Induction coil assembly

An induction coil and assembly technology, applied in the direction of coils, printed circuits connected with non-printed electrical components, electrical components, etc., can solve problems such as mutual matching and circuit connection difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with specific examples, so that those skilled in the art can better understand the present invention and implement it, but the given examples are not intended to limit the present invention.

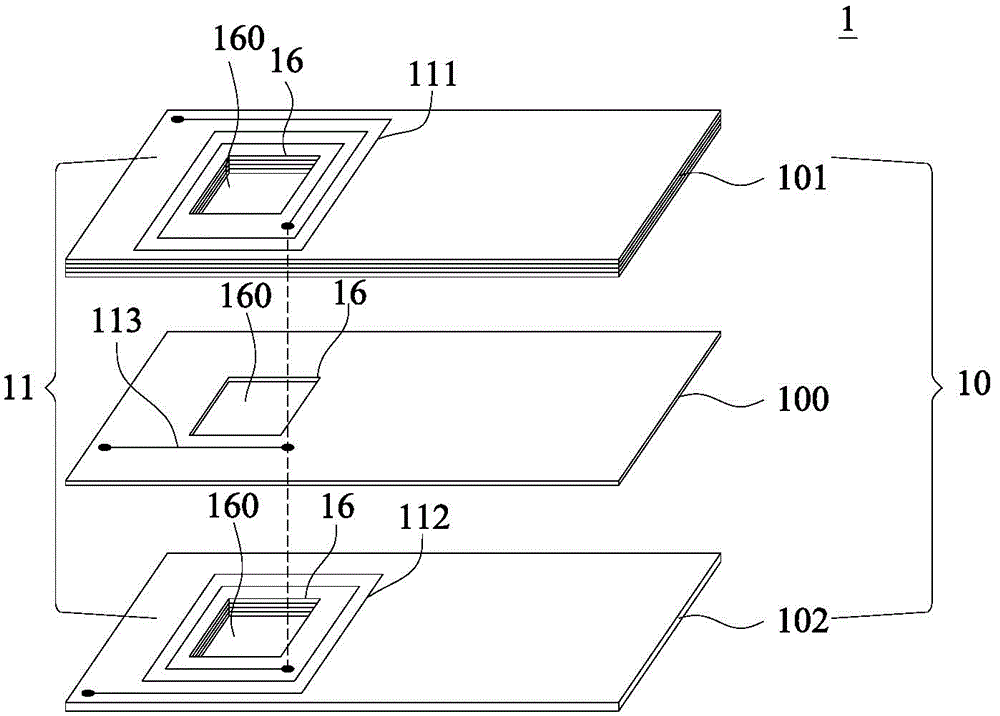

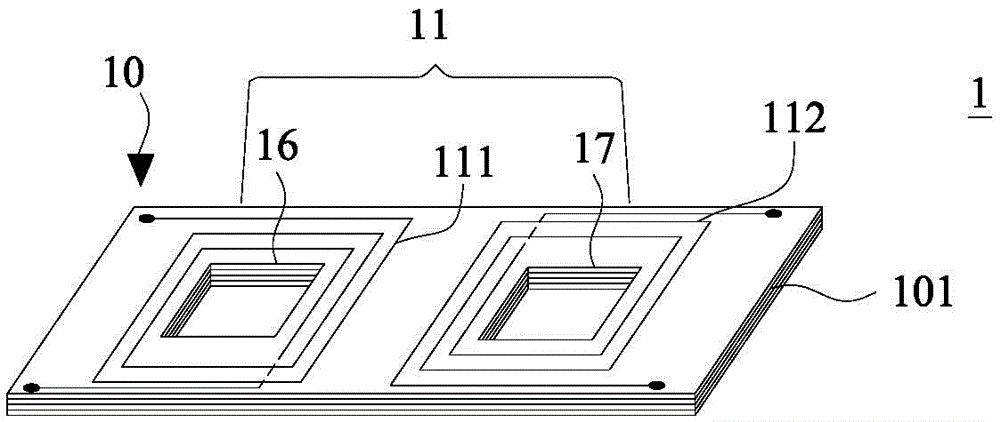

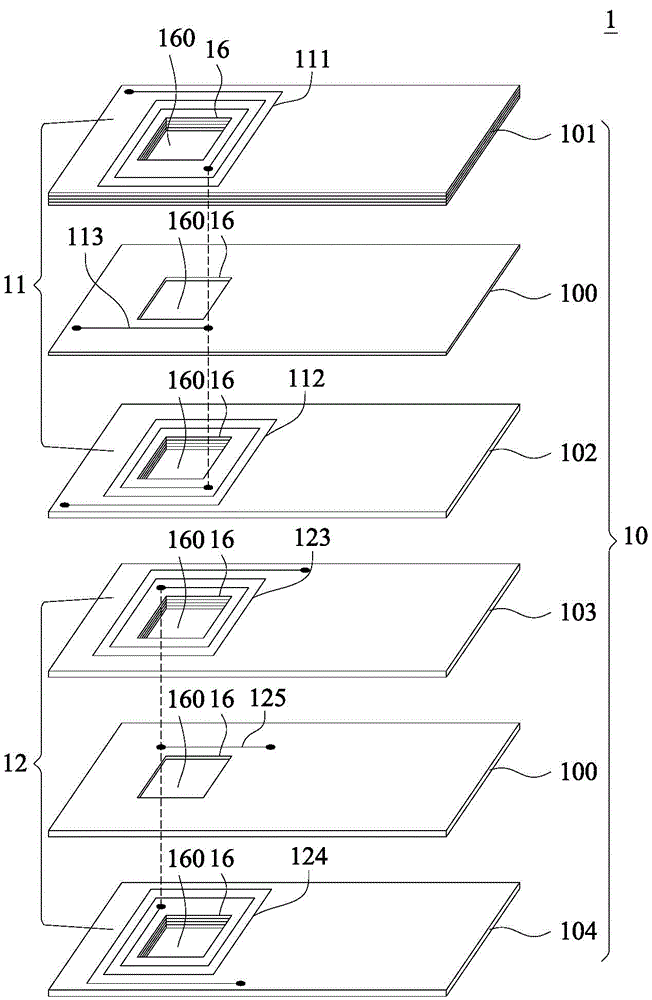

[0053] see figure 1 As shown, an induction coil assembly 1 disclosed in the first embodiment of the present invention includes a printed circuit board 10 and a first planar winding group 11 disposed on the printed circuit board 10 . The printed circuit board 10 has a plurality of circuit layers 100 , and a first block 16 is defined on the printed circuit board 10 . The first planar winding set 11 includes a first planar inductor component 111 , a second planar inductor component 112 and a first tap 113 . Each circuit layer 100 has a first block 16 , and the first block 16 of each circuit layer 100 is aligned with the first blocks 16 of other circuit layers 100 . In addition, the printed circuit board 10 may have a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap