Preparation method of air filtering material

A technology of air filter material and polyester fiber, which is applied in the field of preparation of air filter material, can solve the problems of poor adsorption capacity of pollution particles, reduced filtering effect, poor filtering effect, etc., achieve good hydrophobicity, improve adsorption capacity, and improve The effect of filtering ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

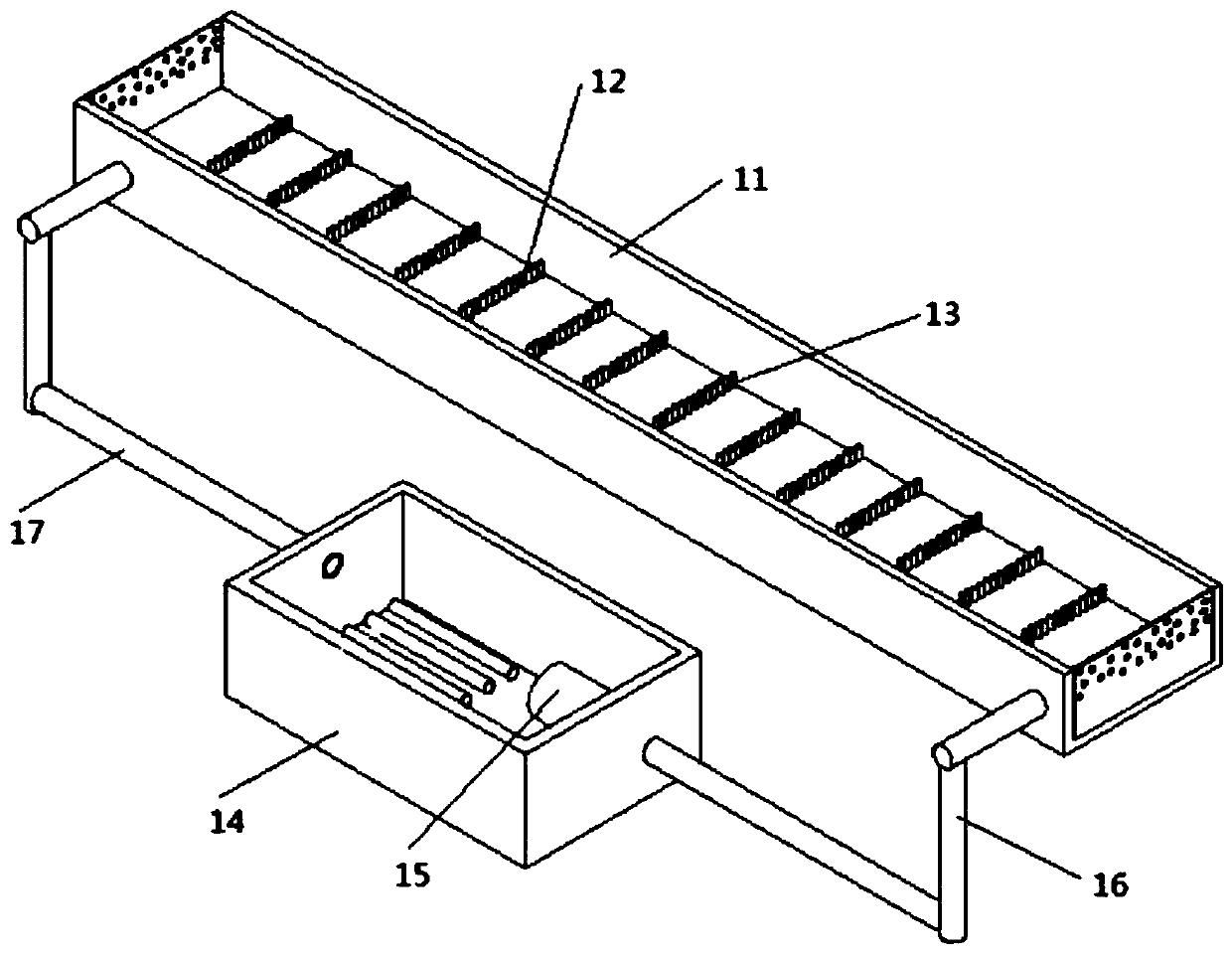

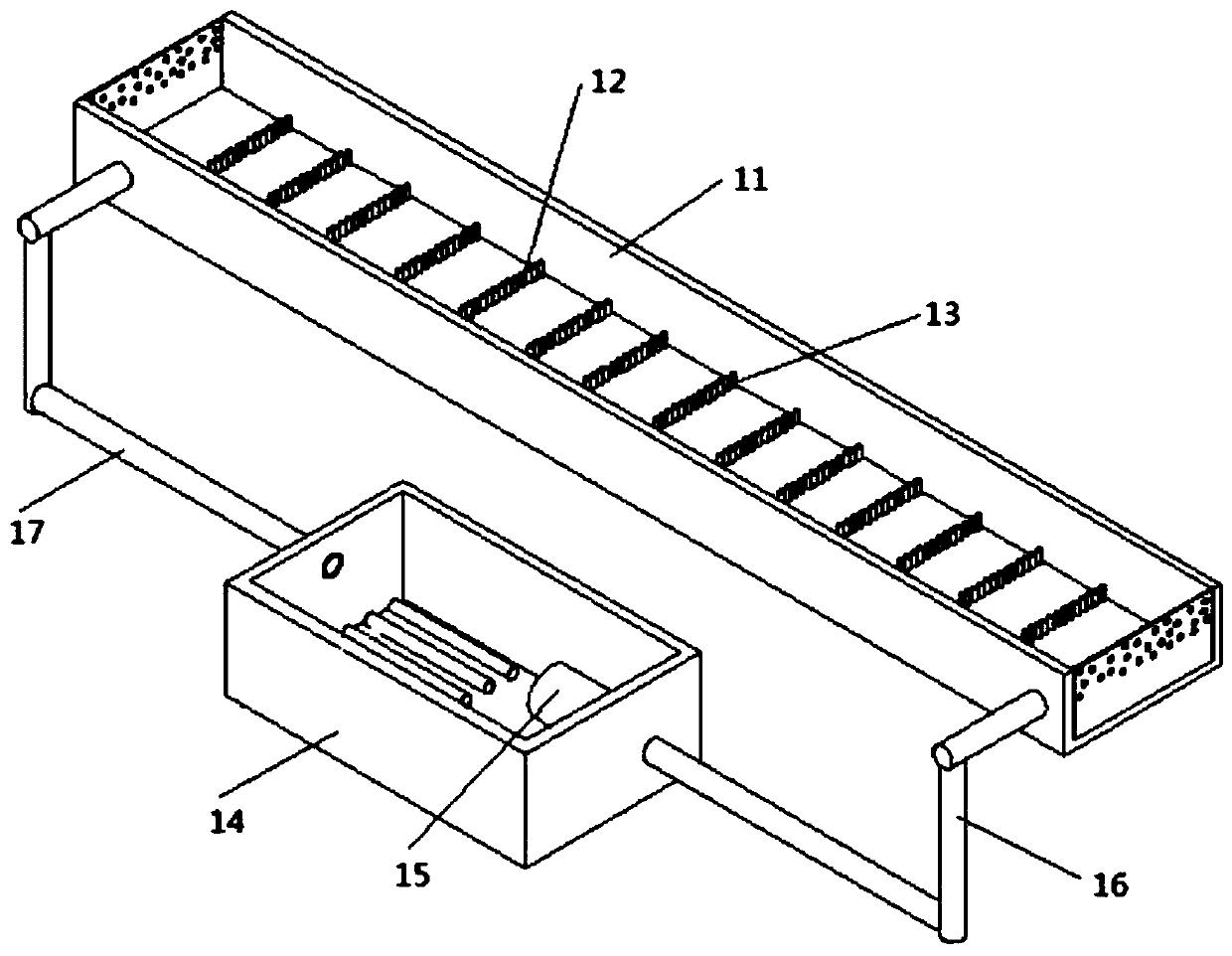

Image

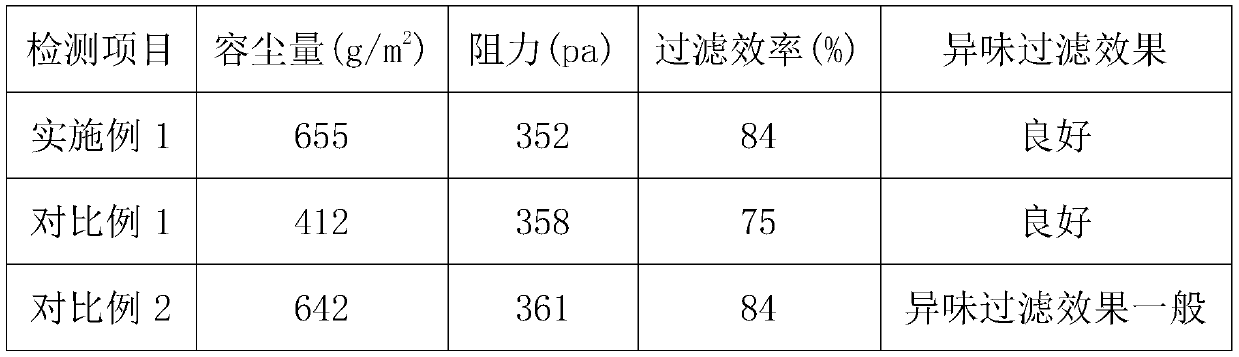

Examples

Embodiment 1

[0035] A preparation method of air filter material, comprising the steps of:

[0036] Step 1: Pretreatment of fibers, configure sodium hydroxide solution with a concentration of 10%-15%, heat the sodium hydroxide solution to 45-55°C, add polyester fiber to it and soak for 15-30min, then separate solid and liquid, pass Rinse with deionized water at 45-55°C and dry to obtain preliminary treated polyester fibers;

[0037]Step 2: Preparation of hydrophobic fibers, take absolute ethanol and heat it to 50-60°C, add acrylate to the hot absolute ethanol solution and stir to dissolve to obtain an alcohol solution of acrylate, wherein the amount of acrylate added in absolute ethanol 1-3g / L, the polyester fiber is added to the alcohol solution of acrylate and then poured into the advection tank for reaction. After irradiating with high-energy rays for 15-25 minutes, the solid-liquid separation is carried out. After the polyester fiber is naturally cooled, it is rinsed with deionized water

Embodiment 2

[0048] A preparation method of air filter material, comprising the steps of:

[0049] Step 1: Pretreatment of fibers, configure sodium hydroxide solution with a concentration of 10%-15%, heat the sodium hydroxide solution to 45-55°C, add polyester fiber to it and soak for 15-30min, then separate solid and liquid, pass Rinse with deionized water at 45-55°C and dry to obtain preliminary treated polyester fibers;

[0050] Step 2: Preparation of hydrophobic fibers, take absolute ethanol and heat it to 50-60°C, add acrylate to the hot absolute ethanol solution and stir to dissolve to obtain an alcohol solution of acrylate, wherein the amount of acrylate added in absolute ethanol 1-3g / L, the polyester fiber is added to the alcohol solution of acrylate and then poured into the advection tank for reaction. After irradiating with high-energy rays for 15-25 minutes, the solid-liquid separation is carried out. After the polyester fiber is naturally cooled, it is rinsed with deionized wate

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap