Automatic spraying device applied to SPE film and achieving method of automatic spraying device

A technology of automatic spraying and realization method, applied in the direction of spraying device, spraying device, etc., can solve the problems affecting the uniformity of spraying, adding a large amount of dispersant, affecting the regularity of film formation, etc., to ensure uniformity and avoid uneven temperature distribution Uniformity, the effect of uniform thickness of the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

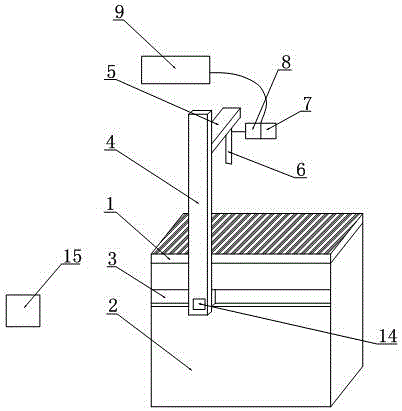

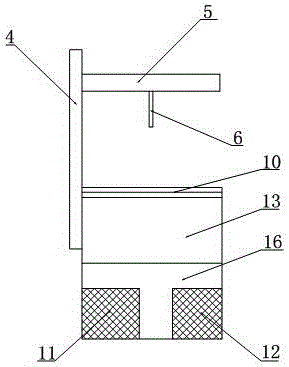

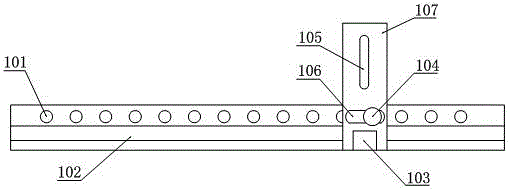

[0047] like figure 1 , 2 As shown, the present invention provides a novel SPE film automatic spraying device, which includes a cabinet 2, a guide rail 3, a catalyst temperature-controlled spraying device, a motor 14 and a PLC control system 15 connected with the motor 14.

[0048]The chassis 2 is divided into three layers from top to bottom, which are the spraying work platform 1, the vacuum chamber 13 and the equipment box 16 in turn, wherein the spraying work platform 1 is used to place the film fixture (for fixing the SPE film), and on the table A sintered porous titanium plate is provided, and an induction coil is evenly embedded in the table; a vacuum pump 12 for evacuating the vacuum chamber to form a negative pressure state and a vacuum pump 12 connected with

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap