Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about "Dirt cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

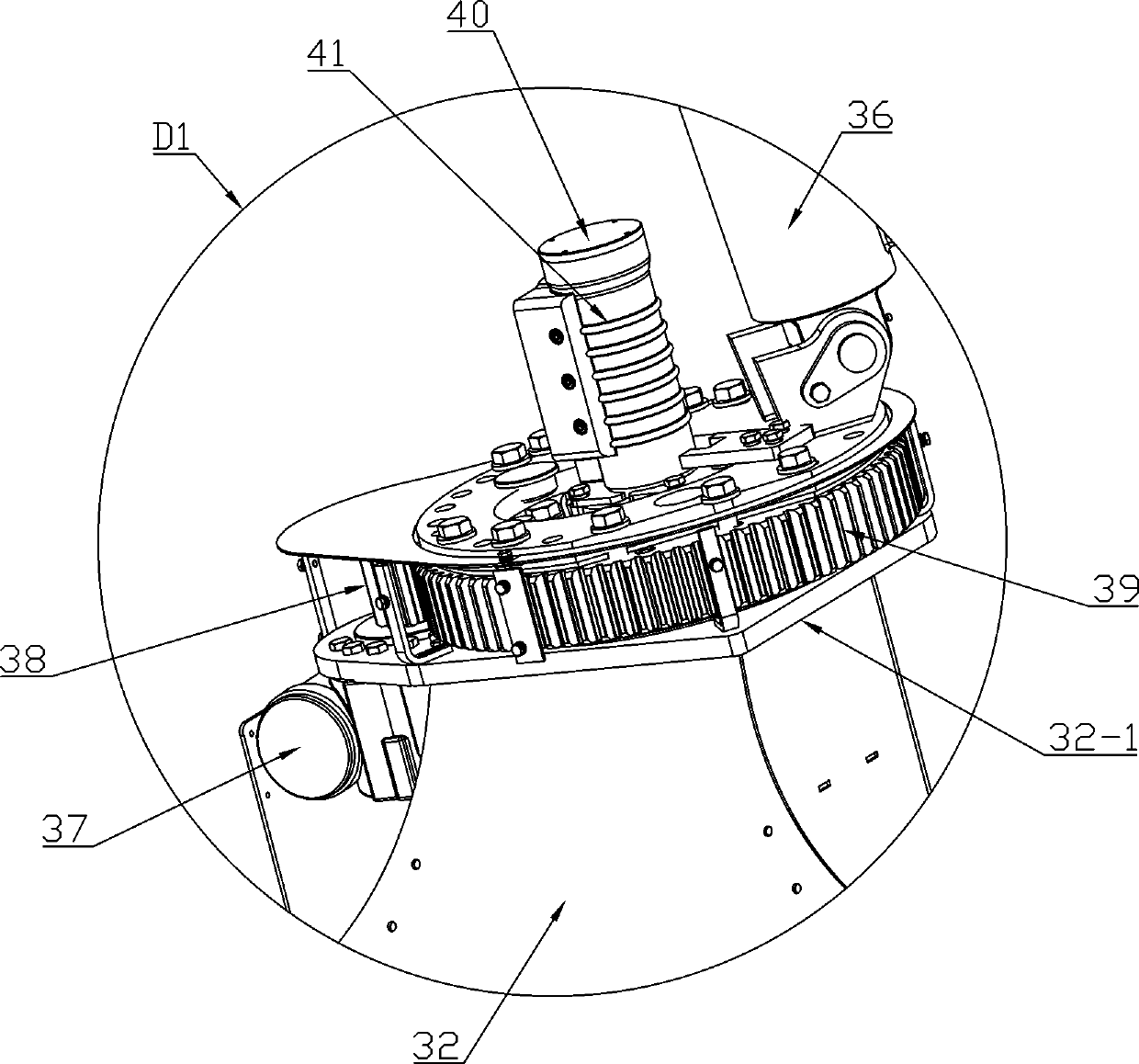

Eccentric rotary cone type stone crushing device for mineral processing

Owner:浙江燕思志网络科技有限公司

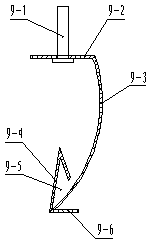

Exhaust hood with adjustable supply air containment air streams and air curtains

ActiveUS20100126494A1Lower energy requirementsReduce exhaust flowDomestic stoves or rangesLighting and heating apparatusWaste management

An exhaust hood and related methods for exhausting fumes are disclosed. The exhaust hood comprises a housing forming a collection region having an entry portion and an upper portion disposed above the entry portion, an exhaust inlet coupled with the housing and configured to draw air from the entry and upper portions, and a supply assembly coupled with the housing and configured to output a flow of supply air. The supply assembly is configured to direct a first portion of the supply air across the collection region generally towards the exhaust inlet and direct a second portion of the supply air generally downward away from the collection area. The directed first portion of the supply air divides the collection region into the entry and upper portions. The portion of the supply air directed into at least the first portion or the second portion can be adjustable.

Owner:STREIVOR AIR SYST

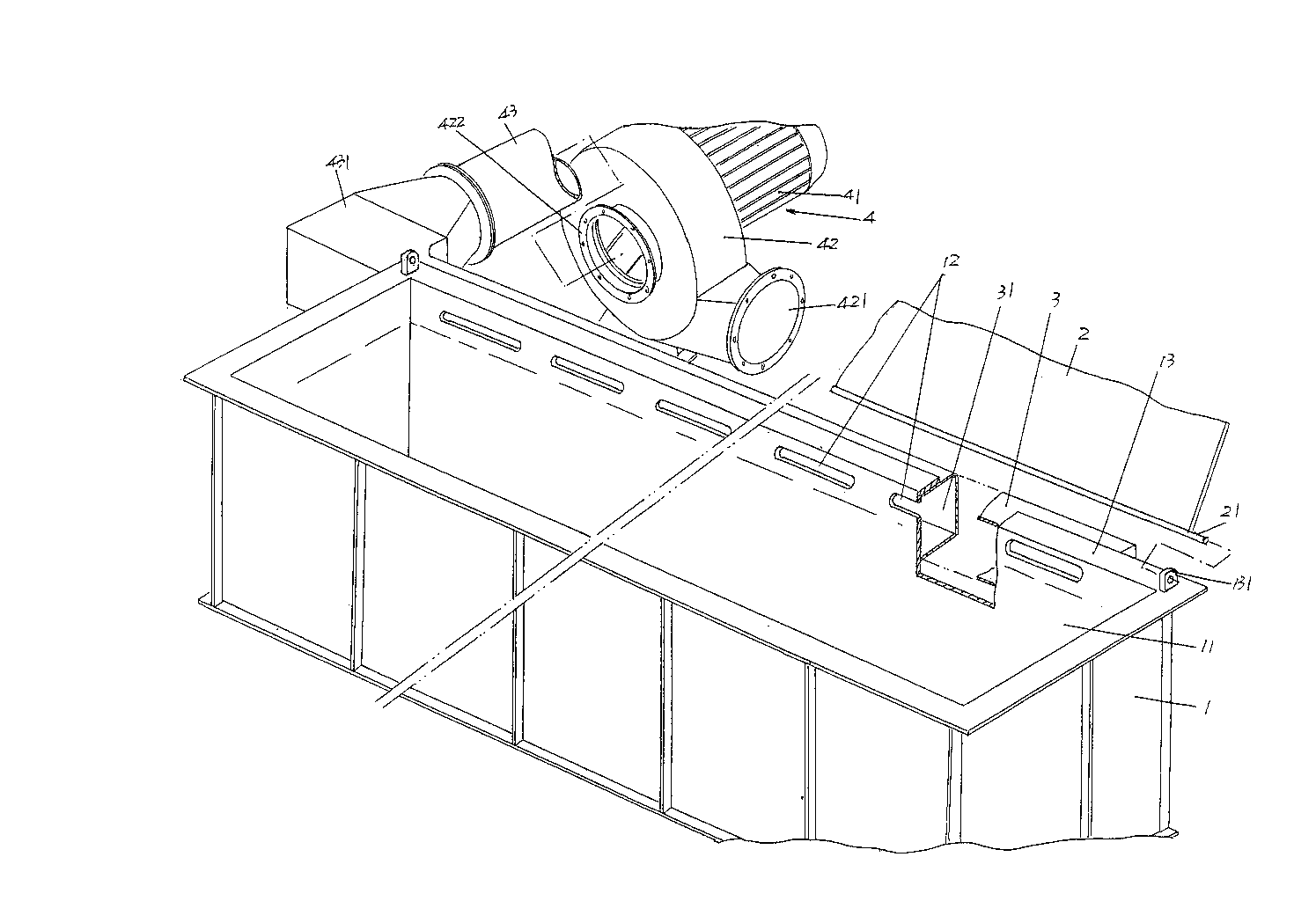

Plate strip surface scale removal device and method

Owner:BAOSHAN IRON & STEEL CO LTD +1

Internal combustion engine exhaust cooling and removal apparatus

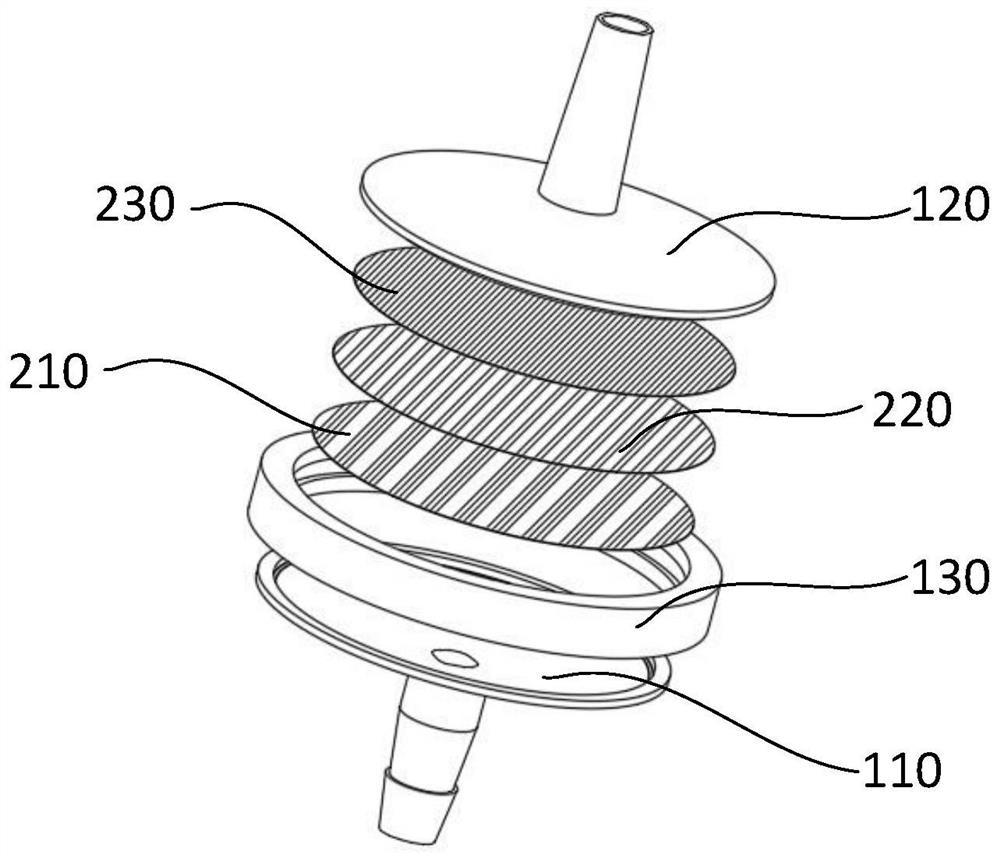

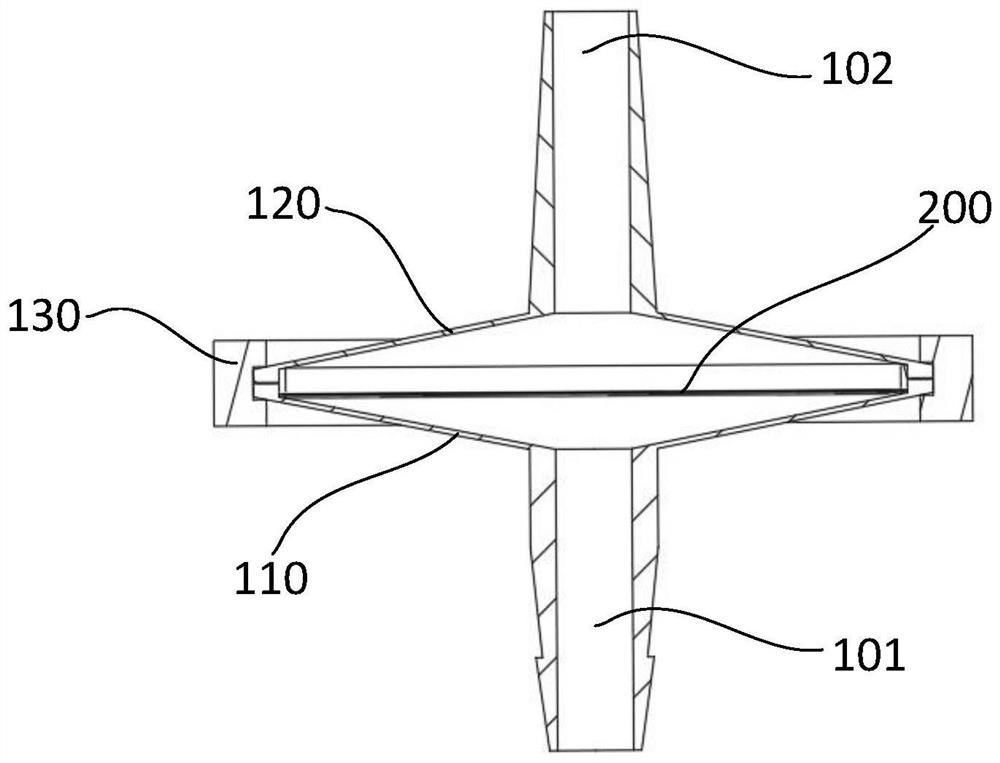

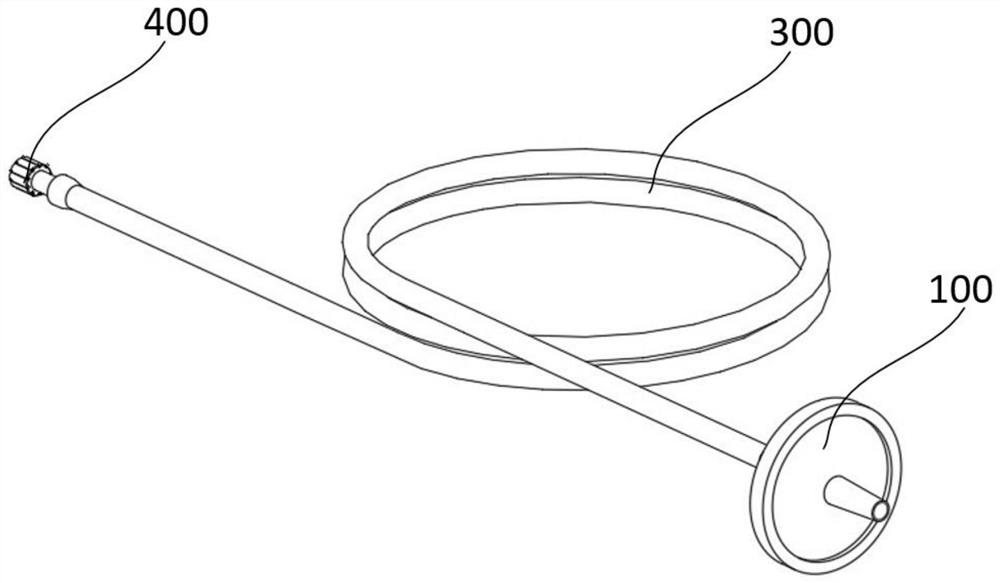

An internal combustion engine exhaust cooling and removal apparatus includes a heat exchange assembly connected to an exhaust pipe of an internal combustion engine. A flexible hose is connected to the heat exchange assembly, and an exhaust fan assembly is connected to the flexible hose. Use of the internal combustion engine exhaust cooling and removal apparatus of the invention provides a clean air environment in an indoor confined space by removing the engine exhaust gases which are hazardous to one's health. The apparatus of the invention is especially useful with non-electric powered tools and machines, such as for indoor excavations with diesel-powered excavators or other construction equipment. The apparatus of the invention can also be used with diesel-powered saws.

Owner:PATRY IVAN J

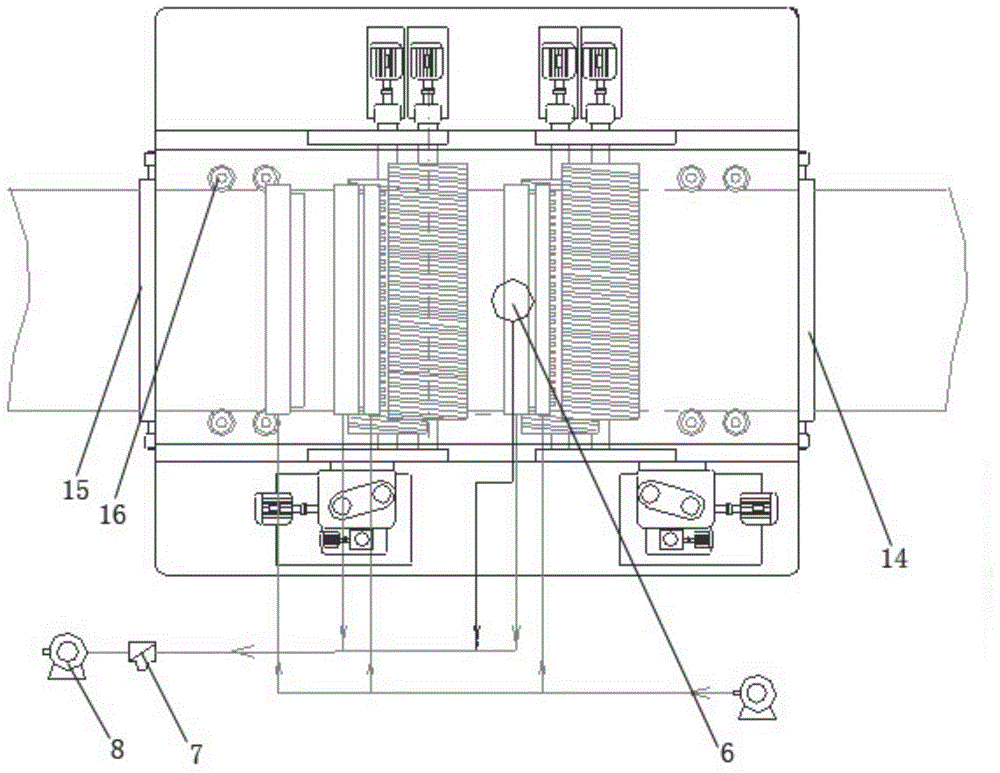

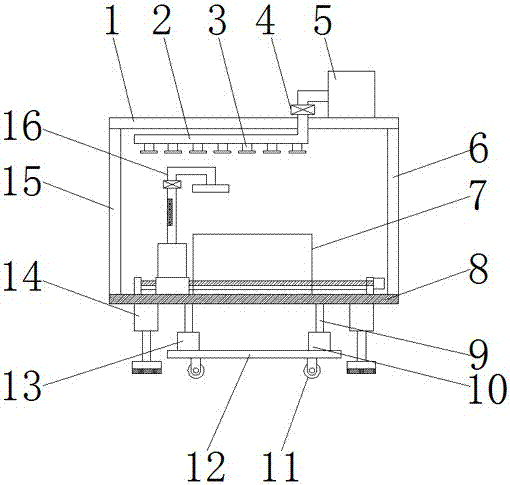

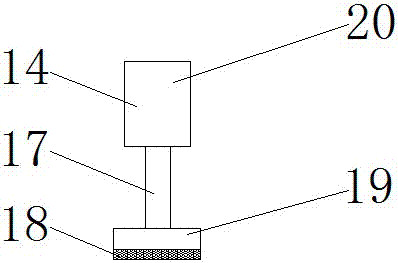

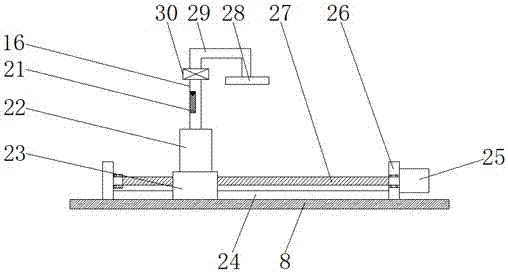

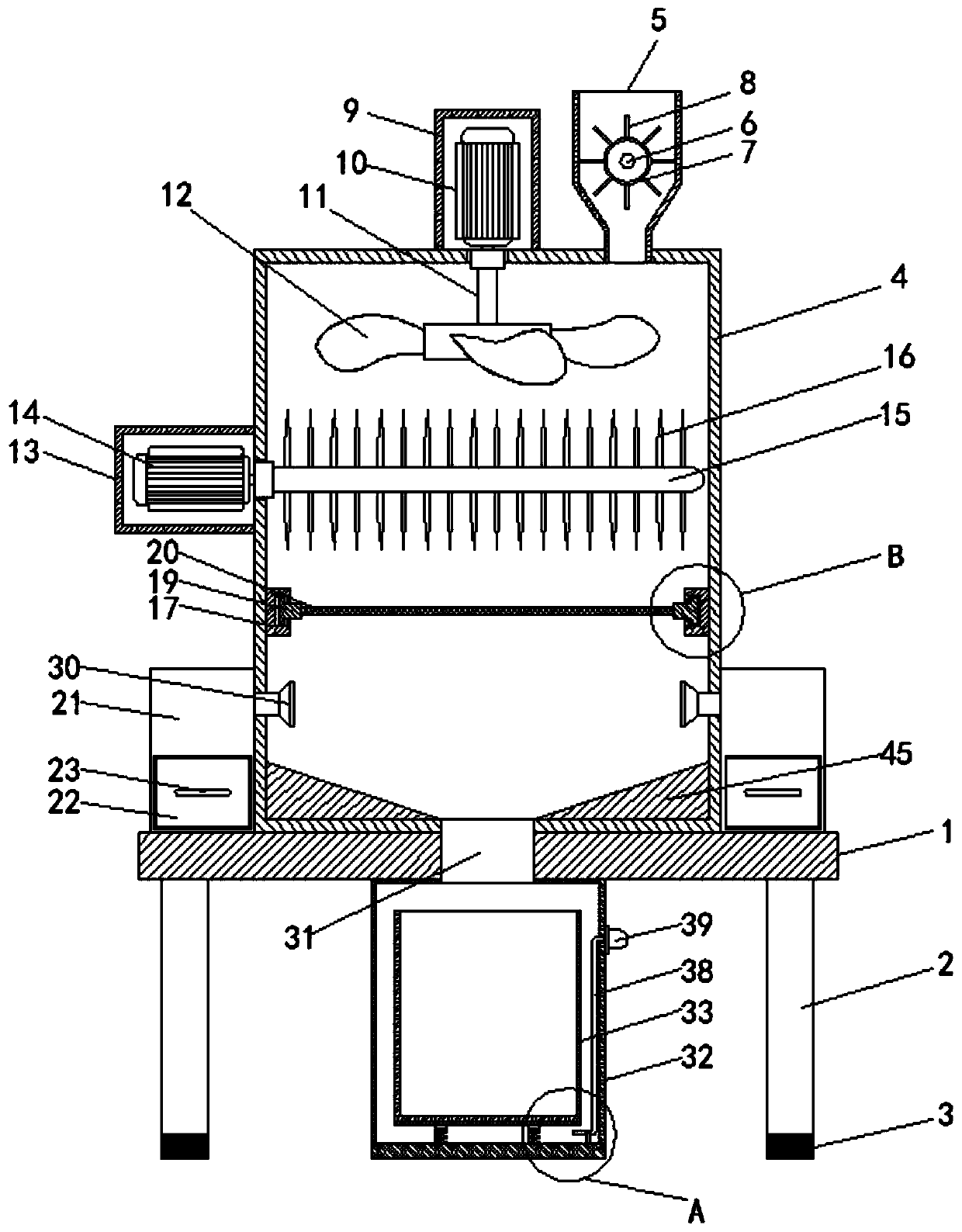

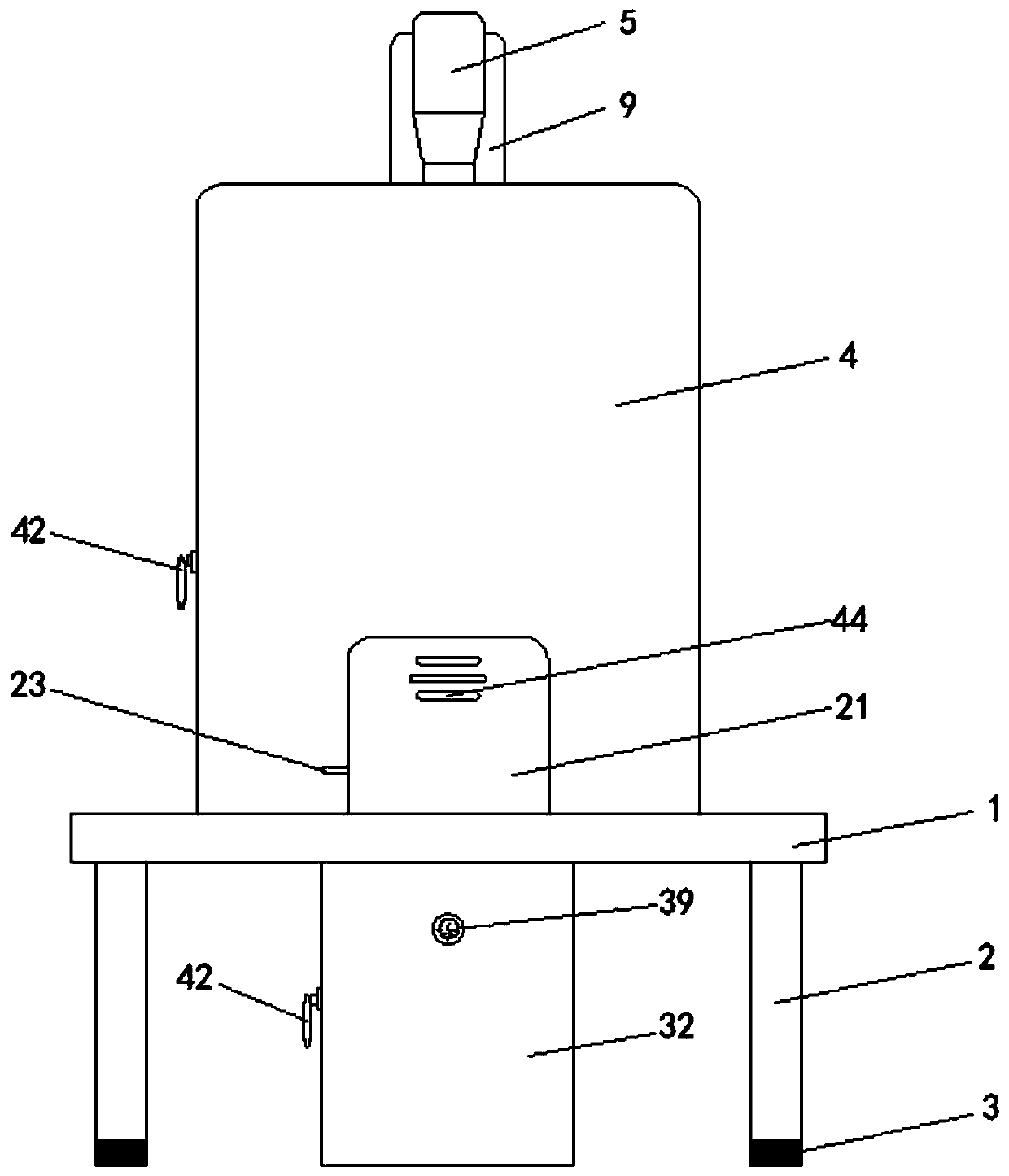

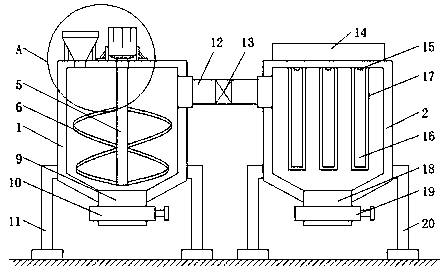

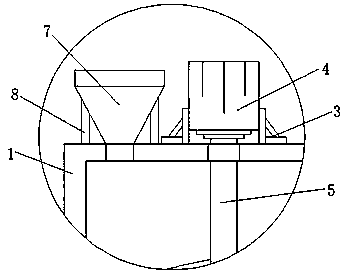

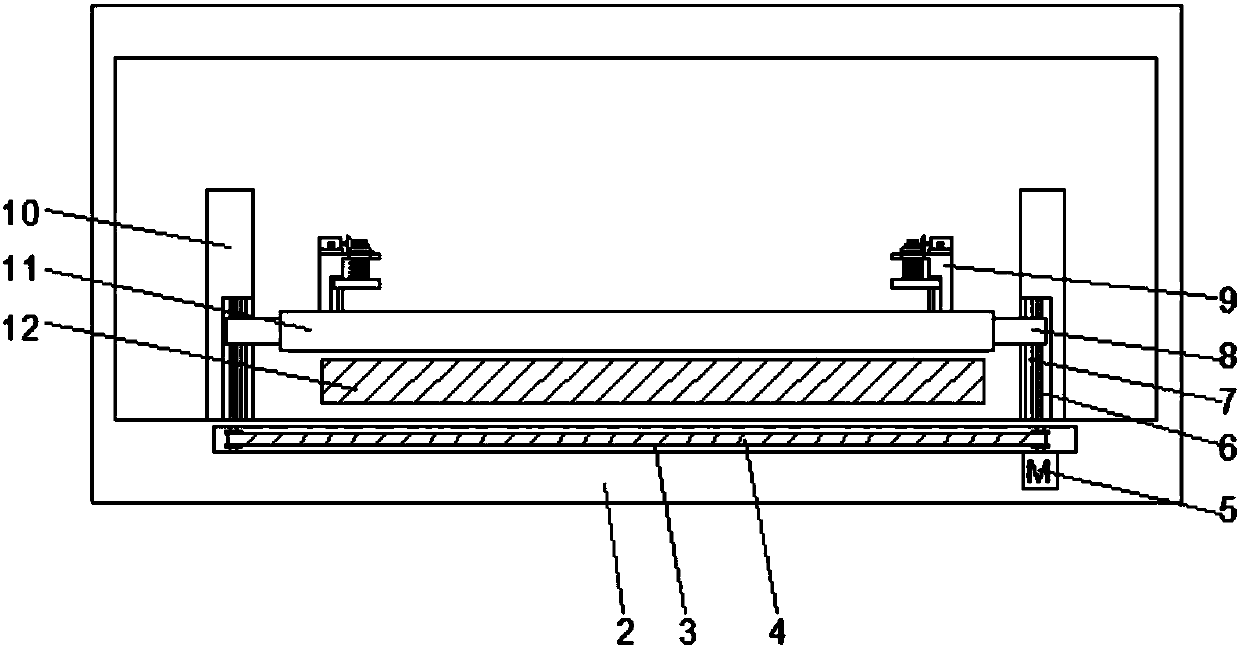

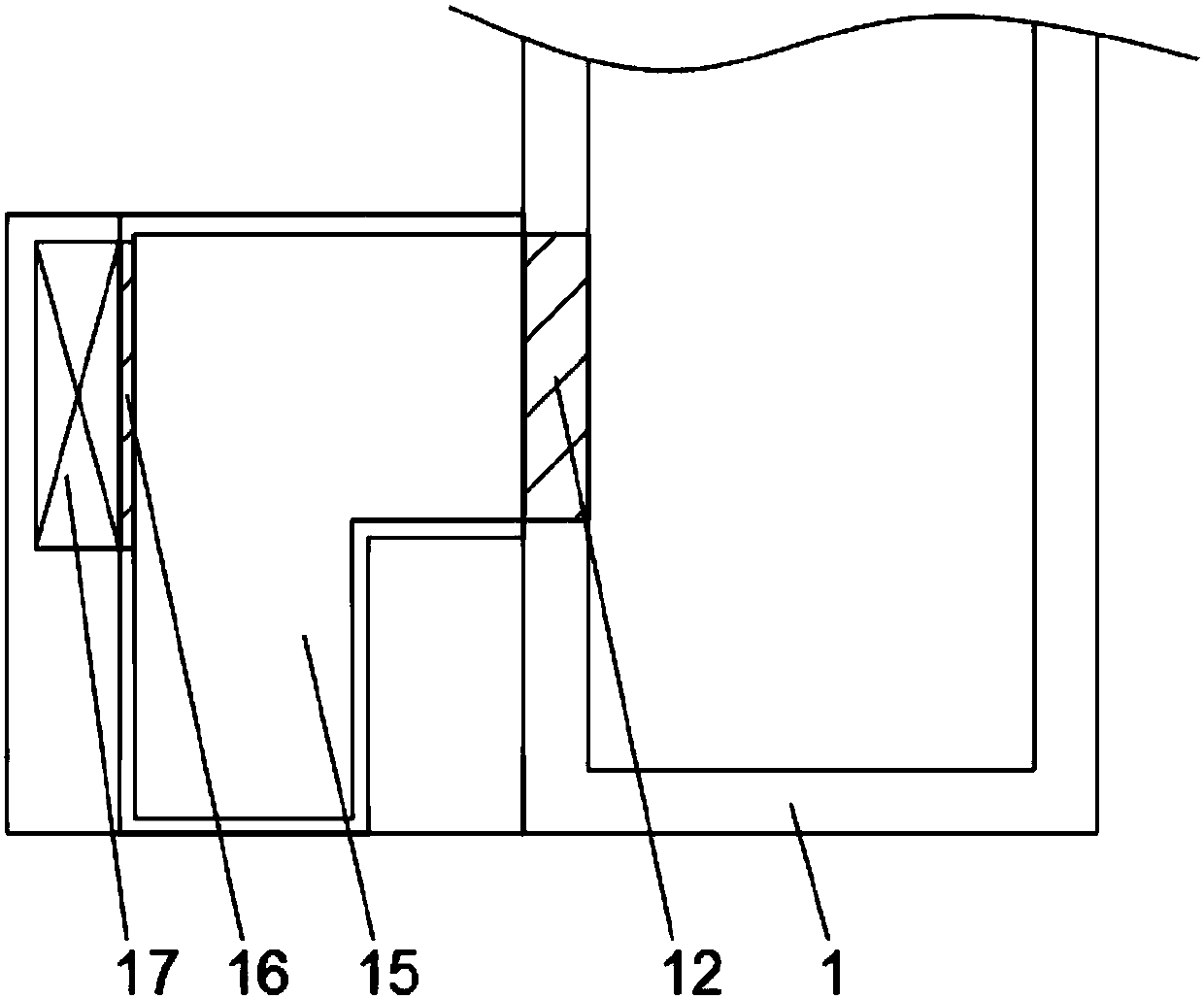

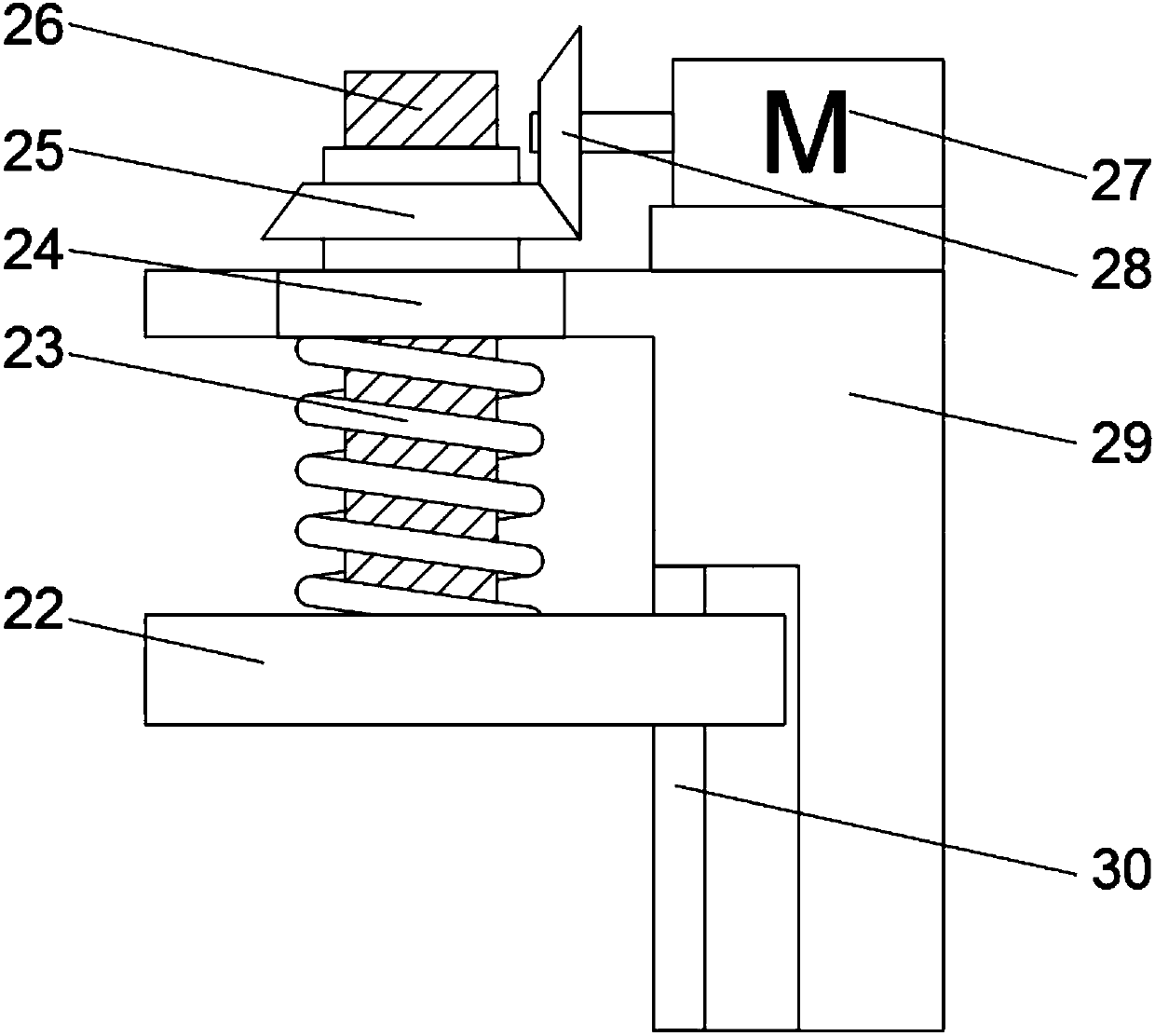

Environmentally-friendly textile machine with functions of shock absorption and cotton flock absorption

PendingCN107575718AAchieve absorptionAchieve separationNon-rotating vibration suppressionDirt cleaningWater diversionWater pipe

The invention discloses an environmentally-friendly textile machine with functions of shock absorption and cotton flock absorption. The environmentally-friendly textile machine with the functions of shock absorption and cotton flock absorption comprises a hydraulic expansion link, an exhaust fan, a booster pump, a shock absorption device, a baseplate and a base, wherein the hydraulic expansion link is used for adjusting the height of the baseplate and further realizes the adjustment of the height of a textile machine body, thereby meeting the using requirements of operators with different height; the exhaust fan is used for causing cotton flocks generated in the working process of the textile machine body to enter a pipeline through an absorption cover and further enter a cotton flock collecting tank, thereby avoiding the problem that the cotton flocks generated in the working process of the textile machine body float in the air to cause pollution and affect the physical health of bodies of operators in the workshops; the booster pump is used for causing water in a water storage tank to pass through a water diversion pipe and then be sprayed from an atomizing spray head so as to humidify the cotton flocks floating in the air in the workshops, thereby causing the cotton flocks floating in the air in the workshops to fall on the ground under the action of gravity.

Owner:长兴宝诺纺织科技有限公司

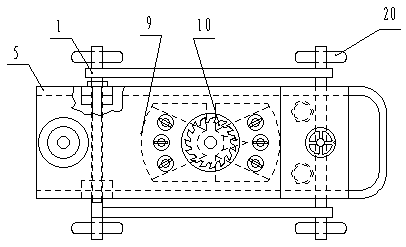

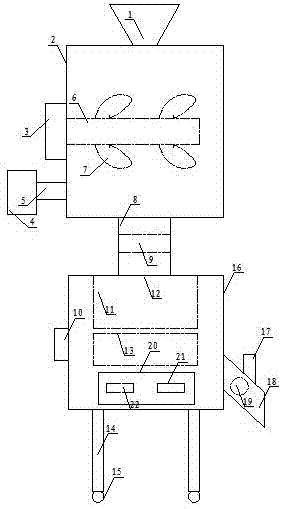

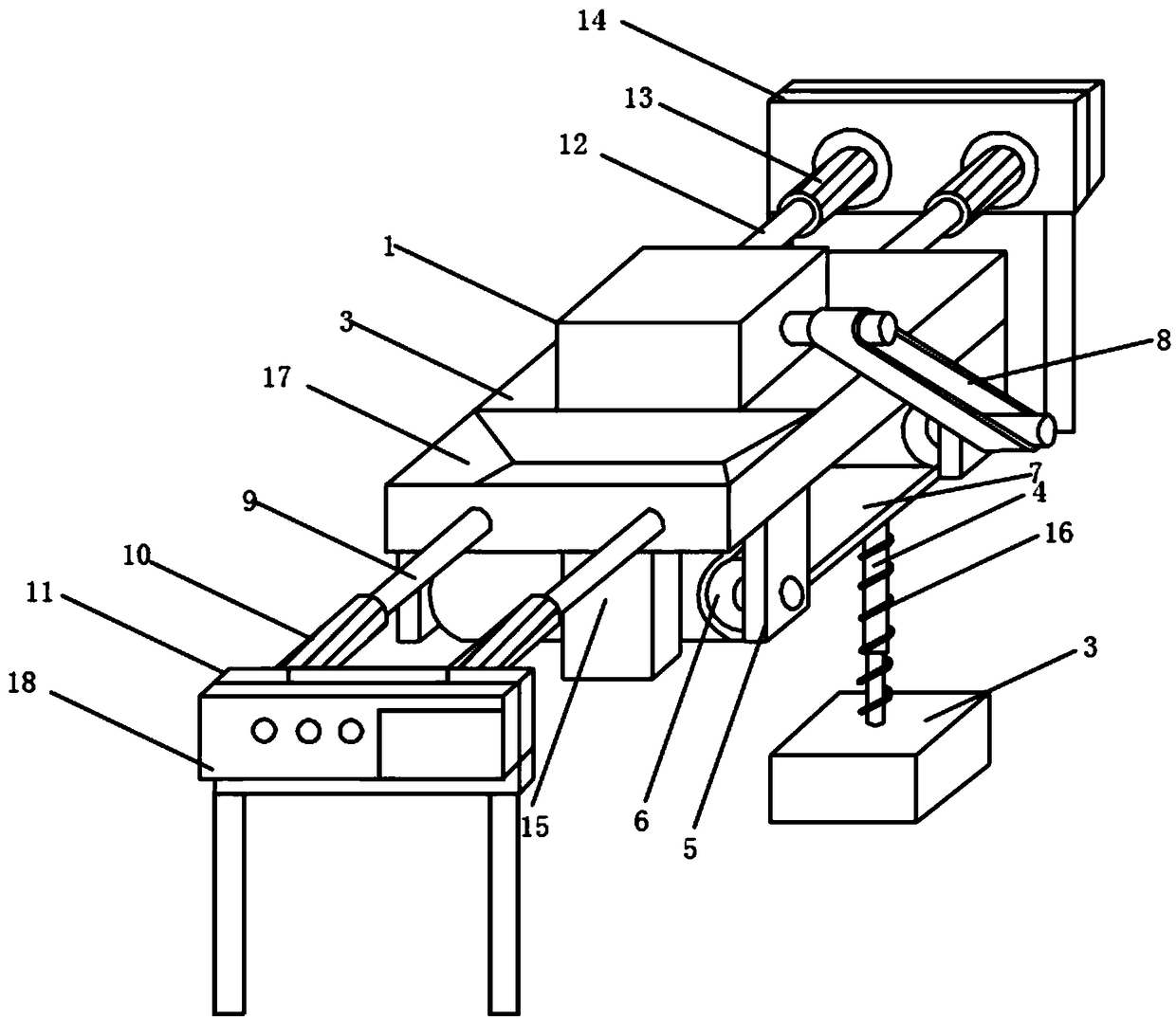

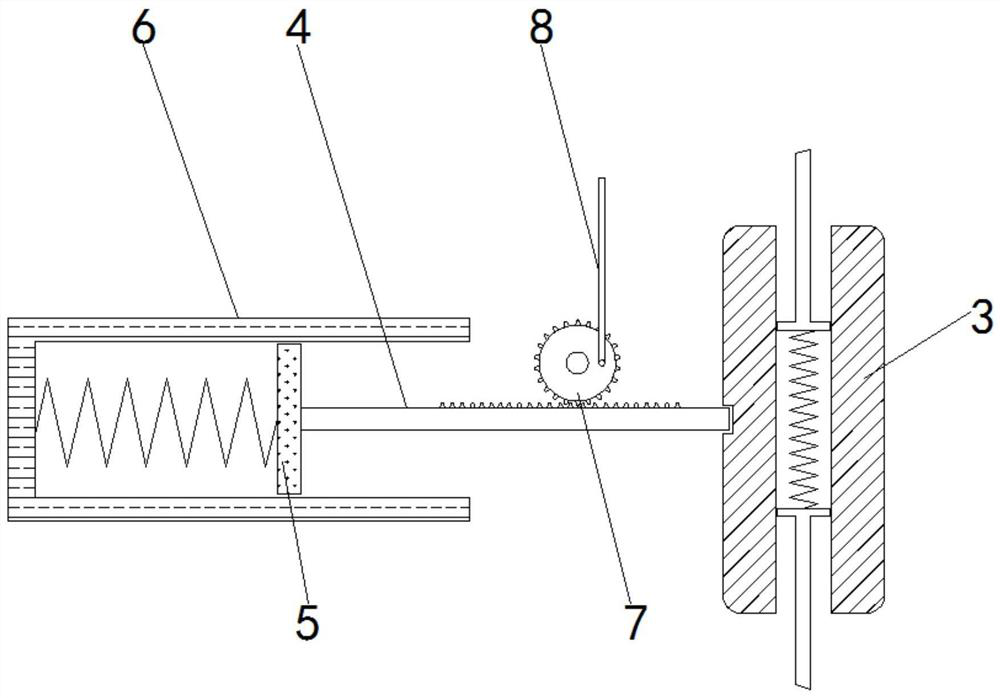

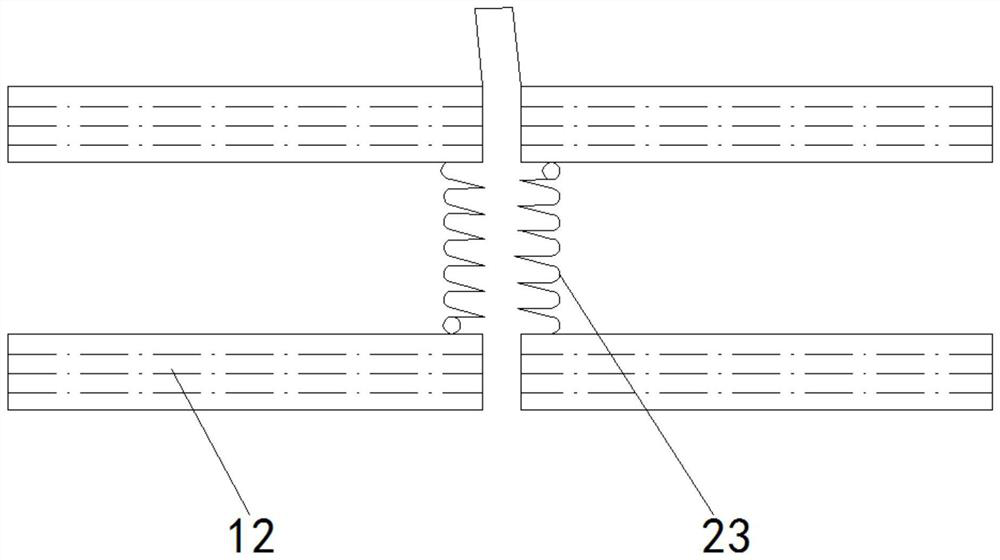

Concrete crushing and recycling device

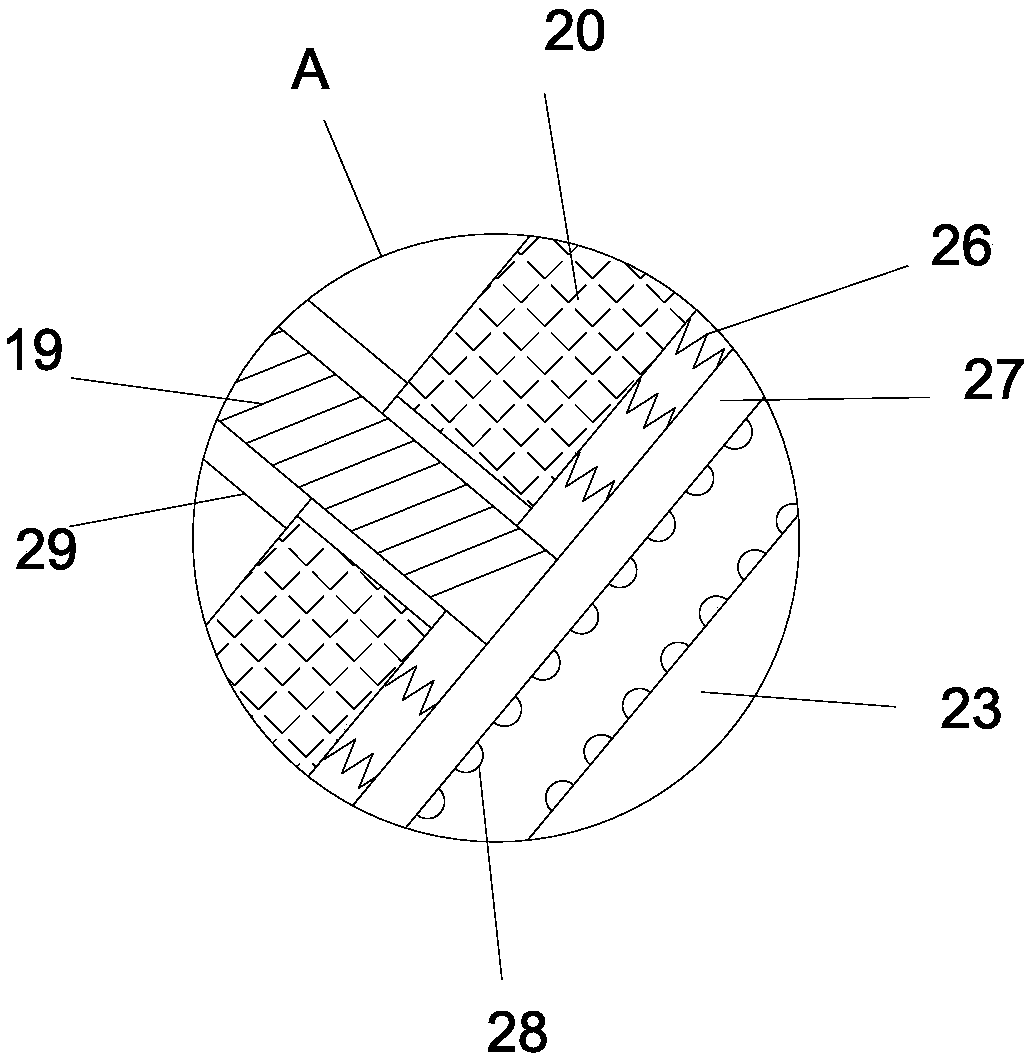

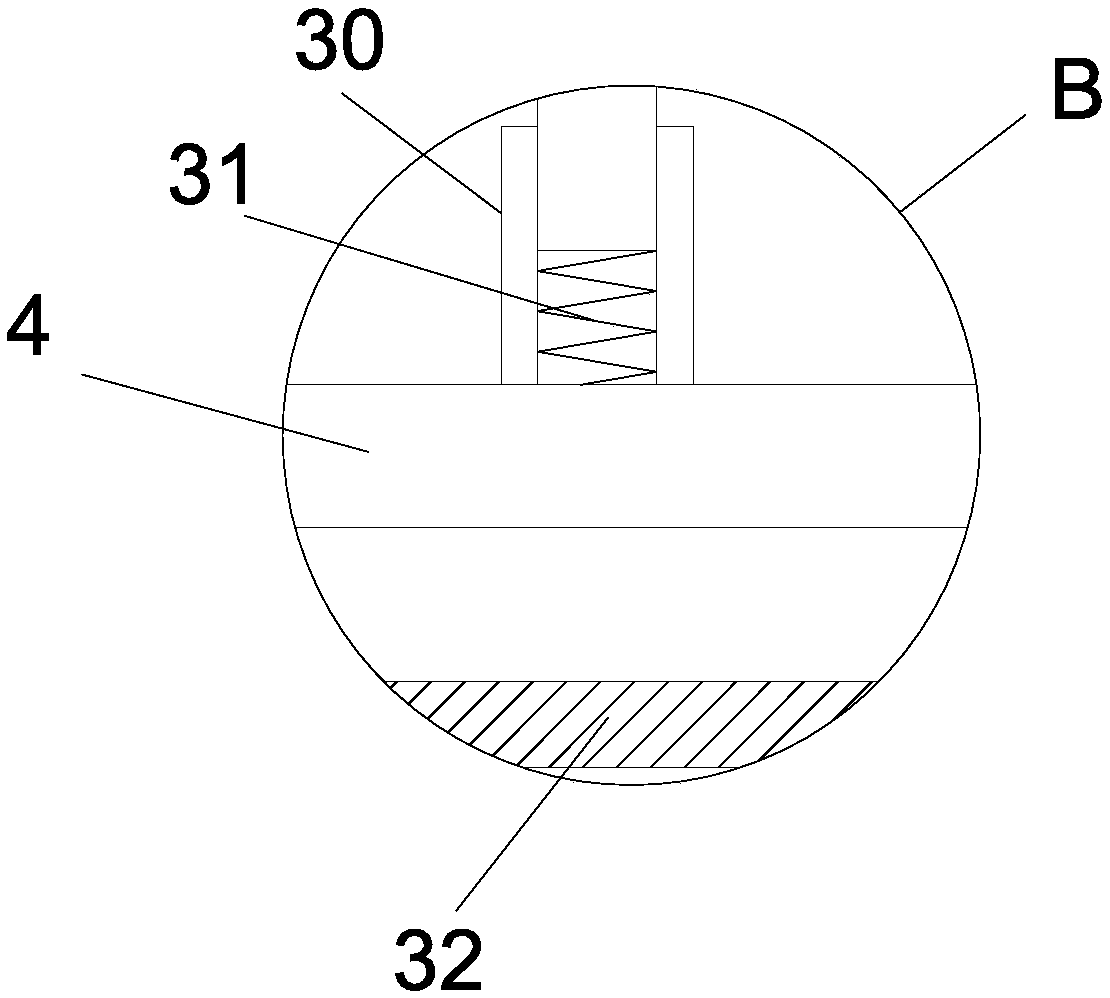

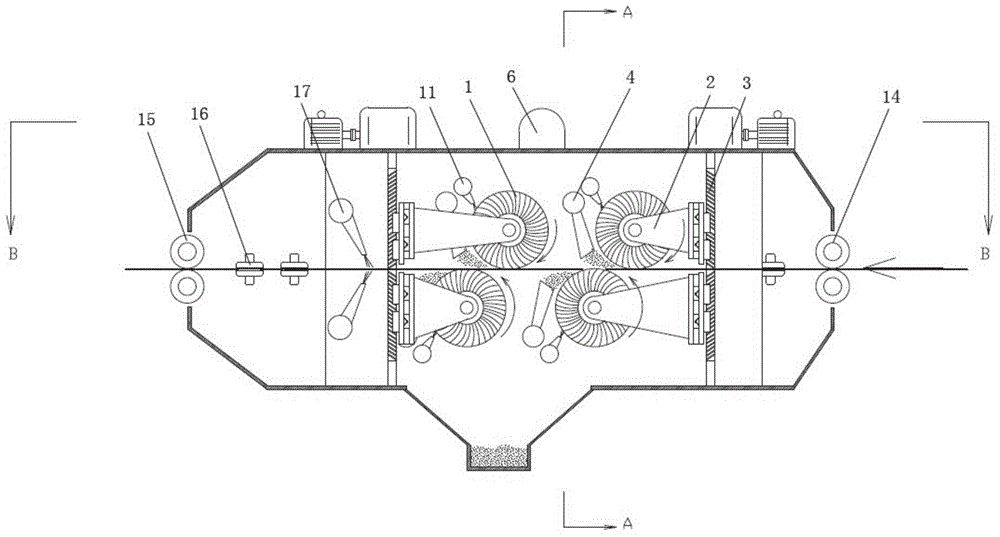

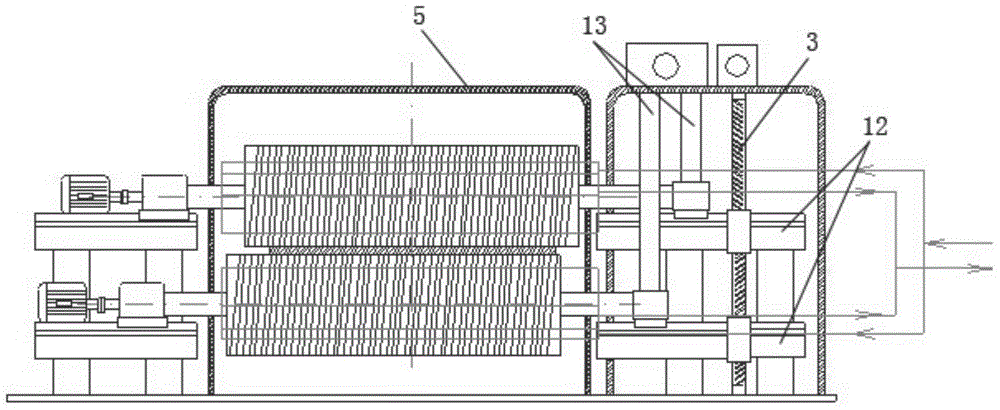

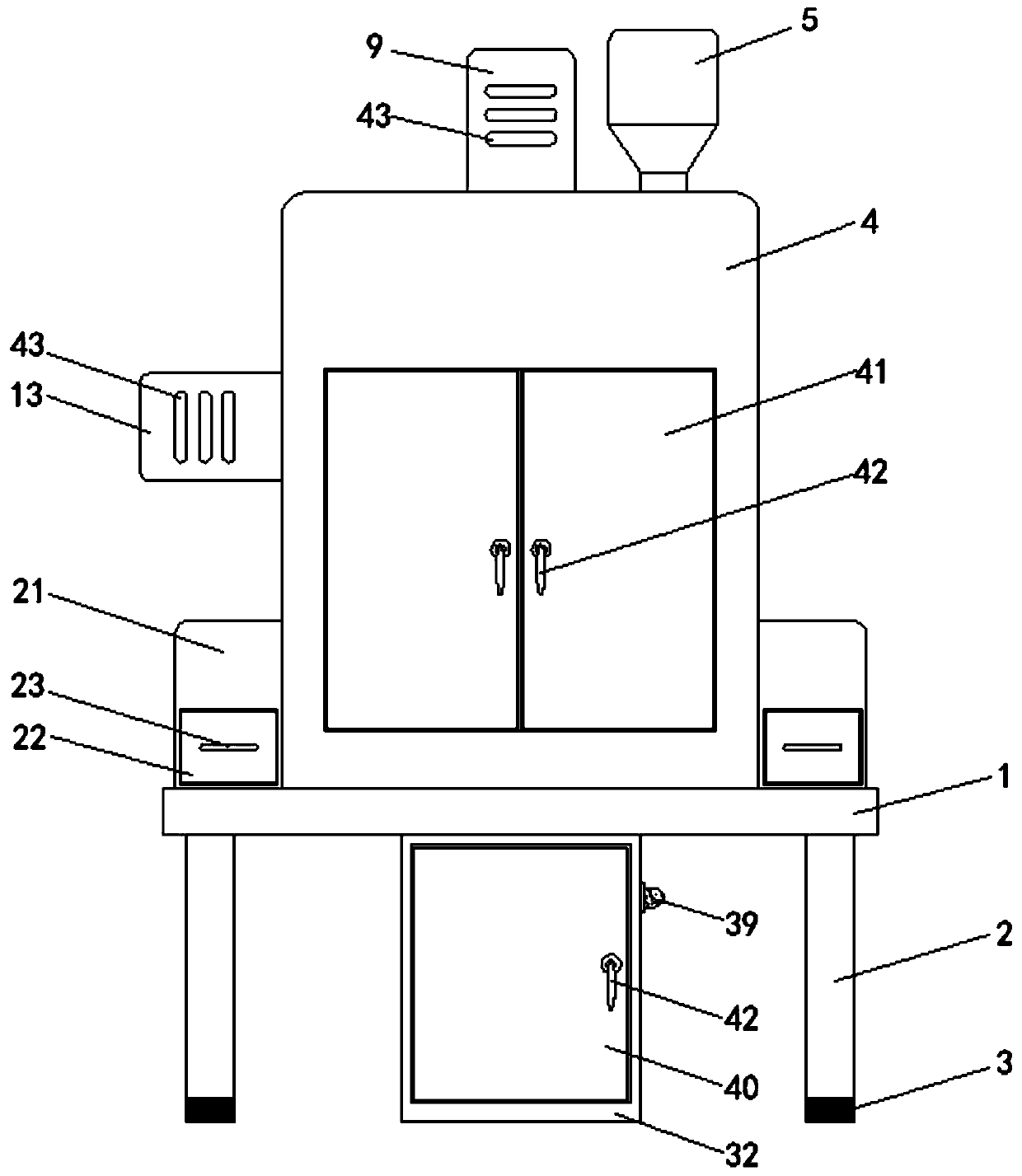

ActiveCN112495476APrevent looseningReal-time adjustmentSievingSolid waste managementEnvironmental engineeringCrusher

The invention discloses a concrete crushing and recycling device. The concrete crushing and recycling device comprises a crushing mechanism, a dust channel and a mud generating mechanism, wherein thedust channel is formed in one side of the crushing mechanism; and the mud generating mechanism is arranged on one side of the dust channel. According to the concrete crushing and recycling device, a crushing roller adjusting mechanism is additionally arranged, and the distance between crushing rollers can be adjusted in real time according to concrete of different sizes, so that the crushing effect is better, jamming is prevented, and the crushing efficiency is improved; and dust generated in the crushing process is collected and made to form mud under the action of an atomization spraying mechanism, and the mud is discharged under the combined action of a mud settling mechanism and a discharge box, so that the dust is effectively controlled, and the environmental pollution is prevented; and meanwhile, the dust can be reprocessed and reutilized, so that raw materials are saved, and waste is prevented.

Owner:GUI ZHOU CHANG TONG DIAN LI XIAN LU QI CAI YOU XIAN GONG SI

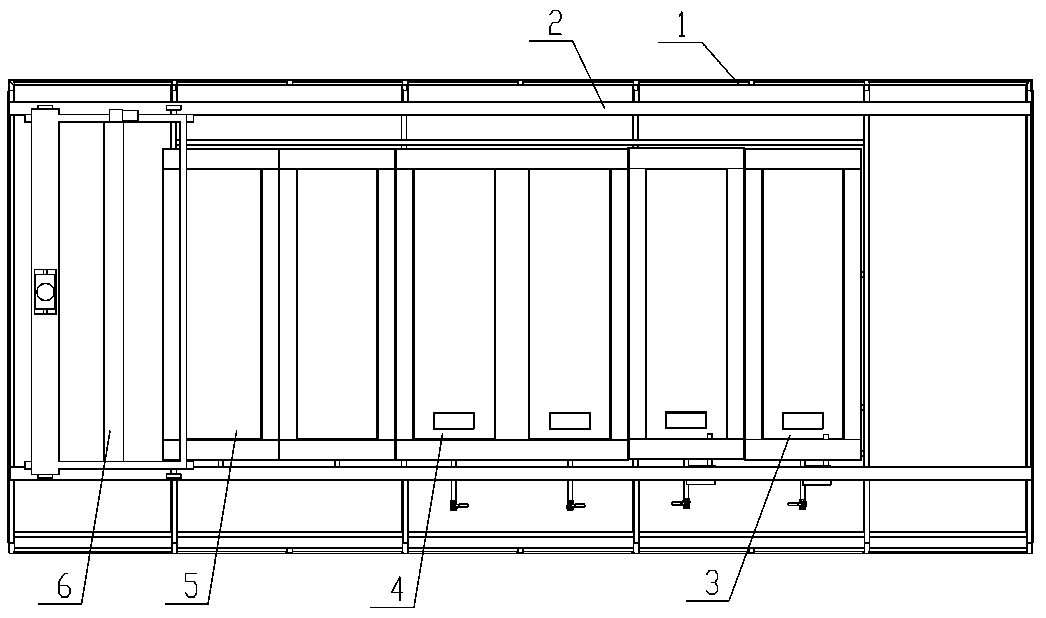

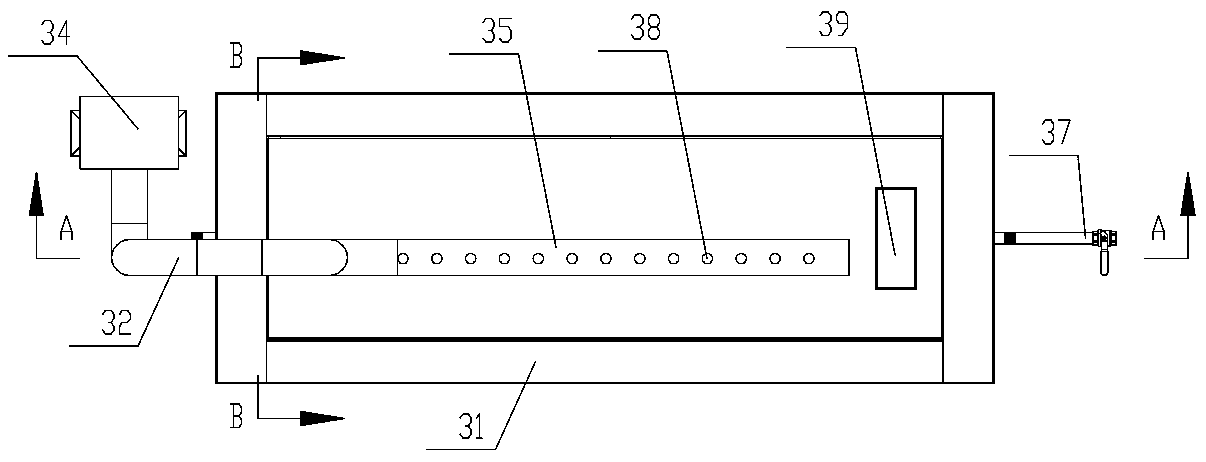

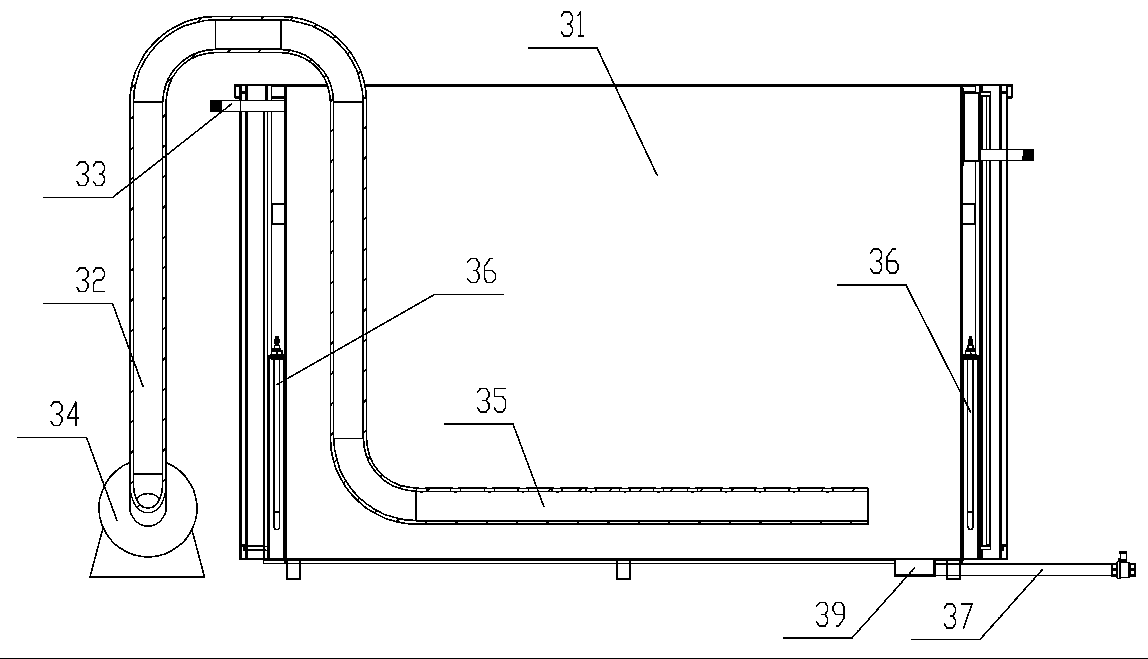

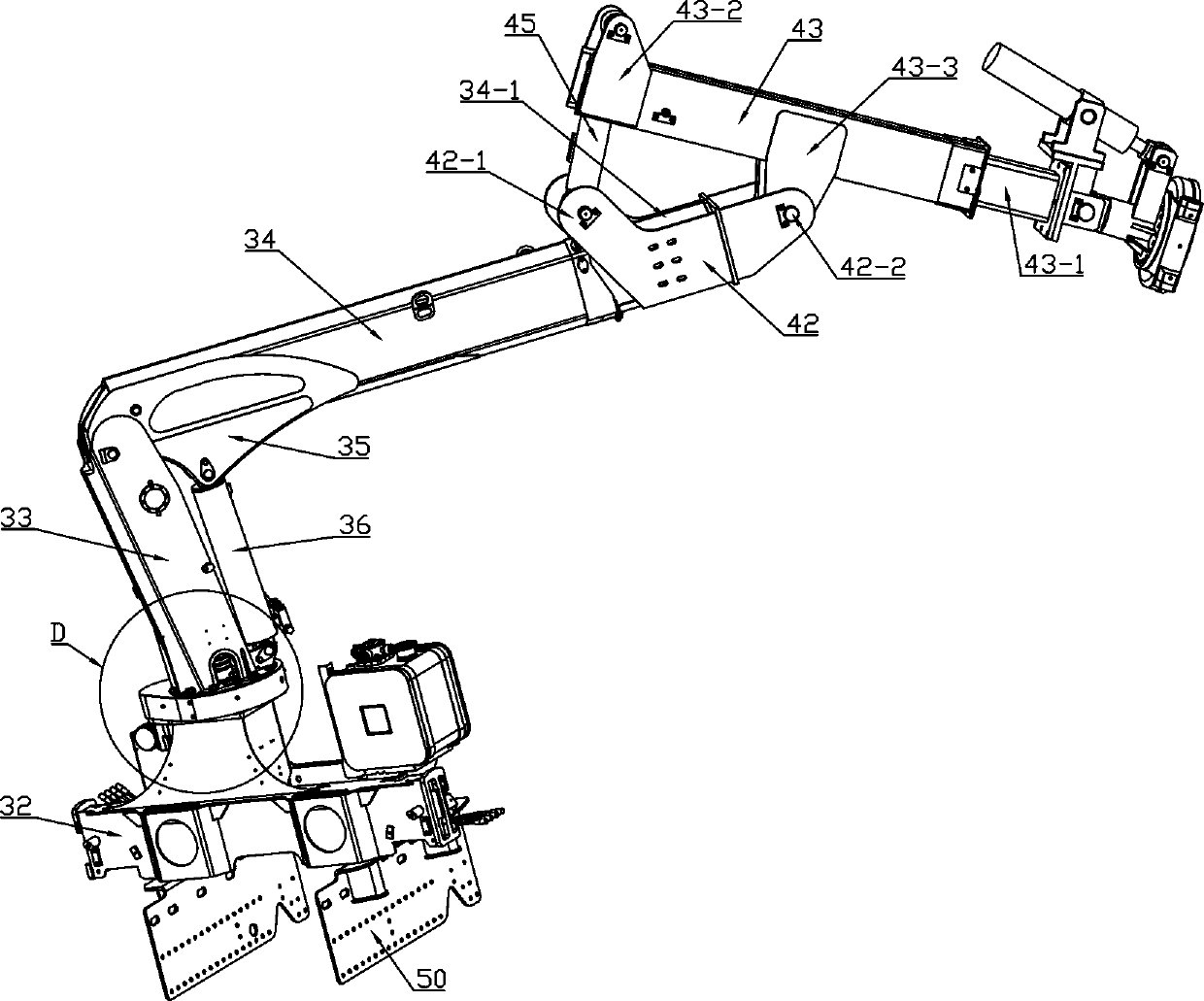

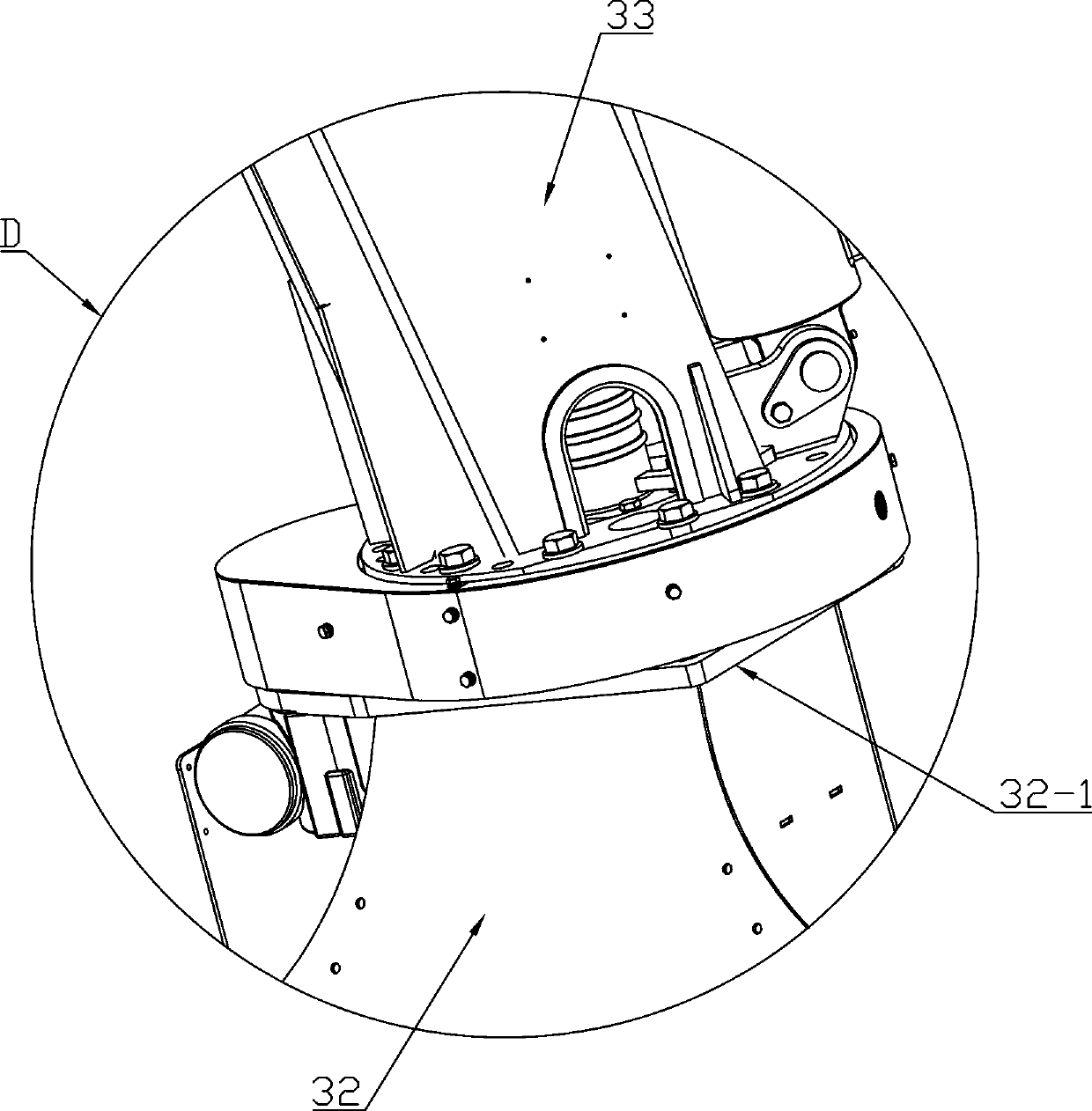

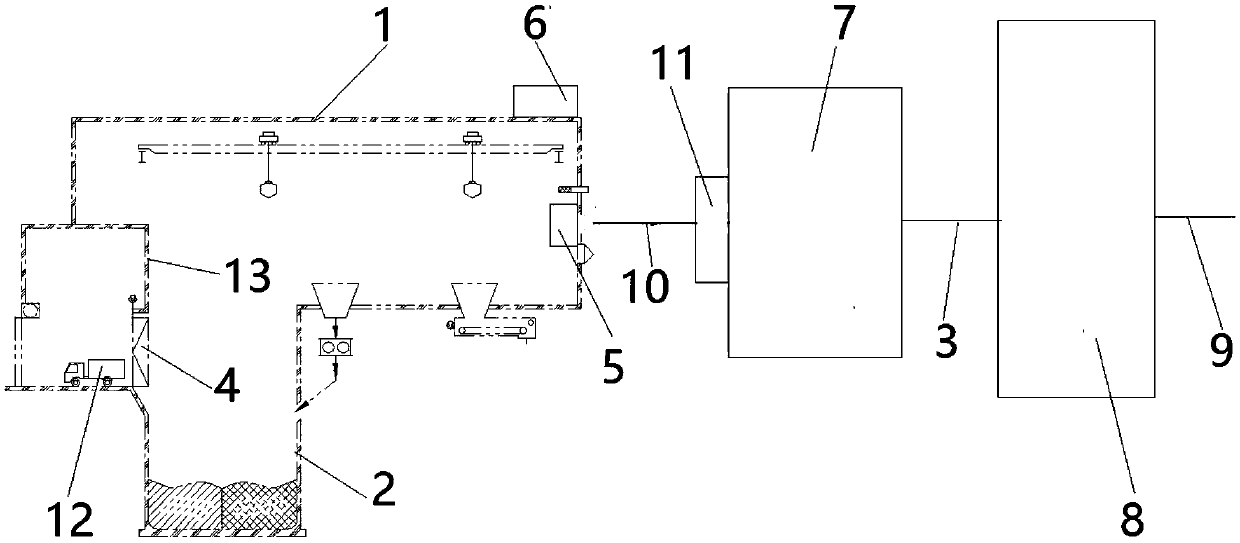

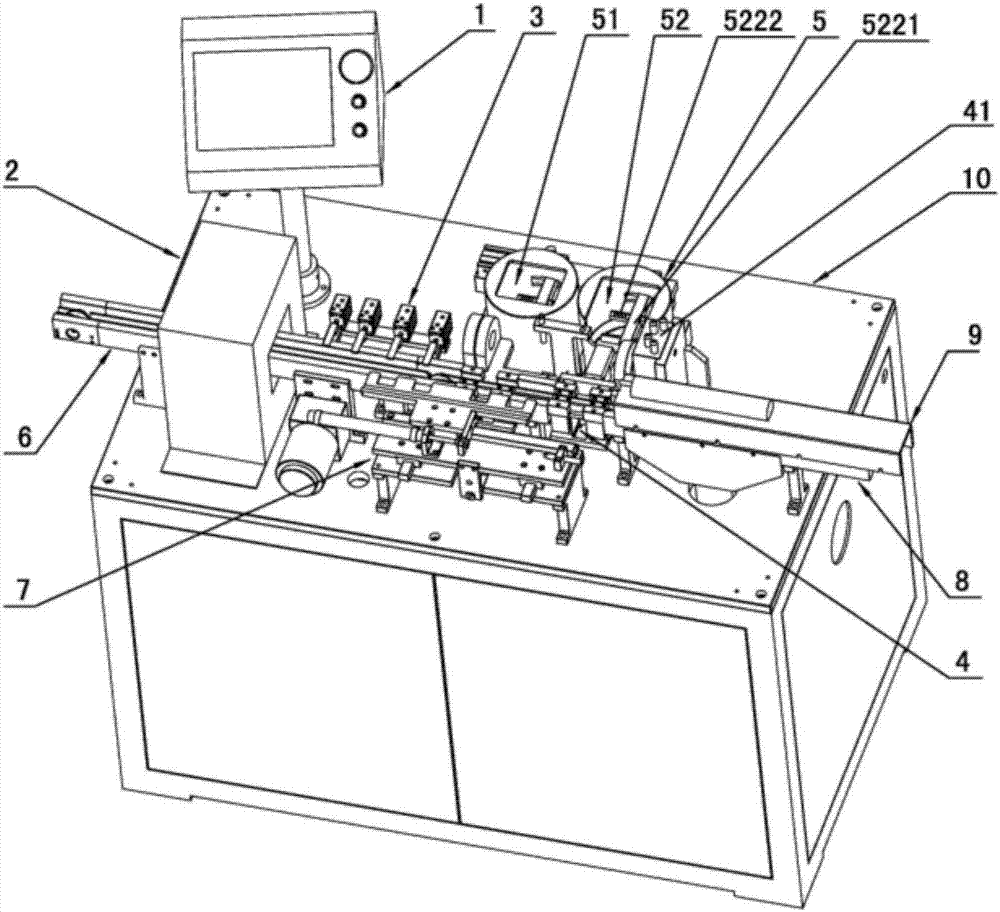

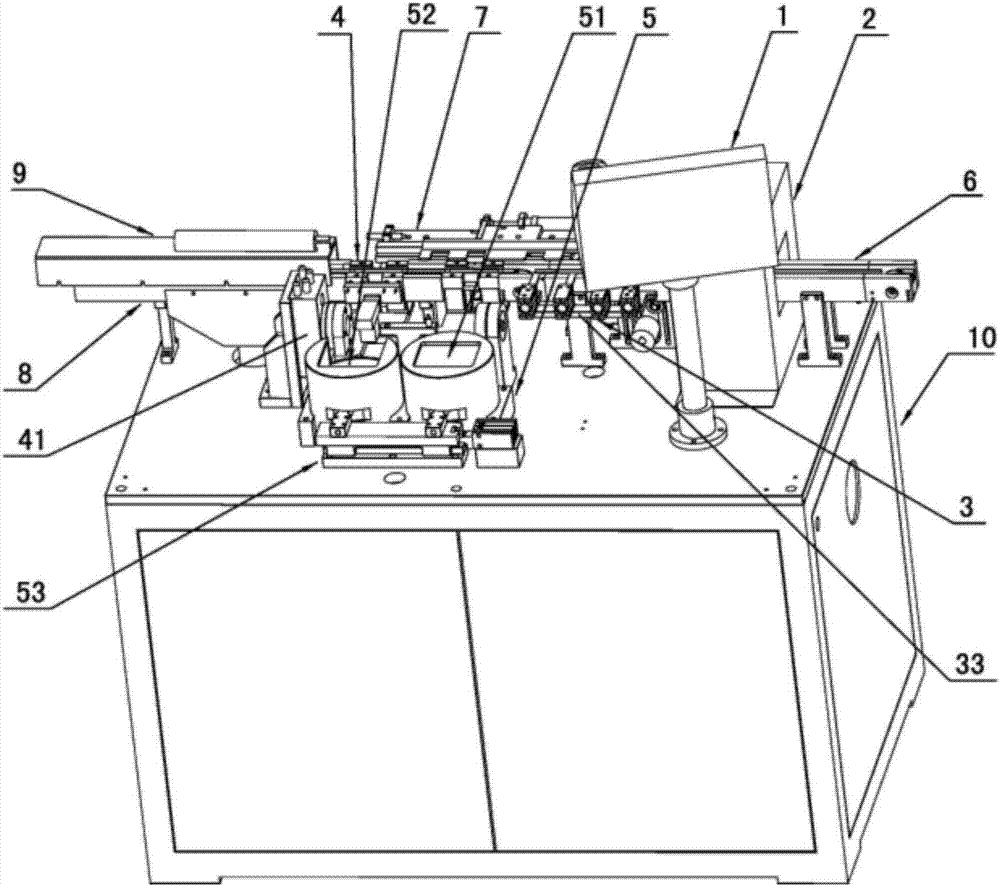

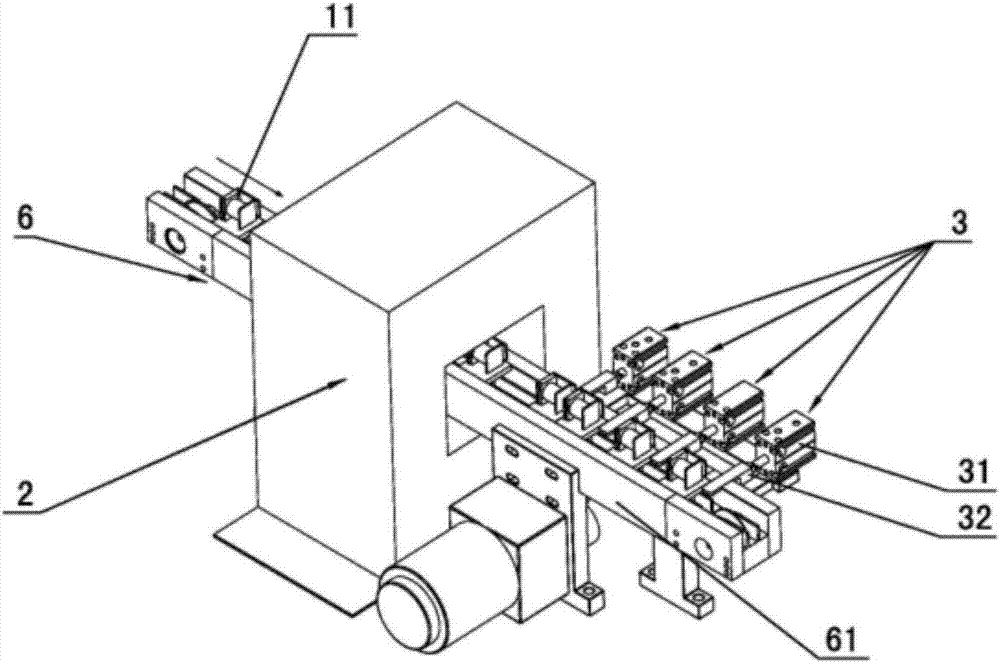

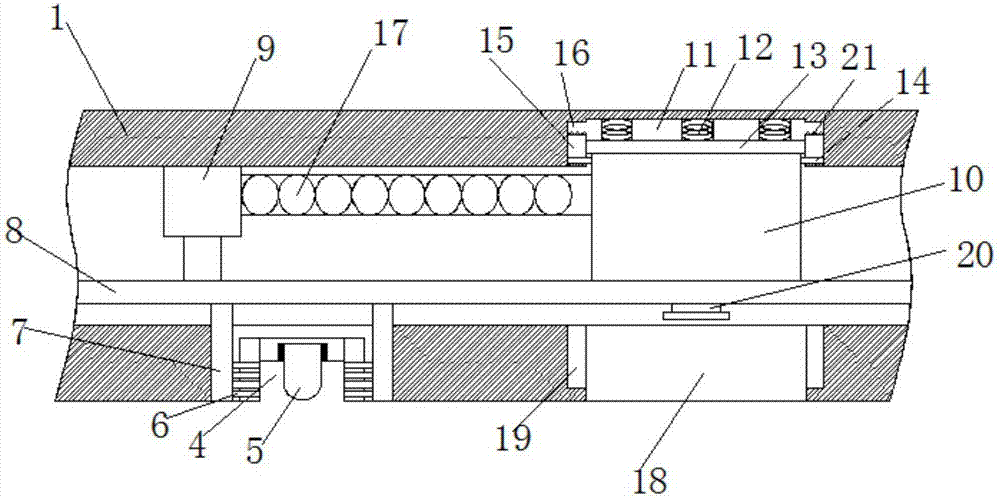

Cleaning system used for metal mask plate

PendingCN109382365AReduce volatilityEasy to fixDrying gas arrangementsDirt cleaningEngineeringMechanical engineering

The invention relates to the technical field of metal mask plates, in particular to a cleaning system used for a metal mask plate. The system includes a closed workshop, a row of cleaning tanks are placed on the floor in a workshop, and dewatering tanks are installed at the back ends of the cleaning tanks. The system is characterized in that two longitudinal beams are installed above the cleaningtanks in the workshop, two longitudinal beams are provided with mechanical arms, the cleaning system further includes a lifting appliance used for loading the metal mask plate, and the mechanical armscan lift or horizontally move the lifting appliance. The cleaning tanks include bubble cleaning tanks and alcohol cleaning tanks. The cleaning efficiency is higher, the cleaning effect is better, theoperation cost is lower, and the system is suitable for improvement of an existing metal mask plate cleaning machine.

Owner:湖北浚山光电有限公司

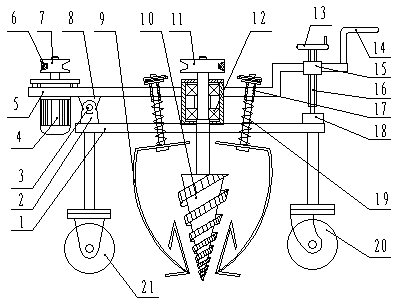

V-shaped grooving machine for pavement bending crack repairing construction

Owner:SHANDONG UNIV OF TECH

Position adjusting system for heliostat cleaning equipment

Owner:CSIC HEBEI CLEANING MACHINE

Waste gas treatment device for garbage storing workshop of cement kiln co-processing domestic garbage system and treatment method thereof

PendingCN107716505AGuaranteed not to leakRealize harmless treatmentDirt cleaningIncinerator apparatusCombustion systemThermodynamics

Owner:ANHUI CONCH DESIGN & RES INST OF BUILDING MATERIALS CO LTD

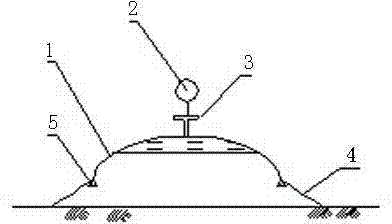

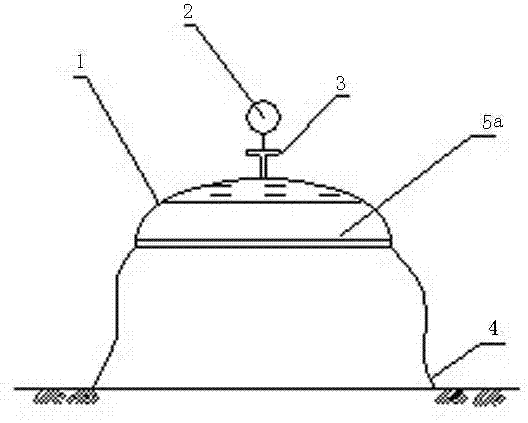

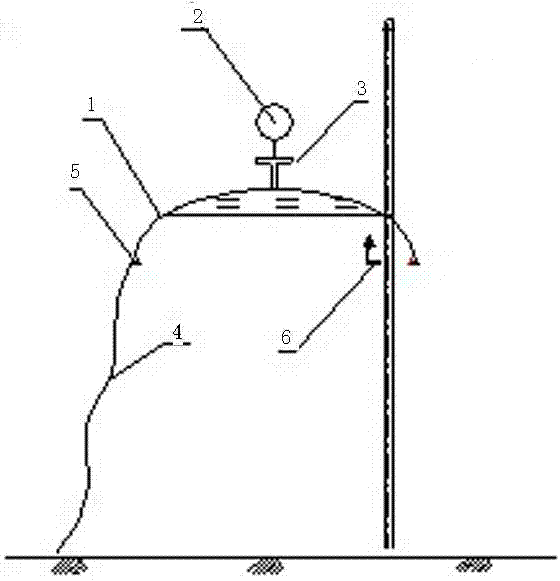

Underwater leaked oil flexible collection cover

Owner:CHINA PETROLEUM & CHEM CORP +1

Grinding equipment for extracting protein

Owner:复向诺唯信生物科技(苏州)有限公司

Novel house building ceiling structure

Owner:奕科建设集团有限公司

Smoke exhaust device and puncture outfit

PendingCN111658085ASimple structureEasy dischargeCombination devicesSurgical needlesEnvironmental engineeringSmoke Emission

Owner:镁格生物科技(江苏)有限公司

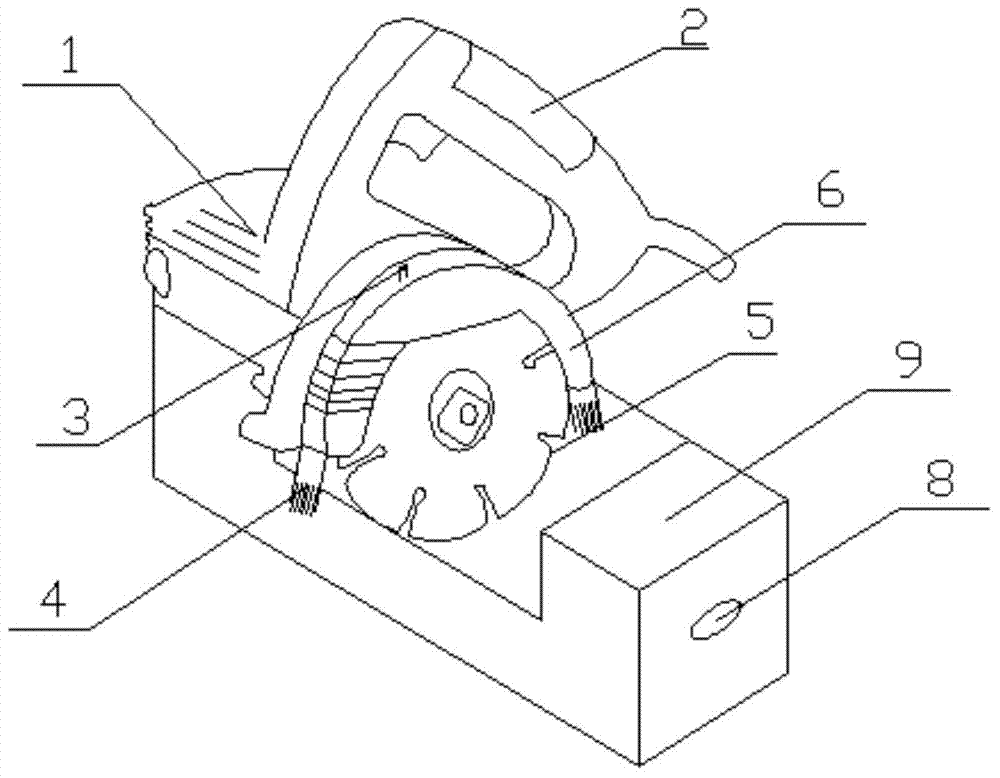

Steel bar cutting machine

Owner:王玉文

Novel flour grinding equipment

Owner:海晓娟

Silicone oven

Owner:江门市亿联硅塑制品有限公司

Acid-washing exhaust gas lead-out device for titanium metal tube

InactiveCN103215606AHarm the collection effectImprove collection effectDirt cleaningTitanium metalWorking environment

Owner:常熟市中钛科技有限公司

Batch-type tea vibration screening plant with dust removal function

InactiveCN108554783ARealize dynamic adsorptionFlexible and convenient adjustmentSievingScreeningTransmission beltReciprocating motion

Owner:永嘉县纳海川科技有限公司

Efficient plastic granulator for preventing air environment pollution

InactiveCN111546531AAvoid pollutionImprove cutting efficiencyDirt cleaningGrain treatmentsRotational axisElectric machine

Owner:张大柱

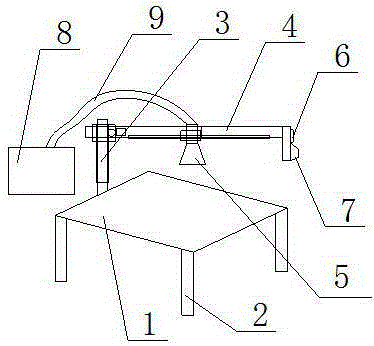

Lathe dedusting device

The invention discloses a lathe dedusting device which comprises a lathe and a dedusting device body. Support legs are arranged under the lathe which is fixed to the support legs. The dedusting device body comprises a support and a dust collector. The support comprises a stand column fixed to one side of the lathe and a support cross beam arranged on the stand column. A dust suction nozzle of the dust collector is arranged on the cross beam. A controller and a handle are arranged at the end, away from the stand column, of the cross beam. The dust collector is controlled by the controller. The lathe dedusting device has the advantages of being simple in structure, easy and convenient to use and good in dedusting effect.

Owner:湖南衡泰机械科技有限公司

Computer intelligent host for software development

InactiveCN112114641ASolve the cooling problemAvoid heat accumulationDigital data processing detailsDirt cleaningEngineeringSoftware development

Owner:广州单凌舫科技有限公司

Environment-friendly wheat seed pre-stirring and dedusting device

InactiveCN110121979AAvoid pollutionAchieve dust removal effectDirt cleaningSeed coating/dressingCouplingEngineering

Owner:田桂华

Non-contact dust removal equipment, system and method

ActiveCN114082712AAvoid secondary pollutionSimple structureDispersed particle filtrationTransportation and packagingProcess equipmentElectrical battery

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

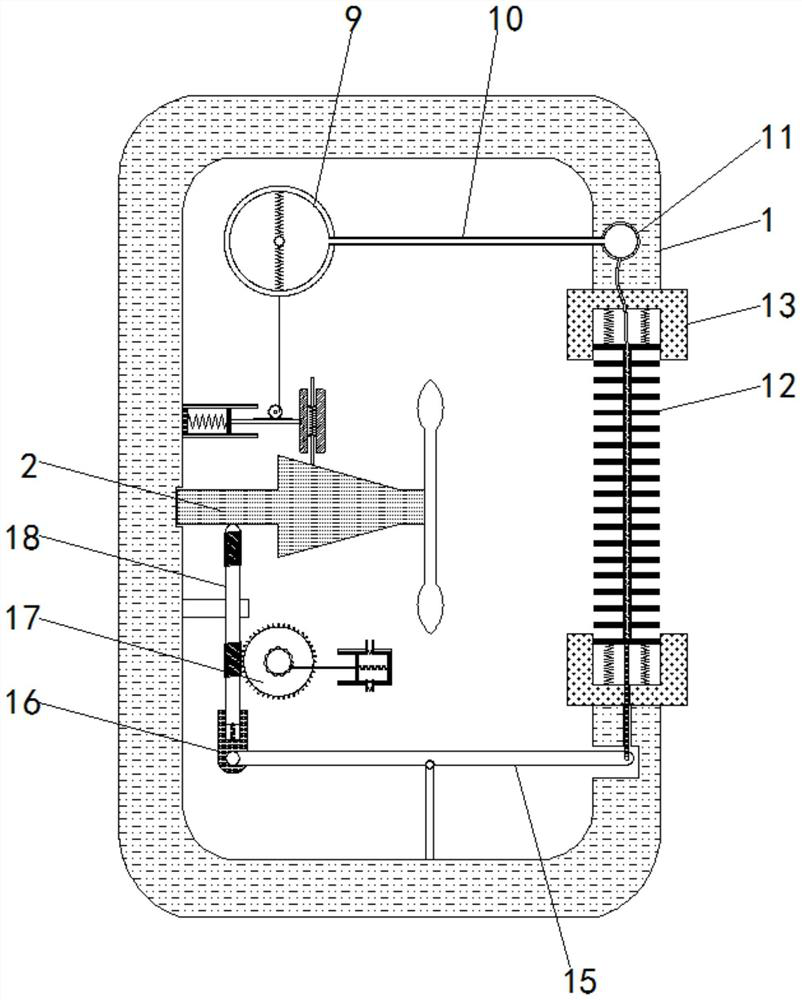

Exhaust gas discharge device for hydraulic press for interior part of high-speed multiple unit train

InactiveCN109228495AAvoid pollutionEasy to switchDirt cleaningPressesHydraulic cylinderControl engineering

The invention belongs to the technical field of high-speed multiple unit train interior-part hydraulic presses, and discloses an exhaust gas discharge device for a hydraulic press for an interior partof a high-speed multiple unit train. The device includes an exhaust hood and four baffles, the exhaust hood is installed at the upper end of a hot press body through a bracket, the hot press body includes a lower cross beam and an upper cross beam, the lower cross beam and the upper cross beam are fixedly connected through four sets of symmetrically arranged stand columns, a hydraulic cylinder isarranged on the upper cross beam, one end of a piston rod of the hydraulic cylinder is fixedly connected with the symcenter of the upper end of an upper die body, an operation platform is arranged onthe upper portion of the lower cross beam, the four baffles are symmetrically arranged on the outer sides of the hot press body, the upper ends of the baffles are hinged to one side of the upper cross beam, the lower ends of the baffles are provided with operation doors, and the upper end of the exhaust hood is symmetrically provided with two first air pipes.

Owner:HEFEI HAIDE HYDRAULIC PRESS

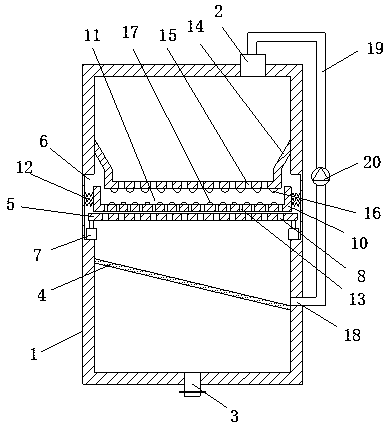

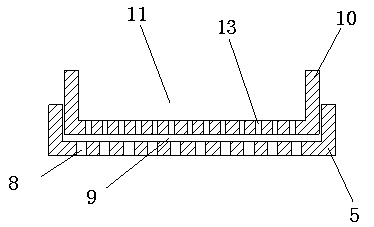

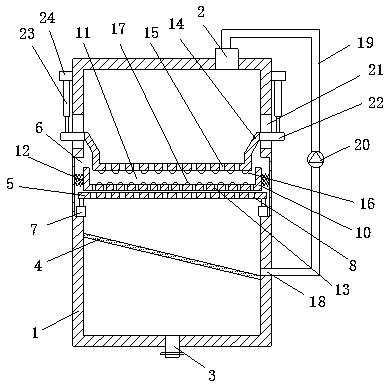

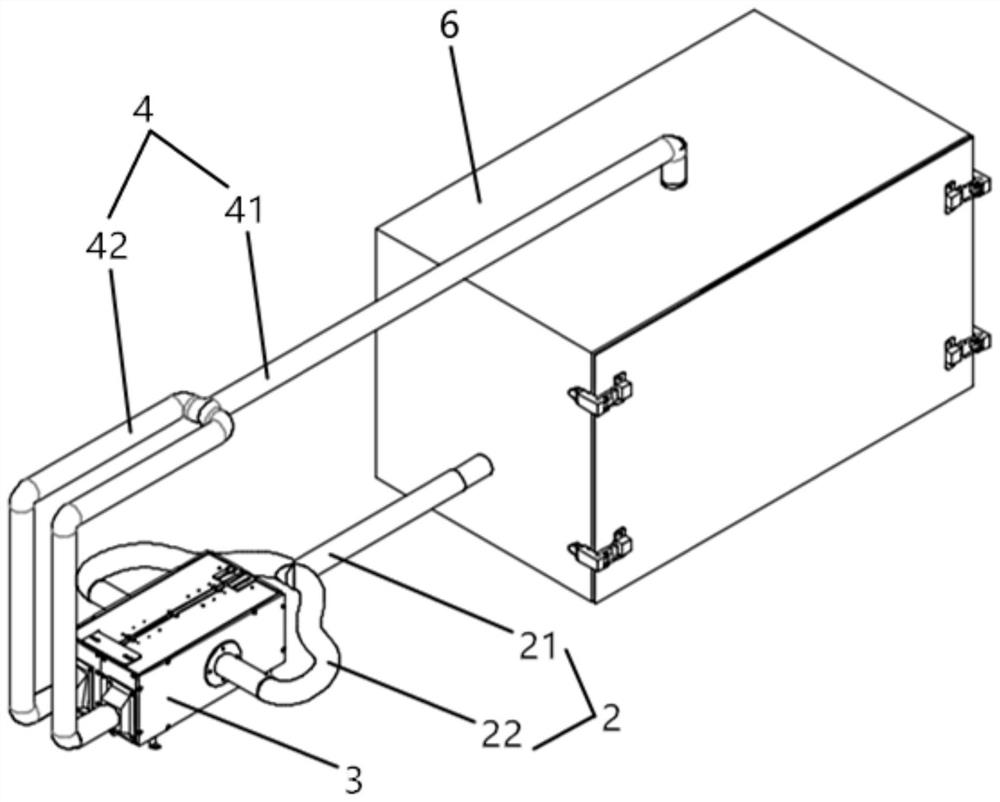

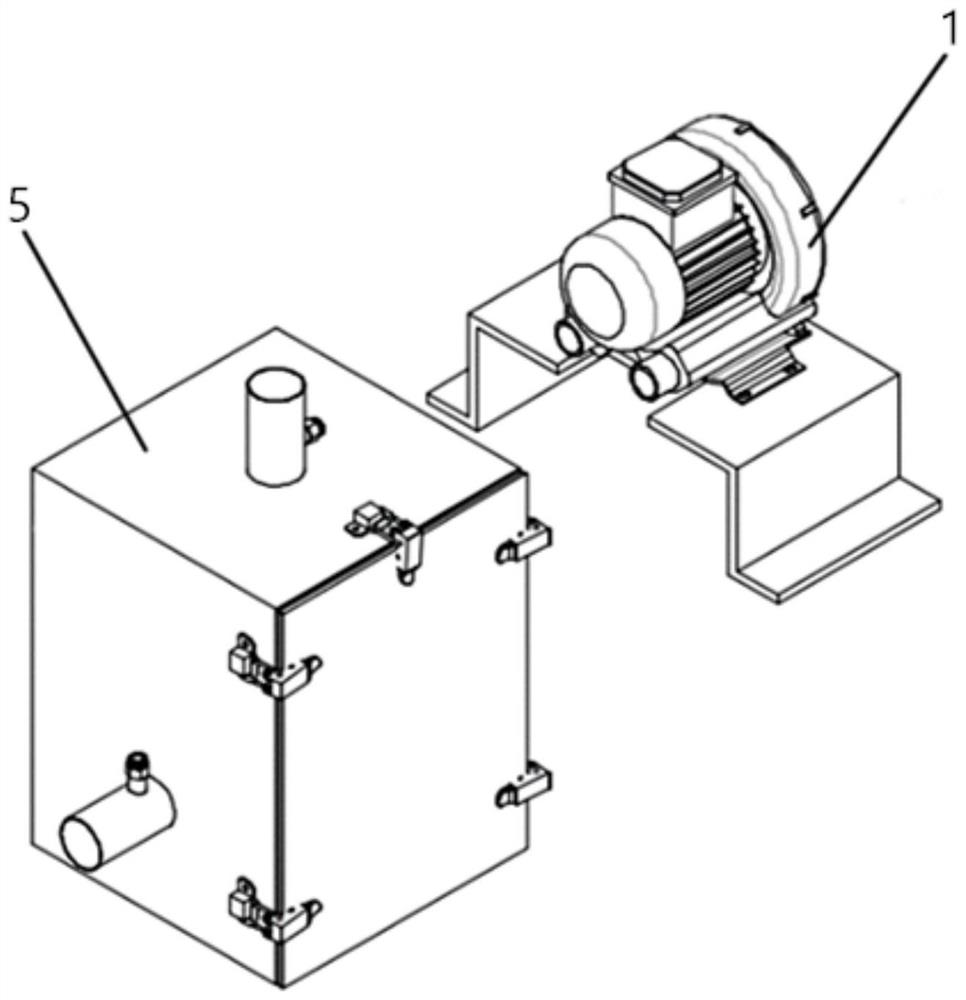

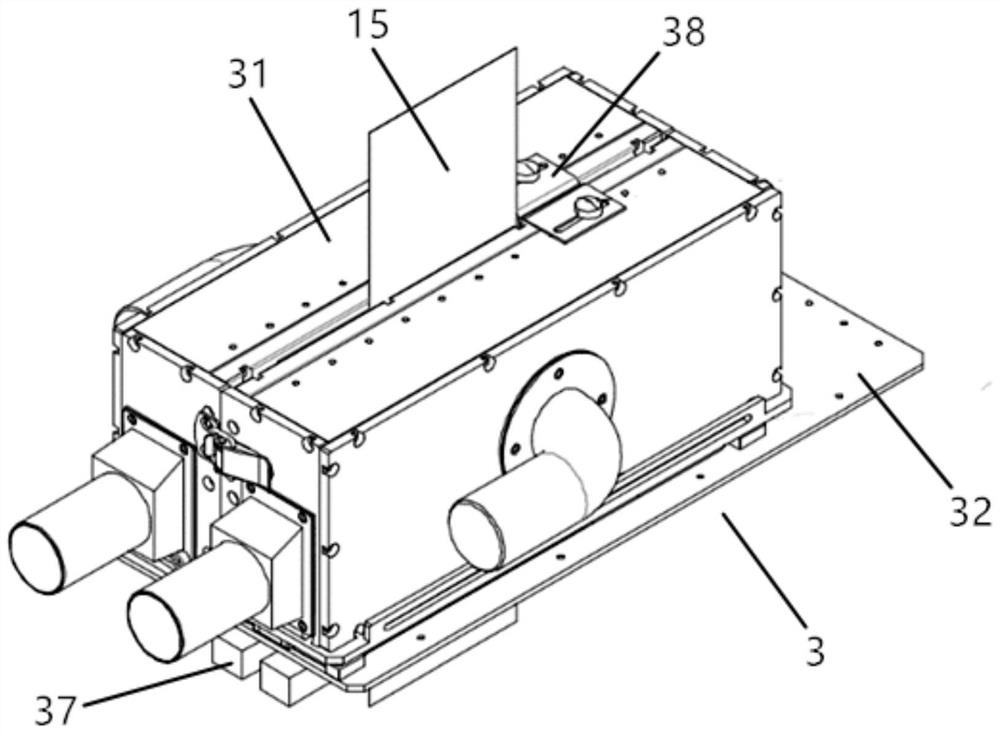

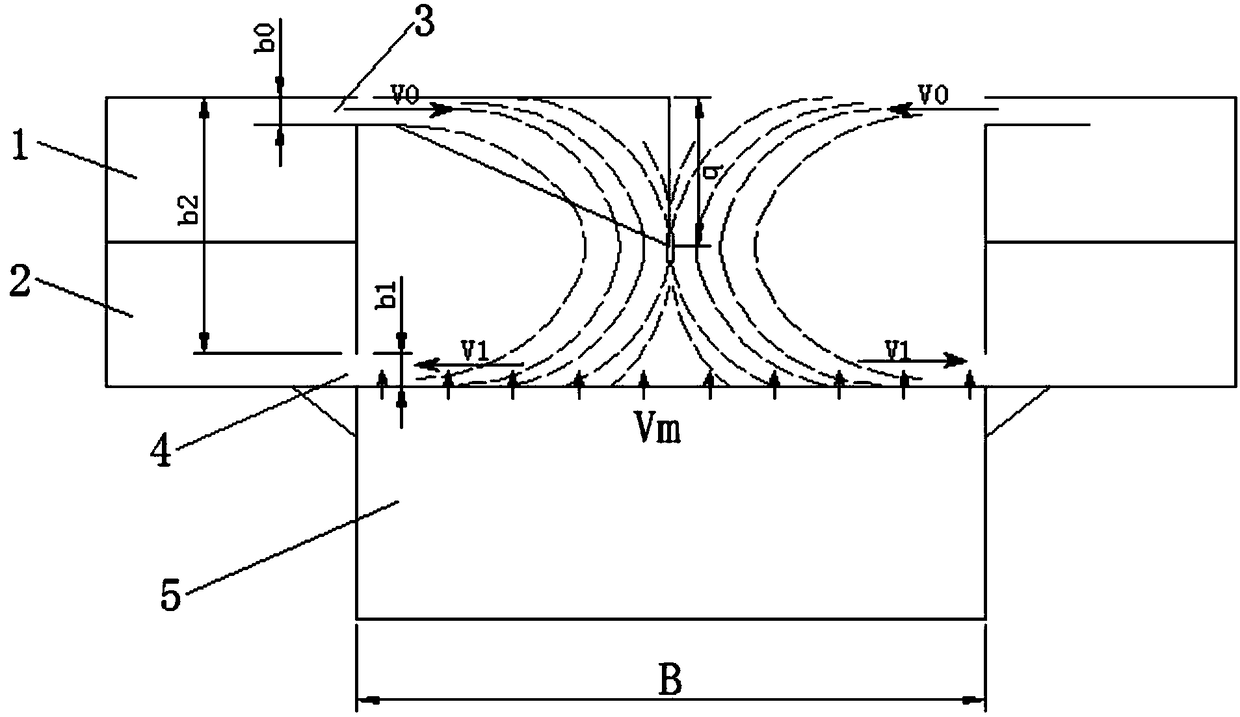

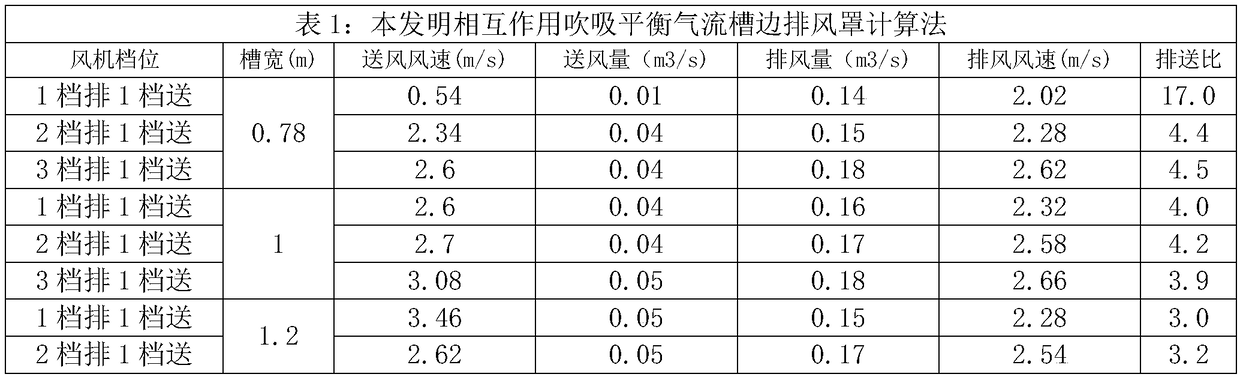

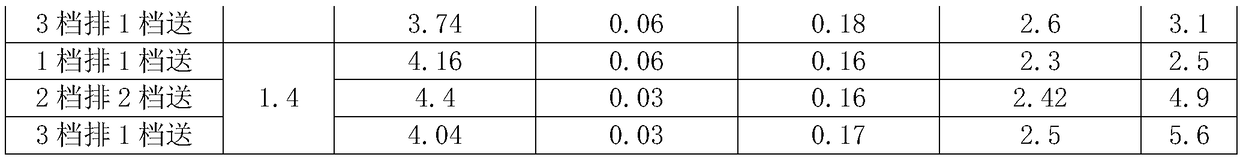

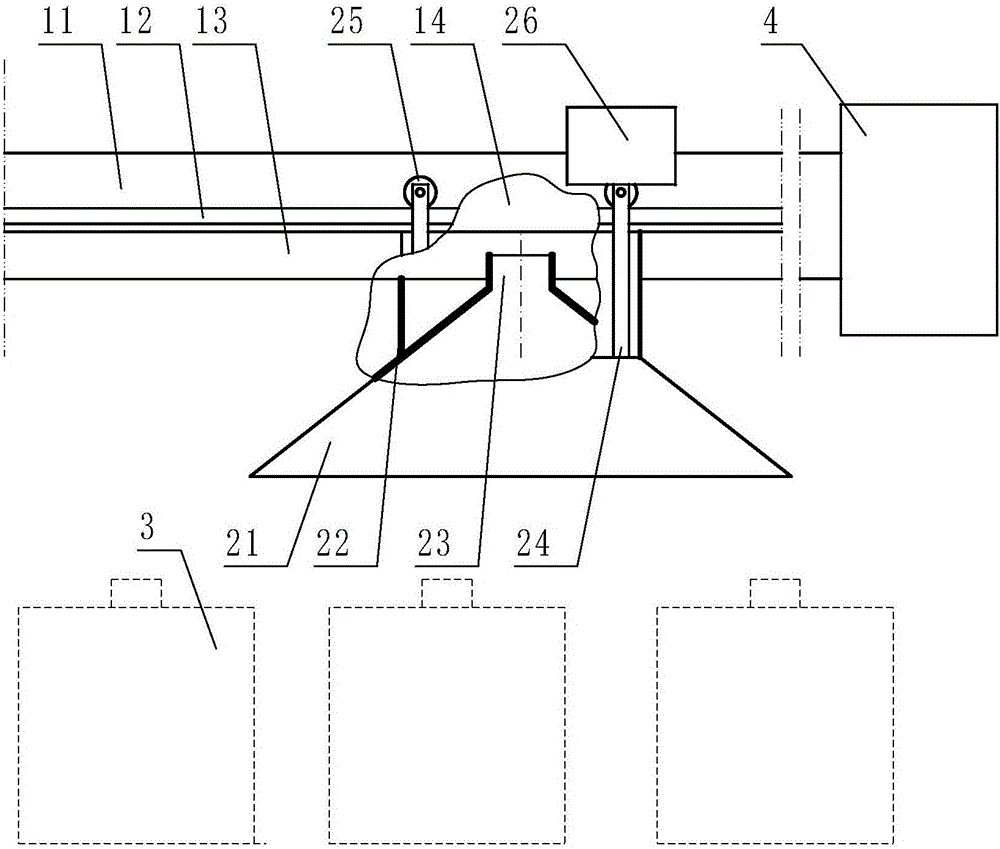

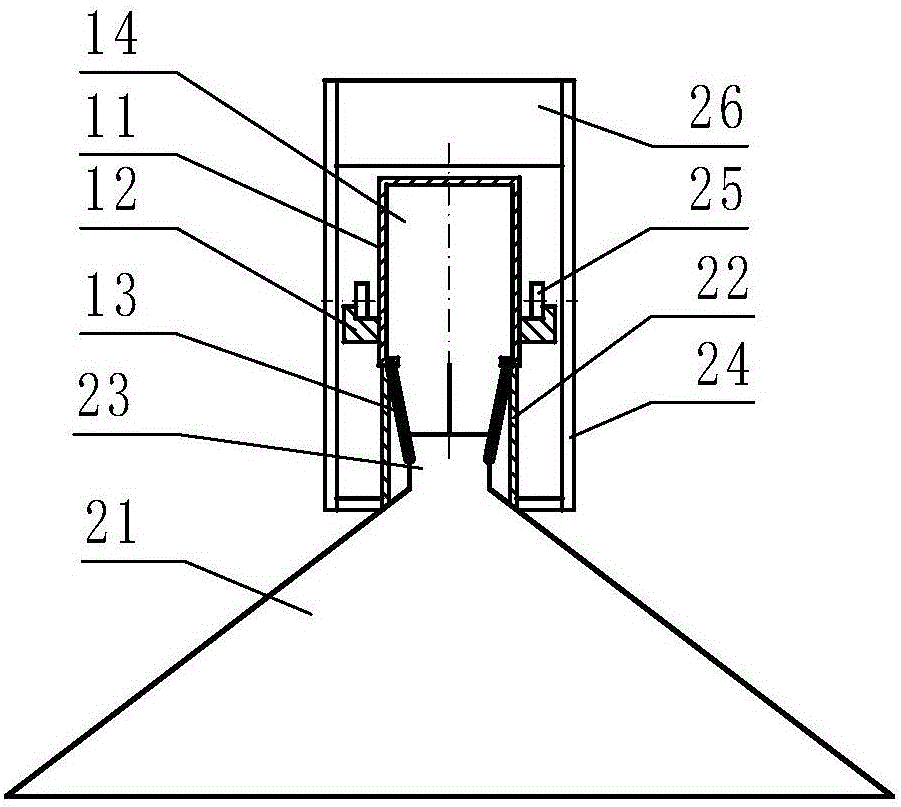

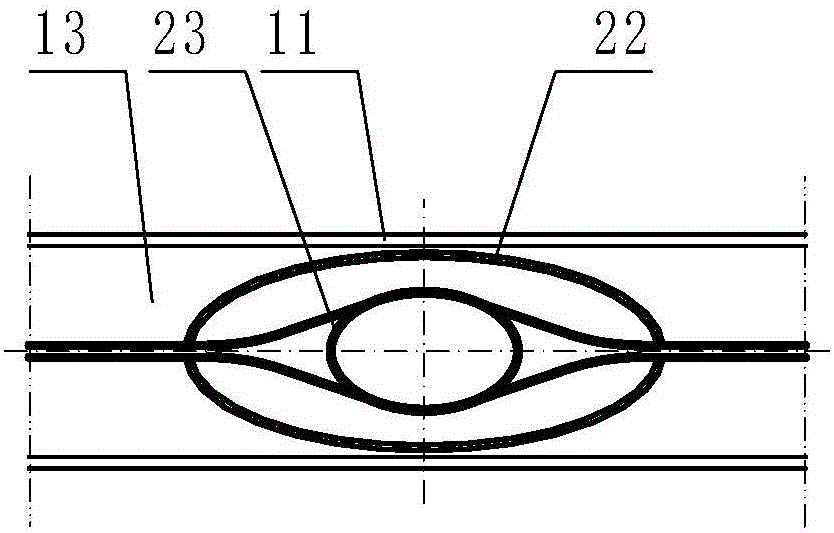

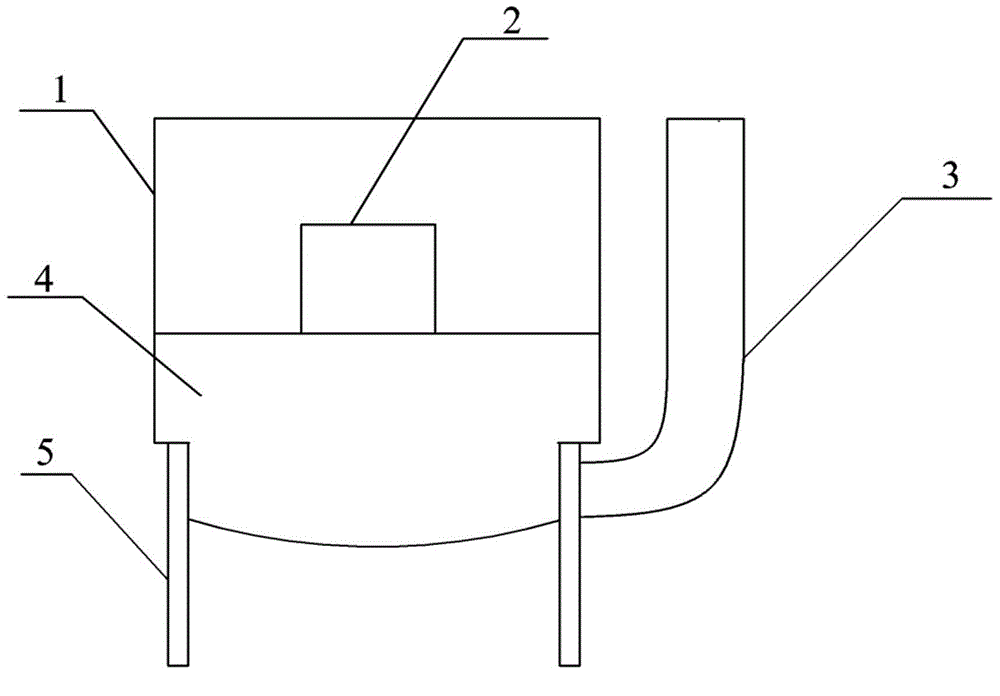

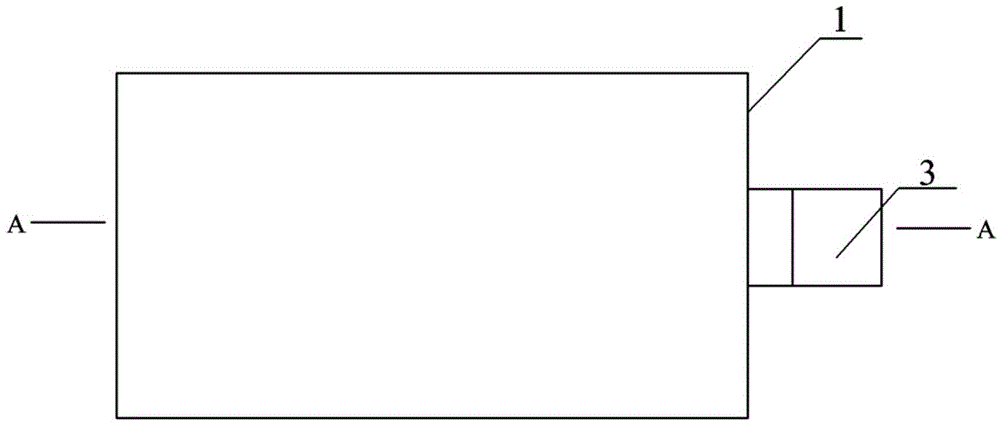

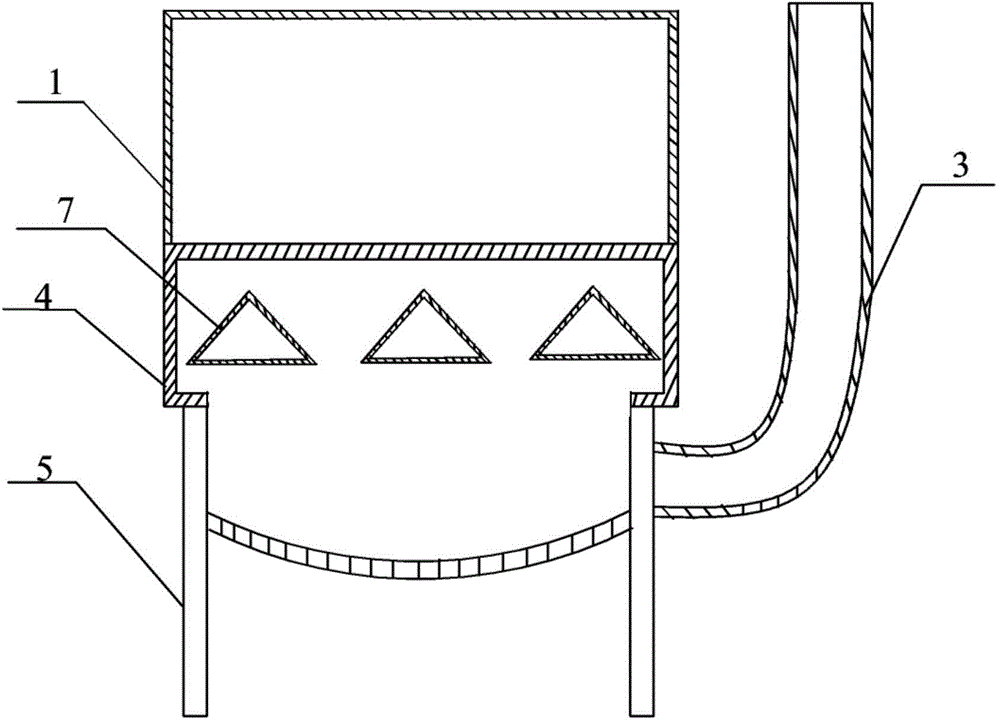

Exhaust hood having interaction effect and keeping blowing-suction balance arranged aside airflow tank

ActiveCN108636973AEnhanced interactionMeet actual production needsDirt cleaningAir volumeEngineering

Owner:SHENYANG JIANZHU UNIVERSITY

Smoke-removing apparatus for carbon disulfide production line and smoke-removing system formed by same

Owner:濮阳天泓实业有限公司

Dust removal working table

Owner:TIANJIN XINYUE JINZHAO TECH DEV

Wound core clamping part fixing device

Owner:海泉风雷新能源发电股份有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap