Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

26 results about "Surface roughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface roughness often shortened to roughness, is a component of surface texture. It is quantified by the deviations in the direction of the normal vector of a real surface from its ideal form. If these deviations are large, the surface is rough; if they are small, the surface is smooth. In surface metrology, roughness is typically considered to be the high-frequency, short-wavelength component of a measured surface. However, in practice it is often necessary to know both the amplitude and frequency to ensure that a surface is fit for a purpose.

Growth stimulating wound dressing with improved contact surfaces

InactiveUS20080177253A1Non-adhesive dressingsWound drainsWound dressingSurface roughness

A wound contact device comprising a permeable material and a wound contact layer having voids extending through the contact layer to a depth in the permeable material. The wound contact layer can comprise a thin sheet or film forming a generally flat and smooth wound contact surface having essentially no discontinuities or gaps. The wound contact layer can comprise a thin sheet of highly calendered fabric forming a wound contact surface having a mean surface roughness in the range of about 0 microns to about 200 microns. In progressive wound healing, an embodiment of the wound contact device having the fabric contact surface is used in earlier healing stages and an embodiment of the wound contact device with film contact surface is used in later healing stages. The wound contact device is particularly useful in wound dressings for use in suction-assisted wound therapy.

Owner:BOEHRINGER TECH

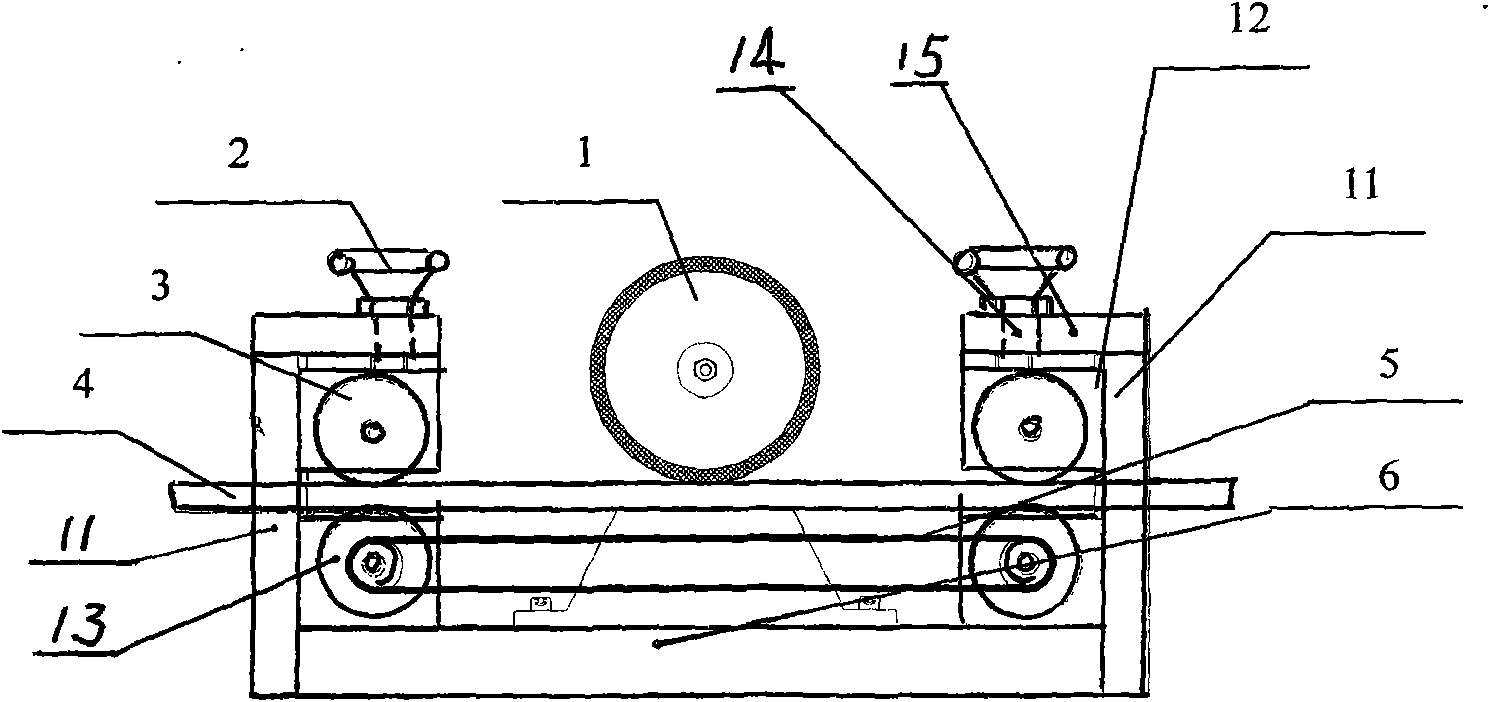

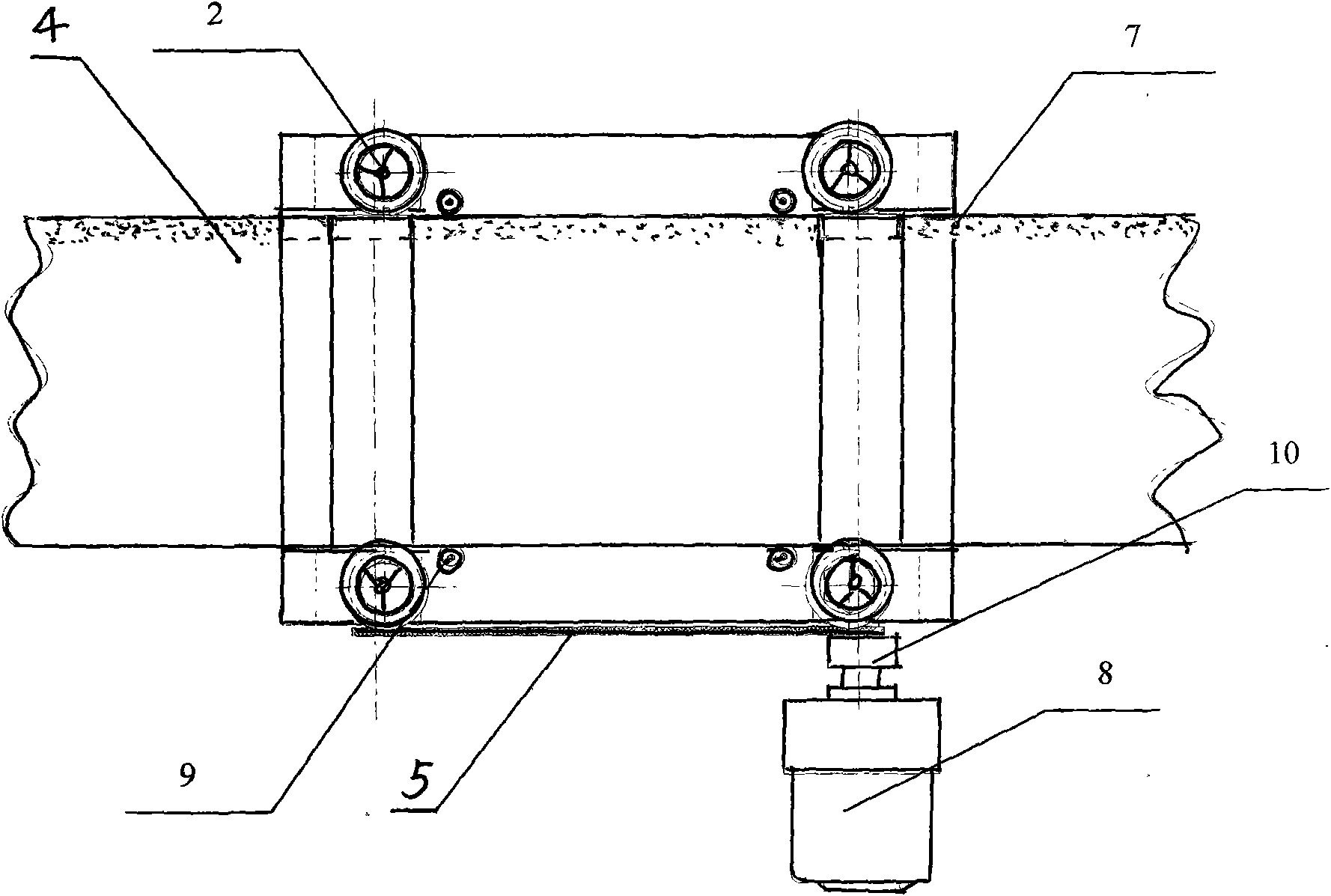

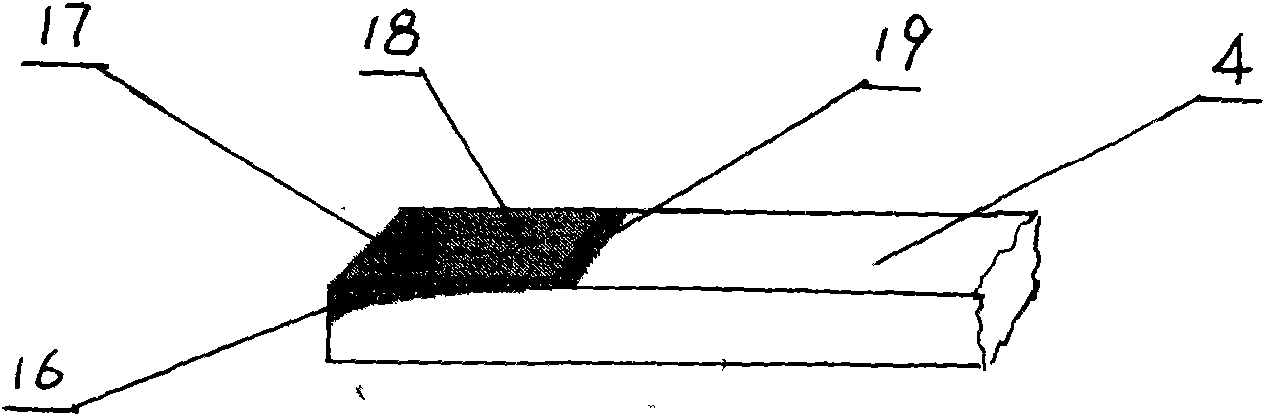

Precision grinding frock clamp, grinding method and product of coating scraper ceramic coating

InactiveCN102059594ALess investmentReduce manufacturing costOther manufacturing equipments/toolsDoctorsCeramic coatingSurface roughness

Owner:SHANDONG UNIV OF SCI & TECH

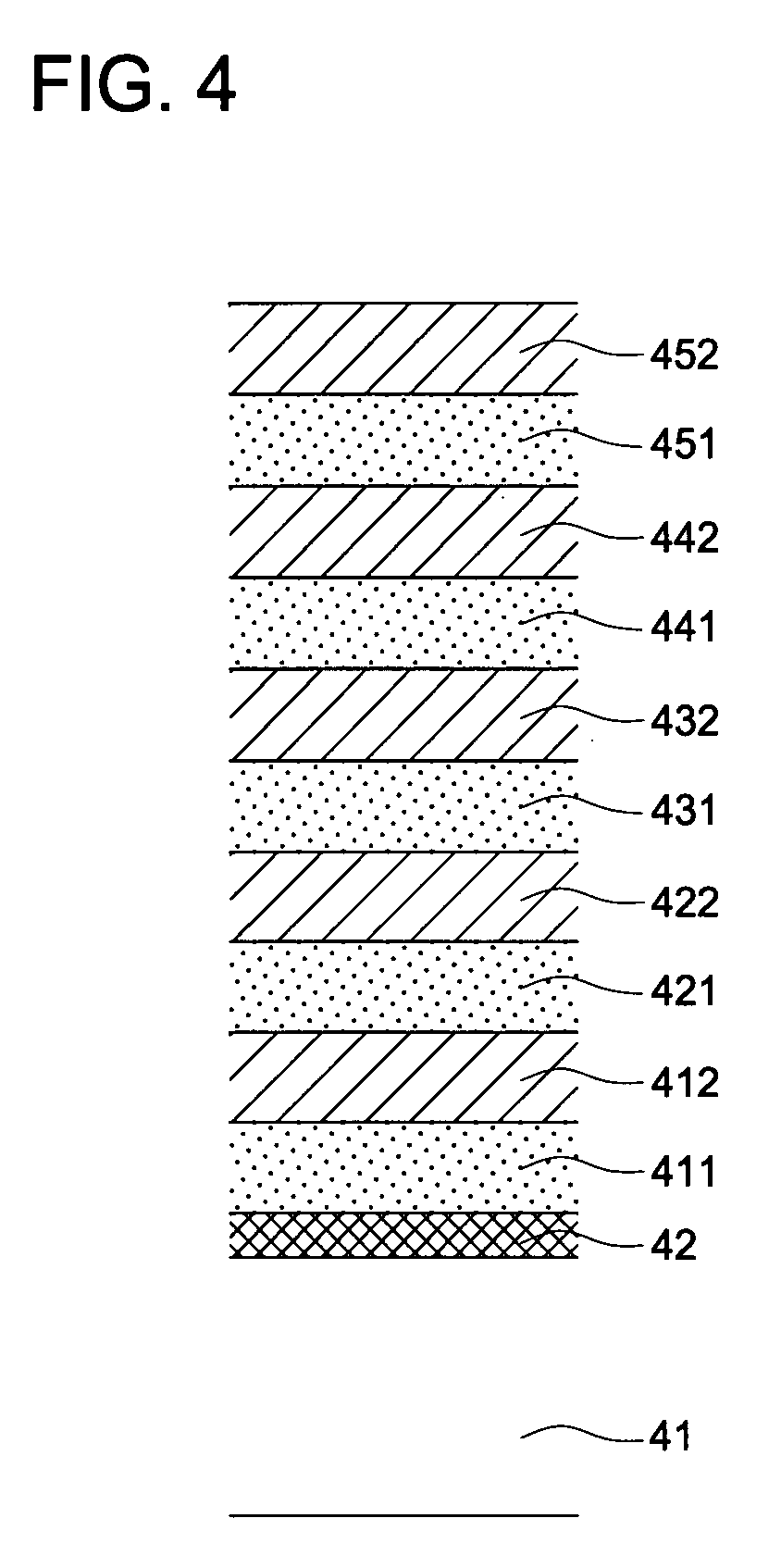

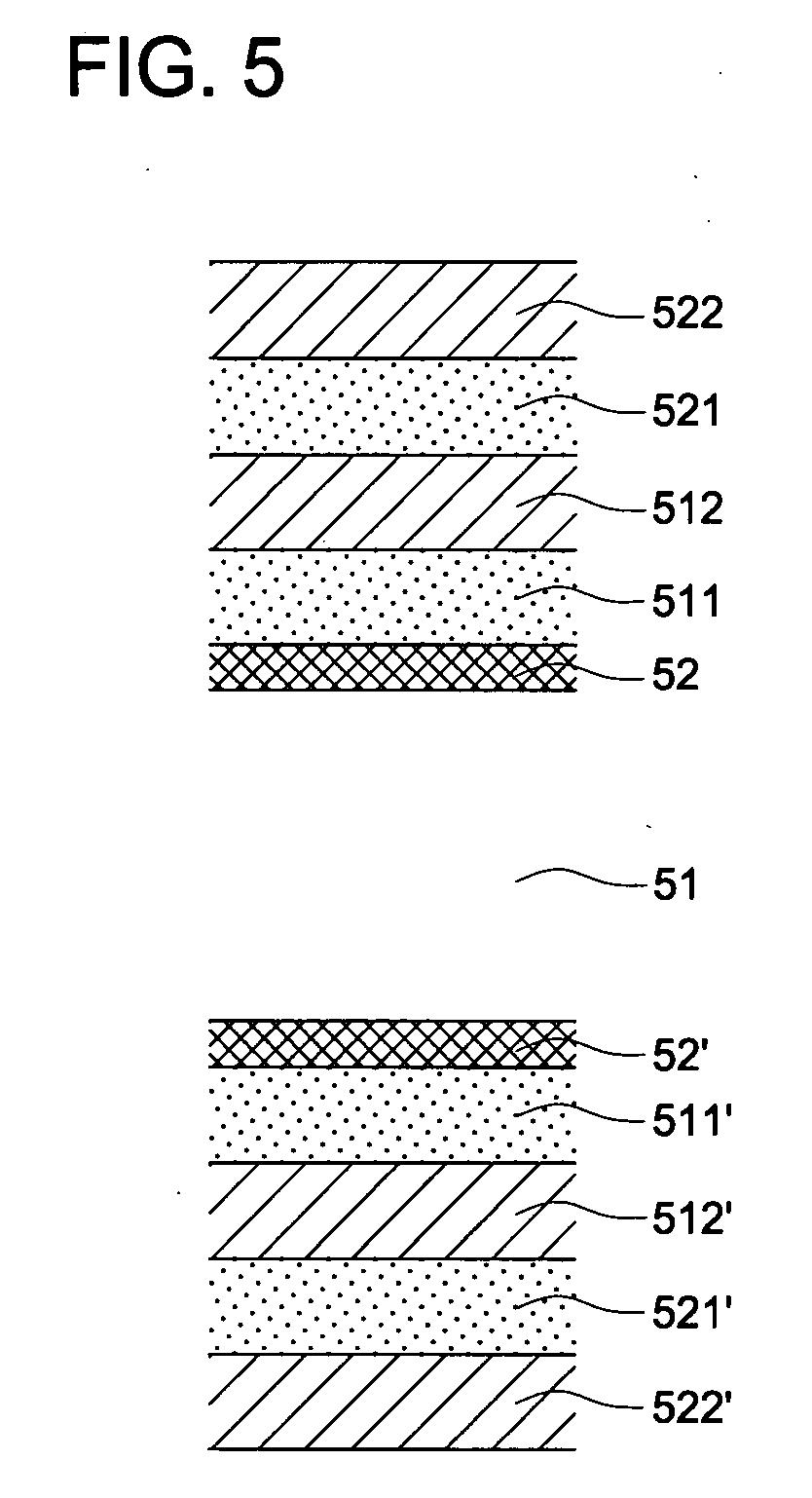

Transparent barrier sheet and preparation method thereof

InactiveUS20070224393A1Improve adhesionAchieve smoothnessLiquid surface applicatorsSynthetic resin layered productsOptoelectronicsSurface roughness

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

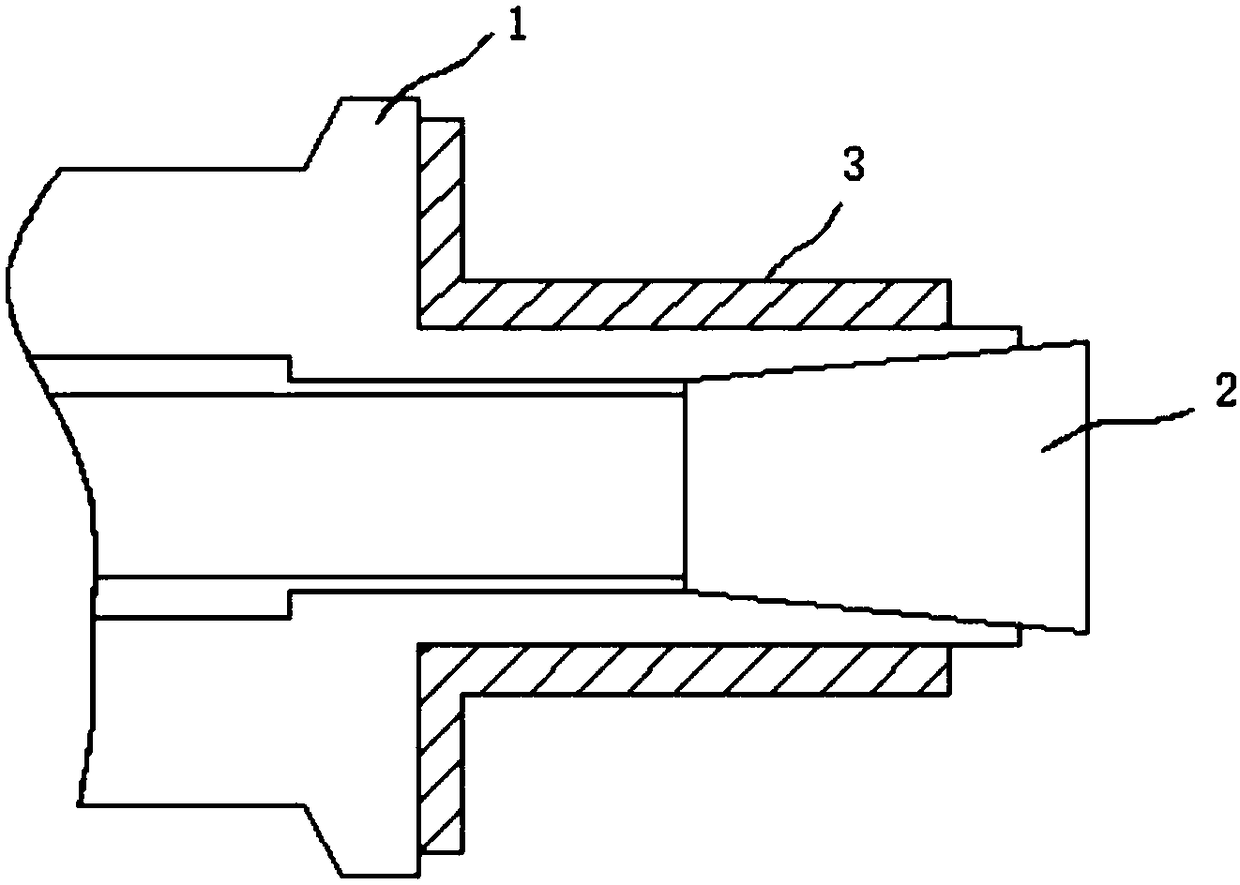

Disposable cutting insert for boring cutter

A disposable cutting insert for a boring cutter can reduce the roughness of a cut surface and achieve a mirror-like surface effect. The disposable cutting insert has a long curved blade edge, and the radius vertex of the long blade edge is deviated slightly from an external side of a vertex of the radius of cutting edge. A short curved blade edge is formed between the radius arc vertex and the radius arc vertex of the cutting edge. The vertical distance of the short curved blade edge is greater than the feed rate. The cutting edge cuts the work piece and the short curved blade edge can scrape a small size of material precisely for scraping the peak cut by the cutting edge and lower the height of the peak, so as to lower the surface roughness, and produce a mirror-like surface for an internal periphery of a bored hole.

Owner:CHANG SC

Method of resistance spot welding aluminum alloy workpieces

ActiveUS20140076859A1Easy to moveEliminate contaminationVehicle componentsWelding/cutting media/materialsSurface roughnessSpot welding

A method of resistance spot welding aluminum alloy workpieces together includes several steps. In one step a welding electrode is provided. The welding electrode has a weld face. In another step, the weld face of the welding electrode is shaped to have a desired radius of curvature. The shaped weld face is then textured to a desired surface roughness, and resistance spot welding using the welding electrode is performed to the aluminum alloy workpieces. In yet another step, the weld face is dressed to an extent sufficient to remove contamination build-up that may have accumulated on the weld face from the aluminum alloy workpieces.

Owner:GM GLOBAL TECH OPERATIONS LLC

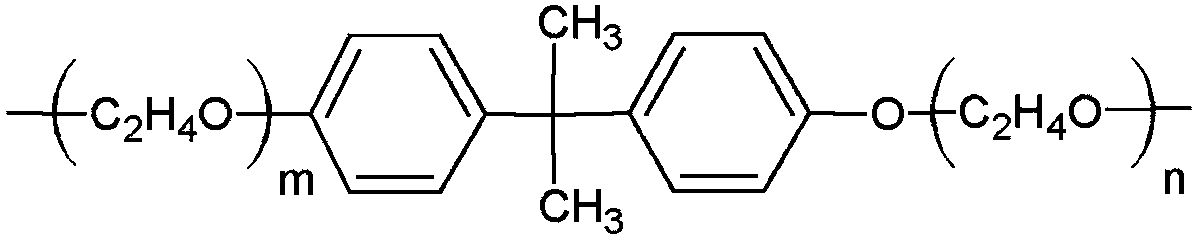

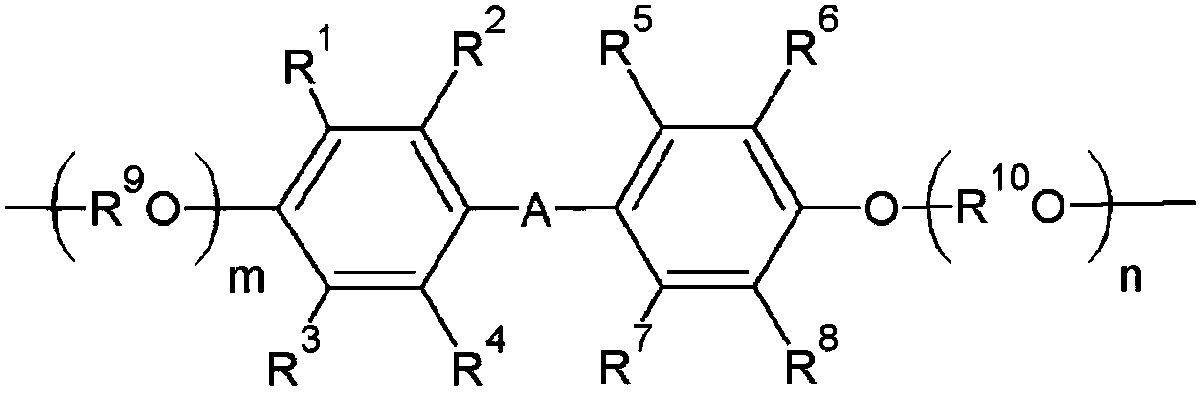

Preparation method for polymer composite electrolyte membrane

ActiveCN106816617AImprove fill rateReduce surface roughnessSolid electrolytesConductive materialPolymer electrolytesCompound a

The invention discloses a preparation method for a polymer composite electrolyte membrane. The preparation method comprises the following steps: compounding a porous membrane containing a low-viscosity polymer electrolyte A solution and a high-viscosity polymer electrolyte B solution. The viscosity of the solution is controlled, and the polymer composite electrolyte membrane prepared by the preparation method has a high filling ration and low surface roughness, so that the comprehensive performances of the polymer electrolyte are greatly improved, and the application prospect is clearer.

Owner:TORAY IND INC

Preparation of aramid fiber modifying solution

Owner:烟台泰和工程材料有限公司 +1

Grind process for optical sapphire crystal substrate

InactiveCN1289261CReduce surface roughnessSize differenceMicrometer

Owner:SHANGHAI XINHUAXIA INDAL

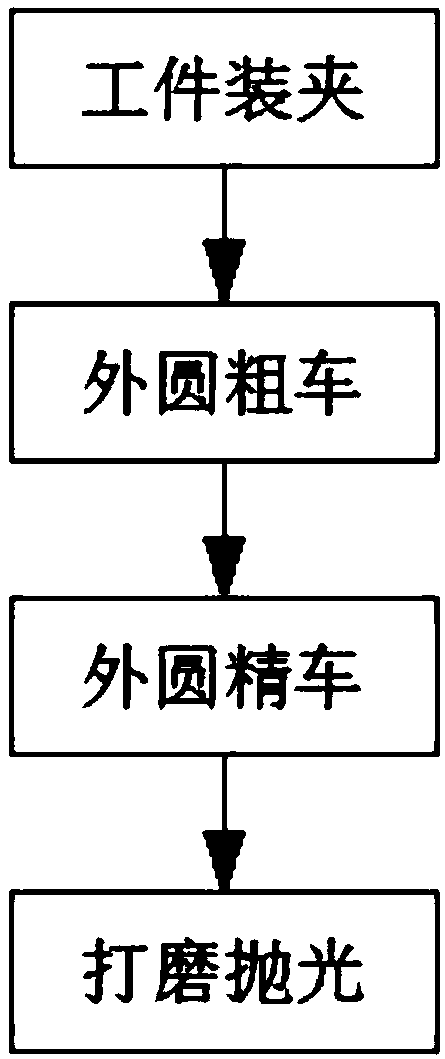

Finish turning method for external circular surface of thin-walled gear ring

InactiveCN108127128AEliminate cutting heatReduce radial forceRadial stressSurface roughness

Owner:JIANGYIN YONGXING MACHINERY MFG

Coating process of outer surface of sculpture

InactiveCN105921387APrevent metal oxidationSufficient adhesionPretreated surfacesSpecial surfacesWeather resistanceSurface roughness

Owner:NANJING CHENGUANG ART ENG CO LTD

Super-liquid-repellent coating film and curable composition for forming super-liquid-repellent coating film

ActiveCN109072008AImprove wear resistancePigmenting treatmentOther chemical processesN-hexadecaneSurface roughness

The present invention addresses the problem of providing a super-liquid-repellent coating film which has improved wear resistance. Provided as a means for solving the problem is a coating film havinga surface which has a fluorine atom content of 1-60 wt%, an average surface roughness Ra of 0.5-20, a surface area ratio of 1.7-5, a contact angle with water of 150 DEG or greater, and a contact anglewith n-hexadecane of 80 DEG or greater and, after a PET film is rubbed thereagainst 100 times under a load of 100 g, has a contact angle with water of 150 DEG or greater.

Owner:DAIKIN IND LTD

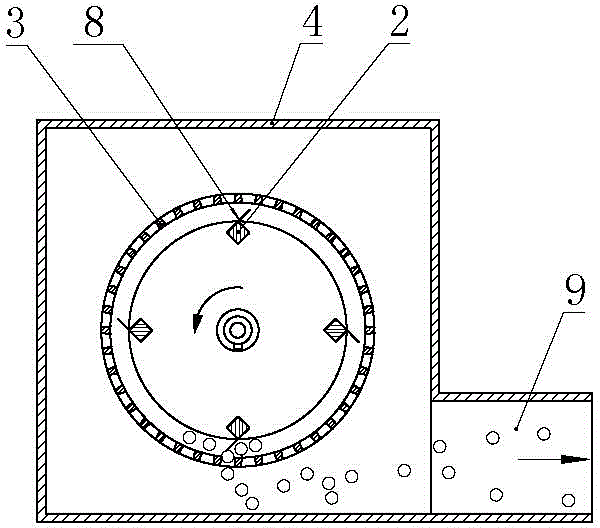

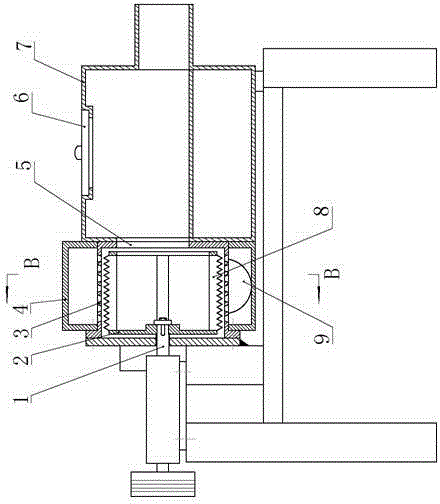

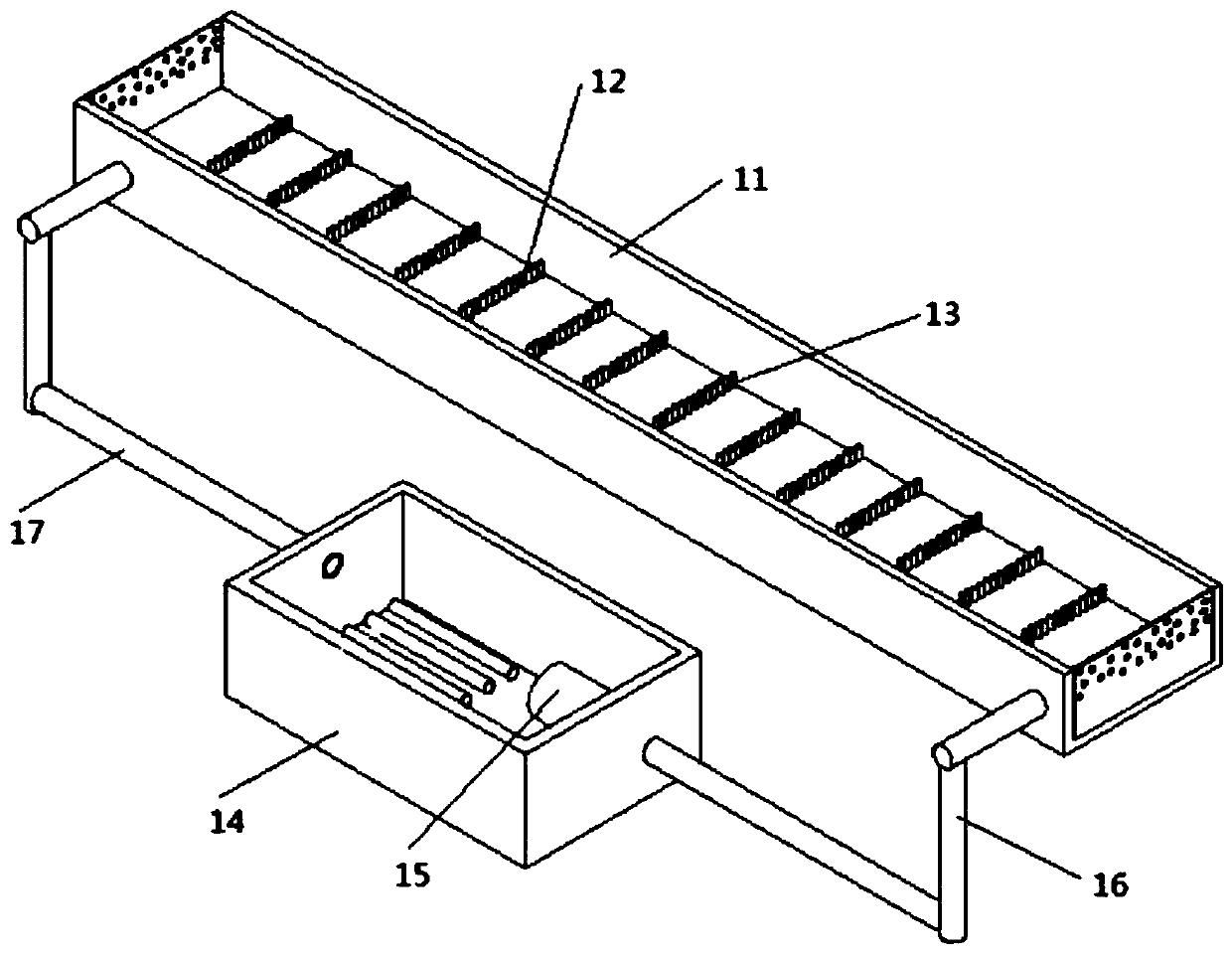

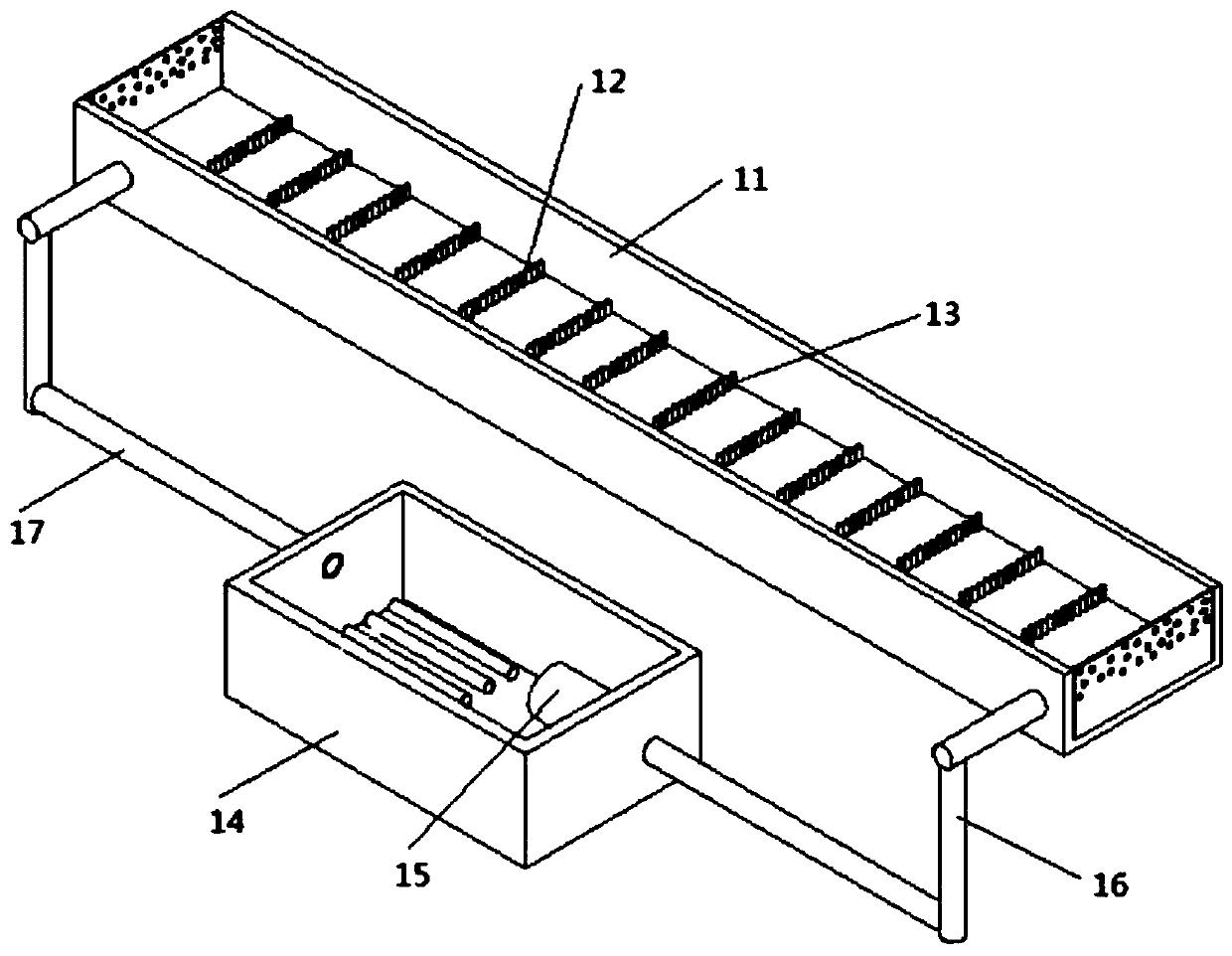

Treatment machine for increasing surface roughness of plastic foam particles

InactiveCN104690954ASmooth entryStir wellRough surfaceSuction force

Owner:LONGKOU ZHENGREN ENERGY SAVING BUILDING MATERIALSEQUIP MFG

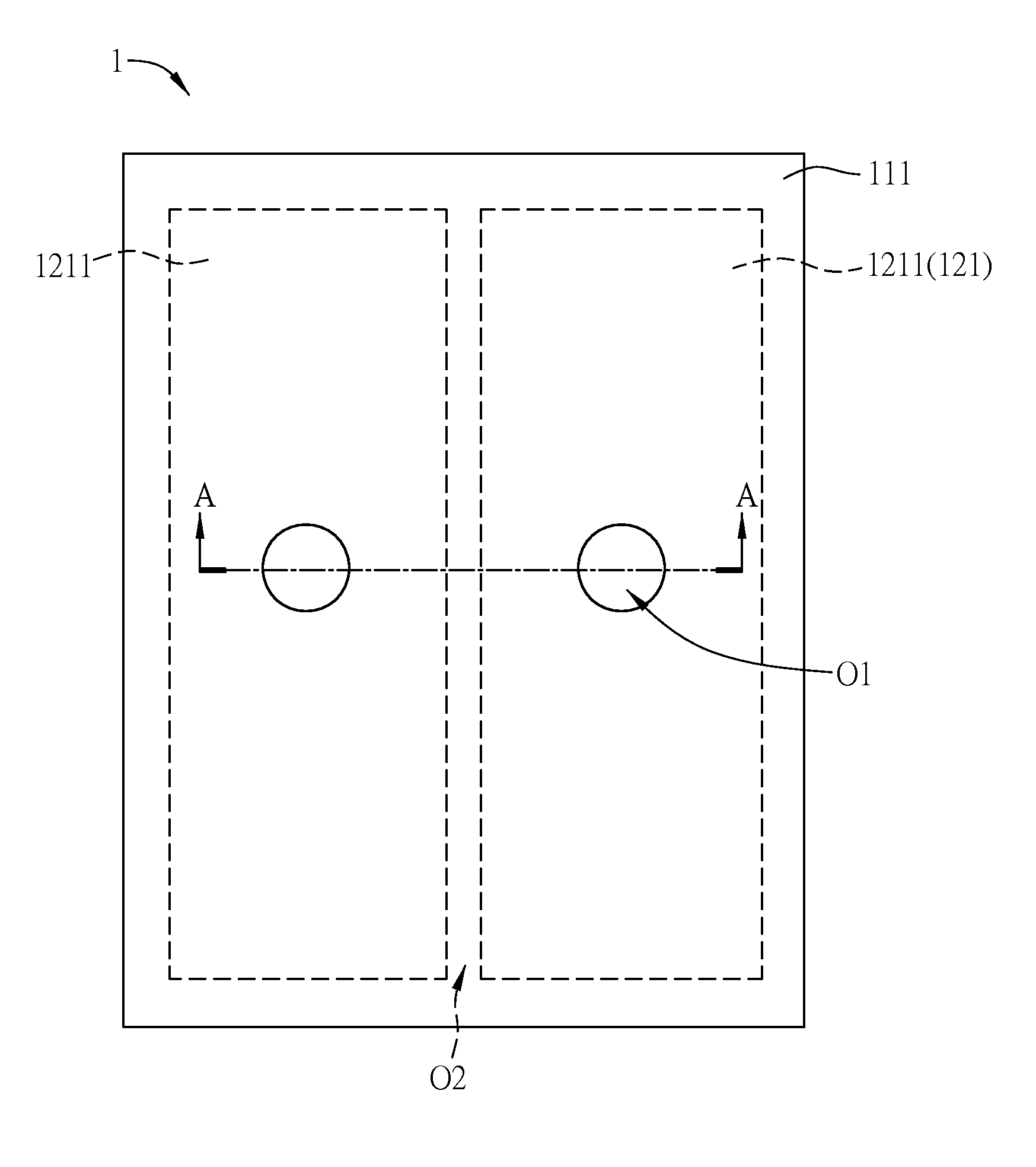

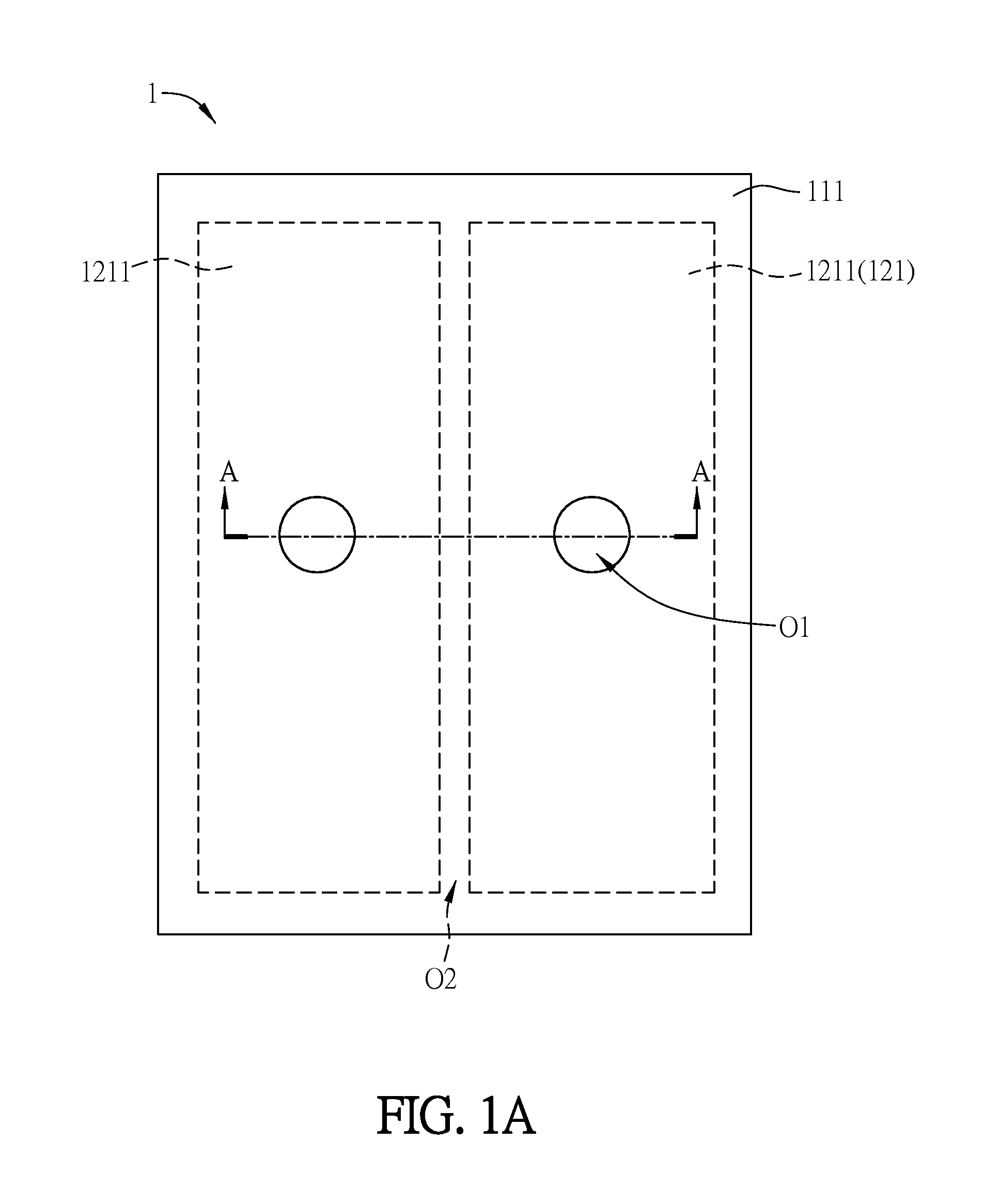

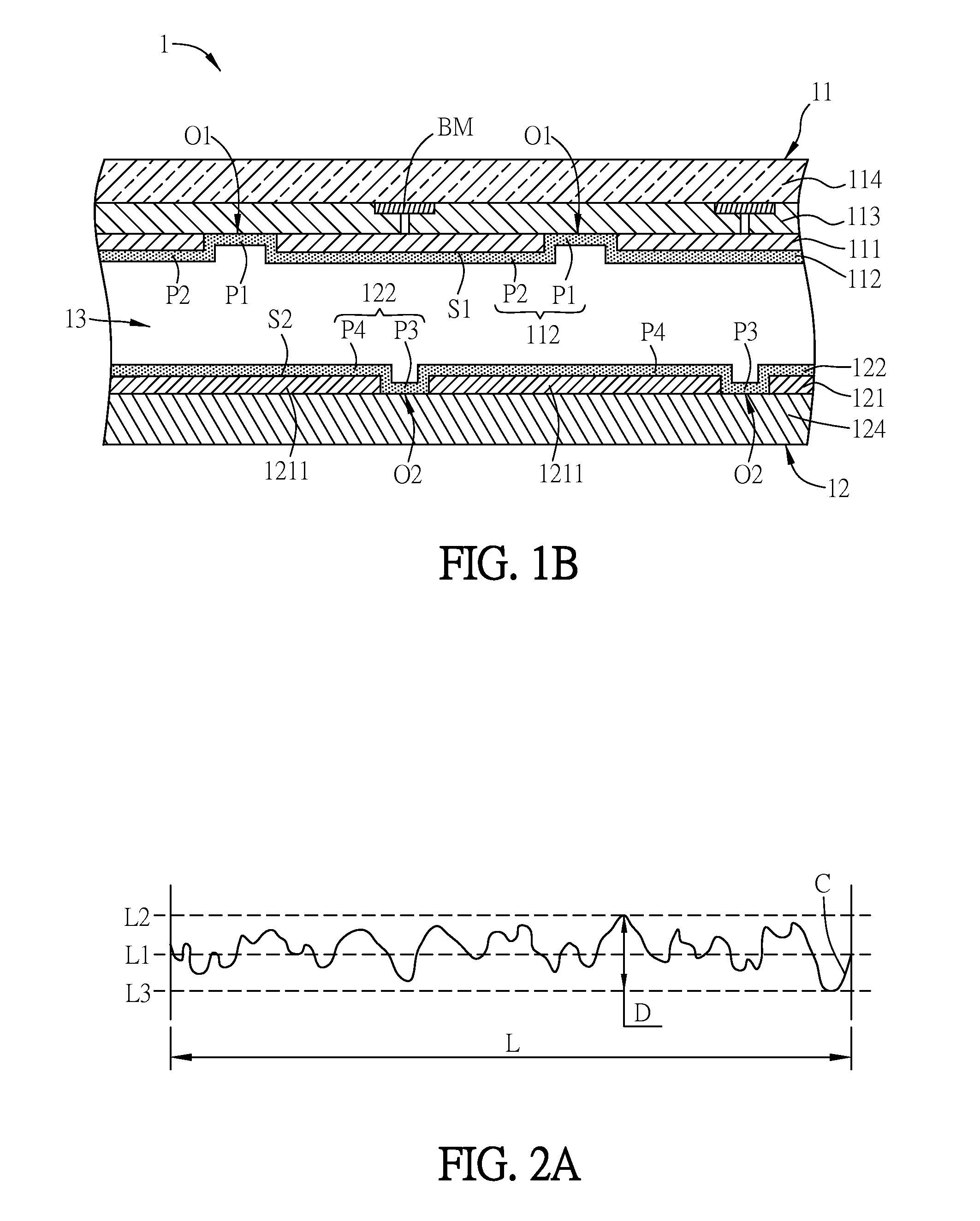

Display panel and display device

ActiveCN110265581AIncrease contrastReduce ejectionSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceSurface roughness

The invention provides a display panel and a display device. The display panel comprises a substrate and a light-emitting layer, a polaroid and a polaroid support layer, which are stacked up on the substrate in sequence. The top surface of the polaroid support layer deviating from the polaroid is provided with a first rough portion for changing surface roughness of the top surface. According to the display panel and the display device, when ambient light enters the display panel through the first rough portion, the first rough portion can make a part of the ambient light have diffuse reflection and cannot enter the display panel, thereby reducing the ambient light entering the display panel; and meanwhile, when the ambient light incident into the display panel is reflected by a metal layer in the light-emitting layer, the outgoing light also has diffuse reflection when passing through the first rough portion, thereby reducing the outgoing light and further improving contrast of the display panel.

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

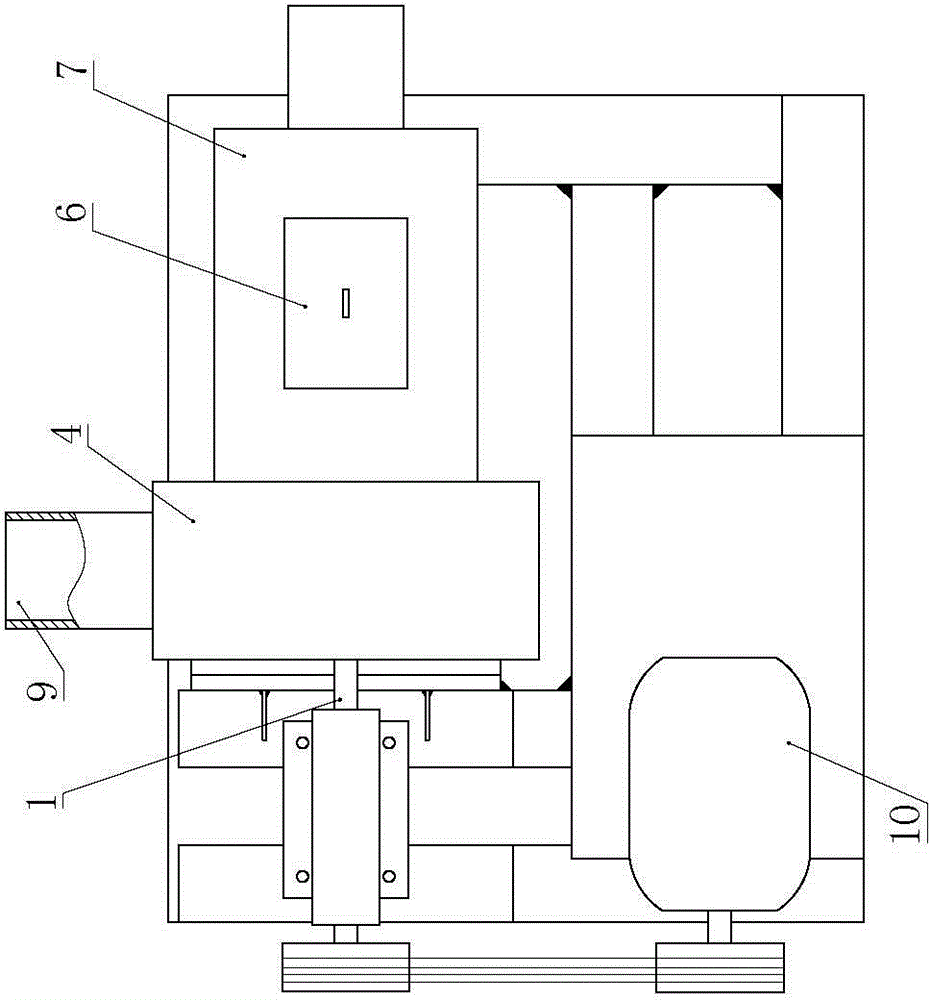

Cutter system for super-speed cutting of numerically-controlled machine tool

ActiveCN107020535AHigh cutting speedImprove machining accuracyDriving apparatusNumerical controlAviation

The invention discloses a cutter system for super-speed cutting of a numerically-controlled machine tool. The system comprises a main shaft, a housing, a locking sleeve and a cutter. The system is characterized in that the upper end of the main shaft is connected with the numerically-controlled machine tool; an input bearing is mounted at the lower end of the main shaft and positioned on the housing; the main shaft is connected with a rotating frame, and a crankshaft is mounted on the rotating frame; an epicycloidal wheel and a cycloidal wheel bearing are mounted in the middle part of the crankshaft, and a planet gear which is engaged with a sun gear is mounted at the lower end of the crankshaft; an output bearing is mounted on the sun gear and positioned on the housing; the sun gear is connected with the upper end of the locking sleeve, and the lower end of the locking sleeve is connected with the cutter. The system has the beneficial effects that the cutting rotation speed is extremely high during the processing of aviation and precision optical devices; the processing effect is good; the processing accuracy is high; extremely high surface roughness can be obtained; the actual engineering requirement of high-speed cutting can be met; the technological gaps can be filled; and moreover, the social benefit and the economic benefit are high.

Owner:TIANJIN POLYTECHNIC UNIV

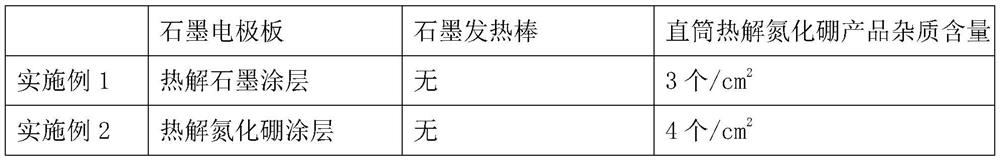

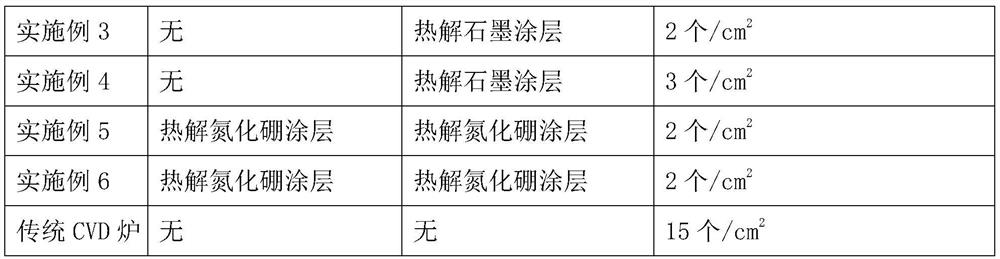

Protection method for graphite part of vacuum furnace

PendingCN111945129AExtended service lifeAvoid pollutionChemical vapor deposition coatingBoron trichlorideSurface roughness

Owner:山东国晶新材料有限公司

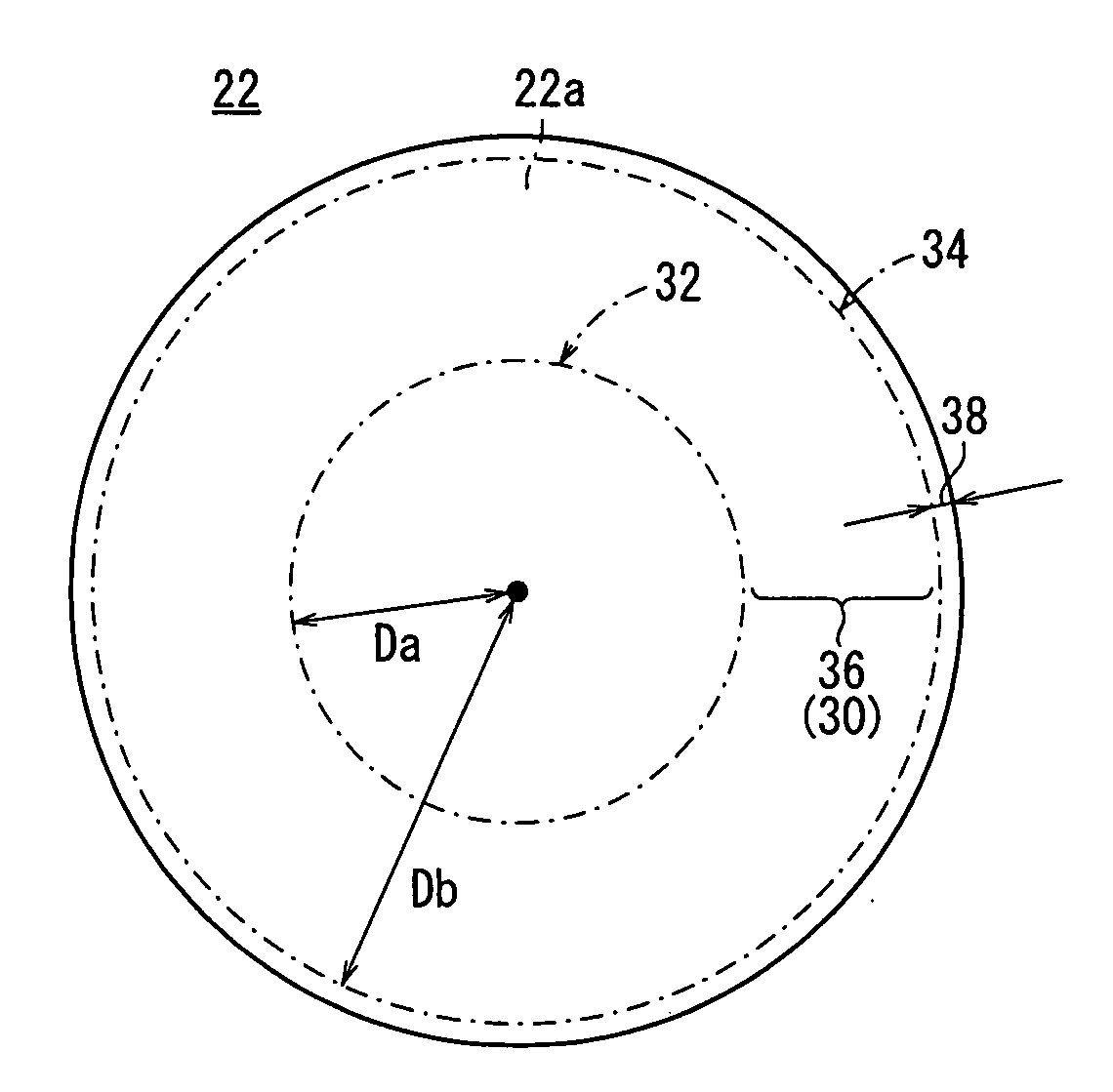

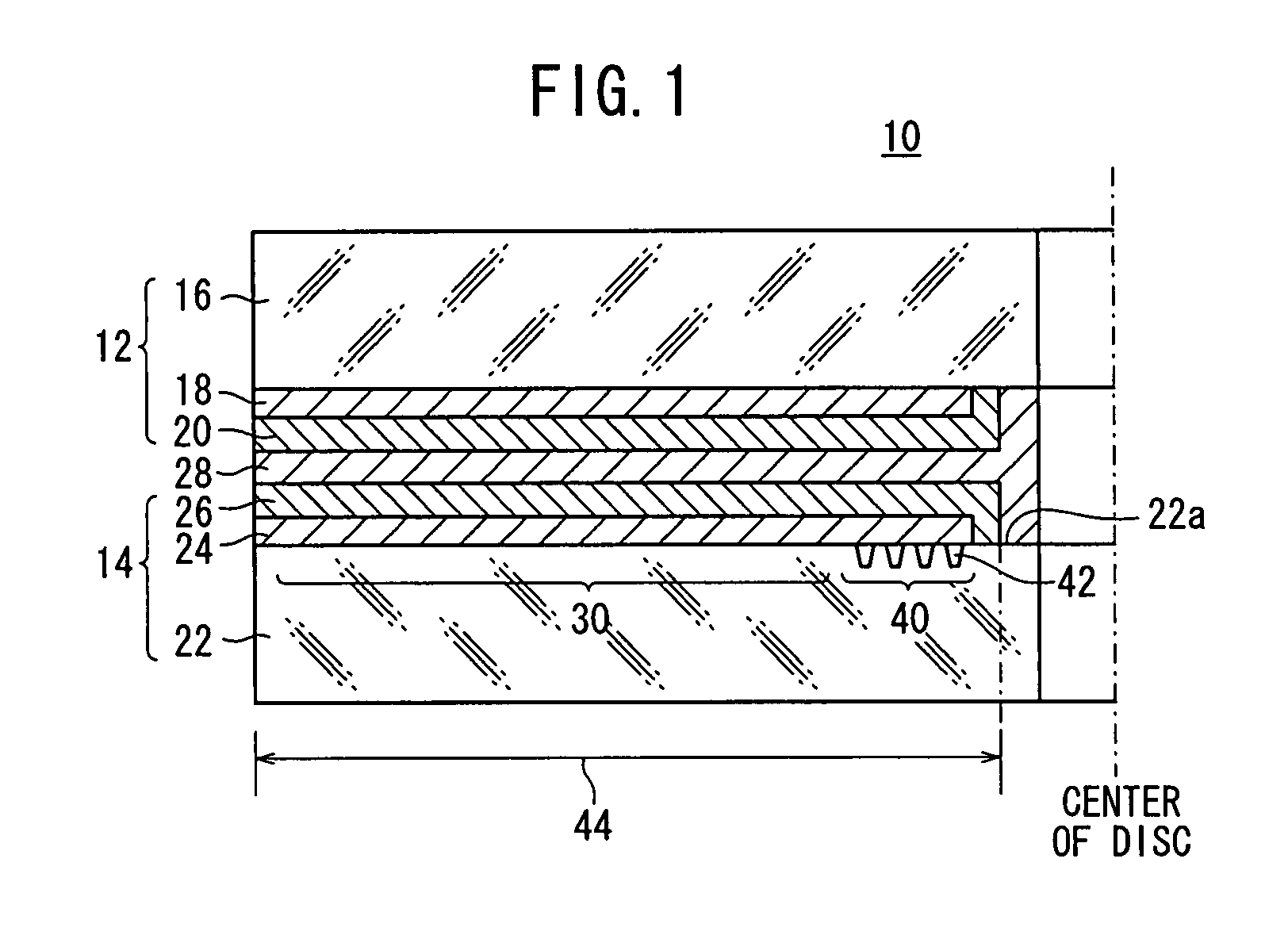

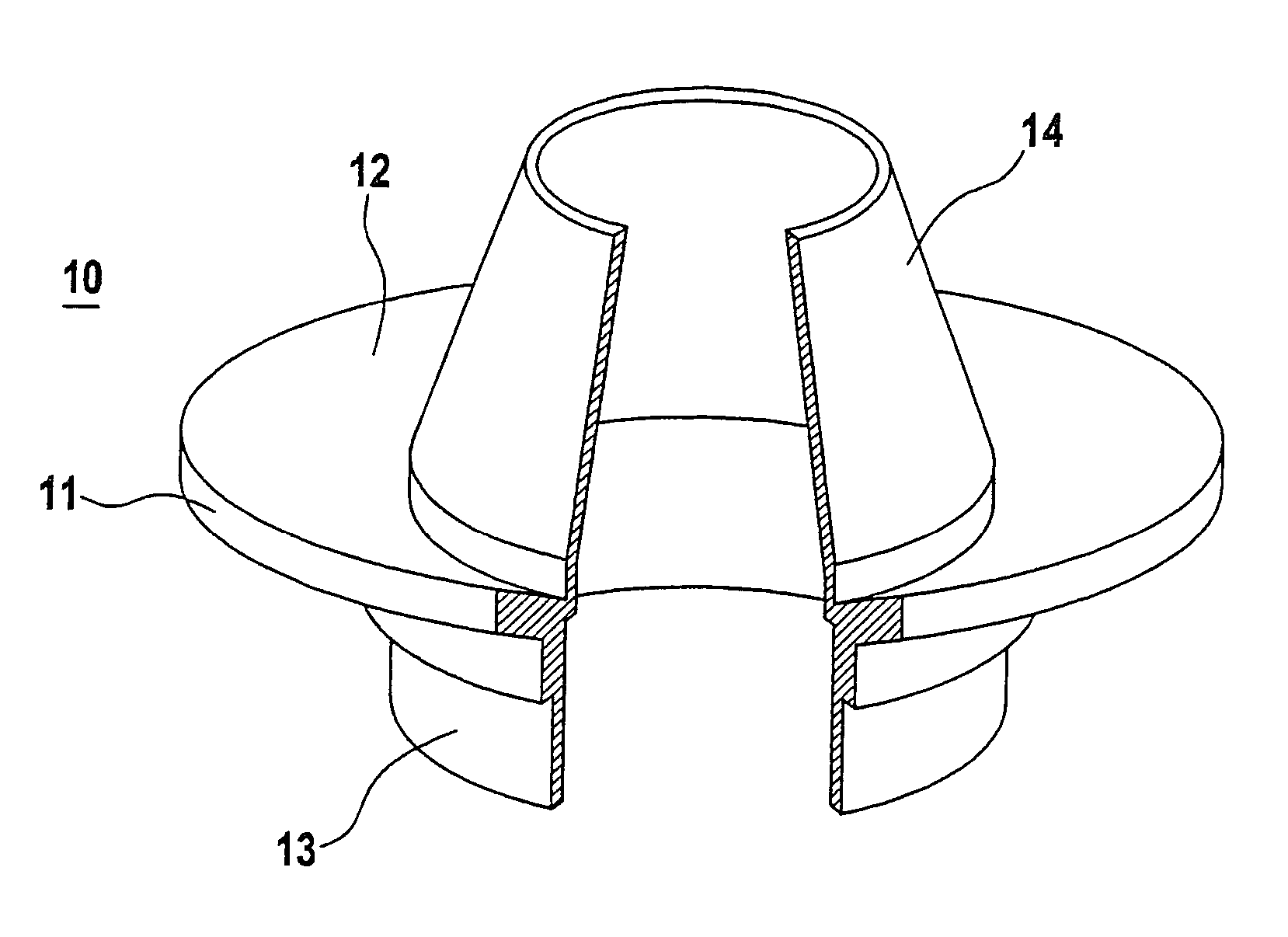

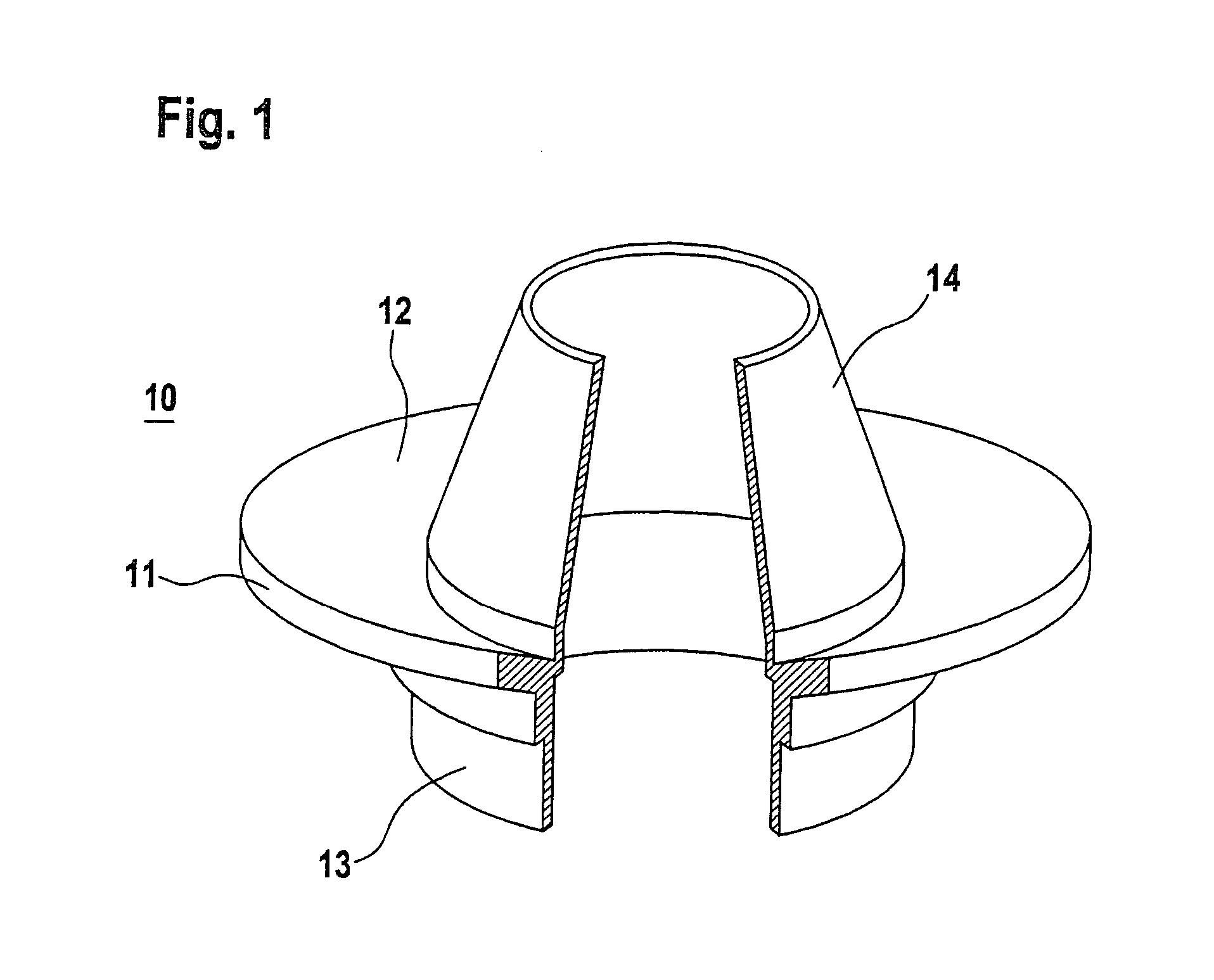

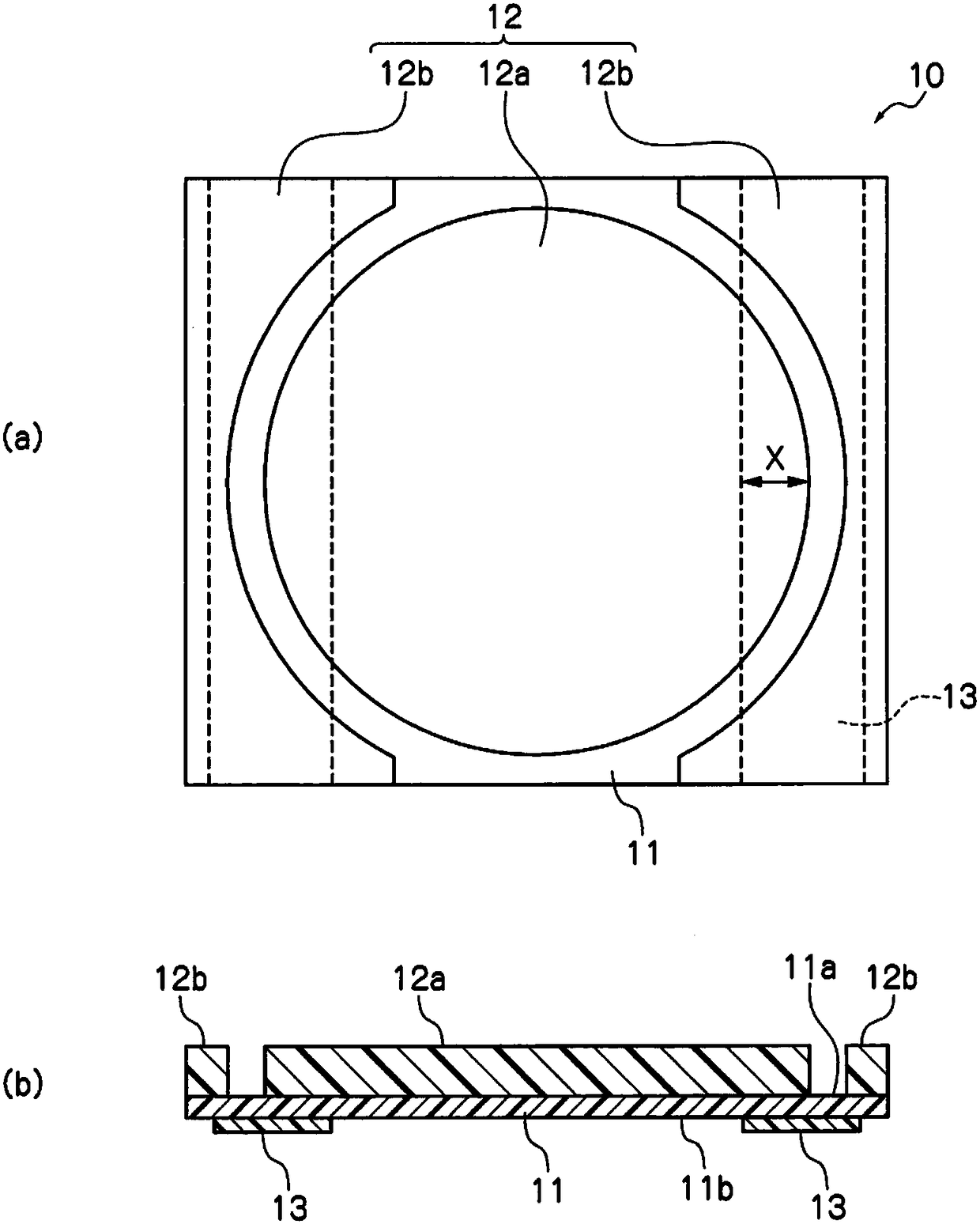

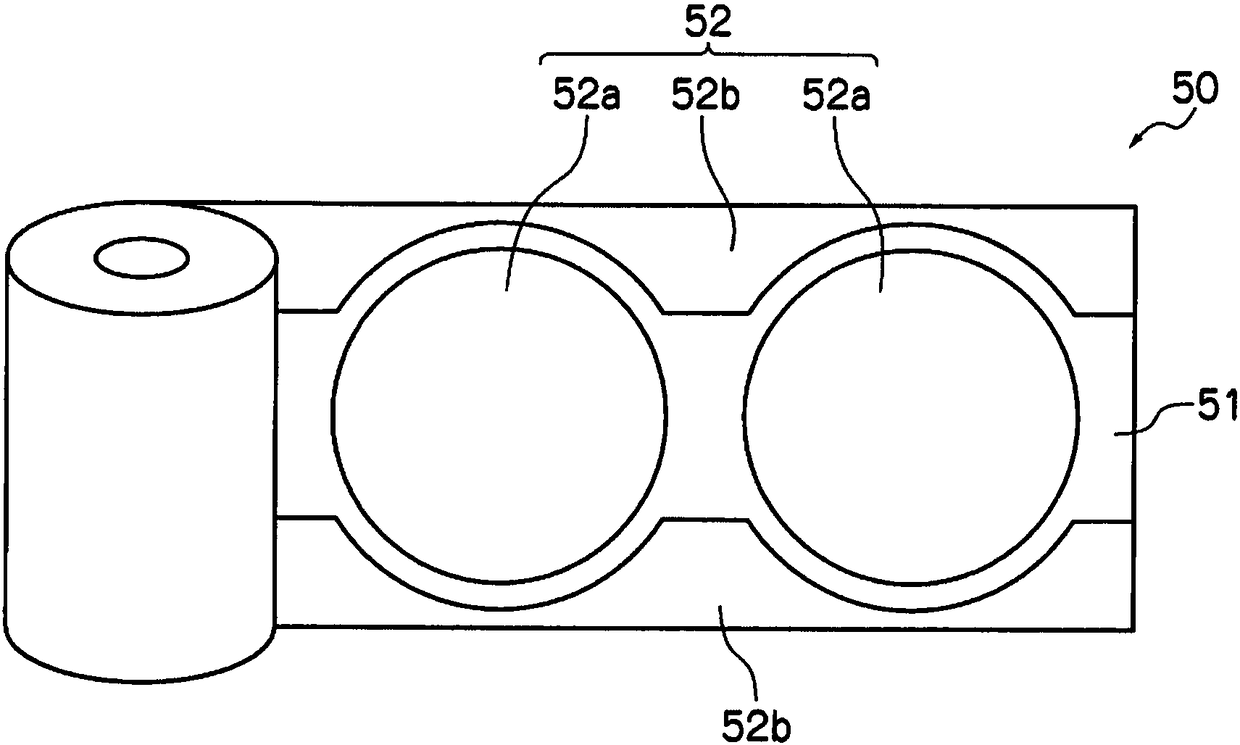

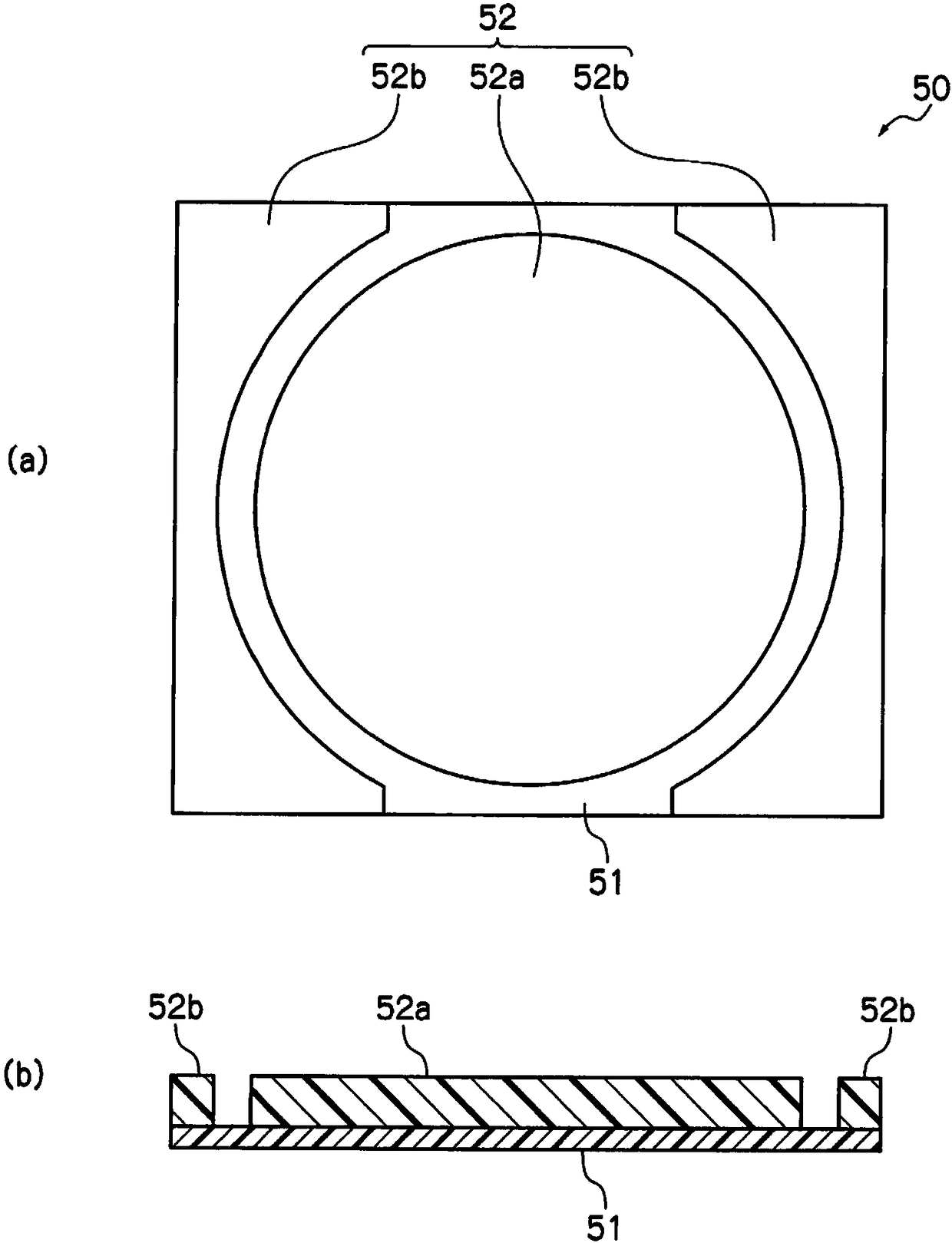

Original glass plate, method of producing original glass plate, stamper for optical recording medium, and method of producing stamper

InactiveUS20080046908A1Flat record carrier containersRecord information storageOptical recordingSurface roughness

Owner:FUJIFILM CORP

Injection-molded foam of resin composition with satisfactory surface property and capable of weight reduction and rib design

Owner:KANEKA CORP

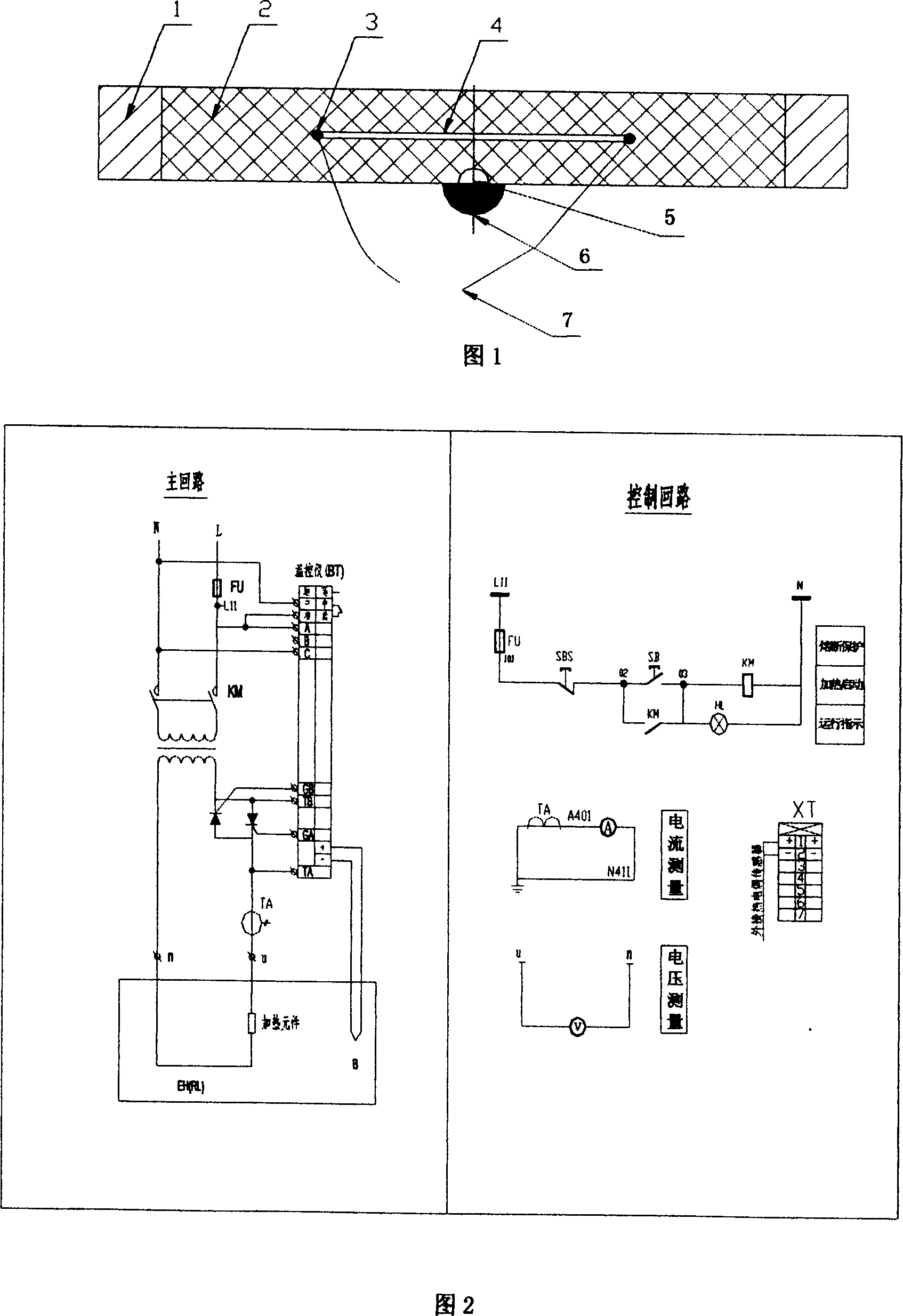

Preparation of the high-performance porcelain heating parts with automatic temperature-control

InactiveCN1997245AImprove pass rateNo pollution in the processHeater elementsHeating element materialsEpoxyTemperature control

Owner:范新宽

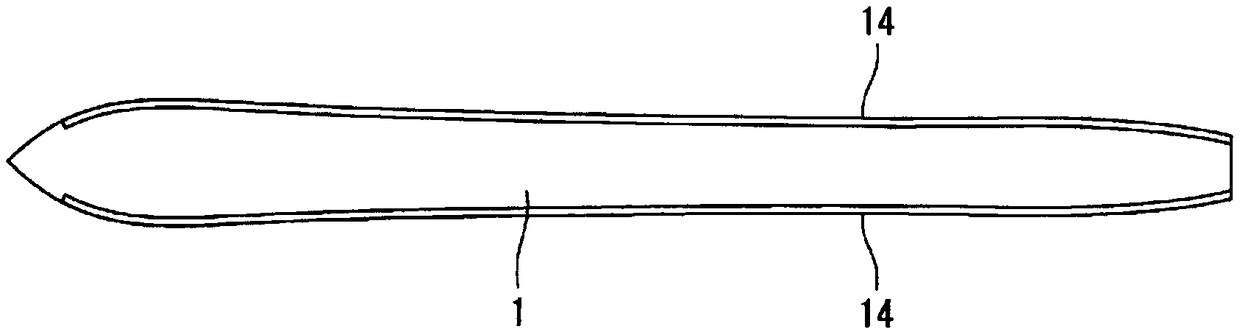

Sliding instrument and method for manufacturing same

ActiveCN109310918AReduce frictional resistanceImprove sliding effectWaterborne vesselsWater sport boardsSurface roughnessSlurry

Owner:FUJIMI INCORPORATED

Method for producing a mirror from a titanium-based material, and a mirror made from such a material

InactiveUS7476145B2Improve wear resistanceEasy to useMirrorsOptical surface grinding machinesSurface roughnessTitanium

Owner:DIEHL BGT DEFENCE GMBH & CO KG

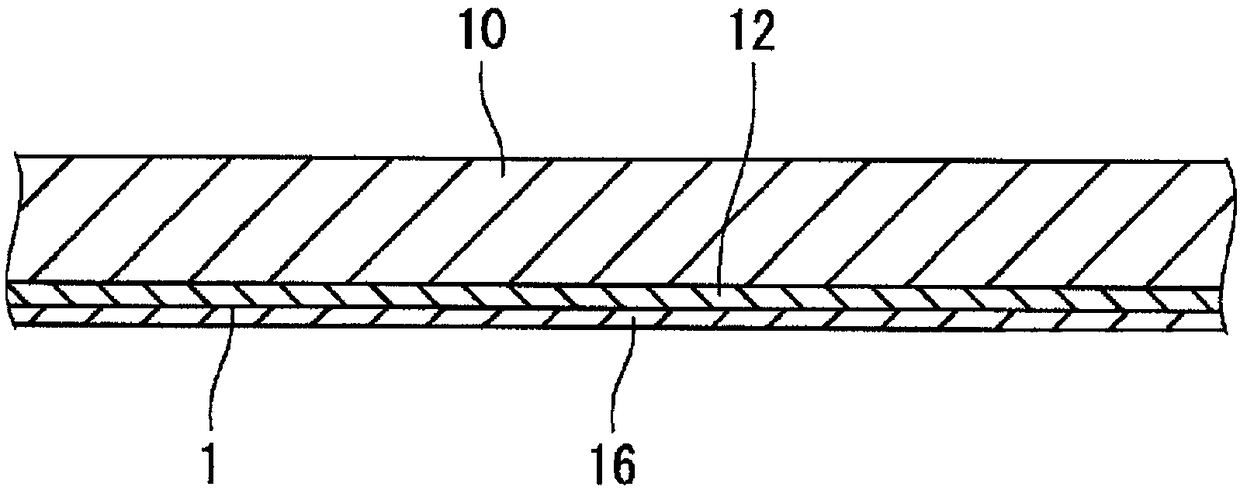

Wafer processing tape

PendingCN108541338AInhibit adhesionPromote withdrawalFilm/foil adhesivesSemiconductor/solid-state device manufacturingWaferingSurface roughness

Owner:FURUKAWA ELECTRIC CO LTD

Preparation method of single-sided high-glossiness 6061-H22 state aluminum alloy mirror plate

Owner:河南明晟新材料科技有限公司

Manufacturing process of vehicle safety belt shaft

The invention discloses a manufacturing process of a vehicle safety belt shaft. The manufacturing process comprises the following steps that blanking is carried out, head pre forming is carried out, specifically, impact is carried out under the combined action of the concave head punching die and the flat head main die; head forming is carried out, specifically, impact is carried out again under the combined action of the punching die and the main die, and thus a head of a product is formed; the diameter reducing of a rod part is carried out, specifically, impact is carried out under the combined action of the punching die, a push pipe and a closed bundle flat main die, and thus the rod part of the product is formed; flange forming is carried out, specifically, impact is carried out under the combined action of a flat hole punching die and a concave ring main die, and thus a flange part of the product is formed; an inner hole is impacted, specifically, impact is carried out under the combined action of the flat hole punching die, a movable inner main die and an hole extruding rod, and thus an inner hole is formed in the rod part of the product; and appearance trimming is carried out, impact is carried out under the combined action of a titanium-plated trimming die and a concave head inner main die, and thus a notch is formed in the flange part of the product. According to the product formed through the above manufacturing process, the surface roughness is greatly reduced, and the phenomenon that a safety belt generates jerking during the use process can be reduced or even avoided.

Owner:WUXI YINGHUSNDARD FASTENER

Making method of high-corrosion-resistance air conditioner support

InactiveCN107702238AThe problem of shortened useful lifeAvoid shortened service lifeLighting and heating apparatusAnti-corrosive paintsRustHeat treating

Owner:成都毅诚机电工程有限公司

Display panel and display device

ActiveUS20150138491A1Improve responseImprove surface roughnessNon-linear opticsDisplay deviceSurface roughness

Owner:INNOLUX CORP

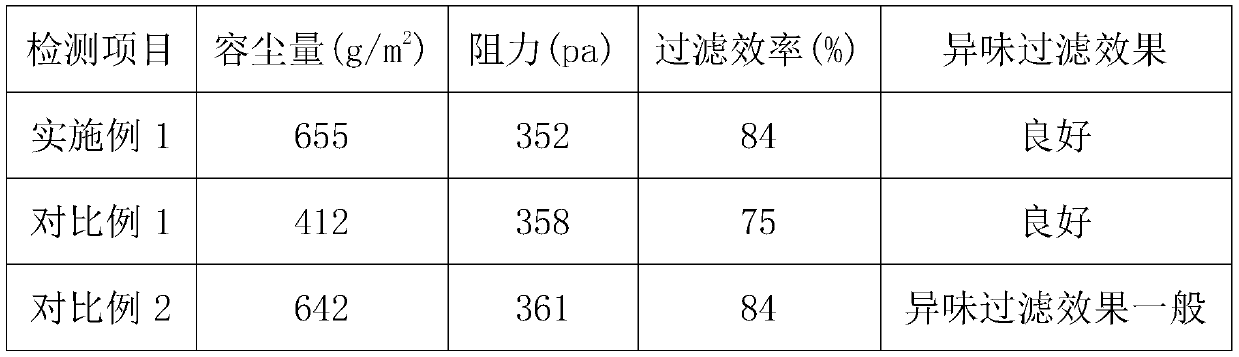

Preparation method of air filtering material

ActiveCN109999570ADamage structureReduce cohesionDispersed particle filtrationFiltration separationPolyesterActivated carbon

Owner:山东奥博环保科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap