Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56 results about "Sodium silicate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium silicate is a generic name for chemical compounds with the formula Na₂ₓSiO₂₊ₓ or (Na₂O)ₓ·SiO₂, such as sodium metasilicate Na₂SiO₃, sodium orthosilicate Na₄SiO₄, and sodium pyrosilicate Na₆Si₂O₇. The anions are often polymeric. These compounds are generally colorless transparent solids or white powders, and soluble in water in various amounts.

Optical element cleaning agent and cleaning method thereof

InactiveCN102102050AEasy to useEasy to cleanInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsUltrasonic assistedWater conductivity

The invention relates to an optical element cleaning agent and a cleaning method thereof. The cleaning agent comprises the following components: sodium hydroxide, sodium tripolyphosphate, sodium silicate, sodium dodecyl benzene sulfonate and emulsifiable penetrant. The cleaning method comprises: preparing a cleaning agent by mixing sodium hydroxide, sodium tripolyphosphate and emulsifiable penetrant according to a weight percentage ratio and dissolving the cleaning agent in water in a container to form cleaning agent aqueous solution I; preparing a cleaning agent by mixing the raw materials including sodium silicate, sodium dodecyl benzene sulfonate and emulsifiable penetrant, and dissolving the cleaning agent in water in a container to form a cleaning agent aqueous solution II; using the cleaning agent aqueous solution I and the cleaning agent aqueous solution II with assistance from ultrasonic waves and a pure water conductivity of greater than 8Mohm, wherein the concentration of the cleaning agent aqueous solution I and the concentration of the cleaning agent aqueous solution II are both 0.1 to 0.8 percent and the temperature of the aqueous solutions is 30 to 70 DEG C; and performing the steps of rinsing, dewatering, steaming and the like to accomplish cleaning. The cleaning method is convenient to use, low in cost and good in cleaning effect.

Owner:JIANGXI PHENIX OPTICS TECH CO LTD

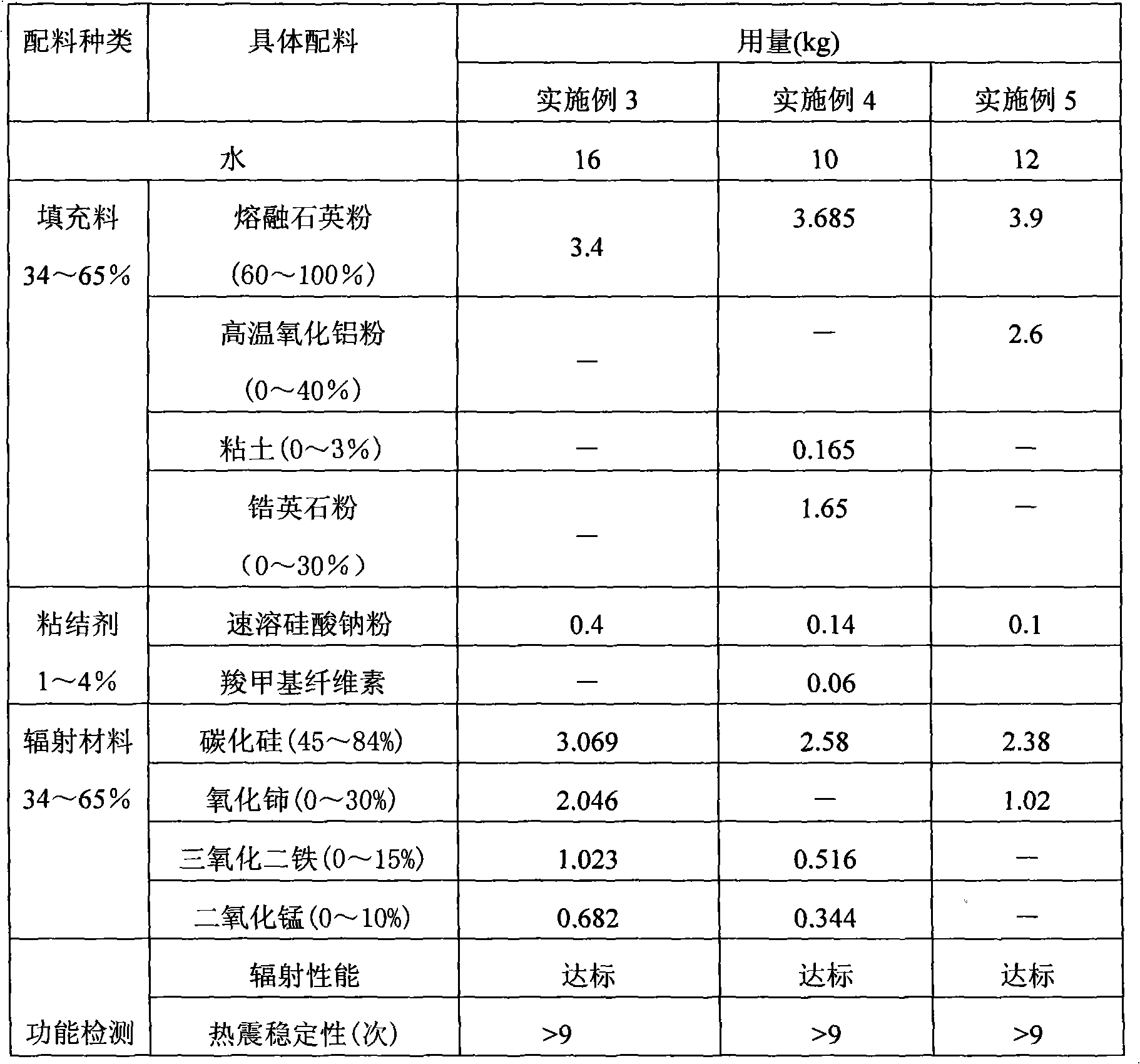

Inorganic radiation paint for inner lining of kiln

InactiveCN101343427AImprove thermal shock resistanceReduce the probability of cracking and falling offChemical industryReflecting/signal paintsCarboxymethyl celluloseFilling materials

Owner:CHINA BUILDING MATERIALS ACAD

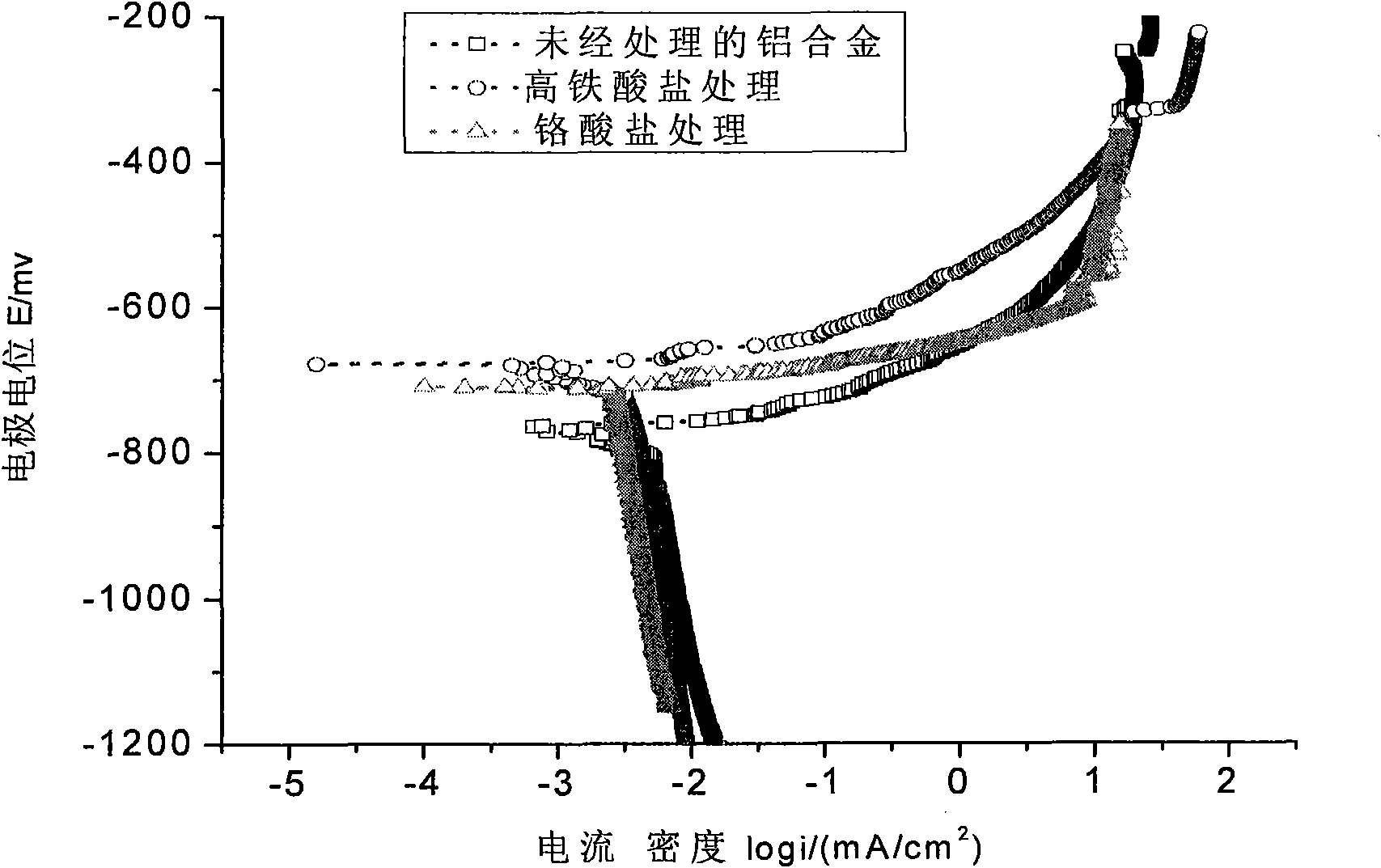

Organic and inorganic composite aluminium alloy non-chromium passivation treatment fluid

InactiveCN101565826AWith "self-healing" functionImprove corrosion resistanceMetallic material coating processesAcrylic resinPhosphoric acid

Owner:UNIV OF SCI & TECH BEIJING

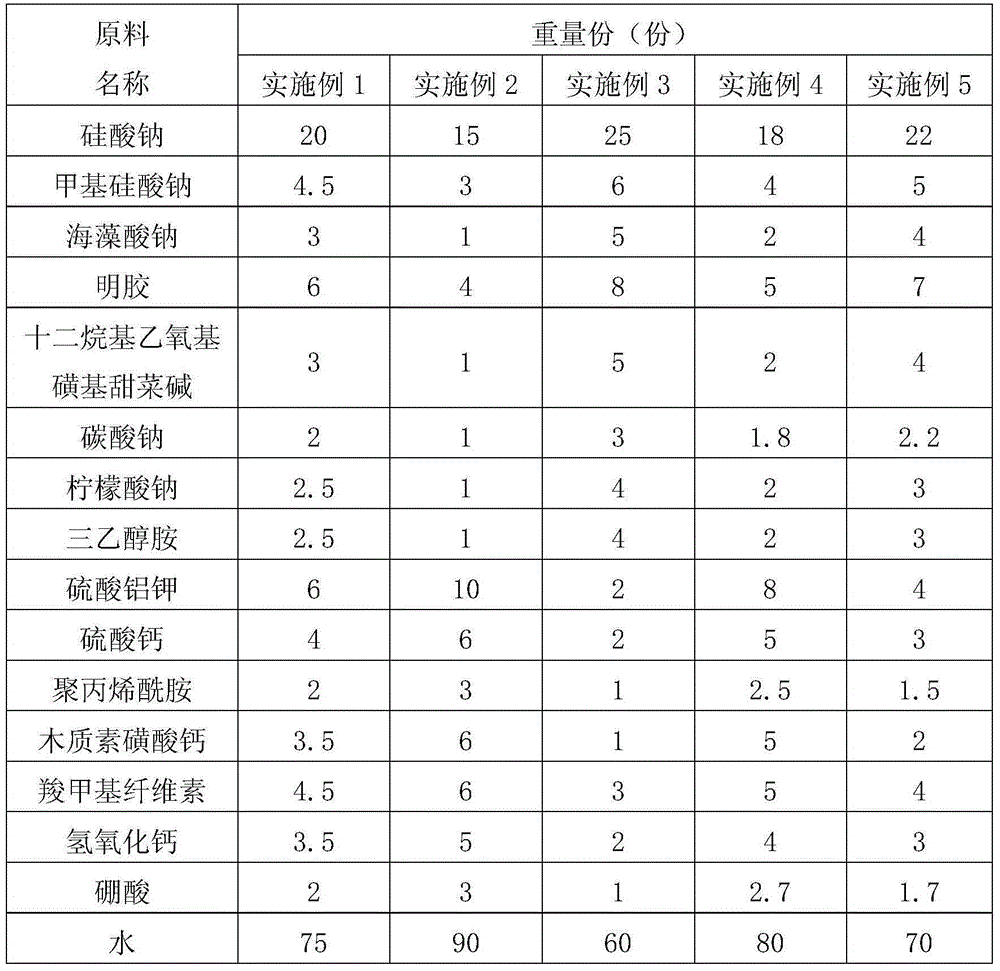

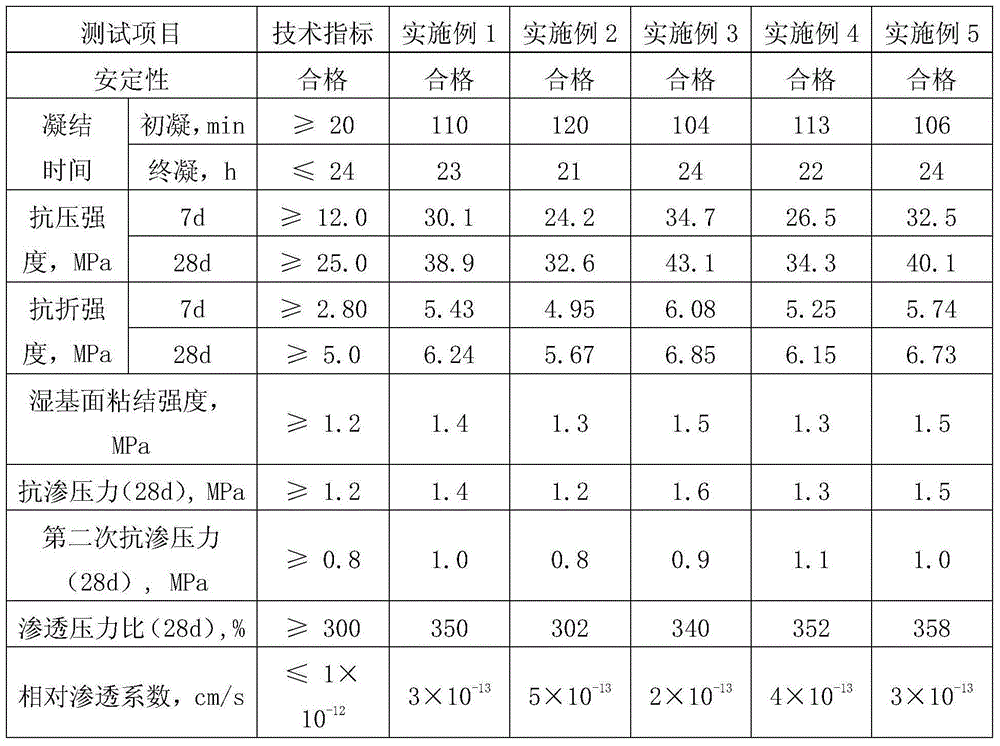

Permeable crystallization type concrete waterproofing agent

Owner:GUILIN HEXIN WATERPROOF DECORATION MATERIAL

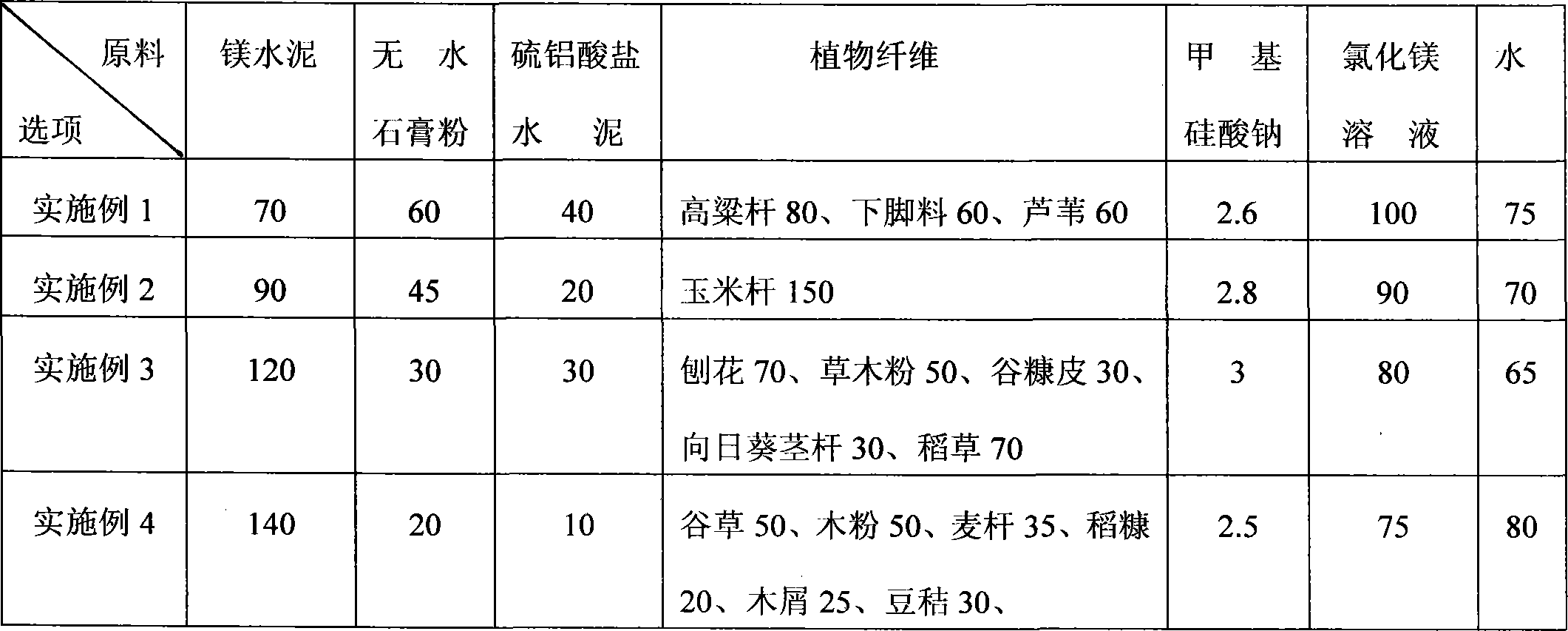

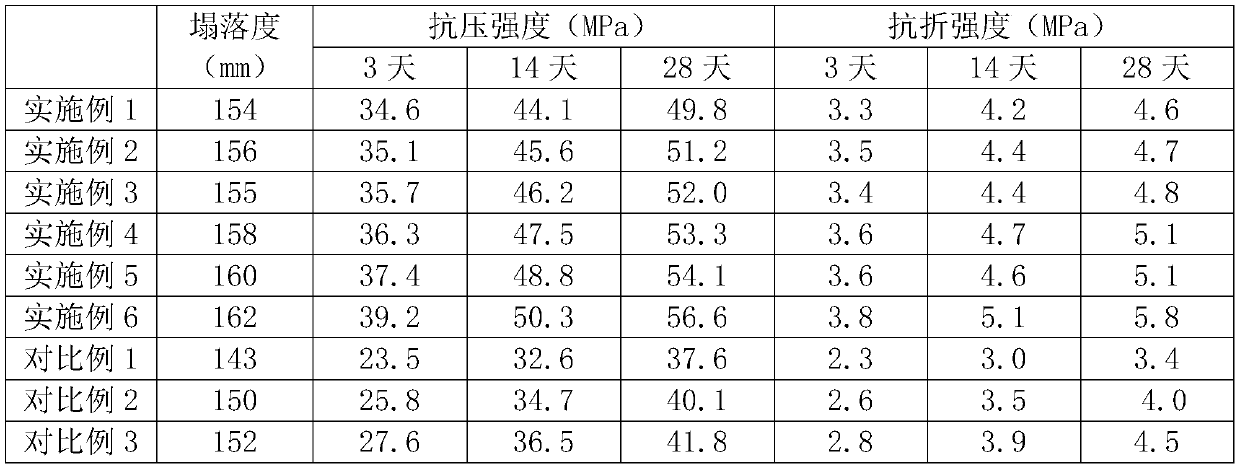

Magnesium-calcium pyrophyte pressed-fibre board and method of manufacturing the same

InactiveCN101172825AObvious beneficial effectGood effectSolid waste managementWeather resistancePlant fibre

Owner:谢涛

Recycled concrete and preparation method thereof

Owner:陕西金基石新型建材有限公司

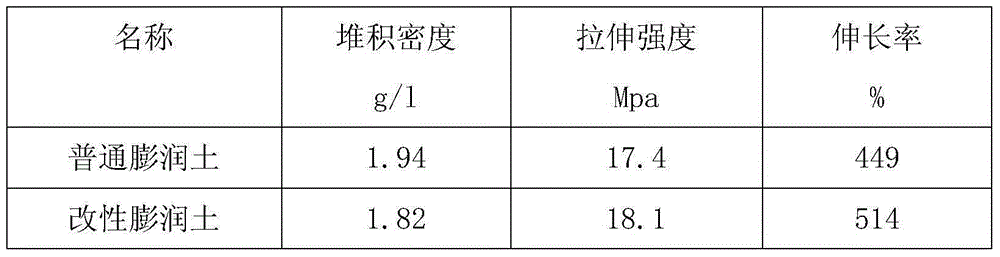

Porous modified bentonite with foaming effect and preparation method thereof

InactiveCN105126779APorousReasonable formulaOther chemical processesAlkali metal oxides/hydroxidesPorositySodium Bentonite

Owner:安徽雪城超细碳酸钙有限公司

Method for making bricks by using construction wastes

The invention discloses a method for making bricks by using construction wastes. The bricks are characterized by comprising the following raw materials: 30-57 parts of crushed aggregates of construction wastes of which the metal particles are removed and the diameter is small than 14mm, 20-40 parts of coal gangue particles, 10-15 parts of phosphate slag with the particle diameter being less than 1mm, 8-15 parts of cement, 0.6-0.8 part of quick lime, 3-18 parts of pulverized fuel ash, 0.01-0.025 part of a hydroxyl silicon sealed curing agent, 8-12 parts of water and 0.1-0.2 part of sodium silicate. The crushed aggregates of construction wastes can be dismantled materials of old buildings or wastes of novel buildings, and an anti-freezing agent or an anti-freezing chlorine salt can be added into the raw materials. The method has the advantages that the proportioning is simple, the energy is renewable, the environment is protected, and the wastes are utilized.

Owner:HEFEI BAOLI ENVIRONMENTAL PROTECTION TECH

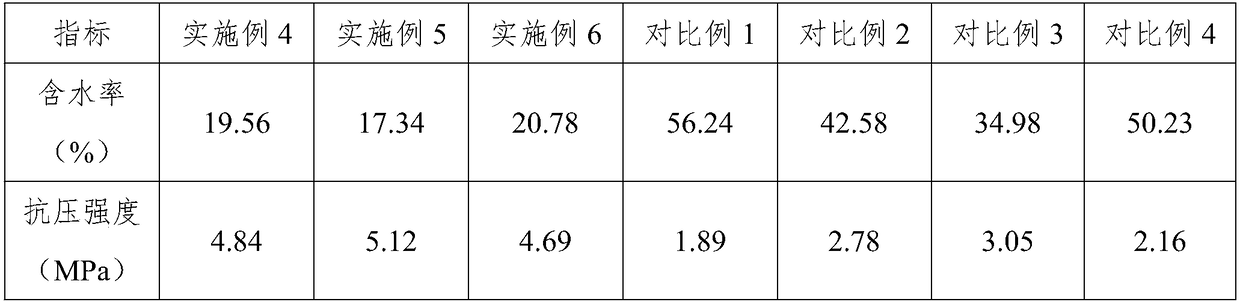

Sludge solidifier and preparation method thereof

ActiveCN108314280AImprove water qualityReduce pollutionFixation/solidifcation sludge treatmentSulfateSludge

Owner:GUANGZHOU WATER CONSERVANCY & HYDROPOWER STATION CONSTR ENG

Environment-friendly, heat-preserving and waterproof building composite board and preparation method thereof

Owner:芜湖浩权建筑工程有限公司

Heat-resistant modified asphalt

Owner:WUJIANG HUAWEI SPECIAL OIL

Molding sand sodium silicate binding and collapsing agent for casting

Owner:QINGDAO WUYANG CASTING MACHINE

Concrete high-efficiency water reducer and preparation method thereof

Owner:KUNMING ANXIA NEW MATERIAL SCI & TECH CO LTD

High-strength crack-resistant concrete and producing method thereof

Owner:南京加豪新型建筑材料有限公司

Antibacterial coating

Owner:王文浩

Environment-friendly ceramic coating material for water faucet

InactiveCN106189561ACorrosion resistantWear-resistantAnti-corrosive paintsCarbon fibersPolybutylene terephthalate

Owner:朱燕华

Cement additive

Owner:TONGLING HAIYUAN SUPERFINE POWDER

Honeycomb denitration catalyst with water resistance and preparation method therefor

InactiveCN105413678AHigh mechanical strengthExtended service lifeGas treatmentDispersed particle separationPtru catalystFlue gas

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

Preparation method of graphene and inorganic polymer composite electrode

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

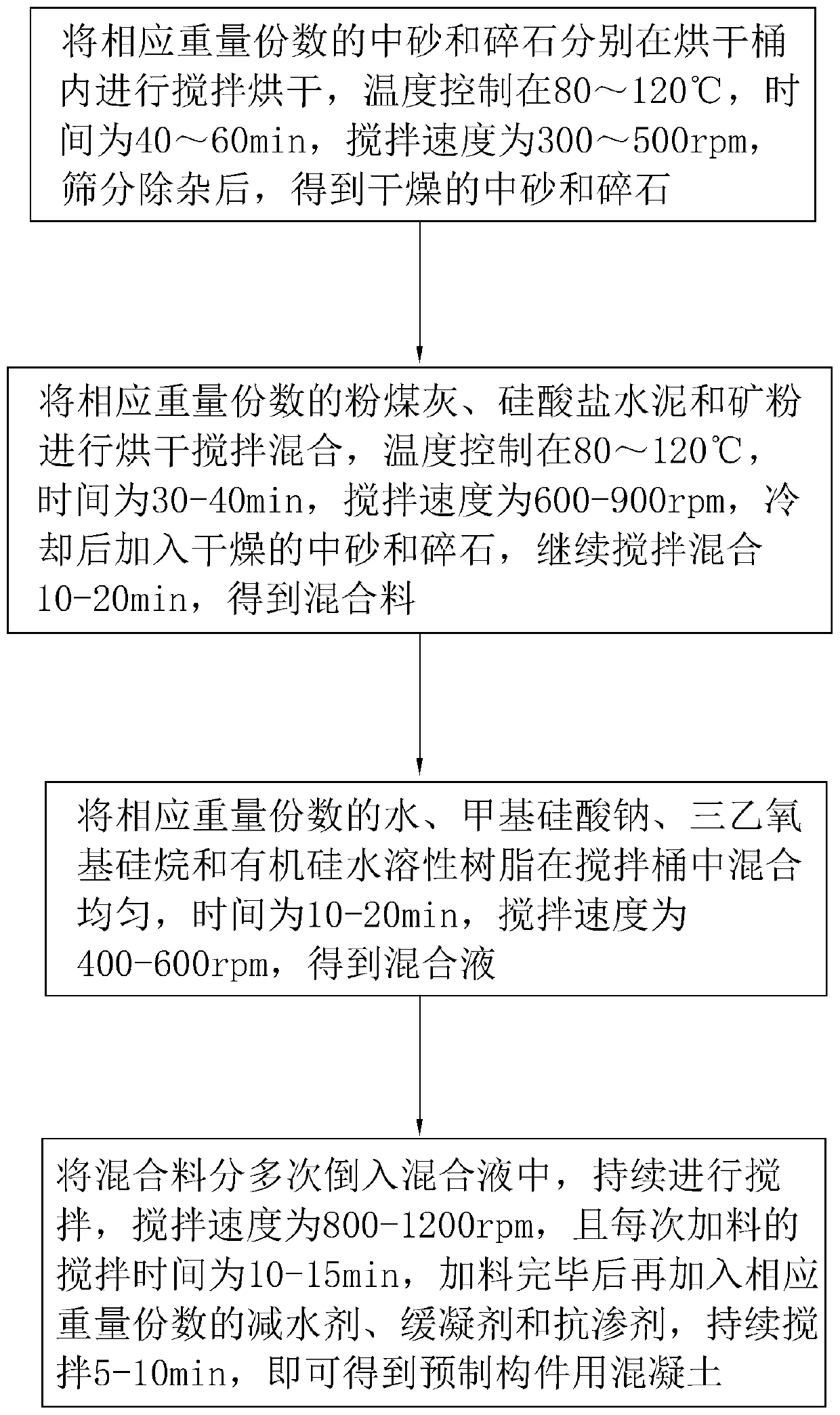

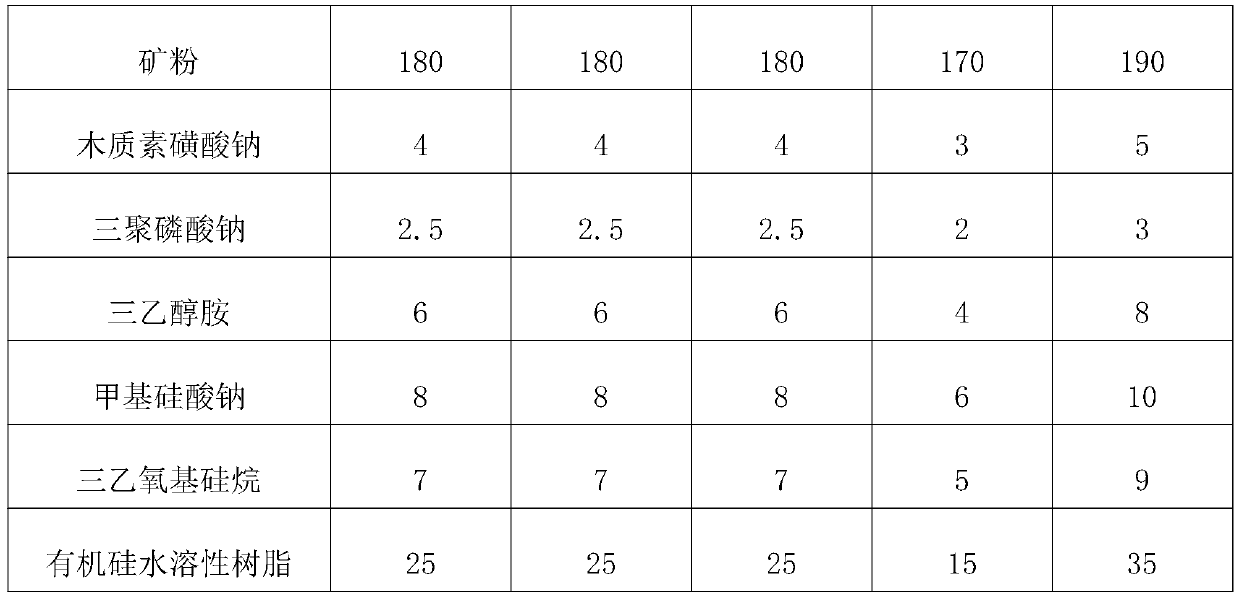

Concrete for prefabricated part and preparation method thereof

Owner:上海石化安东混凝土有限公司

Sealing adhesive used for automobile part changing

Owner:绩溪县徽洋车桥有限责任公司

Ceramic tile green body produced by ceramic waste and preparation method thereof

InactiveCN107857567ALow costProtect environmentCeramic materials productionClaywaresScrapSodium silicate

The invention discloses a ceramic tile green body produced by ceramic waste. The ceramic tile green body is characterized by being prepared from the following raw materials in percentage by weight: 15-35% of clay, 40-60% of polishing waste, 10-30% of waste green body powder, 0-10% of sand, 0.5-3% of talcum, 0.5-1% of sodium silicate, 0.2-0.5% of a water reducing agent and the balance of water. Theceramic tile green body is produced by the processed waste green body and the waste powder in the process of producing semi-finished products of ceramic factories; the waste raw materials are fully utilized; the cost is reduced; meanwhile, the water reducing agent is added into the ceramic material, so that the ceramic products can be degraded into powder under the natural condition; the environment is protected.

Owner:恩平市新锦成陶瓷有限公司

Dedicated fruit tree set fertilizer

InactiveCN106748288AImprove fertilityAvoid the effects of organic pollutionBio-organic fraction processingAlkali orthophosphate fertiliserPotassium permanganateOrganic component

The invention discloses dedicated fruit tree set fertilizer which is prepared from the following raw materials in parts by weight: 34 to 36 parts of soybean meal, 15 to 18 parts of needle mushroom dreg, 20 to 24 parts of monosodium glutamate residue, 3 to 4 parts of potassium pyrophosphate, 4 to 6 parts of ammonium bicarbonate, 1 to 2 parts of sodium polyphosphate, 2 to 3 parts of sodium silicate, 10 to 14 parts of chitosan, 0.3 to 0.5 part of potassium permanganate, 1.5 to 1.8 parts of manganese sulfate, 1 to 2 parts of acrylamide, 0.3 to 0.4 part of N,N'-methylene bisacrylamide, 2 to 3 parts of ammonium persulfate, 1 to 2 parts of zinc acetate, 0.2 to 0.4 part of yttrium nitrate, a defined amount of absolute ethyl alcohol and a defined amount of water. According to the fertilizer disclosed by the invention, organic components and inorganic components are reasonably matched; thus, the fertilizer has comprehensive nutrient elements and is easy to decompose and absorb; meanwhile, a release characteristic of a coating material of the fertilizer aims at different growth stages of a fruit tree germination stage, a growth period and a fruit swelling period; counterpart supplying of the total nutrient amount is achieved, fertilizer consumption is reduced, nutrient utilization rate is improved at the same time, a fertilizing process is simplified, and economic benefit of planting fruit trees is improved.

Owner:SUZHOU TIANYU CULTURE GRP

Electrochemical stripping solution formula for vacuum ion plating

Owner:广州市双石金属制品有限公司

Antibacterial ceramic glaze and preparation method thereof

PendingCN109399933AImprove antibacterial propertiesGuaranteed glaze effectMontmorilloniteSodium silicate

The invention discloses an antibacterial ceramic glaze and a preparation method thereof. The glaze includes 30-50 parts of montmorillonite, 30-50 parts of talc, 10-30 parts of quartz, 5-10 parts of barium carbonate, 5-15 parts of manganese dioxide, 10-25 parts of sodium silicate, 20-50 parts of feldspar, 5-10 parts of titanium dioxide, and 2-10 parts of silver nitrate. The antibacterial performance of the glaze can be enhanced while the glaze effect is ensured, and the antibacterial ceramic glaze can keep a stable and sustained antibacterial effect at high temperatures.

Owner:FOSHAN UNIVERSITY

Composite material for producing PVC plastic steel section and preparation method thereof

InactiveCN107266823AImprove mildew resistanceImprove high temperature resistancePlasticizerMagnesium stearate

The invention belongs to the technical field of door and window materials, and provides a composite material for producing PVC plastic steel sections and a preparation method thereof, wherein the composite material comprises the following raw materials in parts by weight: 160-190 parts of PVC, 2-6 parts of magnesium stearate, 11-13 parts of Phenolic Resin, 15-25 parts of polyethylene wax,-2-9 parts of sodium silicate, 1-4 parts of basalt fiber, 1.2-3.5 parts of forsterite powder, 2-4 parts of an anti-aging agent, 0.2-3.1 parts of a plasticizer, 0.4-2 parts of an additive and 1-2 parts of nano silver. The composite material uses the PVC as a main material, the anti-aging agent is compounded to improve the anti-aging properties of the material, the nano silver is compounded to improve the mildew resistance of the material, the basalt fiber is compounded to improve the mechanical properties and the anti-aging properties of the material, the forsterite powder is compounded to improve the high-temperature resistance, the plasticizer is compounded to make the mechanical properties of the material good, and the aging rate is reduced.

Owner:HEFEI YIZHI DOORS & WINDOWS CO LTD

Straw fiber material and preparation method thereof

InactiveCN107815749AConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsCoal Tar PitchesSodium silicate

Owner:WUHU BLUE SKY ENG PLASTIC CO LTD

Garden seedling soilless planting culture fluid and its preparation method

InactiveCN107365212AImprove disease resistancePromote photosynthesisAnimal corpse fertilisersExcrement fertilisersPlant hormoneRare-earth element

Owner:何玉莲

Production method of negative-ion chinlon short fibers

InactiveCN105671674ANegative ion function is goodGood effectMonocomponent polyamides artificial filamentArtifical filament manufactureFiberFlexural strength

The invention discloses a production method of negative ion nylon staple fiber, which comprises the following steps: 1) dropping 5-10 wt% sodium silicate aqueous solution into a suspension liquid of 300-400 mesh tourmaline fine powder with a solid content of 40-60% , keep the constant temperature at 50-70°C for 10-30 minutes, then separate the solid from the liquid and dry the solid to obtain anion particles; 2) mix nylon slices and anion particles at a weight ratio of 10-5:1, and heat up to a molten state , granulating to obtain the masterbatch; 3) spinning the masterbatch, cleaning, drying and winding the spinning to obtain far-infrared nylon staple fibers. Compared with the prior art, the nylon staple fiber obtained by the invention has good anion function, long-lasting effect, a tensile strength of more than 120Mpa, and a bending strength of more than 150Mpa.

Owner:ZHANGJIAGANG ANSHUN TECH DEV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap