Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14 results about "Crank" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A crank is an arm attached at a right angle to a rotating shaft by which reciprocating motion is imparted to or received from the shaft. It is used to convert circular motion into reciprocating motion, or vice versa. The arm may be a bent portion of the shaft, or a separate arm or disk attached to it. Attached to the end of the crank by a pivot is a rod, usually called a connecting rod (conrod). The end of the rod attached to the crank moves in a circular motion, while the other end is usually constrained to move in a linear sliding motion.

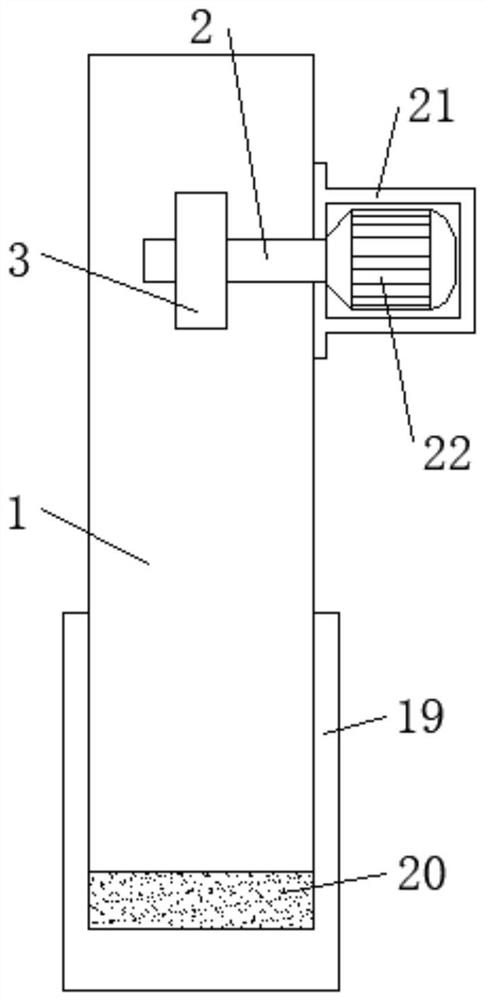

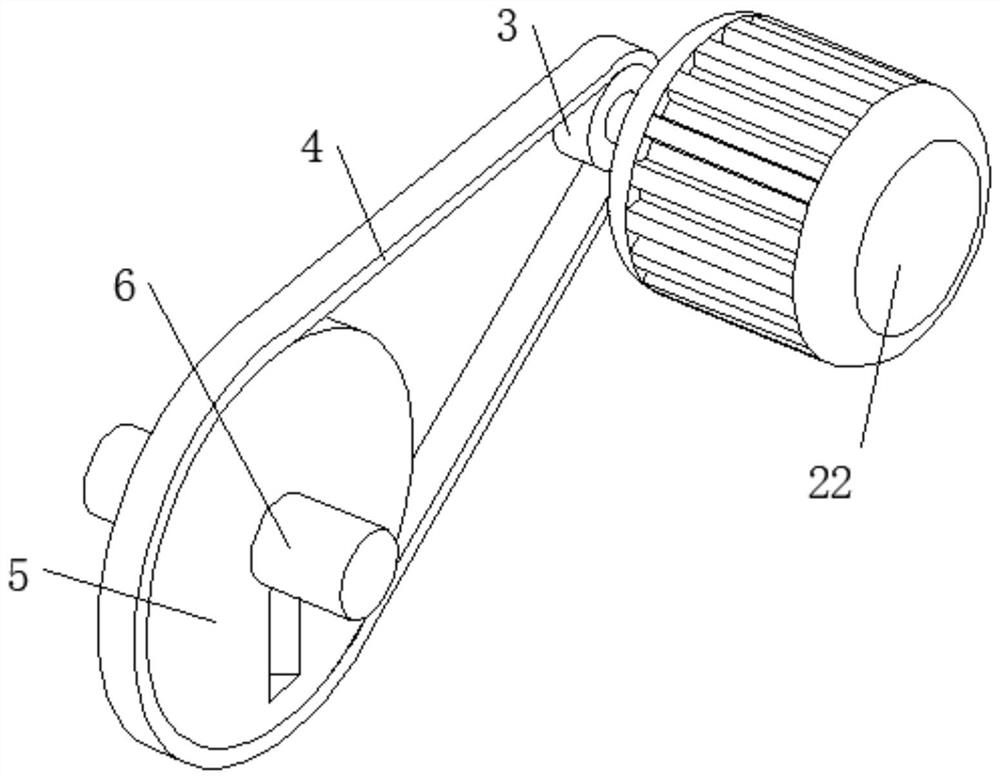

Oil pumping unit dynamic balance timely automatic regulating device and control method thereof

InactiveCN102817588AImprove adaptabilityImprove convenienceFluid removalAuto regulationDynamic balance

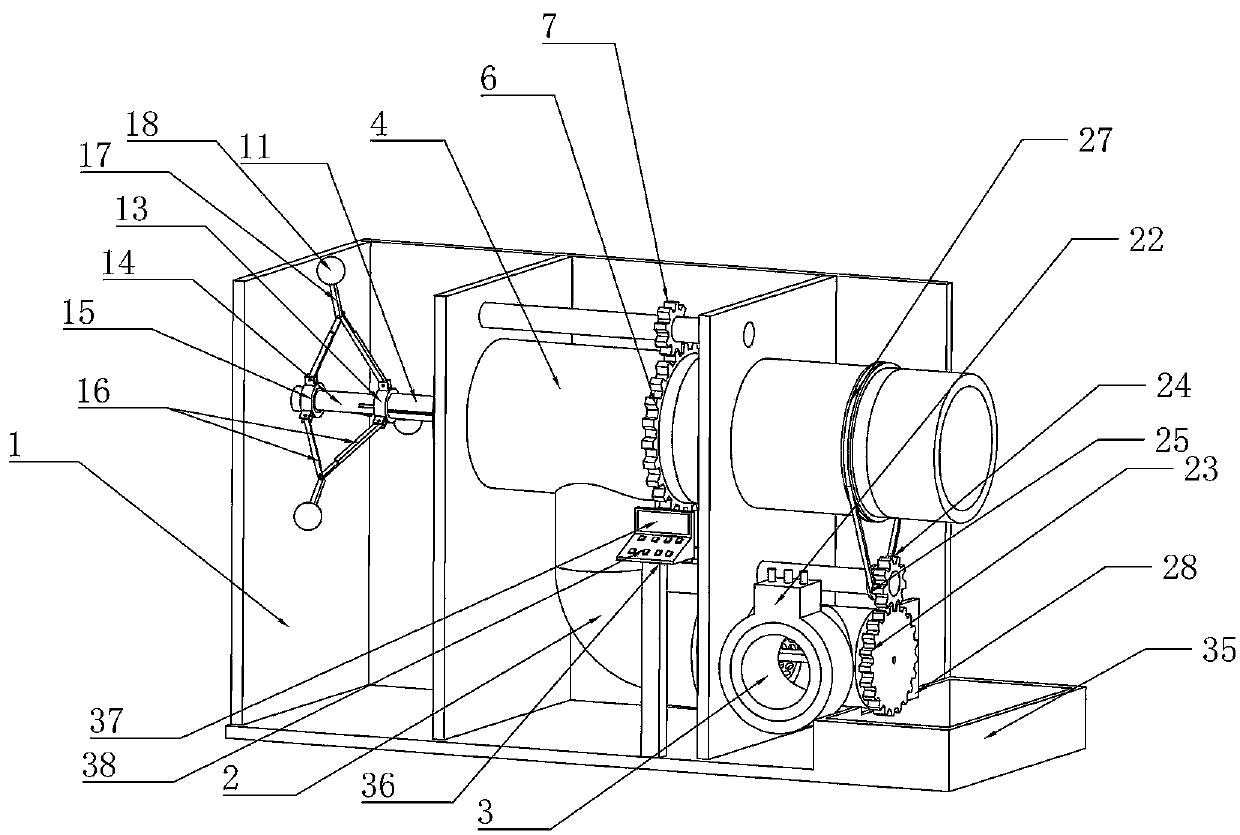

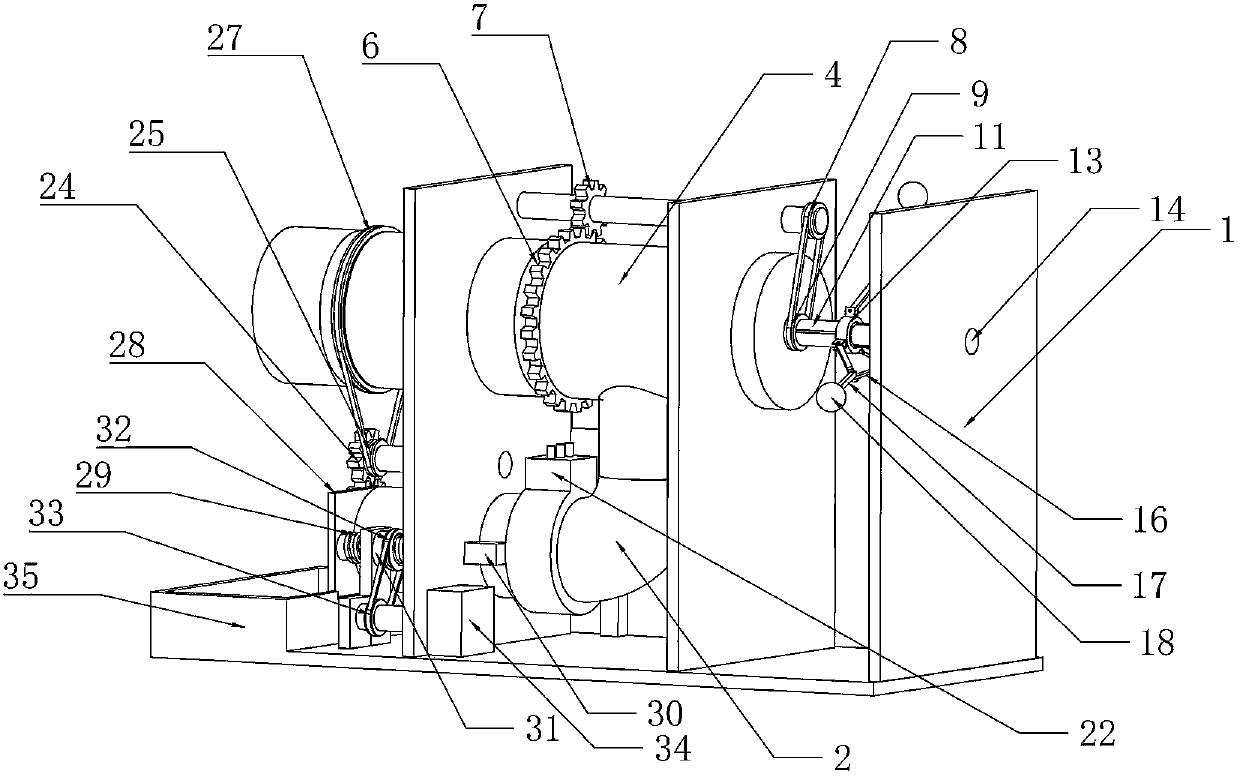

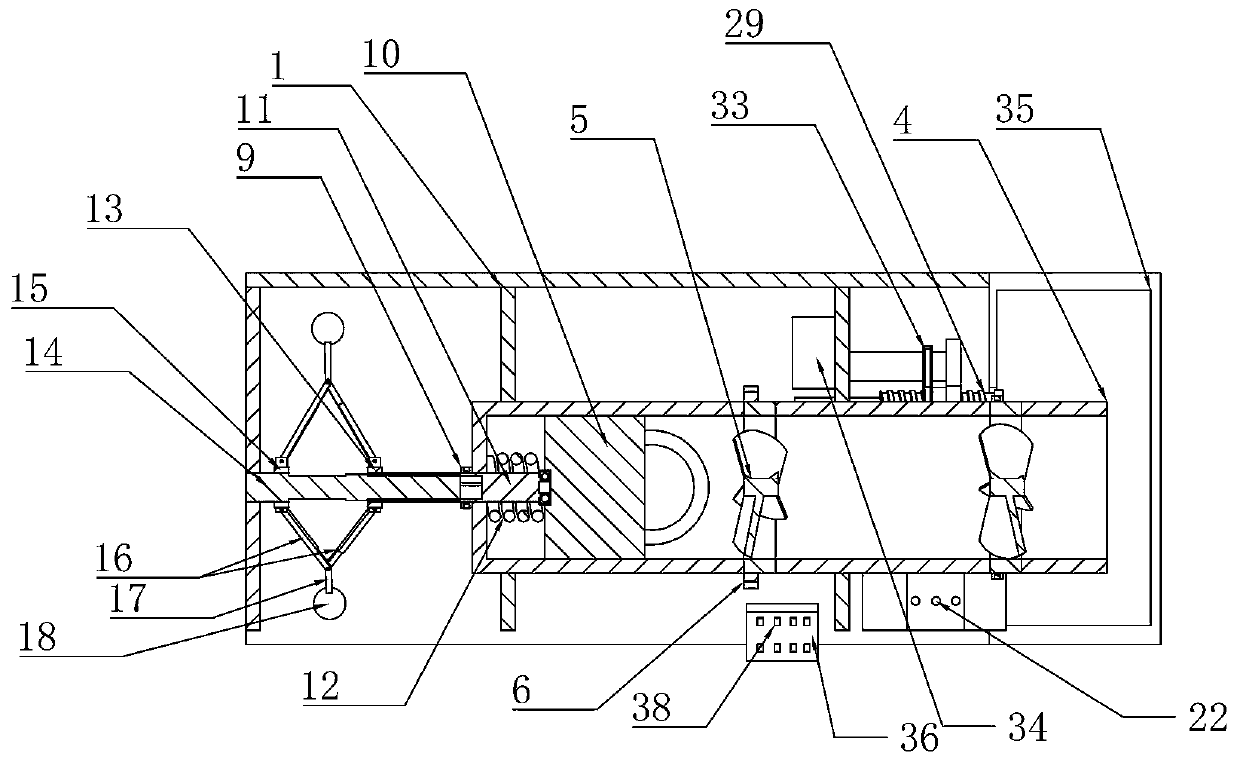

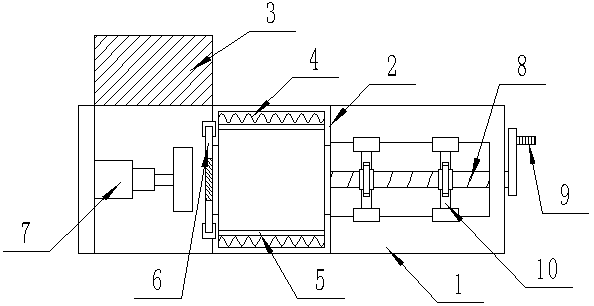

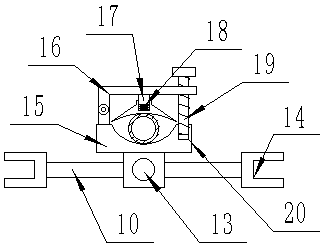

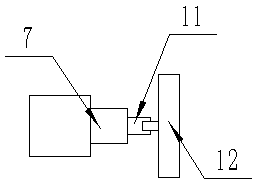

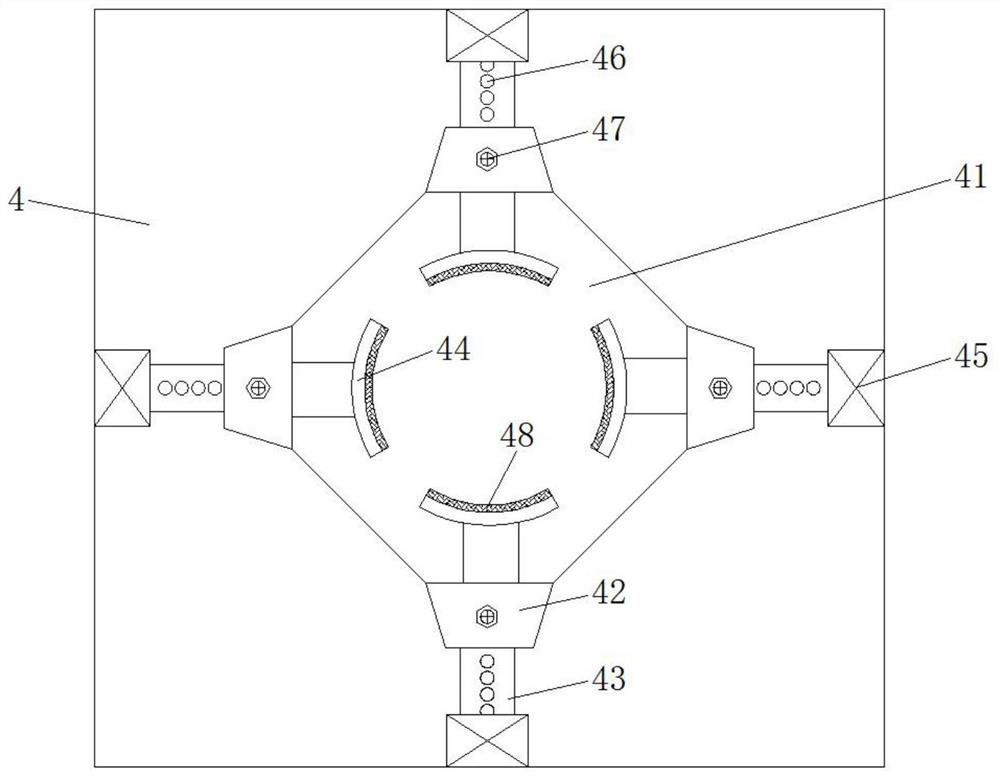

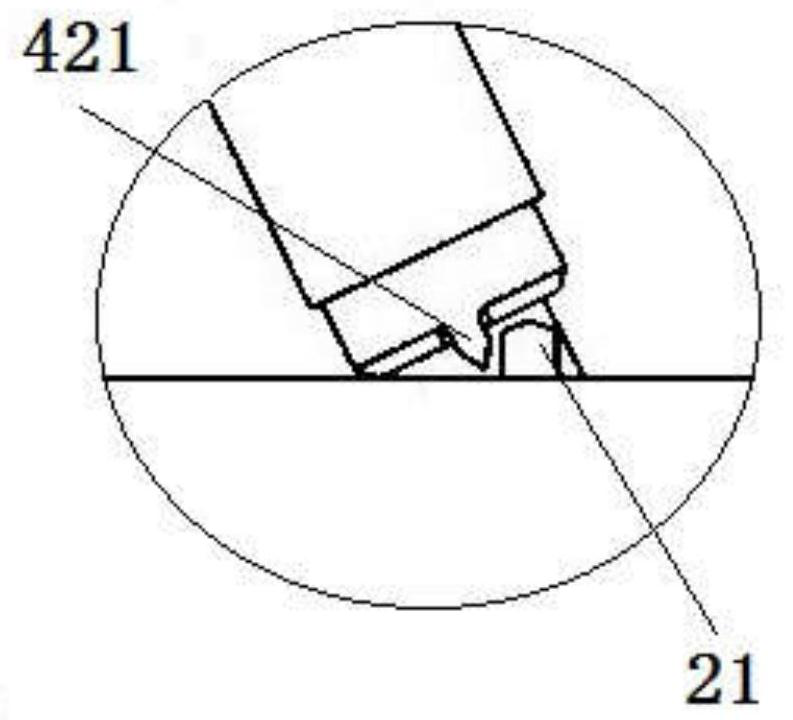

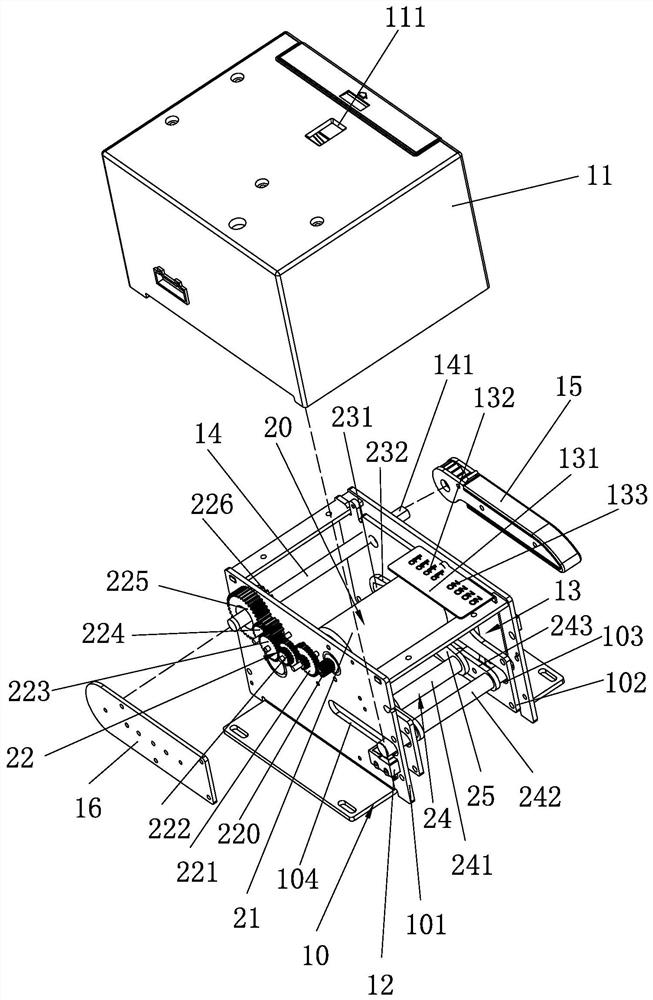

The invention provides an oil pumping unit dynamic balance timely automatic regulating device and a method for improving an existing oil pumping unit with a crank and a fixed balance weight by utilizing the device. According to the oil pumping unit dynamic balance timely automatic regulating device, an adjustable balance weight part of the oil pumping unit dynamic balance timely automatic regulating device is arranged on the side surface of the crank, the adjustable balance weight part timely moves on the side surface of the crank so as to excellently regulate the dynamic balance of an oil pumping unit, further, the adjustable balance weight part comprises a carrier and one or a plurality of balance weights, the carrier can move along the crank side surface, the one or the plurality of balance weights is / are detachably arranged on the carrier, a hydraulic mechanism drives the carrier, a control device with a central processing unit (CPU) microprocessor detects the dynamic balance of the oil pumping unit and timely controls the hydraulic mechanism, then the timely dynamic balance control of the oil pumping unit is achieved, thereby the control capacity of the oil pumping unit dynamic balance is improved, simultaneously the electrical energy is saved, and the production cost is reduced.

Owner:孙显清

Automation control device for fluid flow speed

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Variable-diameter flaring machine for PVC pipe production

Owner:江苏万隆管业有限公司

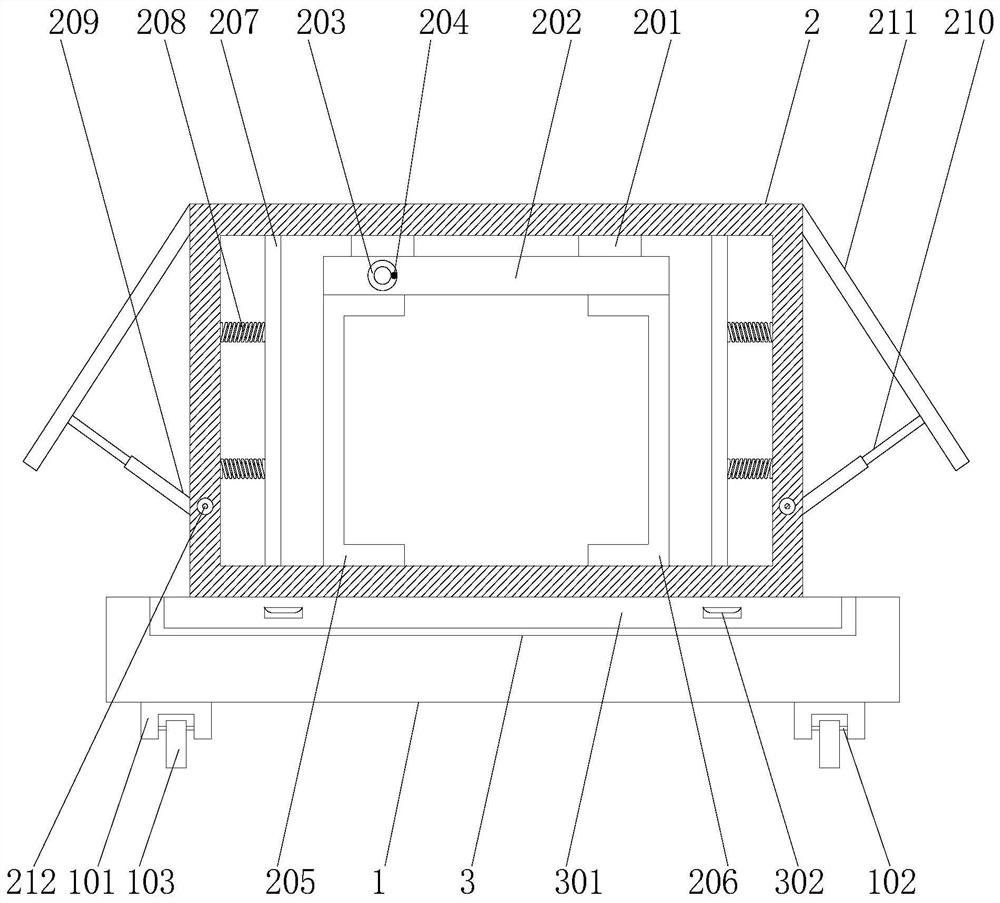

Mounting base for industrial robot and mounting method thereof

Owner:NANJING NIEBO INTERNET OF THINGS TECH CO LTD

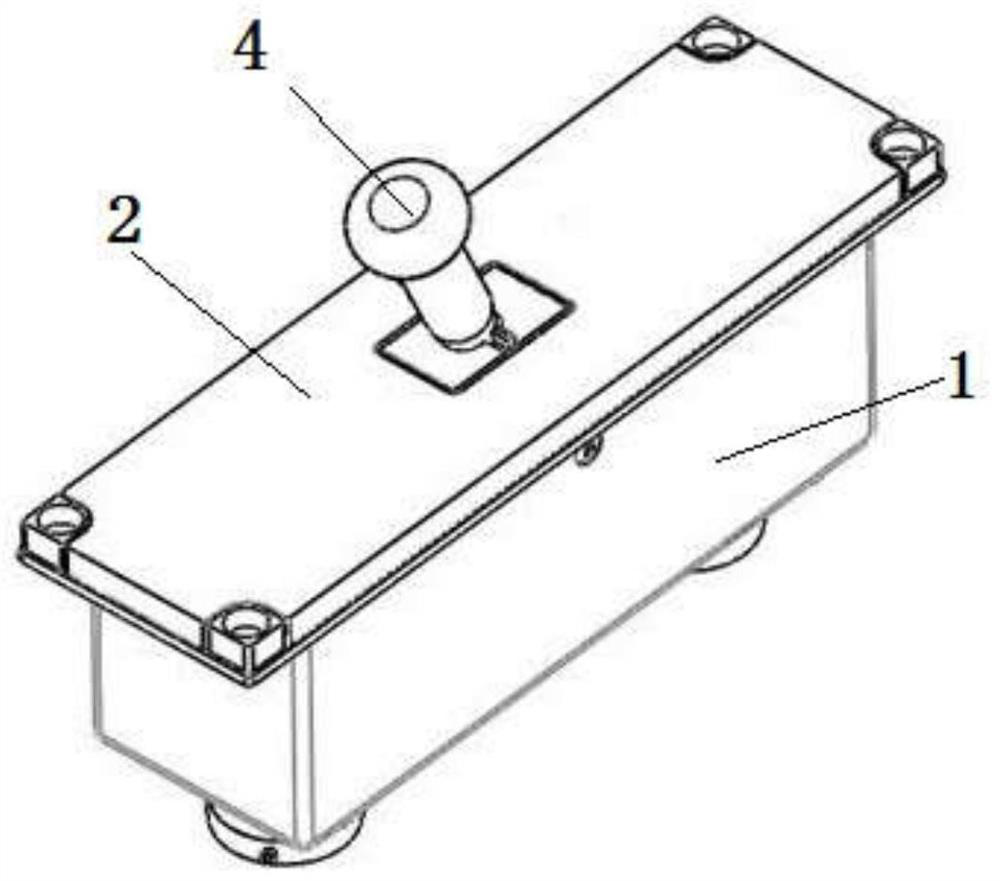

Dual-mode switch box

PendingCN112271096AGood anti-misoperation performanceEasy wiringTumbler/rocker switch detailsSwitch boxCrank

Owner:沈阳兴华航空电器有限责任公司

Electric operating mechanism of molded case circuit breaker

PendingCN112542363ASimple structureReliable transmissionProtective switch operating/release mechanismsElectric machineCrank

Owner:ZHEJIANG ALST ELECTRICAL

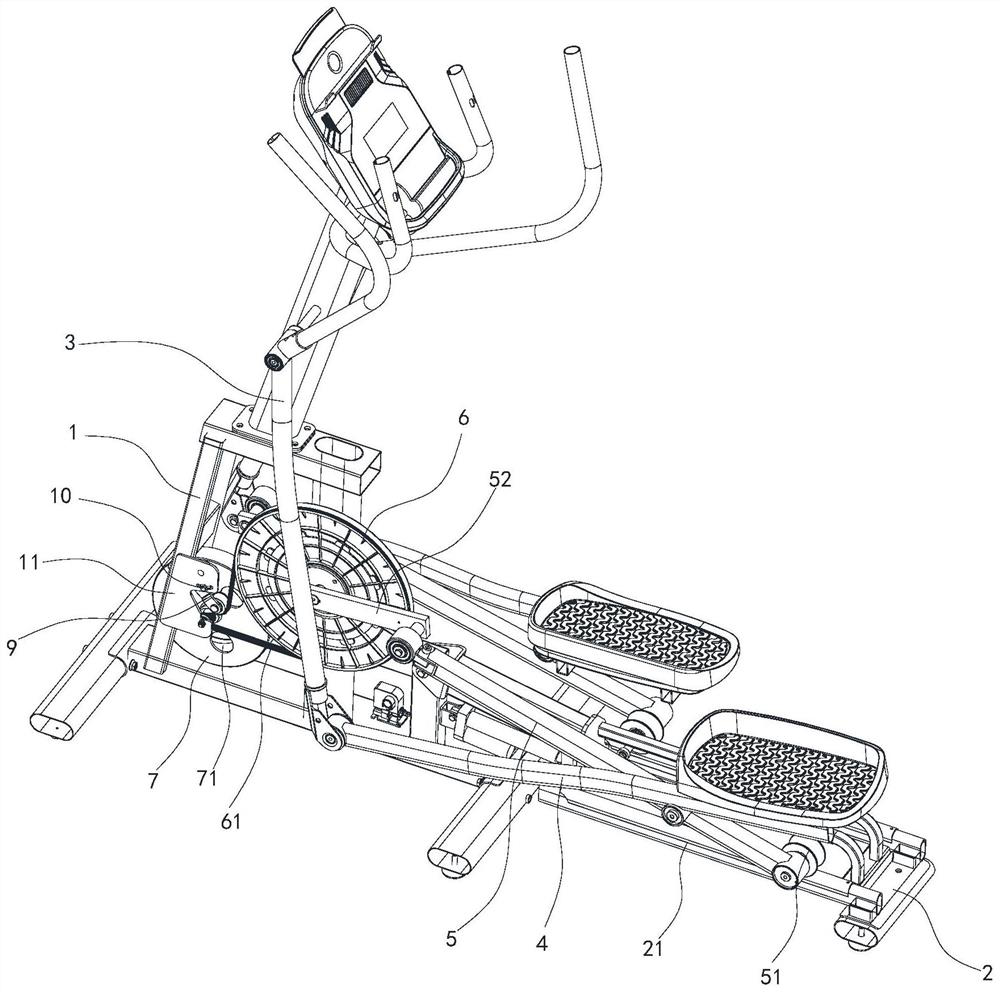

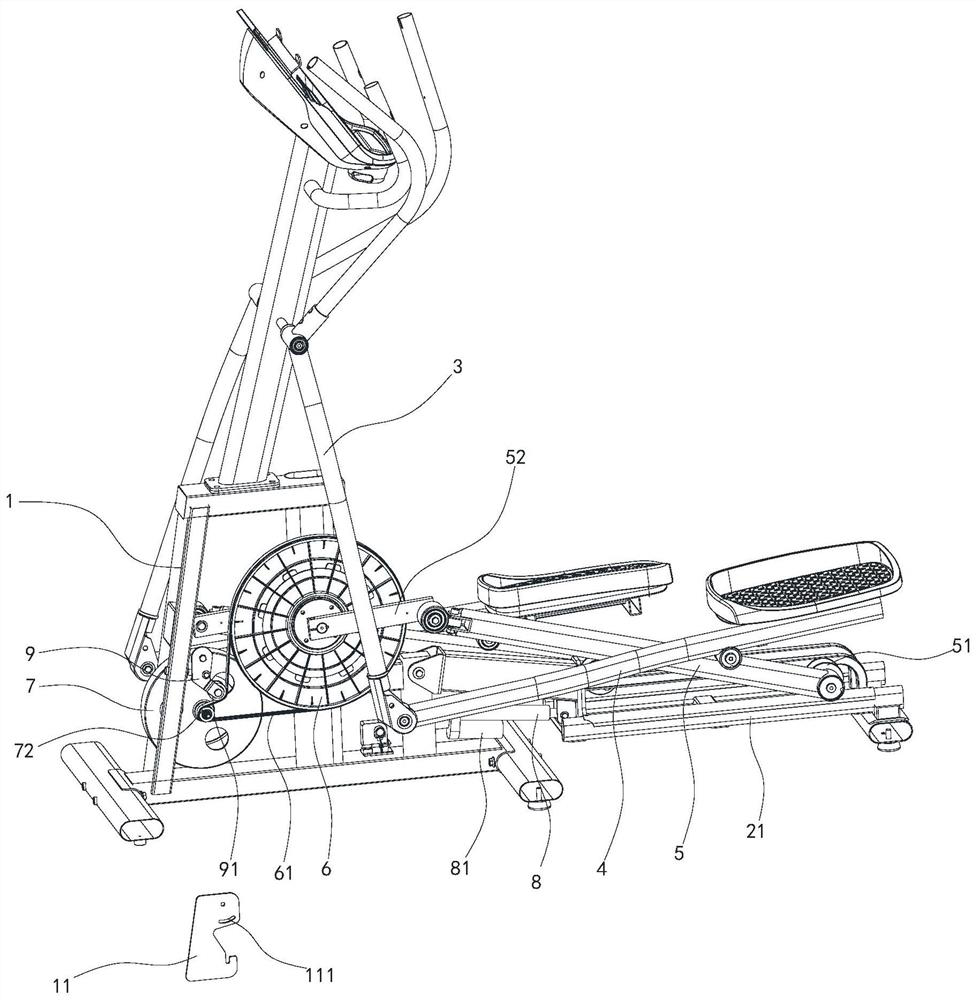

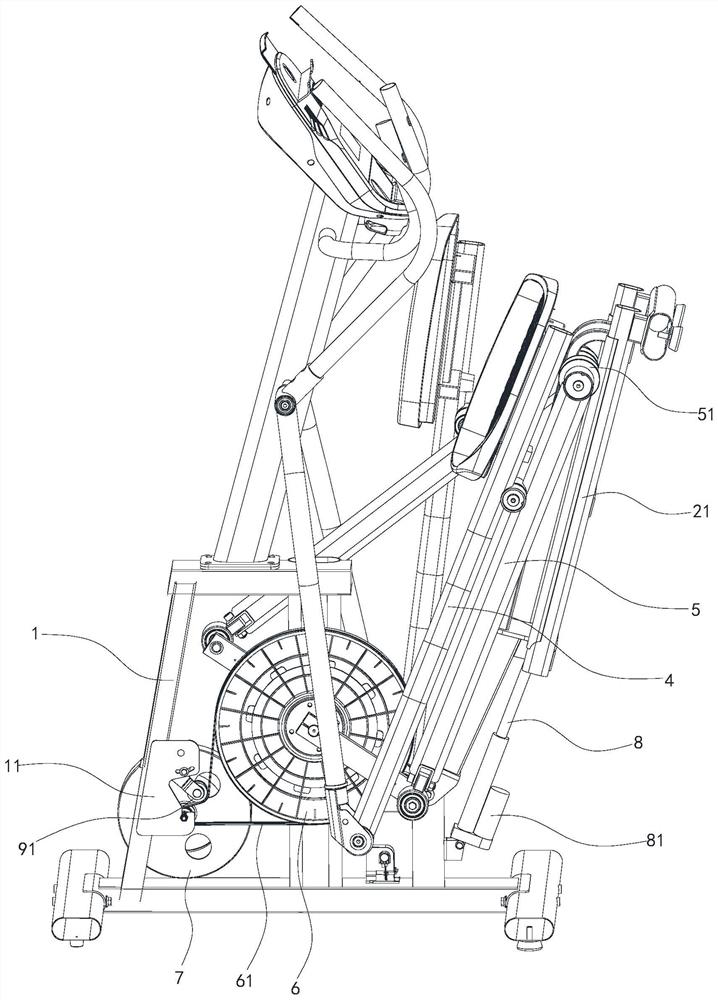

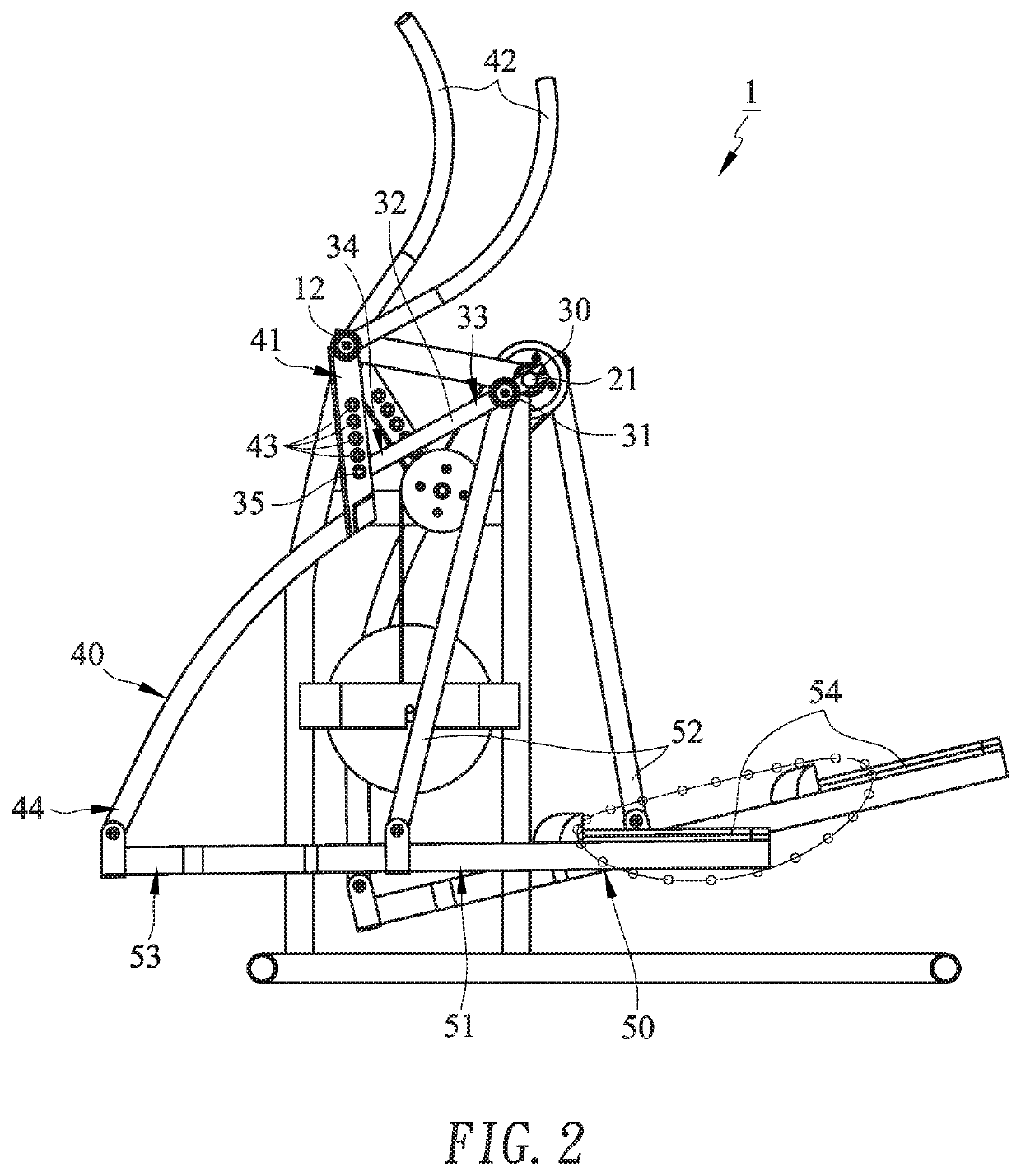

Elliptical machine

Owner:ZHEJIANG EVERBRIGHT IND

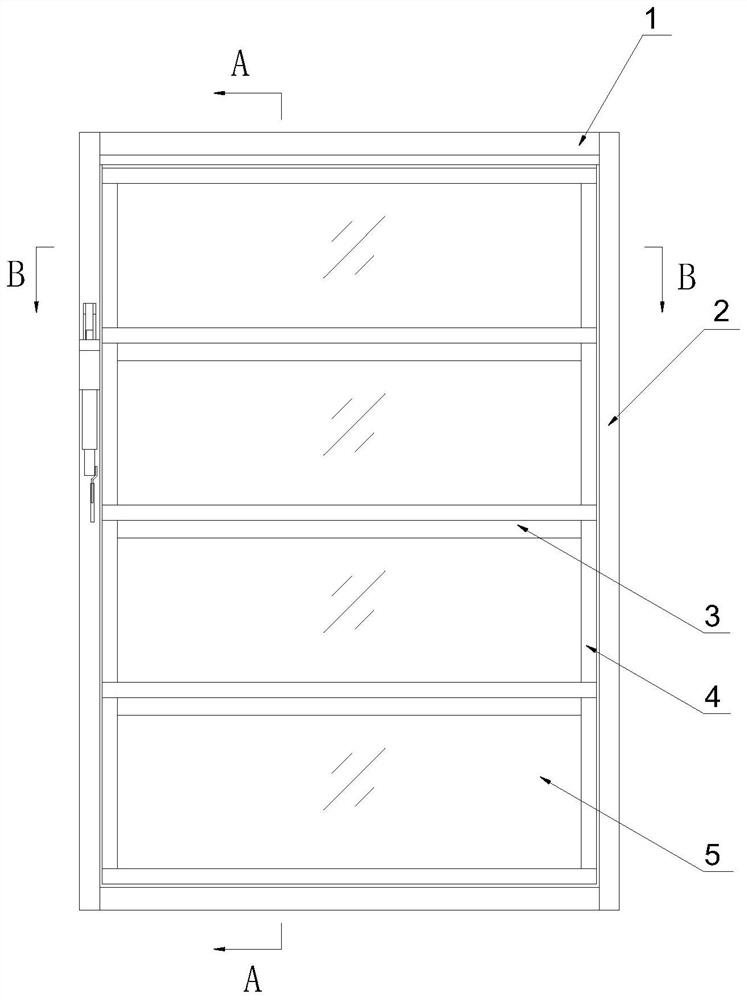

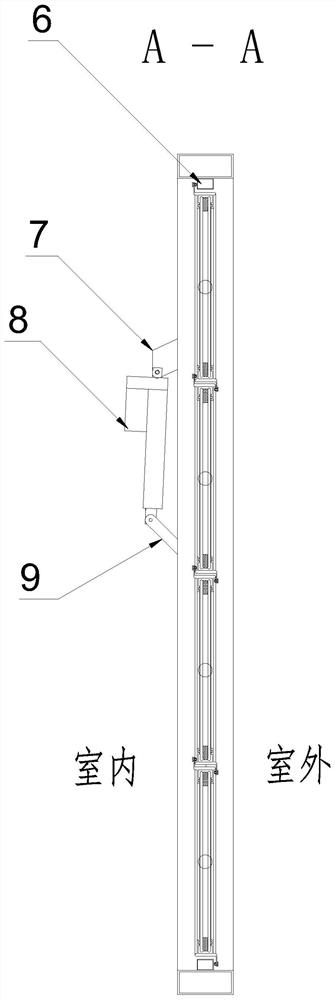

Hollow glass shutter

Owner:BEIJING XINGJUFANGYUAN AUTOMATIC DOORS & WINDOWS TECH CO LTD

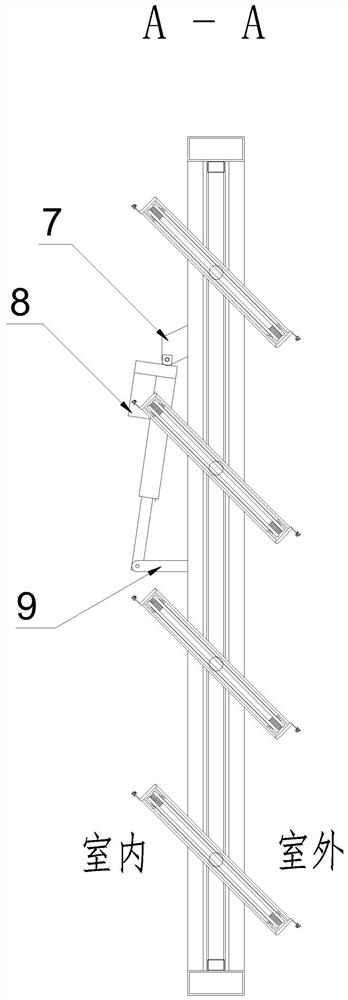

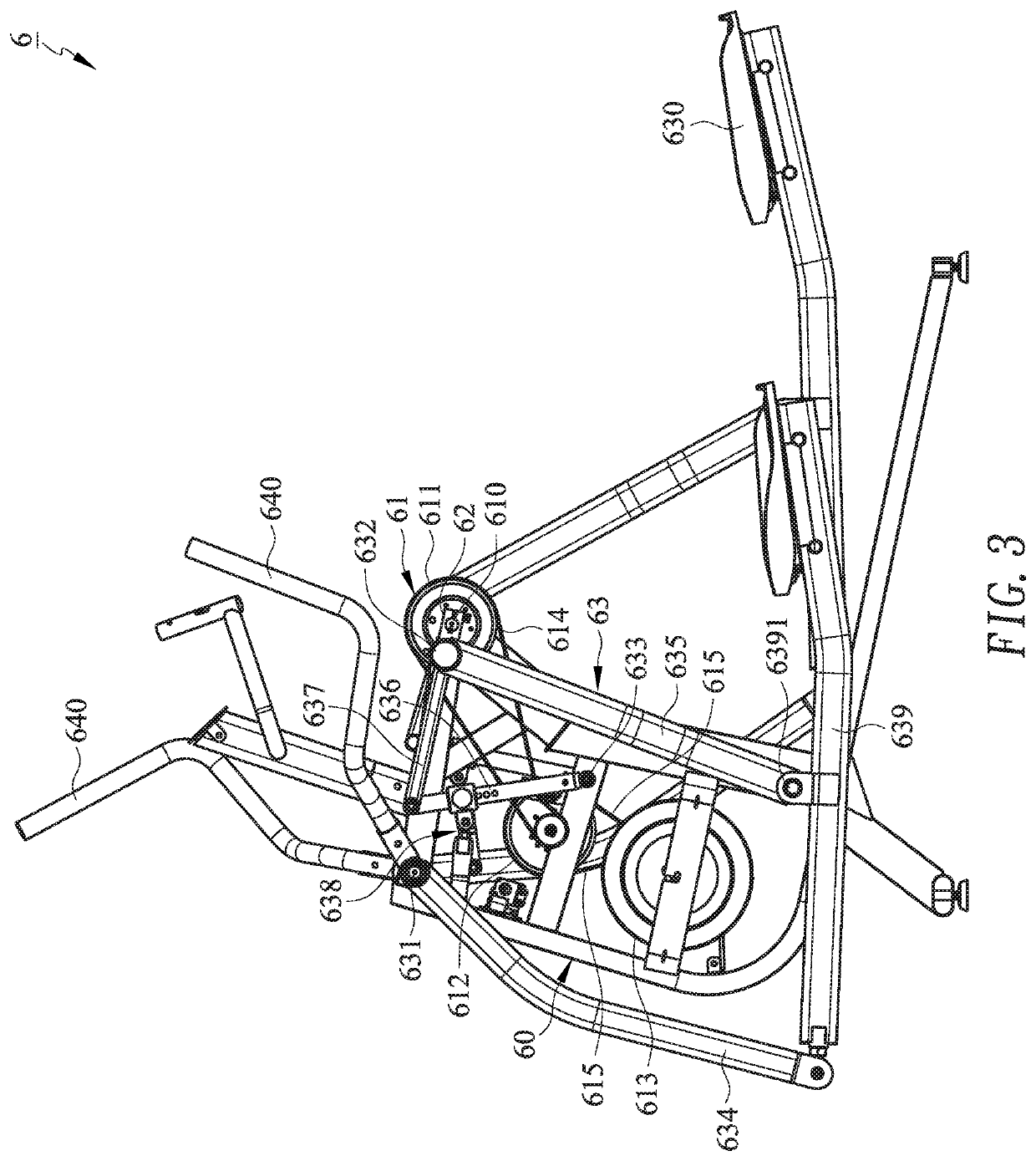

Elliptical trainer

Owner:DYACO INT INC

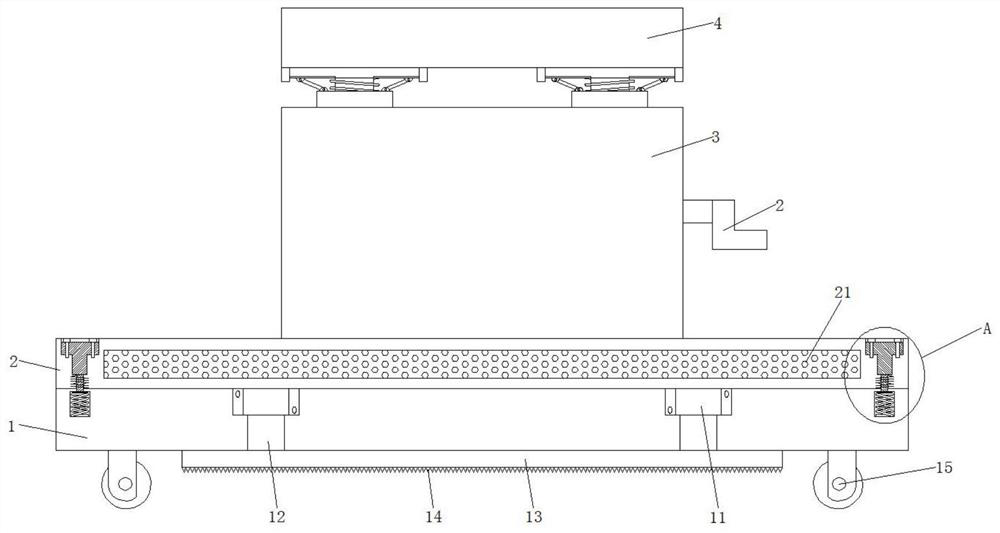

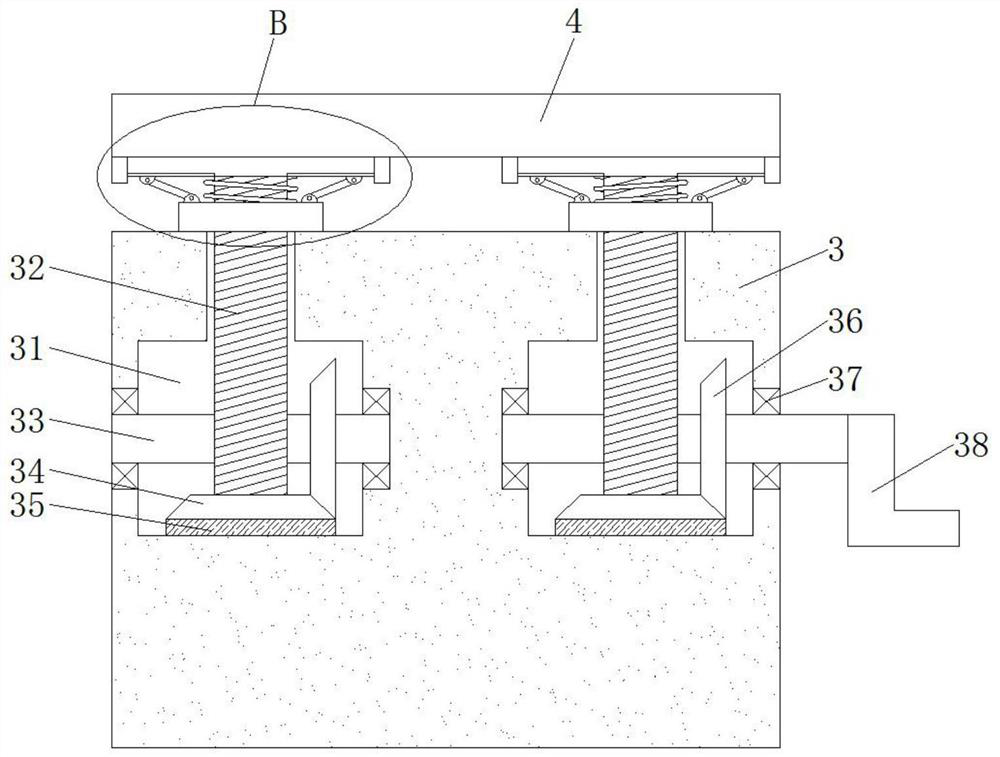

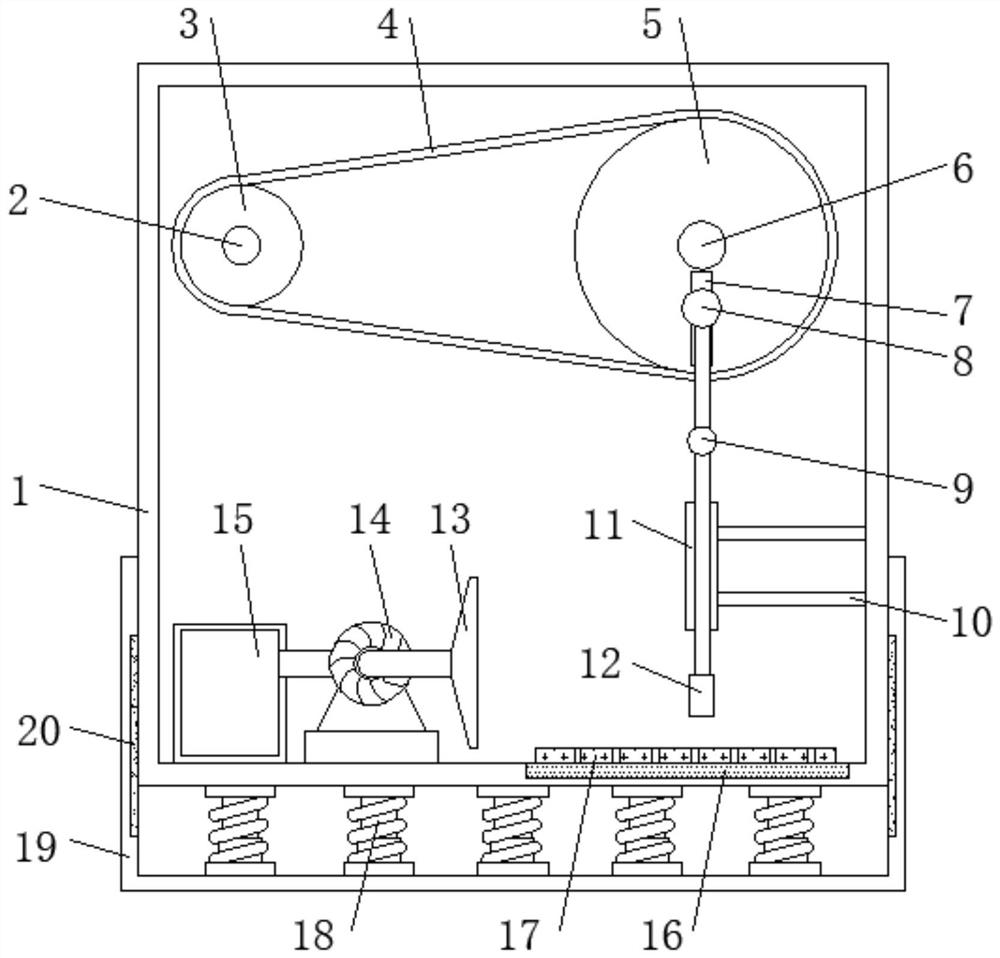

Uniform heating equipment for cylindrical workpiece

PendingCN112247065AEvenly heatedAvoid the effects of oxidative decarburizationHeating/cooling devicesCrankEngineering

Owner:欧阳建福

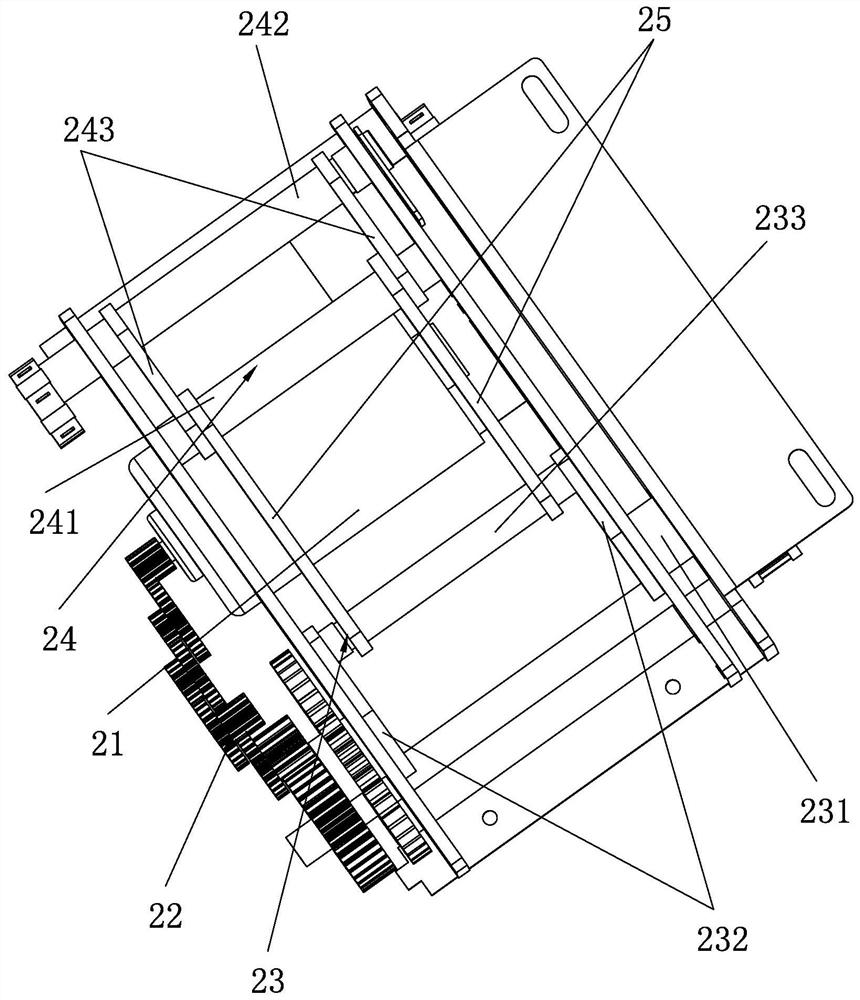

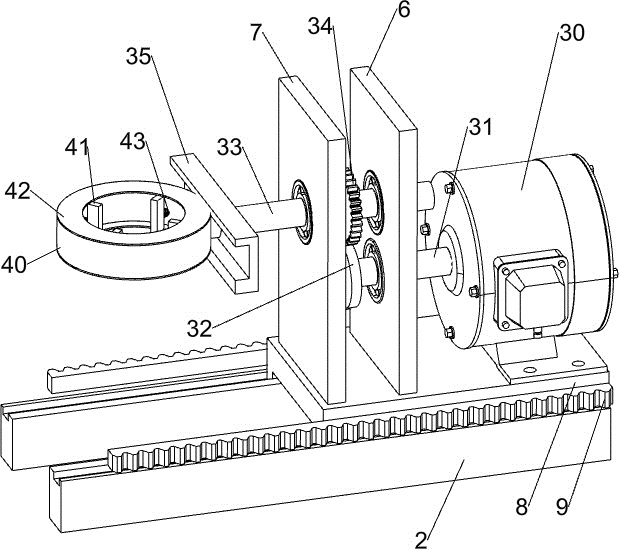

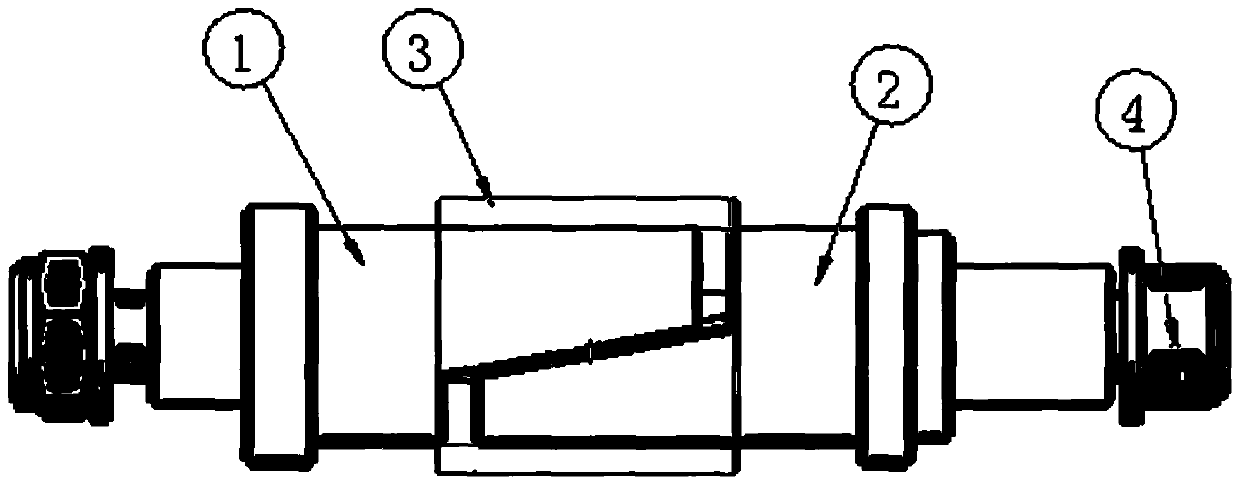

Middle shaft structure of exercise bicycle

InactiveCN110917570AMovement coordination devicesCardiovascular exercising devicesJackshaftRolling-element bearing

Owner:青岛艺格运动器材有限公司

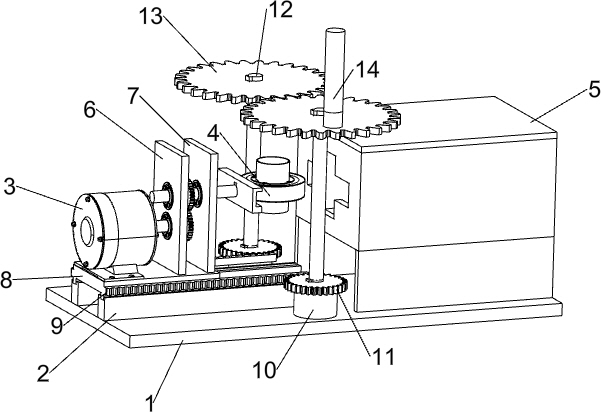

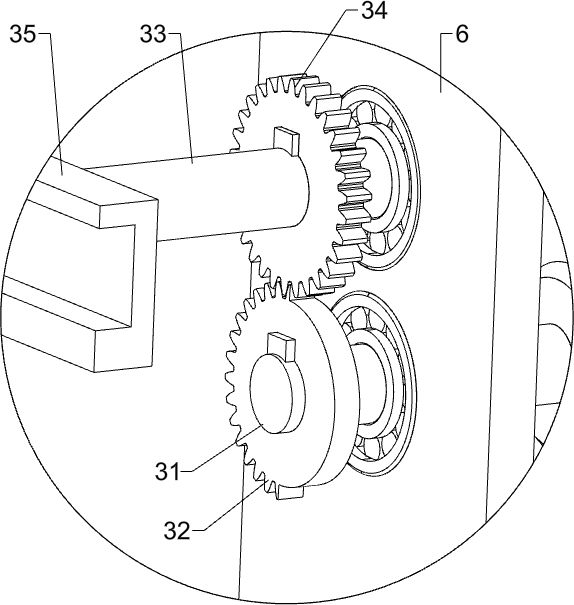

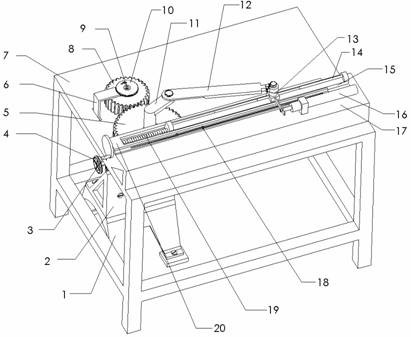

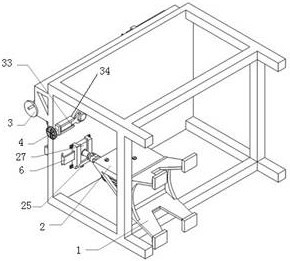

Experimental method for backlash characteristic of experiment platform

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

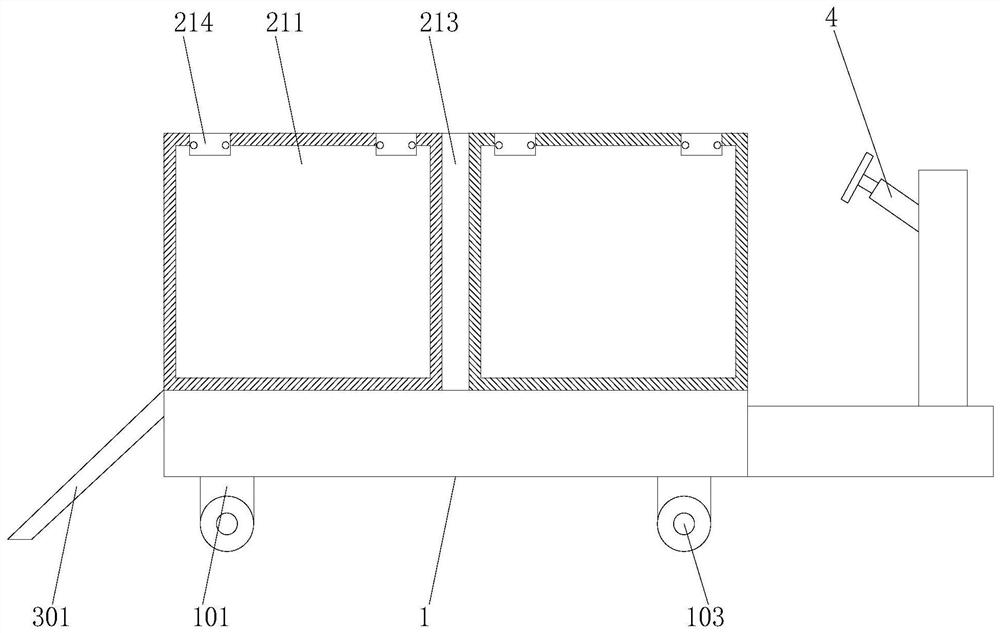

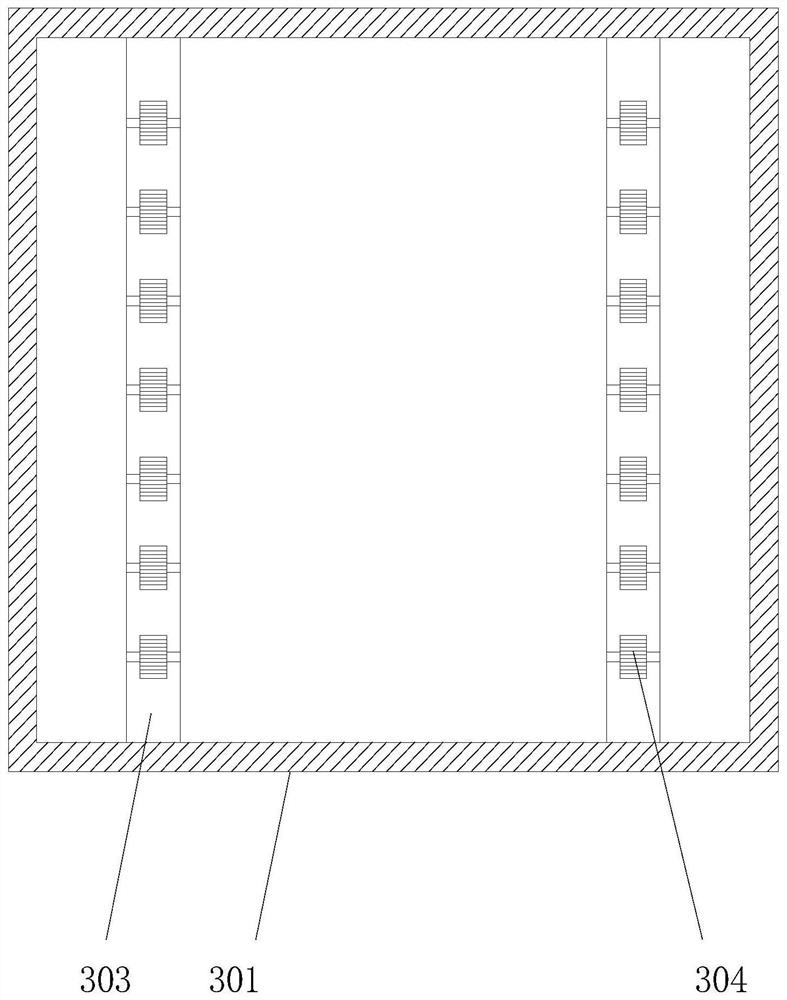

Carrying truck for red brick production

Owner:娄底国盛新型建材有限公司

Adjustable stamping equipment for hardware product machining

Owner:江门市冠奇不锈钢制品有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap