Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

20 results about "Yttrium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Yttrium is a chemical element with the symbol Y and atomic number 39. It is a silvery-metallic transition metal chemically similar to the lanthanides and has often been classified as a "rare-earth element". Yttrium is almost always found in combination with lanthanide elements in rare-earth minerals, and is never found in nature as a free element. Y is the only stable isotope, and the only isotope found in the Earth's crust.

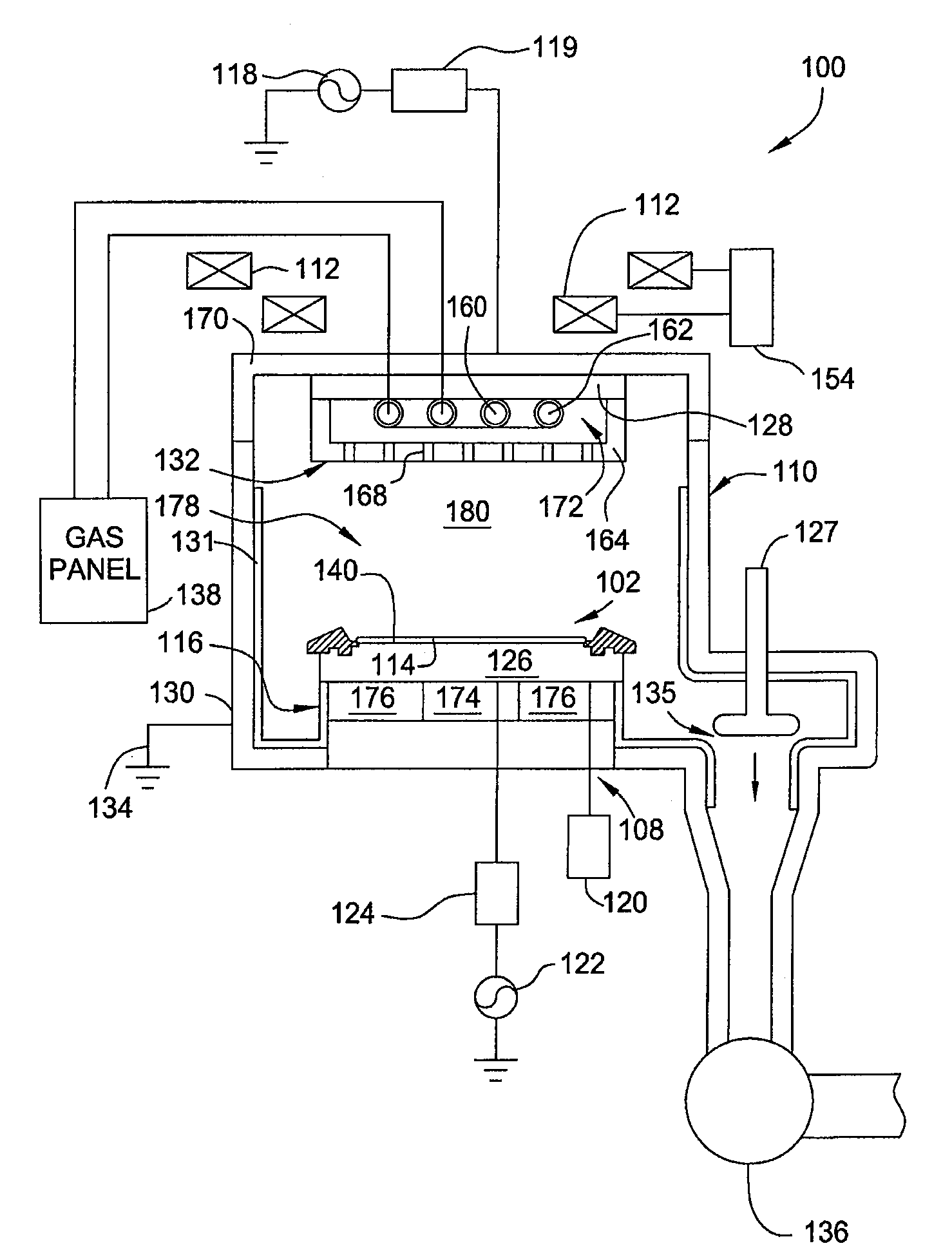

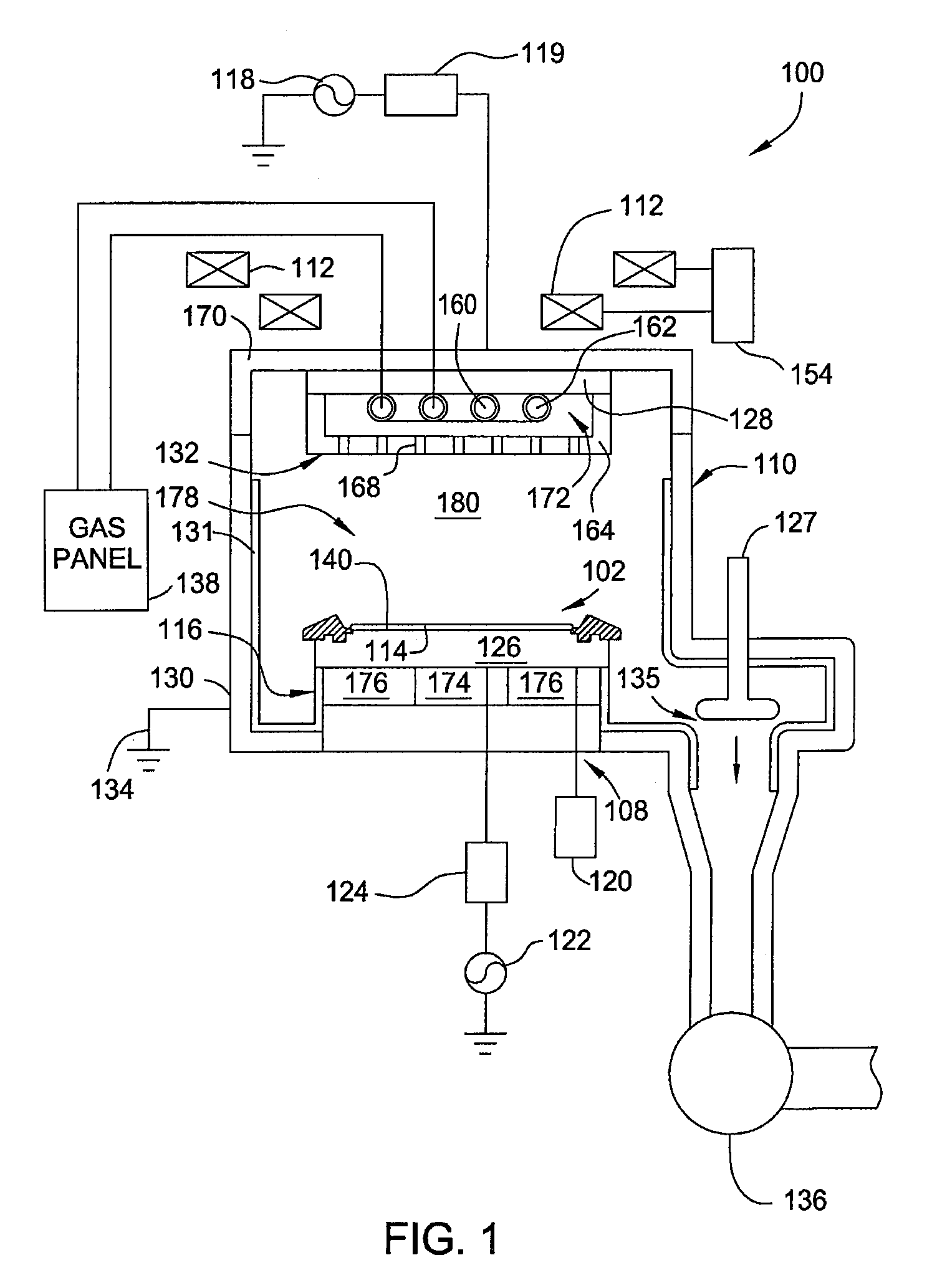

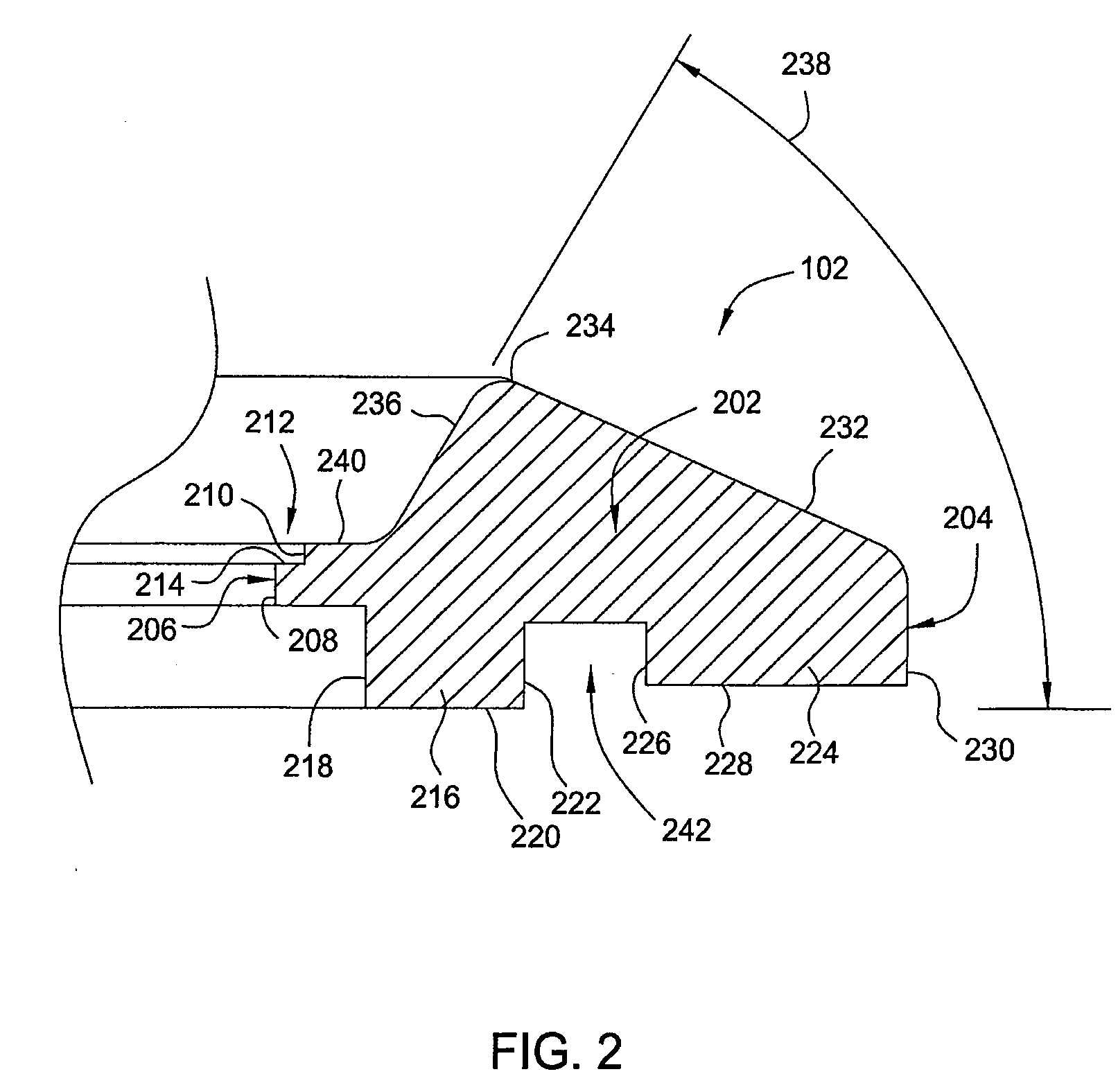

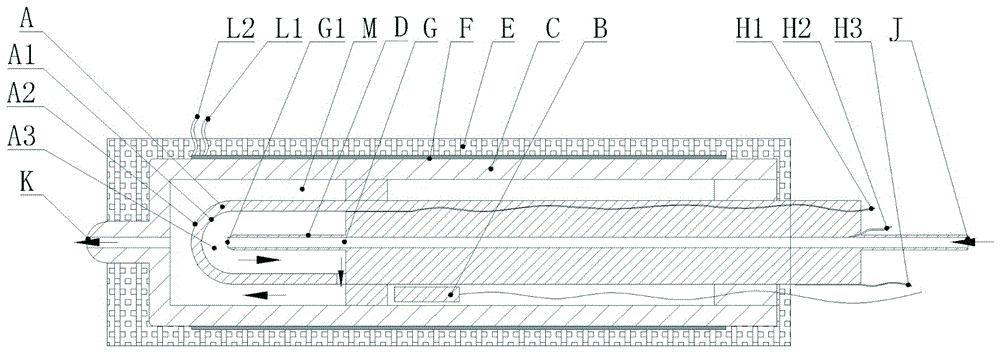

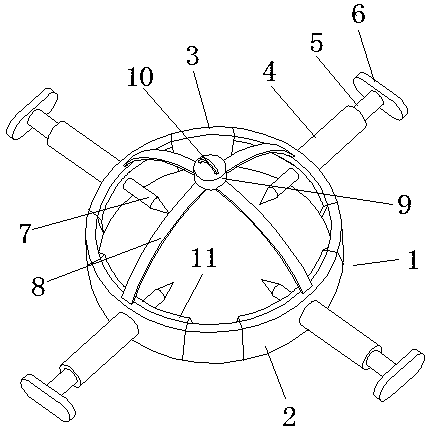

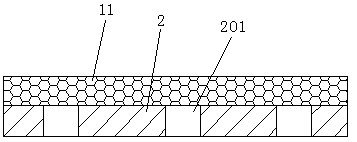

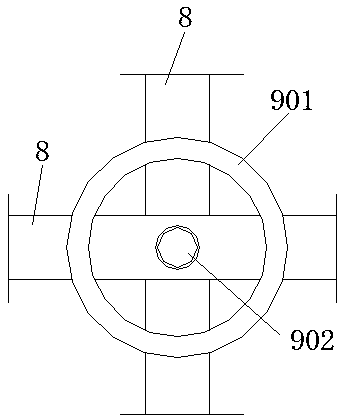

Low sloped edge ring for plasma processing chamber

ActiveUS20100059181A1Electric discharge tubesSemiconductor/solid-state device manufacturingEngineeringYttrium

Owner:APPLIED MATERIALS INC

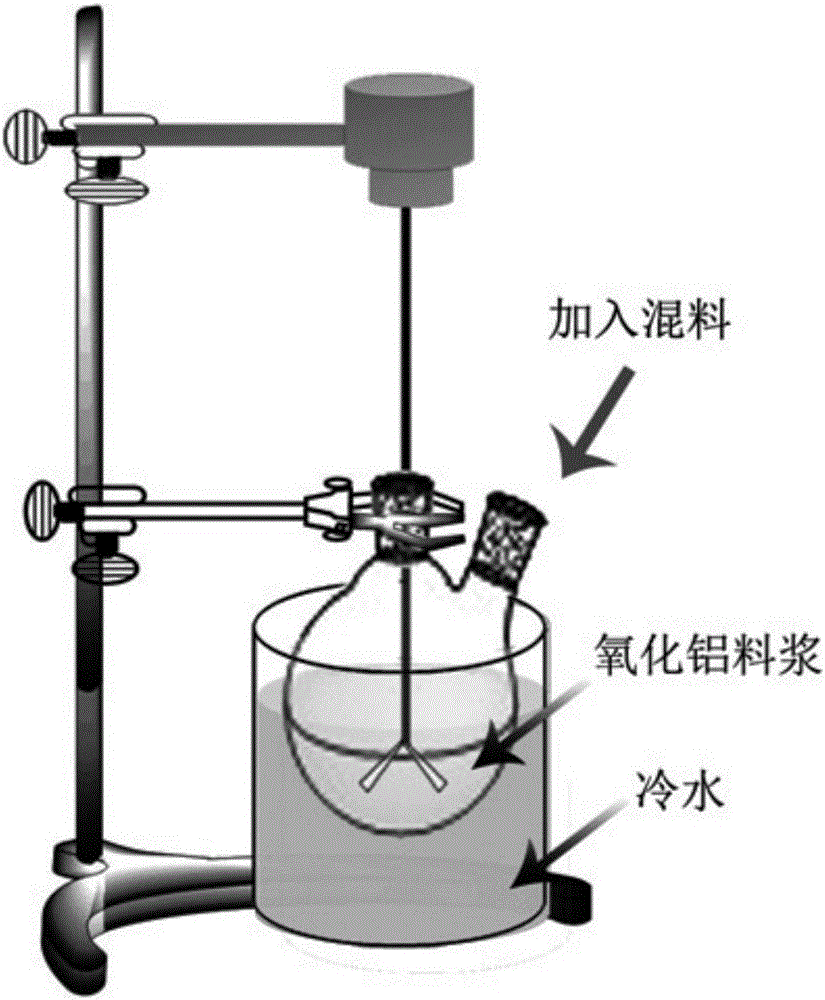

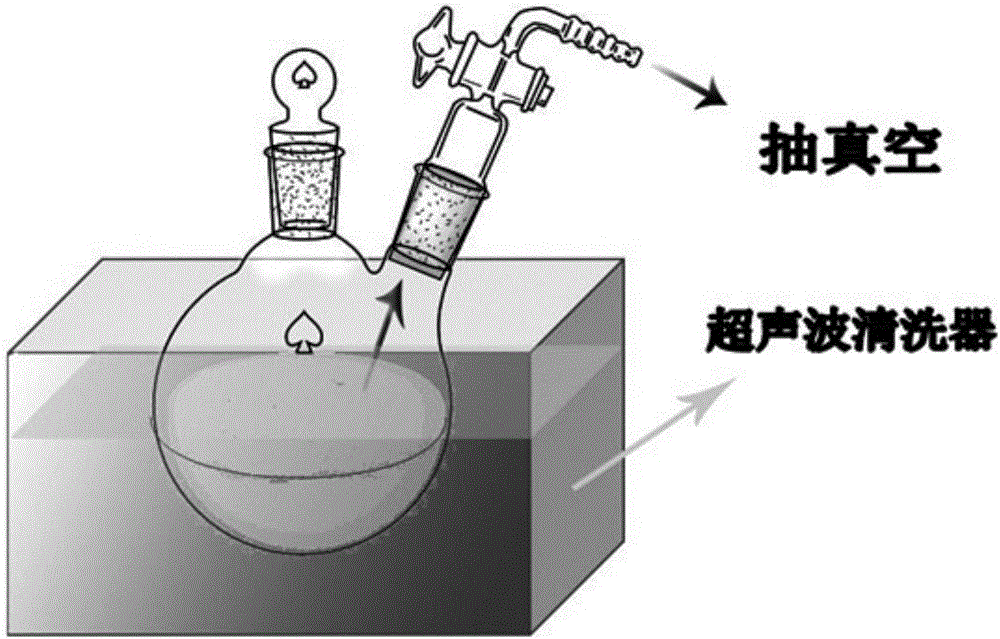

Method for producing rare earth ion doped yttrium aluminum garnet nano phosphor powder

InactiveCN101602944AImprove uniformityOvercoming phenomena such as reunionLiquid spraying apparatusGrain treatmentsHigh concentrationRare-earth element

The invention discloses a method for producing a rare earth ion doped yttrium aluminum garnet nano phosphor powder. The general formula of the nano powder is (Y1-xLnx)3Al5O12, wherein Ln is one of rare earth elements Ce and Eu, x is more than or equal to 0.0 and less than or equal to 0.1, mixed solution of nitrates or acetates of Al, Y and Ln is used as a mother liquor of salt, and mixed solution of NH4HCO3 and NH3.H2O is used as solution of compound precipitator; the ammonia water is used for adjusting the pH value of the solution of compound precipitator to 10; and the mother liquor of salt undergoes ultrasonic atomization and then is sprayed in the solution of compound precipitator which is continuously stirred, and after complete reaction, the mixed solution if filtered, washed, dried, repeatedly ball-milled and calcined to obtain uniform and dispersed rare earth ion doped YAG nano phosphor powder. The method has the advantages that the produced nano phosphor powder is uniform and dispersed, the granularity is small (between 50 and 70 nanometers), and the generated phase is unitary; and the high-concentration uniform doping of the rare earth ions is realized, so that the rare earth ion doped yttrium aluminum garnet nano phosphor powder can be obtained in high efficiency.

Owner:NINGBO UNIV

Dual-phase Mg-Li-Zn-Y magnesium-lithium alloy enhanced by effectively utilizing rare earth element Y and preparation method

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

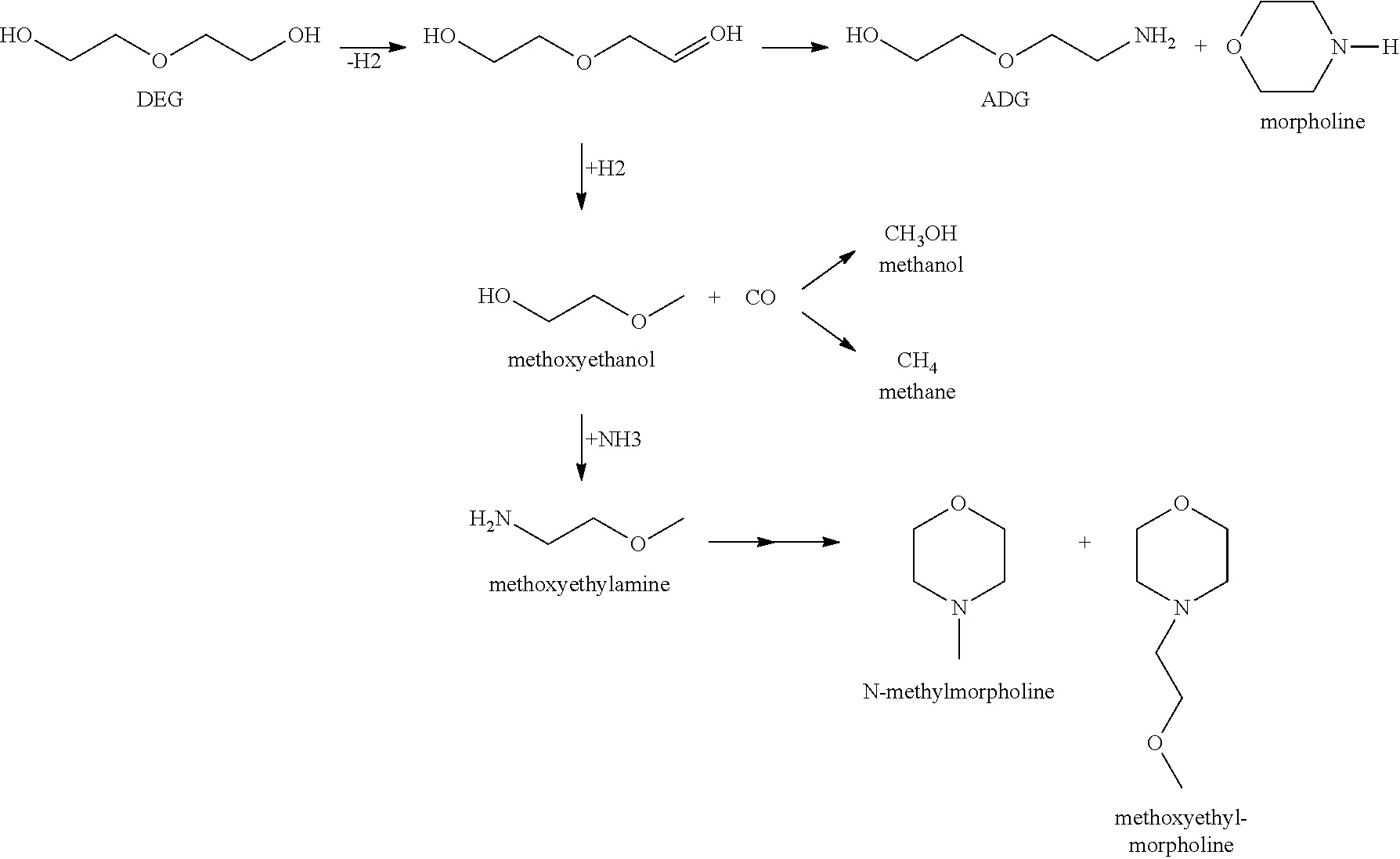

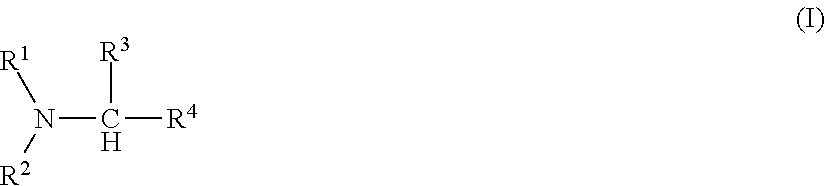

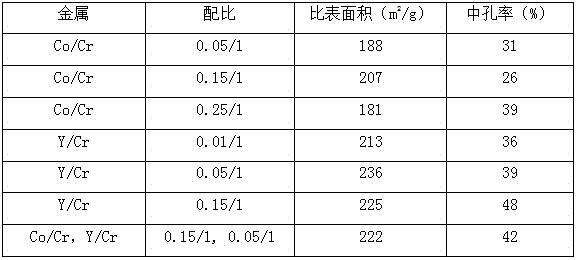

Catalyst and process for preparing an amine

ActiveUS8318982B2Enhances their economic viabilitySpeed up the conversion processOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCeriumKetone

Owner:BASF AG

Nickel-chromium-molybdenum-niobium corrosion resistant welded alloy and manufacturing method thereof

Owner:DANYANG XINHANG SPECIAL ALLOY

Preparation method of fluorination catalyst

Owner:JIANGSU SANMEI CHEM

Novel powder metallurgical gear

InactiveCN106041095AUniform densityLarge elongationTransportation and packagingMetal-working apparatusCarbon fibersALUMINUM STEARATES

Owner:黄宇

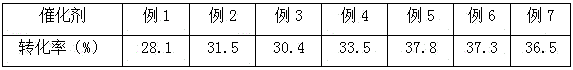

Rare-earth metal arylamine group compound as well as preparation method and application thereof

InactiveCN103626806AClear structureRaw materials are easy to obtainOrganic-compounds/hydrides/coordination-complexes catalystsGroup 5/15 element organic compoundsYttriumKetone

The invention discloses a rare-earth metal arylamine group compound as well as preparation method and application thereof. The invention discloses the rare-earth metal arylamine group compound which is characterized in that a general formula of the rare-earth metal arylamine group compound is (2,6-R12PhNH)5LnLi2(THF)2, wherein Ln is a rear-earth metal selected from one of neodymium, samarium, ytterbium or yttrium; R1 is selected from one of hydrogen, methyl or isopropyl. The rare-earth metal arylamine group compound has the advantages that the rare-earth metal arylamine group compound has a definite structure; raw materials used in the preparation method are simple, easily obtained and cheap; the reaction process is simple and easily operated; the rare-earth metal arylamine group compound product is conveniently purified and the yield of the product is high; the rare-earth metal arylamine group compound has a high activity when acting as a single component catalyst to catalyze a hydrogen phosphine reaction of aldehyde or ketone and phosphite ester; the use amount of the catalyst is less; the yield is high; a substrate has wide universality; a new and simple method is provided for synthesis of a-hydroxyphosphonate.

Owner:SUZHOU UNIV

Dedicated fruit tree set fertilizer

InactiveCN106748288AImprove fertilityAvoid the effects of organic pollutionBio-organic fraction processingAlkali orthophosphate fertiliserPotassium permanganateOrganic component

The invention discloses dedicated fruit tree set fertilizer which is prepared from the following raw materials in parts by weight: 34 to 36 parts of soybean meal, 15 to 18 parts of needle mushroom dreg, 20 to 24 parts of monosodium glutamate residue, 3 to 4 parts of potassium pyrophosphate, 4 to 6 parts of ammonium bicarbonate, 1 to 2 parts of sodium polyphosphate, 2 to 3 parts of sodium silicate, 10 to 14 parts of chitosan, 0.3 to 0.5 part of potassium permanganate, 1.5 to 1.8 parts of manganese sulfate, 1 to 2 parts of acrylamide, 0.3 to 0.4 part of N,N'-methylene bisacrylamide, 2 to 3 parts of ammonium persulfate, 1 to 2 parts of zinc acetate, 0.2 to 0.4 part of yttrium nitrate, a defined amount of absolute ethyl alcohol and a defined amount of water. According to the fertilizer disclosed by the invention, organic components and inorganic components are reasonably matched; thus, the fertilizer has comprehensive nutrient elements and is easy to decompose and absorb; meanwhile, a release characteristic of a coating material of the fertilizer aims at different growth stages of a fruit tree germination stage, a growth period and a fruit swelling period; counterpart supplying of the total nutrient amount is achieved, fertilizer consumption is reduced, nutrient utilization rate is improved at the same time, a fertilizing process is simplified, and economic benefit of planting fruit trees is improved.

Owner:SUZHOU TIANYU CULTURE GRP

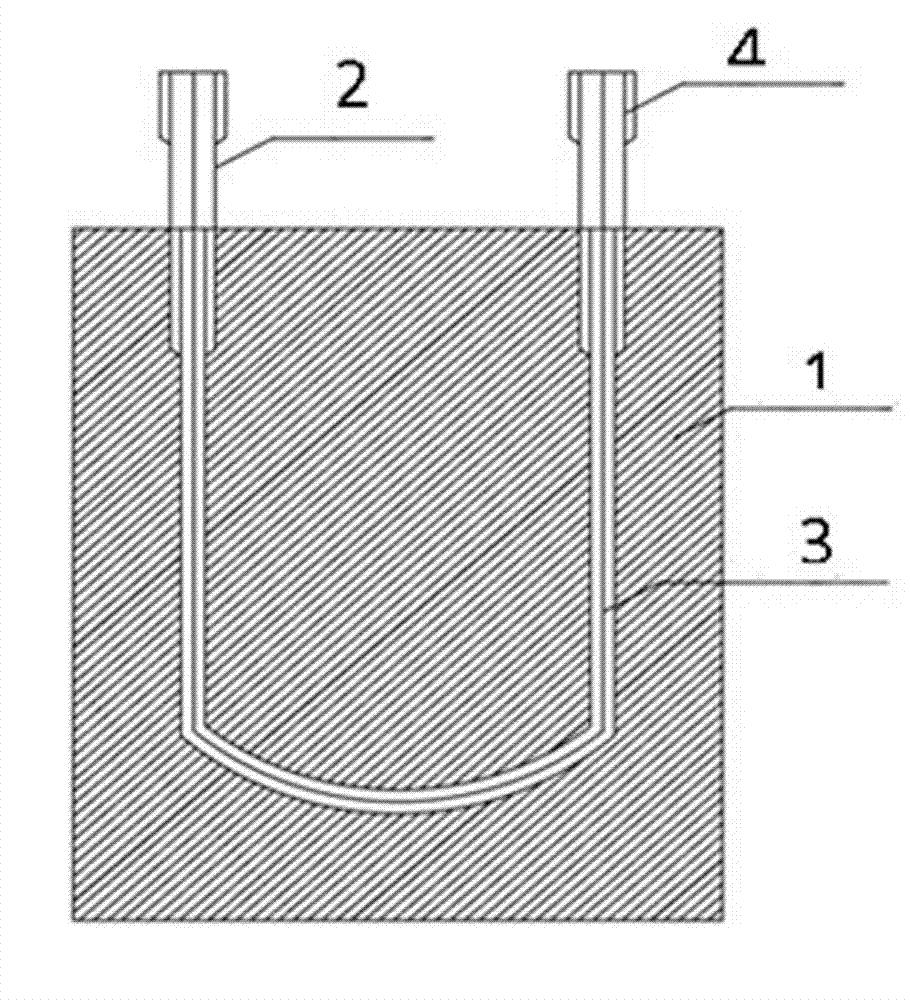

Method for manufacturing a thermal barrier

ActiveCN102575370AWon't clogAvoid it happening againEngine manufactureElectrolytic inorganic material coatingCeramic coatingLanthanide

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A +1

Anti-corrosion iron-based powder metallurgy self-lubricating CNG engine valve seat ring and making method thereof

Owner:安徽马仪科技股份有限公司

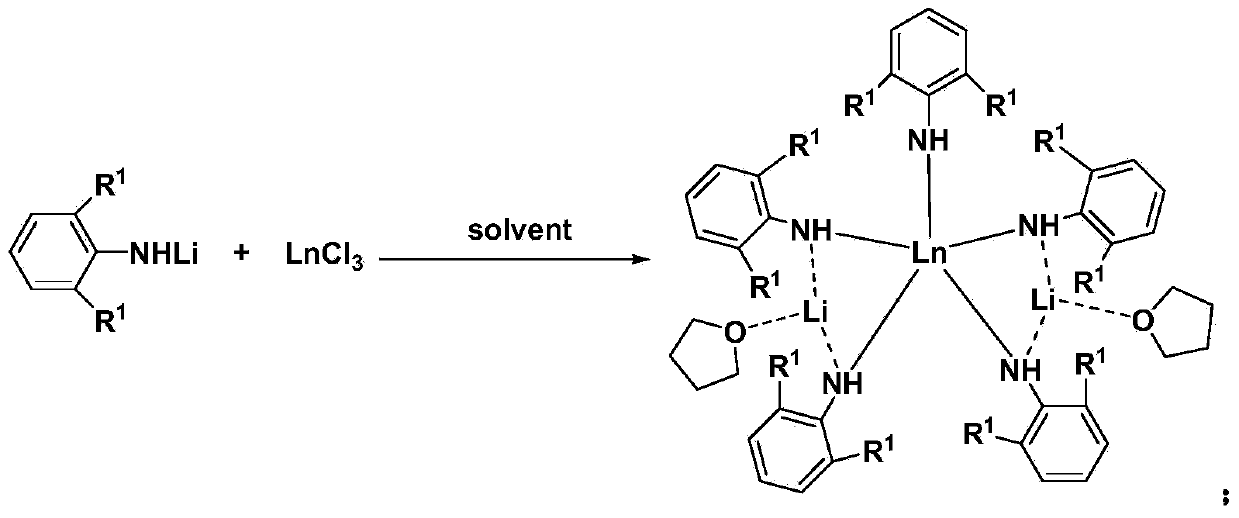

Fire ion detector

PendingCN106841445AAvoid safety hazardsSolve the big problem of difficult monitoringComponent separationChemical industryNitrogen gas

Owner:成都凯圣捷科技有限公司

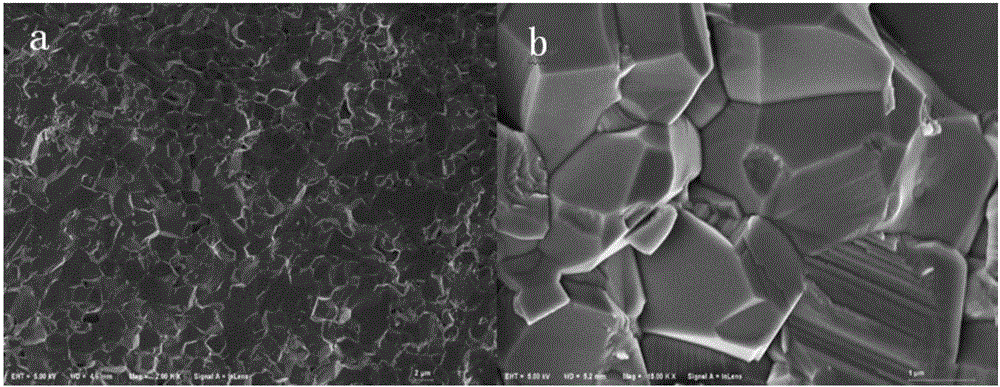

High-purity nano aluminium oxide biological ceramic formed through starch curing and preparation method and application thereof

InactiveCN106045481ACorn starchYttrium

Owner:WUHAN UNIV OF TECH

Preparation method of cobalt oxide coated nickel hydroxide composite material for alkaline rechargeable battery

InactiveCN108091845AHigh specific capacityExtended service lifeCell electrodesNickel accumulatorsAlkaline waterCalcium hydroxide

The invention discloses a preparation method of a cobalt oxide coated nickel hydroxide composite material for an alkaline rechargeable battery. The preparation method comprises the following steps: (1) preparing nickel chloride, cobalt sulfate and yttrium sulfate into nickel cobalt yttrium saline solution and injecting a potassium hydroxide solution and an ammonium hydroxide complexing agent intoa reaction kettle to perform chemical precipitation to obtain a yttrium doped spherical nickel hydroxide precursor; (2) weighing the defined amount of yttrium doped spherical nickel hydroxide precursor, putting into a sealed oxidizing reactor and inflating O2 to perform oxidization; (3) adding a Mg(OH)2 alkaline water solution into the oxidizing reactor after reaction finishes to perform thermal-insulation treatment. According to the alkaline rechargeable battery spherical nickel hydroxide material prepared by the preparation method disclosed by the invention, electrical conductivity and cycling stability of spherical nickel hydroxide are greatly improved; when the spherical nickel hydroxide material is applied to the alkaline rechargeable battery, the battery has the advantages of high specific capacity and longer service life.

Owner:NINGBO HIGH TECH ZONE JINZHONG INFORMATION TECH CO LTD

Stainless steel material with shape memory function and preparation method thereof

ActiveCN107937836AYttriumMemory functions

Owner:XINGHUA GUANGFU METAL PROD

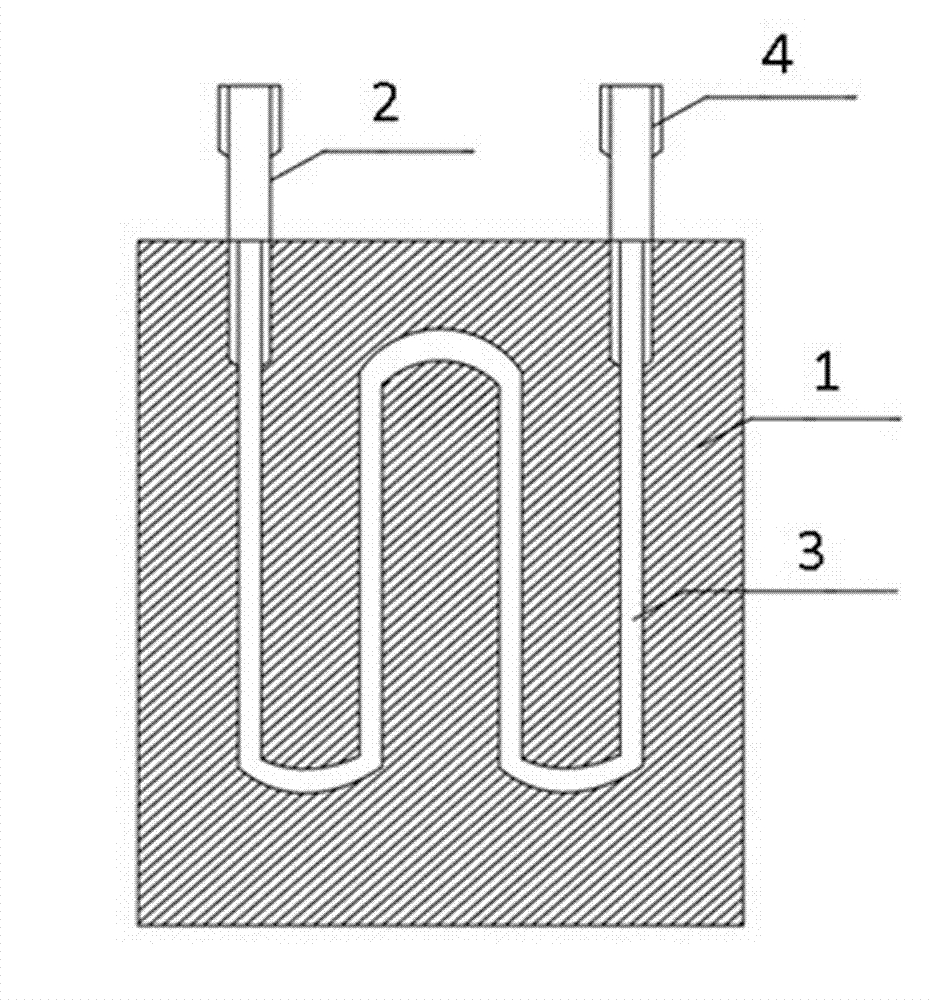

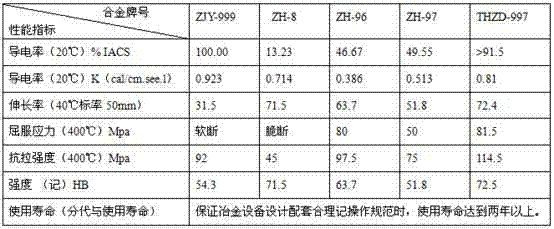

Conductive copper water jacket and casting process thereof

Owner:WUWEI HUICHENG IND TRADE

High-efficient composite filter material prepared by blending melt-blown polypropylene with modified pseudo-boehmite and used for sewage treatment and preparation method thereof

InactiveCN104759266AImproved purification and adsorption capacityStable and efficient structureOther chemical processesAlkali metal oxides/hydroxidesRare earthLanthanum

Owner:BENGBU DEMO FILTRATION TECH

Steel material with surface containing rare earth yttrium element and preparation method thereof

InactiveCN101805887AReduce dosageImprove antioxidant capacityVacuum evaporation coatingSputtering coatingRare-earth elementPlasma diffusion

Owner:GUILIN UNIV OF ELECTRONIC TECH

Vanadium/yttrium co-doped DLC coating and preparation method thereof

ActiveCN113913735AReduce internal stressImprove adhesionVacuum evaporation coatingSputtering coatingYttriumVanadium atom

The invention discloses a vanadium / yttrium co-doped DLC coating and a preparation method thereof. The preparation method comprises the following steps of firstly depositing a Cr or Ti undercoat on a substrate, and then depositing a CrC or TiC transition coating on the surface of the undercoat; and next, depositing the vanadium / yttrium co-doped DLC coating on the surface of the transition coating by taking vanadium and yttrium as doped metal sources. The DLC coating is doped with the vanadium element and the yttrium element at the same time, the internal stress of the DLC coating can be greatly reduced, therefore the adhesive force of the DLC coating to the substrate is remarkably enhanced, and the film-substrate binding force is up to 70 N or above. Meanwhile, through doping of the vanadium, a chemical transfer membrane with lubricity can be formed in the friction process of the coating, and therefore the wear resistance of the coating is improved. Through doping of the yttrium, dense fine particles of non-columnar crystal nanostructures can be formed, the surface roughness of the coating is reduced, and therefore the wear resistance of the coating is improved. By doping the yttrium, the graphitization temperature of DLC can be increased, and therefore the thermal stability of the DLC is improved.

Owner:广州今泰科技股份有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap