Dual-mode switch box

A switch box, dual-mode technology, applied in the aerospace field, can solve problems such as affecting the reliability of life-saving products, greatly affecting the electronic components, reducing the overall life of the product, etc., to improve the anti-electromagnetic environment interference ability, and the internal structure is compact. , the effect of simple wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings.

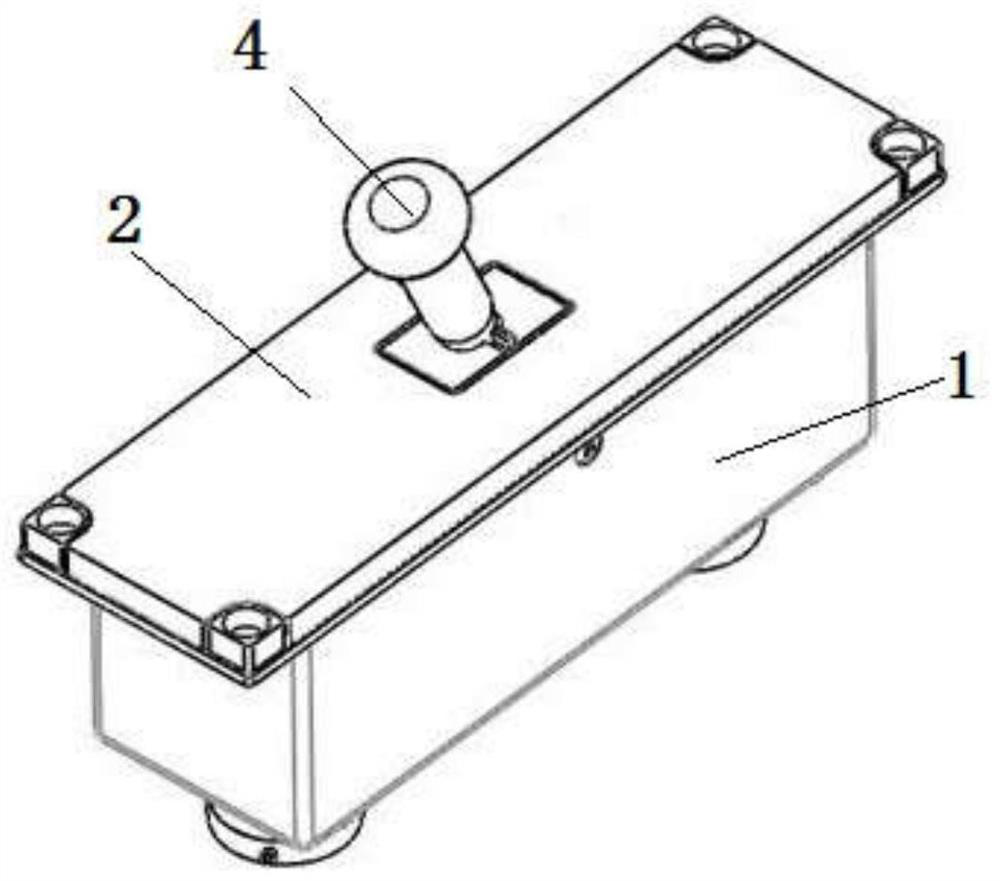

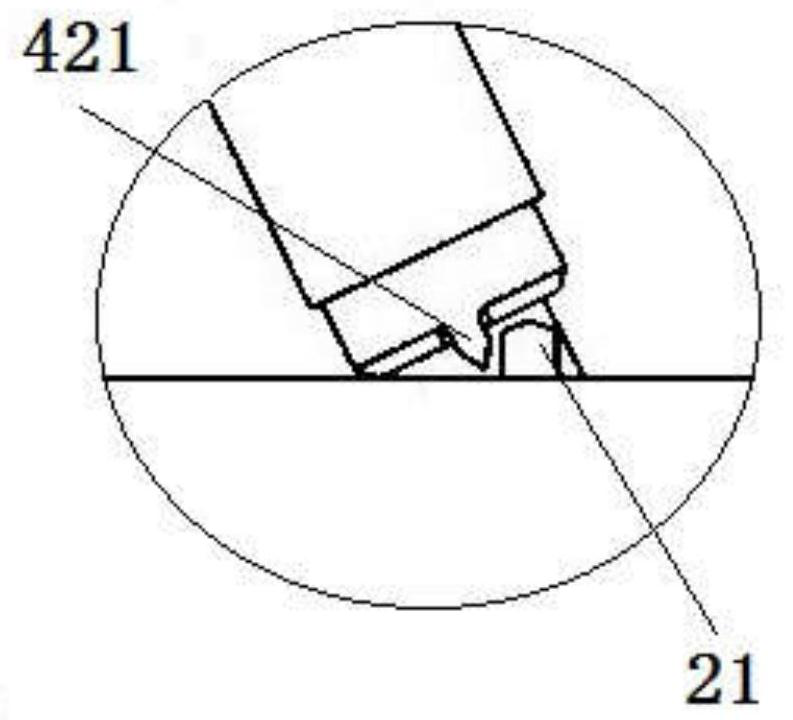

[0020] like Figure 1-Figure 5 As shown, a dual-mode switch box includes a housing 1, a mounting panel 2, a mounting bottom plate 3, a crank link mechanism 4, a switch box assembly 5, a first electrical connector 6, a second electrical connector 7 and wires, A first electrical connector 6, a switch box assembly 5 and a second electrical connector 7 are fixed on the mounting base plate 3 in sequence from left to right, and the casing 1 is vertically fixed on the top surface of the mounting base 3, so The housing 1 has a cavity inside, the bottom edge of the housing 1 is flush with the edge of the top surface of the mounting base plate 3, the mounting panel 2 is vertically fixed on the top of the housing 1, and the center of the mounting panel 2 has a crank arm. The opening of the connecting rod mechanism 4, the middle section of the crank connecting rod mechanism 4 is rot

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap