Multi-knife automatic knife changing type powder laying scraper knife device of 3D printer

A 3D printer and automatic tool change technology, applied in the field of additive manufacturing, can solve the problems of troublesome operation, waste of inert gas, and need to replace blades, so as to reduce production costs and save time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

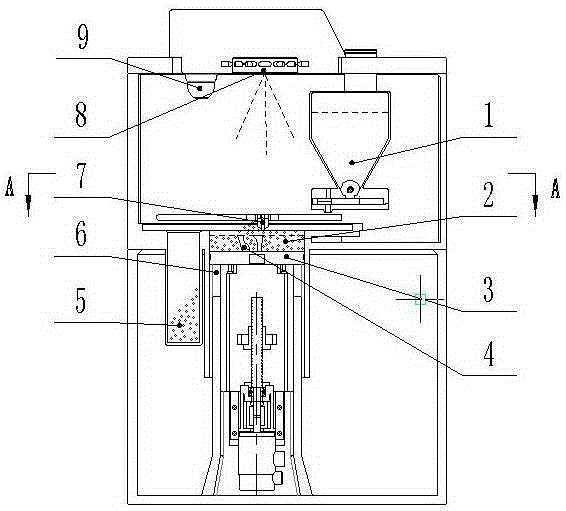

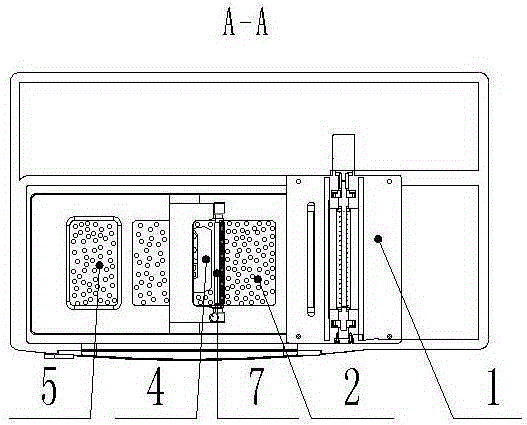

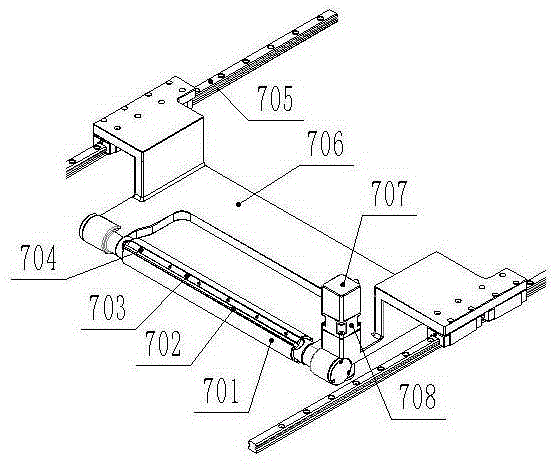

[0013] 1. If image 3 , Image 6 Shown is the embodiment of the powder spreading scraper device. The powder spreading scraper device is placed above the sintered molding or solidified molding surface, can reciprocate along the guide rail (705), and scrape it with its scraper blade (702). Powder, complete the powder spreading process; the powder spreading scraper device is equipped with multiple scraper blades (702), of which the bottom scraper blade is the working blade, and the rest of the blades are spare blades, and the spare blades can be automatically exchanged under the control of the control system to the working position below.

[0014] 2. If Figure 5 , Image 6 As shown, the scraper blade (702) is embedded in the trapezoidal groove of the knife holder shaft (701), and the scraper blade (702) is pressed by the pressing bar (703) and the screw (704). The section of the pressing bar (703) Trapezoidal or wedge-shaped.

[0015] 3. If image 3 , Figure 4 As shown, the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap