Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14 results about "Oil pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The oil pump in an internal combustion engine circulates engine oil under pressure to the rotating bearings, the sliding pistons and the camshaft of the engine. This lubricates the bearings, allows the use of higher-capacity fluid bearings and also assists in cooling the engine.

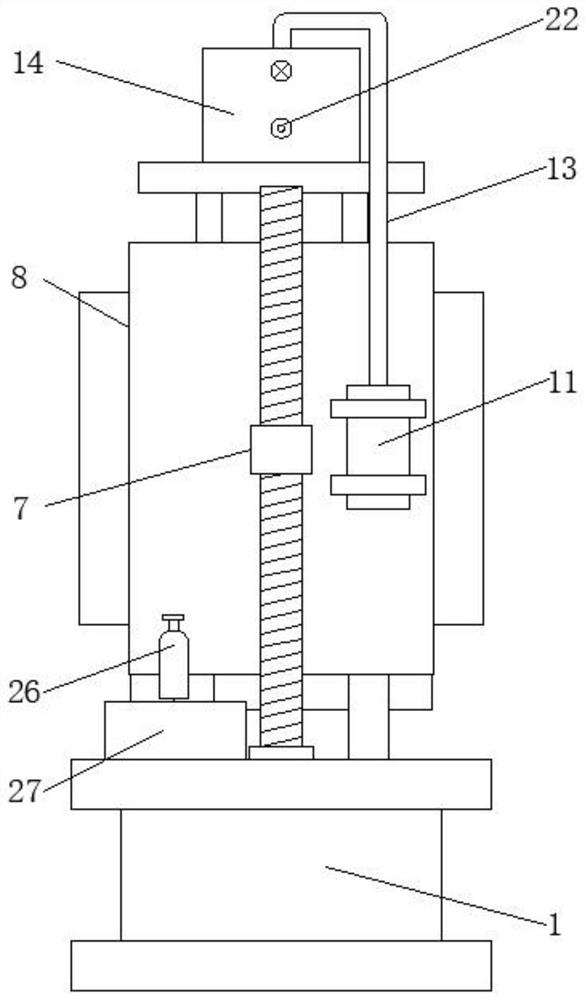

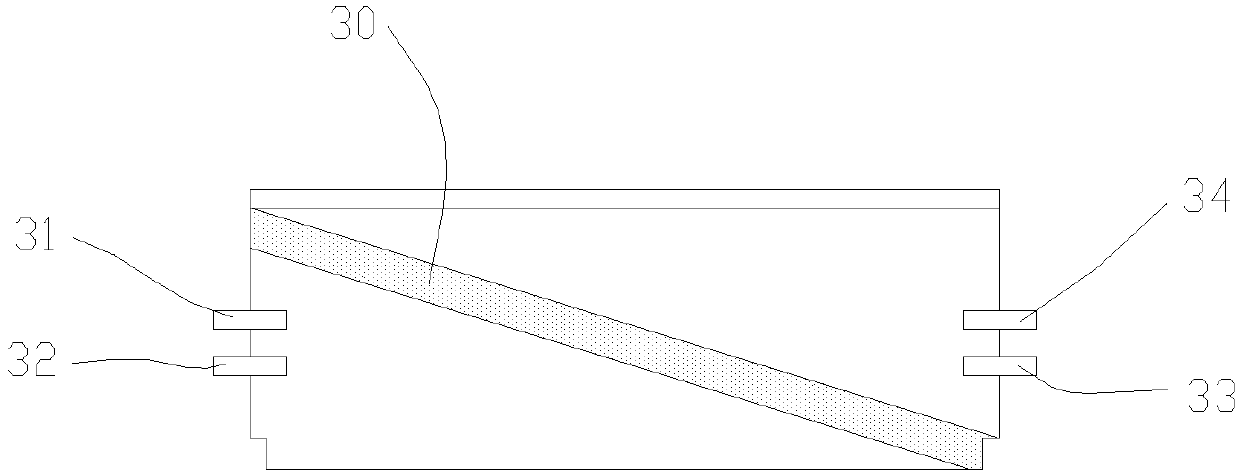

Oil pumping unit dynamic balance timely automatic regulating device and control method thereof

InactiveCN102817588AImprove adaptabilityImprove convenienceFluid removalAuto regulationDynamic balance

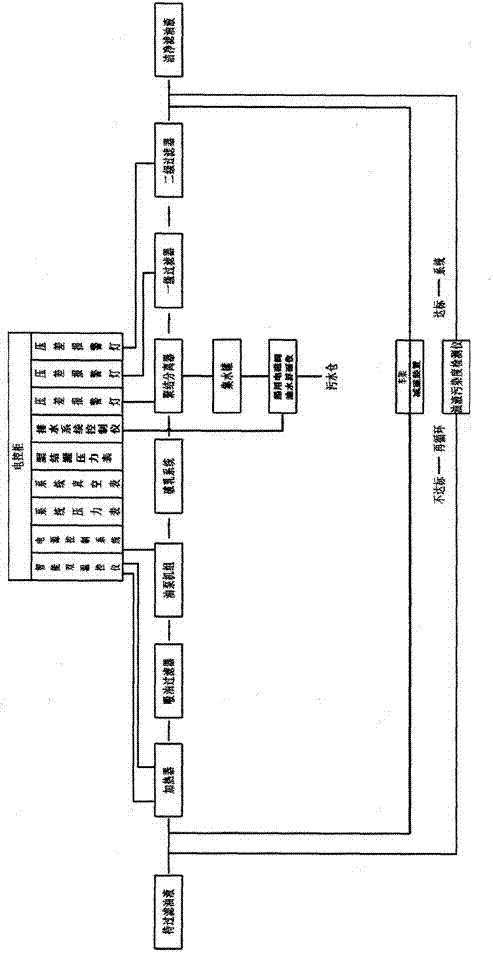

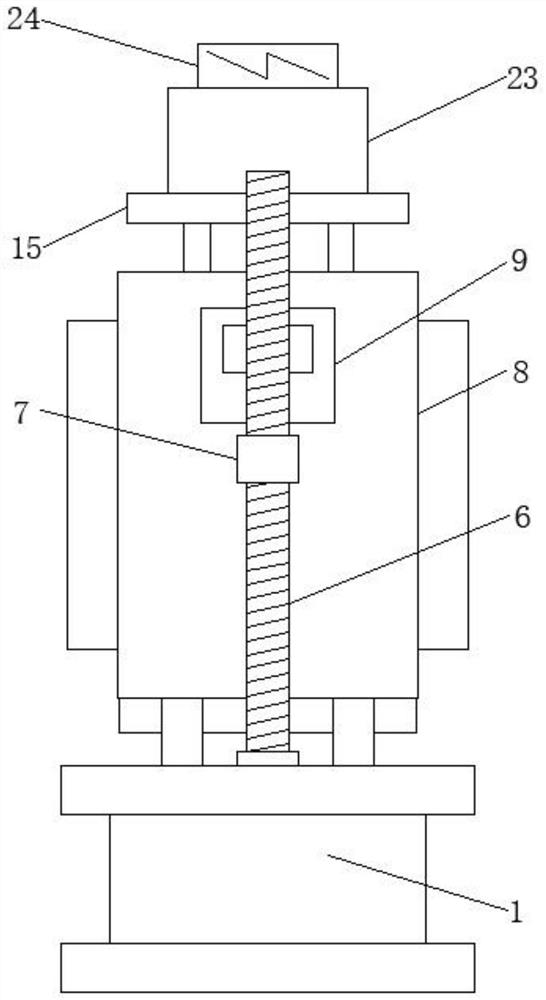

The invention provides an oil pumping unit dynamic balance timely automatic regulating device and a method for improving an existing oil pumping unit with a crank and a fixed balance weight by utilizing the device. According to the oil pumping unit dynamic balance timely automatic regulating device, an adjustable balance weight part of the oil pumping unit dynamic balance timely automatic regulating device is arranged on the side surface of the crank, the adjustable balance weight part timely moves on the side surface of the crank so as to excellently regulate the dynamic balance of an oil pumping unit, further, the adjustable balance weight part comprises a carrier and one or a plurality of balance weights, the carrier can move along the crank side surface, the one or the plurality of balance weights is / are detachably arranged on the carrier, a hydraulic mechanism drives the carrier, a control device with a central processing unit (CPU) microprocessor detects the dynamic balance of the oil pumping unit and timely controls the hydraulic mechanism, then the timely dynamic balance control of the oil pumping unit is achieved, thereby the control capacity of the oil pumping unit dynamic balance is improved, simultaneously the electrical energy is saved, and the production cost is reduced.

Owner:孙显清

Water dividing oil purifier for lubricating oil used by ship

PendingCN107158750AChange physical and chemical propertiesExtended service lifeLiquid separation auxillary apparatusPropulsion power plantsControl systemFiltration

Owner:XINXIANG RIXIN PURIFY EQUIP

Oil-immersed transformer capable of cleaning impurities

InactiveCN112466616AEasy to check and maintainIncrease heightTransformers/reacts mounting/support/suspensionTransformers/inductances coolingElectric machineTransformer oil

Owner:江苏永刚电力设备有限公司

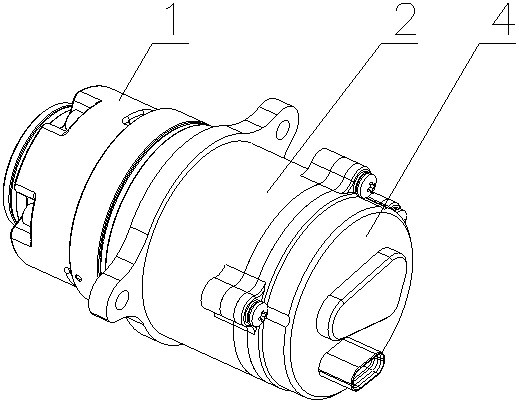

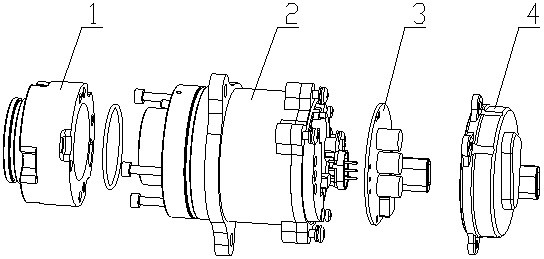

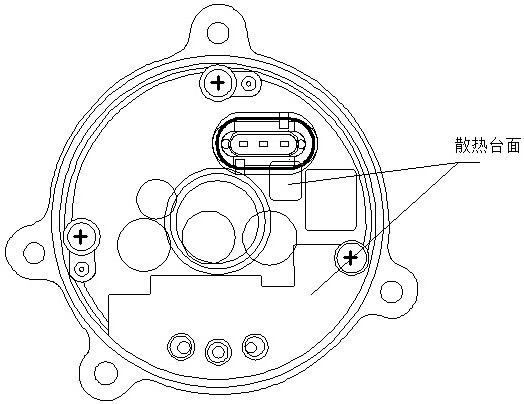

Automobile electronic oil pump driving system

PendingCN112165281AReduce dependenceReduce connectionsAssociation with control/drive circuitsSingle motor speed/torque controlBrushless motorsElectric machine

Owner:湖南东嘉智能科技有限公司 +1

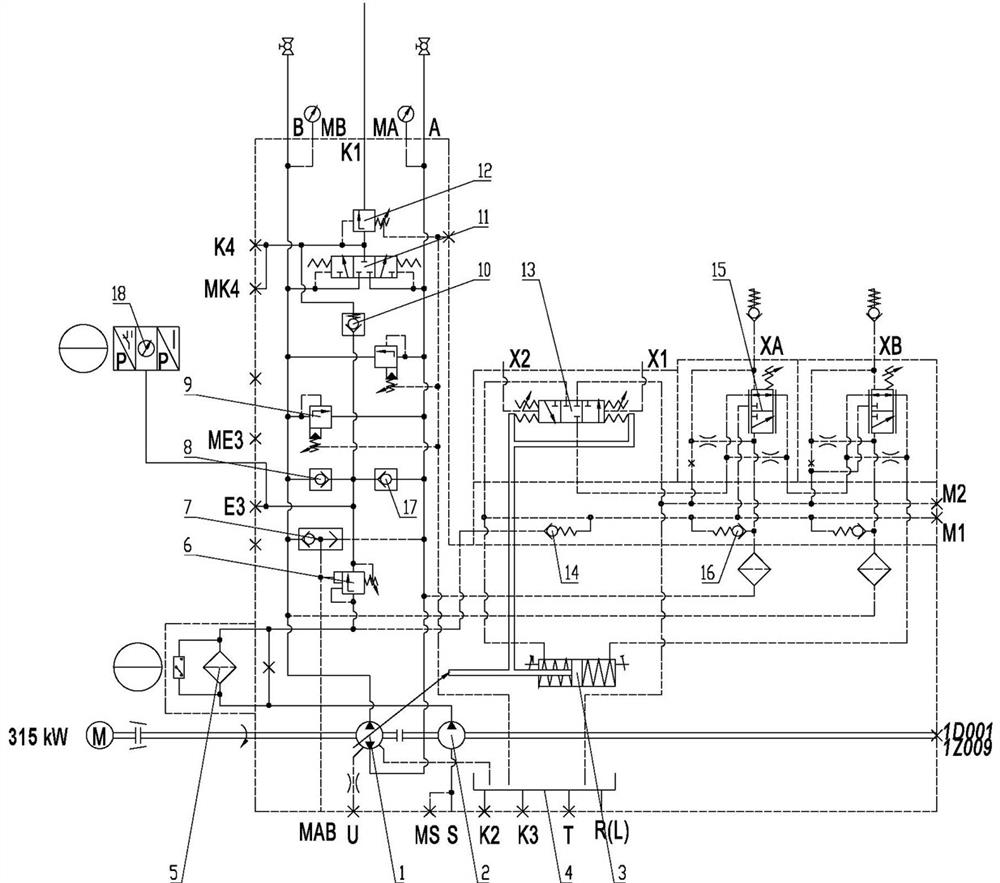

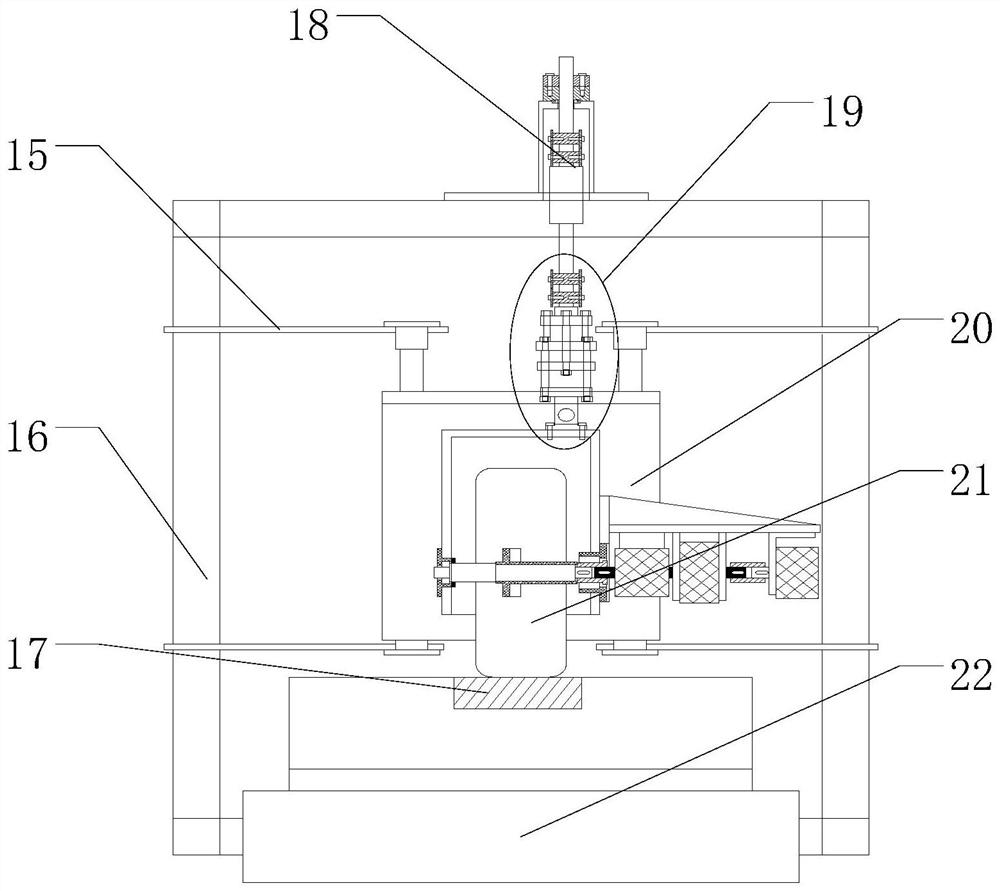

Bidirectional braking hydraulic machine and working method thereof

PendingCN113459558AImprove work efficiencyImprove working precisionPress ramHydraulic cylinderFour-way valve

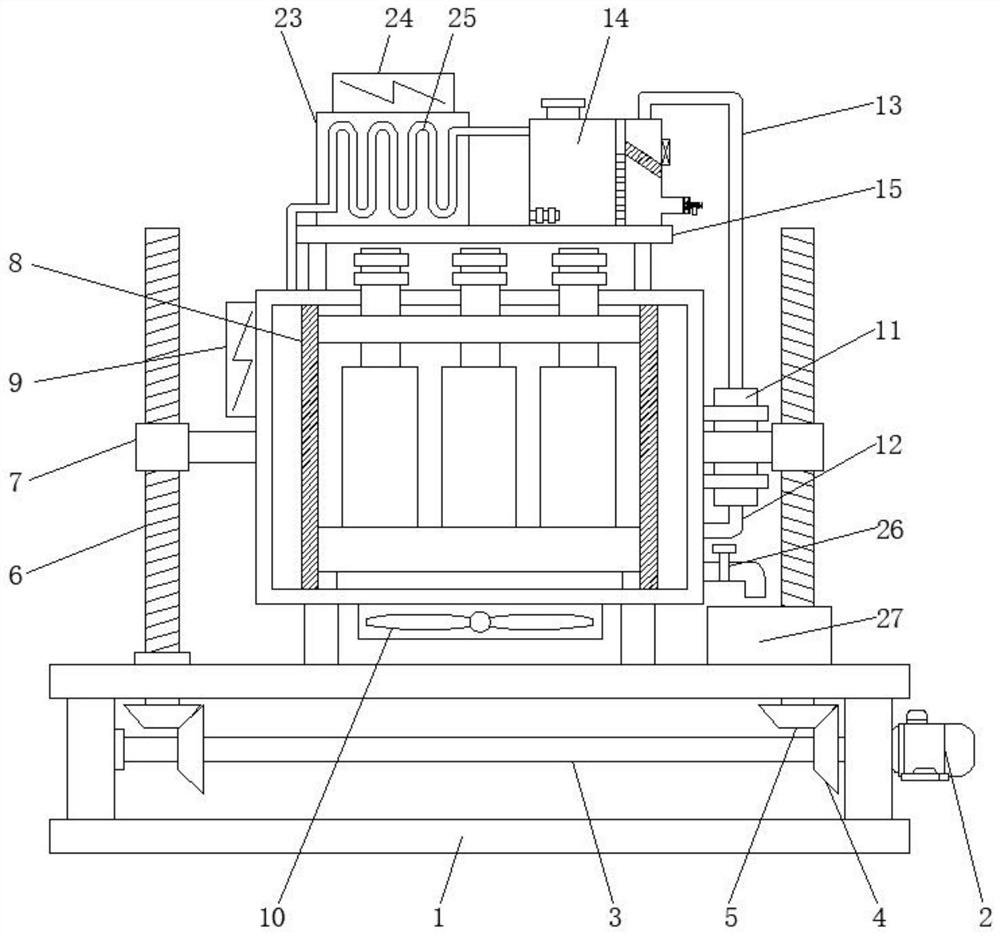

The invention discloses a bidirectional braking hydraulic machine and a working method thereof. An oil outlet of an oil tank is connected with the input end of an oil pump; a hydraulic directional valve and a first electromagnetic directional valve are both three-position four-way valves, when the first electromagnetic directional valve is in the middle position, a first oil port and a second oil port of the first electromagnetic directional valve are connected with the hydraulic directional valve, a third oil port of the first electromagnetic directional valve is connected with the oil tank, and a fourth oil port of the first electromagnetic directional valve is connected with the output end of the oil pump; when the hydraulic reversing valve is in the middle position, a first oil port of the hydraulic reversing valve is connected with the oil tank, a second oil port is connected with an oil inlet of an overflow valve, a third oil port is connected with the output end of the oil pump, a fourth oil port is connected with rodless cavities of two hydraulic cylinders, a fifth oil port is divided into two paths, one path is sequentially connected with a throttling valve and rod cavities of the two hydraulic cylinders, the throttling valve is connected with a second electromagnetic reversing valve in parallel, and the other path is connected with an overflow valve; and an oil outlet of the overflow valve is respectively connected with an oil inlet of a third electromagnetic directional valve and the oil tank; and an oil outlet of the third electromagnetic directional valve is connected with the oil tank. Bidirectional pressing forming is achieved, the quality of formed parts and the production efficiency are improved, and the production cost is greatly reduced.

Owner:SHAANXI UNIV OF SCI & TECH

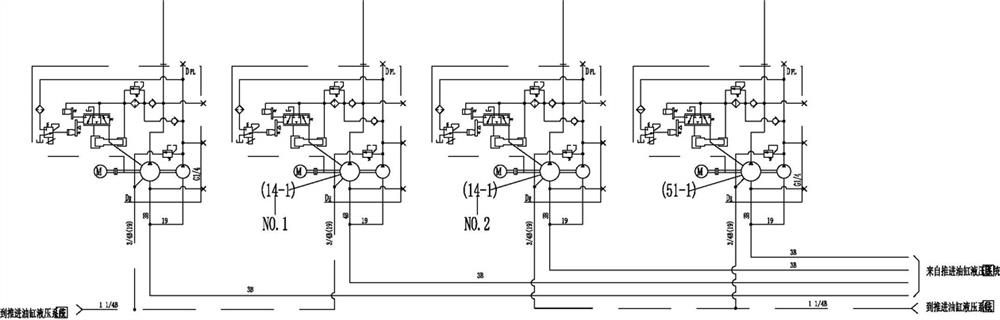

Screw machine closed hydraulic system for shield machine and shield machine

PendingCN112610547ASo as not to damageAvoid damageFluid-pressure actuator safetyServomotorsEngineeringMachine

Owner:JIANGSU KAIGONG TUNNEL MACHINERY

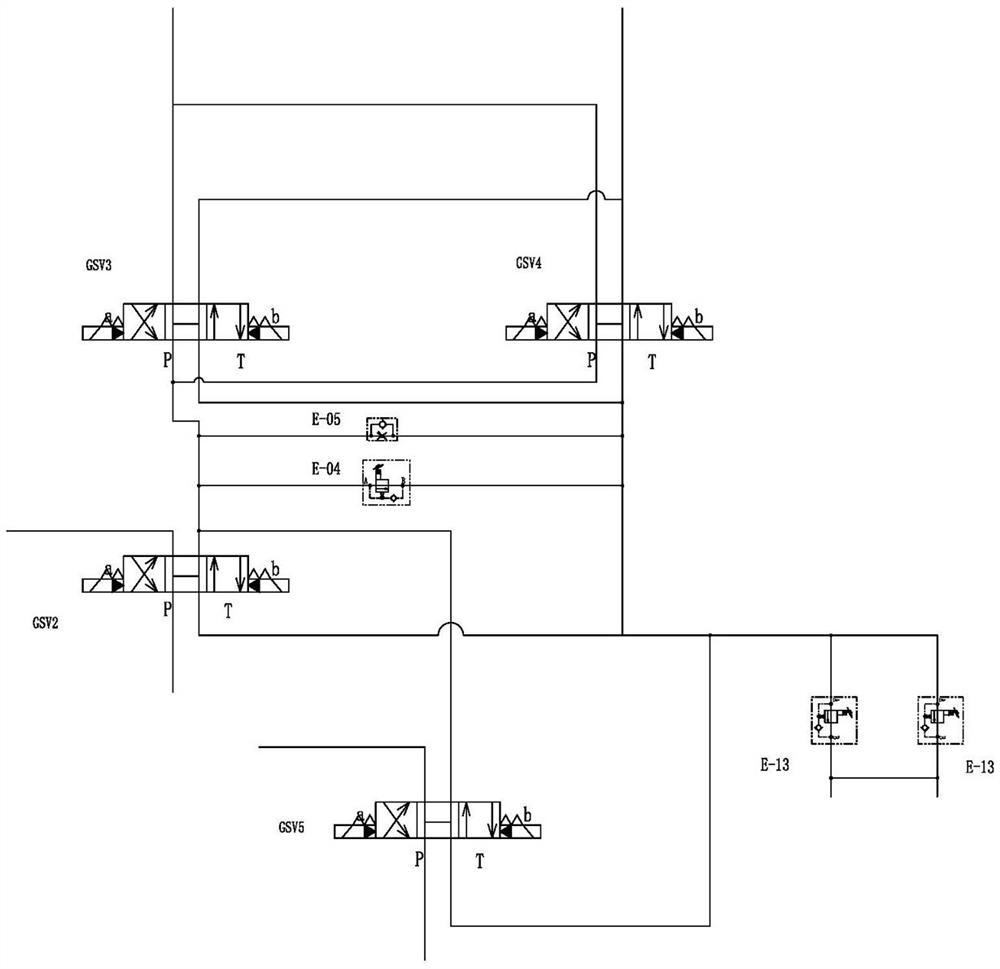

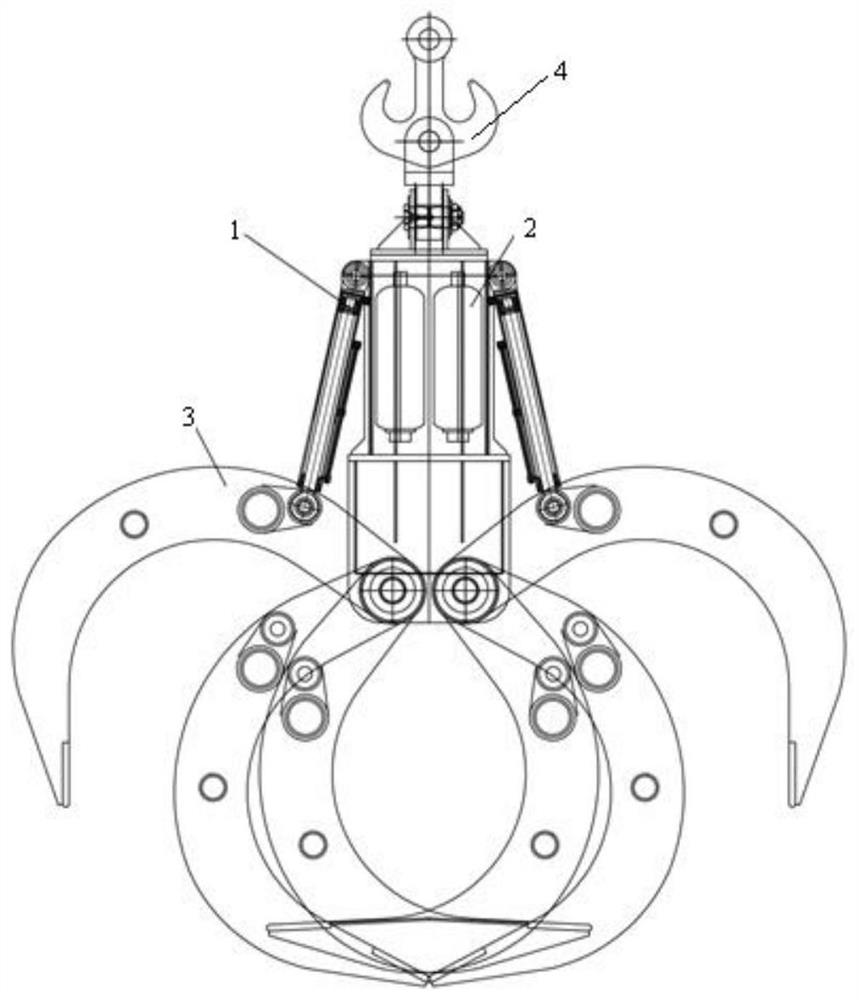

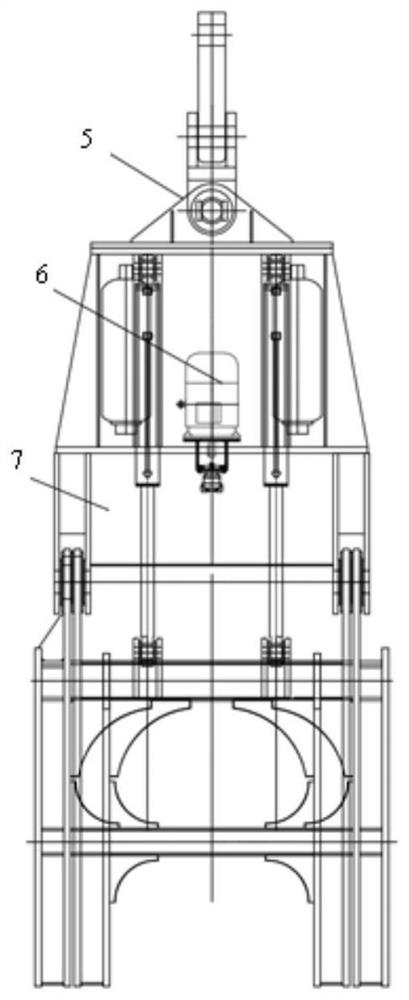

Operating system and method of electric hydraulic gripping apparatus in container loading and unloading equipment

PendingCN112897330AEasy to operateFast clamping speedServomotor componentsServomotorsPower efficientControl system

Owner:ENBEILI KUNSHAN MACHINERY

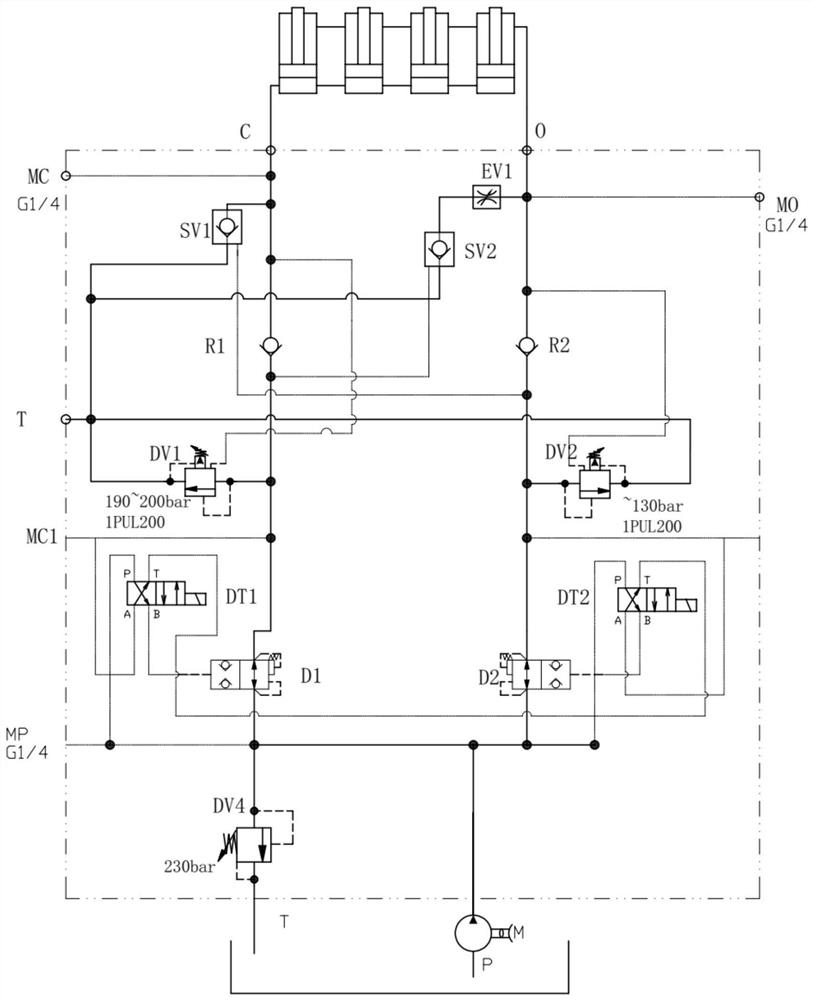

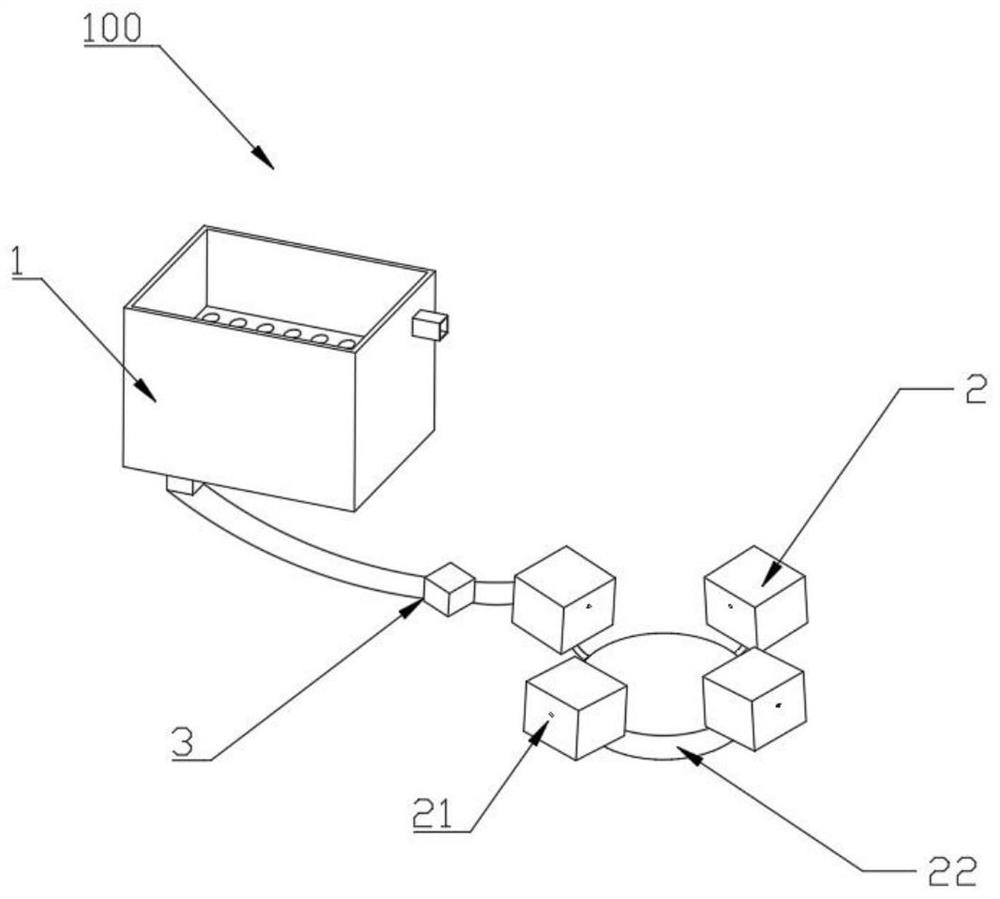

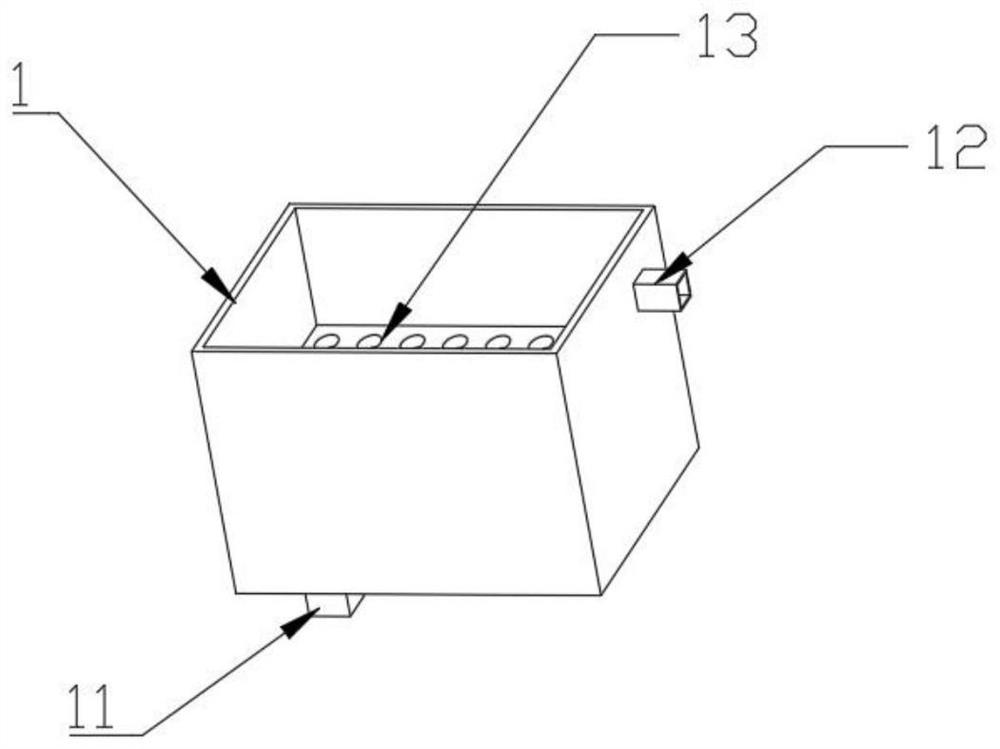

Double-oil-inlet type hydraulic integrated valve group and double-oil-pump type hydraulic station for large filter press

PendingCN114412870APressurize fastPressurization simplifiedFluid-pressure actuator testingServomotor componentsFilter pressOil pump

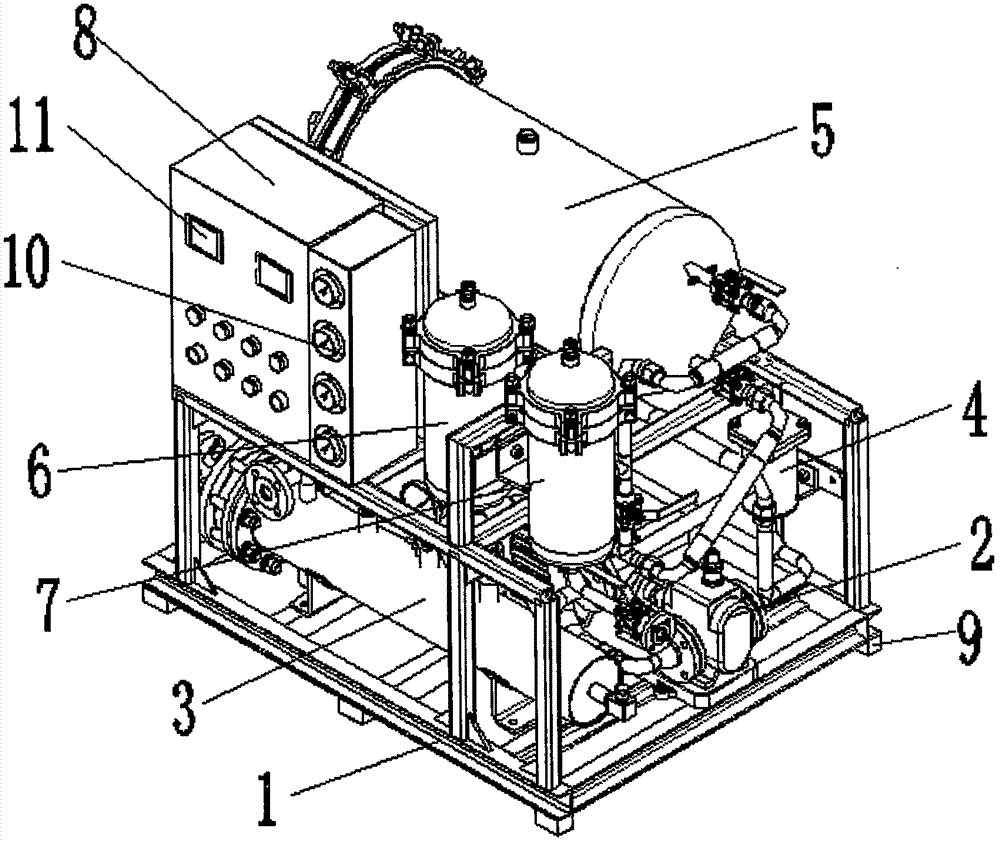

According to the double-oil-inlet type hydraulic pile-up valve group and the double-oil-pump type hydraulic station for the large filter press, the key points of the innovative scheme are that the hydraulic pile-up valve group comprises a hydraulic pile-up valve, an electro-hydraulic directional control valve, a hydraulic control one-way valve and an electromagnetic relief valve; the double-oil-inlet hydraulic pile-up valve is mainly characterized in that an existing single-oil-inlet hydraulic pile-up valve is improved into a double-oil-inlet hydraulic pile-up valve, so that double large electric oil pump sets and the hydraulic pile-up valve can be directly connected through double hydraulic oil pipes, and a three-way connector is omitted; the functions of hydraulic oil reversing, overflow pressure stabilizing and non-return pressure maintaining are achieved. The double-oil-pump type hydraulic station uses the hydraulic pile-up valve group, and solves the problems that a single-oil-inlet type hydraulic pile-up valve needs to be indirectly connected with a double-large electric oil pump group and the hydraulic pile-up valve by means of a three-way joint, the structure is complex, the number of oil pipe joints is large, the failure rate is high, and certain pressure loss exists after hydraulic oil is converged through the three-way joint; an oil inlet hole of the hydraulic pile-up valve is close to an oil tank cover, the installation space is limited, and the three-way connector is difficult to install and detach.

Owner:JINGJIN ENVIRONMENTAL PROTECTION INC

Novel internal circulation engine

Owner:艾士成

Constant-speed rotation and anti-lock controller for wheel type high-speed anti-skid instrument

PendingCN113588542AReduce the impact of testingImprove the simulation effectUsing mechanical meansMaterial analysisHydraulic motorDrive shaft

Owner:HARBIN INST OF TECH +1

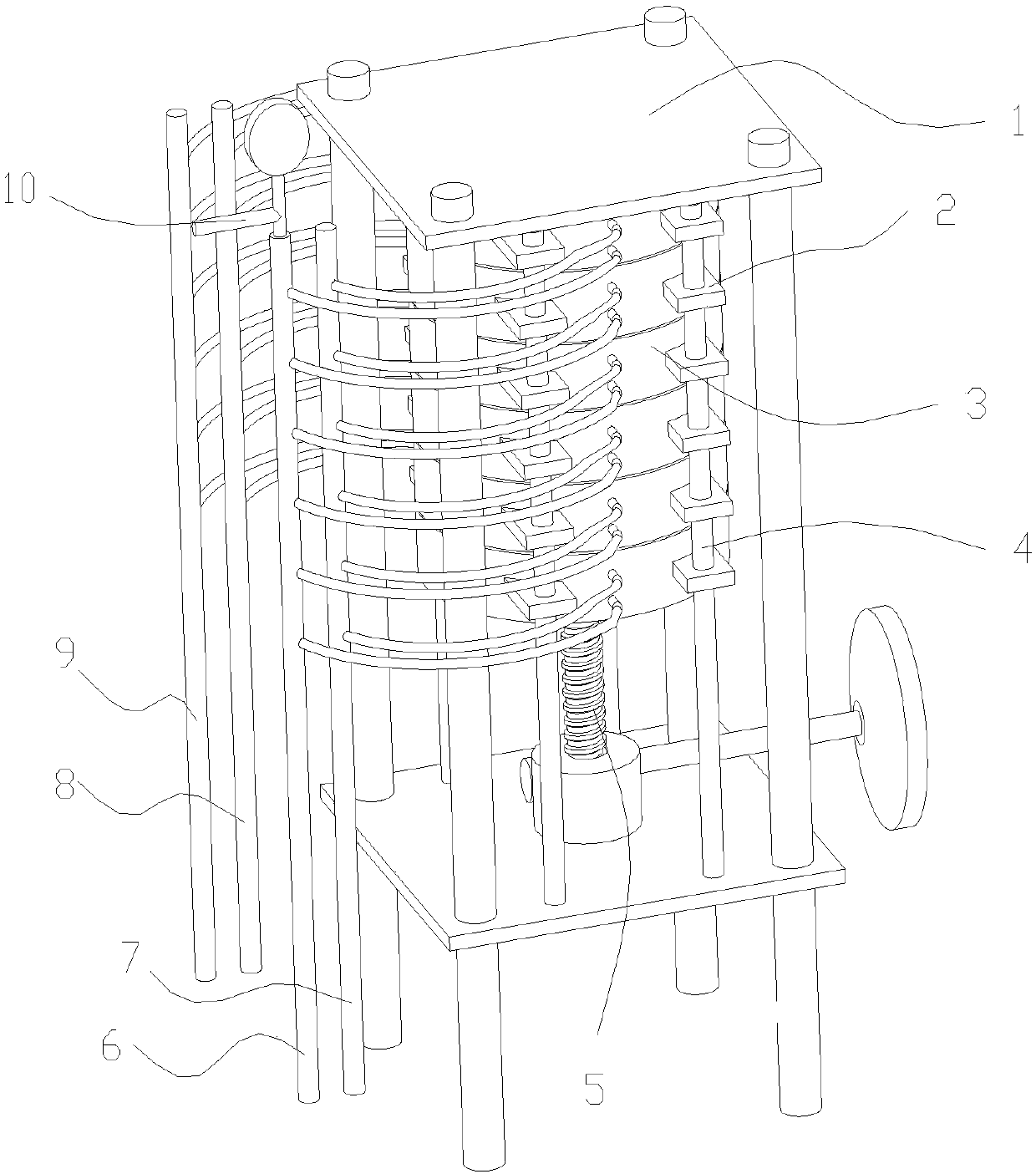

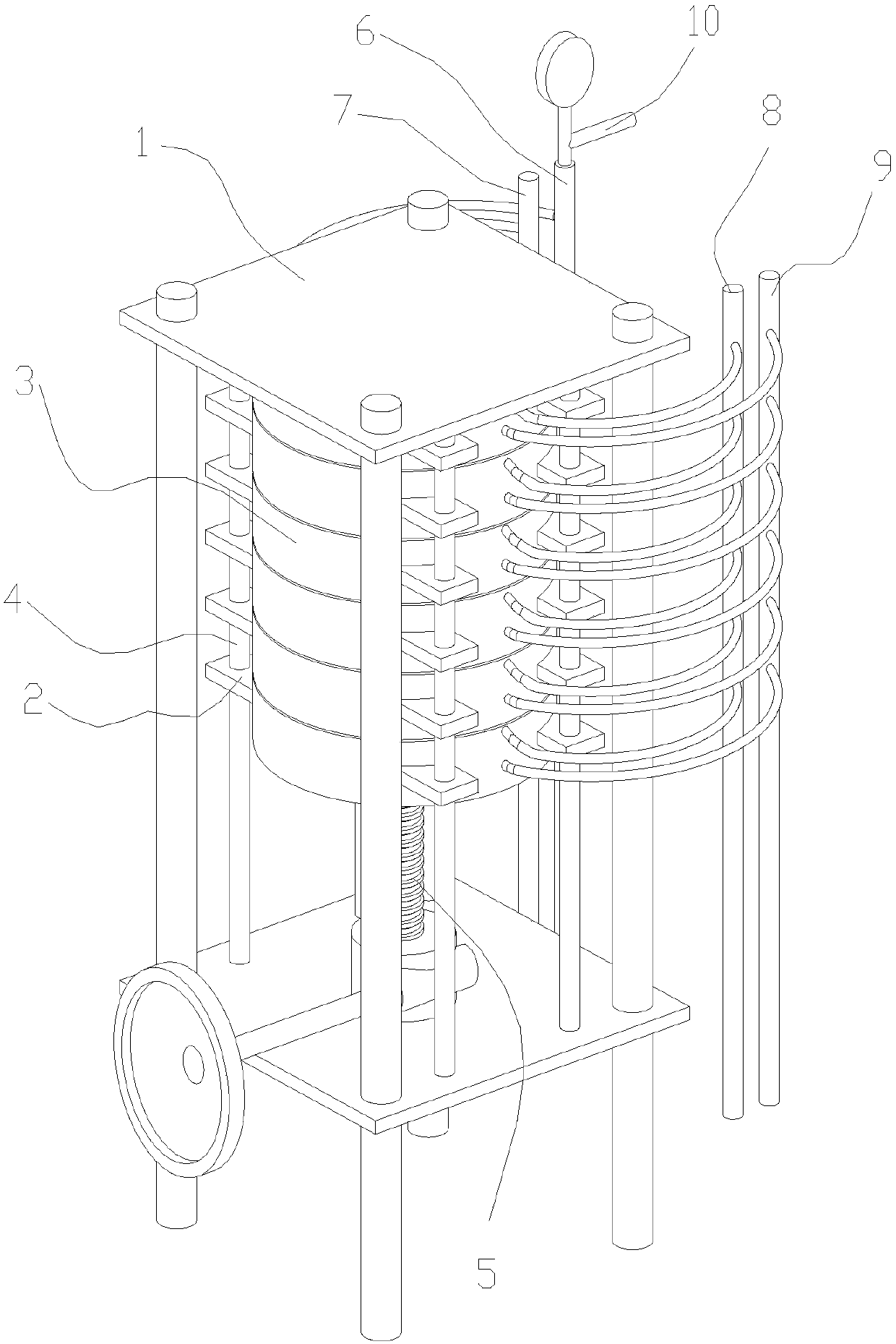

Flywheel energy storage oil pumping machine

Disclosed is a flywheel energy storage oil pumping machine, comprising an electric motor (1) and a control device (3), and also comprising a rotary spindle (2), a lifting roller (4) for lifting an oil sucker rod, a roller drive wheel (6), an energy adjustment flywheel (7), a transmission (8) and an energy feedback device (9), wherein the lifting roller (4)is sheathed on the rotary spindle (2), and the separation and reunion between the rotary spindle (2) and the lifting roller (4) are achieved via a clutch (5); the roller drive wheel (6) is fixedly connected to the lifting roller (4); and a low-speed end of the transmission (8) is connected to the rotary spindle (2), and a high-speed end is connected to the energy adjustment flywheel (7). The flywheel energy storage oil pumping machine is simple in structure, low in cost, small in size, light in weight, small installation capacity of an electric motor, low in energy consumption, high in efficiency and low in failure rate, and has nearly no pollution in a power grid.

Owner:QIU YONGAN

Oil filter

PendingCN107823940AHigh purityReduce oxidation progressFatty-oils/fats refiningFiltration circuitsPressure generationOil filter

Owner:青岛六一机械有限公司

Control method of ultrahigh pressure water jet robot cutting system

InactiveCN106003247AOvercoming the noiseExtend your lifeMetal working apparatusUltra high pressureWater discharge

The invention discloses a control method of an ultrahigh pressure water jet robot cutting system. The control method mainly includes the steps that an oil pump motor is started; water pressure and air pressure are detected; a booster pump is started to work; low-pressure water and compressed air are sucked in; a left cylinder starts to work; high-pressure water is discharged; after water discharge lasts for set time, a right cylinder works to discharge high-pressure water; a robot controls a cutting head to work; safety detection is carried out, if safety is detected, cutting work is started, and if not, the system is powered off; and an adsorption device adsorbs abrasive materials and waste water and meanwhile absorbs remaining energy of water jets. Thus, the defects that in the prior art, devices are complex in control structure, large noise is caused due to the use of water hammers, and equipment is short in service life can be overcome; and the control method achieves the advantages that machinery and a control structure are simplified, service life is prolonged, a phase type supercharger is used so that stable pressure signals can be generated, devices are more reliable, and the service life of equipment is prolonged.

Owner:谢骞

Mixed oil negative-pressure evaporation equipment

PendingCN112717444AIncrease concentrationSave heatEvaporator accessoriesFatty-oils/fats refiningEngineeringOil pump

The invention discloses mixed oil negative-pressure evaporation equipment, and belongs to the field of evaporation equipment. The problems that existing mixed oil evaporation equipment is large in evaporation consumption and poor in stability are solved. The equipment comprises a flash tank, a mixed oil pump, a condenser, a negative pressure water ring pump and a first evaporator, a mixed oil input port, a mixed oil output port and a volatile gas output port are machined in the flash tank, the mixed oil output port of the flash tank is connected with the mixed oil pump, and the volatile gas output port of the flash tank is connected with the condenser; the output end of the mixed oil pump is connected with the input end of the first evaporator, the output end of the first evaporator is connected with the input end of the condenser, and the output end of the condenser is connected with the negative-pressure water ring pump. By means of the mixed oil negative pressure evaporation equipment, the effect of steam in the mixed oil evaporation process is effectively reduced, and the negative pressure in the evapo-separated machine and the vacuum stability of the whole system are guaranteed.

Owner:JIUSAN OILS & GRAINS IND GRP CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap