Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51 results about "Waste material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

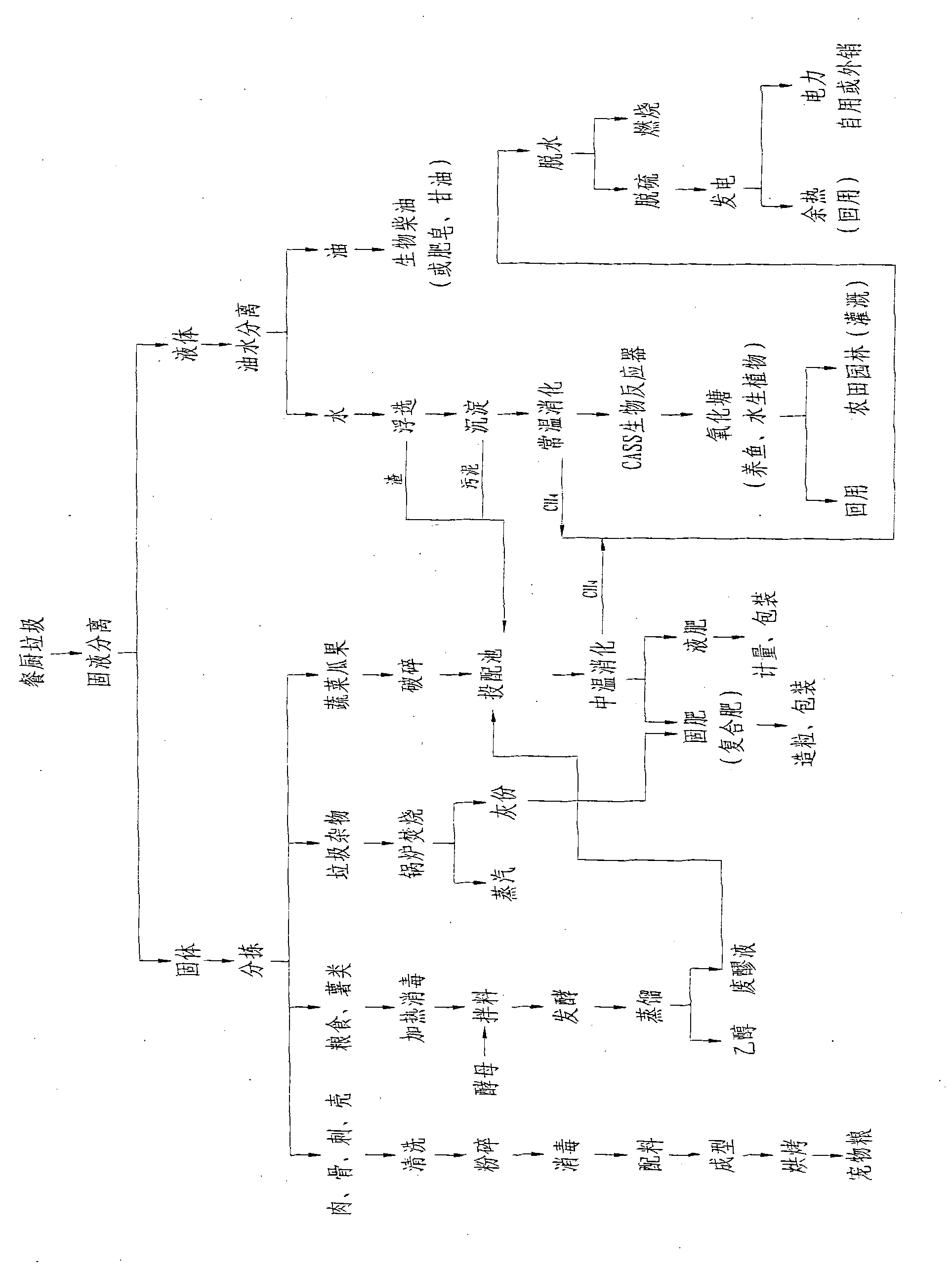

Processing method of changing food waste into resources

InactiveCN101850349AIncrease valueEmission reductionFatty oils/acids recovery from wasteBio-organic fraction processingWater useBiodiesel

Owner:云南天兰环保科技开发有限公司 +1

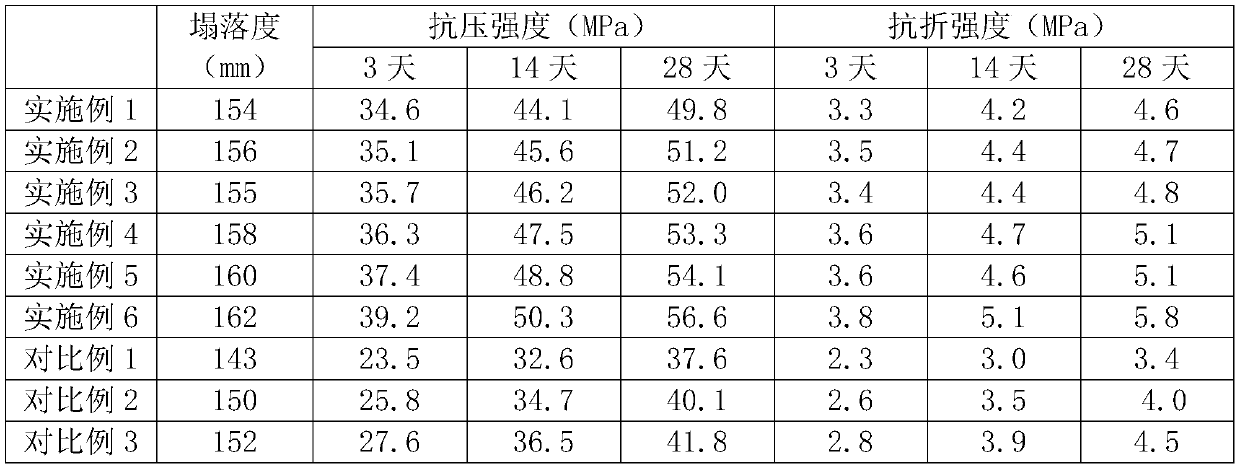

Recycled concrete and preparation method thereof

Owner:陕西金基石新型建材有限公司

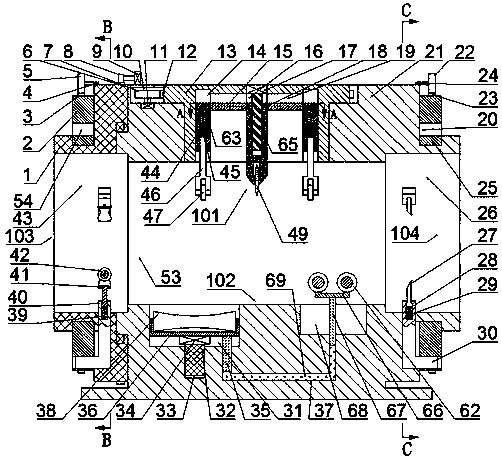

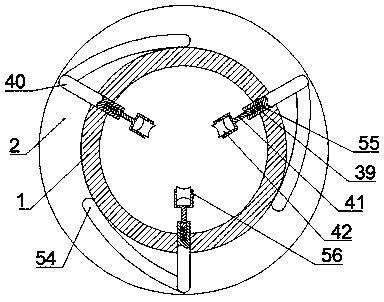

Girdling and stripping device for outer insulating sheath of cable

ActiveCN110994482AReliable cuttingHigh degree of automationApparatus for removing/armouring cablesWire cuttingStructural engineering

Owner:XINYI XIYI ADVANCED MATERIALS RES INST OF IND TECH CO LTD

Integral utilization treatment method for aerating concrete waste material

InactiveCN101215110AHigh activityImprove performanceSolid waste managementCeramicwareBall millGypsum

Owner:HOHAI UNIV

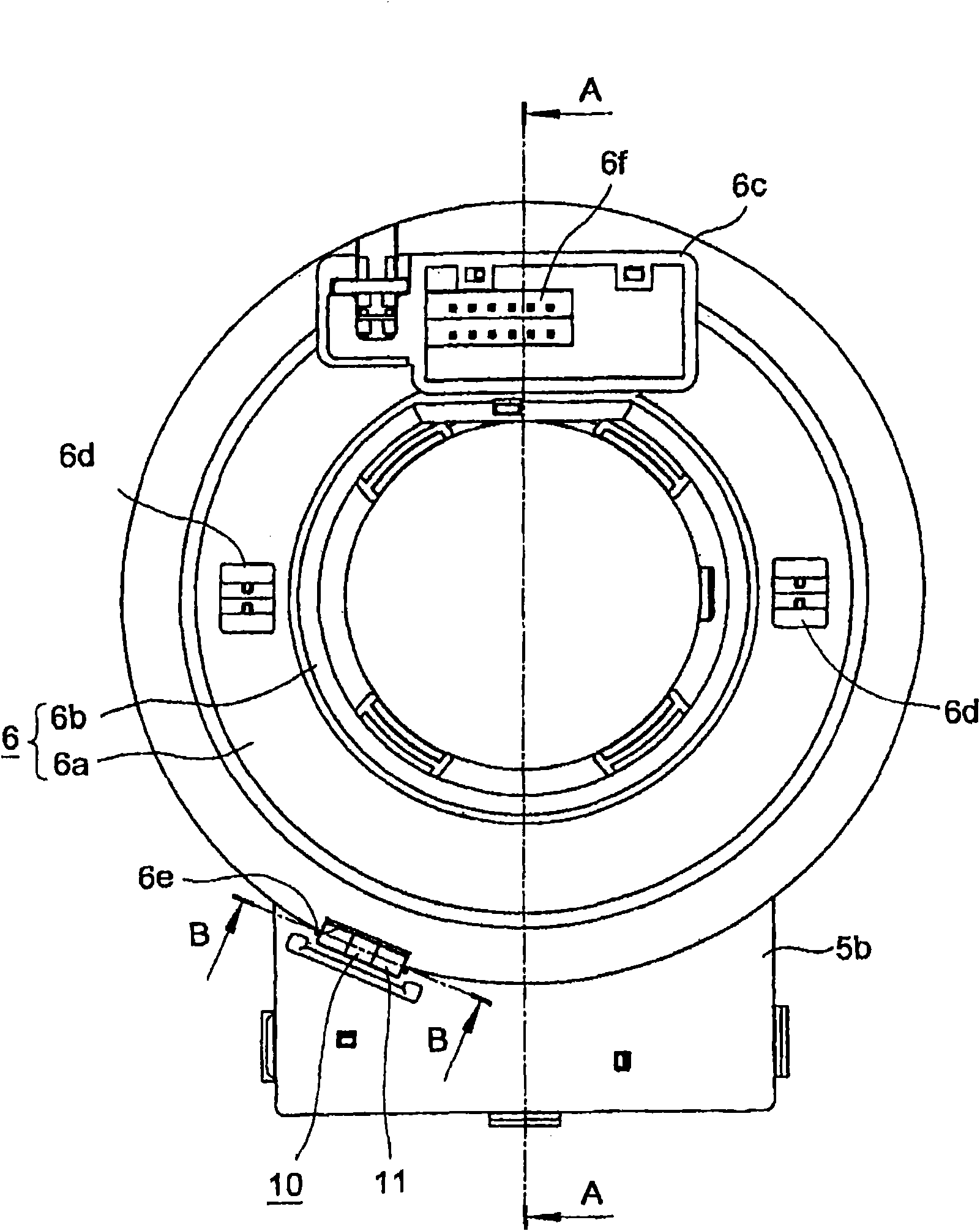

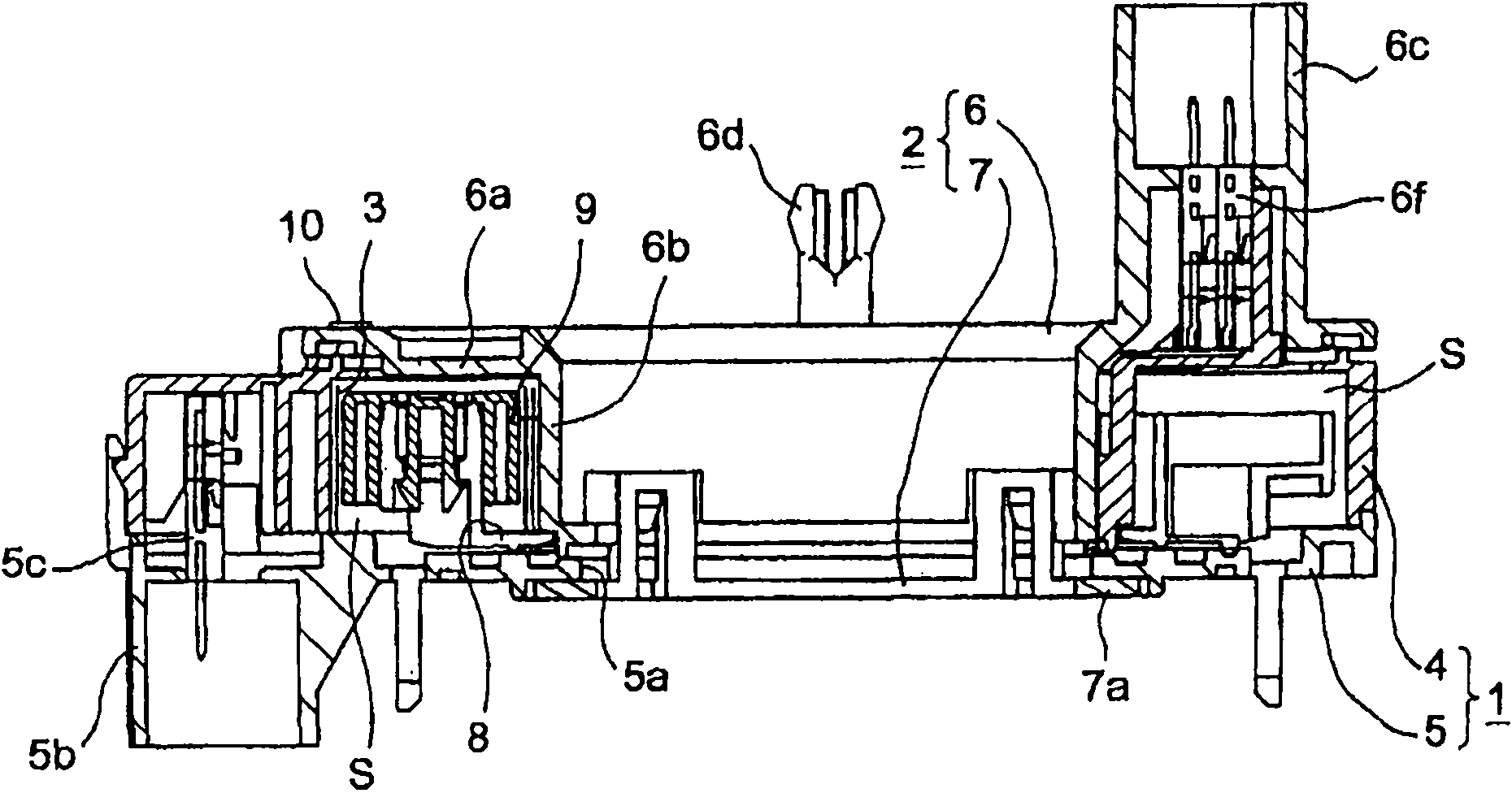

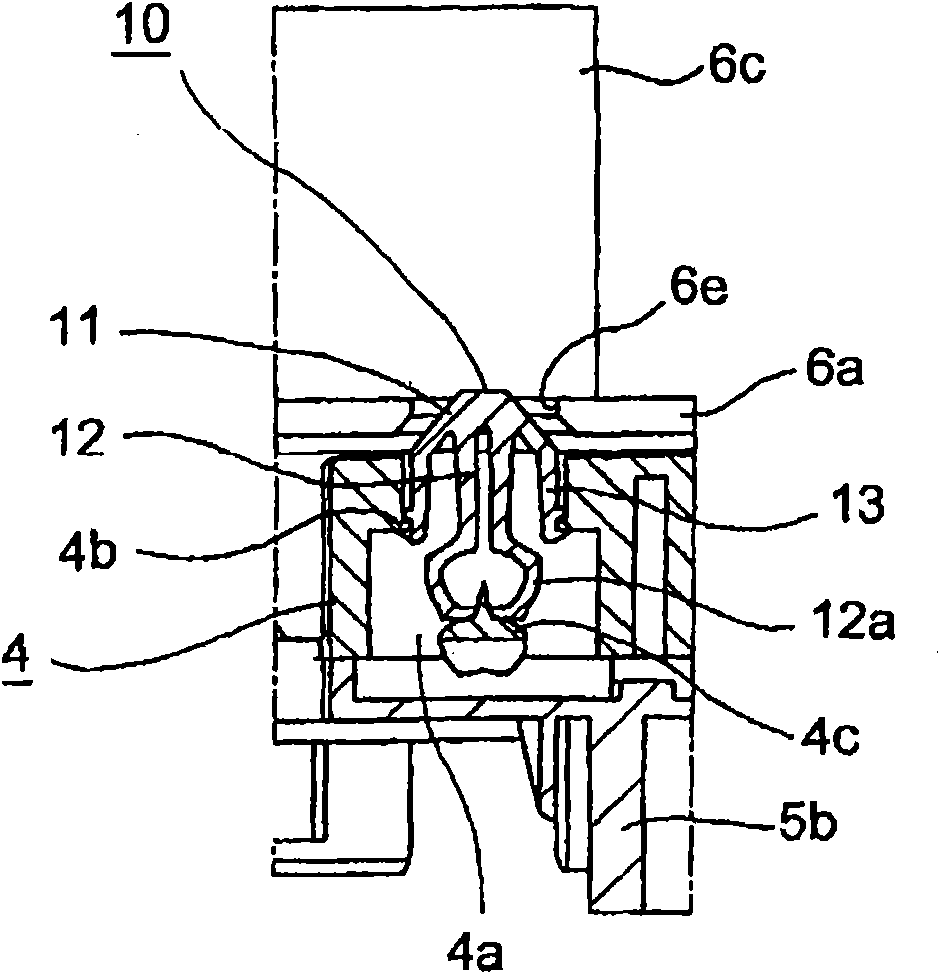

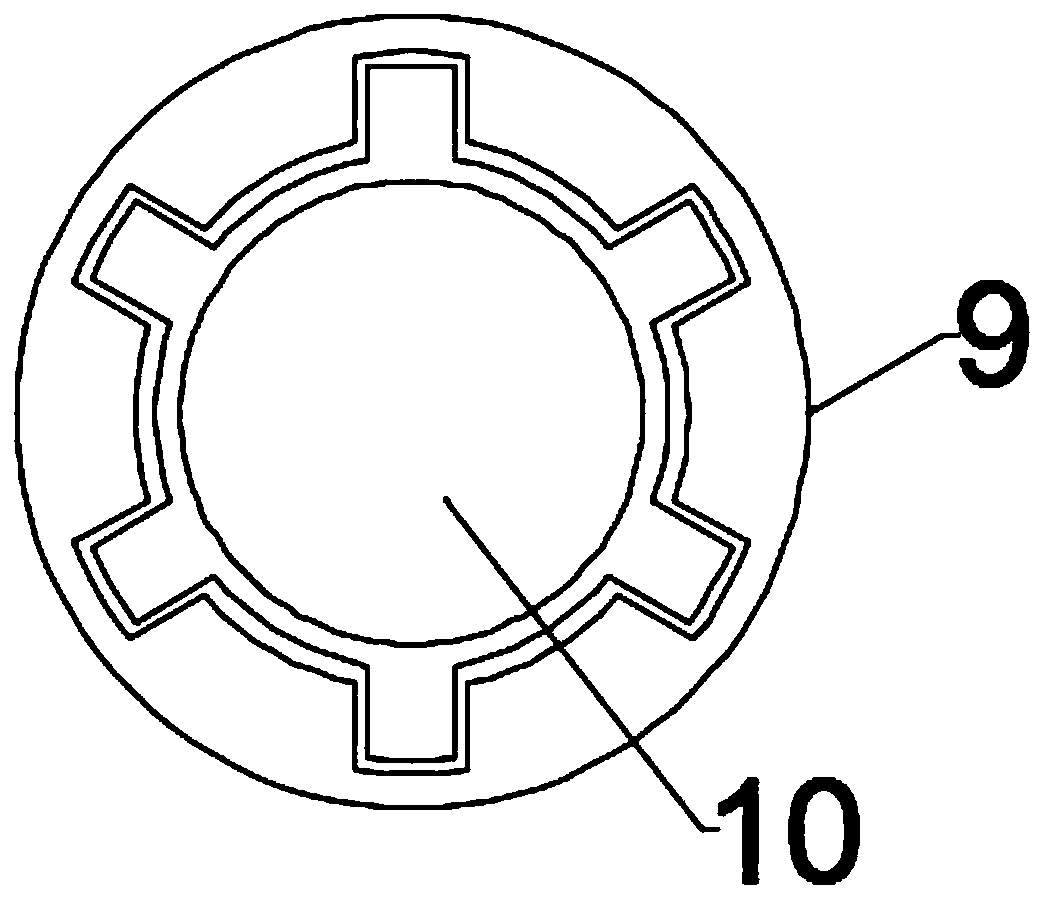

Rotary connector

Owner:ALPS ALPINE CO LTD +1

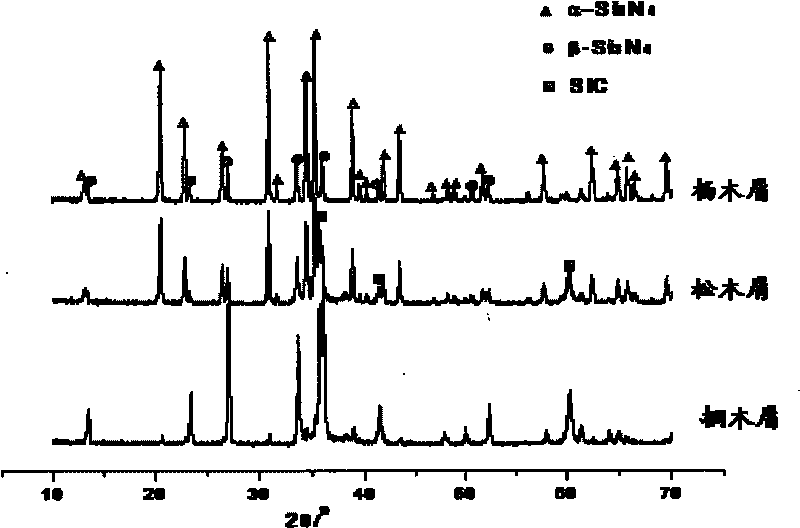

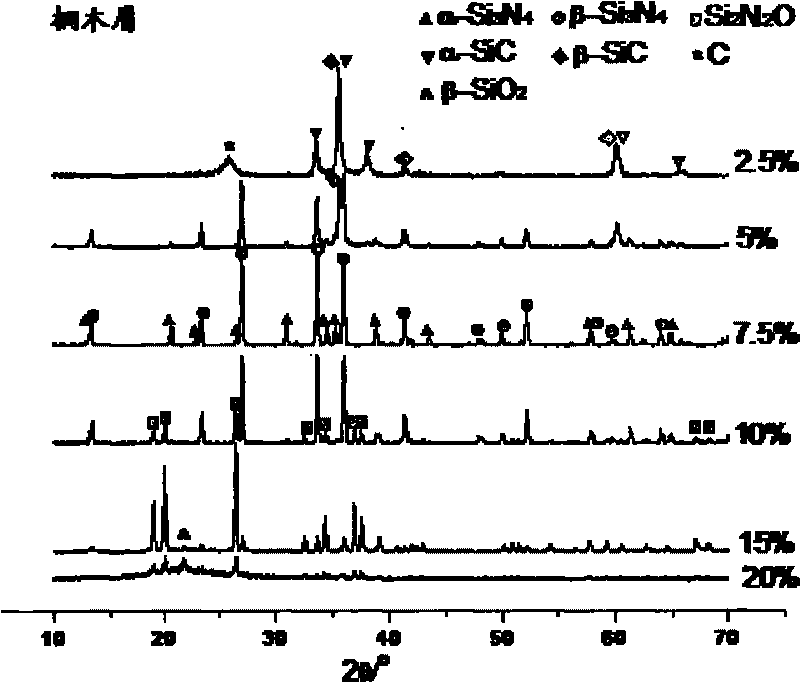

Method for preparing silicon nitride powder with saw dust

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Decorative and thermal-insulation integrated novel lightweight walling material made from polishing brick waste

Owner:ZIBO YONGXU REFRACTORY MATERIALS

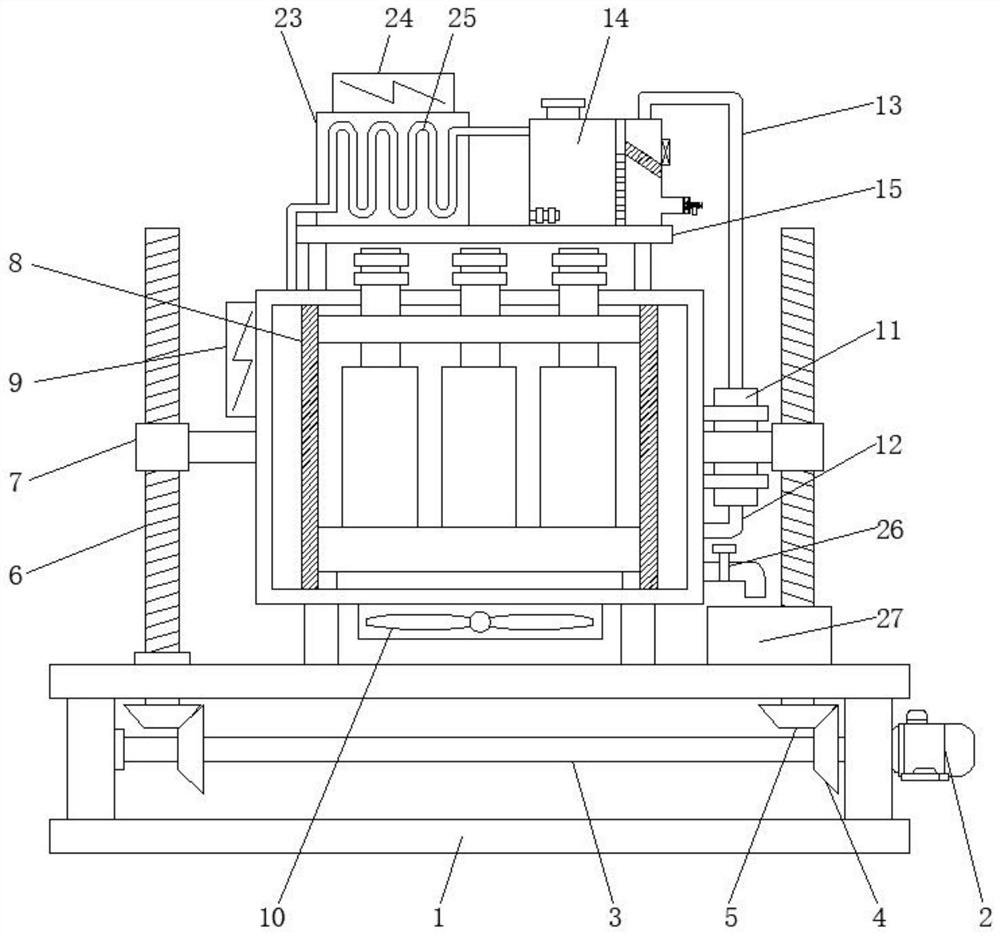

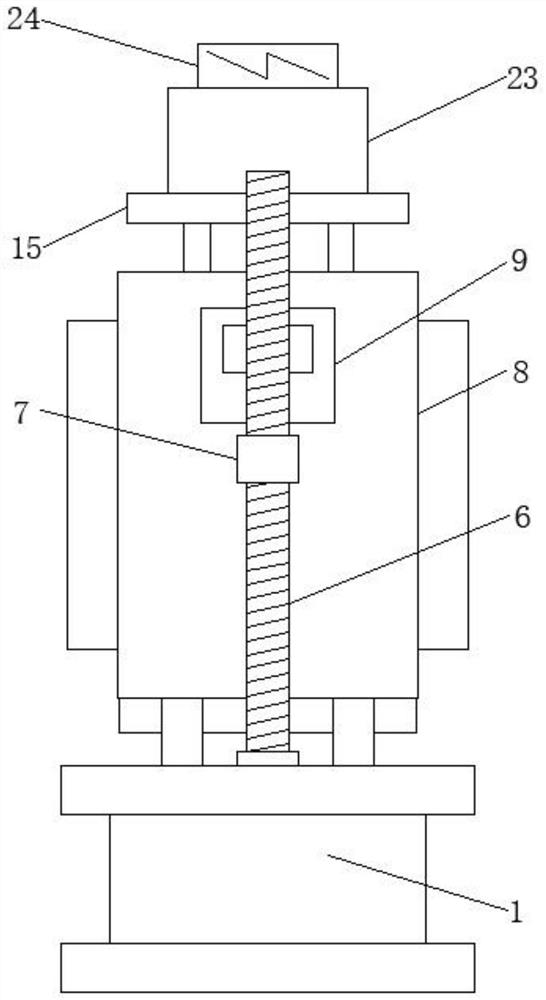

Oil-immersed transformer capable of cleaning impurities

InactiveCN112466616AEasy to check and maintainIncrease heightTransformers/reacts mounting/support/suspensionTransformers/inductances coolingElectric machineTransformer oil

Owner:江苏永刚电力设备有限公司

Intelligent control system for electric mop

InactiveCN106308708AAccurate understandingImprove work efficiencyCarpet cleanersFloor cleanersOperating instructionComputer module

Owner:太仓贝明家日用品有限公司

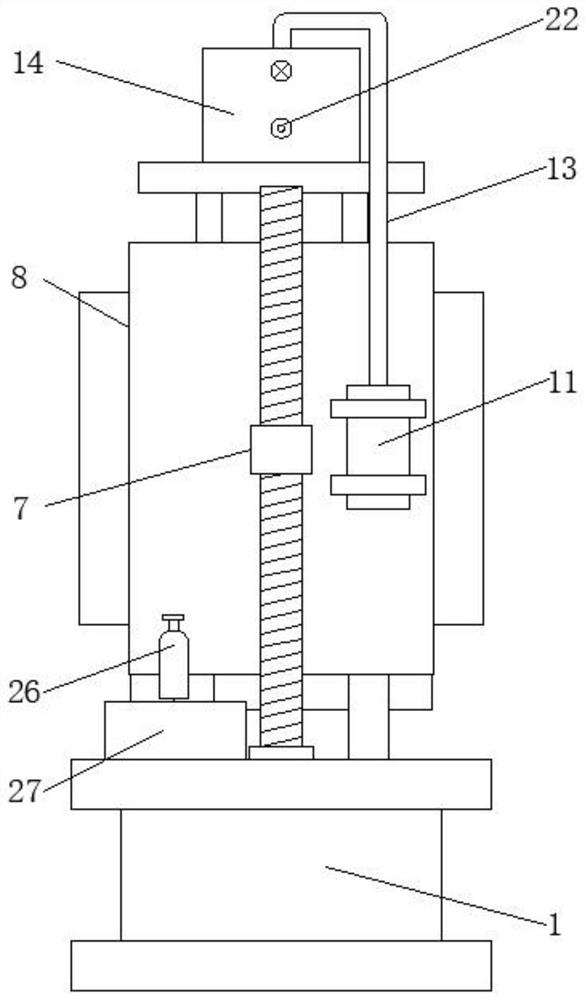

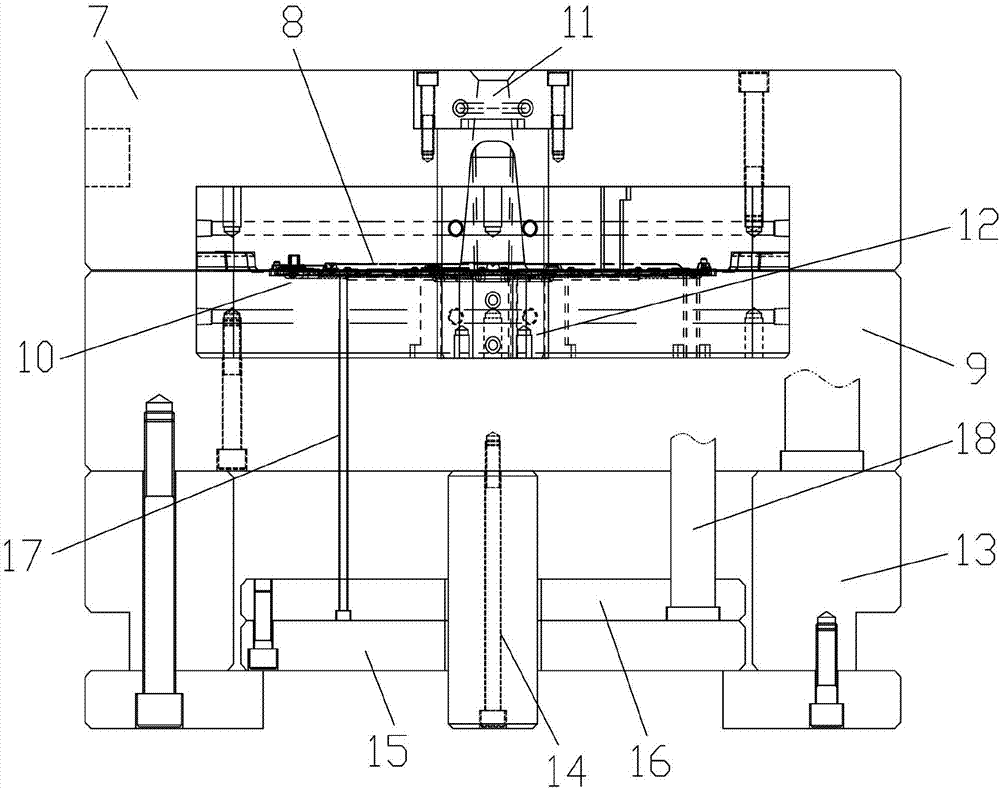

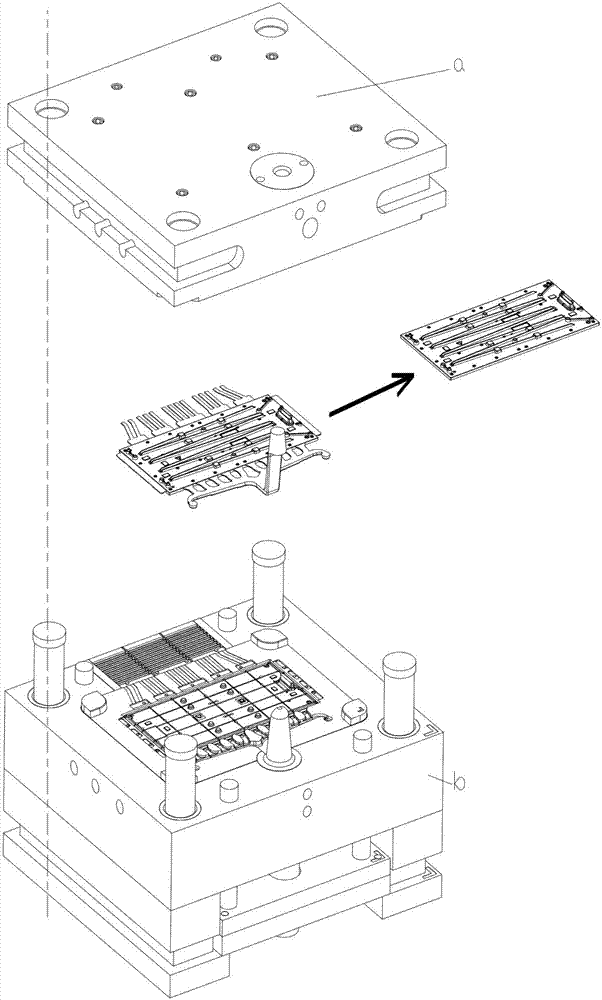

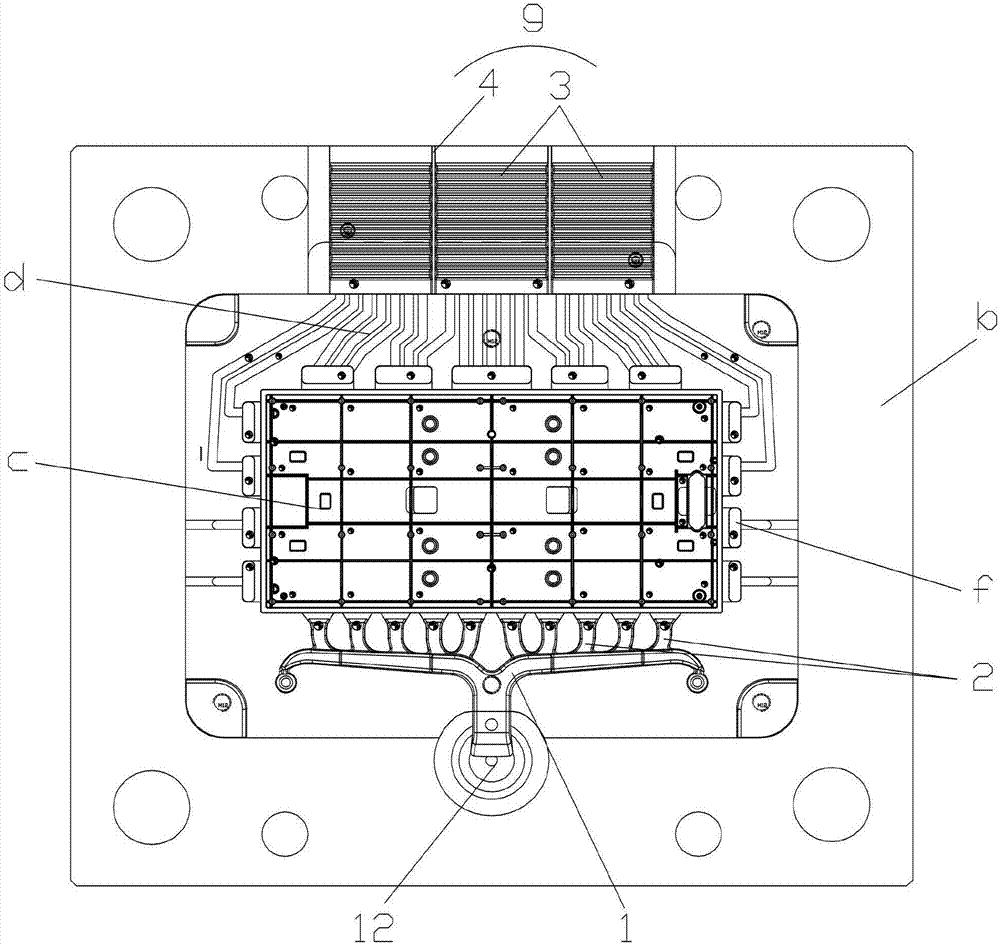

Die-casting forming mold and die-casting forming technology of bottom shell of LED display screen module

Owner:东莞市和镁五金有限公司

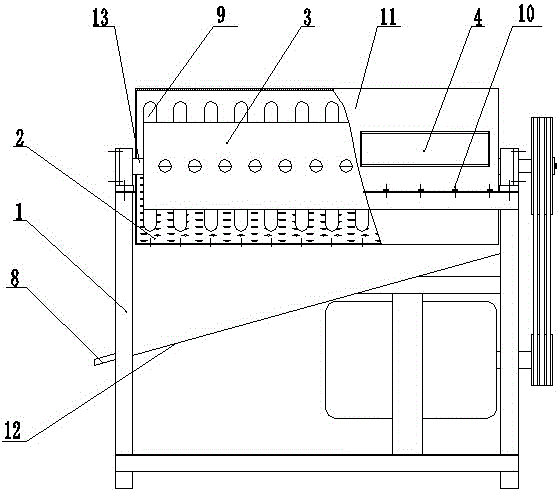

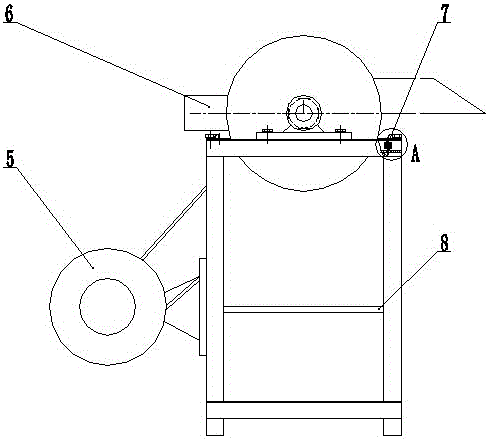

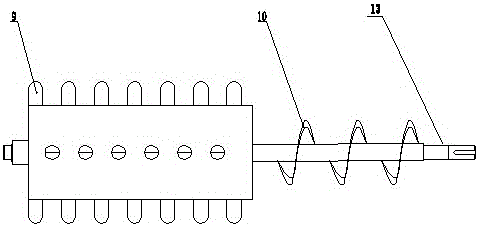

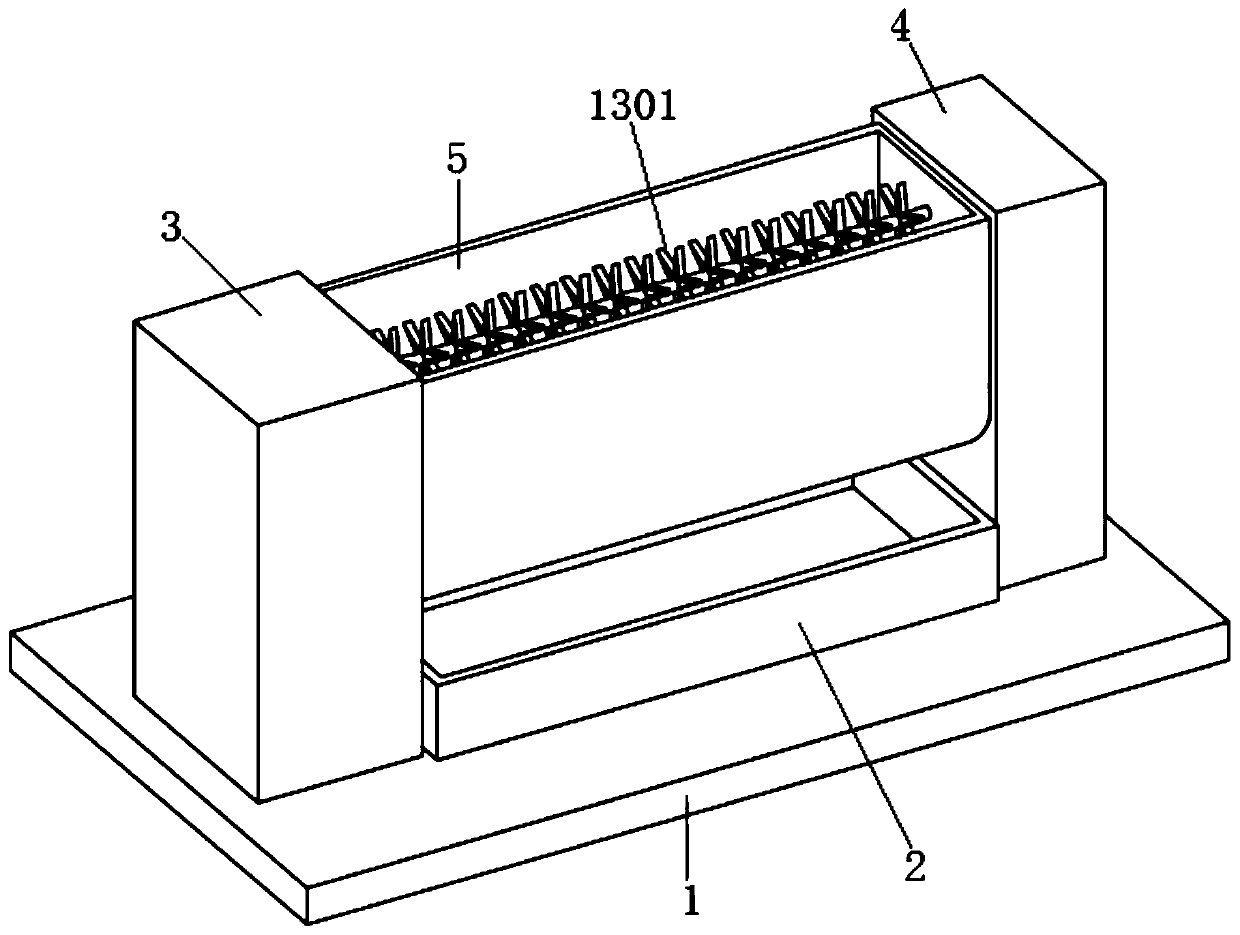

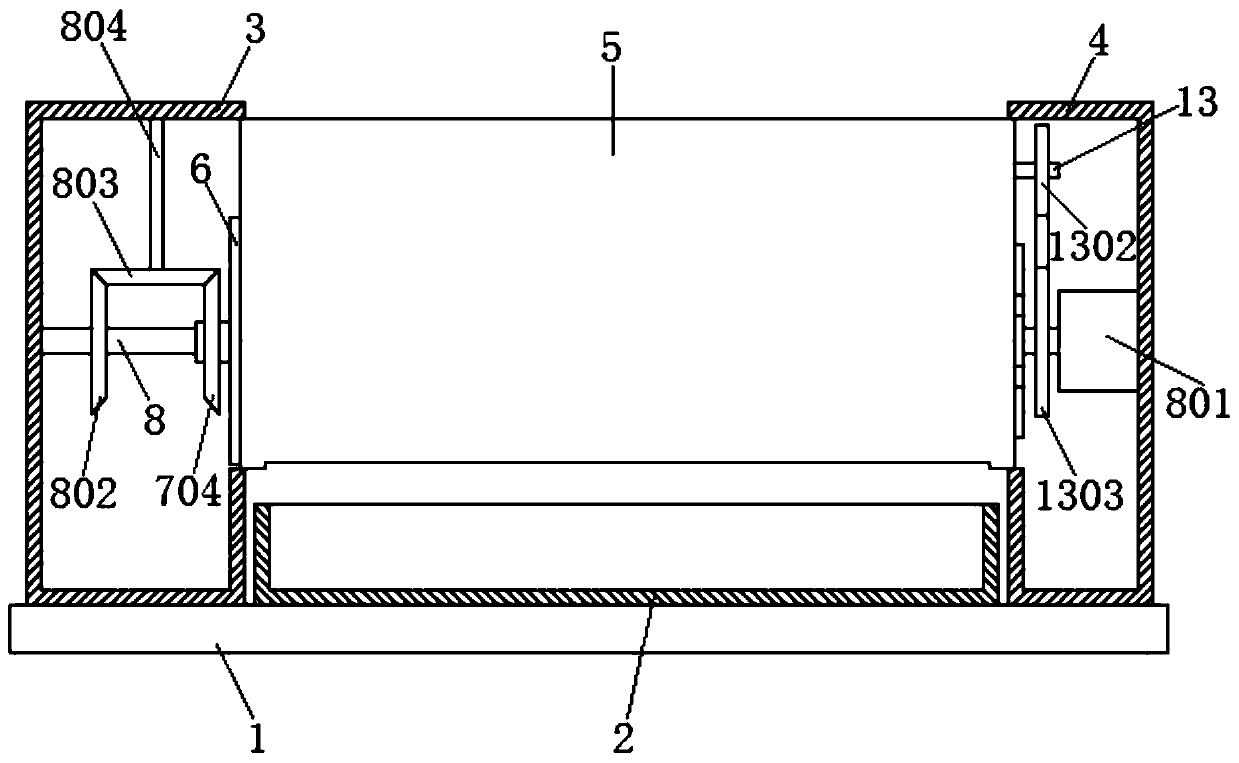

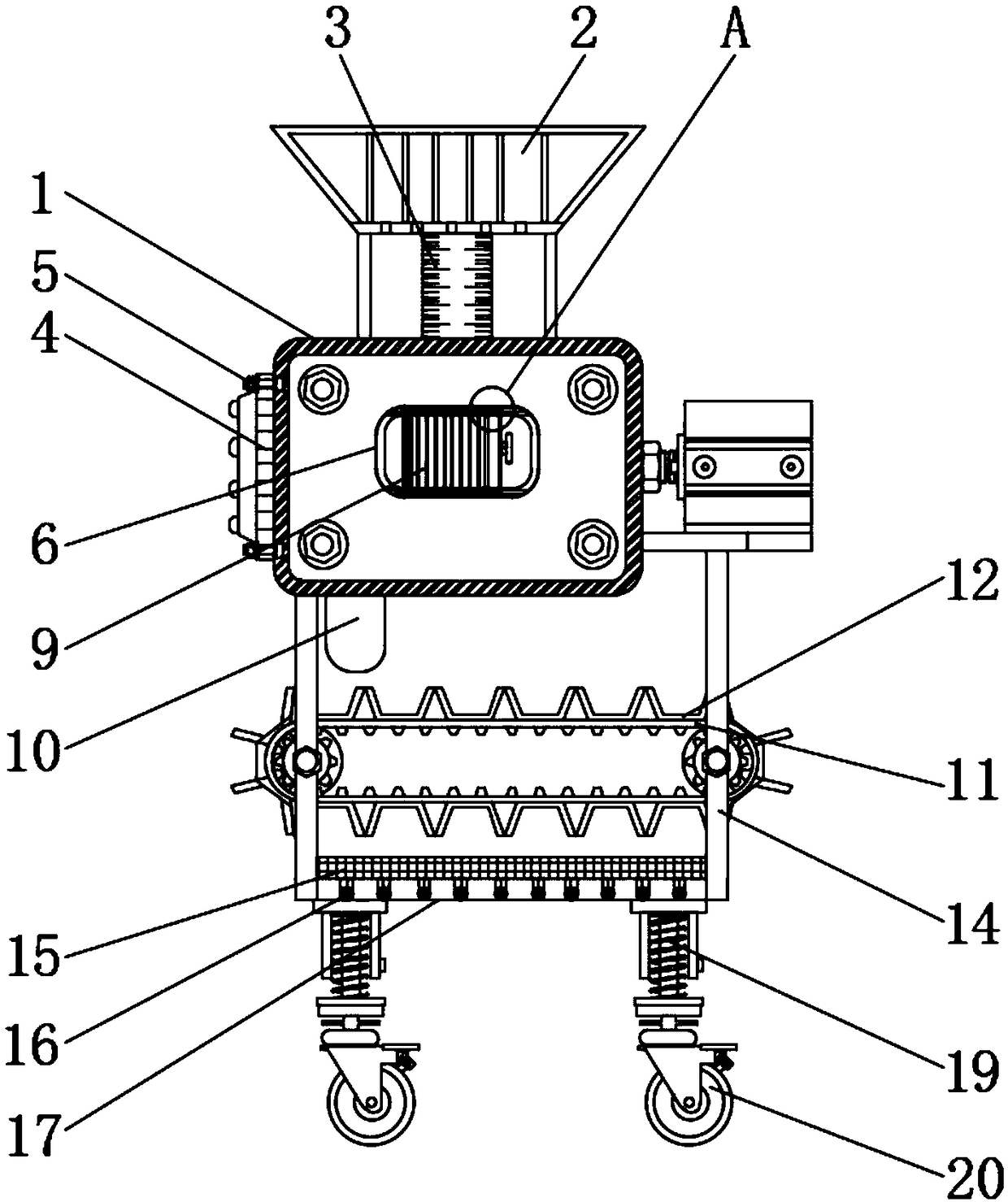

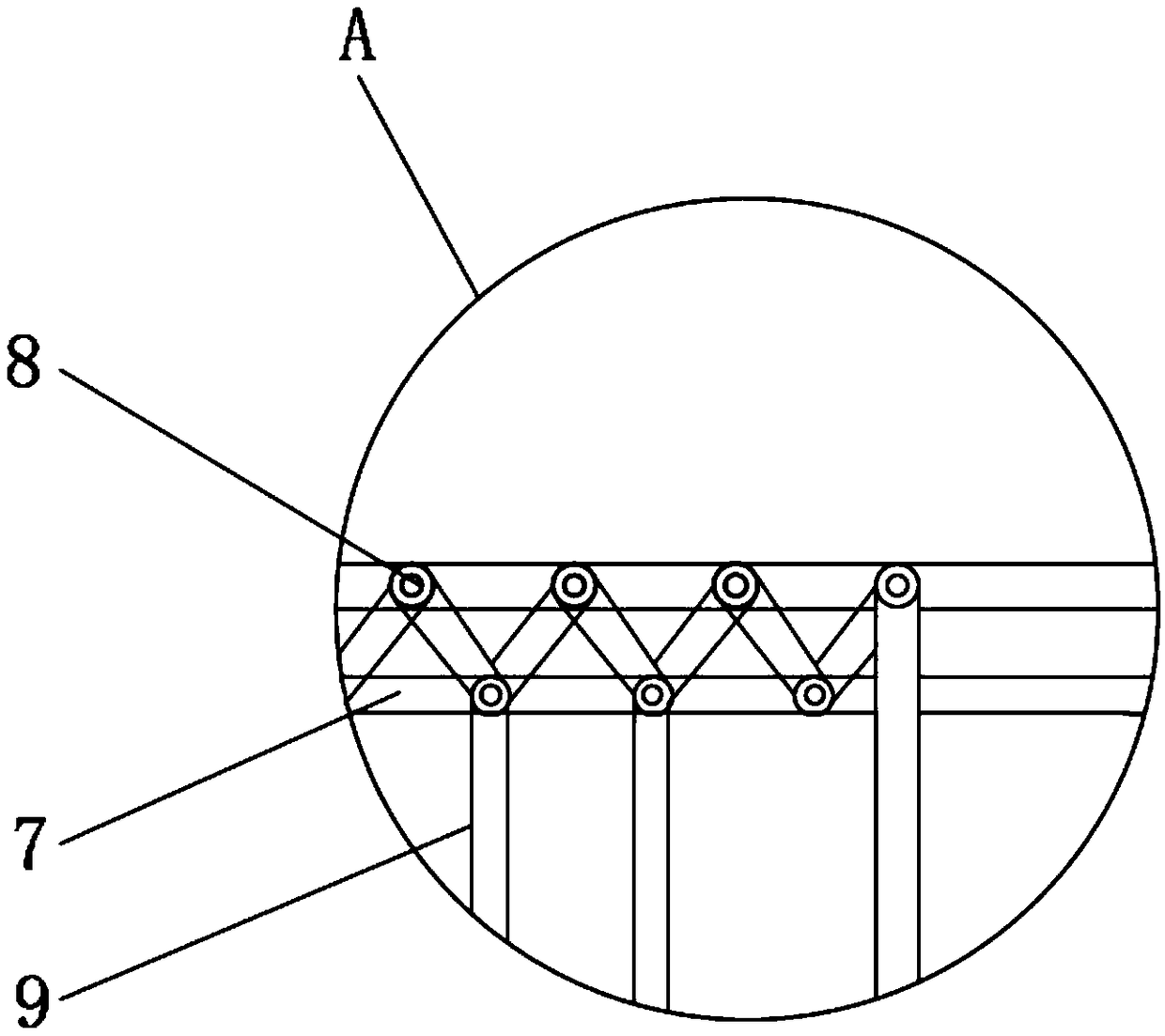

Low-breakage sunflower threshing machine capable of automatically adjusting de-seeding gaps

Owner:HENAN UNIV OF SCI & TECH

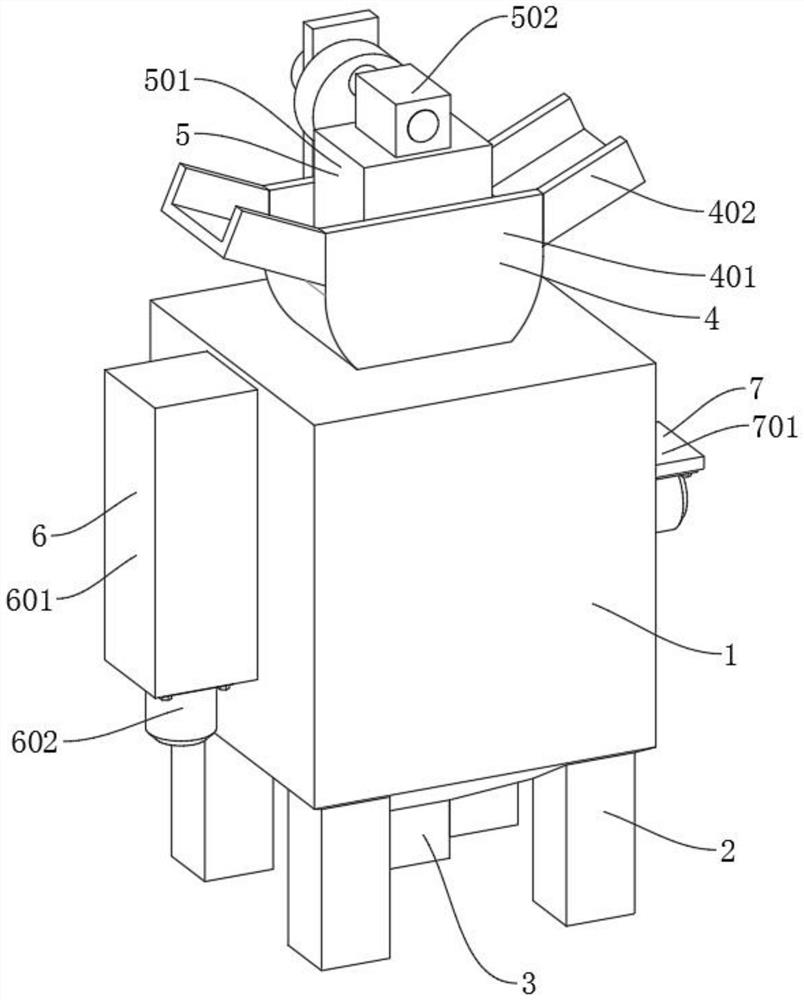

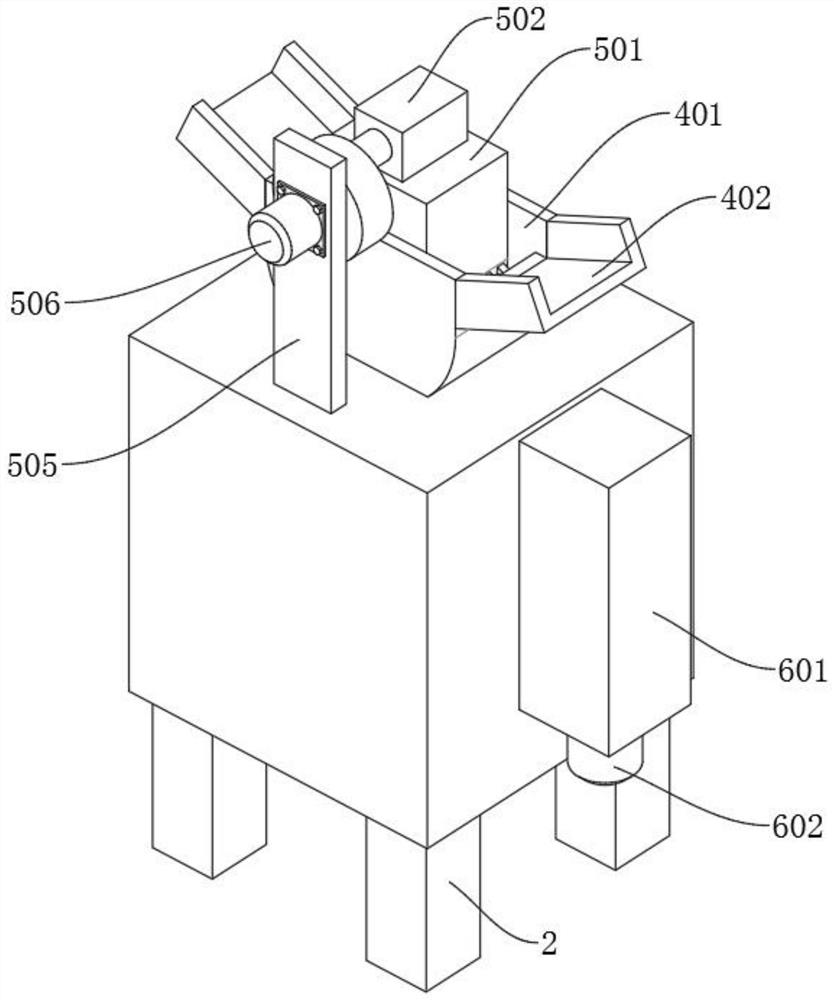

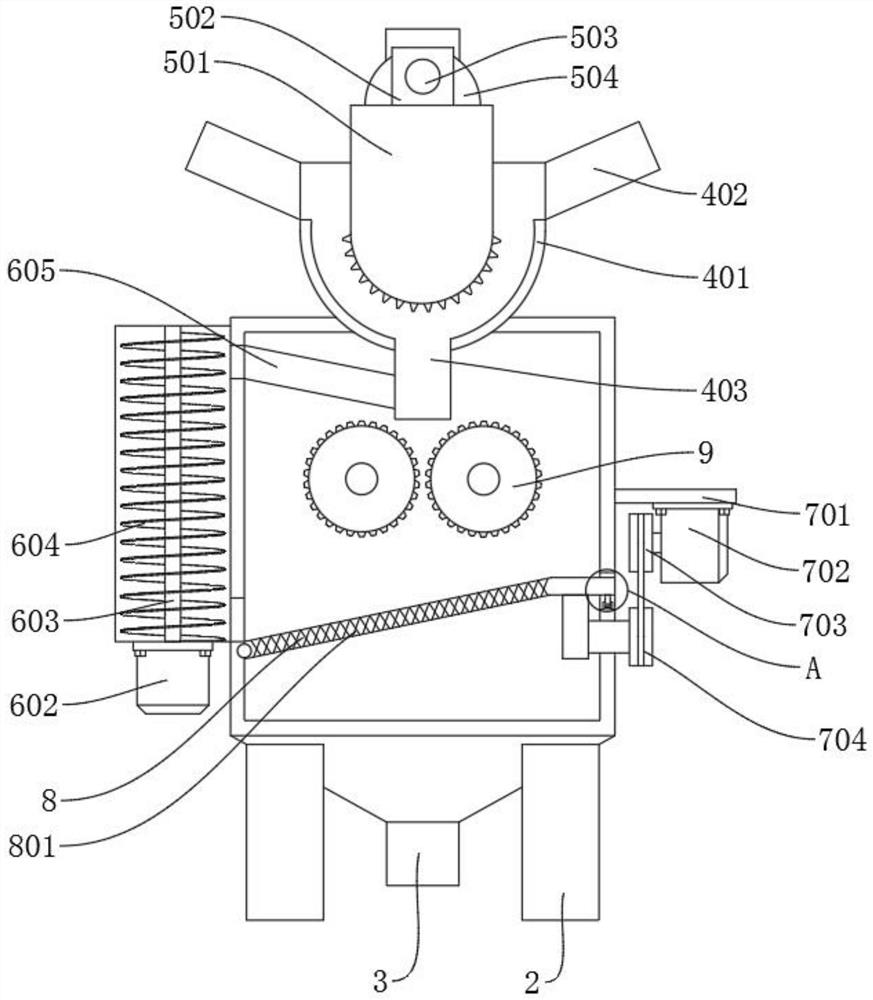

Environment-friendly civil engineering construction waste treatment equipment

PendingCN113713889ASave human effortImprove processing efficiencySievingScreeningConstruction engineeringWaste material

Owner:华新建工集团有限公司

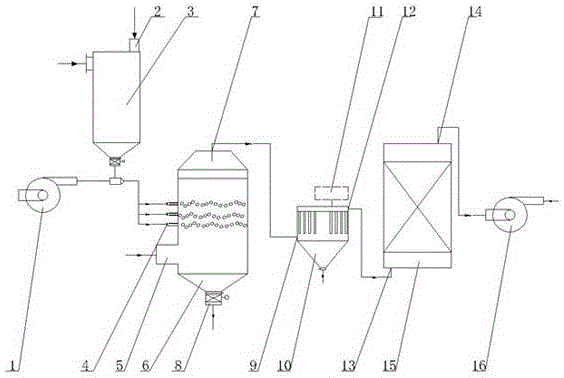

Treatment system of smoke organic waste gas produced in circuit board disassembly

Owner:SOUTH CHINA UNIV OF TECH

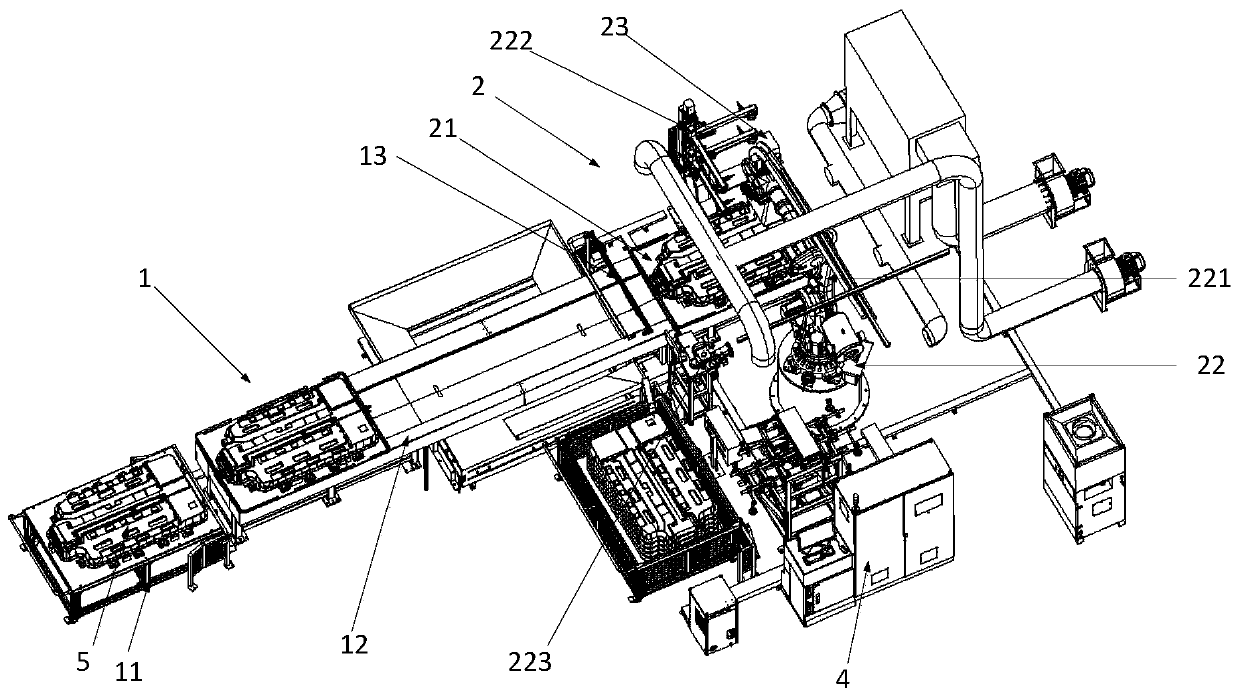

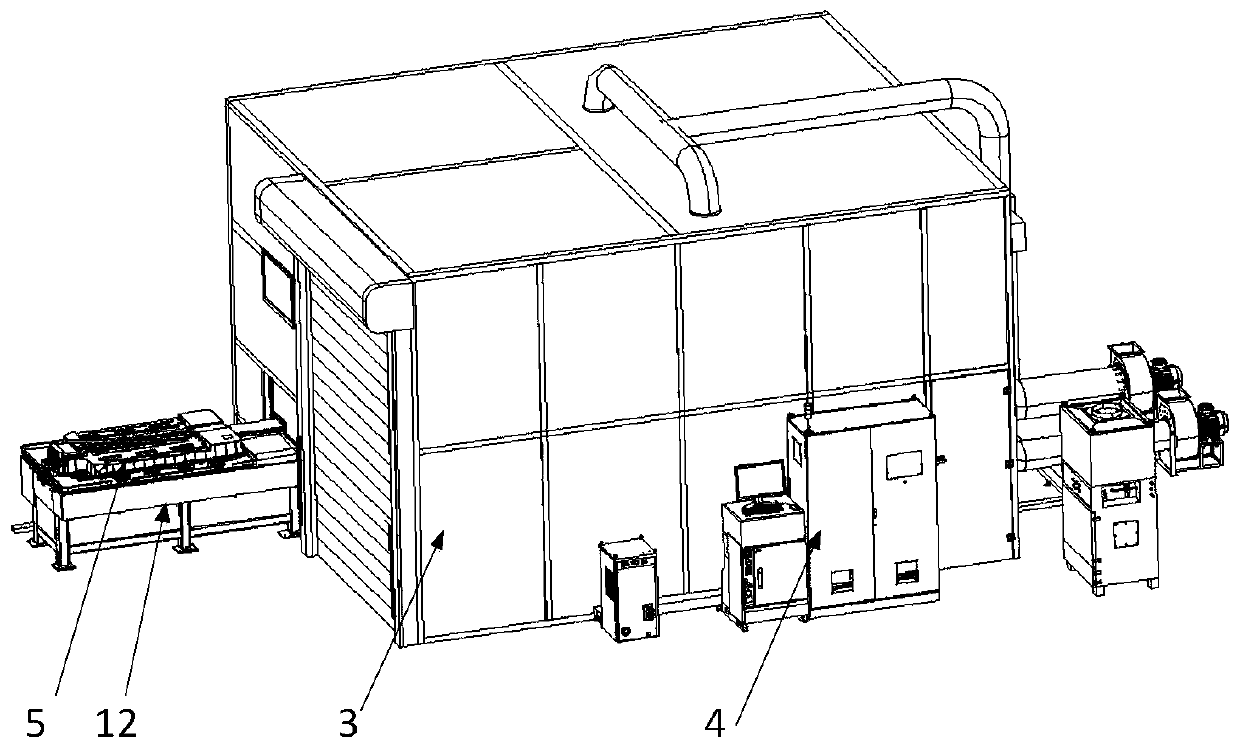

Repaired battery disassembling production line and implementation method thereof

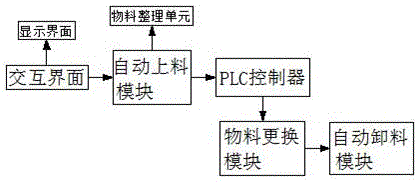

PendingCN111540975AImprove dismantling efficiencyReduce adverse effectsWaste accumulators reclaimingBattery recyclingControl systemProcess engineering

Owner:KUNSHAN WELD MECHANICAL EQUIP

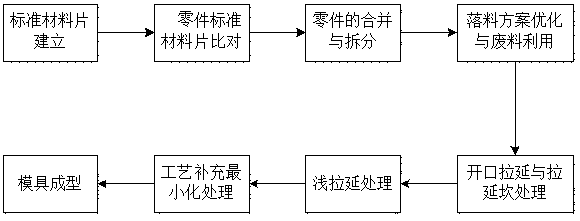

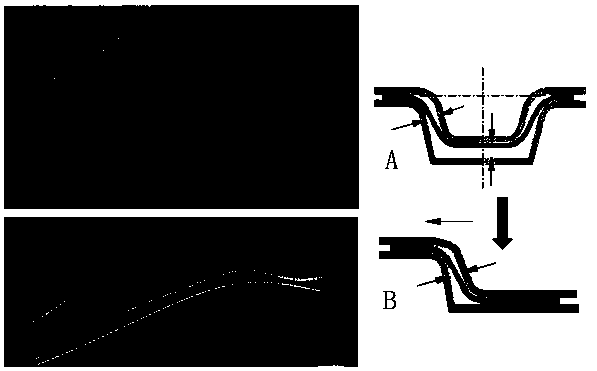

Intelligent forming method for automobile covering part mold

ActiveCN110929337AHigh material utilizationLow costGeometric CADDesign optimisation/simulationWaste materialCost savings

Owner:HEBI TIANQI MOTOR DIES

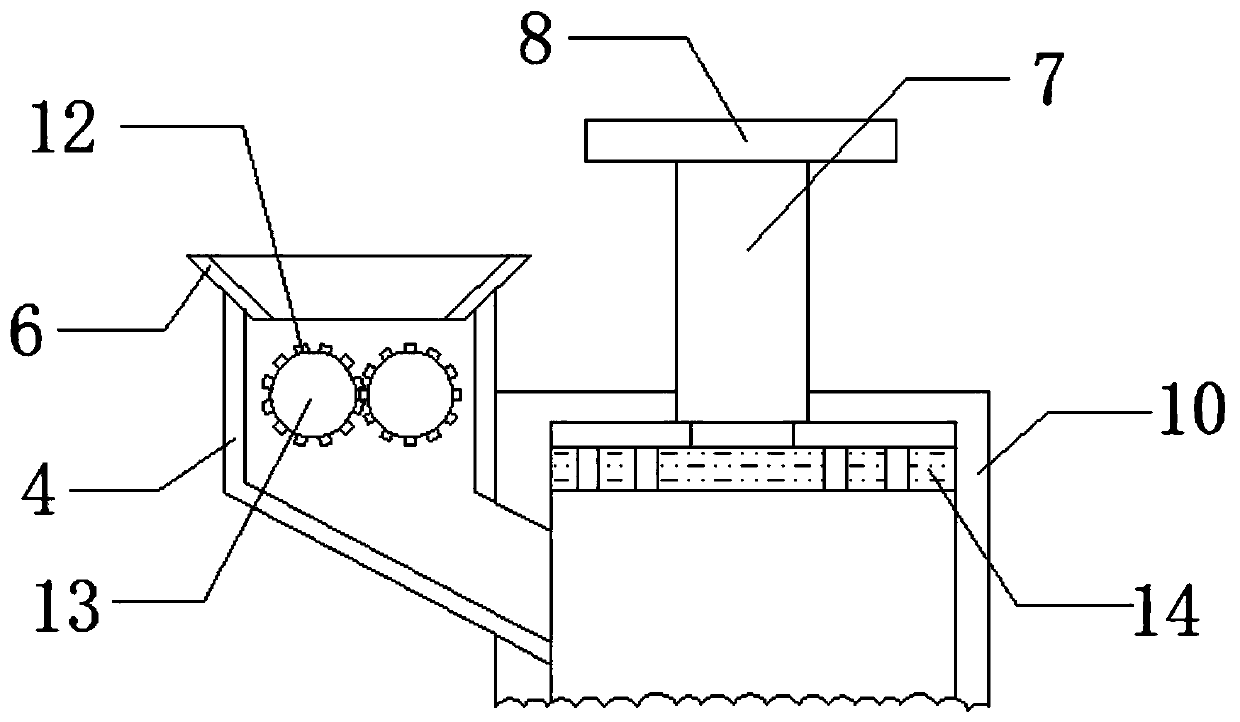

Environment-friendly disposal method for solid waste

InactiveCN110883059AIncrease unloading speedAvoid cloggingSolid waste disposalGrain treatmentsElectric machineEnvironmental engineering

The invention discloses an environment-friendly disposal method for solid waste. The solid waste to be disposed is put into a disposal box by a feeding hole and a feeding plate; a first motor drives afirst crushing roller to rotate, so the waste is preliminarily crushed; the crushed waste falls onto a second crushing roller, and a second motor drives the second crushing roller to rotate, so the waste can be further crushed; the crushed waste falls into a filtering screen, so the waste can be screened by the filtering screen; the screened waste falls onto a discharge plate and is discharged via a discharge hole; and chippings adhering to the inner wall of a device can be cleared by a vibration motor, so the discharge speed of the waste can be increased. The environment-friendly disposal method for the solid waste disclosed by the invention has the beneficial effects that the waste inside the device can be cleared through a vibration mode, so the discharge speed of the device can be increased; and the waste is prevented from adhering to the inside of the device and thus chocking the device, and thus influences on discharge of the device can be avoided.

Owner:TIANMEN YITIAN BEVERAGE TECH CO LTD

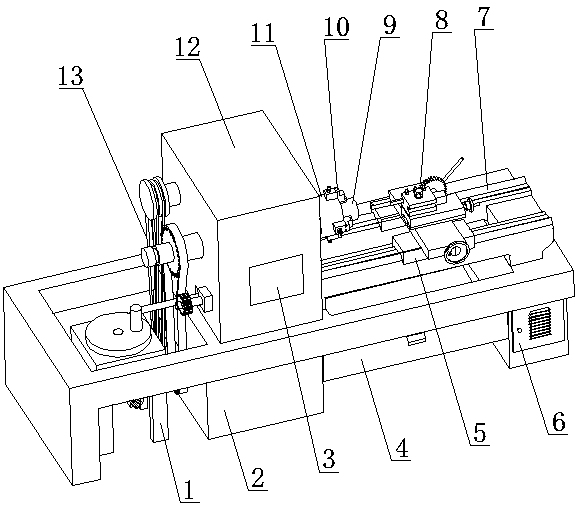

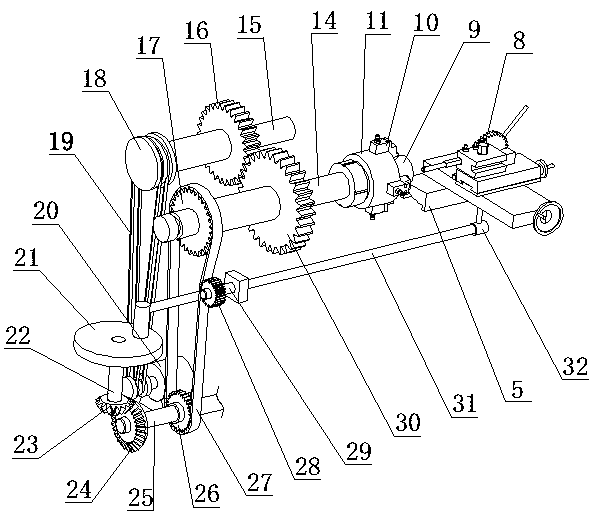

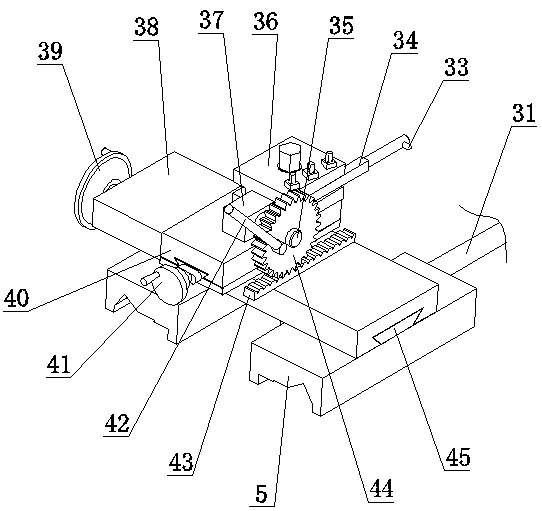

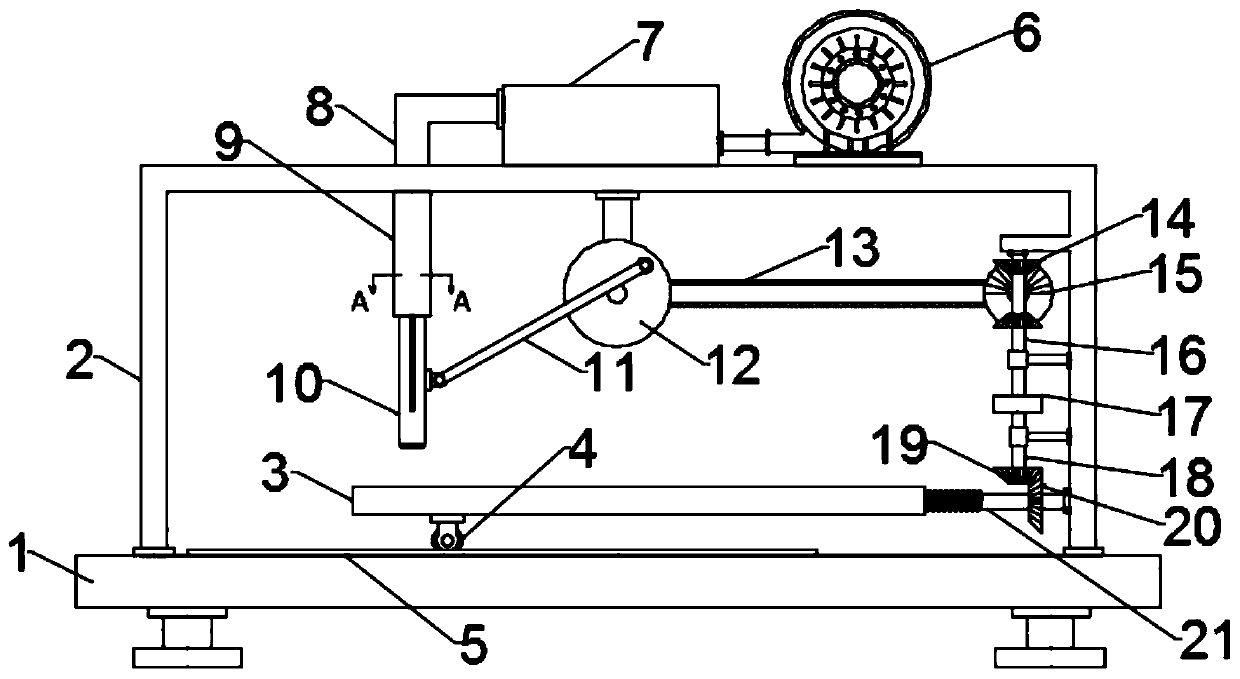

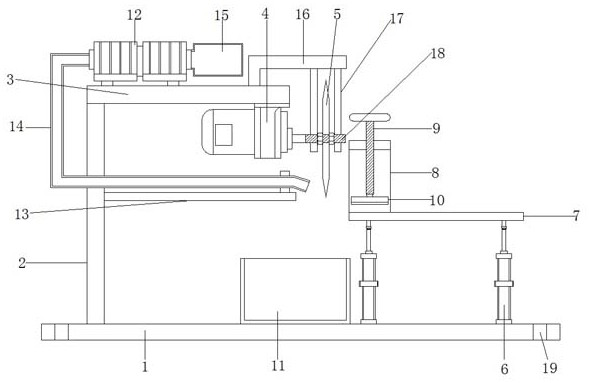

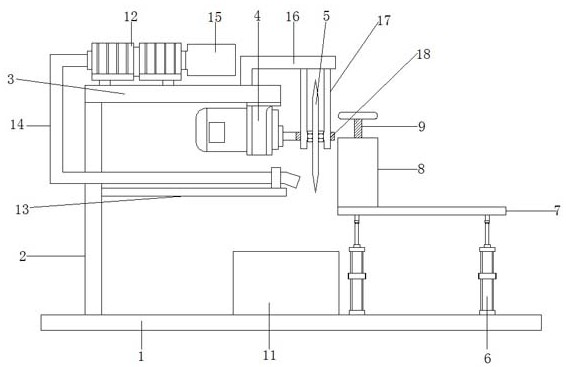

Shaft sleeve oil groove machining lathe

Owner:泉州市金典机械发展有限公司

Non-woven fabric punching equipment capable of processing waste

InactiveCN111496902AInnovative designEasy to punchMetal working apparatusPunchingProcess engineering

Owner:温州晨曦工艺品有限公司

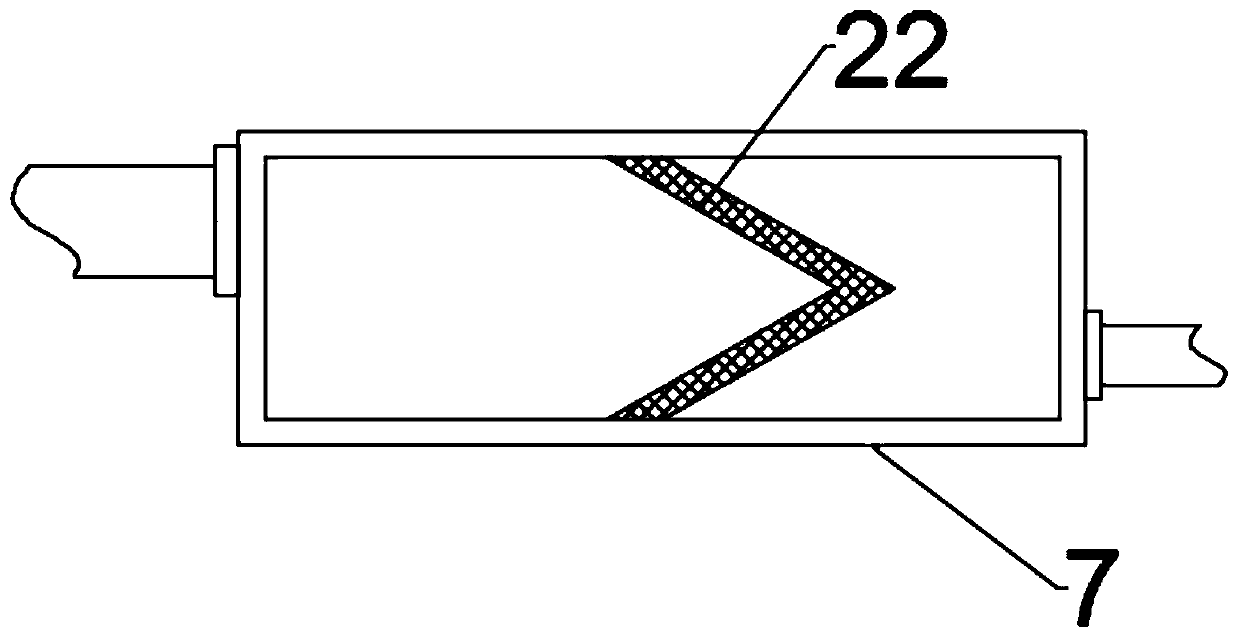

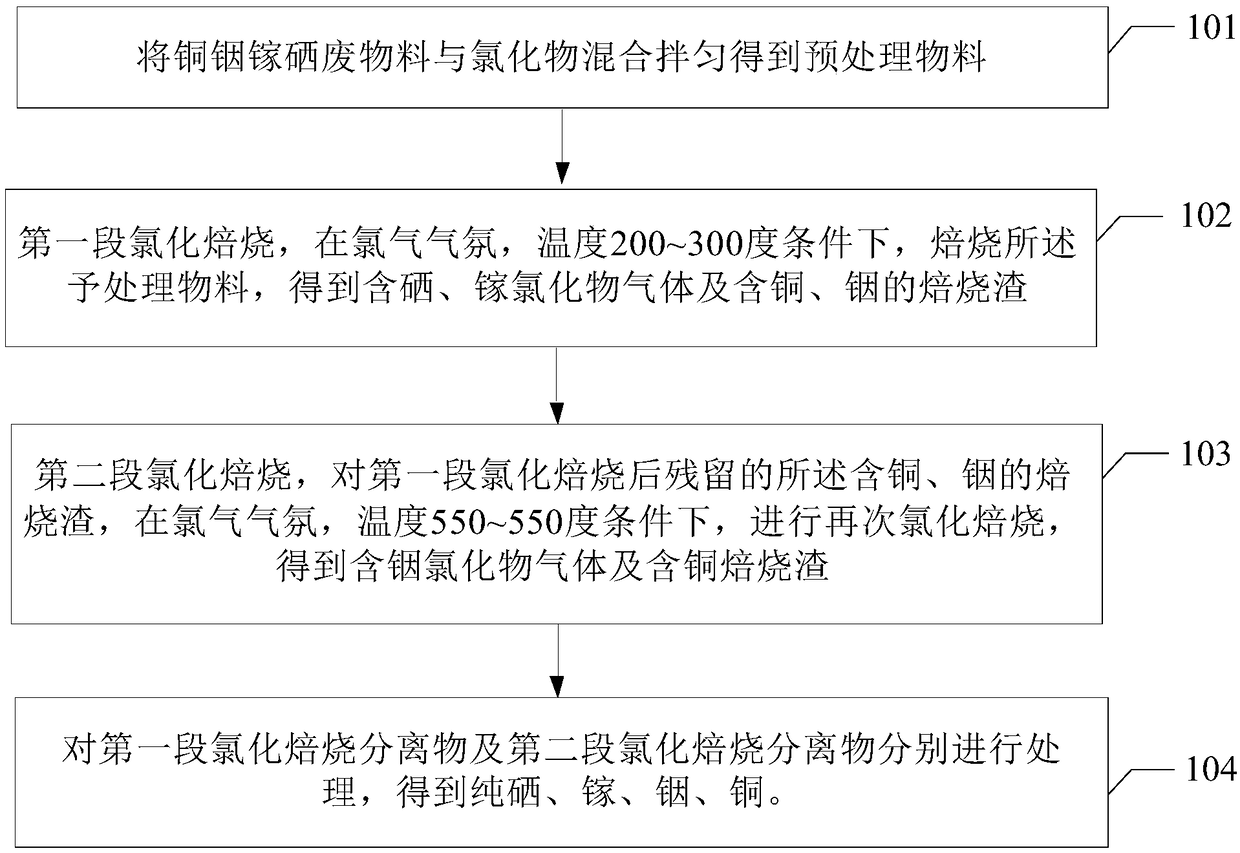

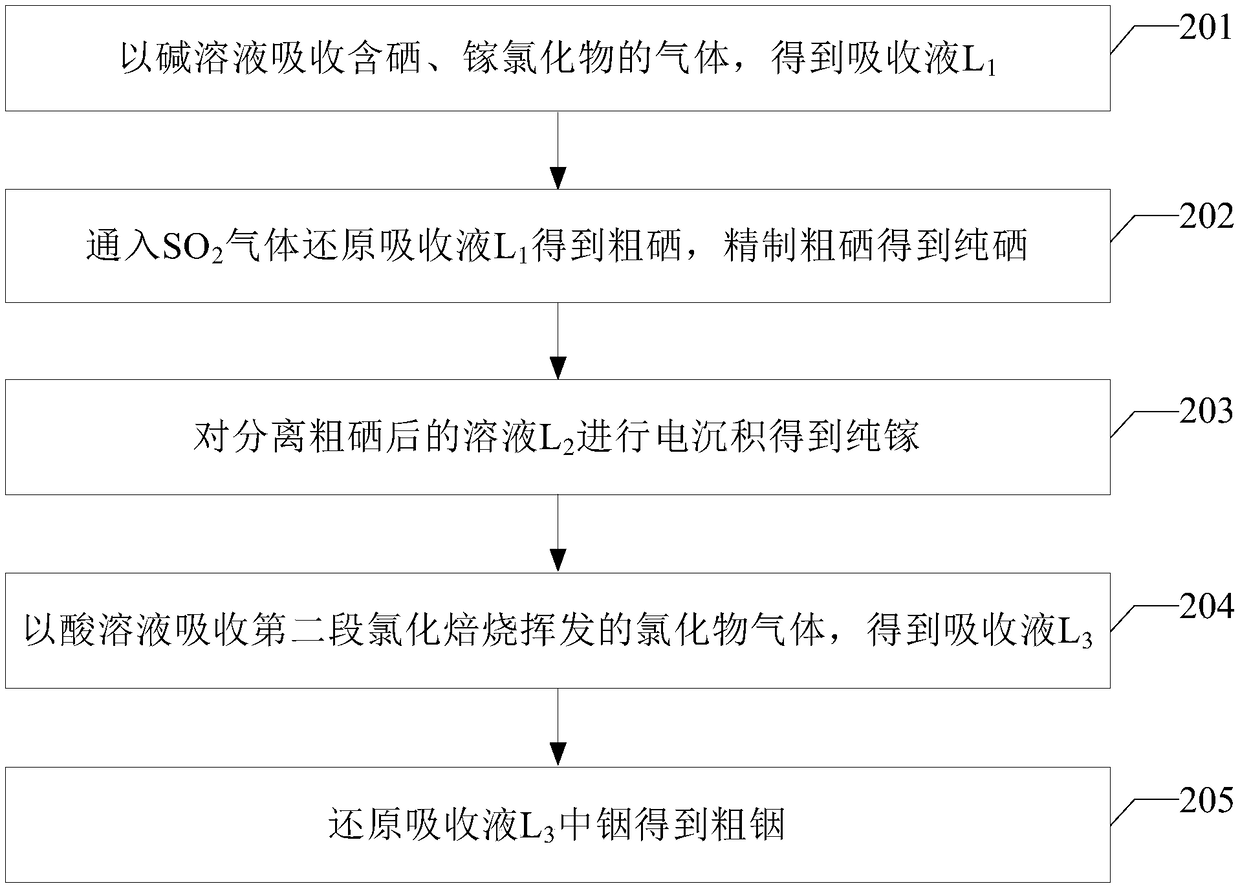

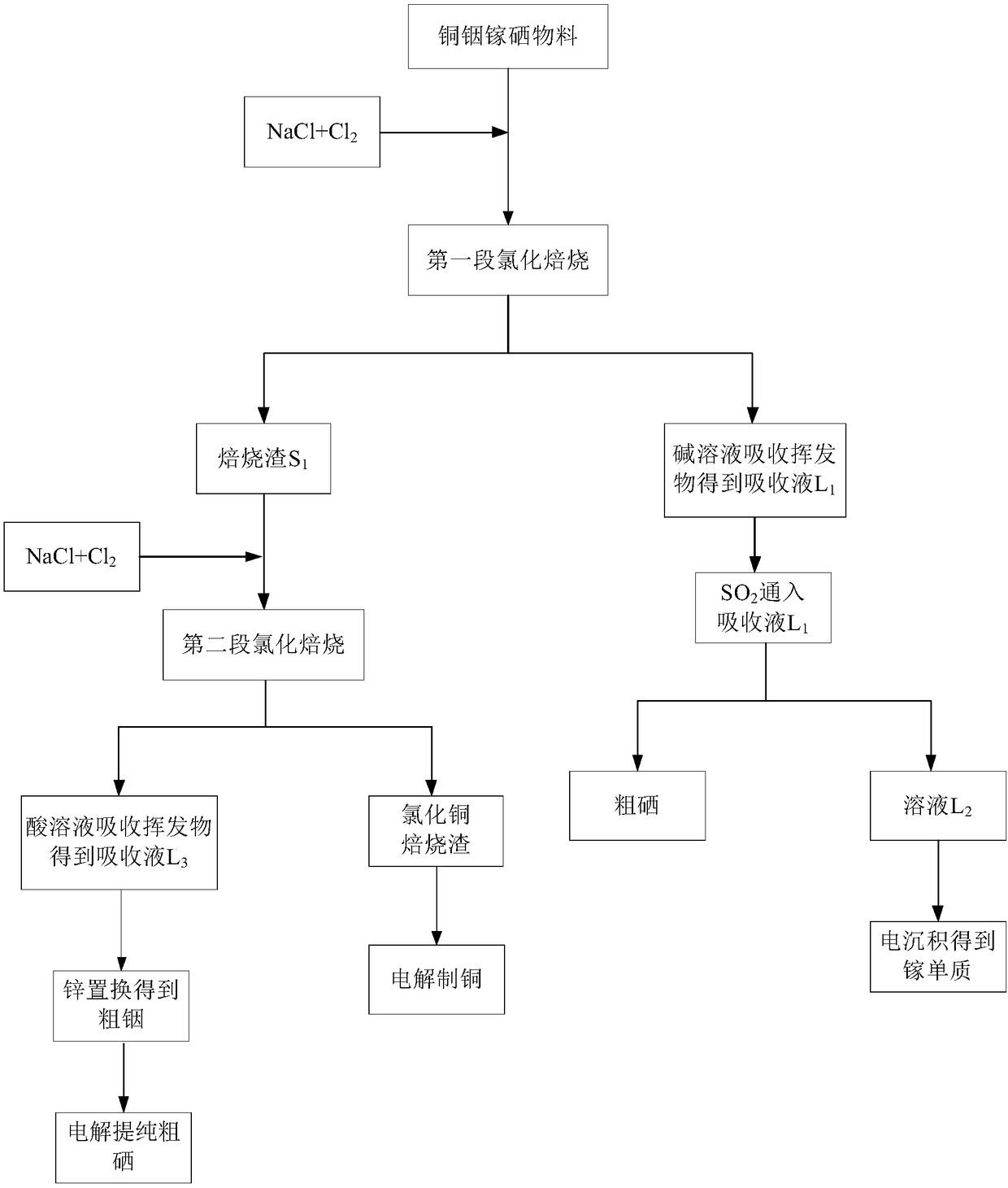

Recycling method of copper-indium-gallium-selenium waste material

Owner:HANERGY NEW MATERIAL TECH CO LTD

Building waste crushing device with dust removal function

ActiveCN114100756AConstruction waste recoveryDispersed particle filtrationWaste materialLight reflection

Owner:徐州金塘再生资源有限公司

Packaging bag waste collection machine

The invention discloses a packaging bag waste collection machine. The packaging bag waste collection machine comprises a collecting assembly and a guide assembly; the collecting assembly comprises a barrel seat, a charging barrel, a collecting rotation shaft, a barrel cover and a collecting motor; the charging barrel is located on the barrel seat; the collecting rotation shaft is rotationally arranged at the bottom of the charging barrel in a penetrating mode and stretches into the barrel seat, and the position, located in the barrel seat, of the collecting rotation shaft is sleeved with a first gear; the collection motor is arranged in the barrel seat; an output shaft of the collection motor is provided with a second gear, and the second gear is engaged with the first gear; the barrel cover is movably arranged at the top of the charging barrel; the guide assembly comprises a moving frame, a connection rod, a screw rod, a screw rod nut and a driving motor; the barrel wall is verticallyprovided with a long notch; and the positions, located at the long notch, of the barrel wall are provided with a first slide groove and a second slide groove. According to the packaging bag waste collection machine provided by the invention, packaging bag waste does not need to be manually collected any longer, the problems that the manual collecting efficiency is low, and time and labor are wasted are solved, and accordingly, the production cost is reduced.

Owner:HUNAN HENGSEN AGRI TECH CO LTD

Garbage compressing method for environmental protection

InactiveCN110978596AImprove sufficiencyImprove convenienceDispersed particle separationGrain treatmentsHydraulic cylinderElectric machine

Owner:天门市怡田饮品科技有限公司

Method for producing saline alkali soil conditioning agent through reconstituted tobacco concentrated waste liquor

InactiveCN105777422AIncrease valueLow costCalcareous fertilisersExcrement fertilisersLiquid wasteAlkali soil

The invention discloses a method for producing a saline alkali soil conditioning agent through reconstituted tobacco concentrated waste liquor.Paper-making reconstituted tobacco waste liquor is obtained for filtering separation, a liquid phase portion is fed into concentration equipment to be subjected to low-temperature vacuum concentration, the solid content of the concentrate is 40-55%, 65-85% of the concentrate, 15-35% of an organic matter carrier and 2-6% of a microbial agent are mixed, blended and mixed to be uniform, and low-temperature drying is performed to till the water content reaches 18-22%, and drying is performed after granulation is performed till the water content is lower than 14%.According to the method, the waste liquor can become available resources, waste materials are changed into things of value, the soil conditioning agent can be obtained to improve soil, and economic benefits of a reconstituted tobacco enterprise can be improved.

Owner:YUNNAN FUFA BIOTECH CO LTD

Rare earth crushing device for rare earth waste recovery

ActiveCN111036364AImprove crushing efficiencySimple structural designGrain treatmentsProcess engineeringWaste material

Owner:XUZHOU NANFANG YONGCI MATERIAL

A kind of method of recycling permanent magnet ferrite waste

Owner:自贡市江阳磁材有限责任公司

Puffing device with drying function for potato chip processing

Owner:潍坊华高信息科技有限公司

Cutting device with leftover material collecting function for mechanical equipment production

InactiveCN112157701AEasy to collectReduce manufacturing costMetal working apparatusElectric machineryWorking environment

Owner:湘潭普发工程有限公司

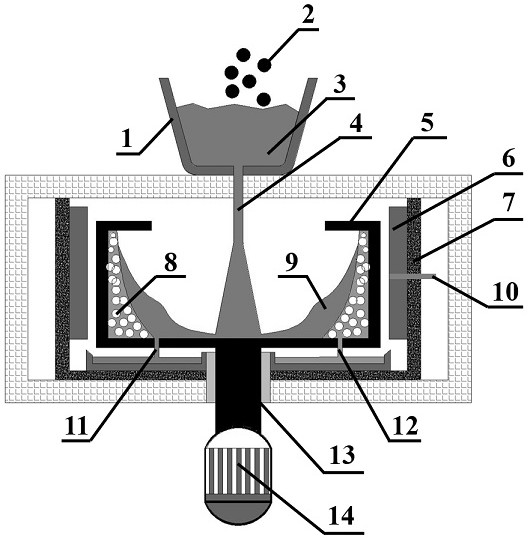

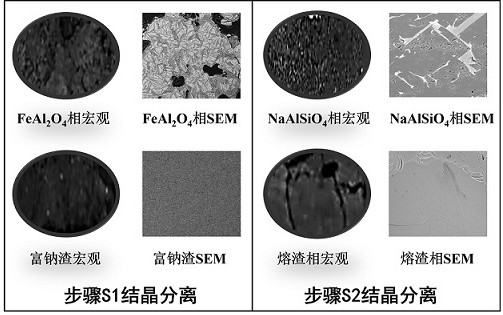

Method and equipment for eliminating high alkalinity of red mud through supergravity

ActiveCN114833166AEliminate high alkalinityEliminate fractional crystallization separationSolid waste disposalProcess efficiency improvementSlagRed mud

Owner:UNIV OF SCI & TECH BEIJING

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap