Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Hydraulic press" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hydraulic press is a machine press using a hydraulic cylinder to generate a compressive force. It uses the hydraulic equivalent of a mechanical lever, and was also known as a Bramah press after the inventor, Joseph Bramah, of England. He invented and was issued a patent on this press in 1795. As Bramah (who is also known for his development of the flush toilet) installed toilets, he studied the existing literature on the motion of fluids and put this knowledge into the development of the press.

Method for drawing and forming parabola revolution body

The invention relates to a method for drawing shaped parabola revolving body, belonging to the technical field of the plastic forming of material processing engineering. The method comprises the following steps: (1) a set of mould is designed according to the final shape of revolving body parts; (2) the first drawing: when being drawn, a movable soft punch cushion block is arranged on a mould punch; the inner shape of the movable soft punch cushion block is similar to the shape of the punch; a movable rigidity limit cushion block is arranged below a blank holder with a belt drawbead; (3) the annealing heat treatment, the annealing heat treatment is carried out on the parts after the first drawing is carried out on the parts; (4) the second drawing, the same set of module is used; when in drawing, the movable soft punch cushion block and the movable rigidity limit cushion block are removed. In the invention, the movable soft punch cushion block is added on a drawing mould rigidity punch for enlarging the plastic forming of the materials in the first drawing; only one set of drawing module is used on an ordinary hydraulic press, therefore, the parahola revolving body parts which are usually formed with 3-4 sets of moulds by the common drawing processing are successfully formed by twice drawing.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Oil pumping unit dynamic balance timely automatic regulating device and control method thereof

InactiveCN102817588AImprove adaptabilityImprove convenienceFluid removalAuto regulationDynamic balance

The invention provides an oil pumping unit dynamic balance timely automatic regulating device and a method for improving an existing oil pumping unit with a crank and a fixed balance weight by utilizing the device. According to the oil pumping unit dynamic balance timely automatic regulating device, an adjustable balance weight part of the oil pumping unit dynamic balance timely automatic regulating device is arranged on the side surface of the crank, the adjustable balance weight part timely moves on the side surface of the crank so as to excellently regulate the dynamic balance of an oil pumping unit, further, the adjustable balance weight part comprises a carrier and one or a plurality of balance weights, the carrier can move along the crank side surface, the one or the plurality of balance weights is / are detachably arranged on the carrier, a hydraulic mechanism drives the carrier, a control device with a central processing unit (CPU) microprocessor detects the dynamic balance of the oil pumping unit and timely controls the hydraulic mechanism, then the timely dynamic balance control of the oil pumping unit is achieved, thereby the control capacity of the oil pumping unit dynamic balance is improved, simultaneously the electrical energy is saved, and the production cost is reduced.

Owner:孙显清

Steel bending equipment for steel machining

InactiveCN112139303AAvoid scratchesAvoid damageShaping toolsMetal-working feeding devicesStructural engineeringContact position

The invention discloses steel bending equipment for steel machining, and belongs to the technical field of steel machining. The steel bending equipment comprises a machine body, lubricating oil tanks,a base, roll shafts, an oil storage box, a positioning mechanism and a mounting seat, wherein the machine body is fixedly installed on the base through a side connecting plate, hydraulic machines arefixedly installed at the top of the machine body, and one ends of hydraulic rods installed at the output ends of the hydraulic machines penetrate through and extend to the outer side of the machine body to be fixedly provided with a bending plate. According to the steel bending equipment, the roller shafts are installed on the equipment, when steel is bent and pressure is applied to the bent position of the steel, the roll shafts replace a bent face to make contact with the steel, and when pressure is applied for bending, the steel can be bent along the smooth surfaces of the roll shafts, compared with traditional bending treatment, the situation that the surface of the steel is scratched and damaged is avoided, and meanwhile, the lubricating oil tanks are installed on the outer side of the equipment in a matched mode, the contact positions between the roll shafts and the steel can be effectively lubricated, and the bending smoothness is further improved.

Owner:赵桂荣

Method for crimping high-pressure cross-linking three-layer co-extrusion continuous produced disc-exchanging conductor

InactiveCN102945710ANo drop in tensile strengthLow technical requirementsConnections effected by permanent deformationCable/conductor manufactureCross-linkElectrical resistance and conductance

Owner:HENGYANG HENGFEI CABLE CO LTD

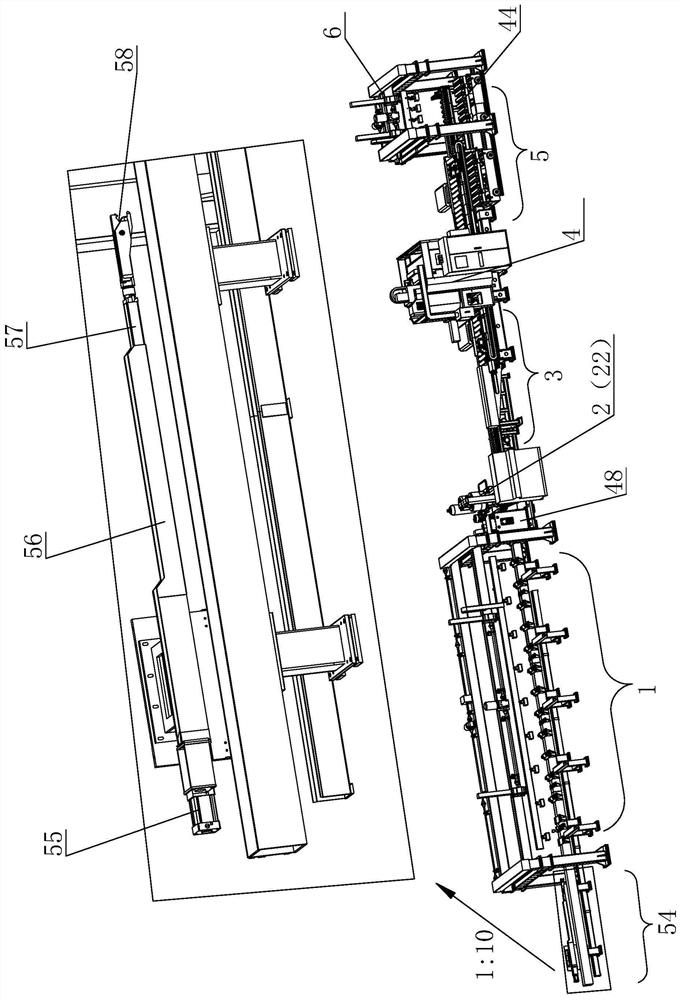

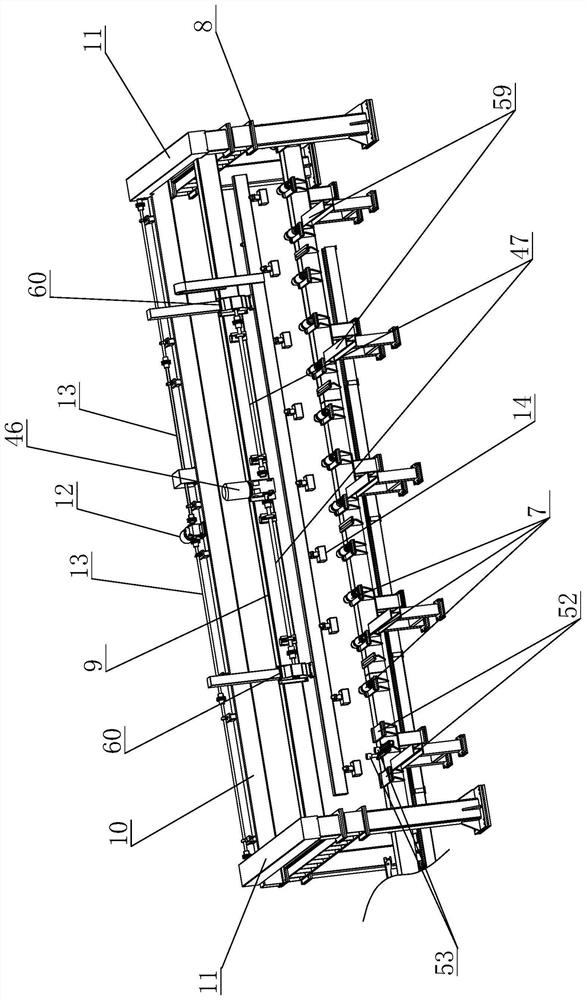

Bidirectional braking hydraulic machine and working method thereof

PendingCN113459558AImprove work efficiencyImprove working precisionPress ramHydraulic cylinderFour-way valve

The invention discloses a bidirectional braking hydraulic machine and a working method thereof. An oil outlet of an oil tank is connected with the input end of an oil pump; a hydraulic directional valve and a first electromagnetic directional valve are both three-position four-way valves, when the first electromagnetic directional valve is in the middle position, a first oil port and a second oil port of the first electromagnetic directional valve are connected with the hydraulic directional valve, a third oil port of the first electromagnetic directional valve is connected with the oil tank, and a fourth oil port of the first electromagnetic directional valve is connected with the output end of the oil pump; when the hydraulic reversing valve is in the middle position, a first oil port of the hydraulic reversing valve is connected with the oil tank, a second oil port is connected with an oil inlet of an overflow valve, a third oil port is connected with the output end of the oil pump, a fourth oil port is connected with rodless cavities of two hydraulic cylinders, a fifth oil port is divided into two paths, one path is sequentially connected with a throttling valve and rod cavities of the two hydraulic cylinders, the throttling valve is connected with a second electromagnetic reversing valve in parallel, and the other path is connected with an overflow valve; and an oil outlet of the overflow valve is respectively connected with an oil inlet of a third electromagnetic directional valve and the oil tank; and an oil outlet of the third electromagnetic directional valve is connected with the oil tank. Bidirectional pressing forming is achieved, the quality of formed parts and the production efficiency are improved, and the production cost is greatly reduced.

Owner:SHAANXI UNIV OF SCI & TECH

Thermal correction method of titanium alloy special-shaped tubular casting

ActiveCN108620452AAvoid secondary crackingImprove efficiencyShaping toolsTitanium alloyMachine press

The invention aims to solve the problems that the temperature of a traditional gas flame correcting and heating process is not uniform, secondary cracking is easily generated, the efficiency is low are solved, an induction heating mode is adopted, a special-shaped movable induction coil is designed according to the section shape of a titanium alloy special-shaped tubular casting, the heating rateand the heating temperature are controlled, the integral heating is carried out on the local part of the casting, and the secondary cracking tendency caused by heat concentration is prevented. A tool,a clamp and a mold are designed, and a deformation part is subjected to plastic deformation through a hydraulic press, so that the casting is corrected. The method is suitable for the thermal state correction of the titanium alloy tubular casting with the wall thickness less than or equal to 20 mm, and the heat correcting efficiency of the casting is greatly improved.

Owner:SHENYANG RES INST OF FOUNDRY

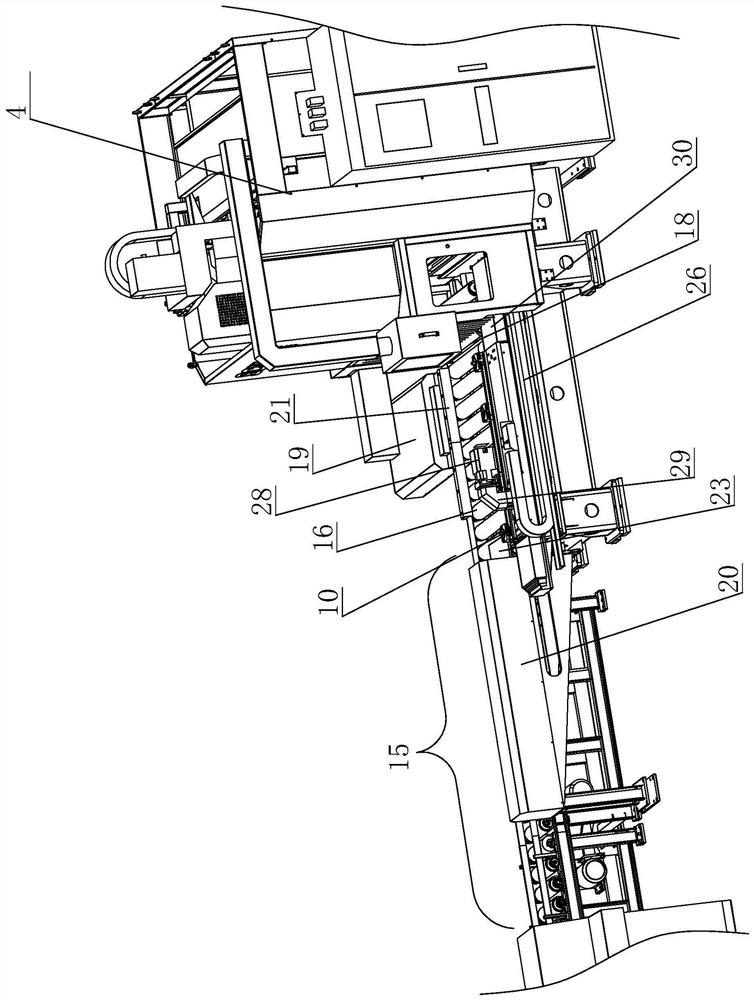

Exhaust gas discharge device for hydraulic press for interior part of high-speed multiple unit train

InactiveCN109228495AAvoid pollutionEasy to switchDirt cleaningPressesHydraulic cylinderControl engineering

The invention belongs to the technical field of high-speed multiple unit train interior-part hydraulic presses, and discloses an exhaust gas discharge device for a hydraulic press for an interior partof a high-speed multiple unit train. The device includes an exhaust hood and four baffles, the exhaust hood is installed at the upper end of a hot press body through a bracket, the hot press body includes a lower cross beam and an upper cross beam, the lower cross beam and the upper cross beam are fixedly connected through four sets of symmetrically arranged stand columns, a hydraulic cylinder isarranged on the upper cross beam, one end of a piston rod of the hydraulic cylinder is fixedly connected with the symcenter of the upper end of an upper die body, an operation platform is arranged onthe upper portion of the lower cross beam, the four baffles are symmetrically arranged on the outer sides of the hot press body, the upper ends of the baffles are hinged to one side of the upper cross beam, the lower ends of the baffles are provided with operation doors, and the upper end of the exhaust hood is symmetrically provided with two first air pipes.

Owner:HEFEI HAIDE HYDRAULIC PRESS

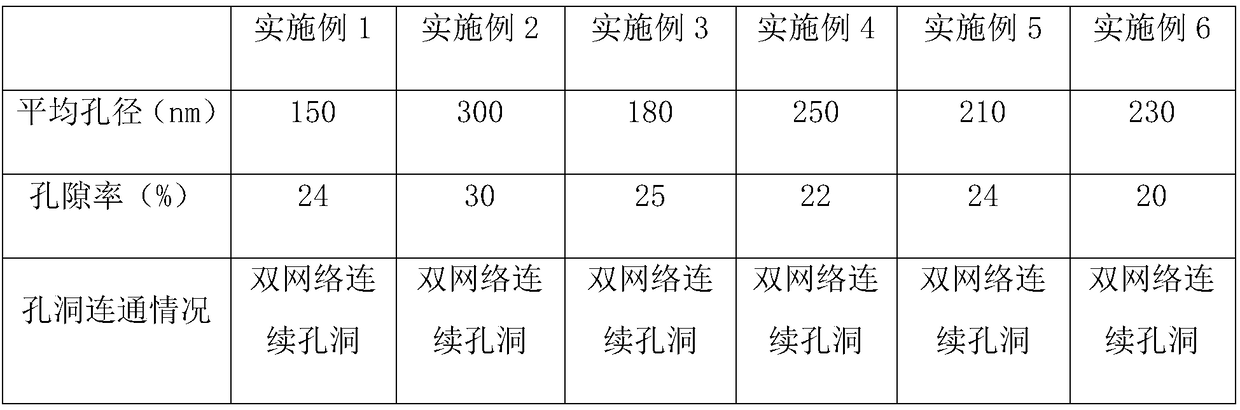

Three-dimensional bi-continuous porous-carbon-based transition metal porous material and preparation method thereof

Owner:台州知管通科技有限公司

Leather shoe cleaning and waxing device

InactiveCN112998623AImprove the inconvenience of maintenanceEasy to cleanFootwear cleanersShoe polishIndustrial engineering

The invention relates to the related technical field of maintenance, in particular to a leather shoe cleaning and waxing device. The leather shoe cleaning and waxing device aims at solving the problems that dirt appears on the surfaces of existing leather shoes, mold appears on the leather shoes after long-time storage, and wrinkles exist on the surfaces of the leather shoes. The invention discloses the leather shoe cleaning and waxing device which comprises a machine body and a shoe polish cavity formed in the machine body, a working inner cavity is formed in the machine body, a clamping mechanism for rapidly filling leather shoes in the working inner cavity and a hydraulic machine cavity are formed in the machine body, a transmission mechanism for providing power for the device to polish and push is arranged on the hydraulic machine cavity, an I-shaped sliding sleeve is connected to the working inner cavity in a sliding mode, and a maintenance mechanism for cleaning dirt of leather shoes in multiple aspects and providing oil for the device is arranged on the I-shaped sliding sleeve.

Owner:WENZHOU JINGMAO TRADING CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap