Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

16 results about "Induction coil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An induction coil or "spark coil" (archaically known as an inductorium or Ruhmkorff coil after Heinrich Rühmkorff) is a type of electrical transformer used to produce high-voltage pulses from a low-voltage direct current (DC) supply. To create the flux changes necessary to induce voltage in the secondary coil, the direct current in the primary coil is repeatedly interrupted by a vibrating mechanical contact called an interrupter. Invented in 1836 by Nicholas Callan, with additional research by Charles Grafton Page and others, the induction coil was the first type of transformer. It was widely used in x-ray machines, spark-gap radio transmitters, arc lighting and quack medical electrotherapy devices from the 1880s to the 1920s. Today its only common use is as the ignition coils in internal combustion engines and in physics education to demonstrate induction.

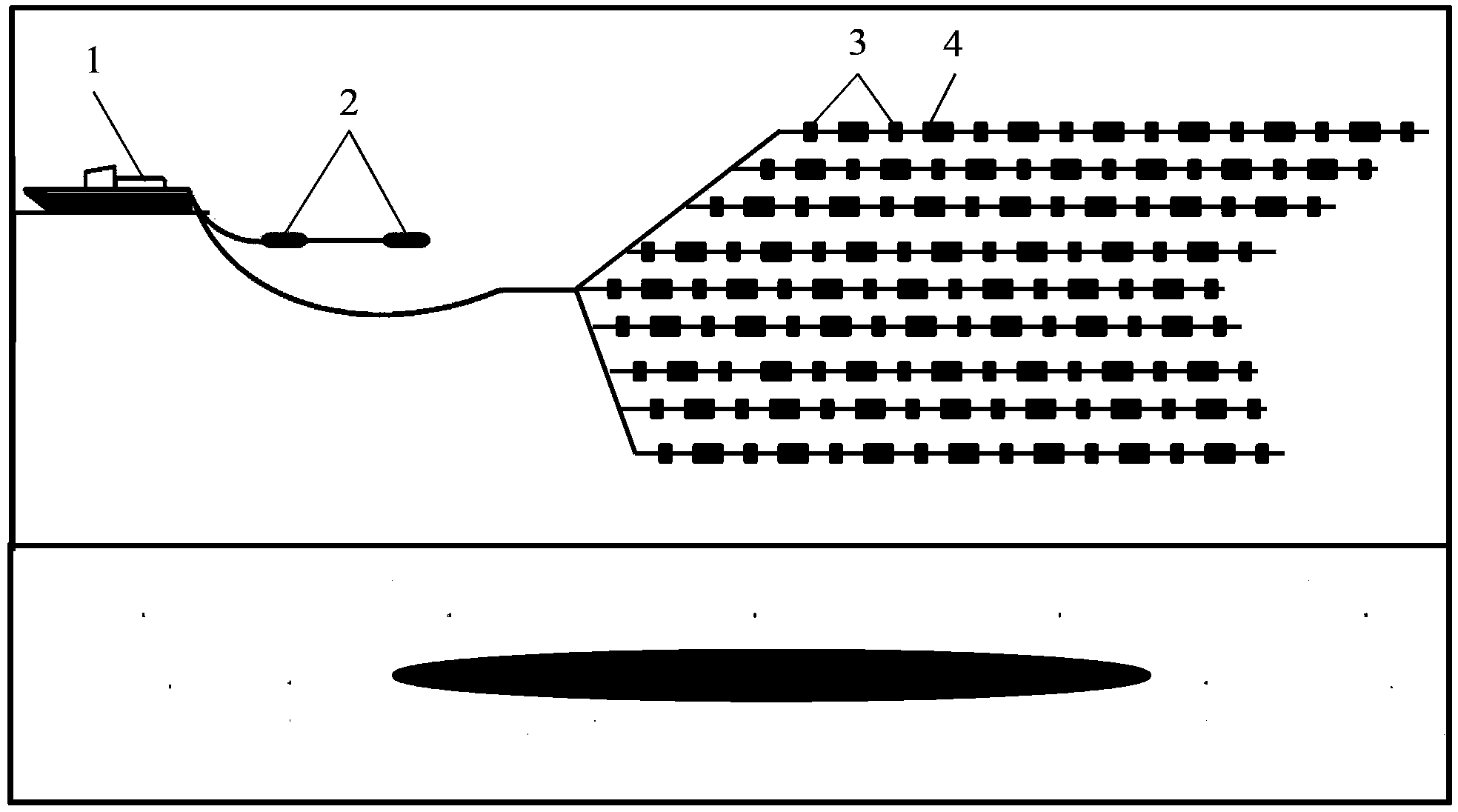

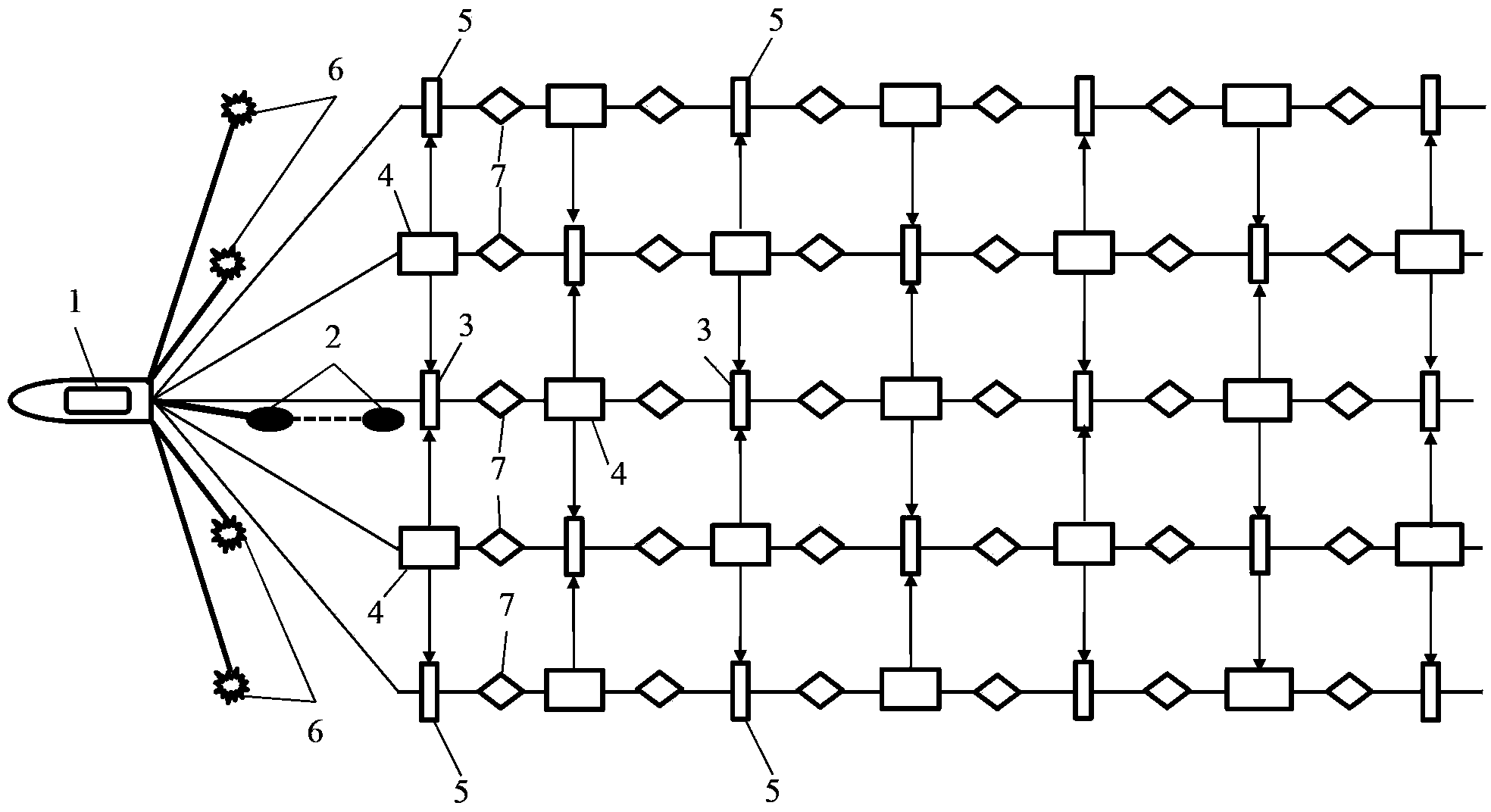

Towrope type ocean controllable source electromagnetism and earthquake data collection system

InactiveCN104280781AImprove reliabilityIncrease the amount of data collectedSeismic signal receiversElectric/magnetic detectionElectric field sensorAccelerometer

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

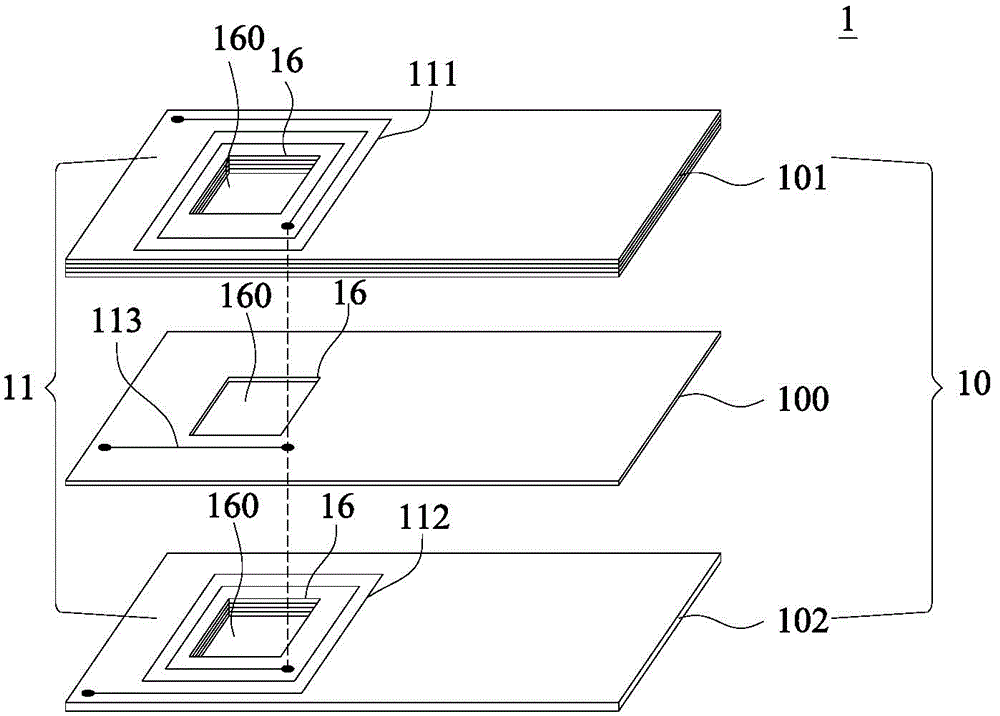

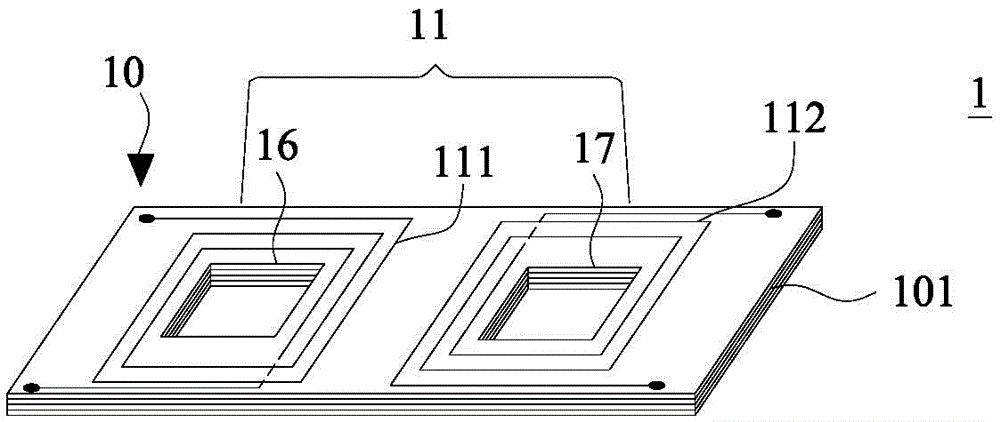

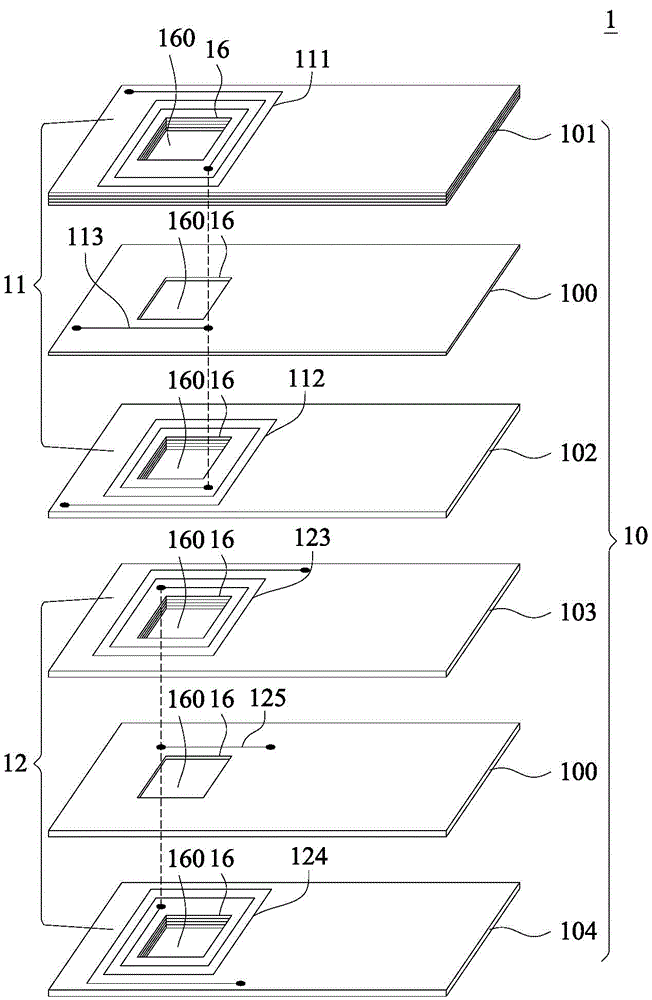

Induction coil assembly

InactiveCN105163489AValid settingsRealize the structurePrinted circuit non-printed electric components associationCoilsPlanar inductorEngineering

Owner:XULI ELECTRONICS CO LTD

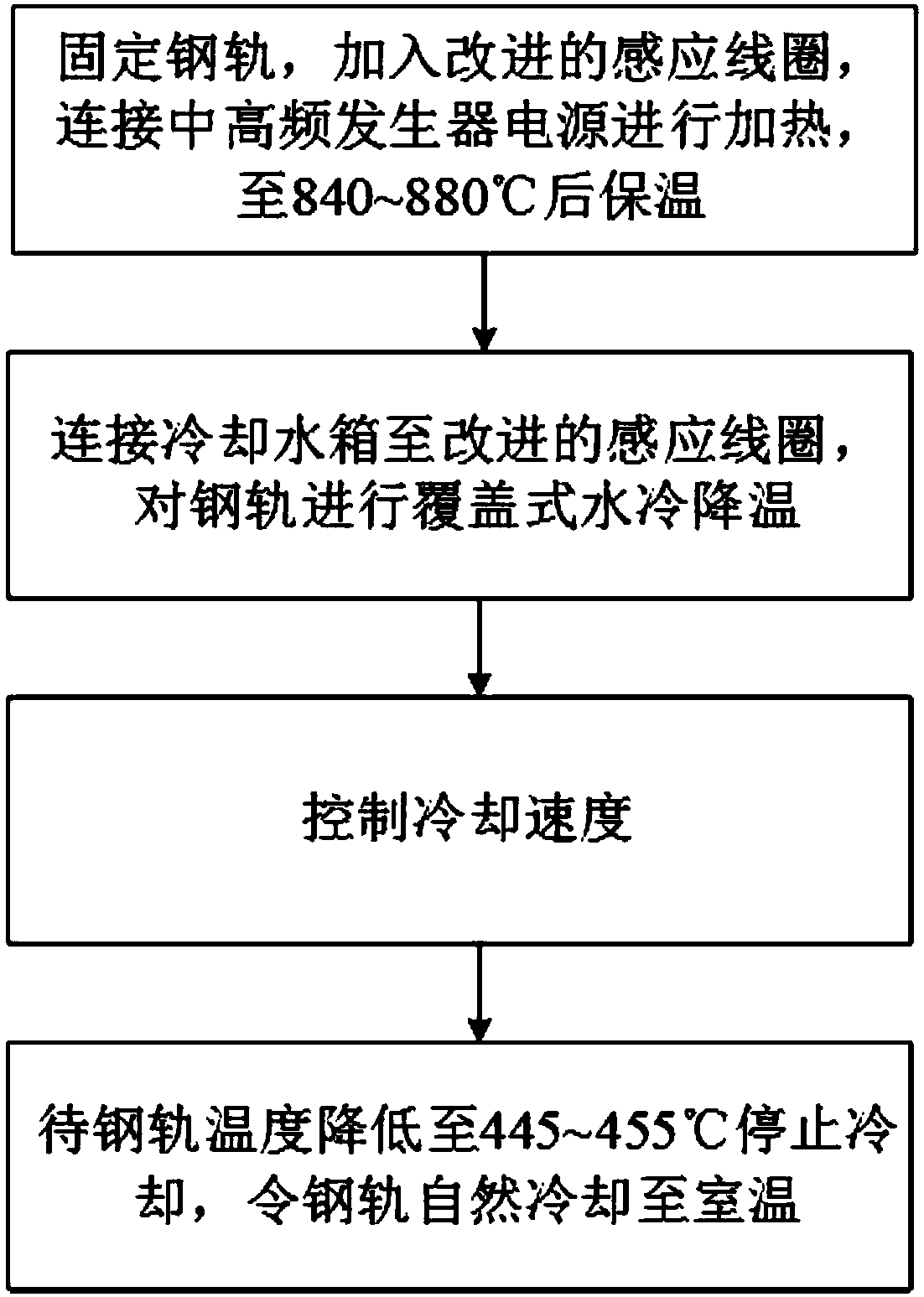

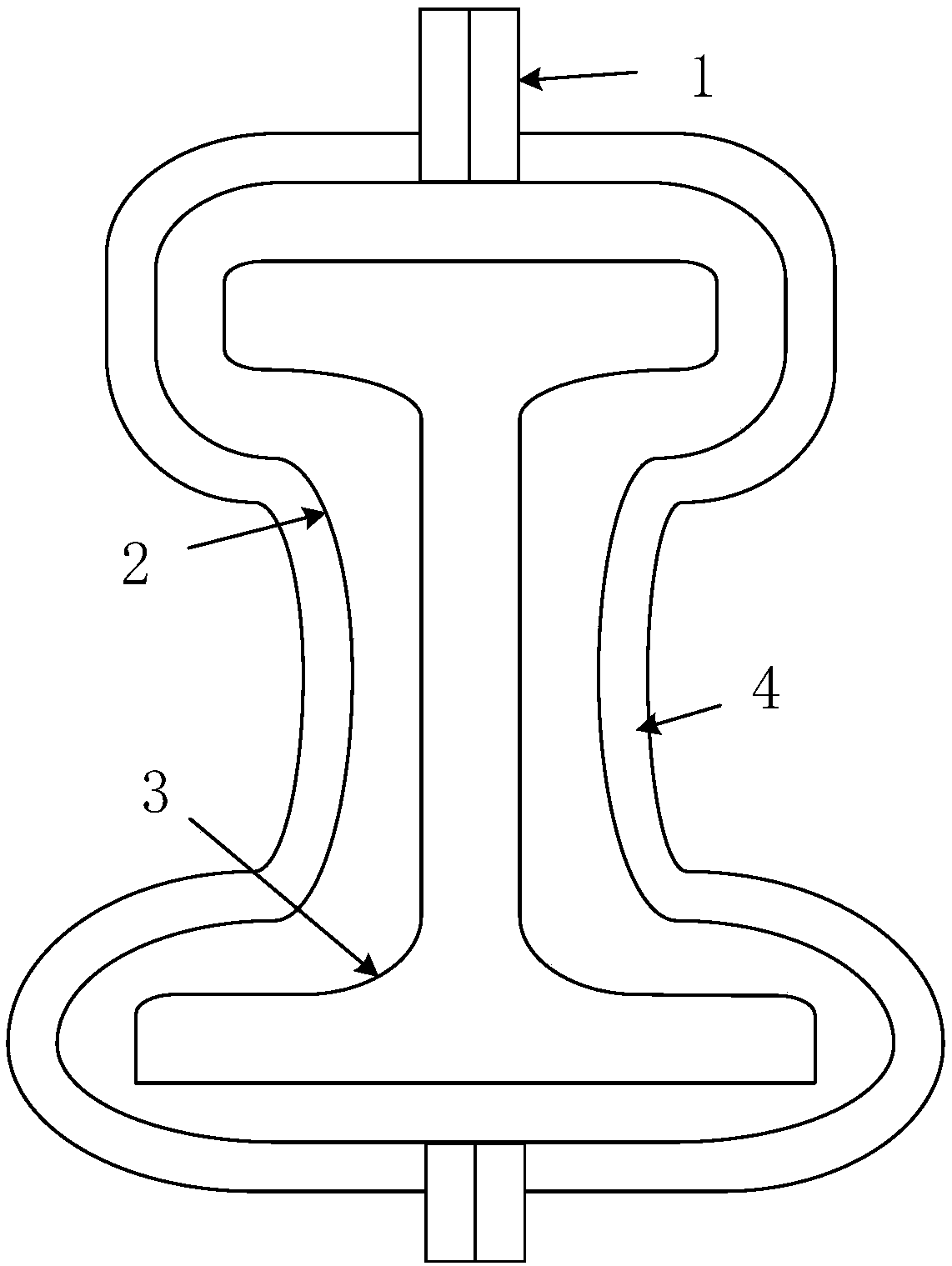

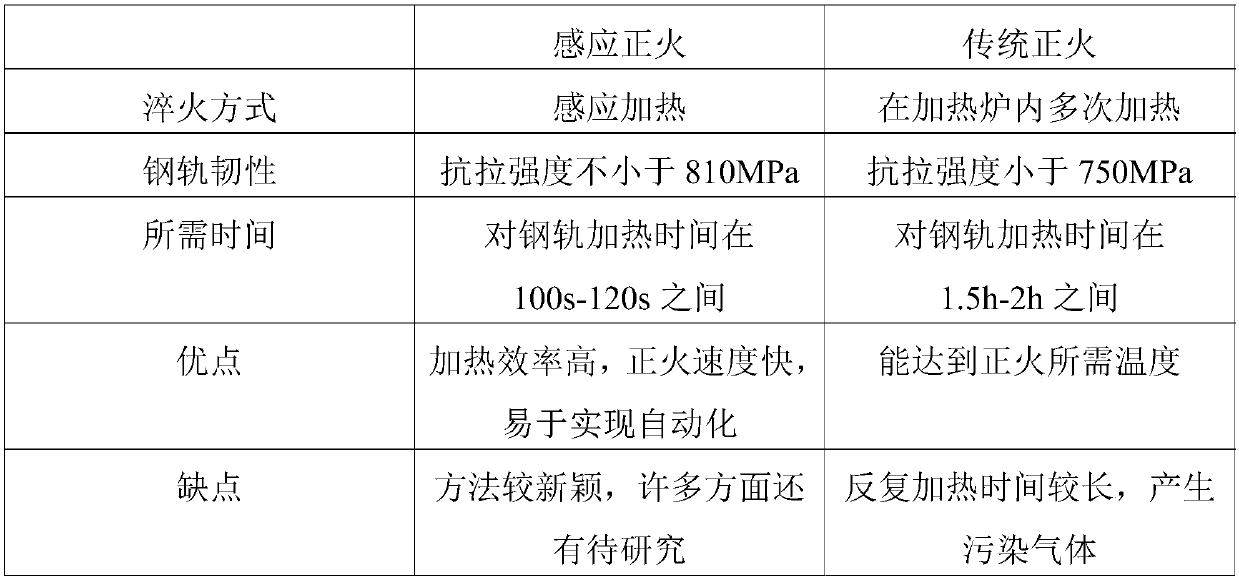

Induction normalizing method for steel rail

InactiveCN109593941AThe skin effect is obviousCool down in timeFurnace typesIncreasing energy efficiencyMedium frequencyFree cooling

Owner:SHANGHAI UNIV OF ENG SCI

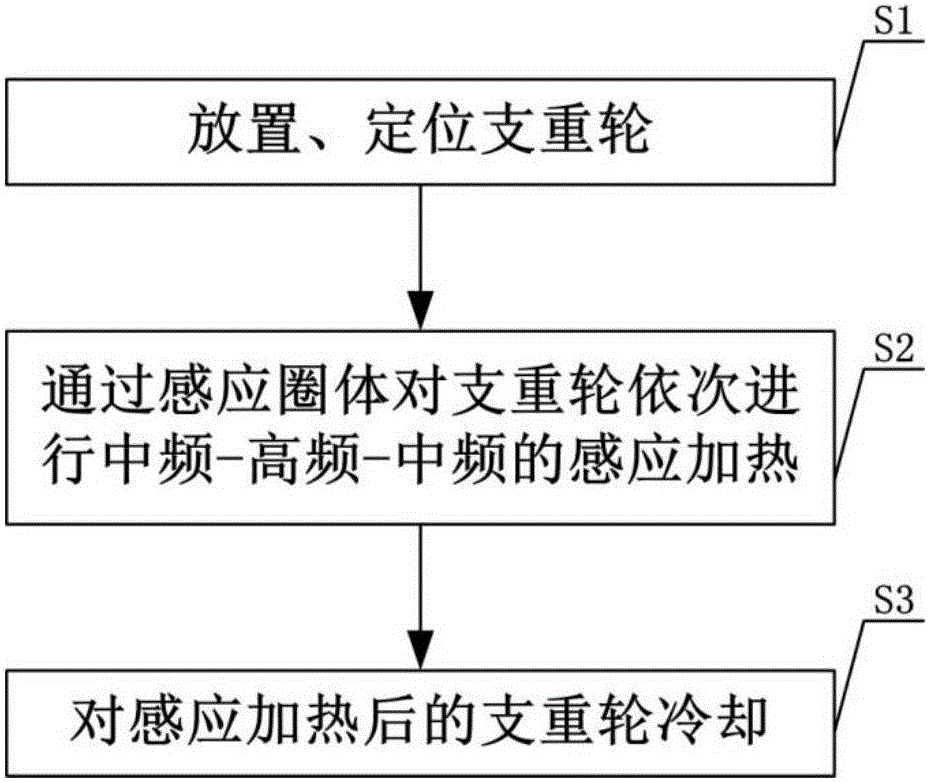

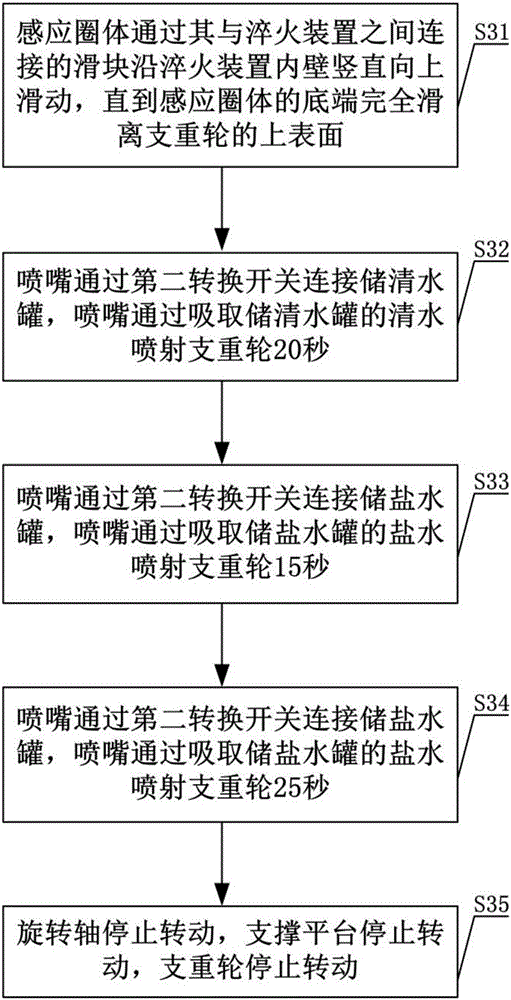

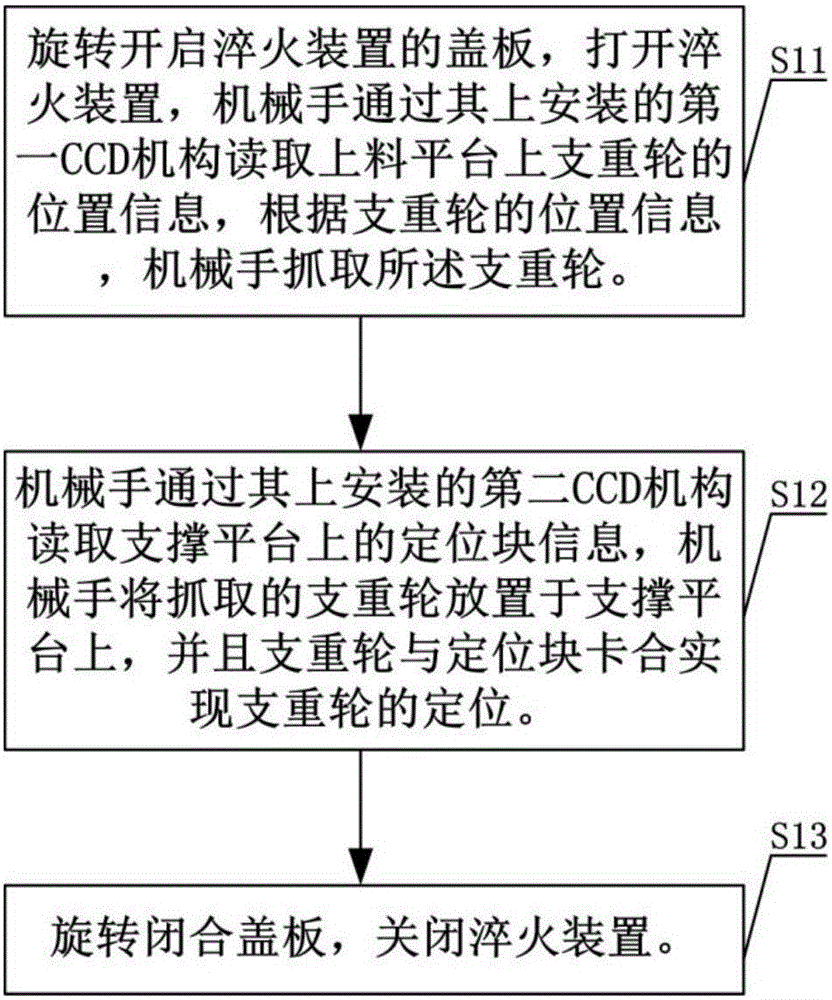

Segmented heating and cooling quenching process for wheel body of thrust wheel

ActiveCN105821195ASolve the speed problemSolve cracking and deformationFurnace typesIncreasing energy efficiencySaline waterIntermediate frequency

Owner:KUSN KENSETABU BUHIN

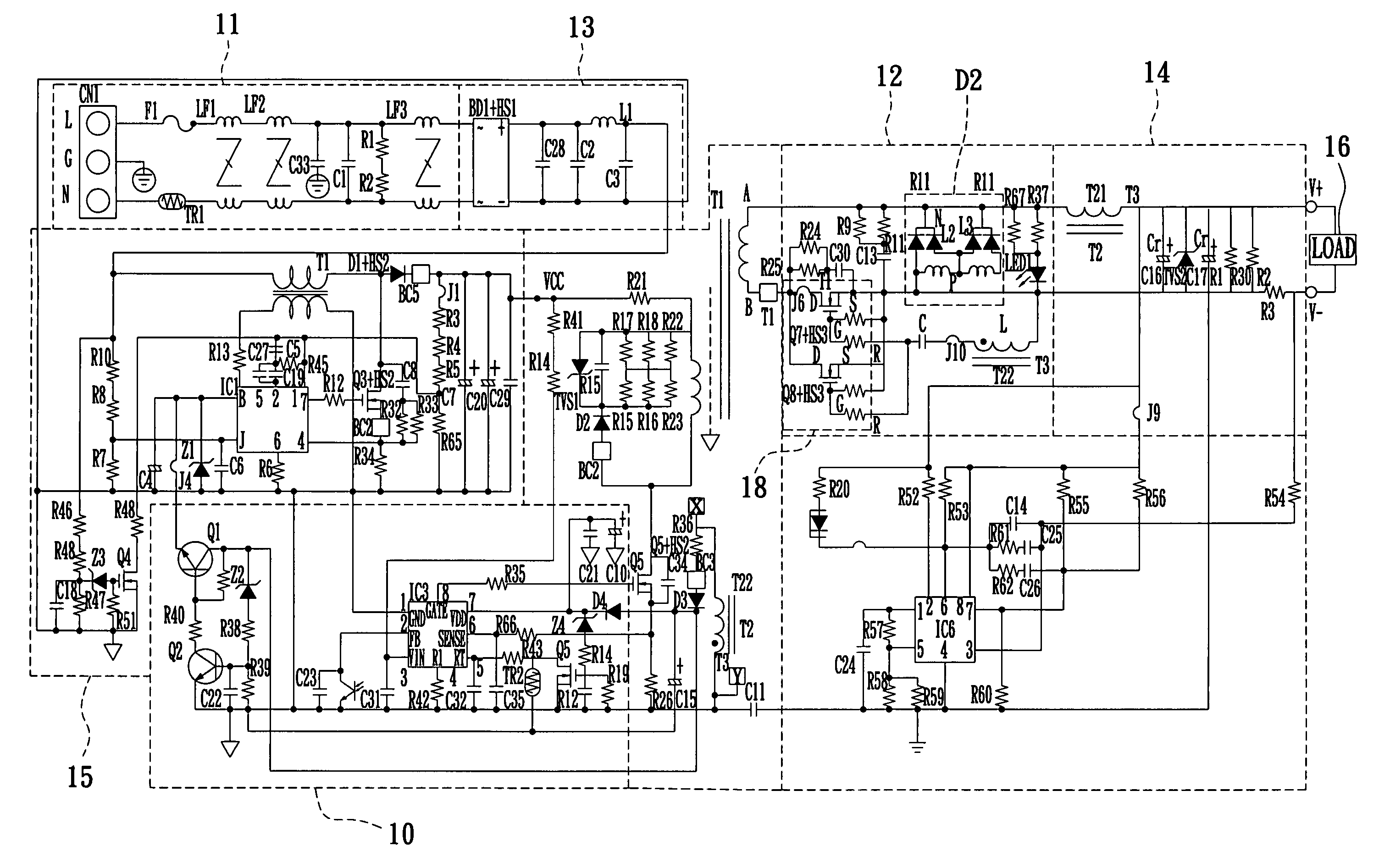

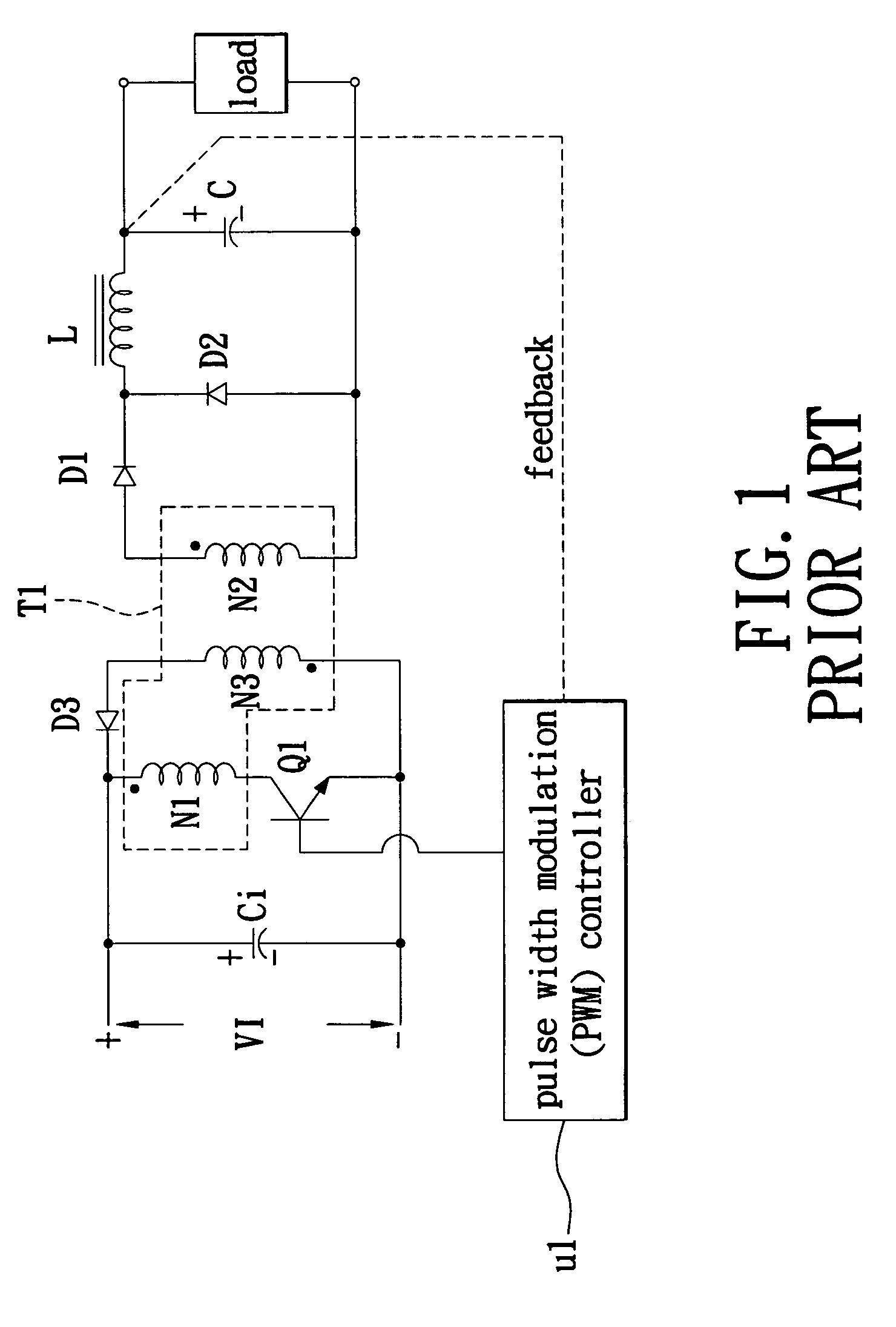

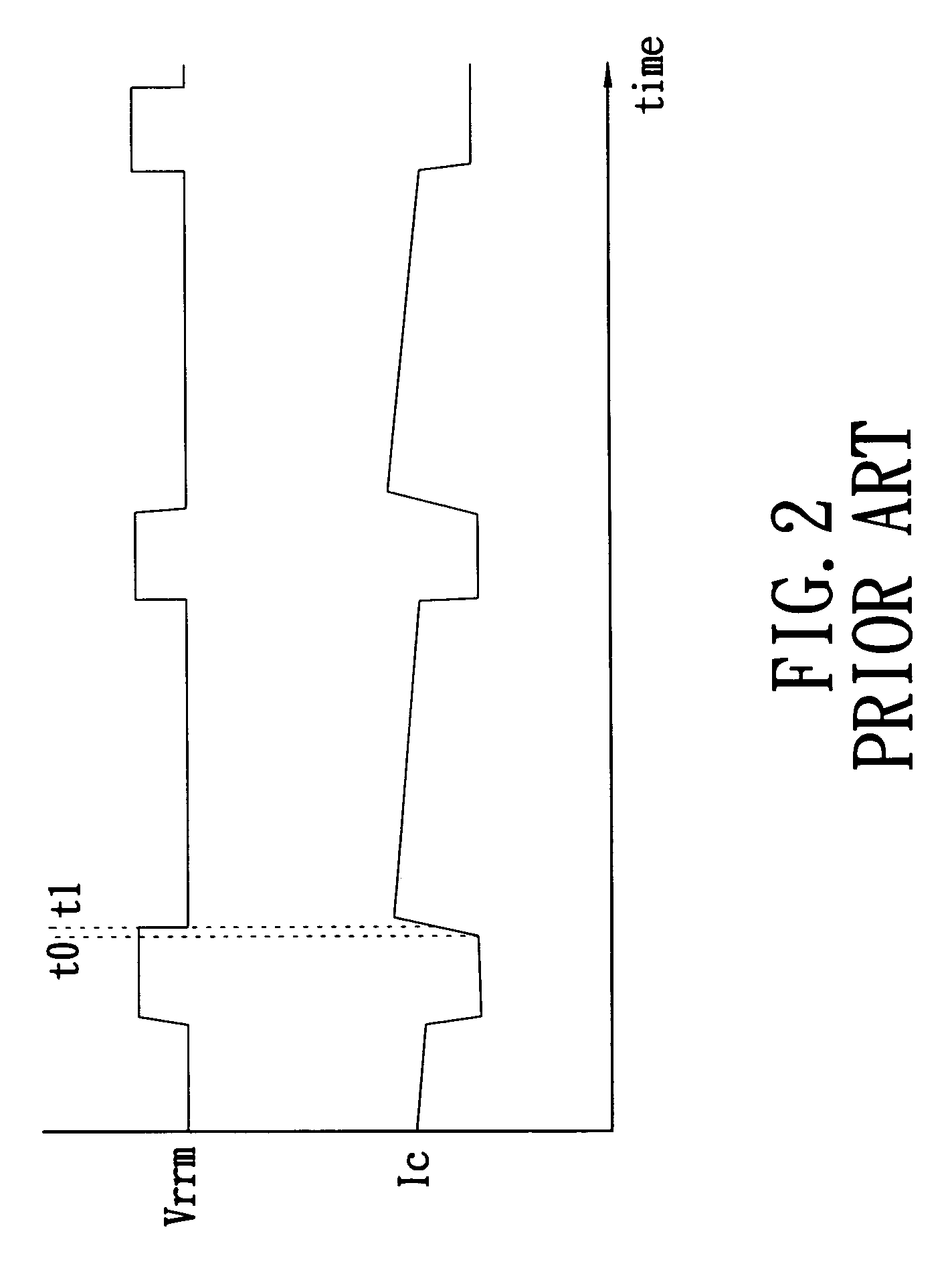

Forward power converter with self-excited synchronous rectifying circuit

InactiveUS6995988B2Stable working powerReduce lossesFinger jointsAnkle jointsSelf excitedFlyback diode

Owner:LITE ON TECH CORP

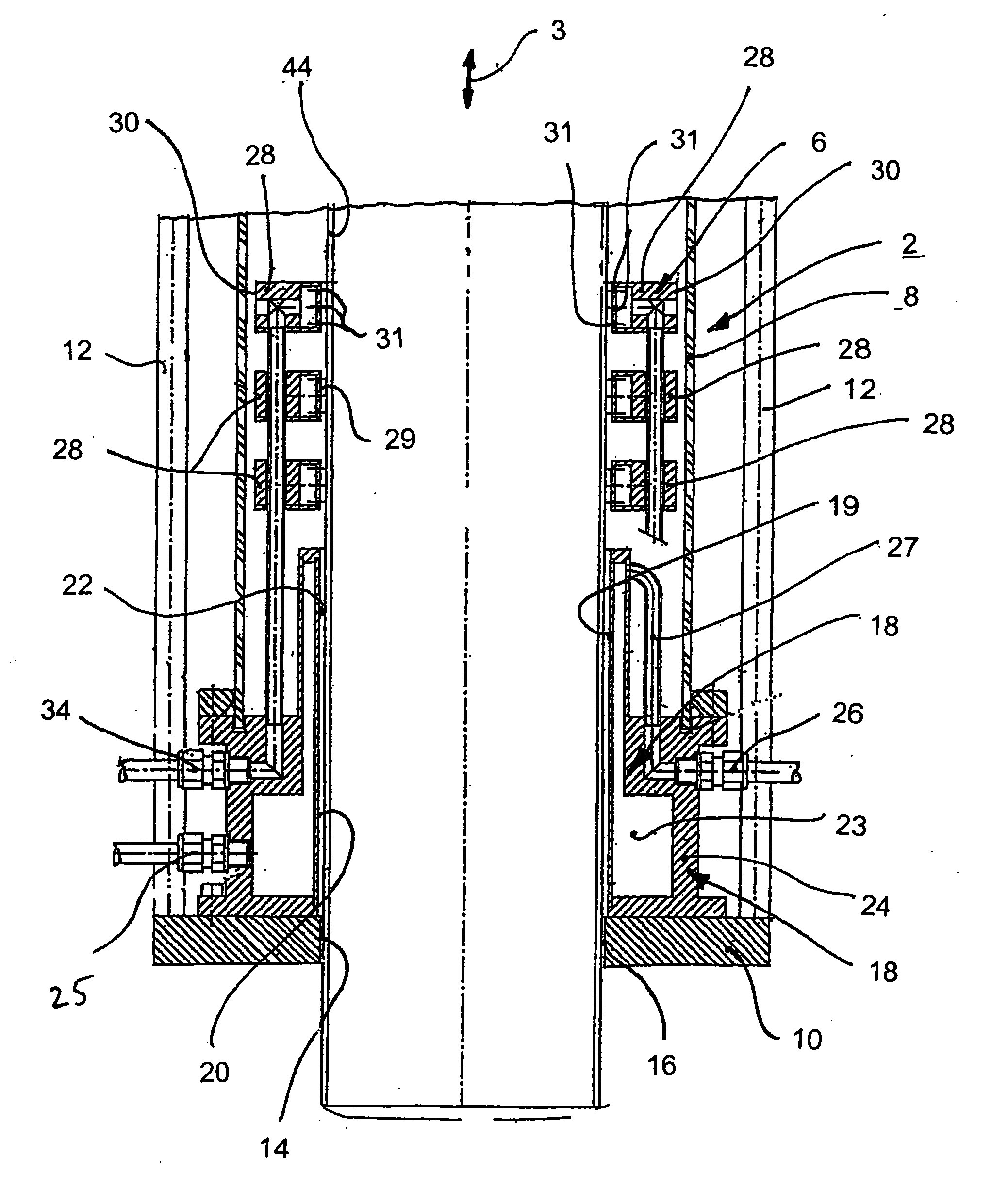

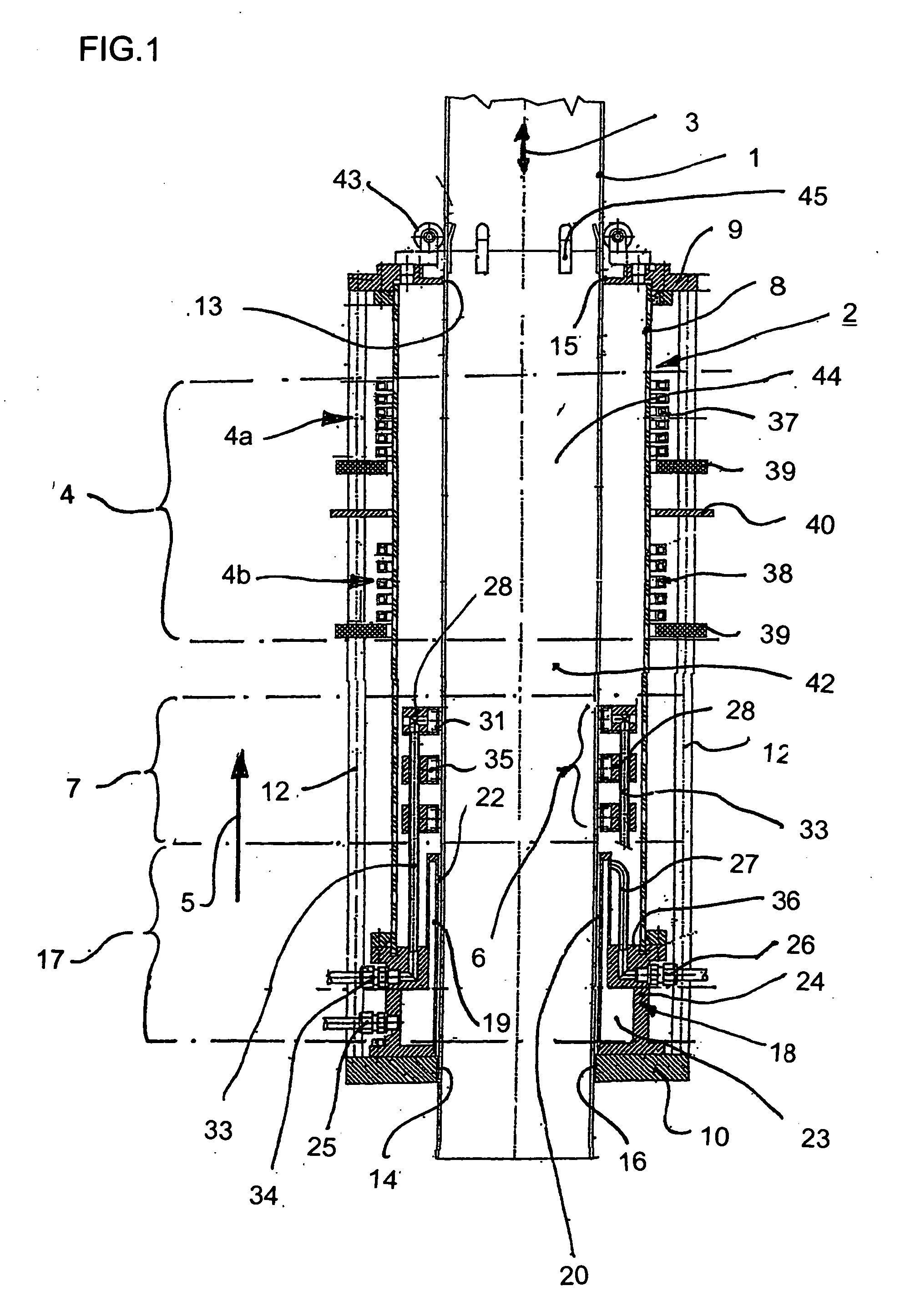

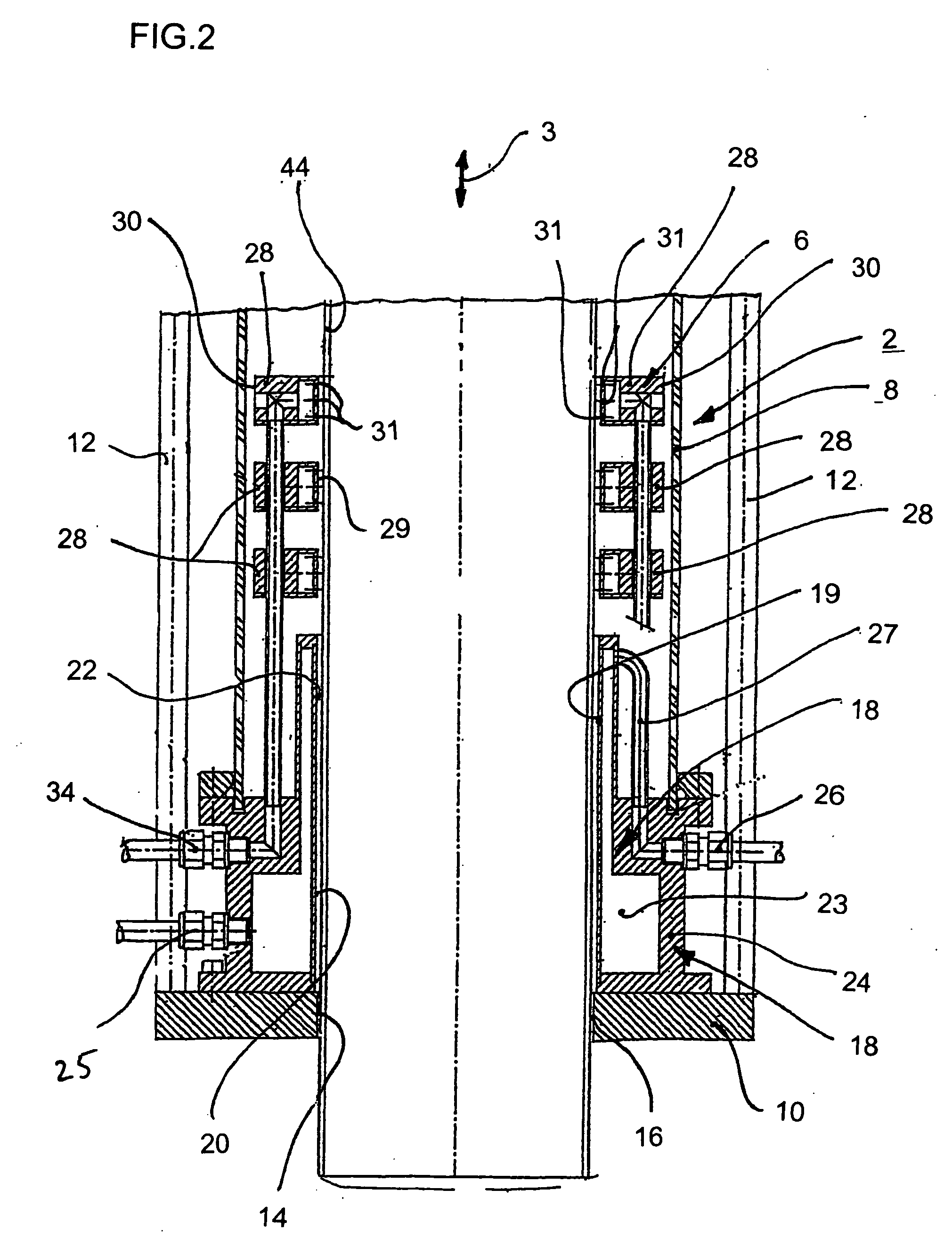

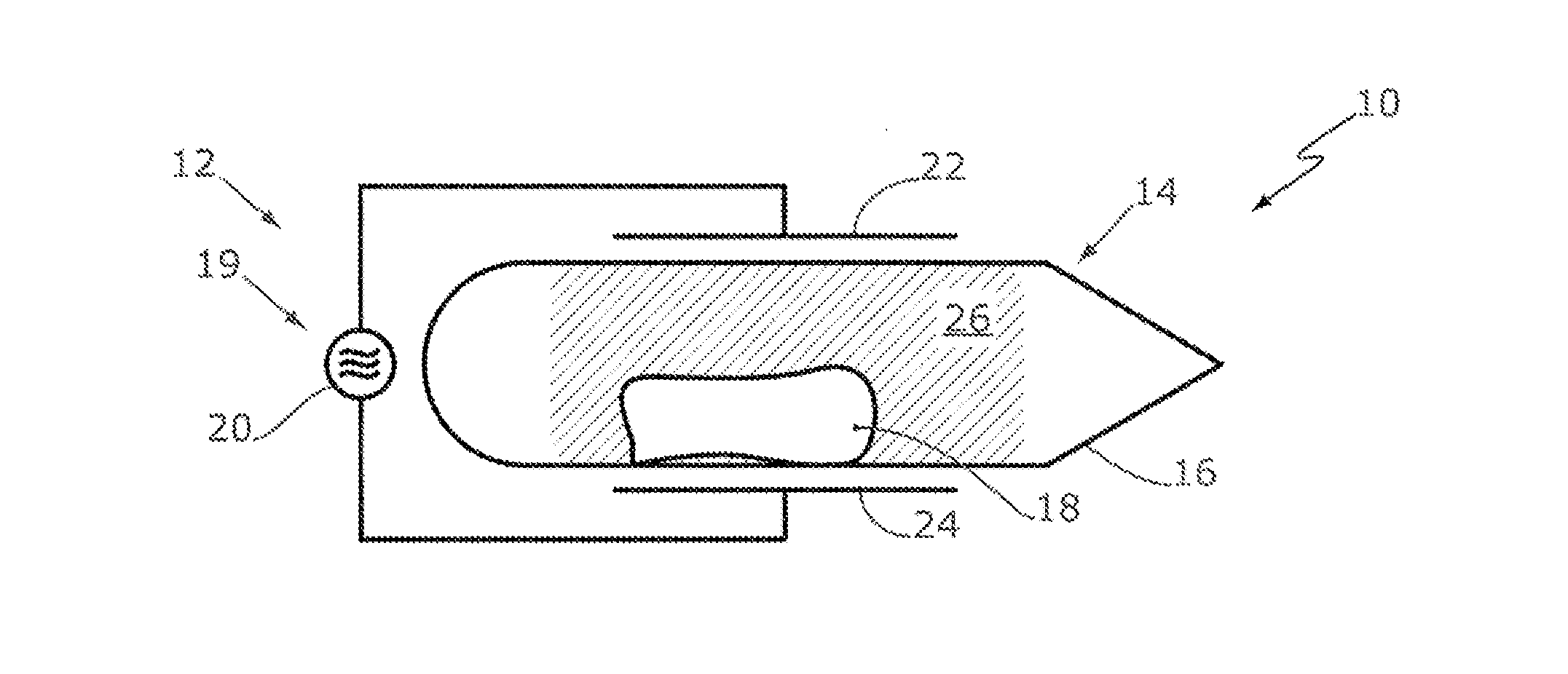

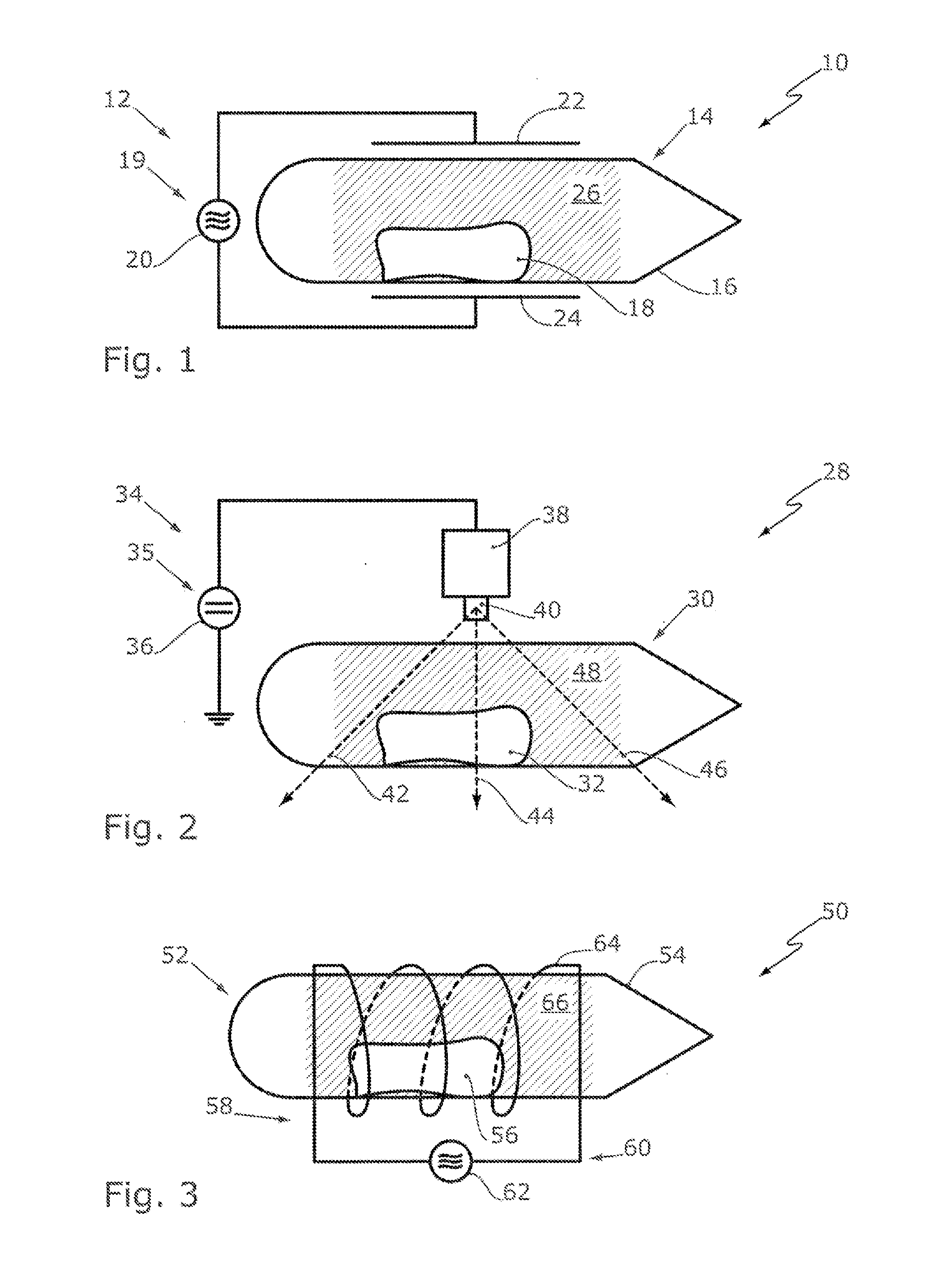

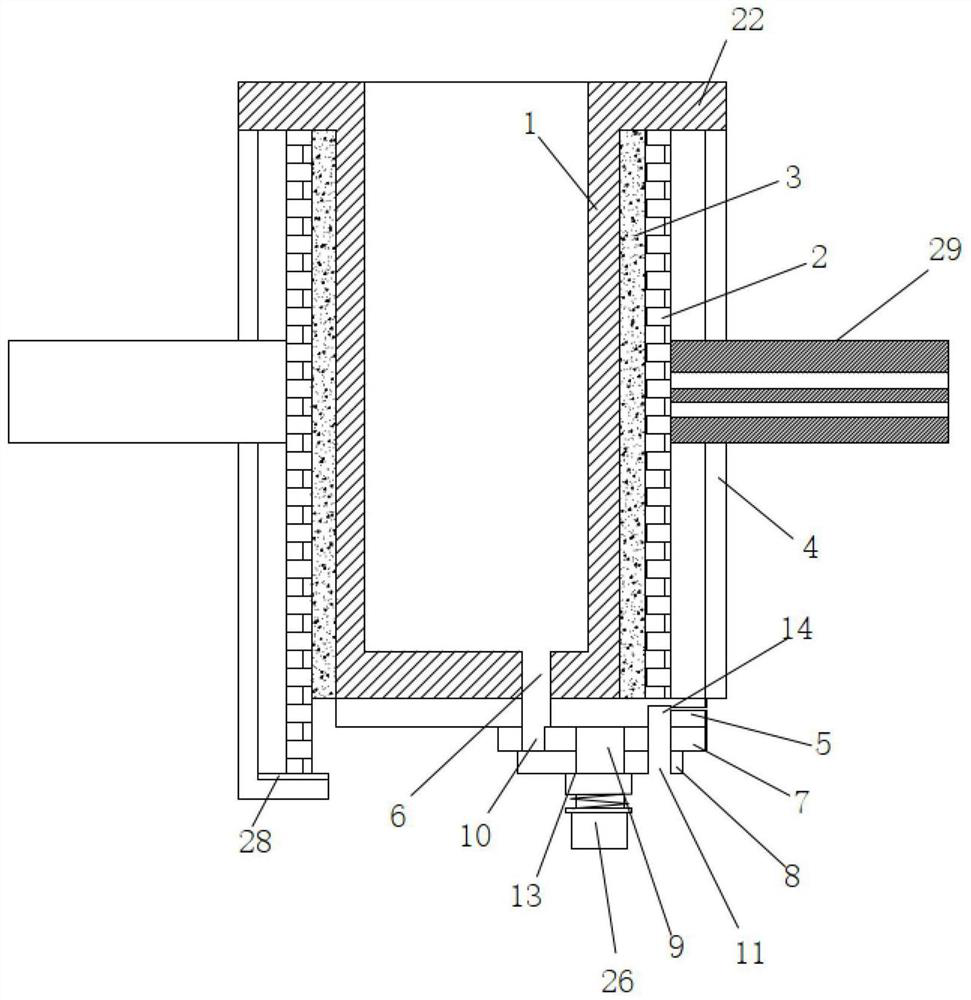

Method and apparatus for heat treating a fuel assembly channel made of a zirconium alloy

InactiveUS20070131218A1Increase variabilityEasy to controlDomestic stoves or rangesCoil arrangementsBeta phaseZirconium alloy

Owner:AREVA GMBH

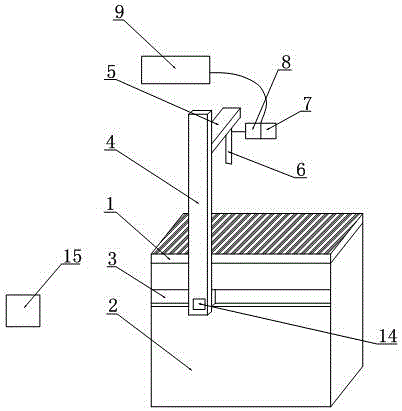

Automatic spraying device applied to SPE film and achieving method of automatic spraying device

ActiveCN105772252AImprove permeabilityAvoid deformationSpray nozzlesTemperature controlControl system

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

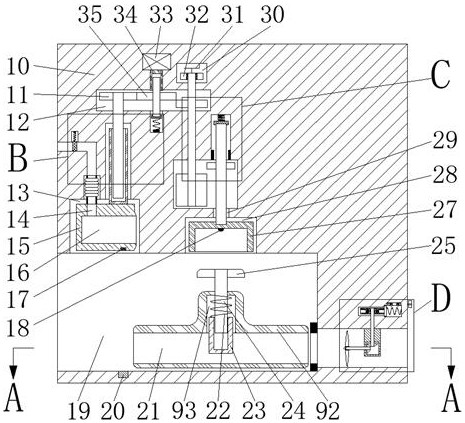

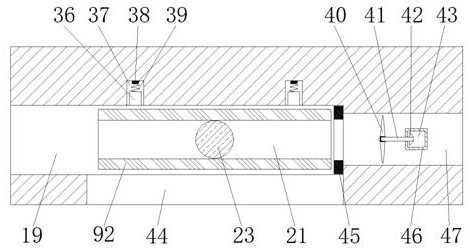

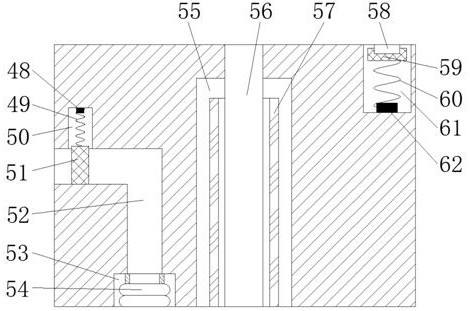

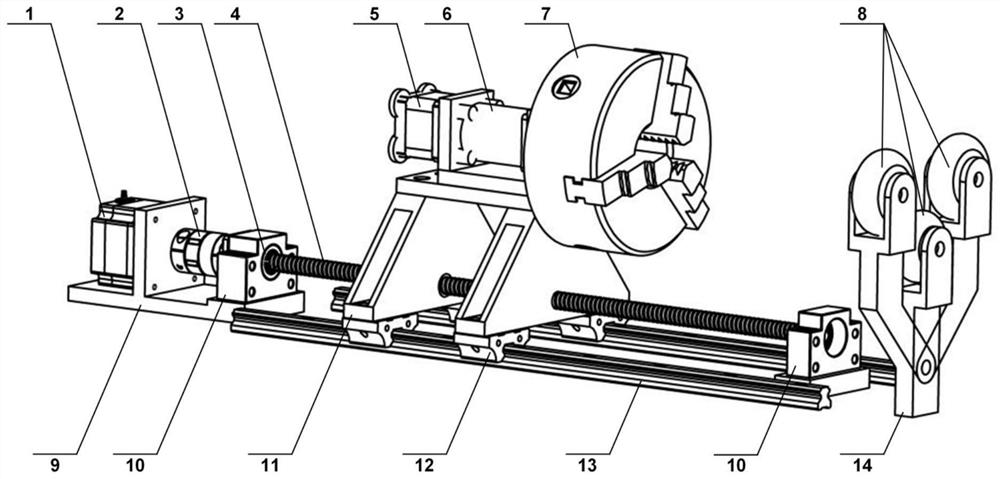

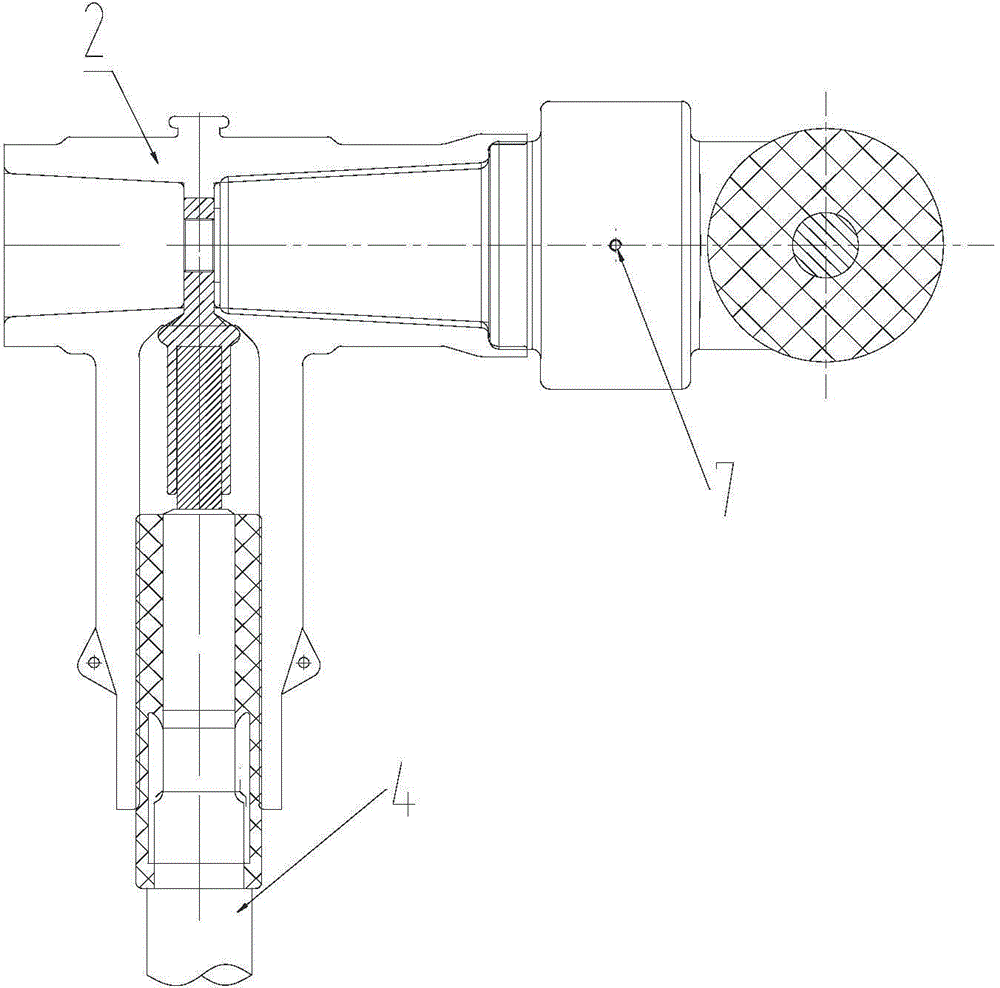

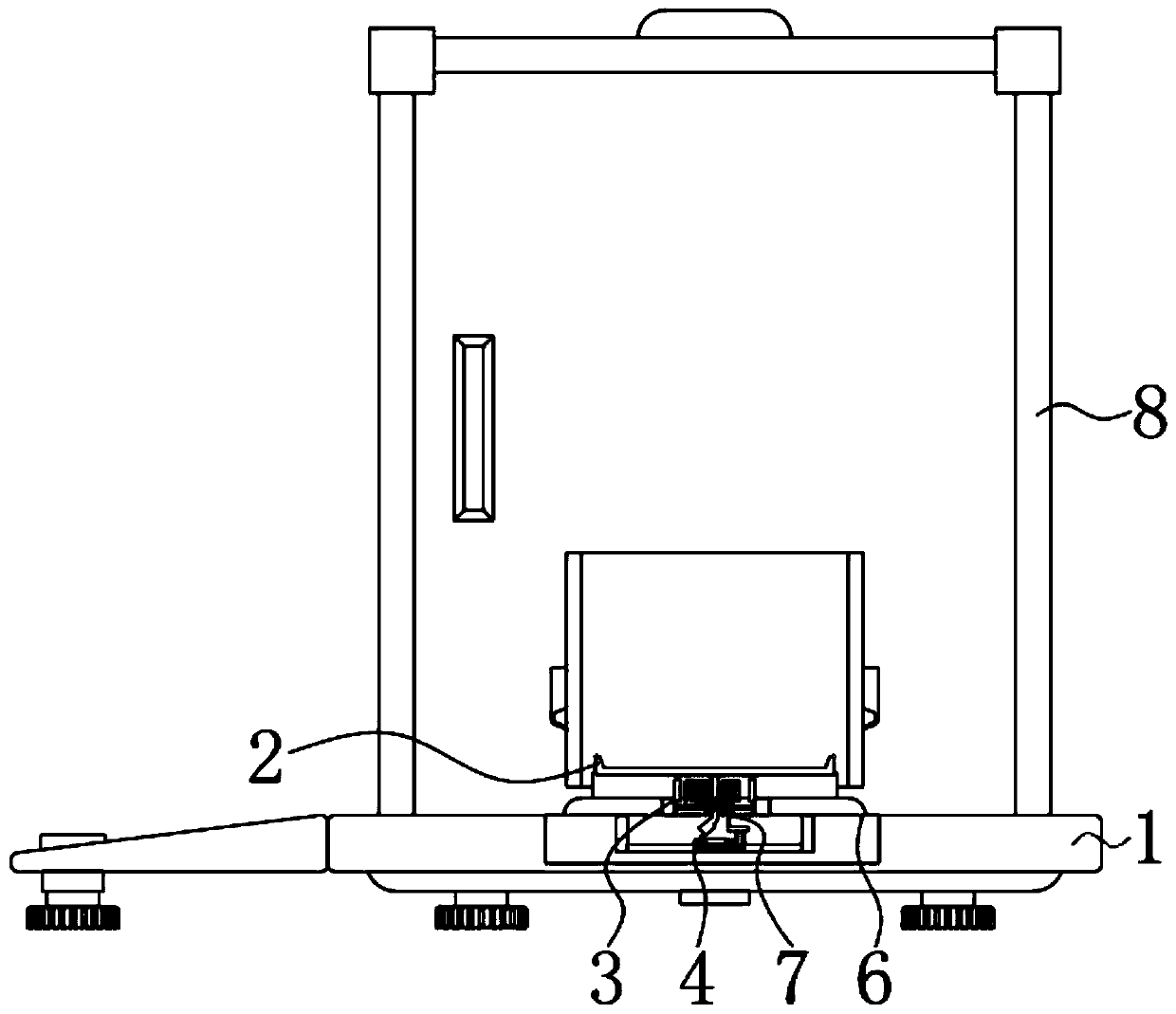

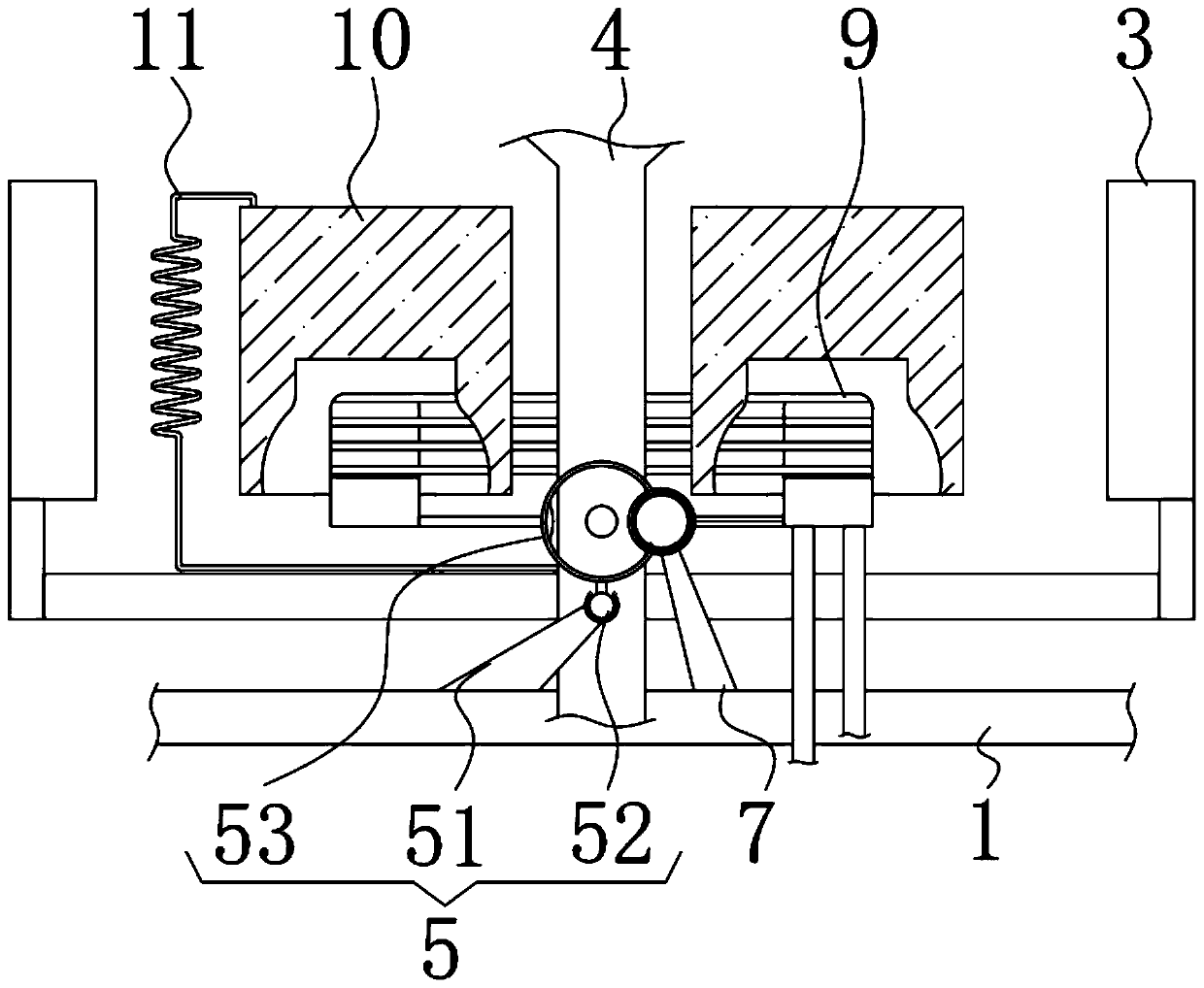

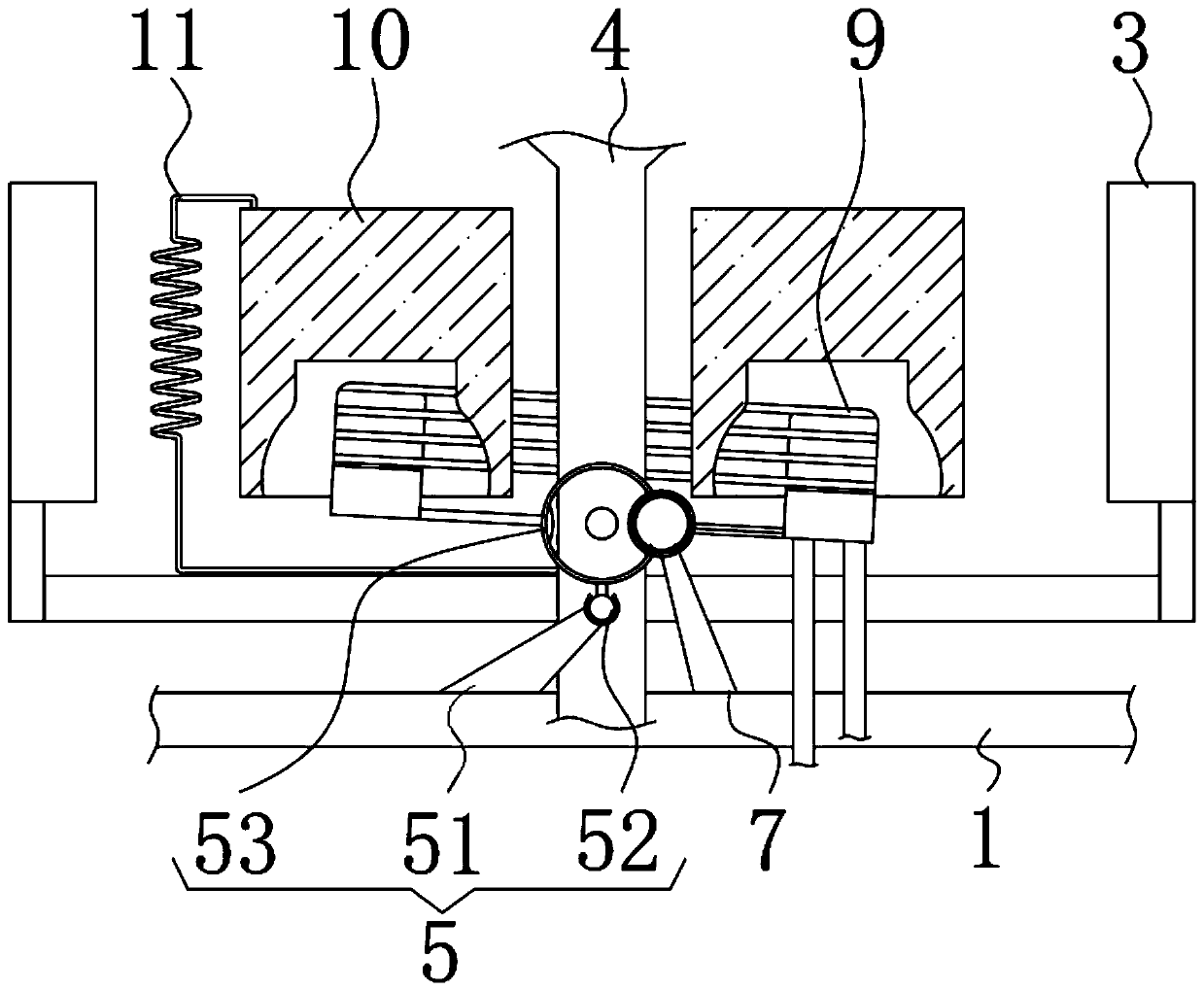

Detection device for automatically fixing pressure regulating valve

InactiveCN112665850AGuaranteed tightnessThe test result is accurateMachine valve testingWork holdersPressure transmissionEngineering

Owner:行唐县雄飞物业管理有限公司

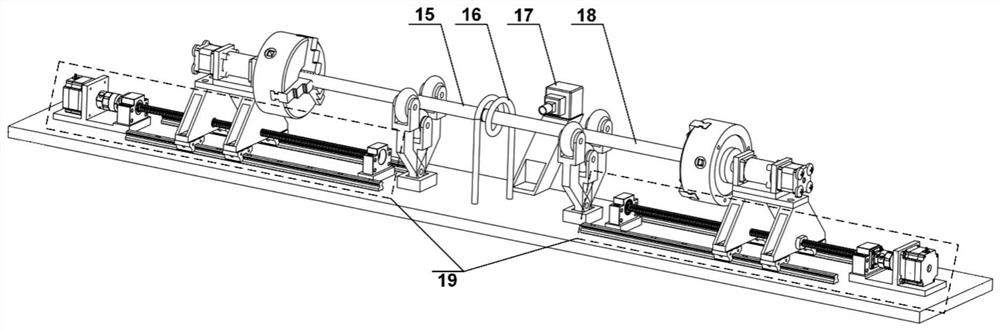

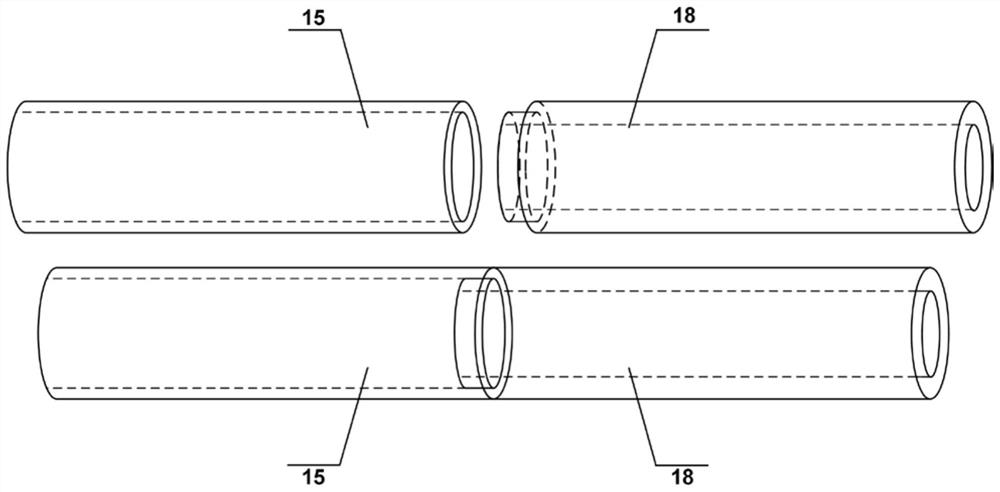

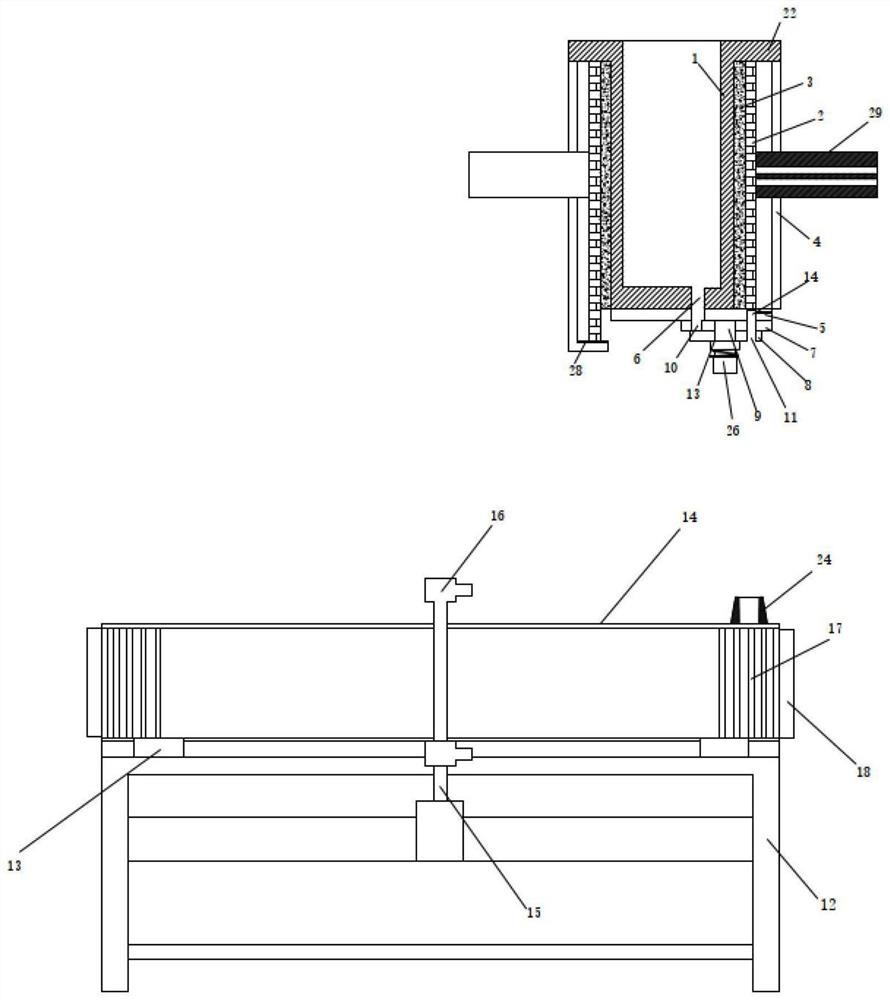

Metal/plastic pipe rotation induction welding device and method

PendingCN113799398ASolution areaSolve the strength problemTubular articlesElectric machineReduction drive

Owner:HARBIN INST OF TECH AT WEIHAI

Plasma installation with a separately transportable vessel

InactiveUS20160287735A1Reduce usageEfficient activationLavatory sanitoryDisinfectionEngineeringInduction coil

Owner:DIENER CHRISTOF HERBERT

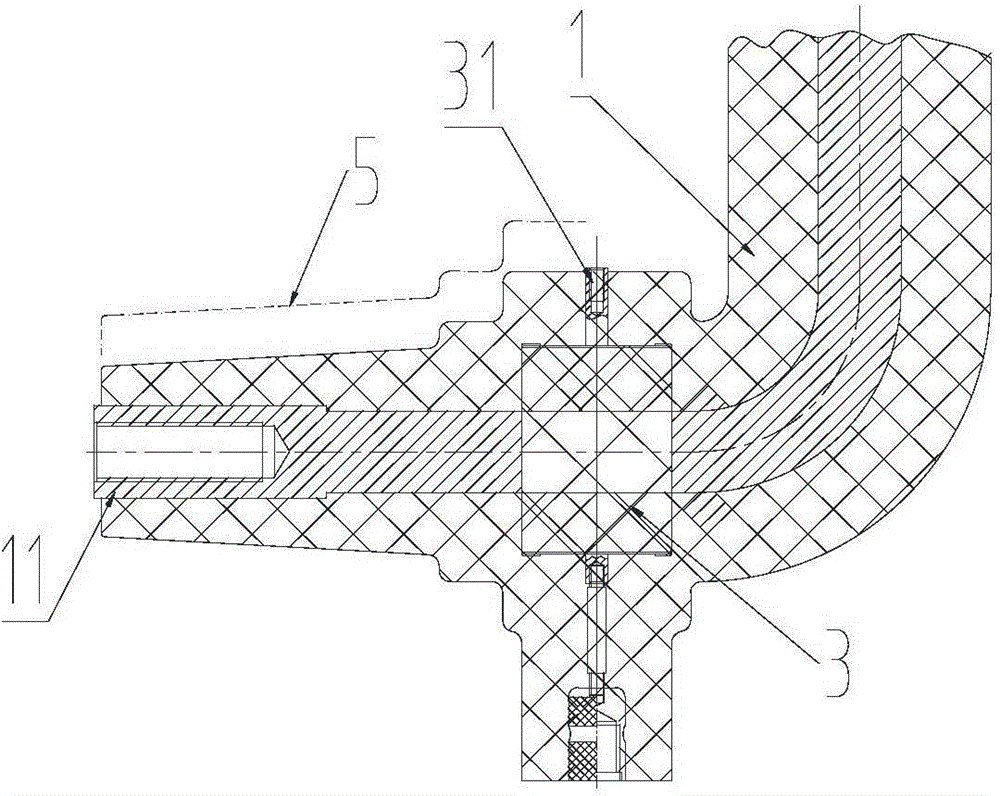

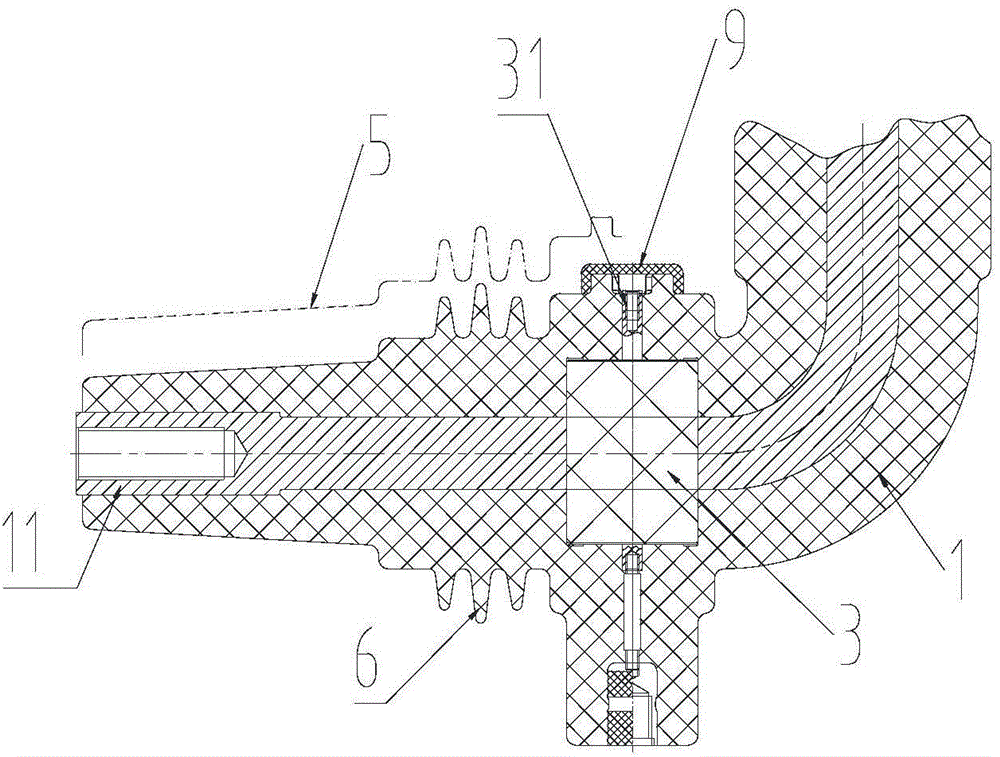

Large creepage distance European joint structure

InactiveCN104917138AExtended service lifeImprove personal safetyCable junctionsElectrical conductorLow voltage

Owner:HANGZHOU SHUGUANG ELECTRIC APPLIANCE

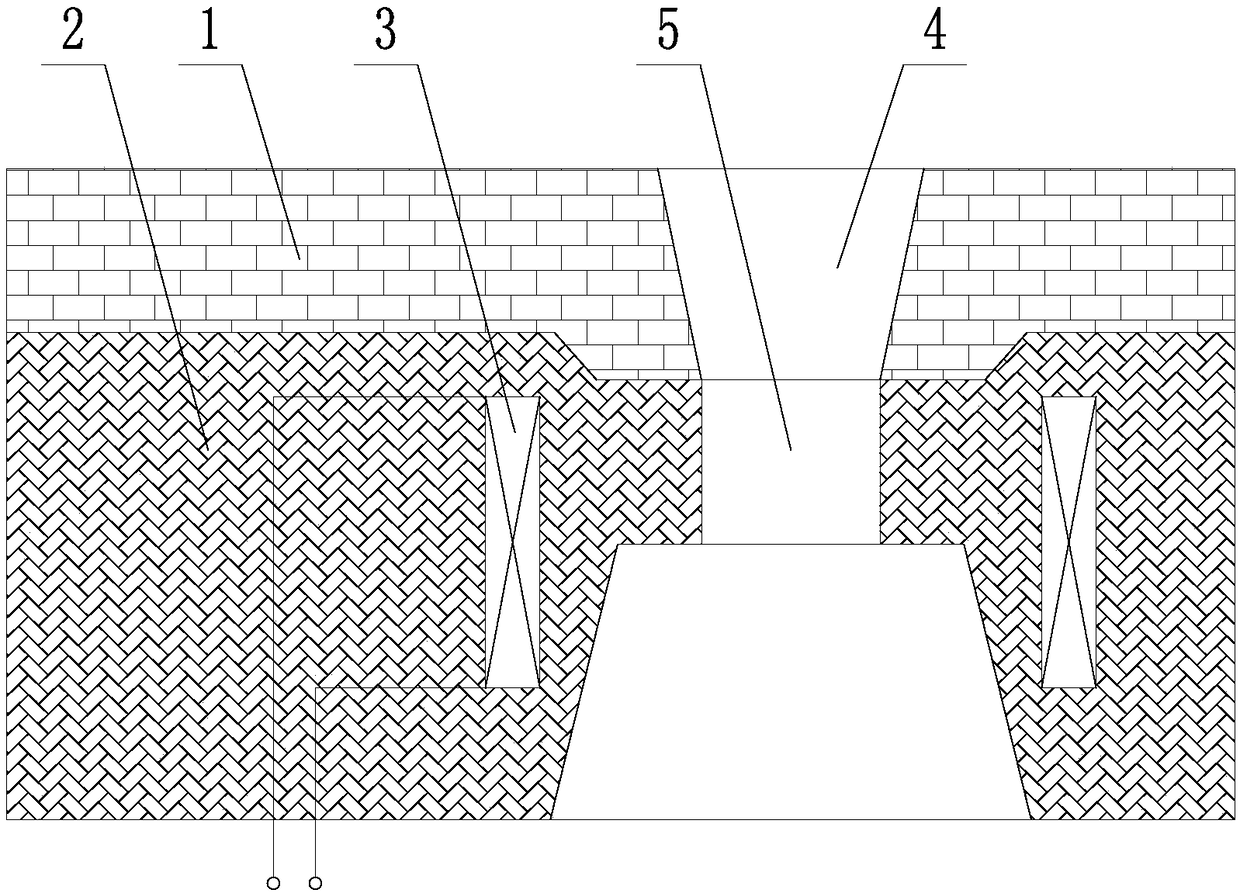

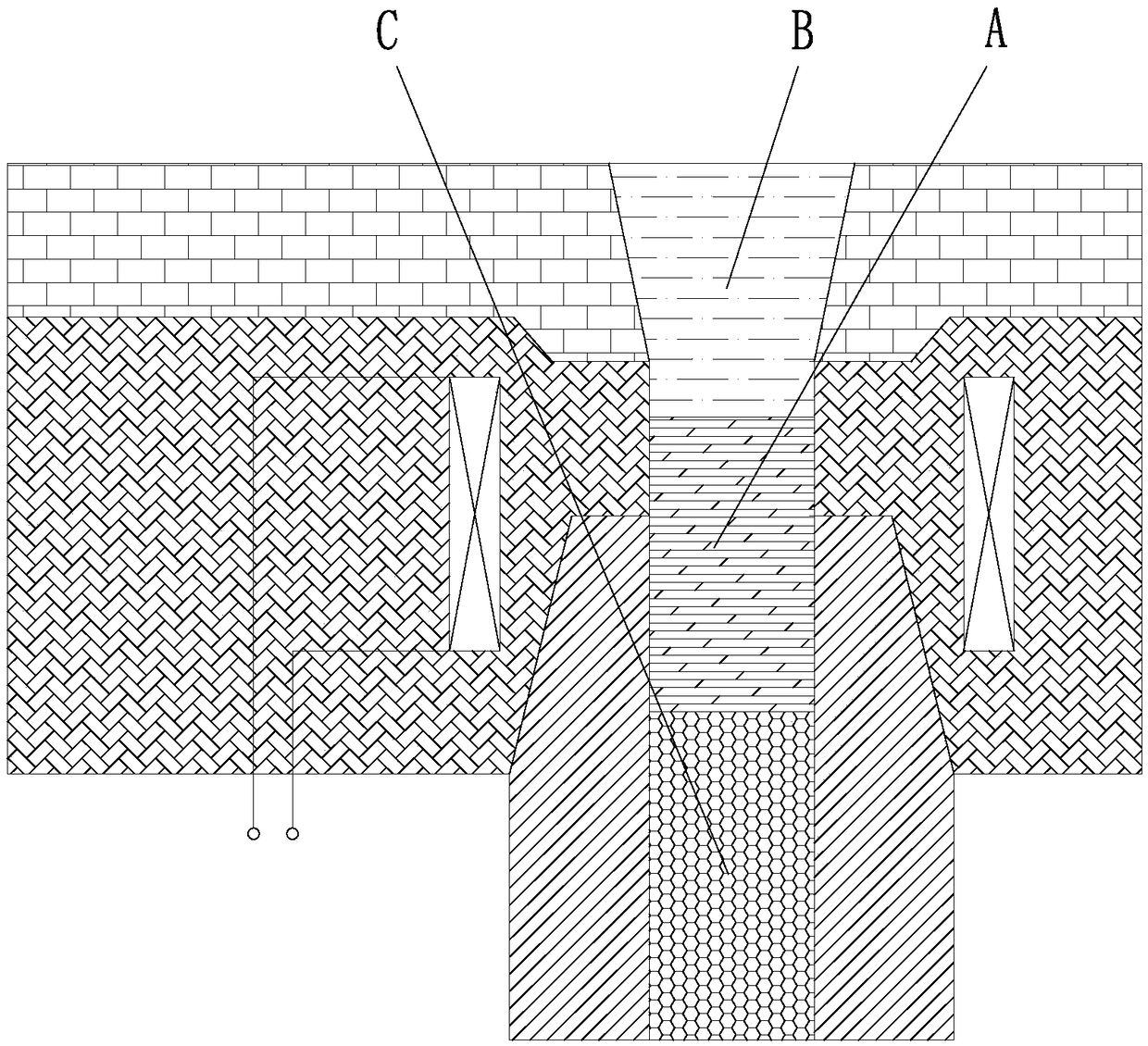

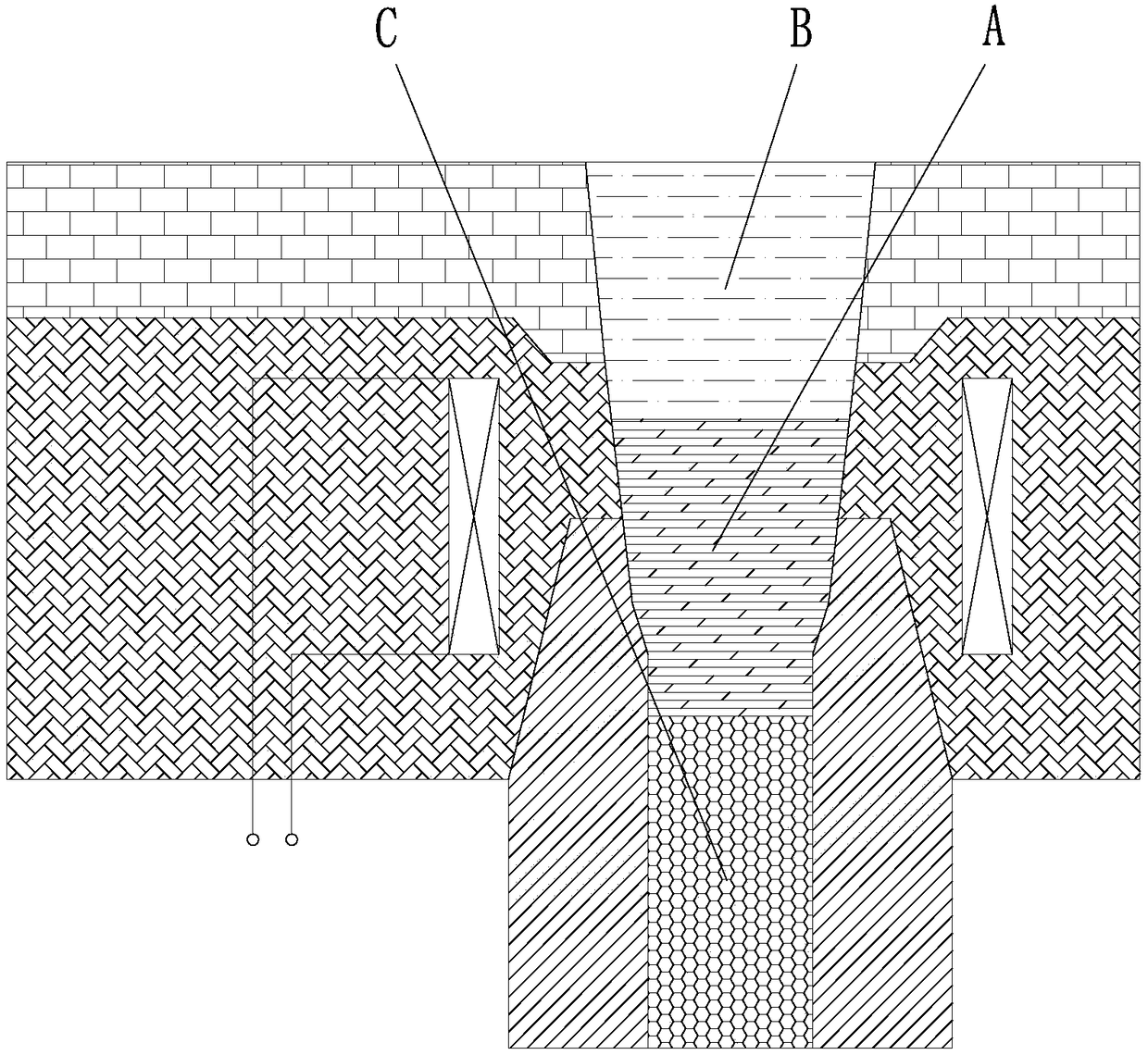

Combined type pocket block based on electromagnetic induction heating tapping technology

ActiveCN108356258ASolve the disadvantages of inability to recover induction coilsAchieve recyclingMelt-holding vesselsEngineeringMolten steel

Owner:NORTHEASTERN UNIV

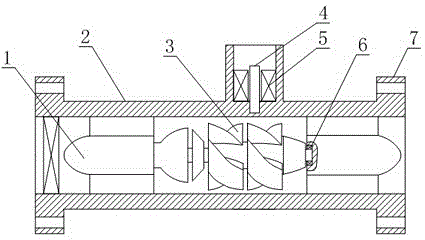

Metering apparatus structure capable of prolong life of flowmeter

Owner:CHENGDU GUOGUANG ELECTRONICS INSTR

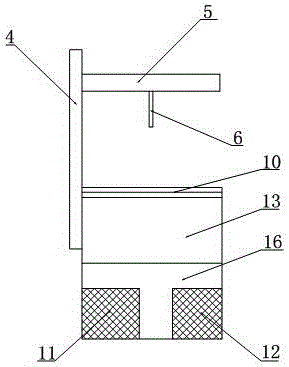

Electronic analytical balance for mass measurement

InactiveCN111579032AIncrease effective lengthSmall sineWeighing apparatus using electromagnetic balancingAnalytical balanceEngineering

Owner:SHANDONG INST FOR FOOD & DRUG CONTROL

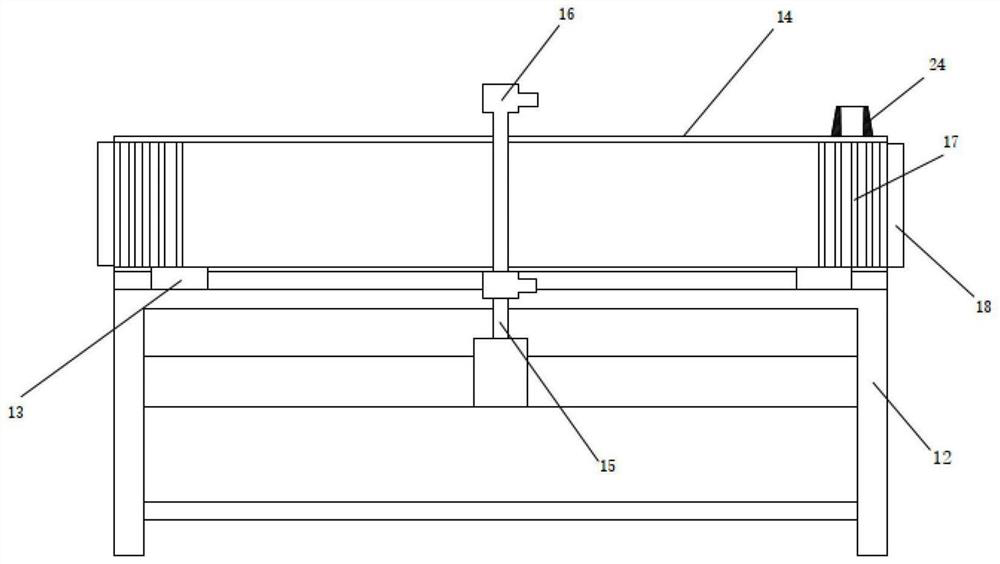

Automatic production system for directional crystallization

ActiveCN114309574ARapid directional cooling crystallizationCasting plantsMolten metal supplying equipmentsThermodynamicsCrucible

Owner:无锡刚正精密吸铸有限公司

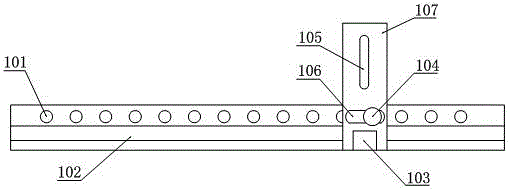

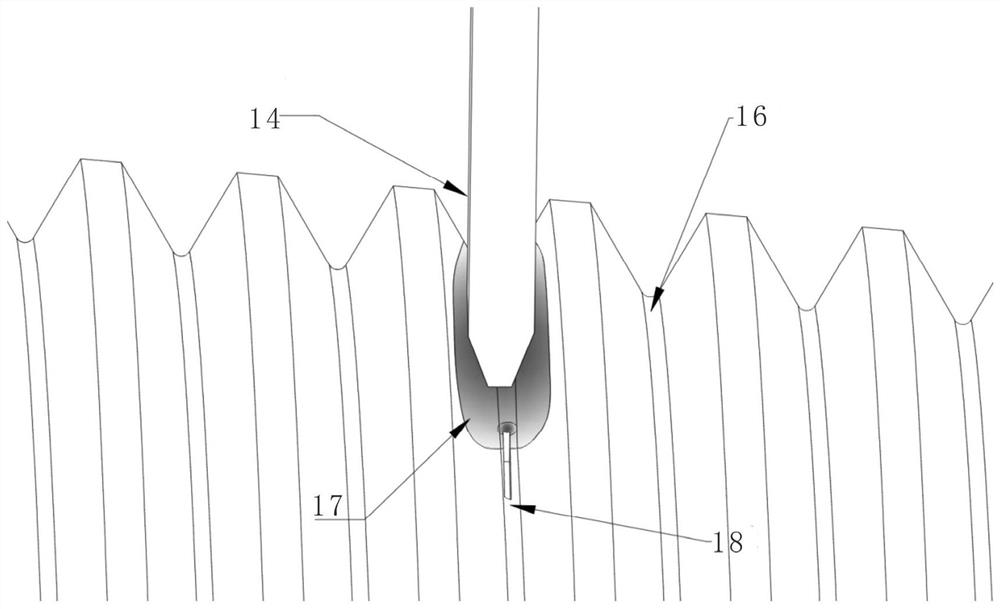

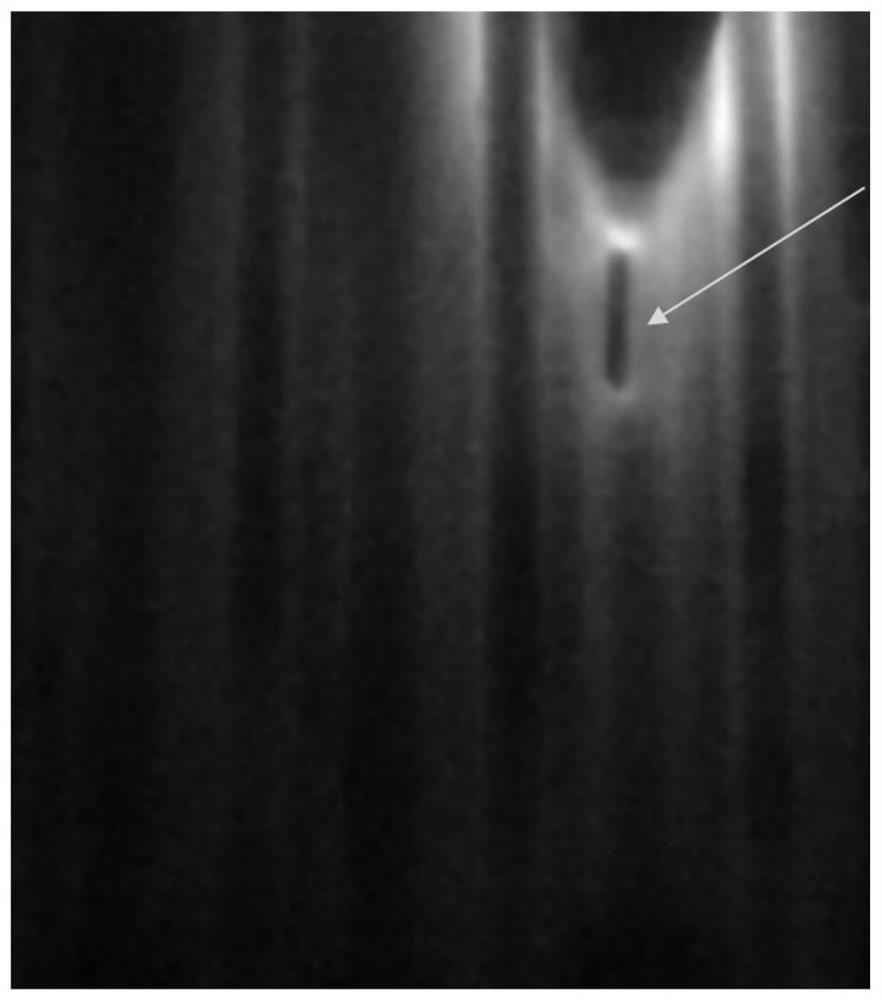

Drill rod thread detection device and method based on ferrite eddy current thermal imaging

PendingCN112114030ANo pollution in the processHigh speedElectric/magnetic position measurementsUsing electrical meansThermographic cameraManganese

Owner:成都鳌峰机电设备有限责任公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap