Preparation method of black pepper low-fat chicken sausage

A black pepper low-fat, production method technology is applied in the field of black pepper low-fat chicken sausage production, which can solve the problems of inconvenient use of sterilization, high energy intake, and inability to use sterilization, etc., to achieve fast placement and fixation, energy intake Low, Flavor Prominent Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

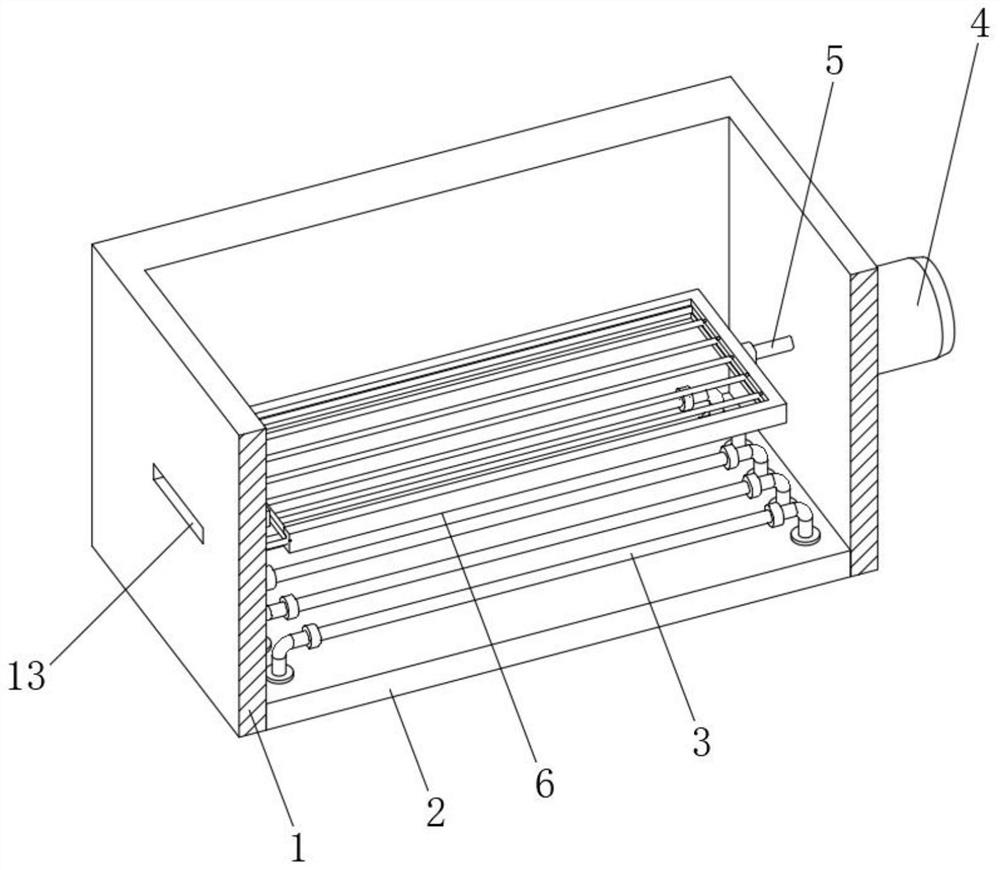

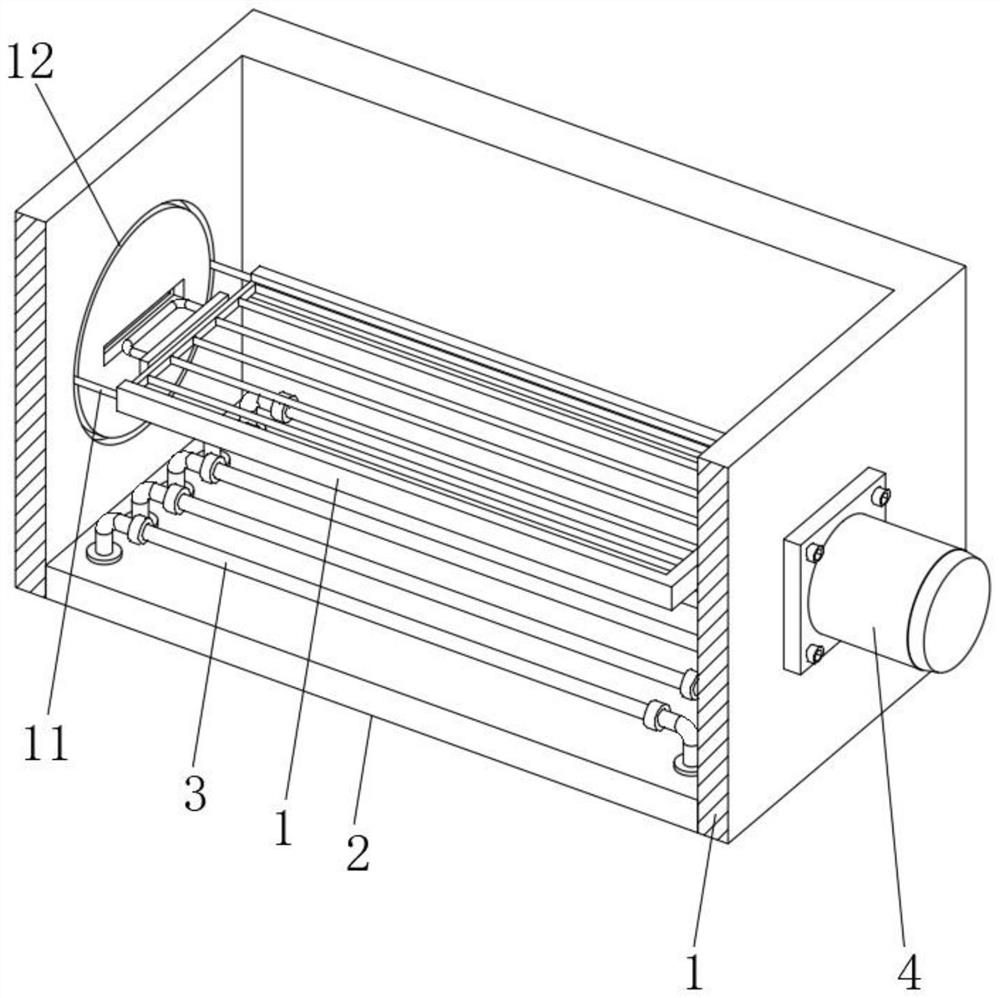

[0032] Such as Figure 1-4 Shown, a kind of making of black pepper low-fat chicken sausage, the making of this black pepper low-fat chicken sausage is made up of the raw material of following parts by weight: chicken breast 58-62 parts, soybean protein 7-9 parts, edible salt 0.4- 0.6 parts, monosodium glutamate 0.1-0.2 parts, compound phosphate 0.2-0.4 parts, sodium nitrite 0.002-0.004 parts, white pepper powder 0.1-0.12 parts, sodium lactate 0.8-1 parts, maltose 1-2 parts, white sugar 1.5-2 parts 0.5-0.6 parts of black pepper powder, 0.08-0.1 parts of black pepper essence, 0.4-0.5 parts of pork paste essence, 0.033-0.035 parts of nisin, and 24-26 parts of ice water.

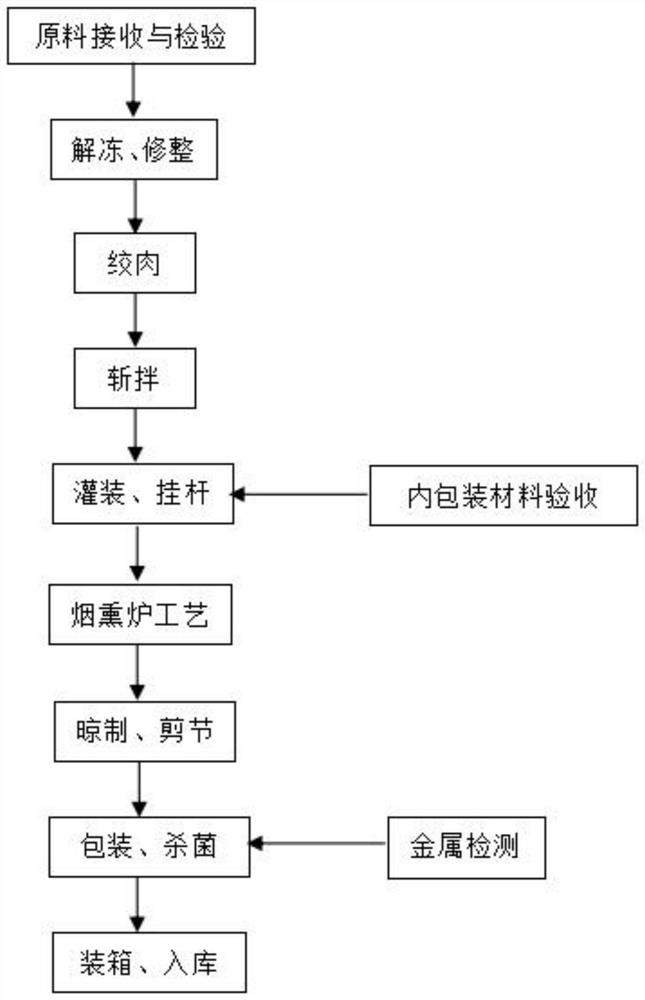

[0033] The specific production method of the black pepper low-fat chicken sausage is as follows:

[0034] Step 1: Raw material reception and inspection, accept raw materials, and conduct quality inspection on raw materials, including production date, quality control and weight weighing;

[0035] Step 2: thawing a

Embodiment 2

[0051] Such as Figure 1-4 Shown, the making of a kind of black pepper low-fat chicken sausage, the making of this black pepper low-fat chicken sausage is made up of the raw material of following parts by weight: chicken breast 9 parts, soybean protein 8 parts, edible salt 0.5 part, monosodium glutamate 0.1 part , 0.3 parts of compound phosphate, 0.003 parts of sodium nitrite, 0.11 parts of white pepper powder, 0.9 parts of sodium lactate, 1 part of maltose, 1.8 parts of white sugar, 0.5 parts of black pepper powder, 0.09 parts of black pepper essence, 0.4 parts of pork paste flavor , 0.034 parts of nisin, 25 parts of ice water.

[0052] The specific production method of the black pepper low-fat chicken sausage is as follows:

[0053] Step 1: Raw material reception and inspection, accept raw materials, and conduct quality inspection on raw materials, including production date, quality control and weight weighing;

[0054] Step 2: thawing and trimming, thawing the raw meat, and

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap