Method for dyeing polyester fiber type material by using oligomer removing agent

An oligomer remover and polyester fiber technology, which is applied in the field of oligomer remover, can solve the problems of fiber glass transition temperature lowering, oligomer diffusion, etc., and achieve the effects of inhibiting adsorption, uniform dyeing, and enhancing product stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

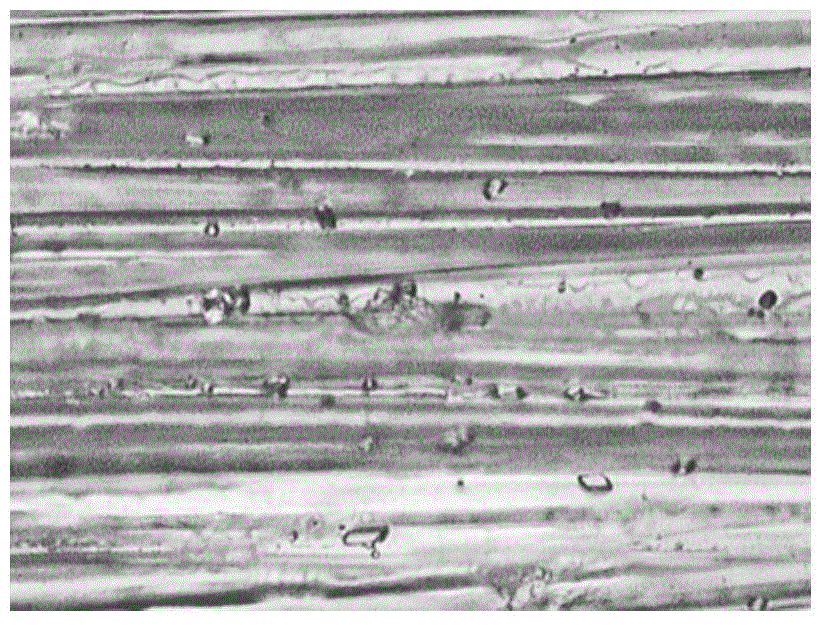

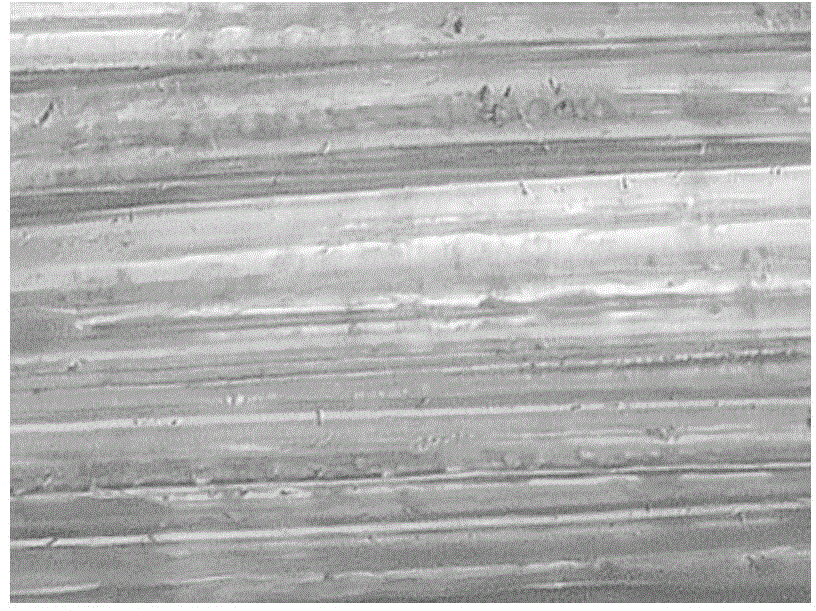

Image

Examples

Embodiment 1

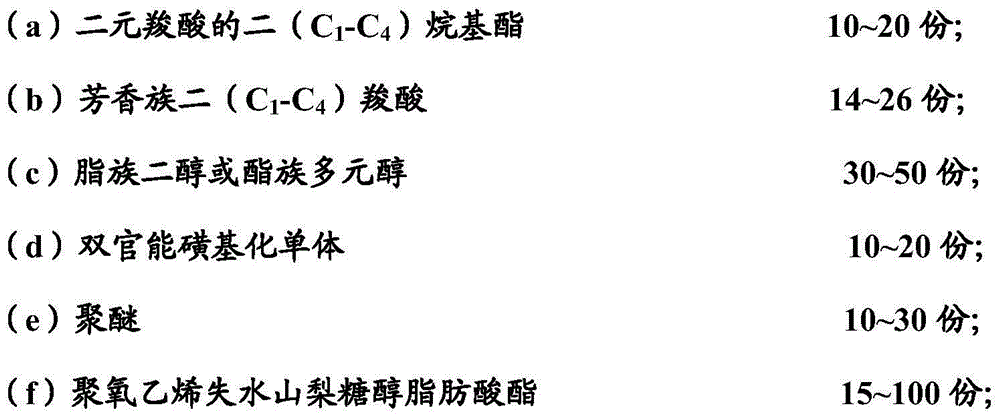

[0029] 1) Weigh 200g of diethyl adipate, 450g of ethylene glycol, 200g of terephthalic acid, 500g of polyoxyethylene sorbitan monolaurate, and 150g of dimethyl isophthalate-5-sodium sulfonate 150g of polypropylene glycol polyethylene glycol block copolymer with a weight average molecular weight of 2000, and 2g of zinc acetate.

[0030] 2) Put the above-mentioned materials into the reaction kettle, heat up to 140° C. for 190 minutes while stirring under nitrogen environment, remove the alcohol by-product of the transesterification reaction, continue to heat up to carry out polycondensation reaction, the reaction temperature is 220° C. for 70 minutes, and then The reaction was continued for 120 minutes at a vacuum degree of -0.08 MP and a temperature of 240° C. to obtain an oligomer remover.

Embodiment 2

[0032] 1) Weigh 100g of diethyl adipate, 500g of ethylene glycol, 260g of terephthalic acid, 800g of polyoxyethylene sorbitan monolaurate, and 100g of dimethyl isophthalate-5-sodium sulfonate 100g of polypropylene glycol polyethylene glycol block copolymer with a weight average molecular weight of 2000 and 2g of zinc acetate.

[0033] 2) Put the above-mentioned materials into the reaction kettle, heat up to 140° C. for 190 minutes while stirring under nitrogen environment, remove the alcohol by-product of the transesterification reaction, continue to heat up to carry out polycondensation reaction, the reaction temperature is 220° C. for 70 minutes, and then The reaction was continued for 120 minutes at a vacuum degree of -0.08 MP and a temperature of 240° C. to obtain an oligomer remover.

Embodiment 3

[0035] 1) Weigh 150g of diethyl adipate, 300g of ethylene glycol, 260g of terephthalic acid, 400g of polyoxyethylene sorbitan monolaurate, and 200g of dimethyl isophthalate-5-sodium sulfonate , weight-average molecular weight is 2000 polypropylene glycol polyethylene glycol block copolymer 300g, zinc acetate 2g.

[0036] Put the above materials into the reaction kettle, heat up to 140°C for 190 minutes while stirring in a nitrogen environment, remove the alcohol by-products of the transesterification reaction, continue to heat up for polycondensation reaction, the reaction temperature is 220°C for 70 minutes, and then The temperature was -0.08MP, and the reaction was continued for 120 minutes at a temperature of 240° C. to obtain an oligomer removing agent.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap