Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

17 results about "Monosodium glutamate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Monosodium glutamate (MSG), also known as sodium glutamate, is the sodium salt of glutamic acid, one of the most abundant naturally occurring non-essential amino acids. Glutamic acid is found naturally in tomatoes, grapes, cheese, mushrooms and other foods. MSG is used in the food industry as a flavor enhancer with an umami taste that intensifies the meaty, savory flavor of food, as naturally occurring glutamate does in foods such as stews and meat soups.

Processing method of vinasse hairtails

Owner:SHENGSI COUNTY SHUNFA AQUATIC PROD FOOD

Snowflake chicken meat bar and preparation method thereof

Owner:濮阳市东大食品有限公司

Matcha beef balls and manufacture method thereof

InactiveCN107173705AKeep the scentIncrease elasticityPre-extraction tea treatmentMonosodium glutamateTangerine Peel

Owner:道真仡佬族苗族自治县忠情牧业有限公司

Purple cabbage beef jerky capable of reducing blood pressure and making method thereof

InactiveCN106213221AImprove textureGood tenderizing effectFood ingredient functionsMonosodium glutamateSodium erythorbate

The invention discloses purple cabbage beef jerky capable of reducing blood pressure and a making method thereof. The beef jerky is made from, by weight, 2-3 parts of purple cabbage, 1-2 parts of bread crumbs, 1-2 parts of sesame oil, 4-5 parts of pear juice, 0.5-1 part of salviae miltiorrhizae, 0.5-1 part of fried medicated leaven, 0.5-1 part of eucommia, 100-110 parts of beef, 0.4-0.5 part of papain, 1.8-2.0 parts of calcium chloride, 1.8-2.0 parts of D-sorbitol, 5-6 parts of salt, 0.03-0.04 part of lactobacillus casei, 0.1-0.2 part of sodium erythorbate, 12-15 parts of fresh ginger slices, 10-12 parts of ginger juice, 2-3 parts of soybean sauce, 5-6 parts of white granulated sugar, 1-2 parts of monosodium glutamate, 6-8 parts of Chinese rice wine, 3-4 parts of Chinese prickly ash, 1-2 parts of cinnamon, 1-2 parts of anise, 1-2 parts of fennel, 18-20 parts of dried orange peel extraction solution with the concentration of 140 mg / ml, and a proper amount of water. Sesame oil improves the taste and flavor of purple cabbage, and the added traditional Chinese medicines have the effects of promoting blood circulation to remove blood stasis and clearing away heart fire and relieving restlessness.

Owner:HEFEI FULAIDUO FOOD

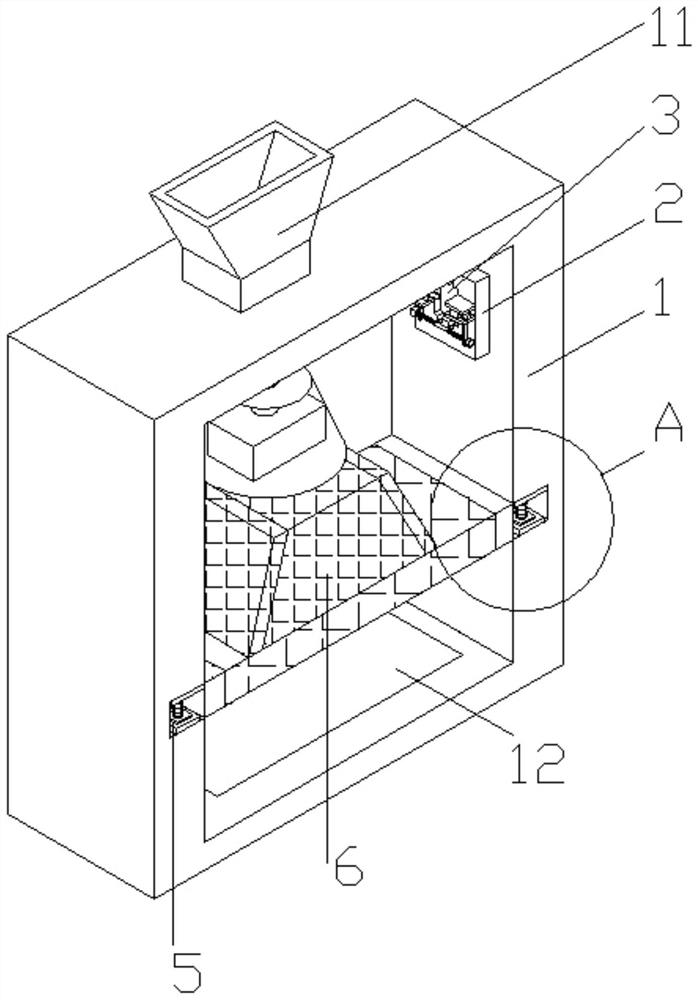

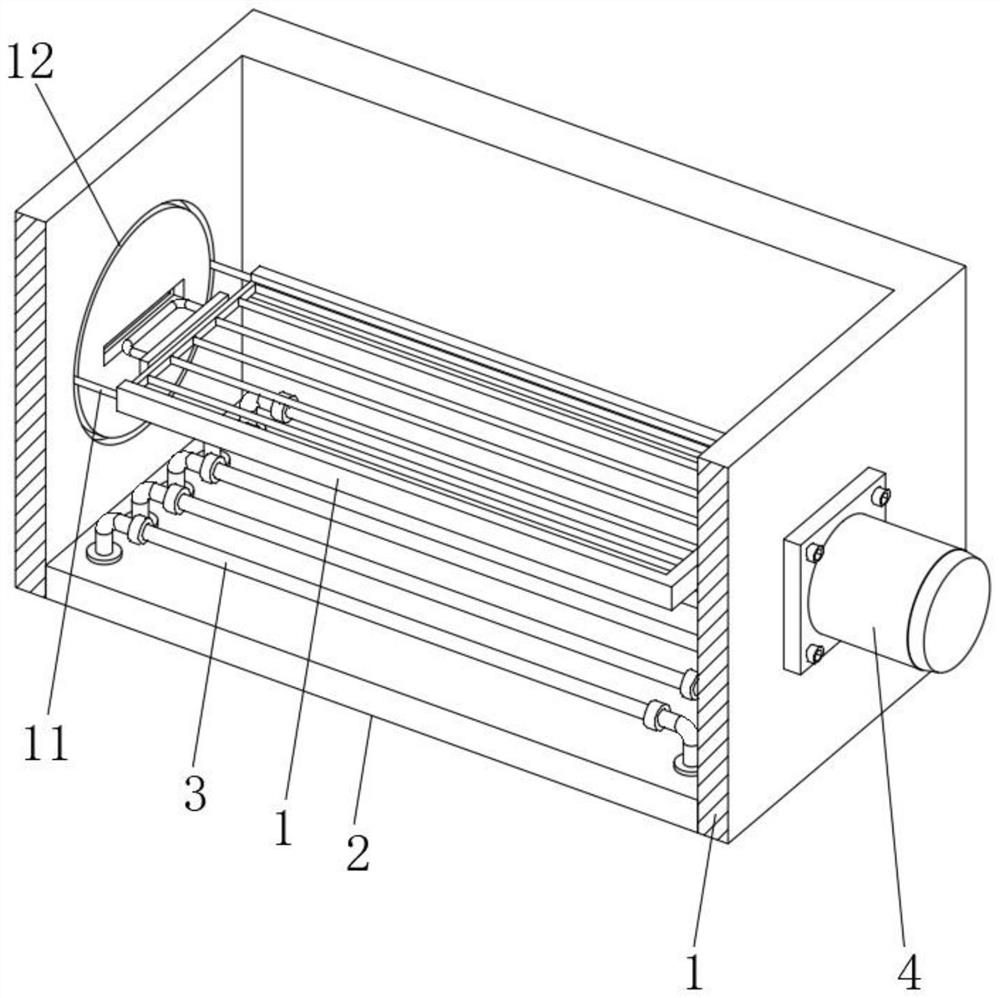

Milling device for monosodium glutamate production

Owner:重庆真渝食品有限公司

Dedicated fruit tree set fertilizer

InactiveCN106748288AImprove fertilityAvoid the effects of organic pollutionBio-organic fraction processingAlkali orthophosphate fertiliserPotassium permanganateOrganic component

The invention discloses dedicated fruit tree set fertilizer which is prepared from the following raw materials in parts by weight: 34 to 36 parts of soybean meal, 15 to 18 parts of needle mushroom dreg, 20 to 24 parts of monosodium glutamate residue, 3 to 4 parts of potassium pyrophosphate, 4 to 6 parts of ammonium bicarbonate, 1 to 2 parts of sodium polyphosphate, 2 to 3 parts of sodium silicate, 10 to 14 parts of chitosan, 0.3 to 0.5 part of potassium permanganate, 1.5 to 1.8 parts of manganese sulfate, 1 to 2 parts of acrylamide, 0.3 to 0.4 part of N,N'-methylene bisacrylamide, 2 to 3 parts of ammonium persulfate, 1 to 2 parts of zinc acetate, 0.2 to 0.4 part of yttrium nitrate, a defined amount of absolute ethyl alcohol and a defined amount of water. According to the fertilizer disclosed by the invention, organic components and inorganic components are reasonably matched; thus, the fertilizer has comprehensive nutrient elements and is easy to decompose and absorb; meanwhile, a release characteristic of a coating material of the fertilizer aims at different growth stages of a fruit tree germination stage, a growth period and a fruit swelling period; counterpart supplying of the total nutrient amount is achieved, fertilizer consumption is reduced, nutrient utilization rate is improved at the same time, a fertilizing process is simplified, and economic benefit of planting fruit trees is improved.

Owner:SUZHOU TIANYU CULTURE GRP

Ghostplant wormwood herb leisure food and preparing method thereof

Owner:万源市花萼绿色食品有限公司

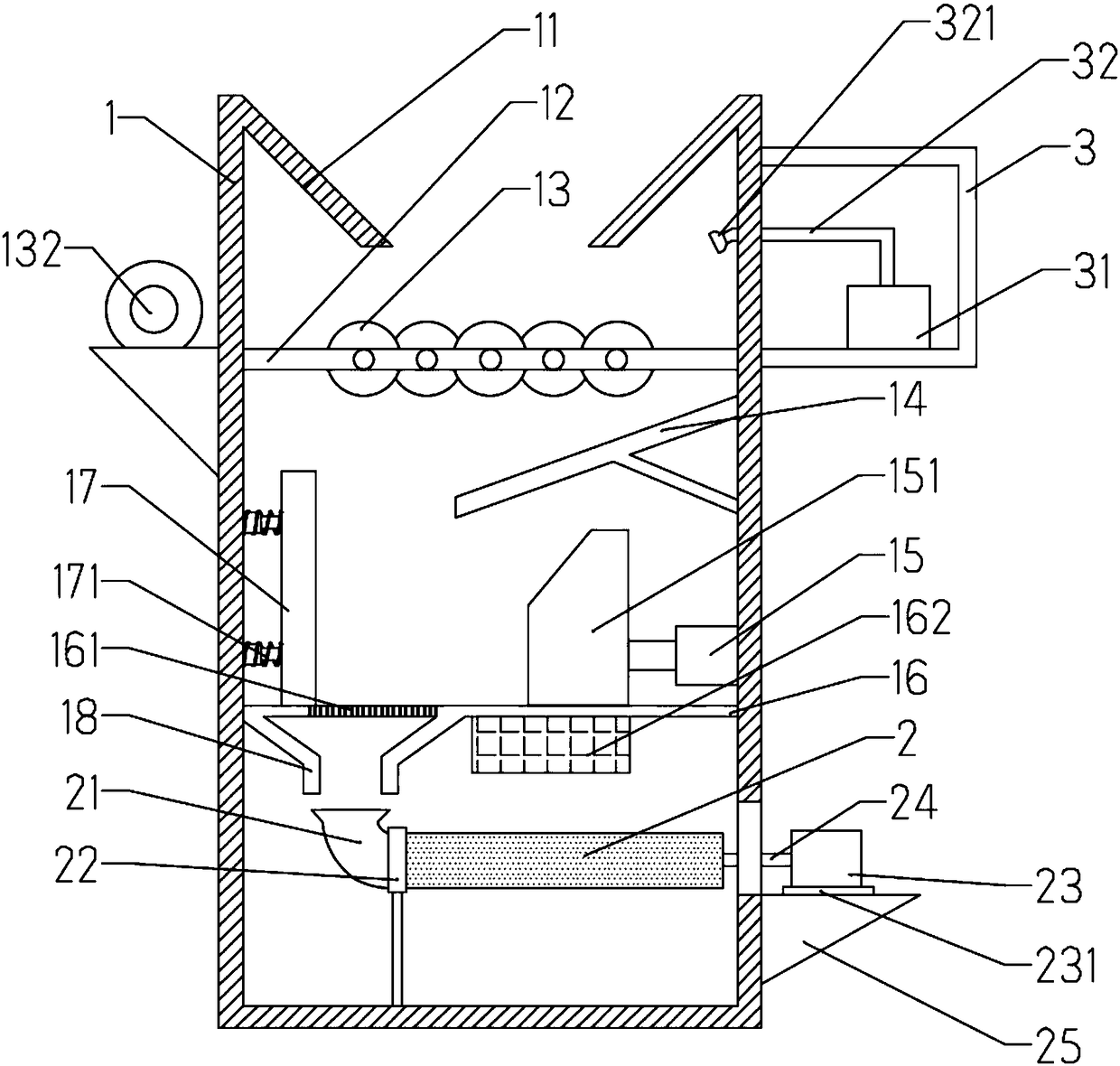

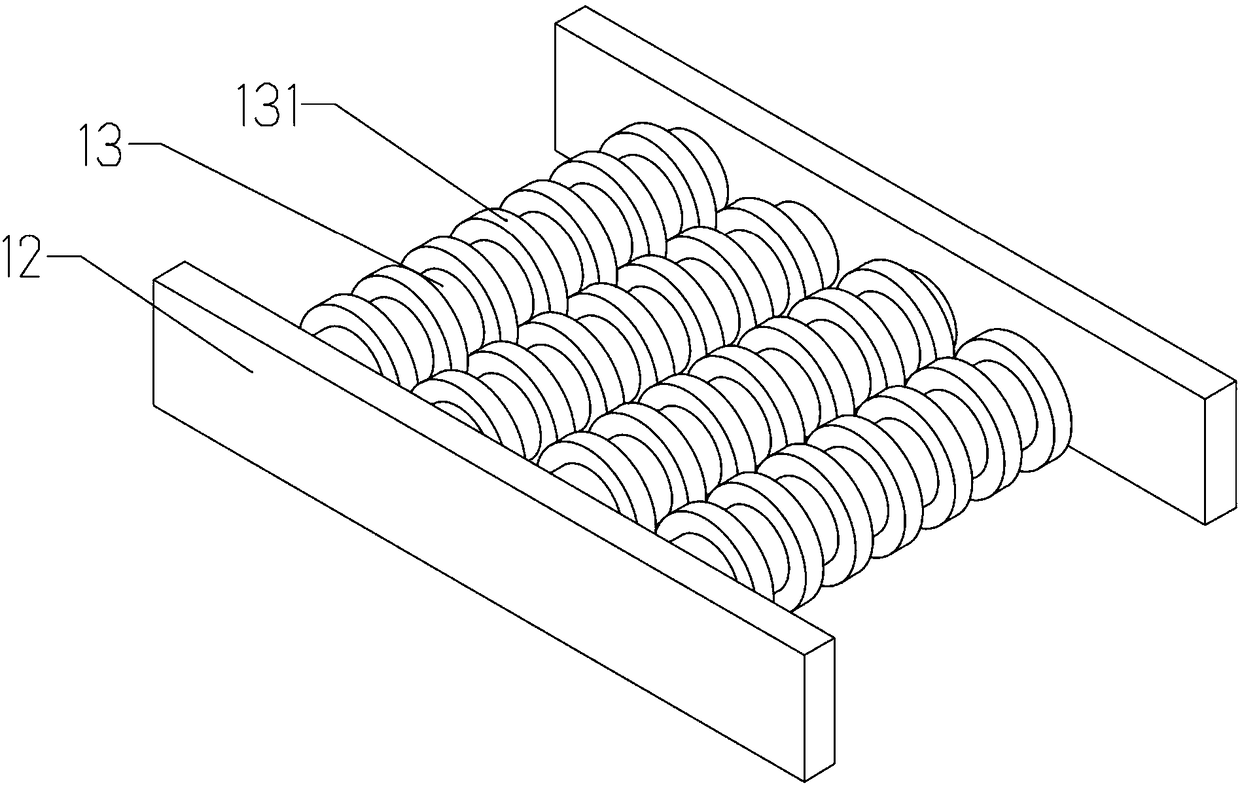

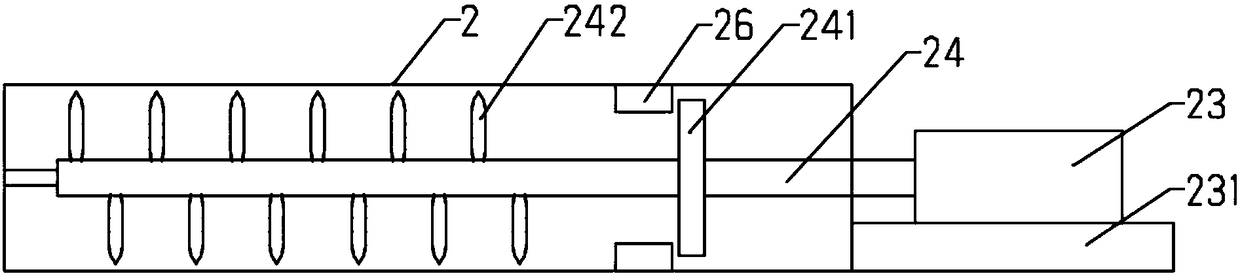

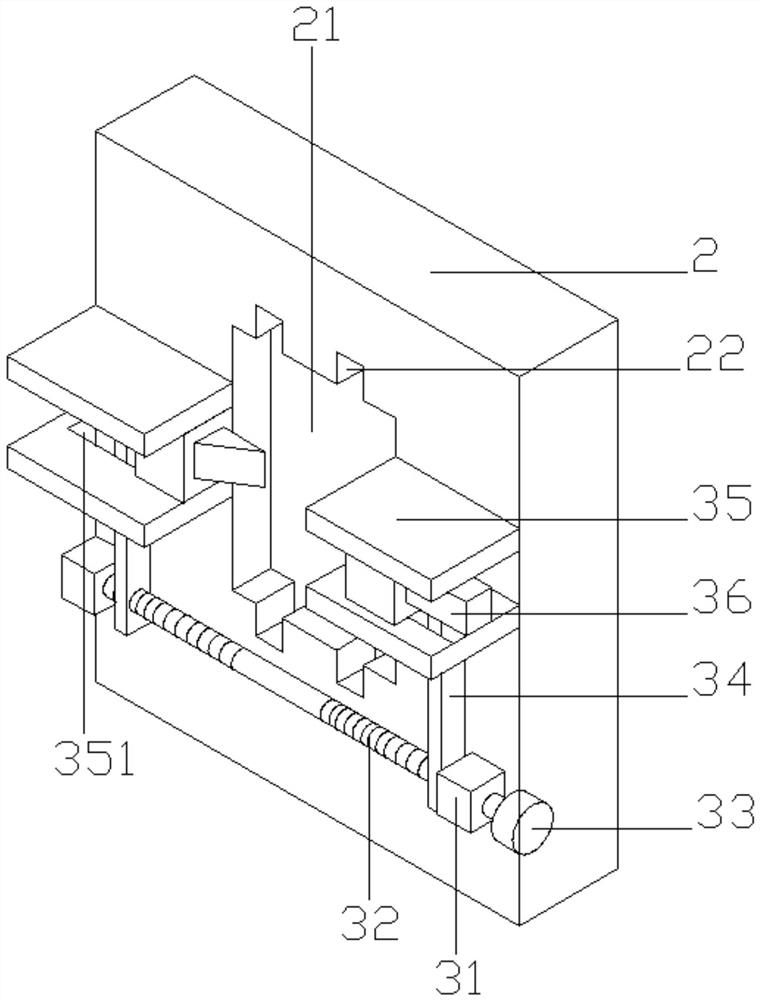

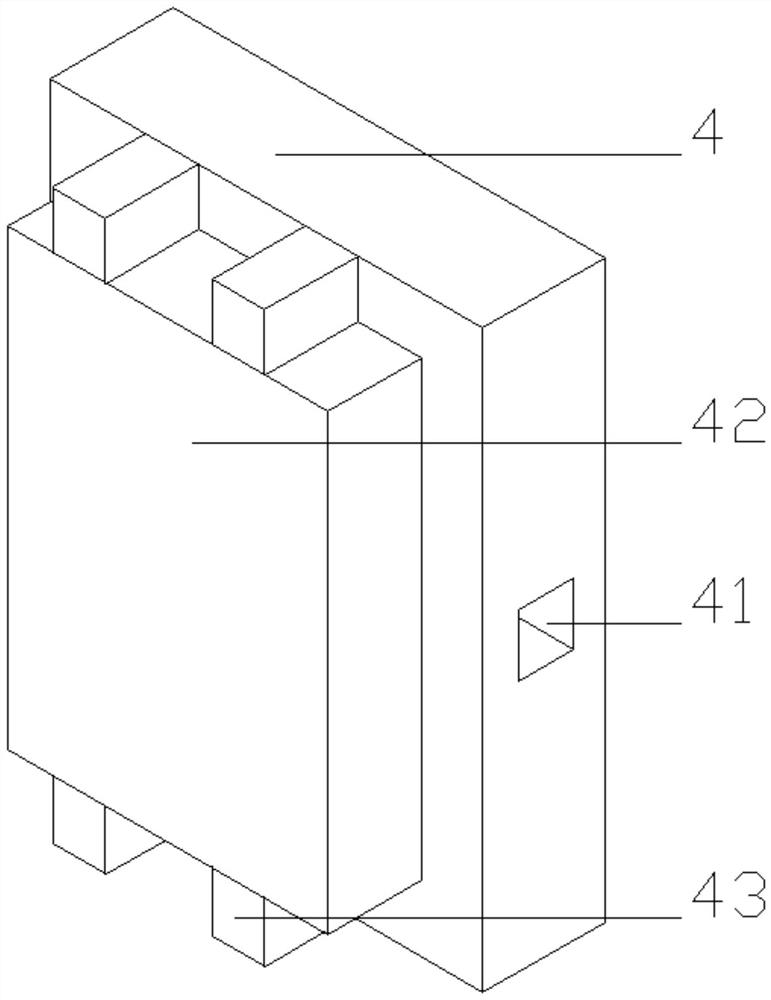

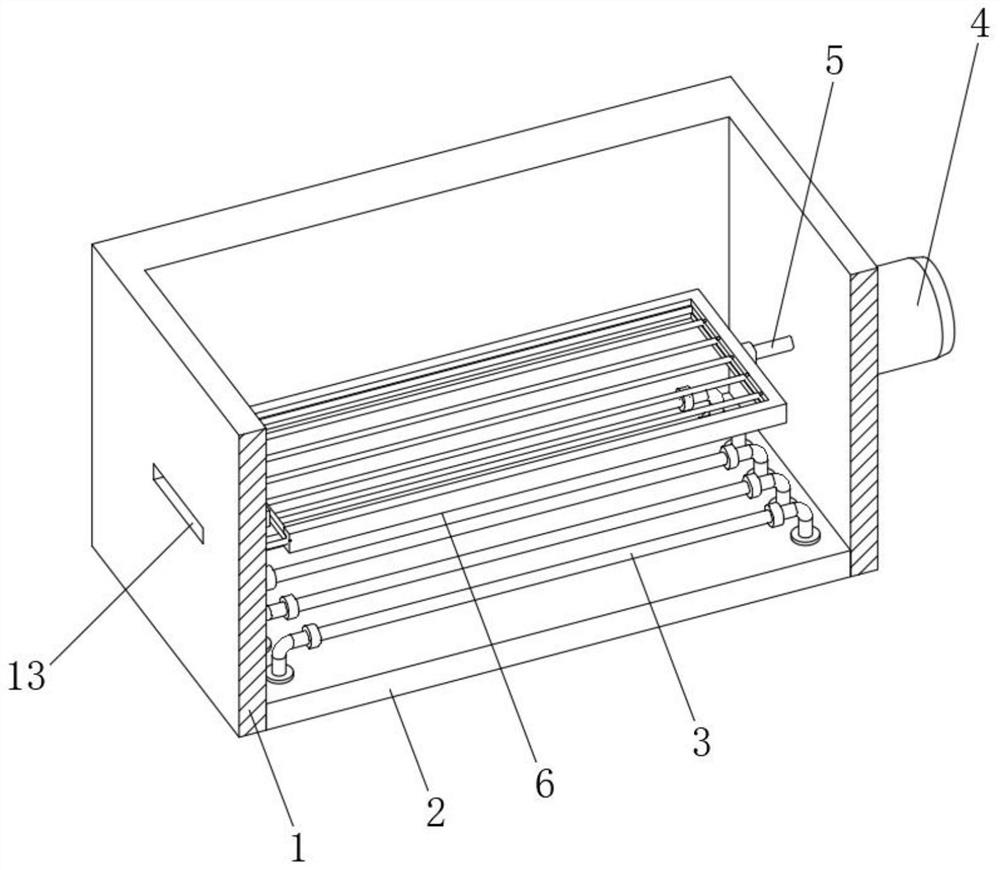

Double-protein sausage and manufacture method thereof

PendingCN112641053ACompact structureSlicing works wellSausage casingsMeat/fish preservation using chemicalsBiotechnologyMonosodium glutamate

Owner:湖南唐人神肉制品有限公司

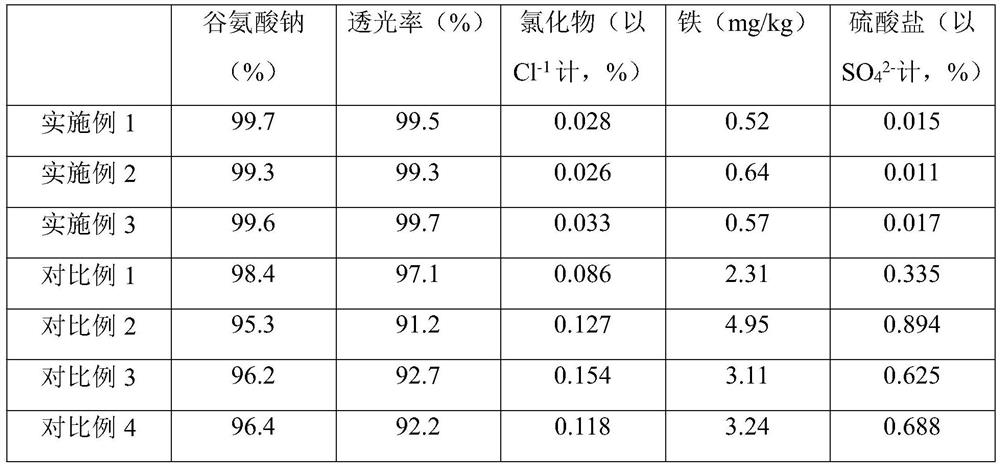

Refining process of monosodium glutamate

ActiveCN113558217AImprove qualitySimple processOrganic compound preparationMicroorganism based processesMonosodium glutamatePhysical chemistry

Owner:温州快鹿集团有限公司

Production method of white sugar garlic

InactiveCN104351697AUnique flavorAdapt to tasteFood preparationSodium acetrizoateMonosodium glutamate

The invention relates to a production method of white sugar garlic. The process sequence comprises the following steps: raw material selection, cleaning, soaking and salting, preserving, re-cleaning, batching, impregnating, draining, packaging, sterilizing, air drying and boxing, wherein for the soaking and salting step, fresh garlic, water and salt are mixed in a mass ratio of 15:10:1 and soaked and salted for 4-8 days, and water in the bottom of a pit is pumped to the upper part for exchange in a soaking and salting process; for the batching step, 60 kg of garlic is added with 40 kg of water, 9-11 kg of white sugar, 1.5-2.5 kg of monosodium glutamate, 2-3 kg of vinegar, 100-200 g of acetic acid, 80-100 g of citric acid, 46-54 g of sodium cyclamate, 10-15 g of acesulfame potassium, 5-7 g of saccharin, 46-54 g of aspartame, 18-22 g of ethylene diamine tetraacetic acid disodium salt, 7-9 g of sodium dehydroacetate, 22-26 g of sodium benzoate and 46-54 g of D-sodium erythorbate. The white sugar garlic is fresh and sweet, is not greasy, has slight sour taste, is unique in flavor, and adapts to the taste of eaters in vast regions.

Owner:朱兴初

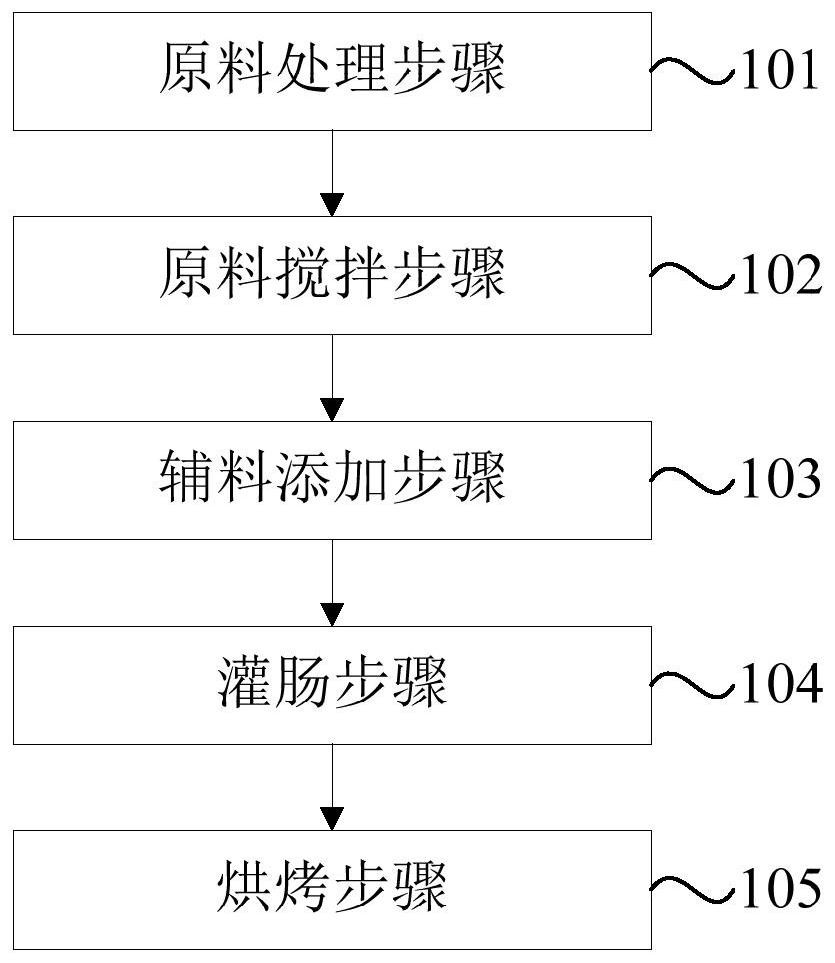

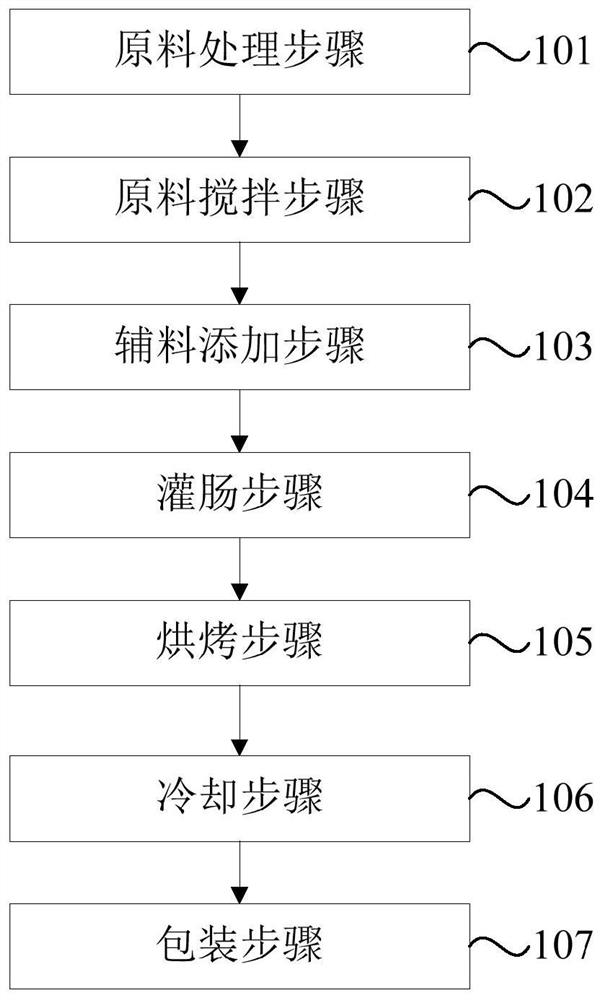

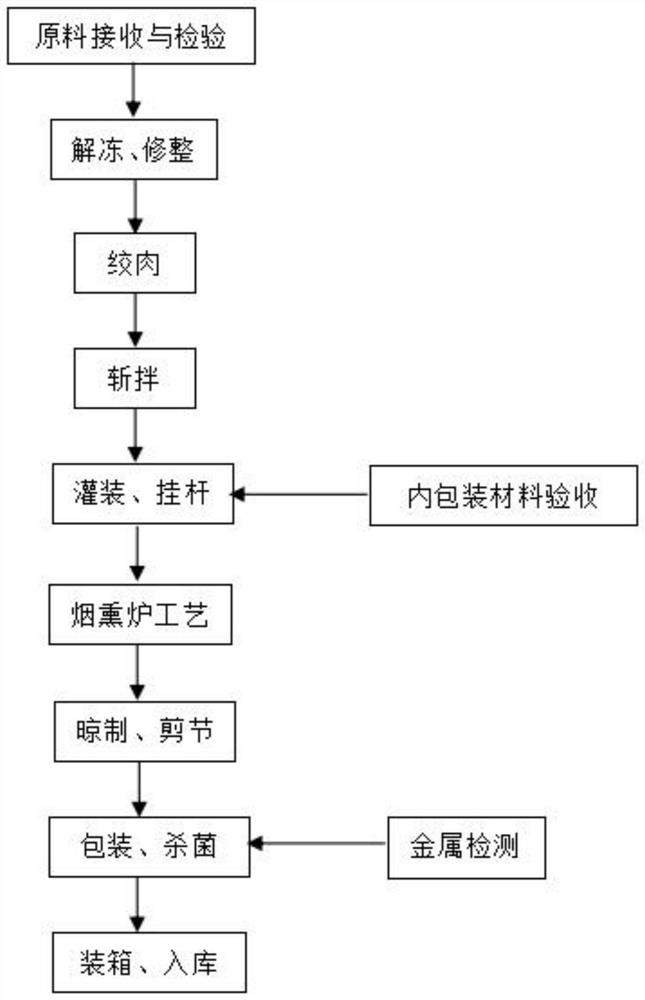

Preparation method of ham sausage

The invention provides a preparation method of a ham sausage. The ham sausage is prepared from 25 parts of streaky pork paste, 25 parts of shrimp flesh, 15 parts of starch, 0.35 part of semen cuscutae, 0.8 part of refined salt, 0.2 part of monosodium glutamate, 0.1 part of fructus lycii, 0.1 part of aniseed powder, and 0.006 part of sodium nitrite. The preparation method comprises the following steps: preparing streaky pork paste and shrimp flesh according to the ratio, and separately crushing the streaky pork paste and shrimp flesh to meat paste; adding monosodium glutamate, refined salt, semen cuscutae, fructus lycii, aniseed powder and sodium nitrite into the meat paste; uniformly mixing; then pouring starch, and uniformly mixing; then filling. The ham sausage is delicious in taste, tasty, and suitable for all people, and has the health care function.

Owner:陈云

Sweet wormwood essential oil long-acting mosquito repellent liquid and preparation method thereof

PendingCN113304077AReduce pollutionReduce harmCosmetic preparationsSievingMonosodium glutamateDecyl glucoside

Owner:YUZHOU TIANYUAN BIOTECH CO LTD

Preserved egg and minced pork flavor cream and preparation method thereof

The invention relates to preserved egg and minced pork flavor cream which comprises, by weight, 60-80 parts of preserved egg and minced pork enzymatic hydrolysate, 3-8 parts of vinegar, 2-5 parts of soy sauce, 2-4 parts of salt, 2-6 parts of glucose, 2-4 parts of white granulated sugar, 4-8 parts of monosodium glutamate, 2-3 parts of yeast extracts and 5-10 parts of corn starch. The flavor cream is remarkable in meat sense, lean meat flavor is rich, fiber sense is clear, the flavor cream has sweet greasy feeling of preserved eggs, characteristics are remarkable, taste is mellow and durable andlingers in mouth for a long time, overall fragrance is pure and coordinated, and the flavor cream can be used for the fields of convenient food, leisure puffed food, dinning and the like.

Owner:SHANDONG TIANBO FOOD INGREDIENTS

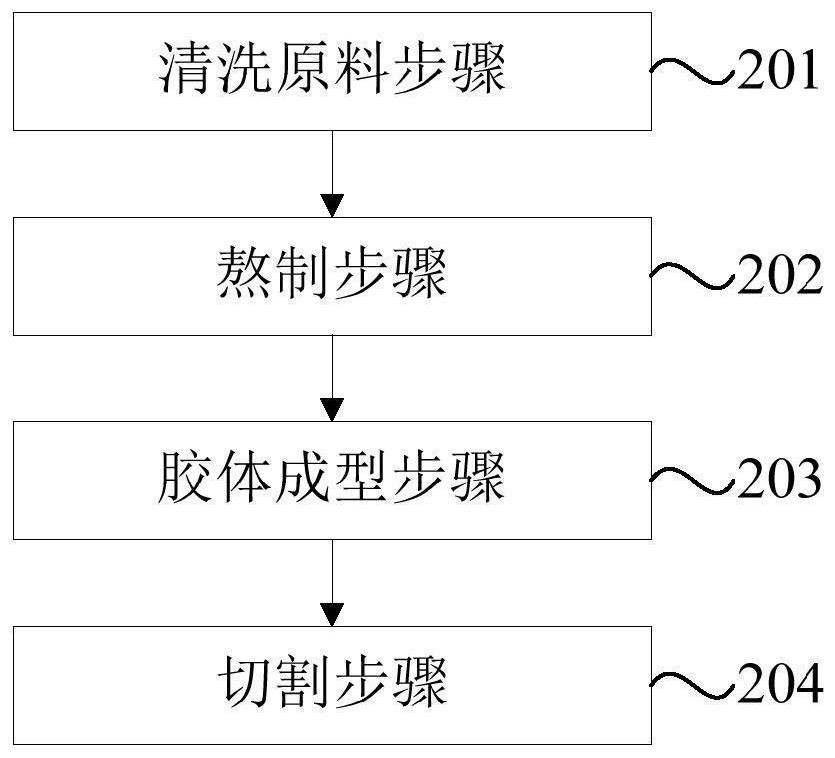

Canned pearl-like tendon ball and manufacturing method thereof

InactiveCN105410513AGood color and fragranceComplete shapeFood preparationMonosodium glutamateSalt water

Owner:CHONGQING FULING ZIZHU FOOD CO LTD

Processing method of handmade rice noodles

Owner:常德市源宏食品有限责任公司

Preparation method of black pepper low-fat chicken sausage

PendingCN114009700AAdd flavorHigh in proteinMeat/sausage hanging-upFood ingredientsBiotechnologyMonosodium glutamate

Owner:上海唐人神肉制品有限公司

Broken-peel pickled pepper red sour soup and manufacture method thereof

InactiveCN112753983ASave time and costLow pollution rateFood scienceBiotechnologyMonosodium glutamate

The invention discloses a broken-peel pickled pepper red sour soup, which comprises the following raw materials in parts by weight: 10-70% of Lycopersicon esculentum, 10-70% of broken-peel pickled peppers, 10-15% of colleseed oil, 1-4% of Zingiber officinale Roscoe, 1-4% of Allium sativum L. and 5-8% of added water. All the raw materials are grinded into a paste, and then, according to parts by weight of the raw material paste, 1-2% of chicken powder, 1-3% of monosodium glutamate, 0.5-2% of lactic acid, 0.5-1% of citric acid, 2-5% of white sugar, 0.5-1% of Litsea pungens Hemsl. oil and 0.1-0.5g / kg of sodium benzoate are added. The manufacture method of the broken-peel pickled pepper red sour soup comprises the following steps of: 1) taking food materials: breaking the Lycopersicon esculentum and the broken-peel pickled peppers for standby, and taking bruised ginger and minced garlic; 2) evenly mixing the food materials, adding the colleseed oil and the water, grinding into an even paste, and heating the even paste at the temperature of 80 DEG C for 7 minutes; 3) seasoning by adding the chicken powder, the monosodium glutamate, the lactic acid, the citric acid, the white sugar and the Litsea pungens Hemsl. oil in sequence; 4) adding the sodium benzoate for corrosion prevention; and 5) after filling is carried out, sterilizing by heating at the temperature of 75 DEG C for 15min, cooling to be 40 DEG C or below, and then, packaging in a box. The invention has a simple technology, waste resources are reasonably utilized, and cost is low.

Owner:GUIZHOU MEITAN FUYING FOOD DEV CO LTD

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap