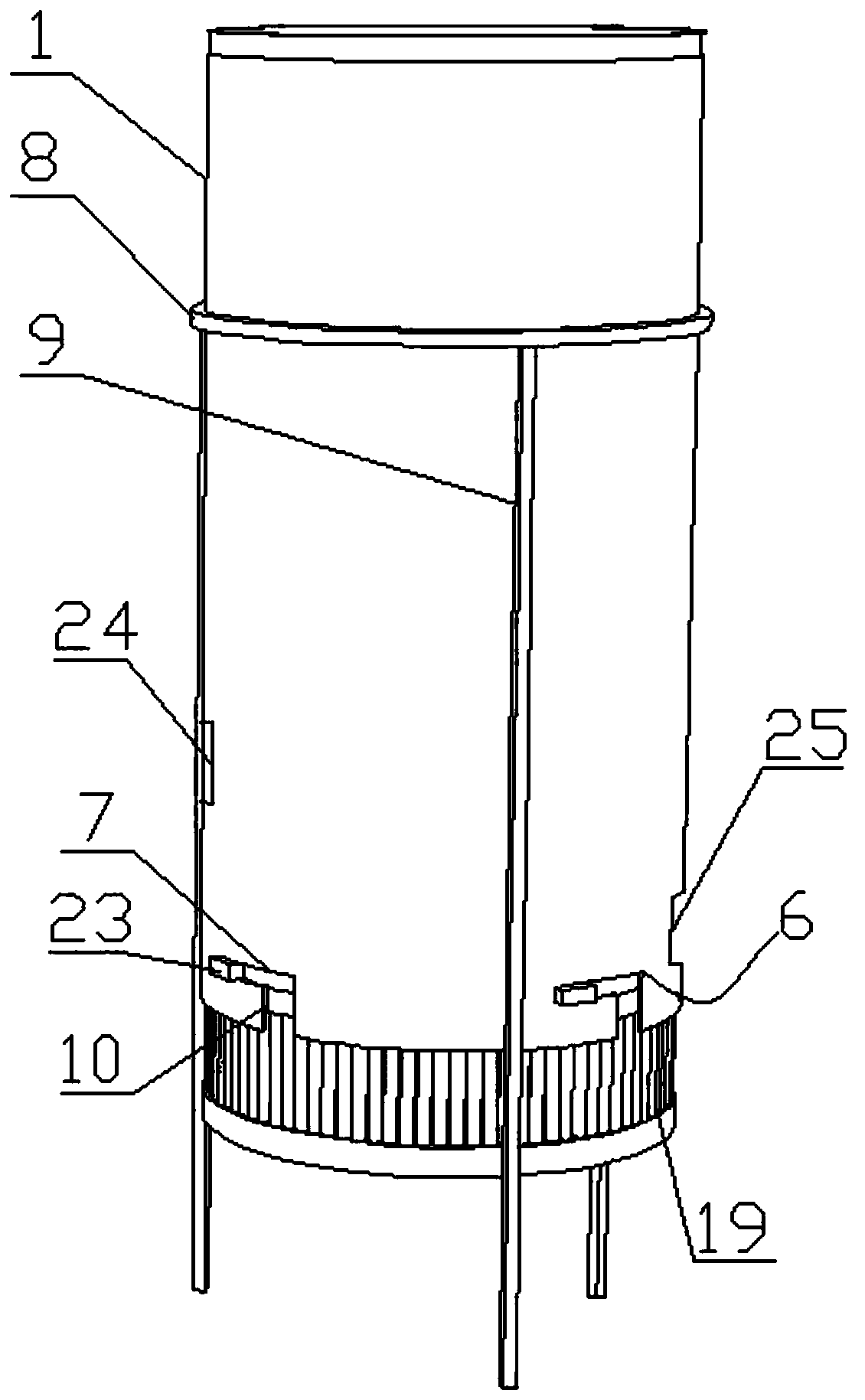

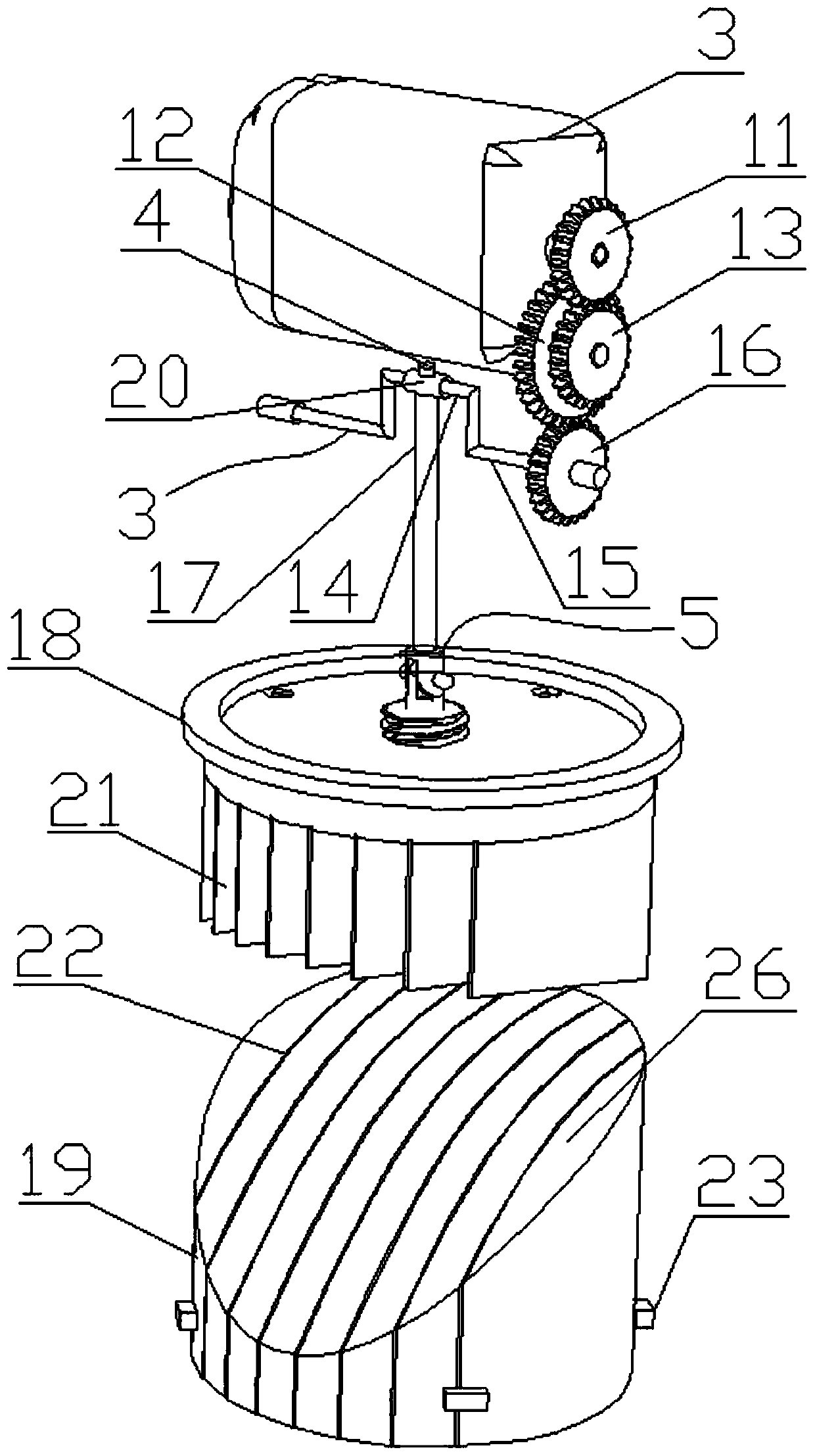

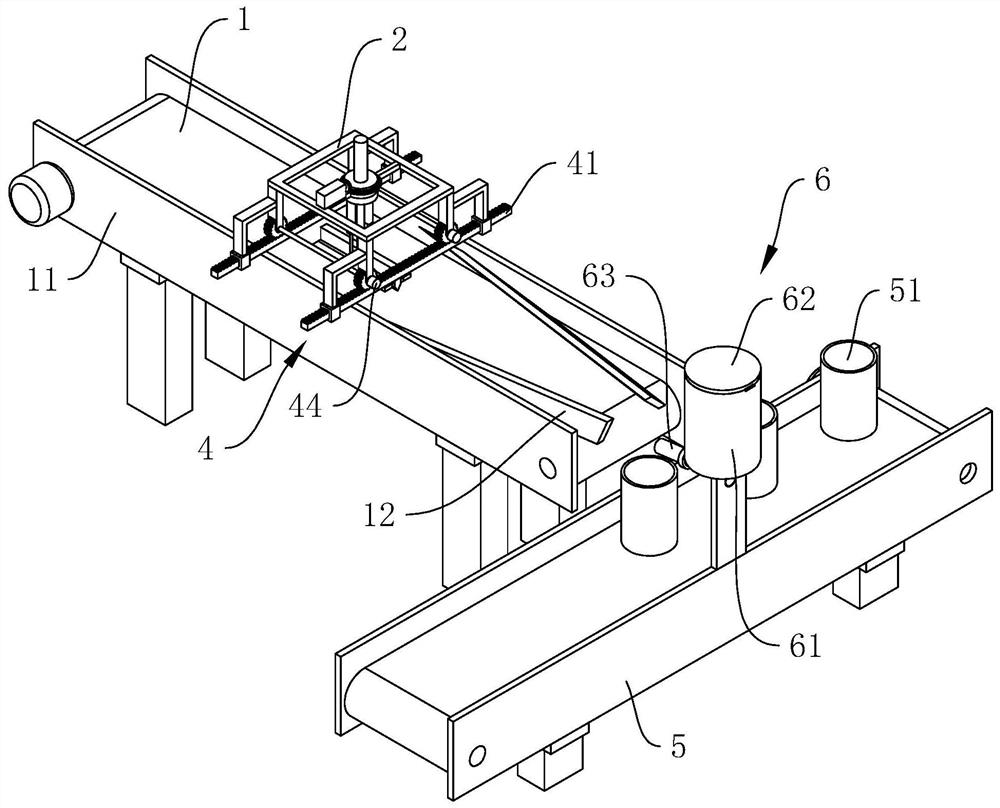

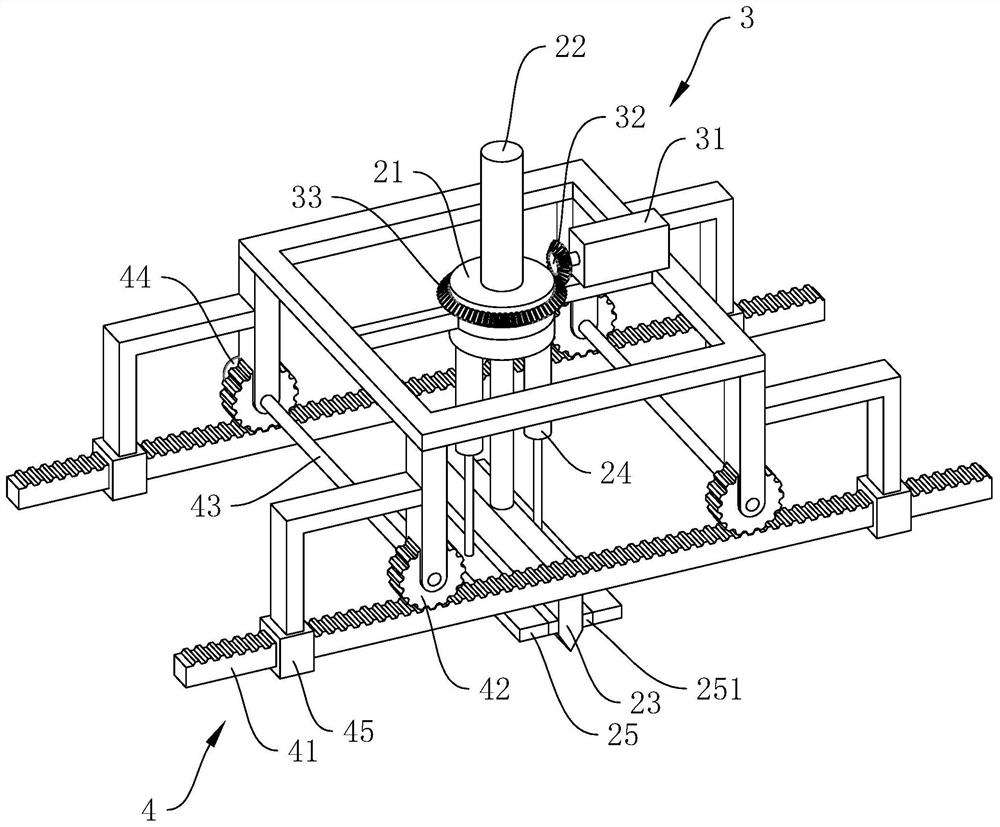

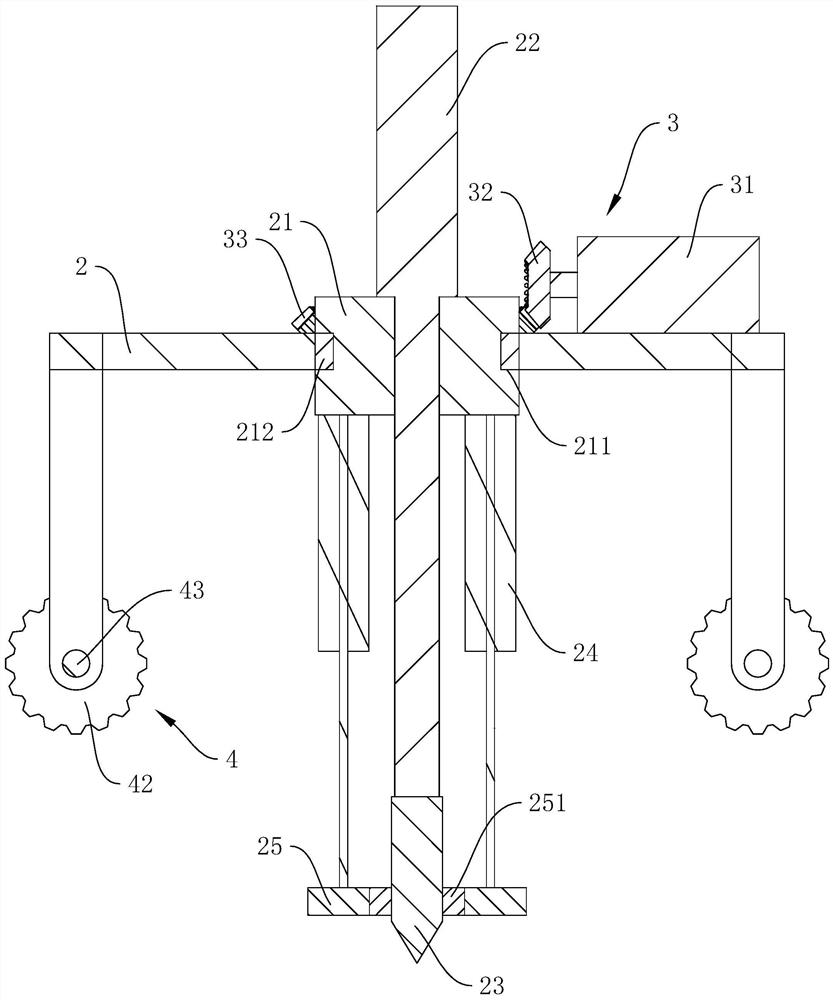

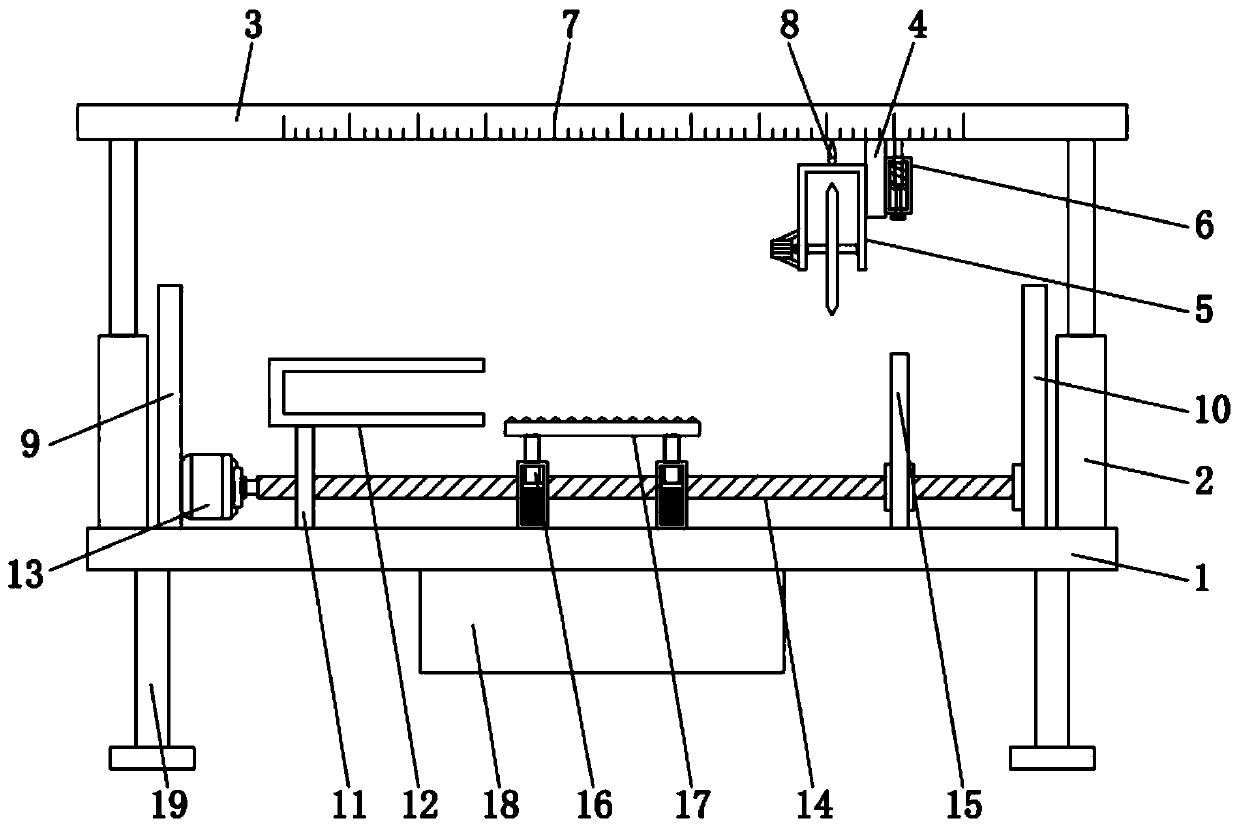

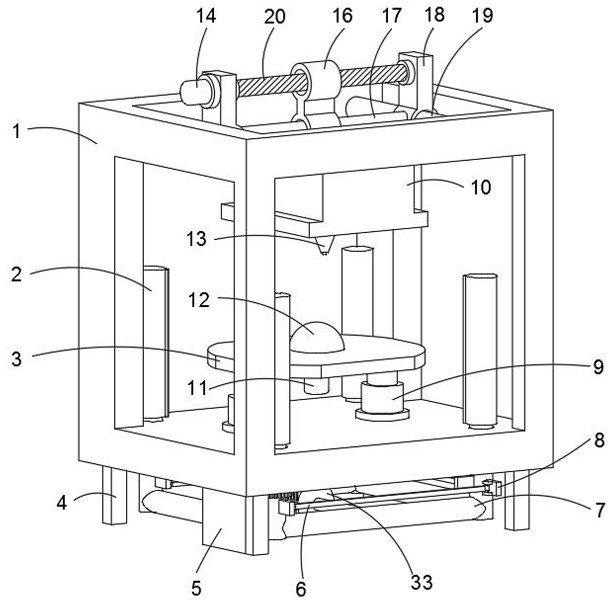

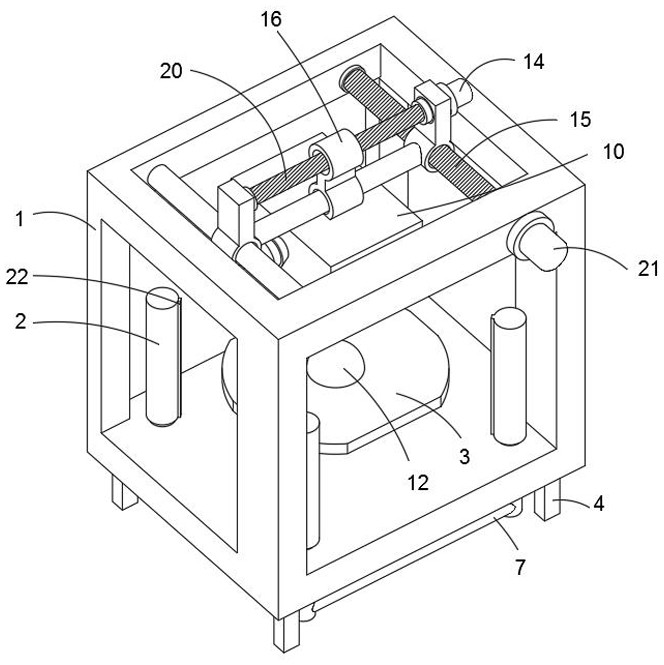

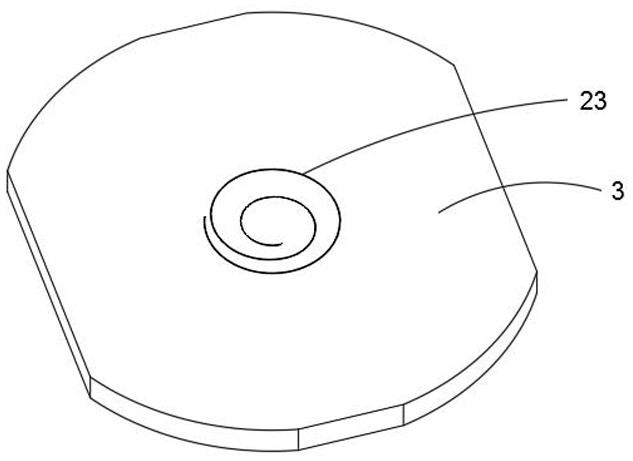

Blade driving mechanism for a table saw

InactiveUS20060191393A1Simple structureEasy to adjustMetal sawing devicesShearing machinesTransverse axisGear wheel

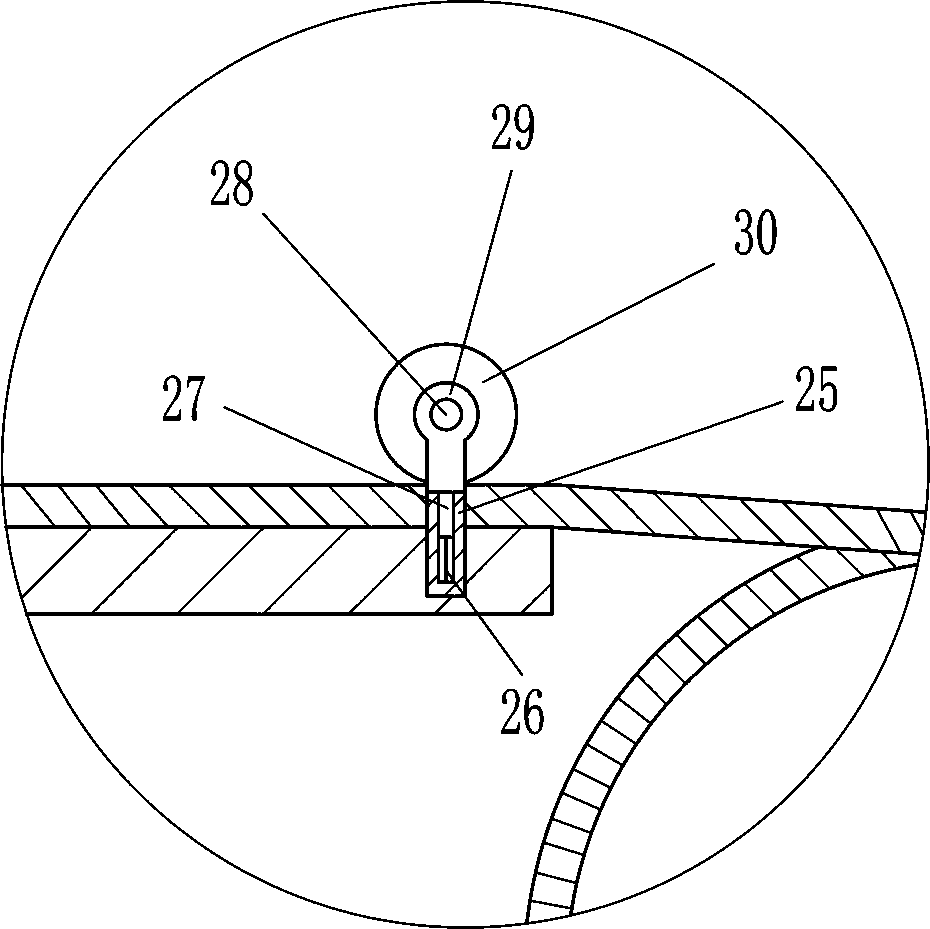

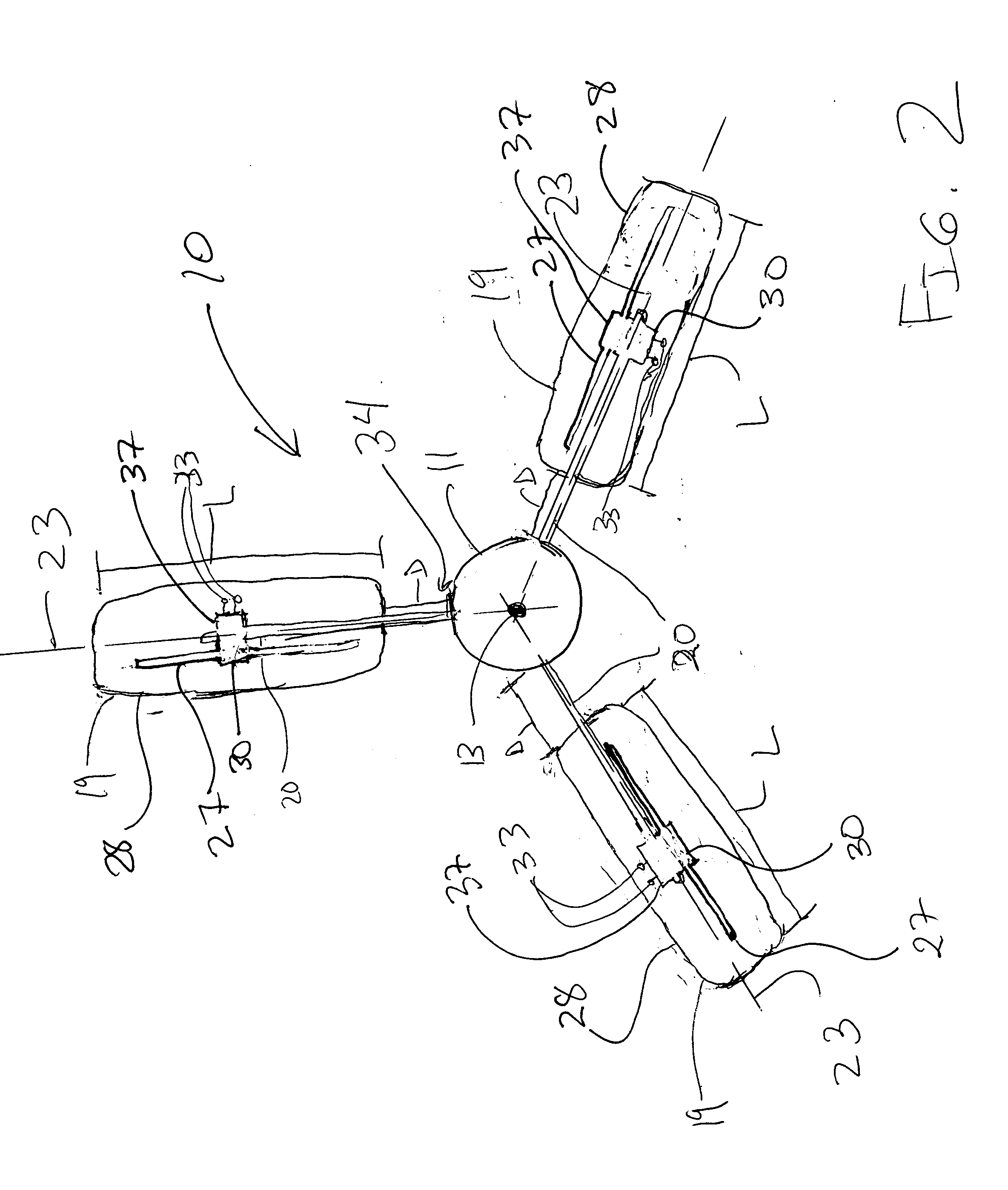

The present invention provides a blade driving mechanism for a table saw, wherein the table saw comprises a main frame and a saw blade mounted to and driven by the blade driving mechanism, and the blade driving mechanism comprises an electrical motor mounted to the main frame, with the motor being capable of sliding with respect to the main frame; a belt driving system for transferring the rotation of an output shaft of the motor to the saw blade; a center-distance setting means connected between the motor and the saw blade, for adjustably setting the center-to-center distance between the motor and the saw blade; and a saw-blade height adjusting device being operable to adjust the height of the of the saw blade. saw-blade height adjusting device comprises a transverse shaft being capable of rotating about a horizontal axis; a handwheel fixed to the outer end of the transverse shaft for driving the transverse shaft to rotate; a vertical screw shaft coupled with the transverse shaft by a set of bevel gears and is driven by the transverse shaft to rotate about a vertical axis; a nut mounted on and engaged with the screw shaft and being capable of moving along the screw shaft by the rotation of the screw shaft; and a guide connected to the nut and supporting the saw blade.

Owner:QINGDAO D& D ELECTRO MECHANICAL TECH

Razor blade unit head and safety razor including such a blade unit

ActiveUS20100175265A1Accurate shavingDomestic articlesMetal working apparatusRest positionKnife blades

Owner:BIC VIOLEX SA

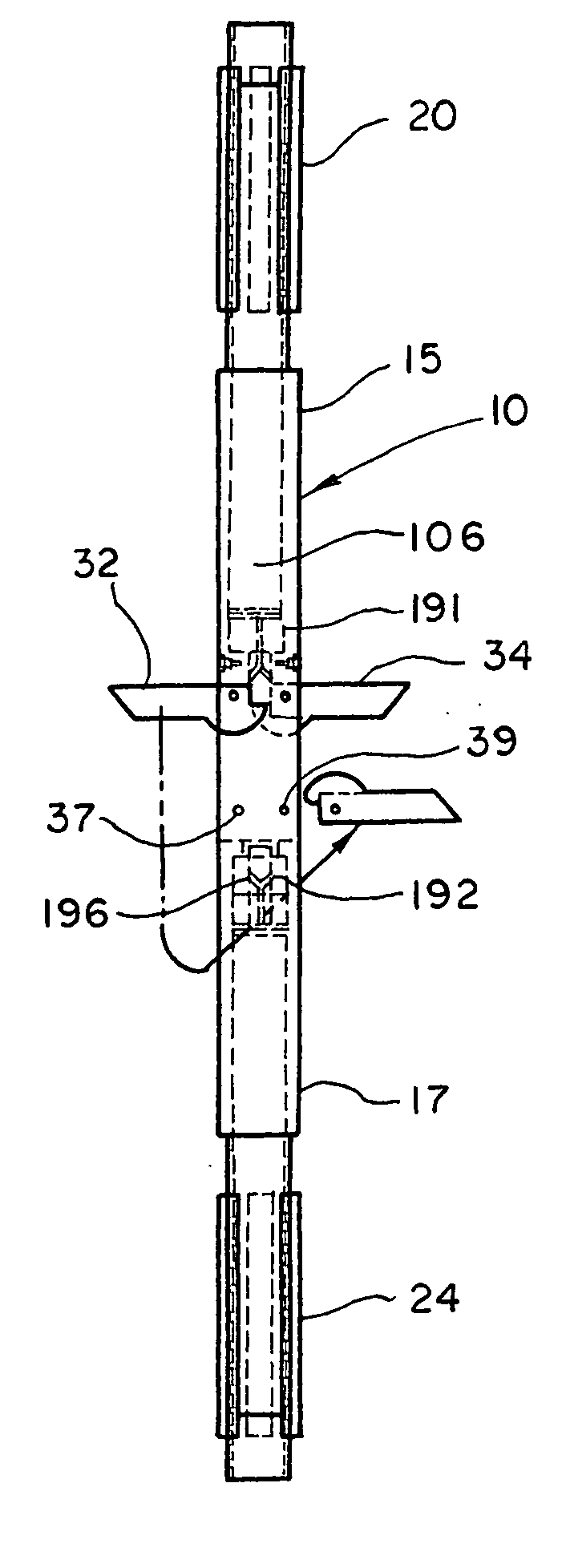

Expandable blade device for stabilizing long bone fractures

InactiveUS20080221575A1Improve stabilityLower the volumeDilatorsExcision instrumentsDistal portionLONG BONE FRACTURE

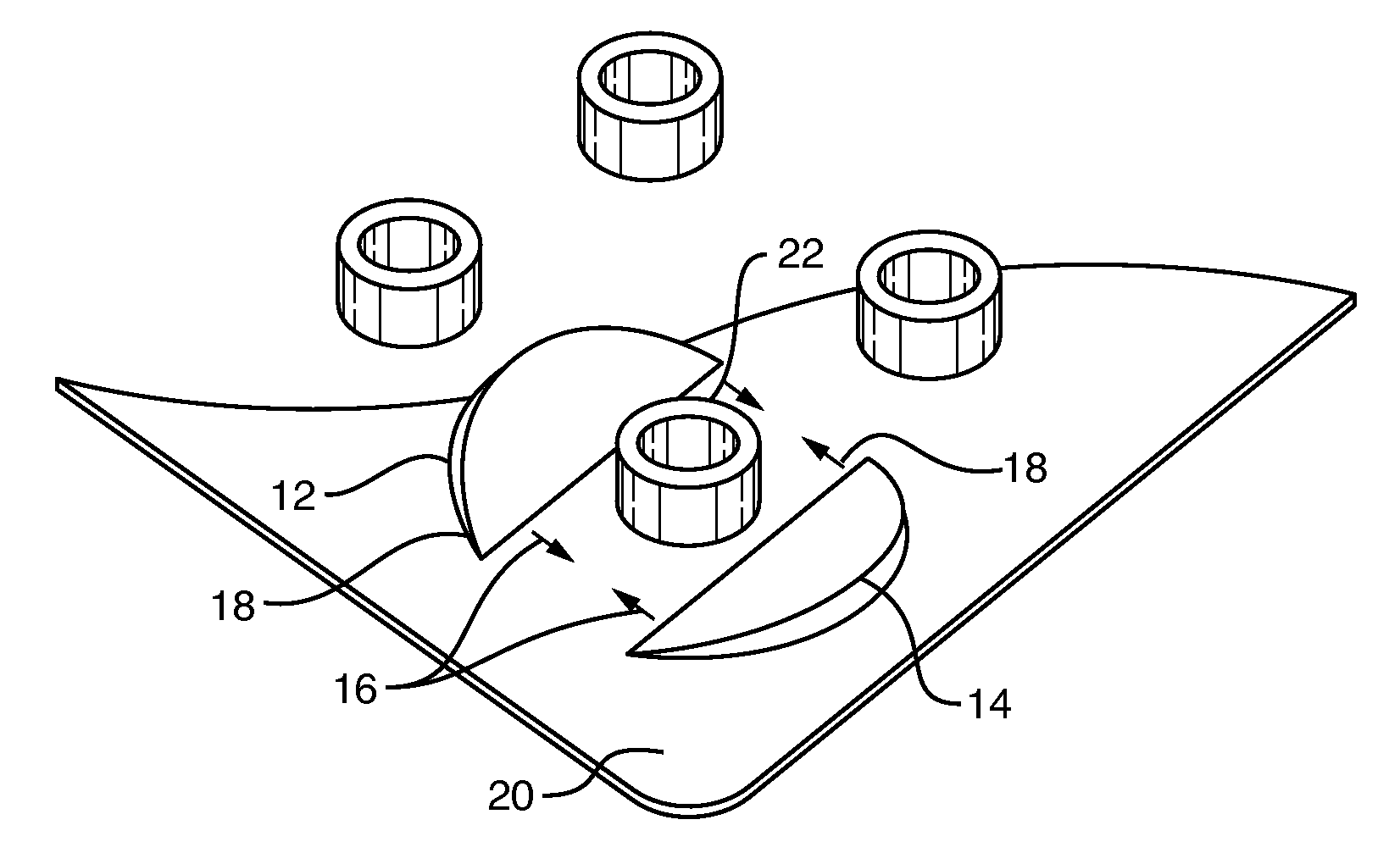

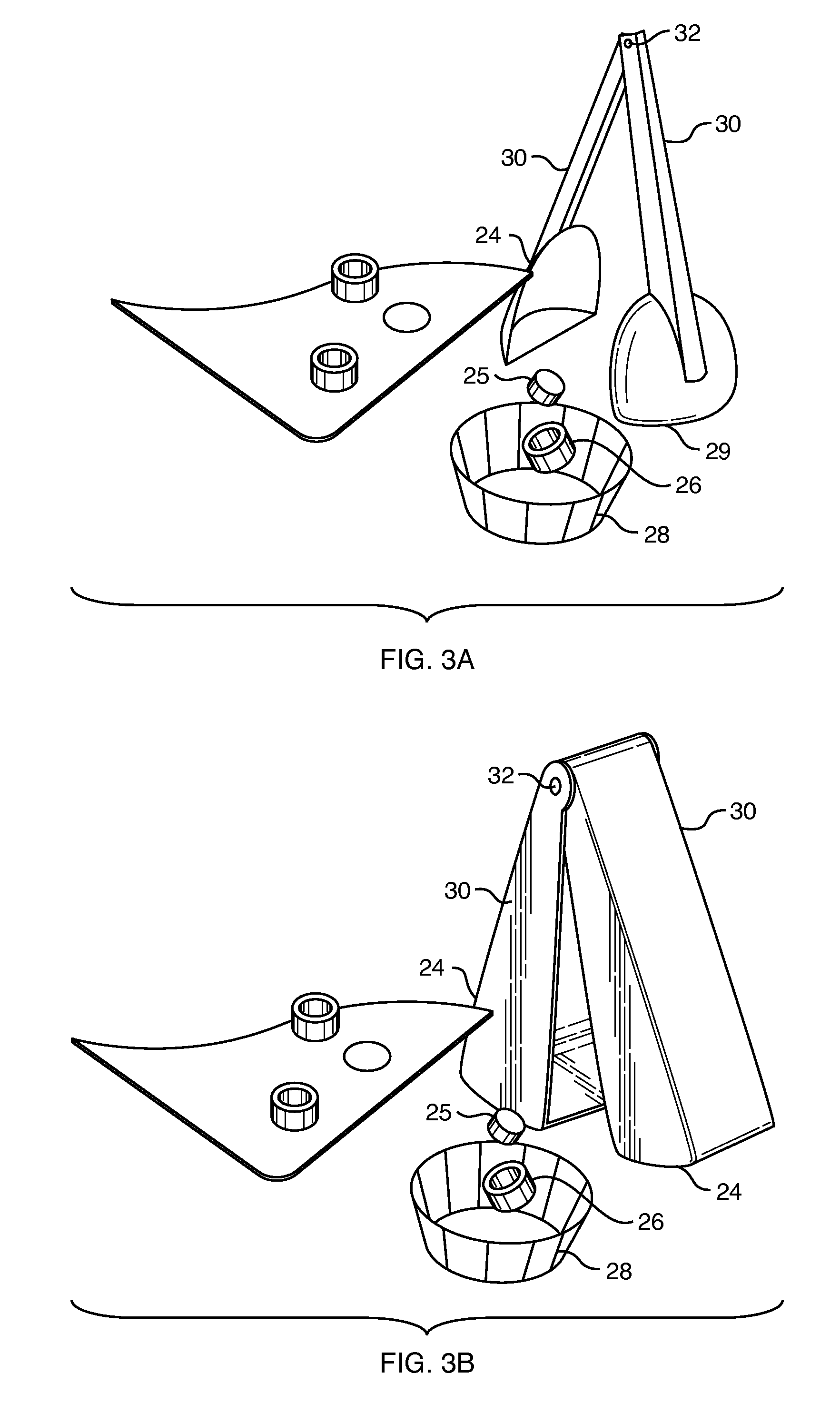

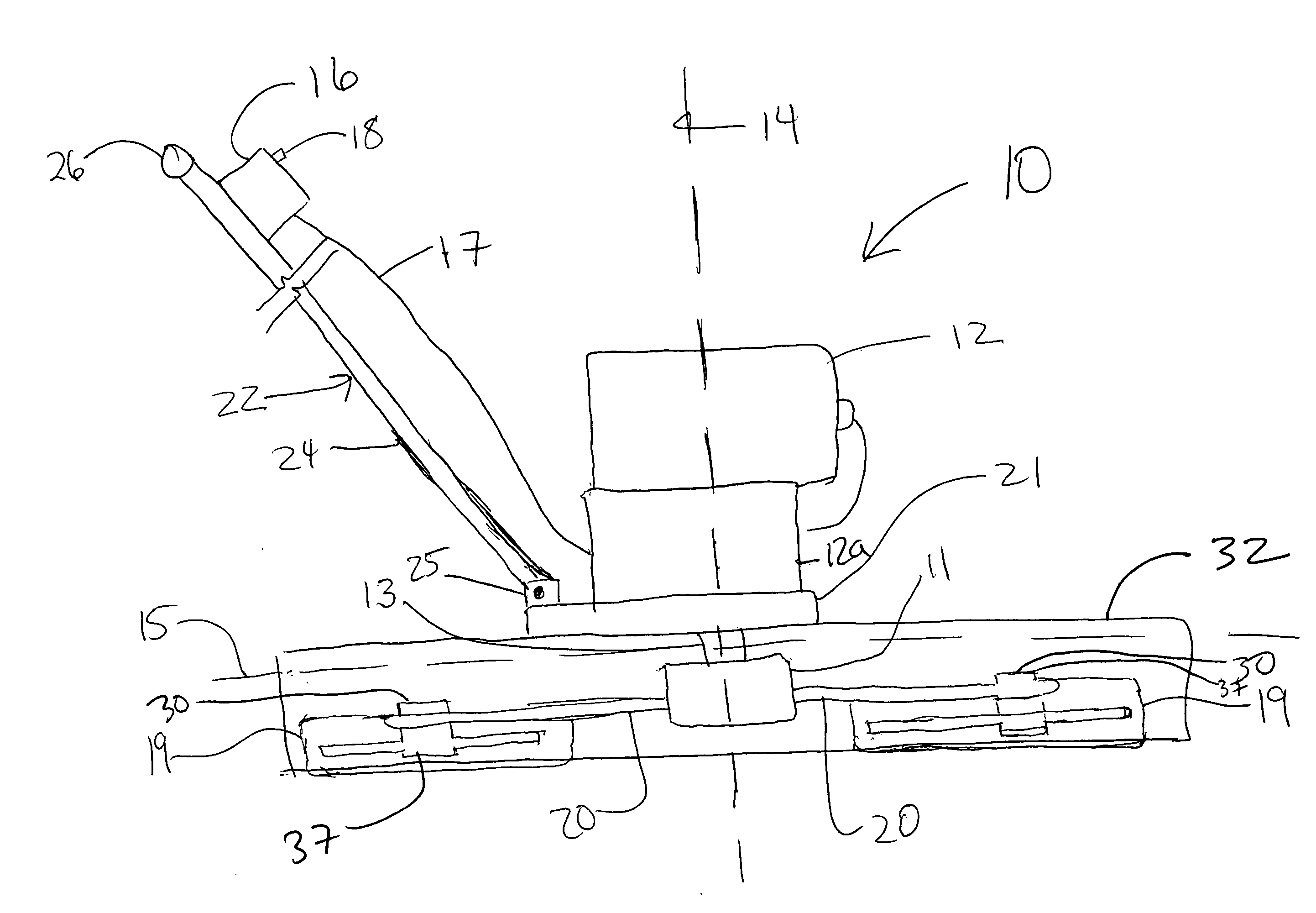

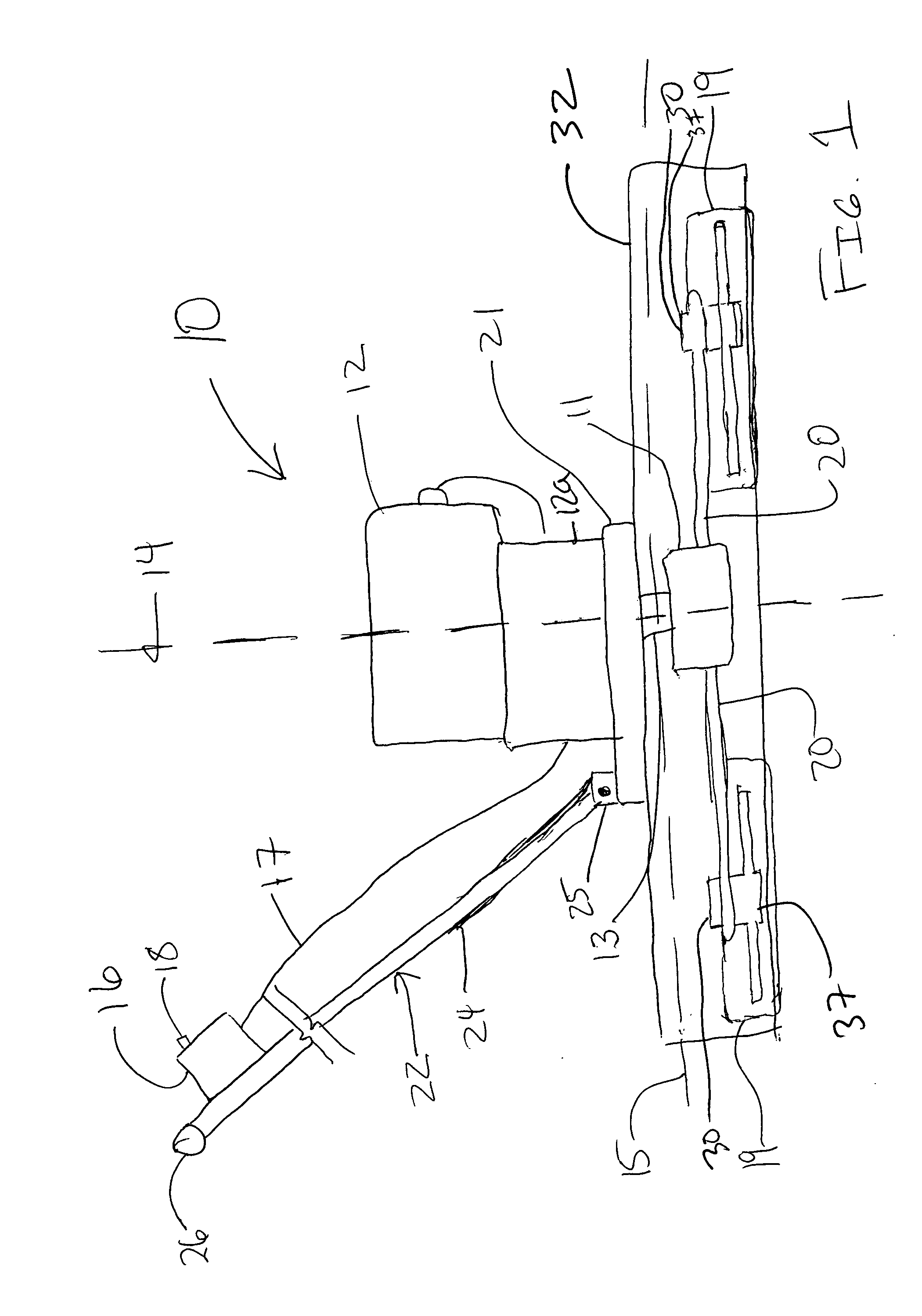

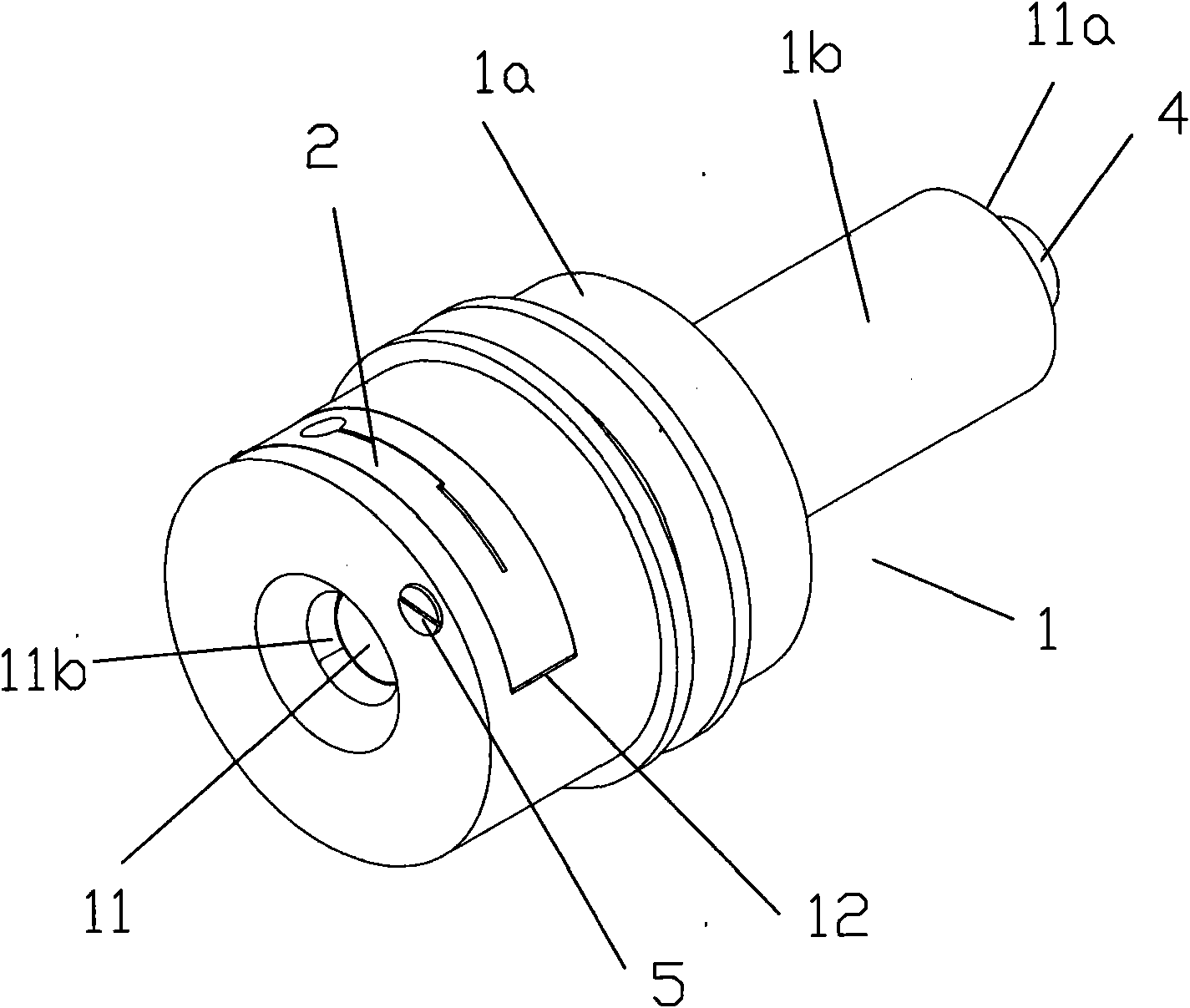

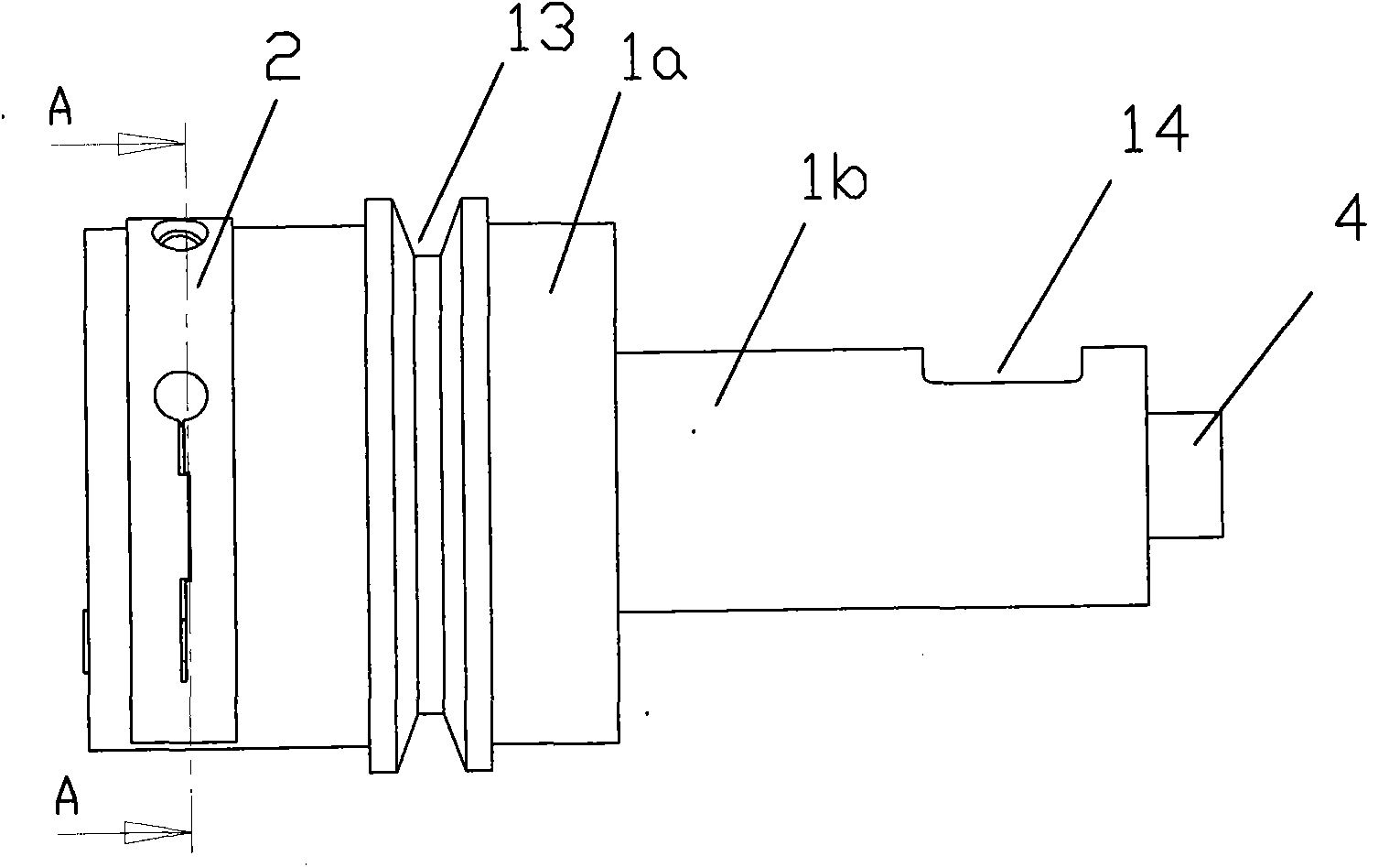

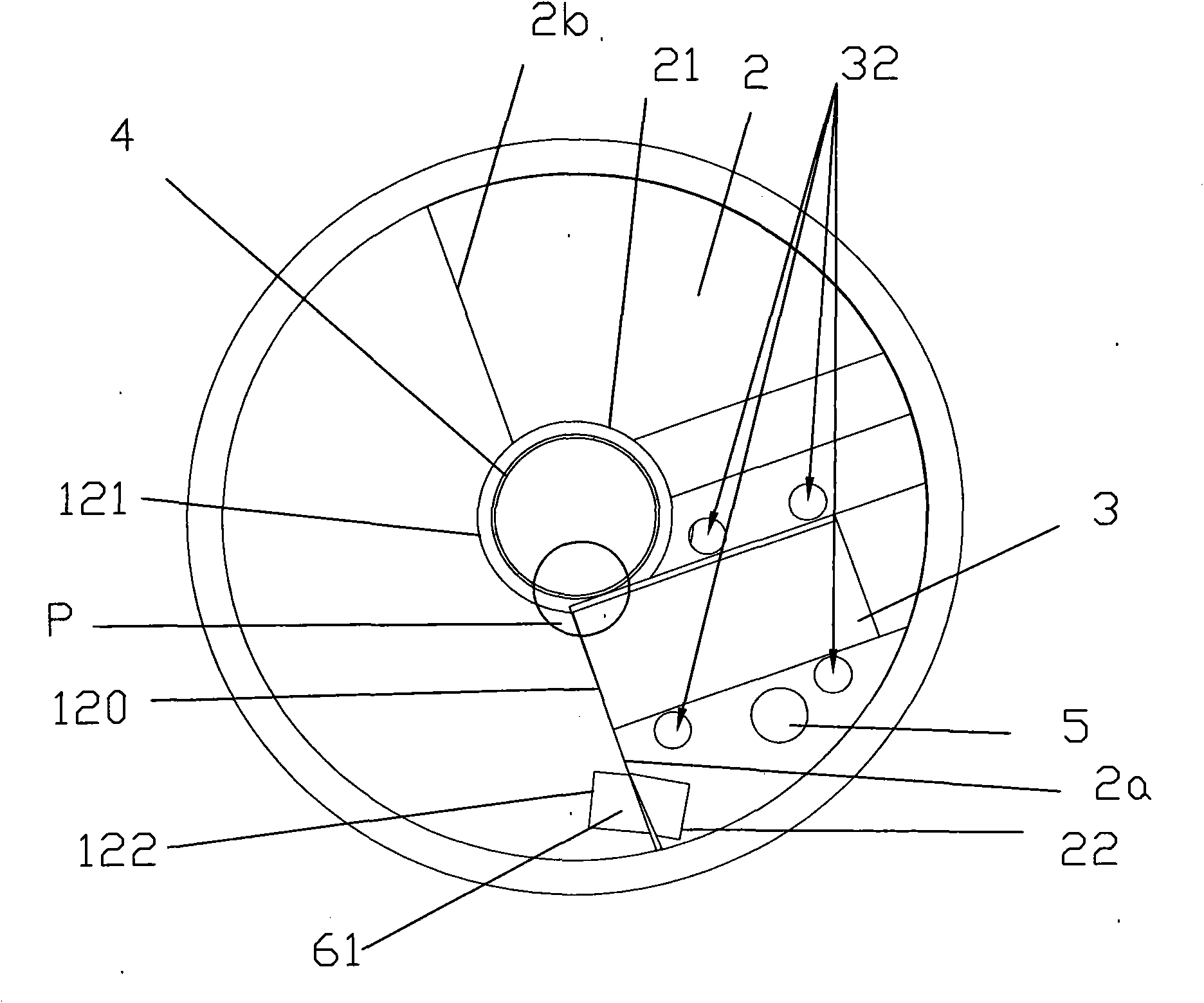

The present invention relates generally to medical devices and medical methods, in particular, devices and methods useful for stabilizing fractures of long bones. In one embodiment, the present invention is a device comprising a housing having a lumen; a plunger having a proximal portion and a distal portion, where the plunger is disposed within the lumen and is movable relative to the housing; a plurality of blades, where the blades can expand radially from the axis of the housing; and a manipulator functionally connected to the plunger, wherein the manipulator is operable to: move the plunger relative to the housing; expand the blades radially from the axis of the housing; and move the blades about the axis of the plunger.

Owner:BETTS ANDRES

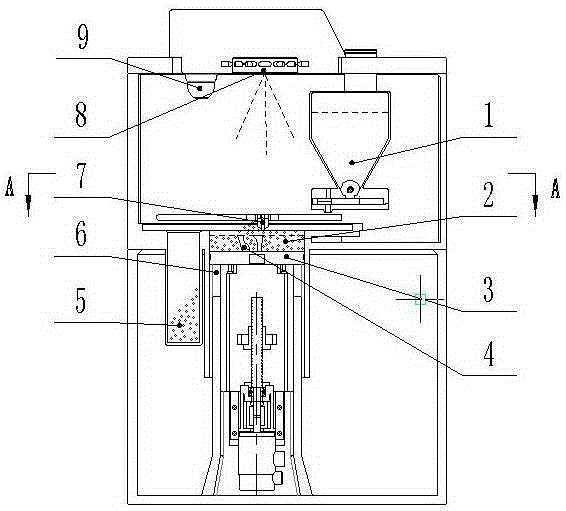

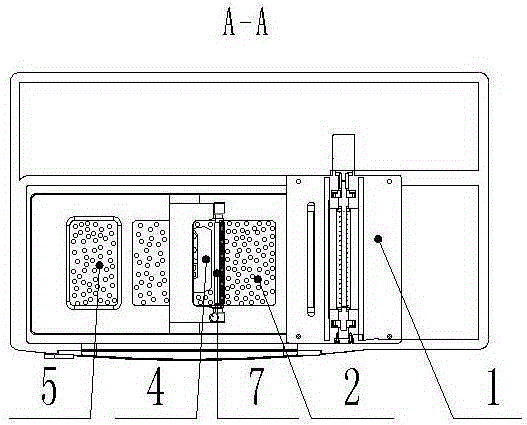

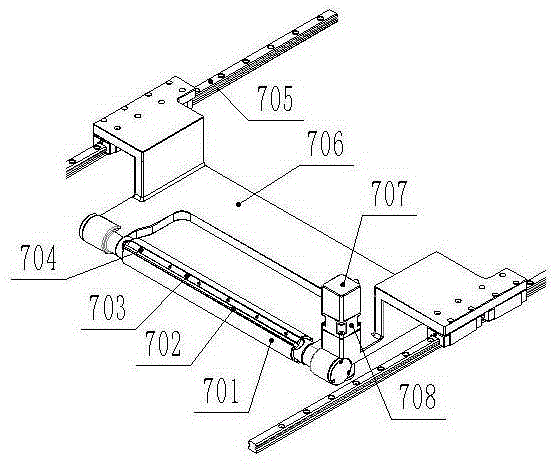

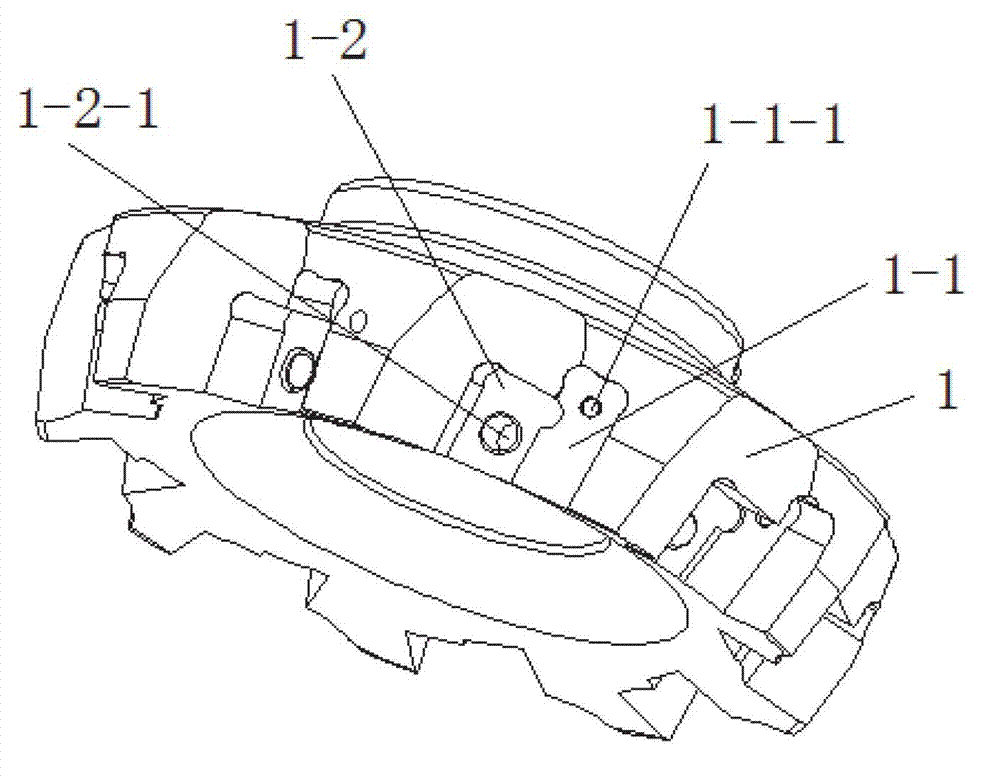

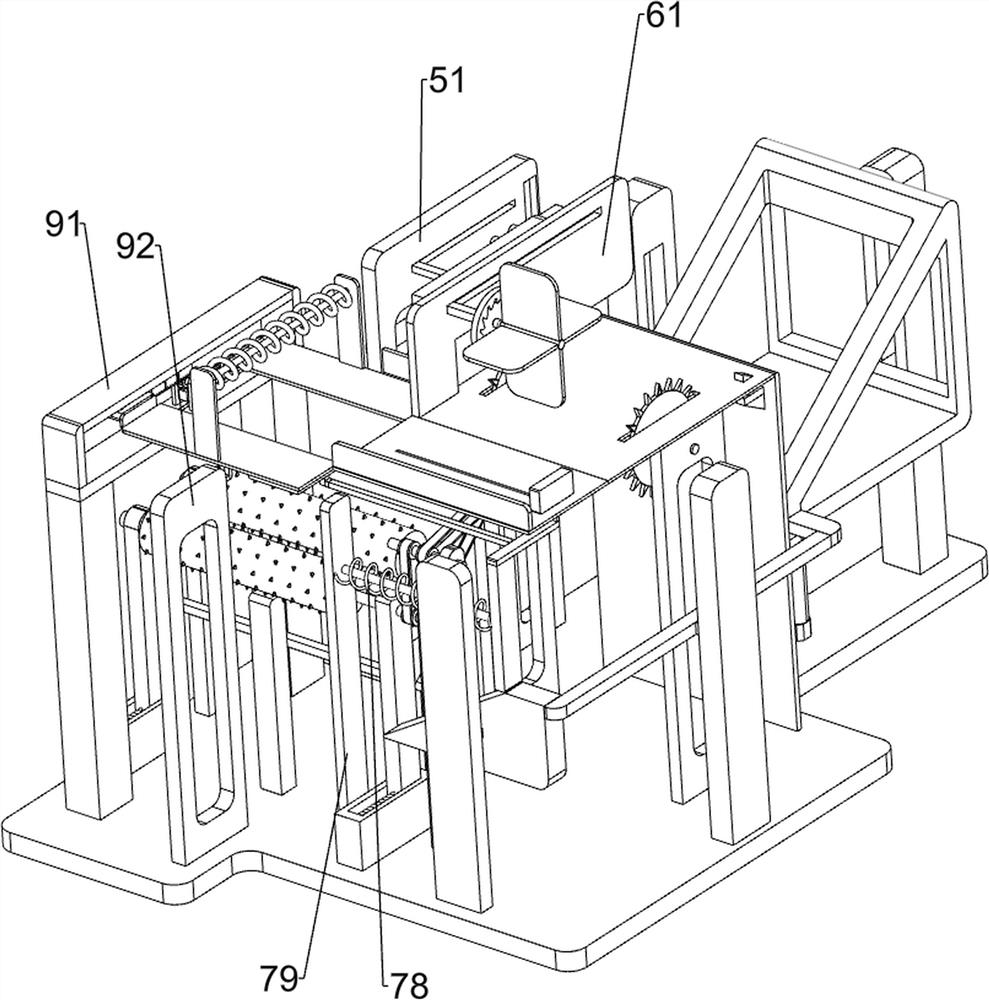

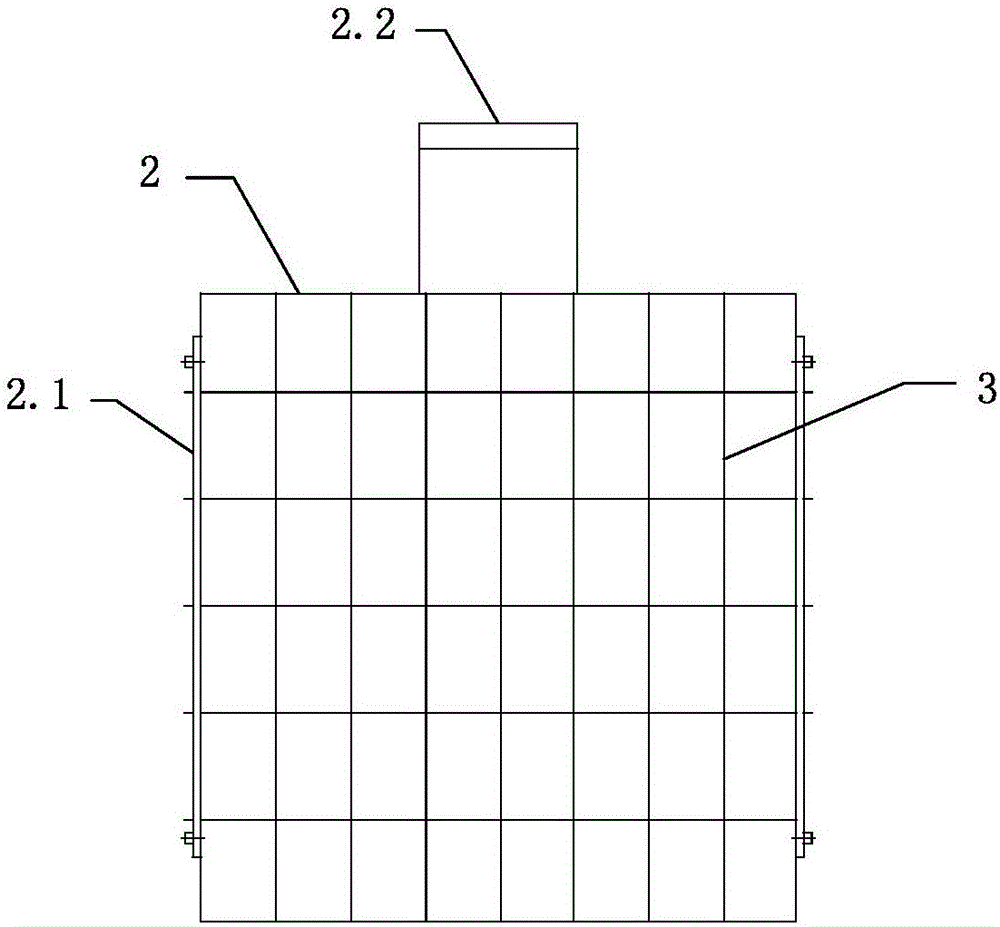

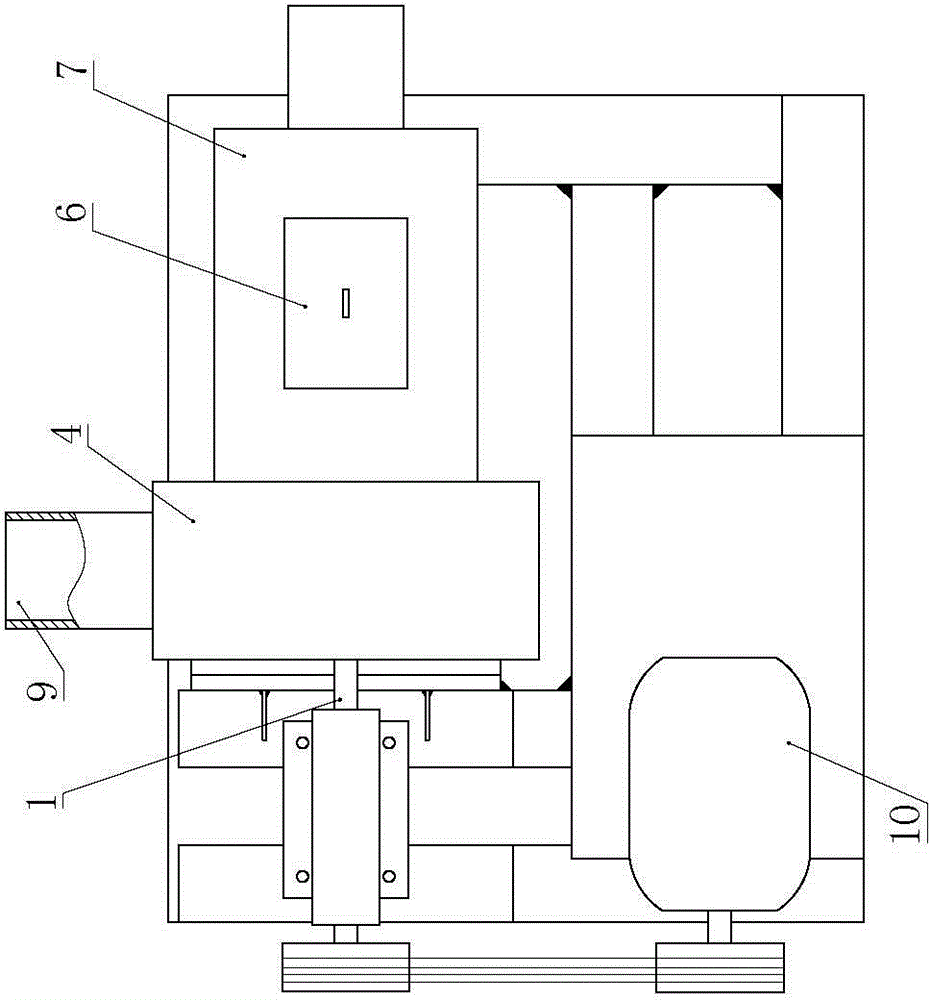

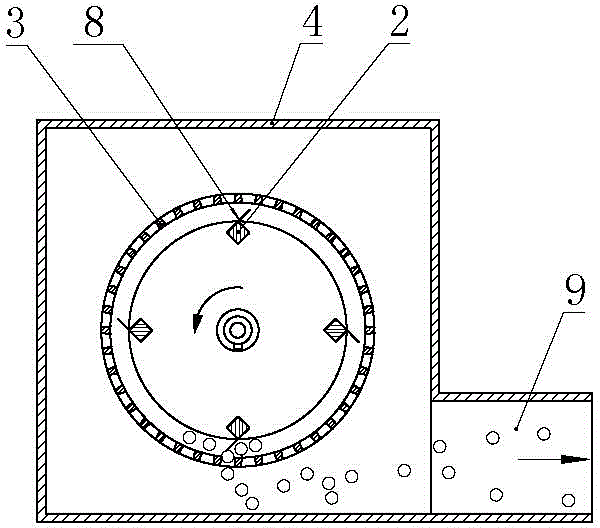

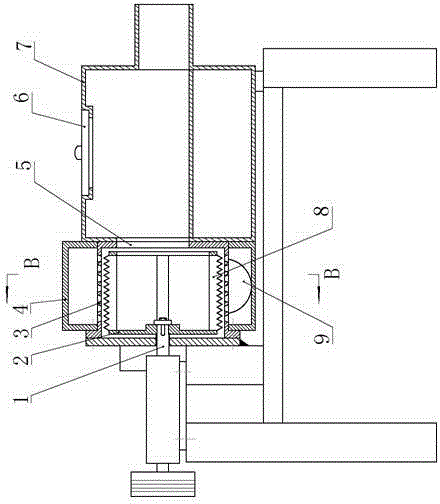

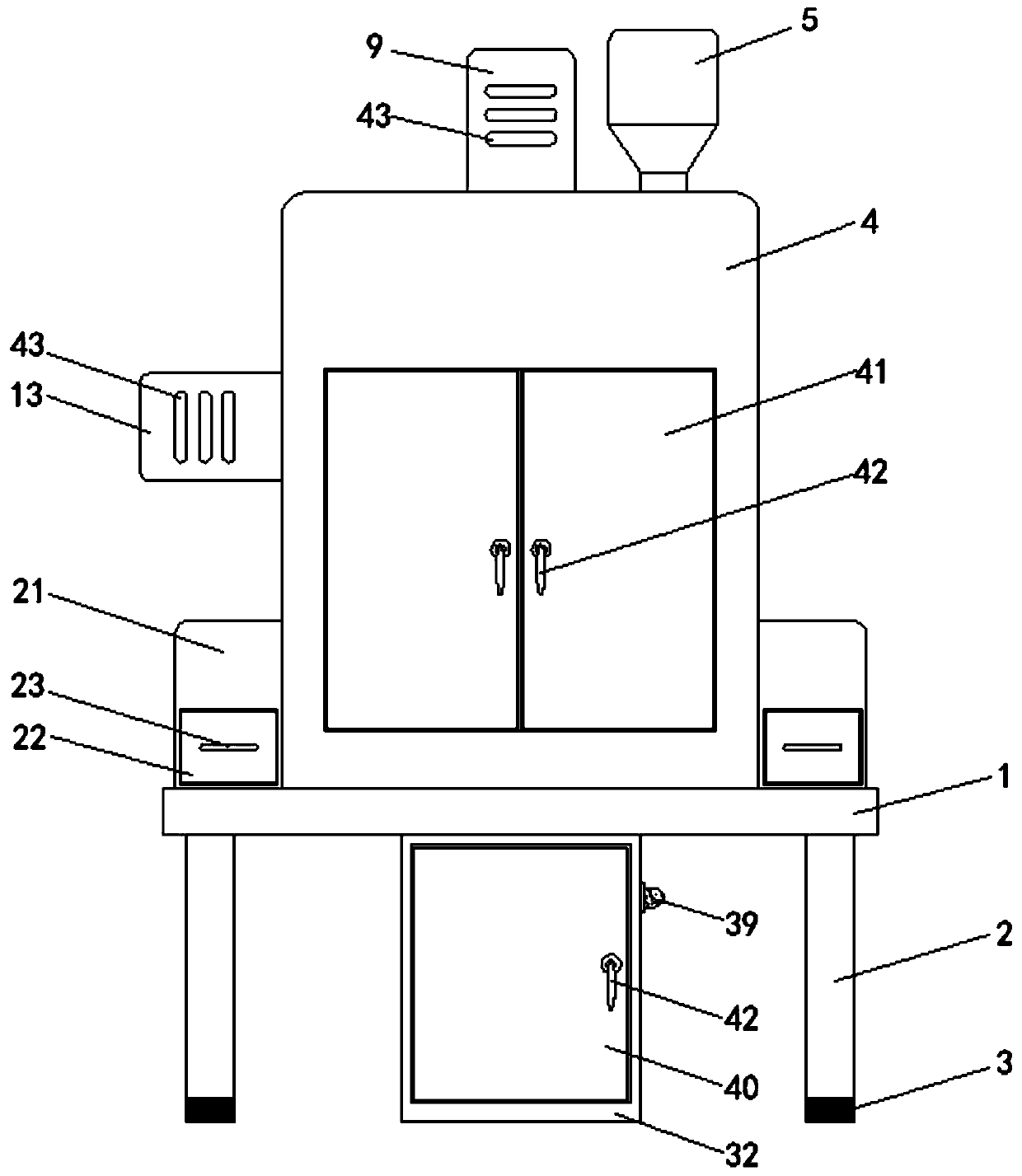

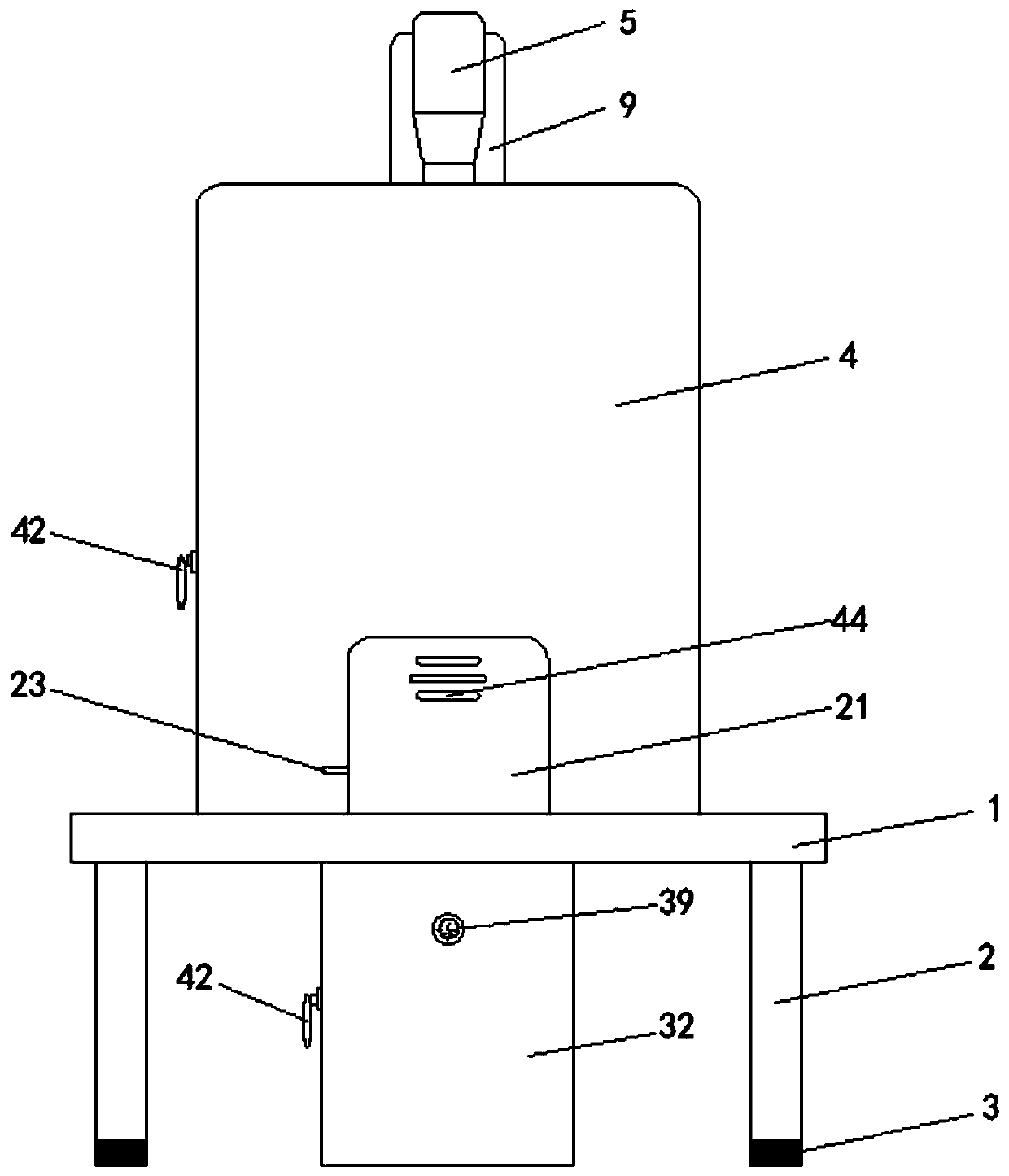

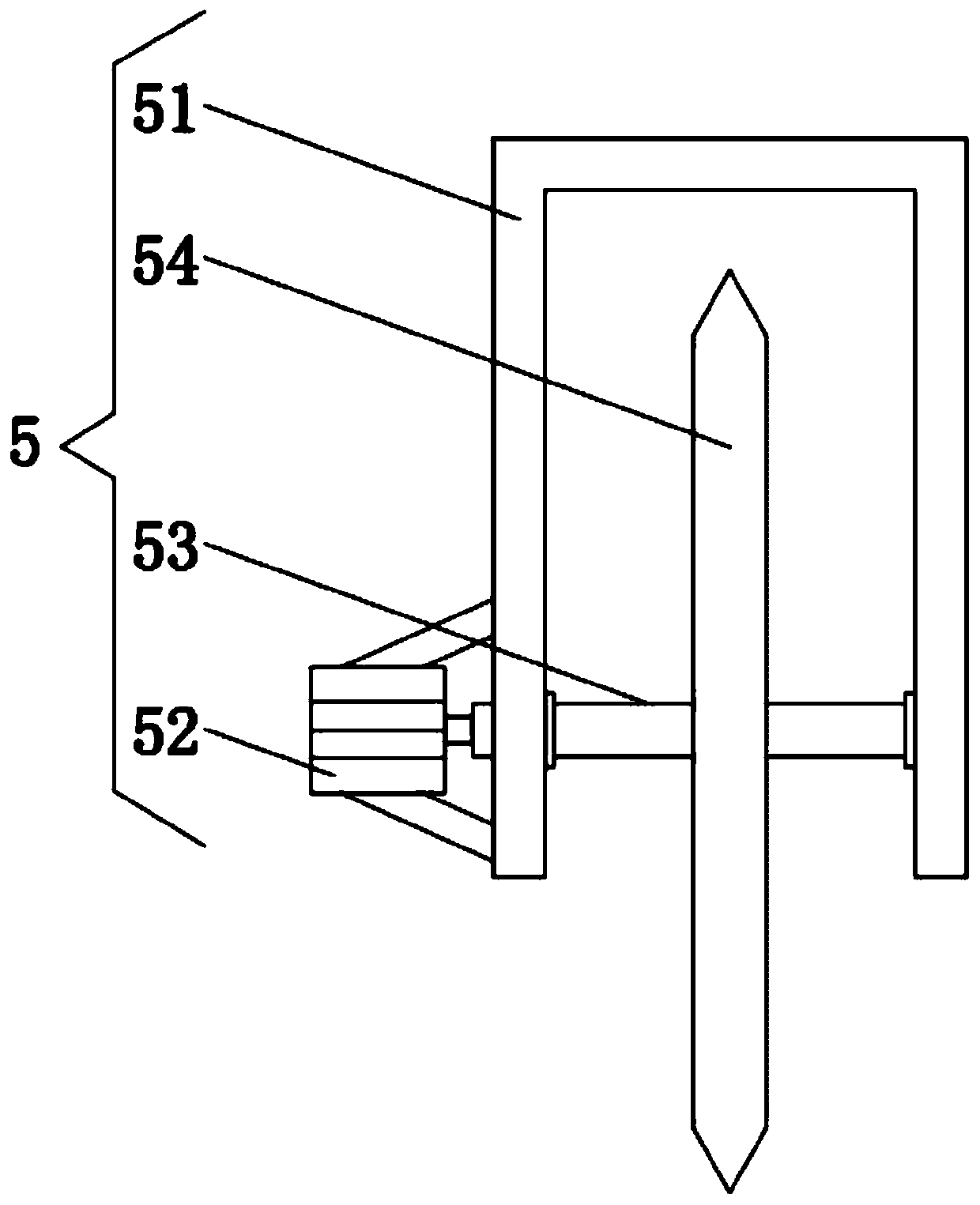

Multi-knife automatic knife changing type powder laying scraper knife device of 3D printer

InactiveCN105172145AGuaranteed normal operationReduce manufacturing costAdditive manufacturing apparatusControl systemReciprocating motion

Owner:党金行

Work cutting apparatus and method for cutting work

InactiveUS6889586B2Improve accuracyIncrease productivityGuide fencesShearing machinesRotational axisSurface mounting

A work cutting apparatus comprises a bed. The bed has an upper surface provided with a column including a rail slidably mounted with a slider. The slider has a front surface mounted with a supporting portion supporting two end portions of a rotating shaft. The rotating shaft is mounted with a plurality of cutting blade blocks. Each of the cutting blade blocks includes a plurality of cutting blades and a thicker cutting blade at each end of the cutting blade block. A table provided with a recess having a V-shaped section is disposed on the bed right beneath the cutting blade blocks. A plurality of works are disposed in the recess, each fixed by a fixing member. The cutting blades lowered while rotating, thereby cutting the works. During this operation, coolant is discharged from a plurality of supplying ports of a coolant supplying portion as well as from a supplying port of a coolant supplying path.

Owner:PROTERIAL LTD

Reversible casing cutter

Owner:ABRADO

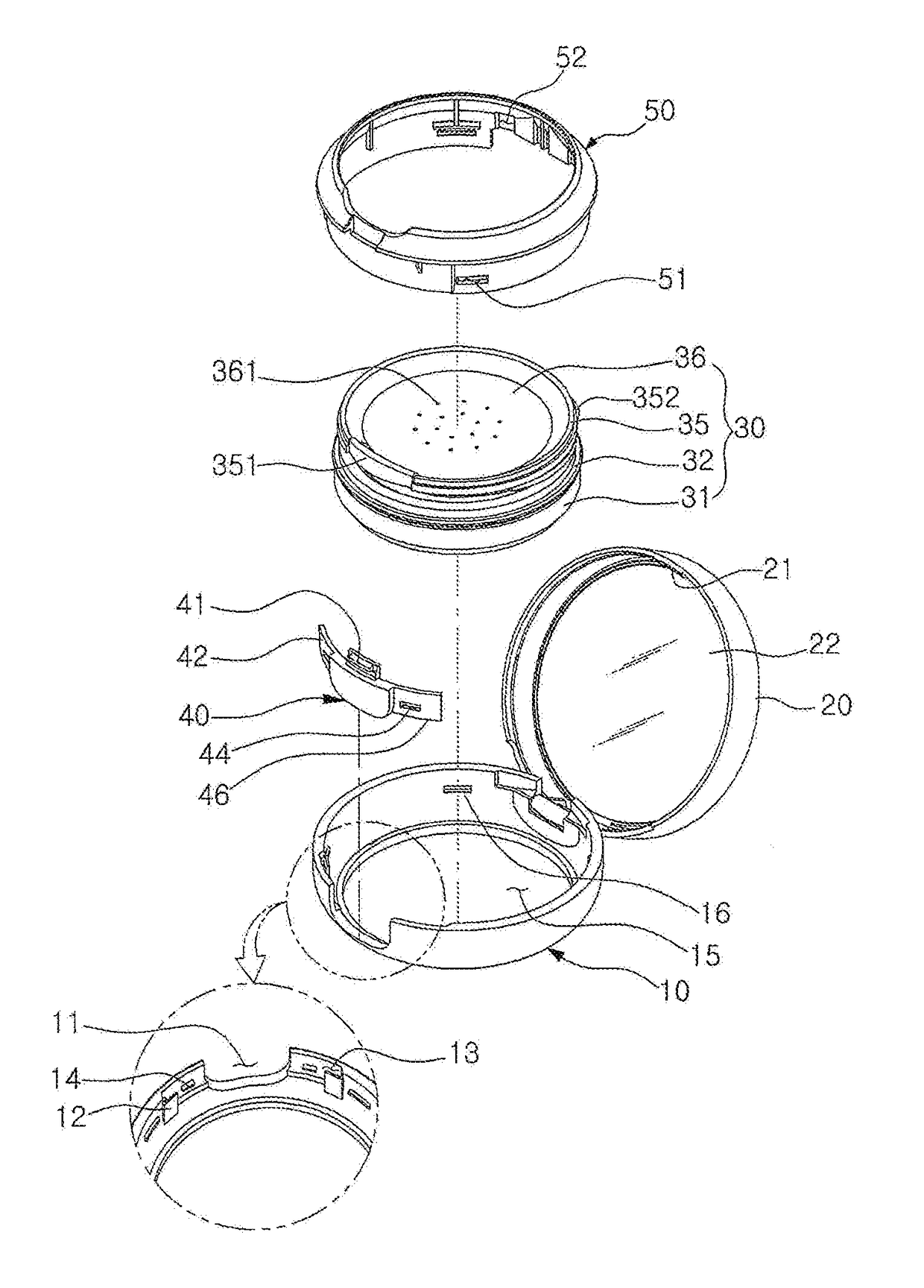

Compact container having button member enabling easy assembly

InactiveUS20180192760A1Avoid separationEasy to assemblePackaging toiletriesPackaging cosmeticsEngineeringKnife blades

Owner:PUMTECH KOREA

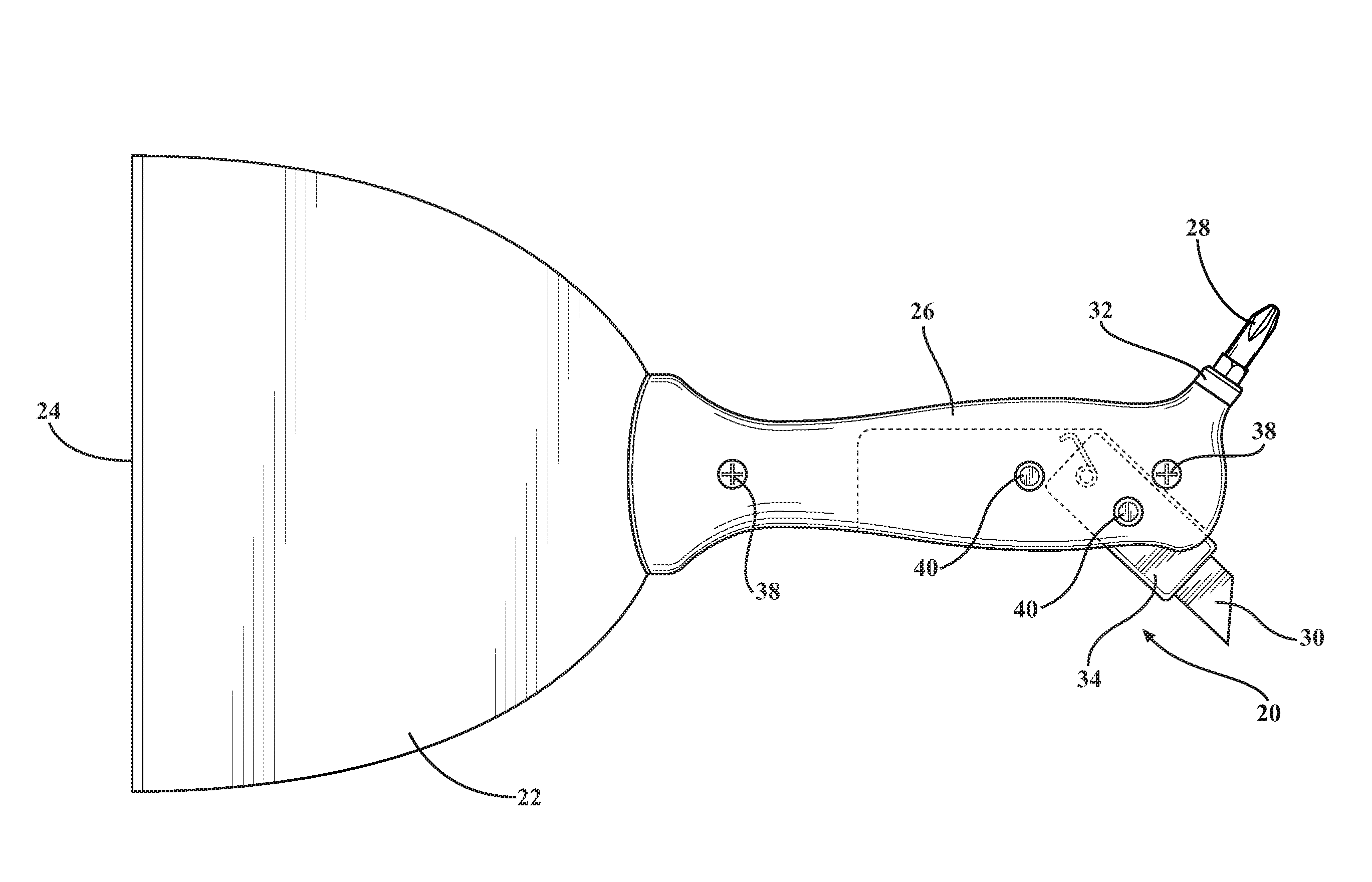

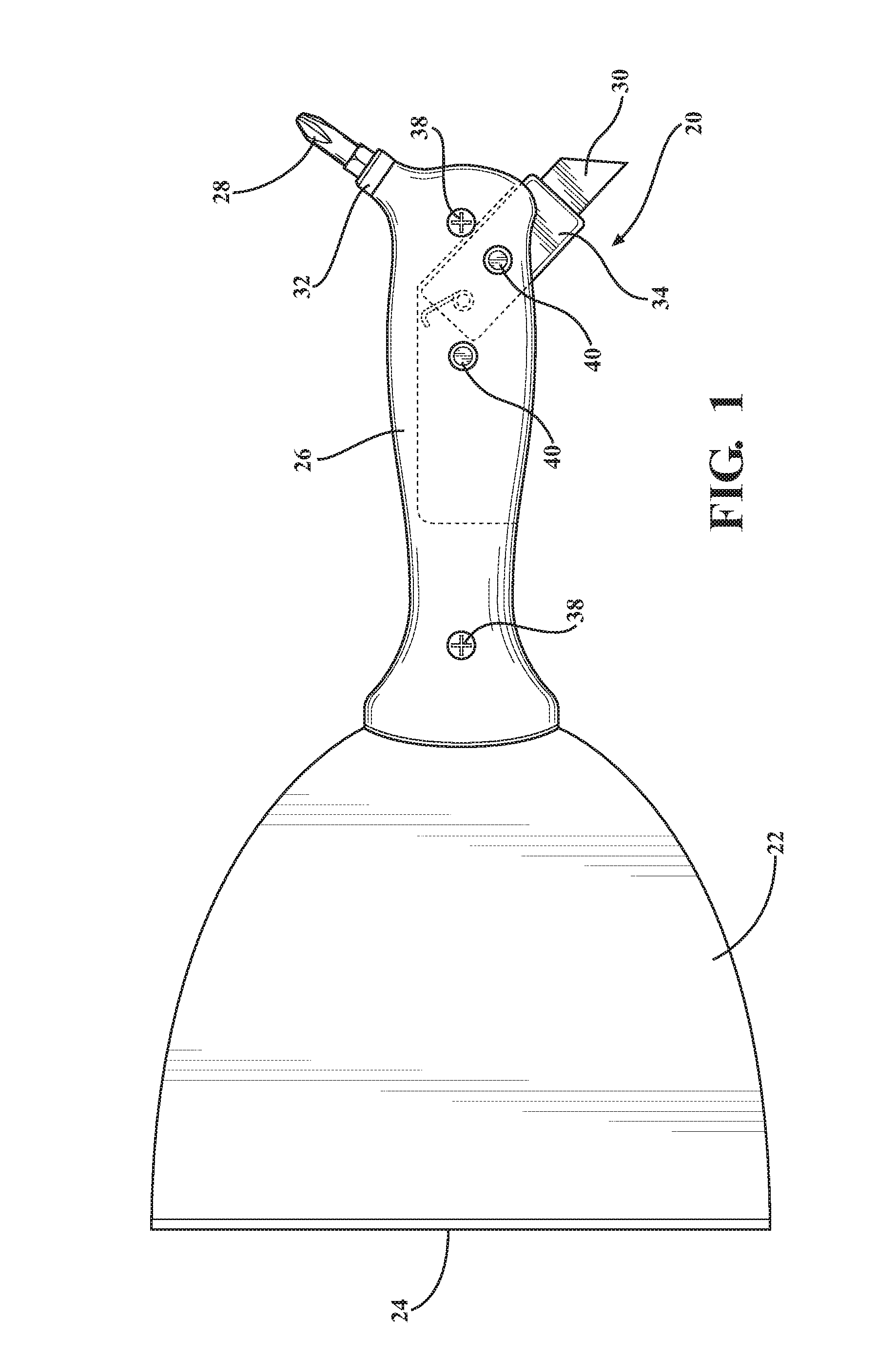

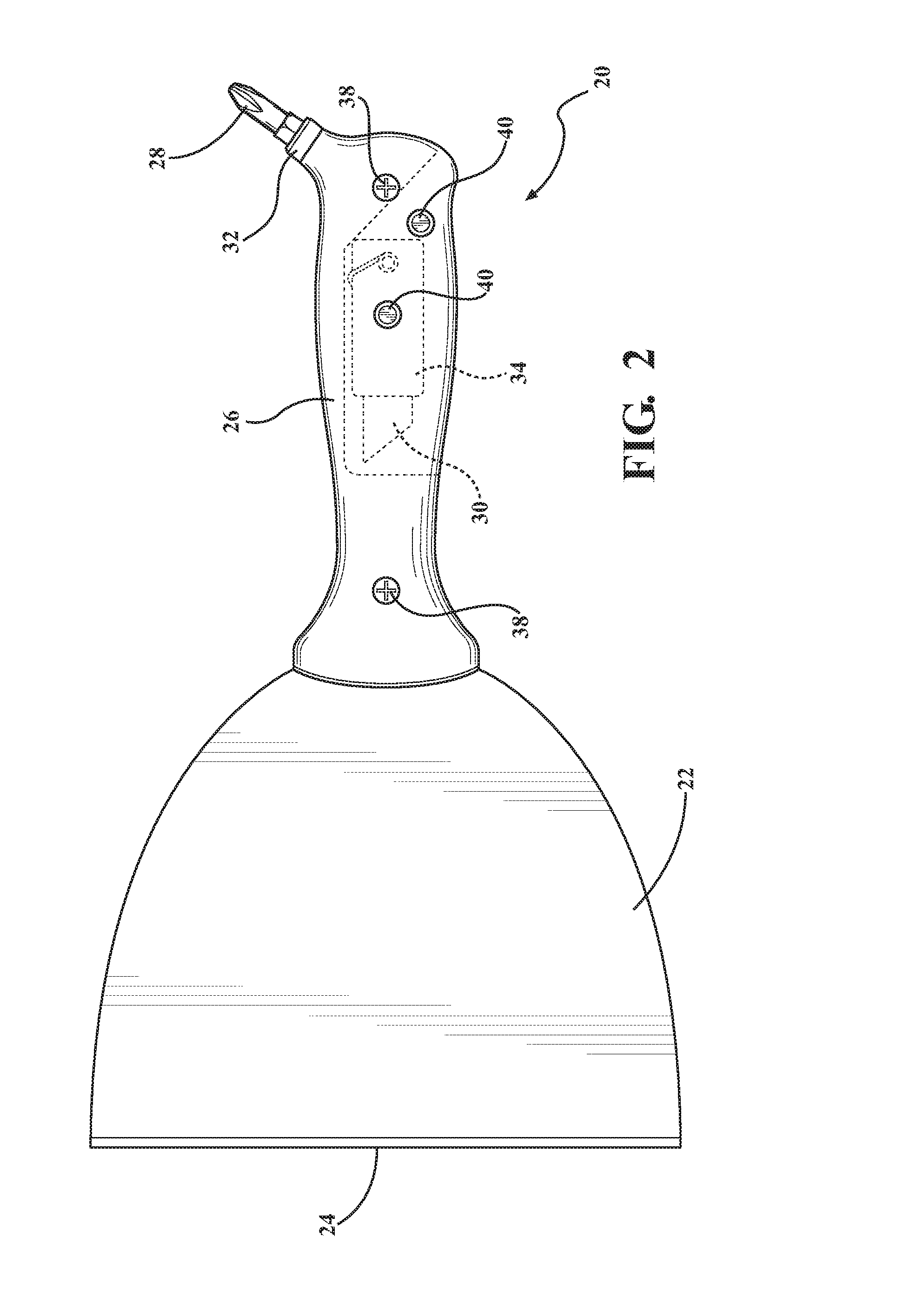

Drywall Knife And Multi-Tool Assembly

Owner:RAYMOND DANIEL J

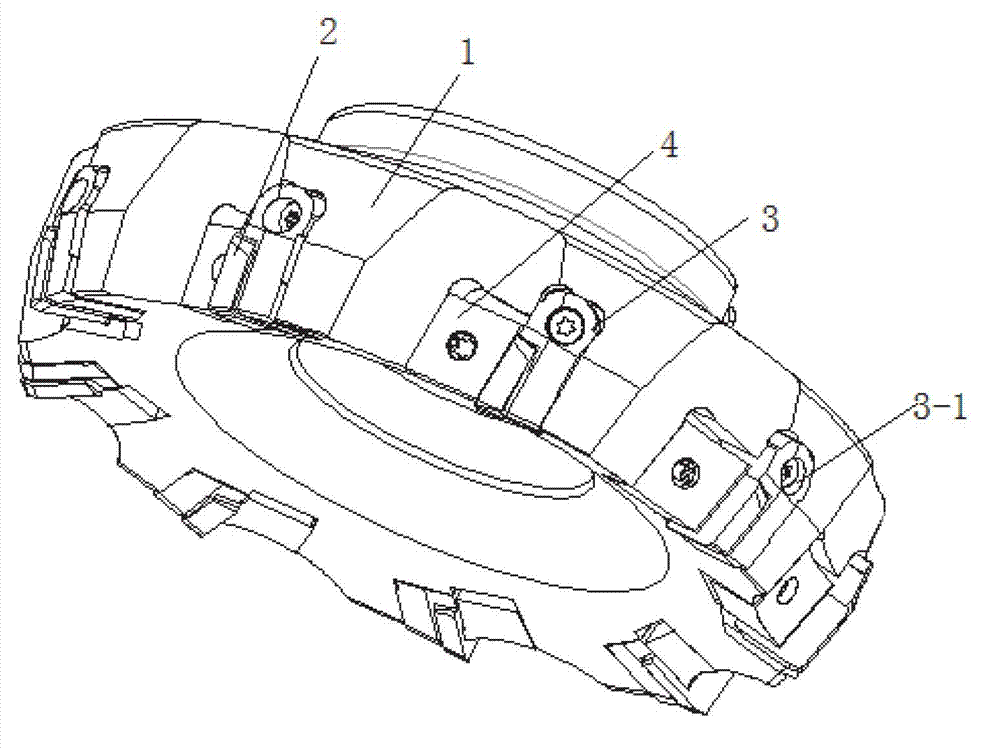

Disposable cutting insert for boring cutter

A disposable cutting insert for a boring cutter can reduce the roughness of a cut surface and achieve a mirror-like surface effect. The disposable cutting insert has a long curved blade edge, and the radius vertex of the long blade edge is deviated slightly from an external side of a vertex of the radius of cutting edge. A short curved blade edge is formed between the radius arc vertex and the radius arc vertex of the cutting edge. The vertical distance of the short curved blade edge is greater than the feed rate. The cutting edge cuts the work piece and the short curved blade edge can scrape a small size of material precisely for scraping the peak cut by the cutting edge and lower the height of the peak, so as to lower the surface roughness, and produce a mirror-like surface for an internal periphery of a bored hole.

Owner:CHANG SC

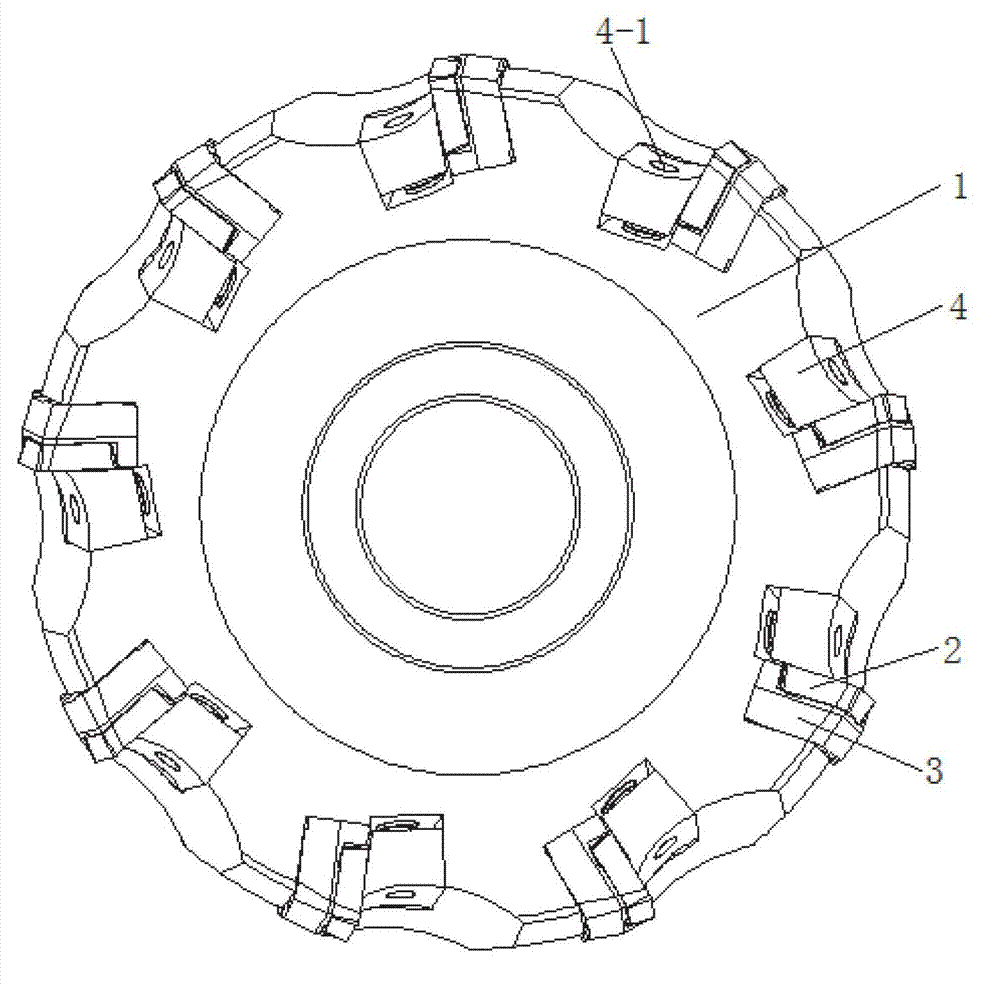

Face milling cutter with indexable inserts and knife pads thereof

The invention discloses a face milling cutter with indexable inserts and knife pads thereof. Each knife pad is provided with a knife pad screw hole and a step groove. The step groove comprises a blade bottom contact face, a blade axial locating face and a blade radial locating face which are connected with each other. A notch with three sides opening is formed in each knife pad. Due to the design of the unique knife pads, blades are not in direct contact with a cutter body, the rigidity of the cutter body is greatly strengthened, the abrasion of the cutter body is reduced, the service life of the cutter is prolonged on the whole, and meanwhile the blades are enabled to be located without the need of being in contact with the cutter body, and the accuracy of repeated locating is high. The service life of the cutter is longer than face milling cutters of other types by more than 50%, the accuracy of processing workpieces is improved by more than one accuracy level, the replacement of the blades is convenient, and the processing cost is reduced greatly.

Owner:常州瑞诺切数控刀具有限公司

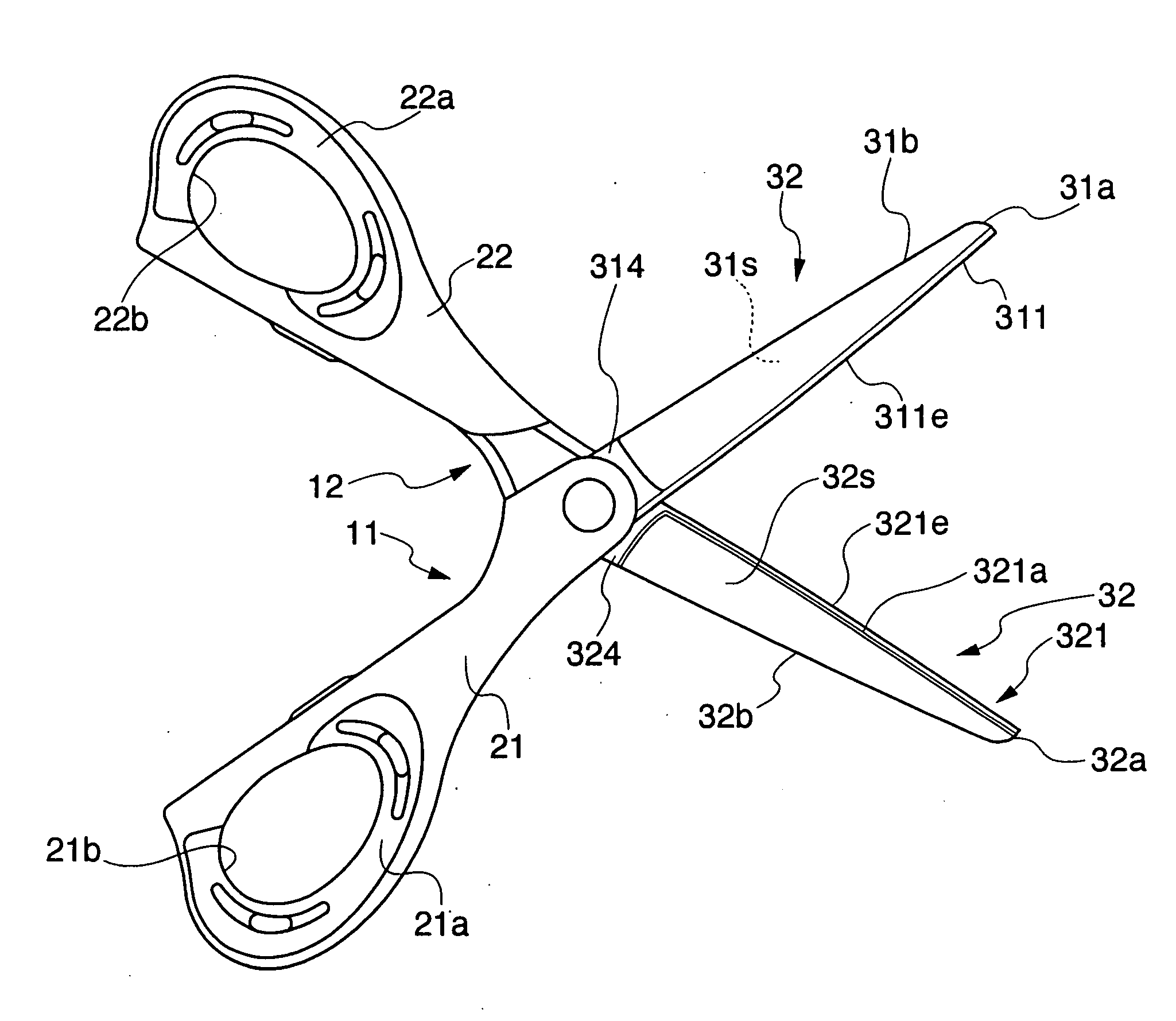

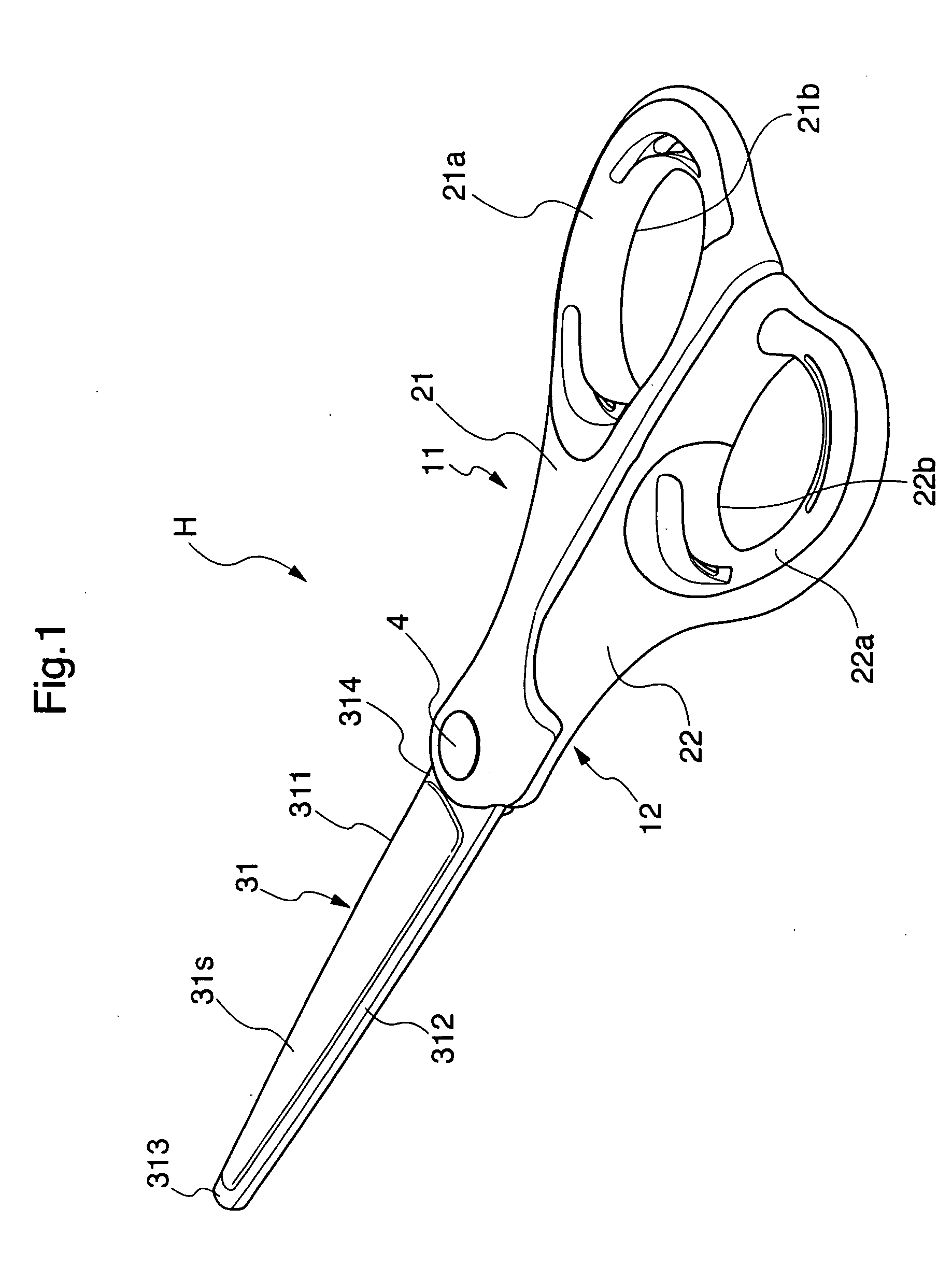

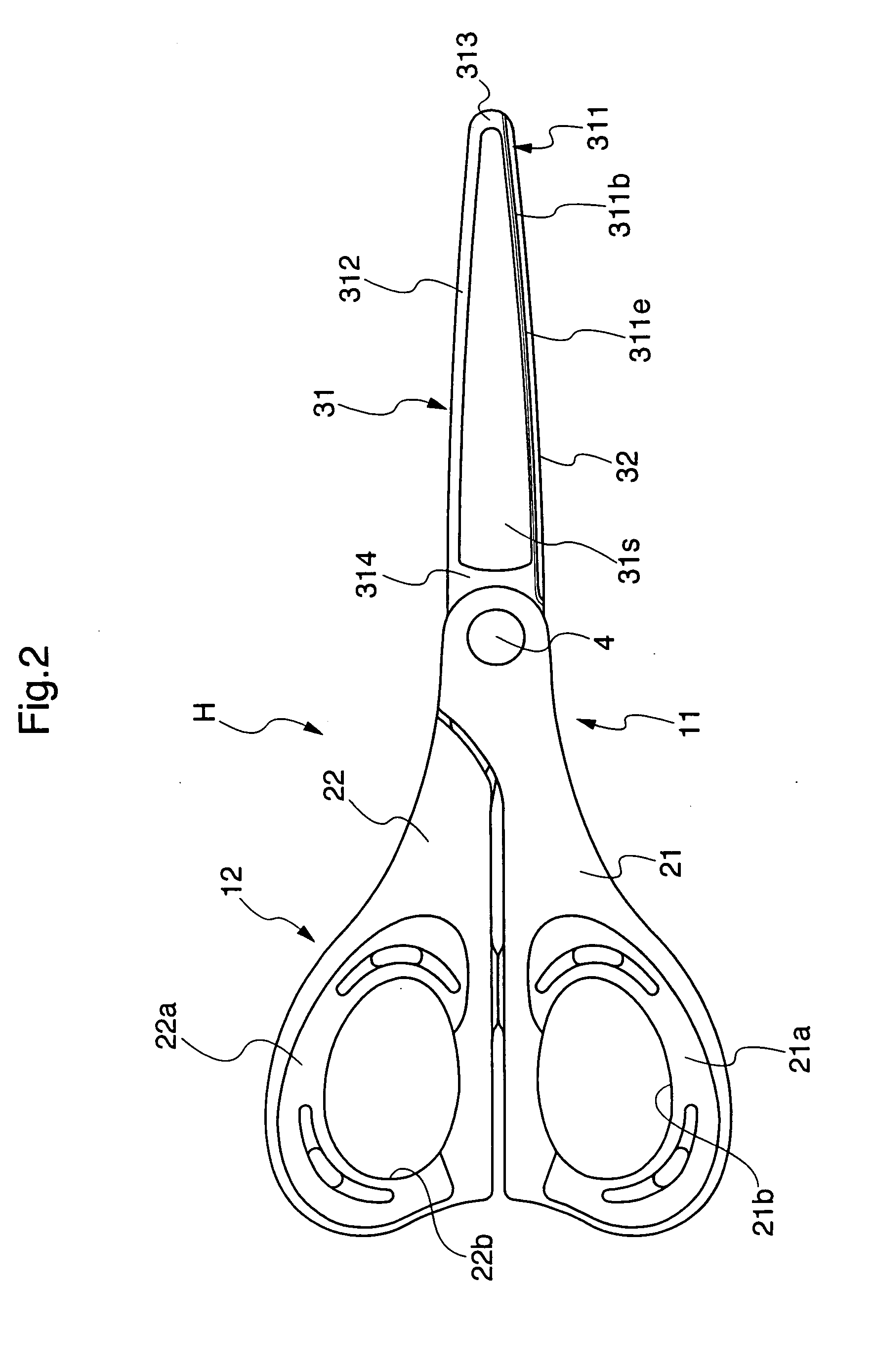

Scissors

Owner:KOKUYO CO LTD

Method and device for dispensing articles from blister packs

InactiveUS20070256307A1Easy to openMetal working apparatusUnpacking by cuttingEngineeringKnife blades

Owner:MANN ANDRE

Power trowelling aggregate decorative stone

Owner:MASTERSON RANDY JAY +3

Rotary cutting tool and method for cutting pipe by same

ActiveCN102335926AOvercome resistanceOvercome frictionMetal working apparatusEngineeringCentrifugal force

Owner:AMSINO MEDICAL KUNSHAN

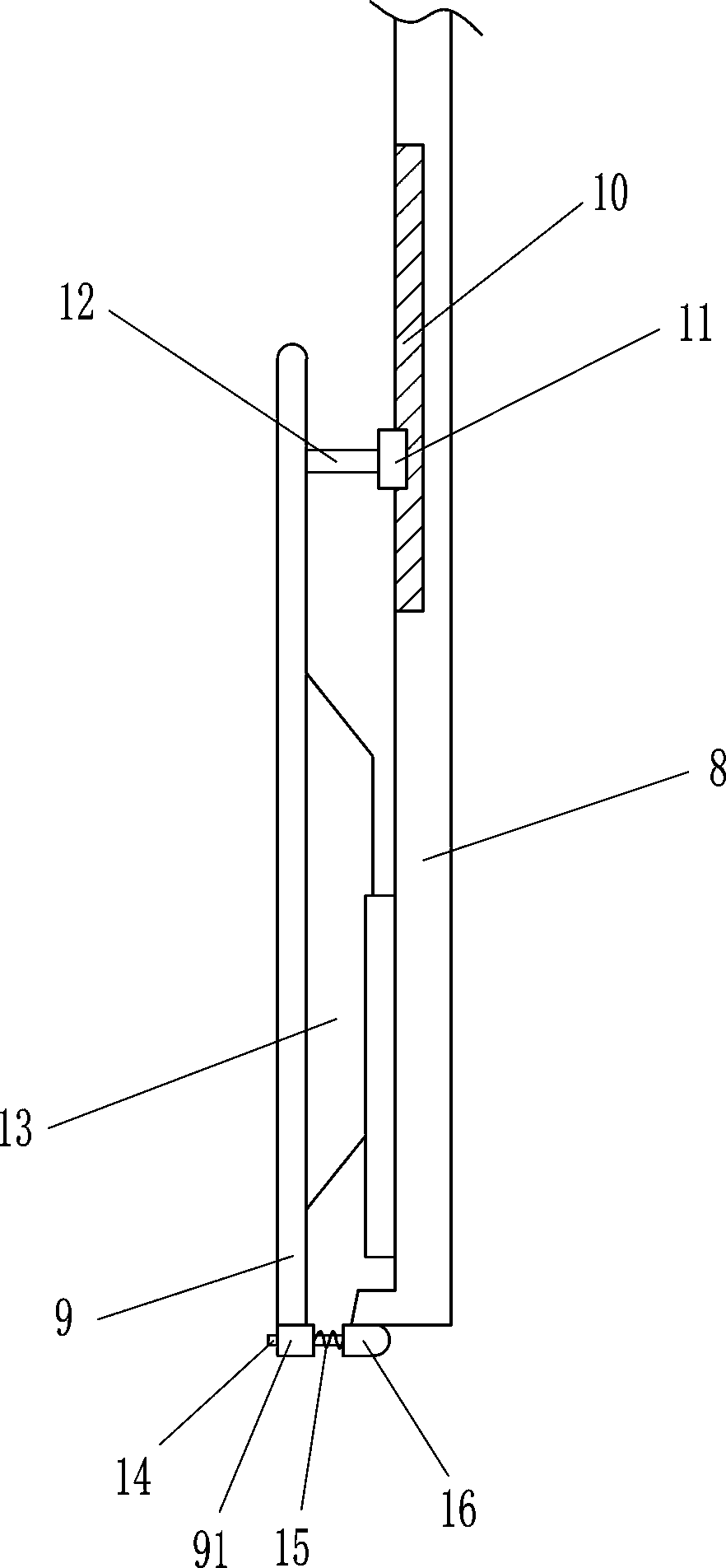

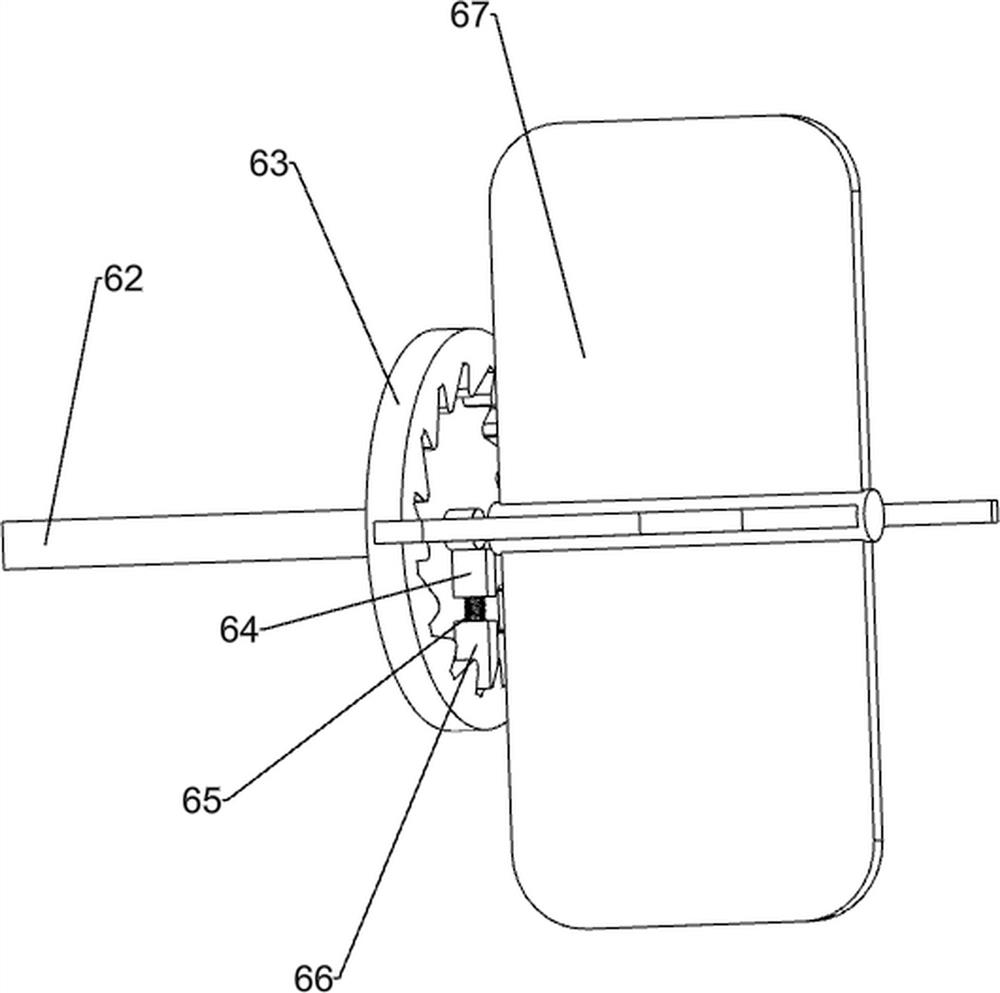

High twig shears applied to charged high-voltage line

InactiveCN106305164AWith insulation functionEasy to trimCuttersCutting implementsPower gridShear mouth

The invention discloses high twig shears applied to a charged high-voltage line. The high twig shears comprise a tool rest, a static blade and a moving blade, the static blade is fixed on the tool rest, and the moving blade forms a hook-shaped shear mouth facing downwards; the tool rest is provided with a power transmission mechanism, a worm is fixed on an output shaft of the power transmission mechanism, a worm gear structure matched with the worm is arranged on the back of the moving blade, and insulating stay cords are connected to a big rotating wheel and a small rotating wheel respectively; a steering block is hinged to the lower portion of the tool rest through a draw-in bolt to form a tool rest steering mechanism; an insulating rod is connected to the lower portion of the steering block. According to the high twig shears, the problem that traditional high twig hears cannot be used on the condition that a high voltage line is charged is solved, operation can be conducted without power interruption, and the reliability of mains supply is guaranteed; meanwhile, the trimming range is widened, and the labor efficiency is improved.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO XUZHOU POWER SUPPLY CO +1

Device for wood cutting

ActiveCN112405711APrevent falling outImprove processing speedFeeding devicesGripping devicesAgricultural engineeringKnife blades

Owner:仙游县三龙古典家具有限公司

Array type meat cutting and skewering device

Owner:DALIAN SHENGJIE VACUUM TECH DEV

Food material slicing device

Owner:XUZHOU UNIV OF TECH

Food processor

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

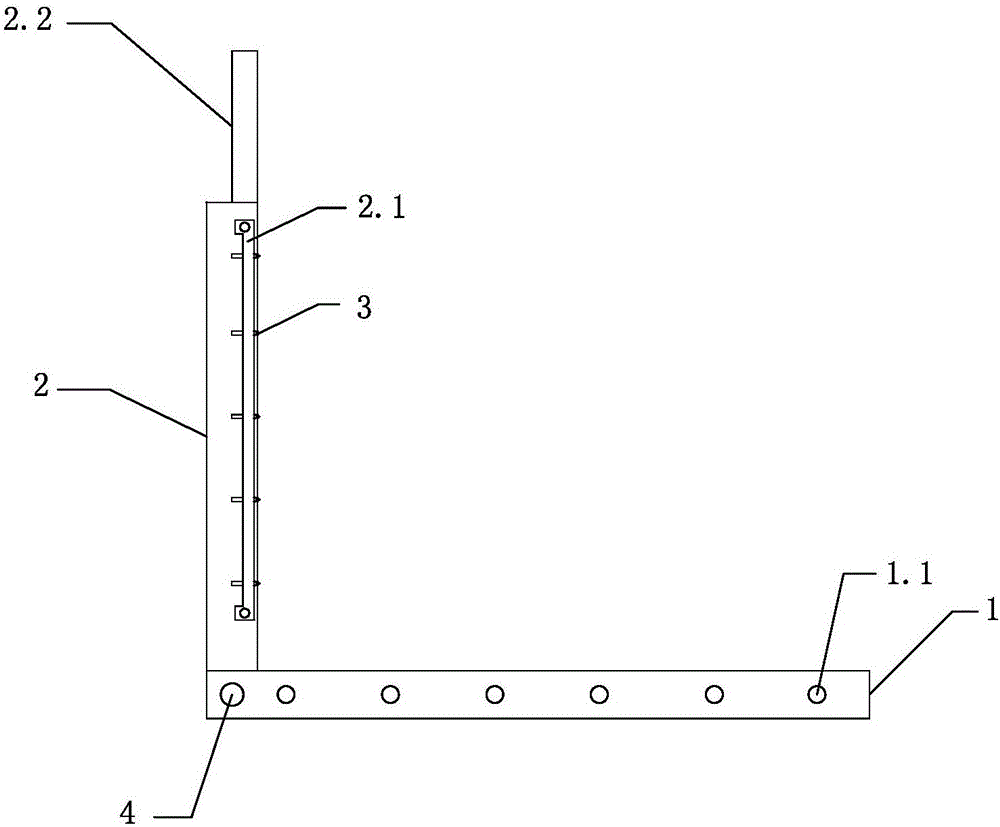

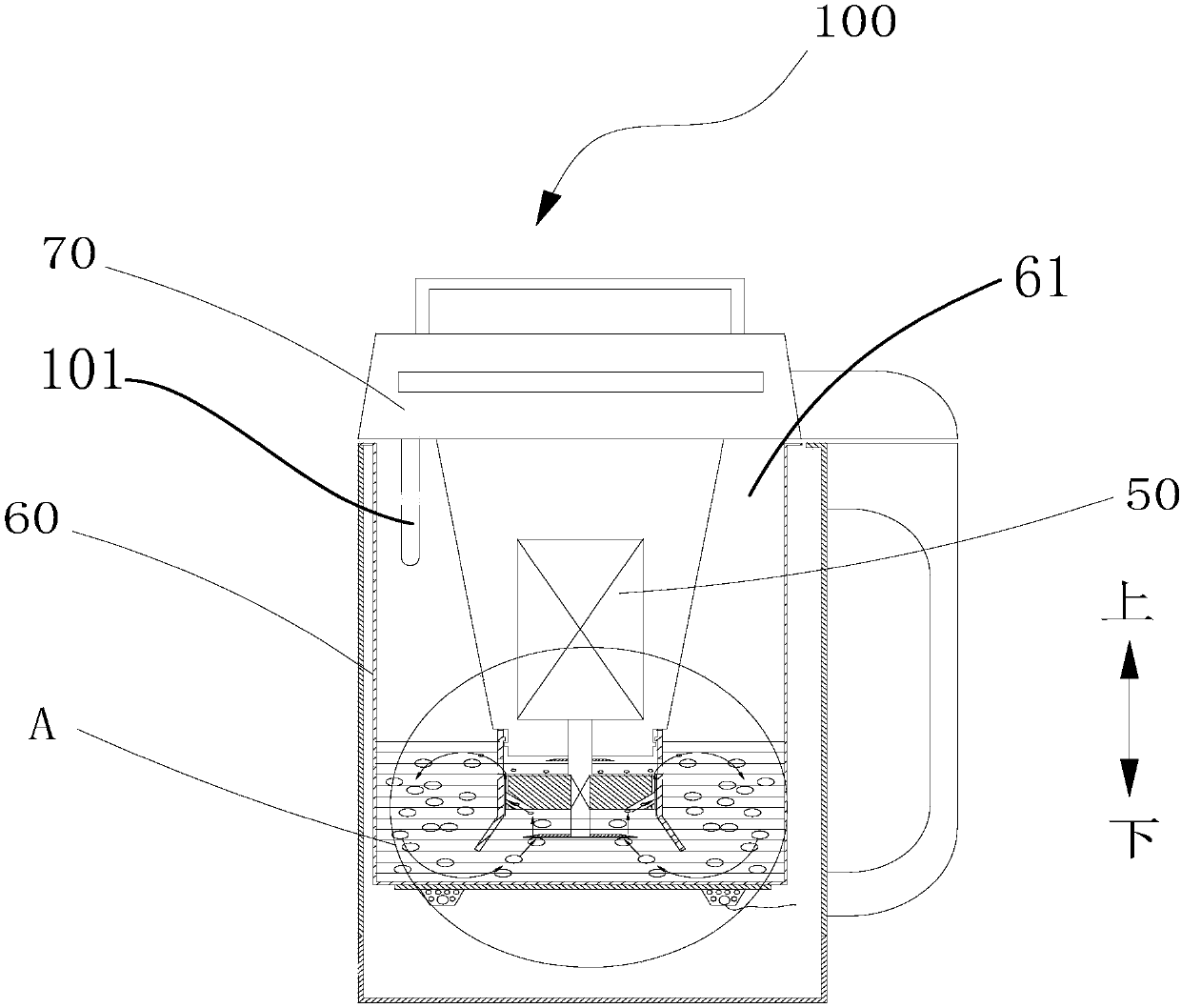

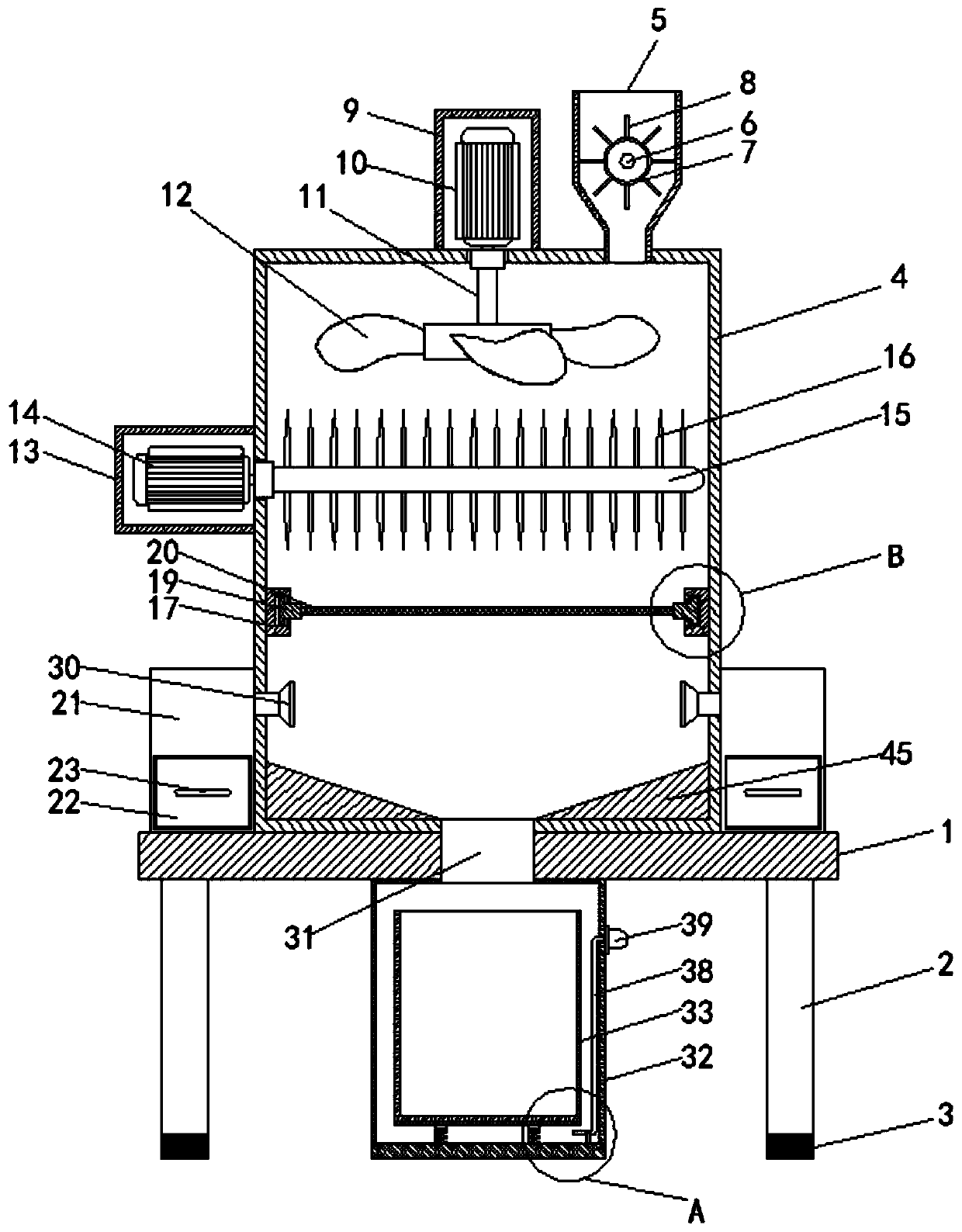

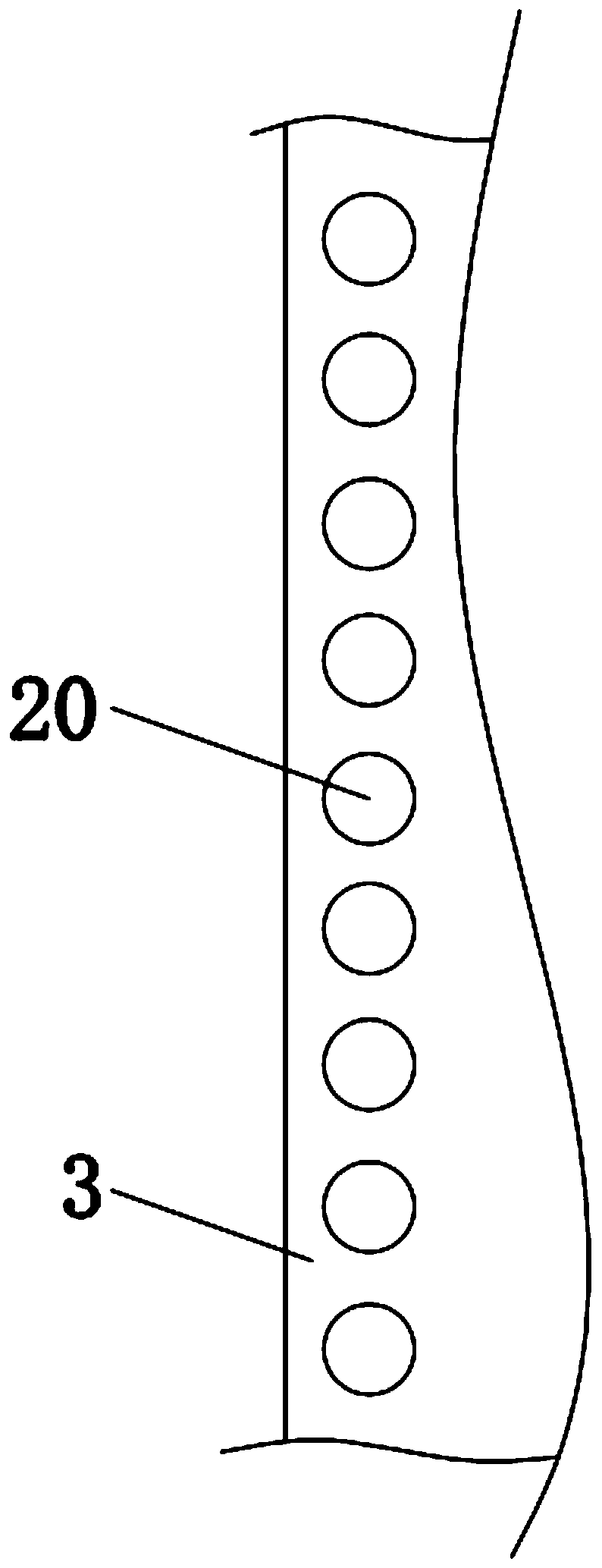

Wastewater treatment device

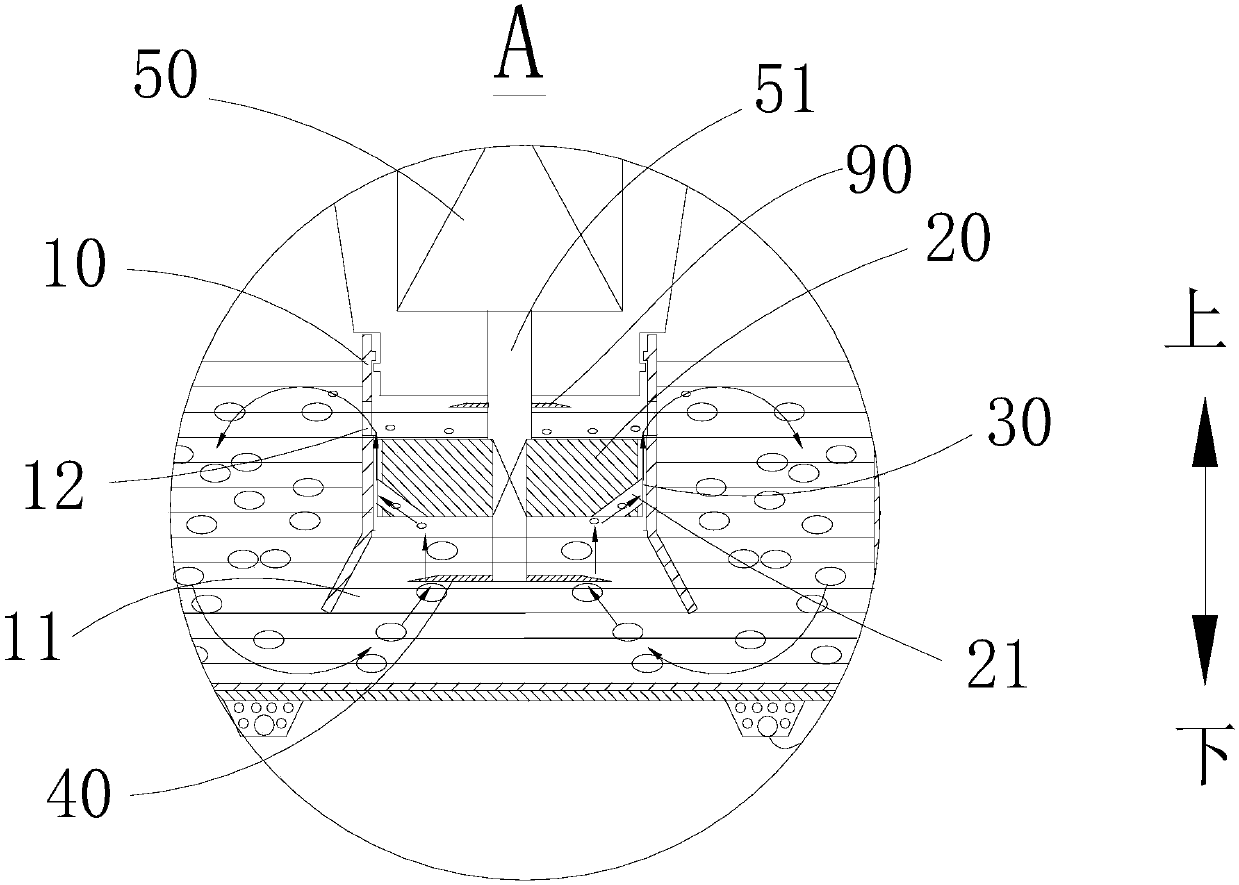

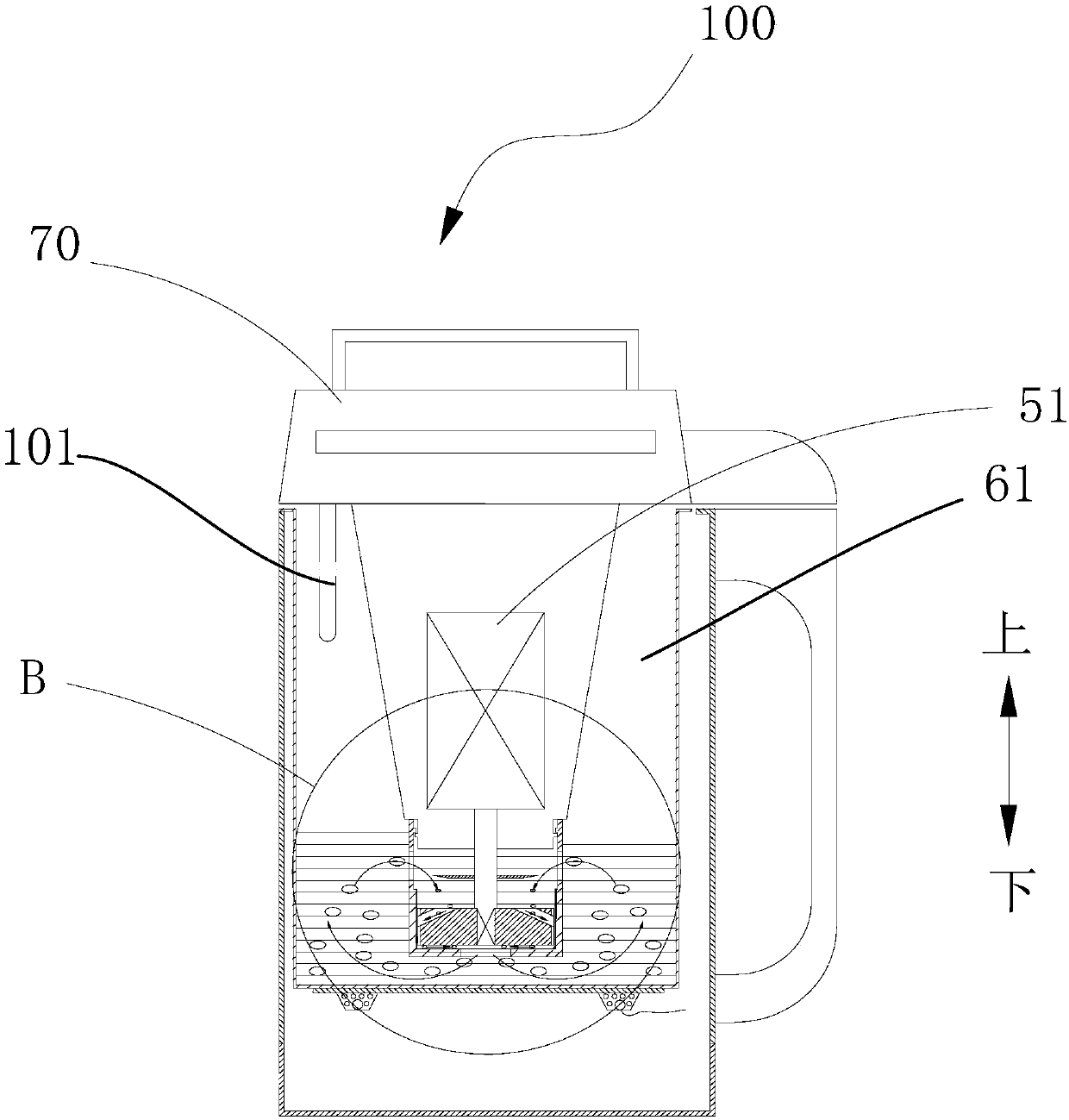

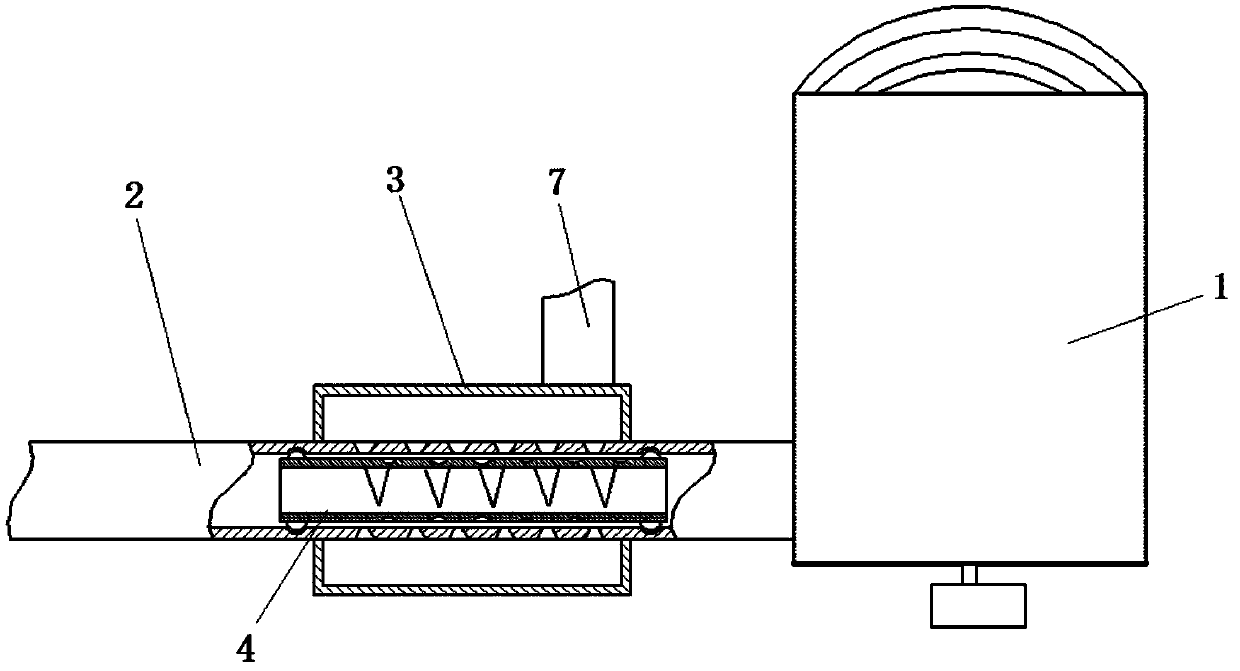

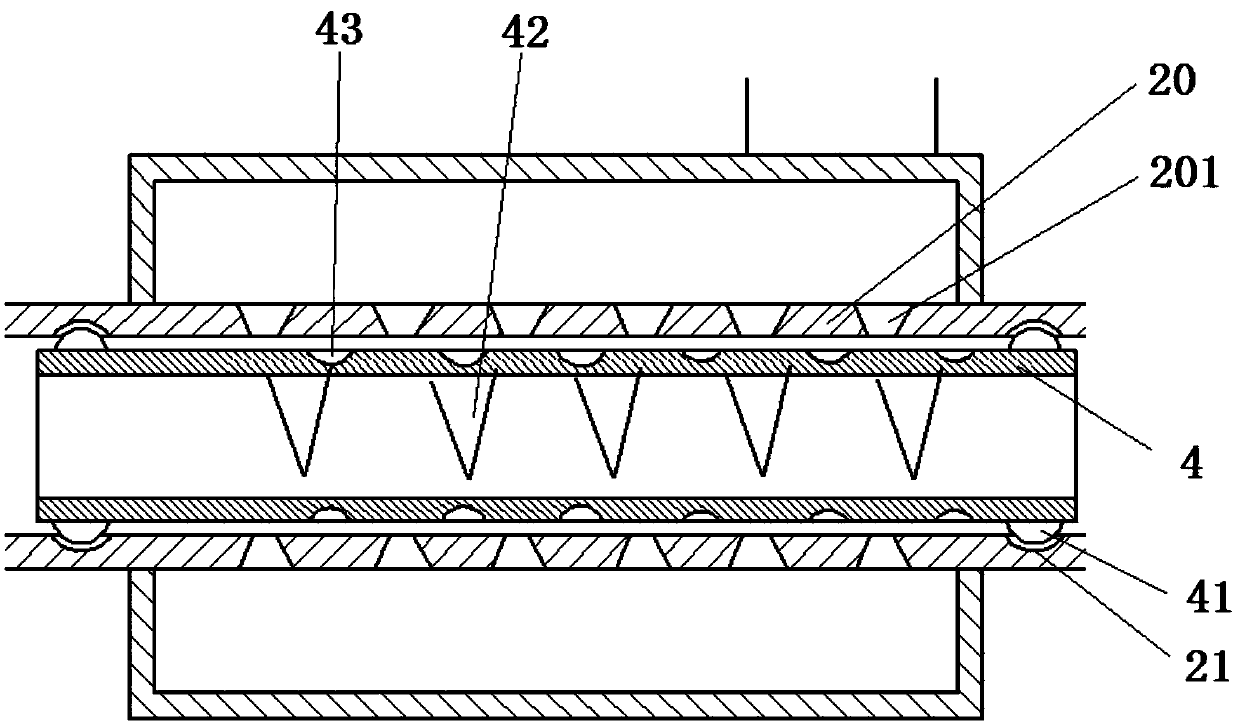

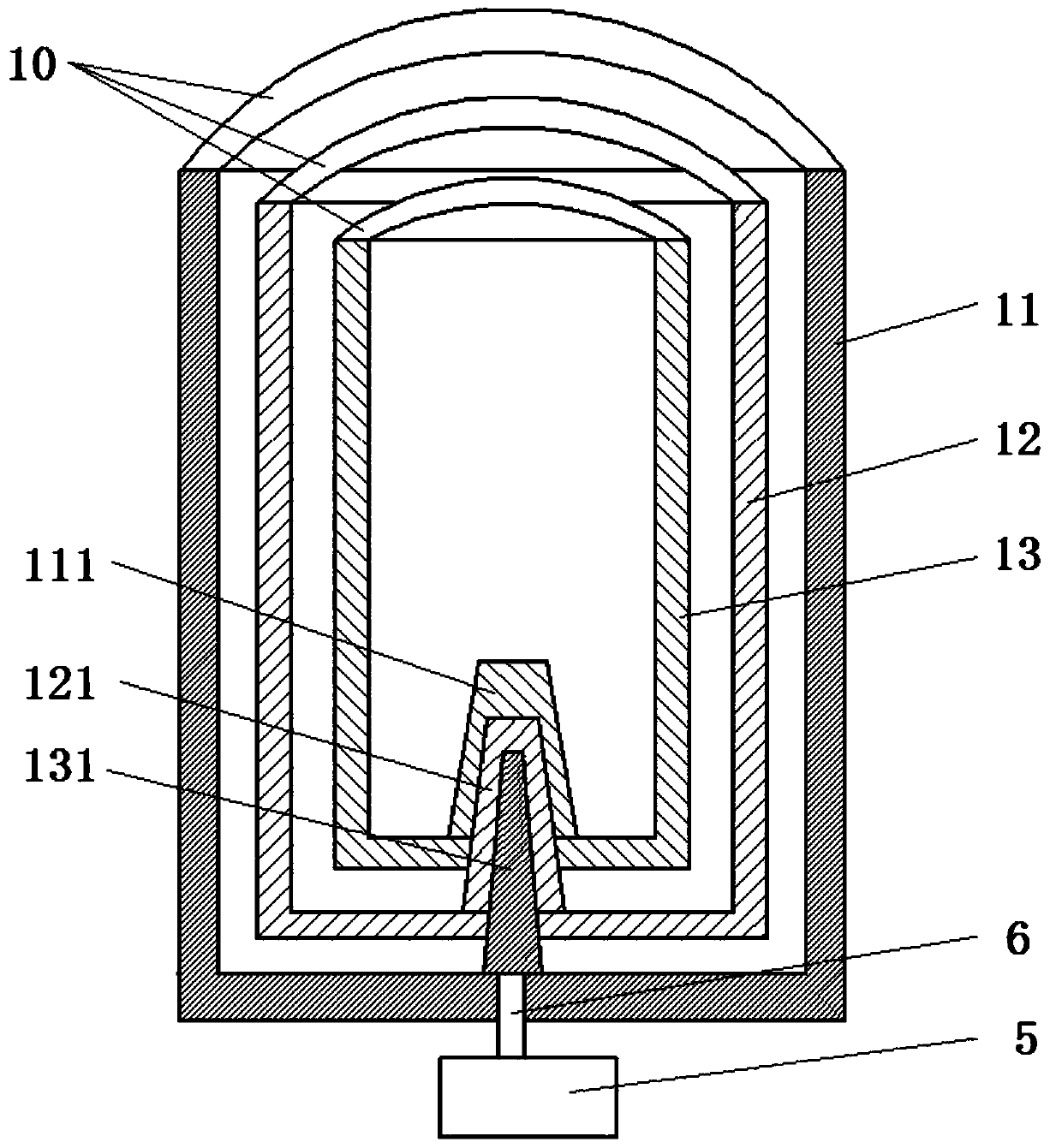

ActiveCN109621544AAvoid cloggingEffective placement of clogsFiltration circuitsKnife bladesSmall hole

The invention relates to the field of filtration, and discloses a wastewater treatment device. The wastewater treatment device comprises a filtering device (1) and a pipeline (2), an external pipeline(3) sleeves a liquid inlet end of the pipeline (2), the external pipeline (3) is connected with a water conveying pipe (7), a plurality of small holes (201) are formed in the wall surface of a dredging pipeline (20), the small holes (201) are uniformly distributed in the dredging pipeline (20), and the diameters of the small holes (201) are gradually increased in the radial direction of the dredging pipeline (20); the wastewater treatment device further comprises a rotary cylinder (4). According to the wastewater treatment device, through helical distribution of the small holes and gradual decline of the diameters of the small holes, the pressure of water injected into the dredging pipeline is increased, action force is applied to the rotary cylinder in the dredging pipeline, so that therotary cylinder rotates, residual impurities are subjected to secondary treatment through rotating knife blades, and the situation that the pipeline is blocked by wastewater which is treated by a filter device is prevented. Through the structure, the filtered wastewater is subjected to secondary treatment, blocking of the pipeline is effectively prevented, the structure is reasonable, and the practicability is high.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Generation method and device for DAF-attached small substrate, storage medium and electronic equipment

ActiveCN112259473ALow costReduce drawingSemiconductor/solid-state device manufacturingMetal working apparatusEngineeringParticle density

The invention discloses a generation method and device for a DAF-attached small substrate, a storage medium and electronic equipment. The method comprises the following steps: enabling a DAF to be attached to the reverse side, where no circuit is laid, of an initial packaging substrate so as to obtain a to-be-cut packaging substrate; and conducting cutting from the front face of the packaging substratea by using a soft knife blade to obtain the DAF-attached small substrate, wherein the soft knife blade is made of artificial diamond with a particle size ranging from 800 to 1200 and particle density ranging from 40 to 60. According to the invention, after the DAF is attached to the reverse side of the initial packaging substrate without the circuit, the soft knife blade made of the artificial diamond with the particle size of 800-1200 and the particle density of 40-60 is used for cutting, so wire drawing problems can be effectively reduced, cutting twice in the prior art is not needed, process complexity is reduced, labor cost and ubstrate cost are saved, and manufacturing cost is saved.

Owner:BIWIN STORAGE TECH CO LTD

Food detection device

PendingCN113655186AImprove detection efficiencyAdjustable cutting angleConveyorsPreparing sample for investigationAgricultural engineeringDistilled water

Owner:浙江九安检测科技有限公司

Treatment machine for increasing surface roughness of plastic foam particles

InactiveCN104690954ASmooth entryStir wellRough surfaceSuction force

Owner:LONGKOU ZHENGREN ENERGY SAVING BUILDING MATERIALSEQUIP MFG

Efficient plastic granulator for preventing air environment pollution

InactiveCN111546531AAvoid pollutionImprove cutting efficiencyDirt cleaningGrain treatmentsRotational axisElectric machine

Owner:张大柱

High-temperature-resistant mica plate edge cutting device and using method thereof

InactiveCN111482998AGuaranteed stabilityImprove stabilityMetal working apparatusEngineeringKnife blades

Owner:扬州瑞宏电工电气有限公司

3D breast printing device

PendingCN112172125AAvoid damageFast printingAdditive manufacturing apparatusDrying gas arrangementsElectric machineryKnife blades

Owner:SHANGHAI PUDONG HOSPITAL

Multi-blade vegetable knife

InactiveCN105643668AHigh speedUniform thicknessMetal working apparatusMetal-working hand toolsEngineeringKnife blades

Owner:YICHENG NO 3 SENIOR HIGH SCHOOL

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap