Screw machine closed hydraulic system for shield machine and shield machine

A hydraulic system and closed-type technology, which is applied in the direction of fluid pressure actuation system safety, fluid pressure actuation system components, mechanical equipment, etc., and can solve problems such as numerous system pipelines, system pressure that cannot be adjusted, and system destructive power increase , to avoid the effect of system overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

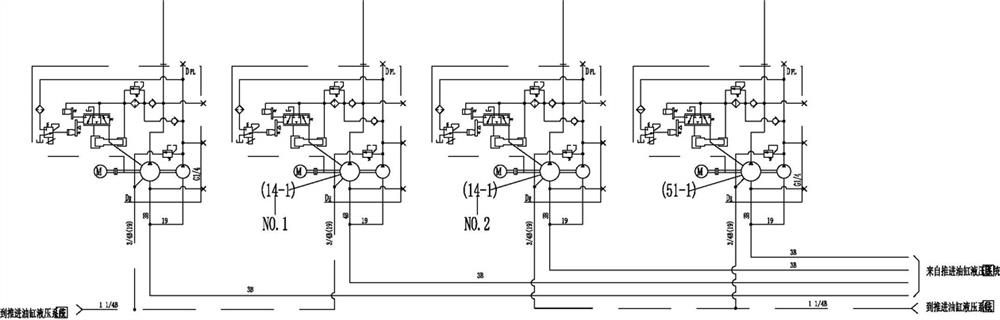

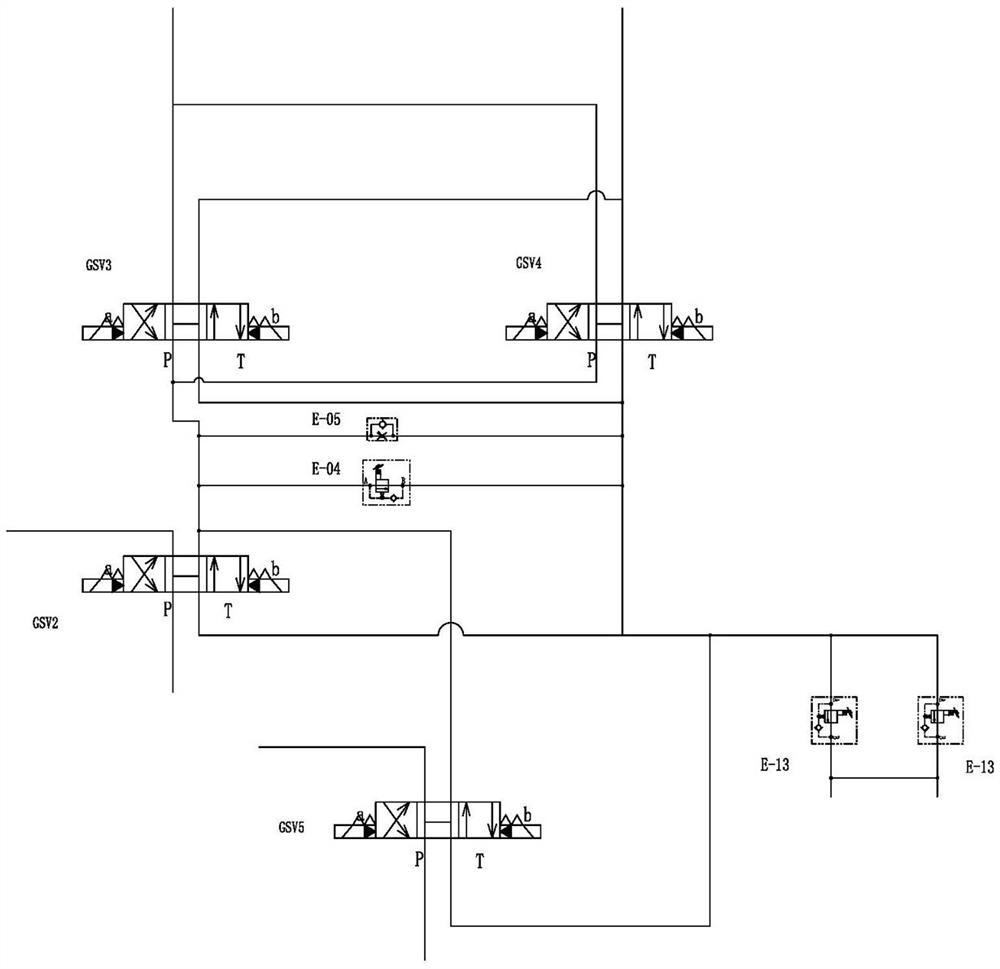

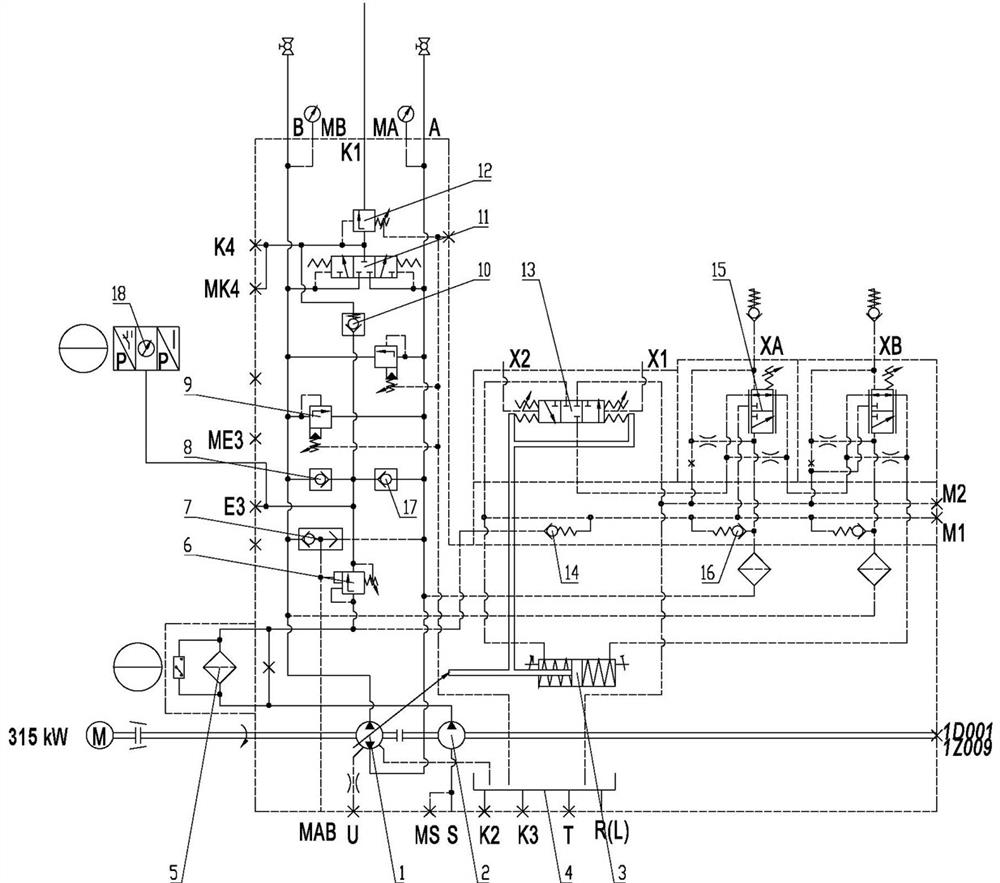

[0035] like image 3 As shown, the present invention provides a shield machine, including a screw machine pump 1, a servo cylinder 3 and a screw machine closed hydraulic system for the shield machine. The screw machine pump 1 adopts axial variable plunger pump, and the motor power is 200KW. The pump model: A4VSG500HD1G / 30R-VZH35F684M is suitable for closed hydraulic system, and the pump displacement is 500cm 3, the screw machine pump 1 has its own charge pump 2 to provide hydraulic oil for the main pump, and the control mode of the screw machine pump 1 is hydraulic control HD1, such as Figure 4 As shown, the control mode is related to the pilot pressure. The pump displacement depends on the s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap