Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about "Conductive material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

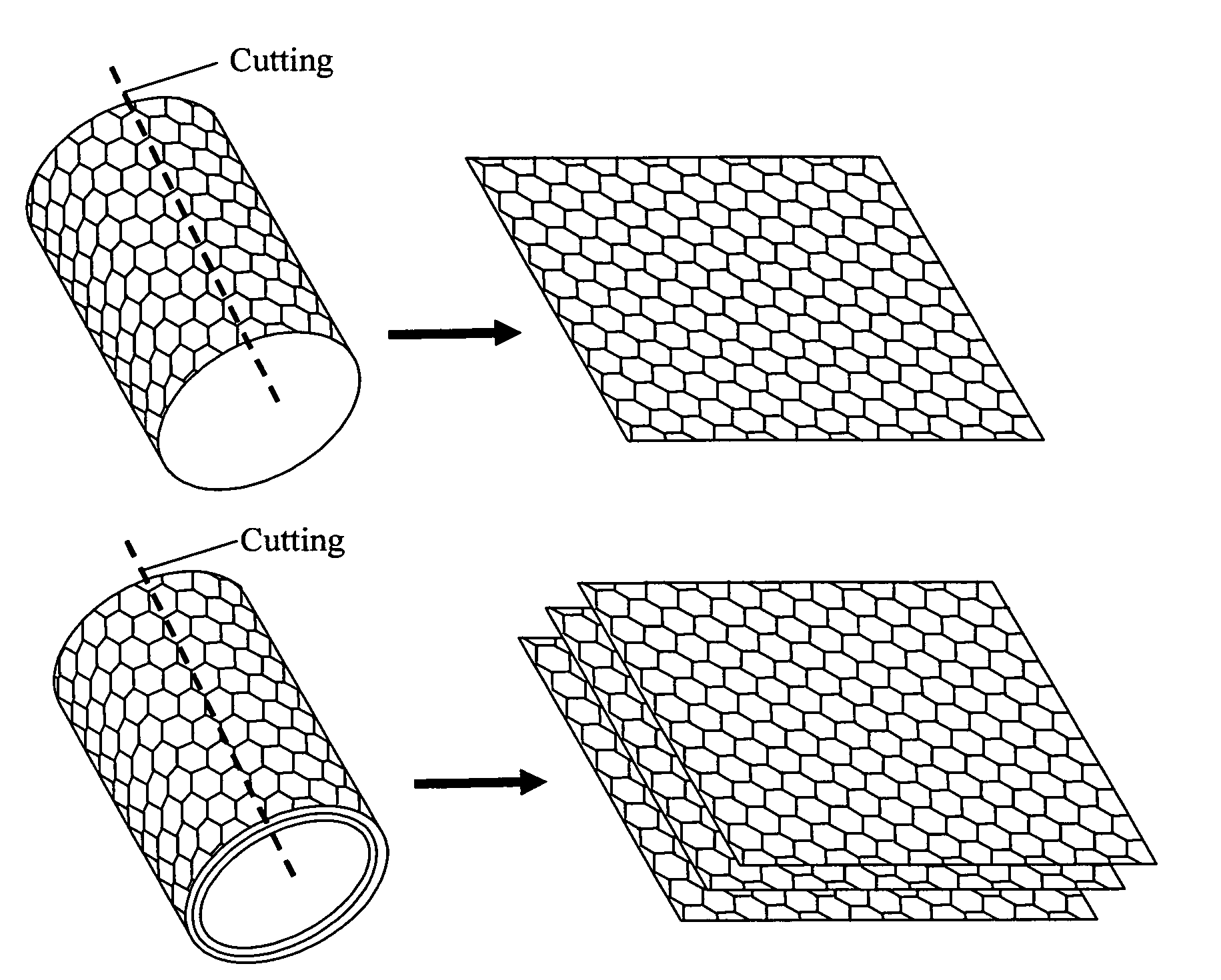

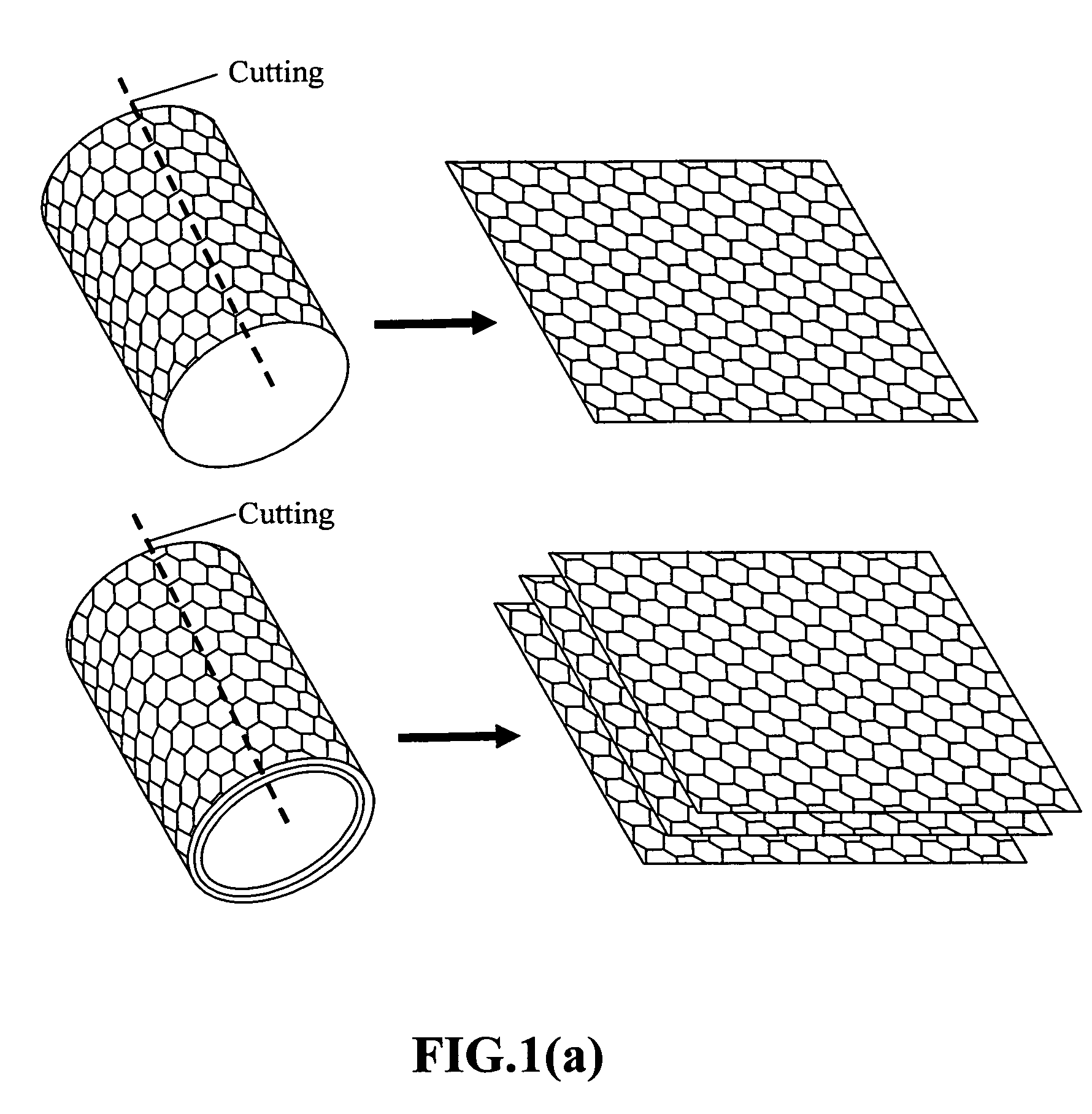

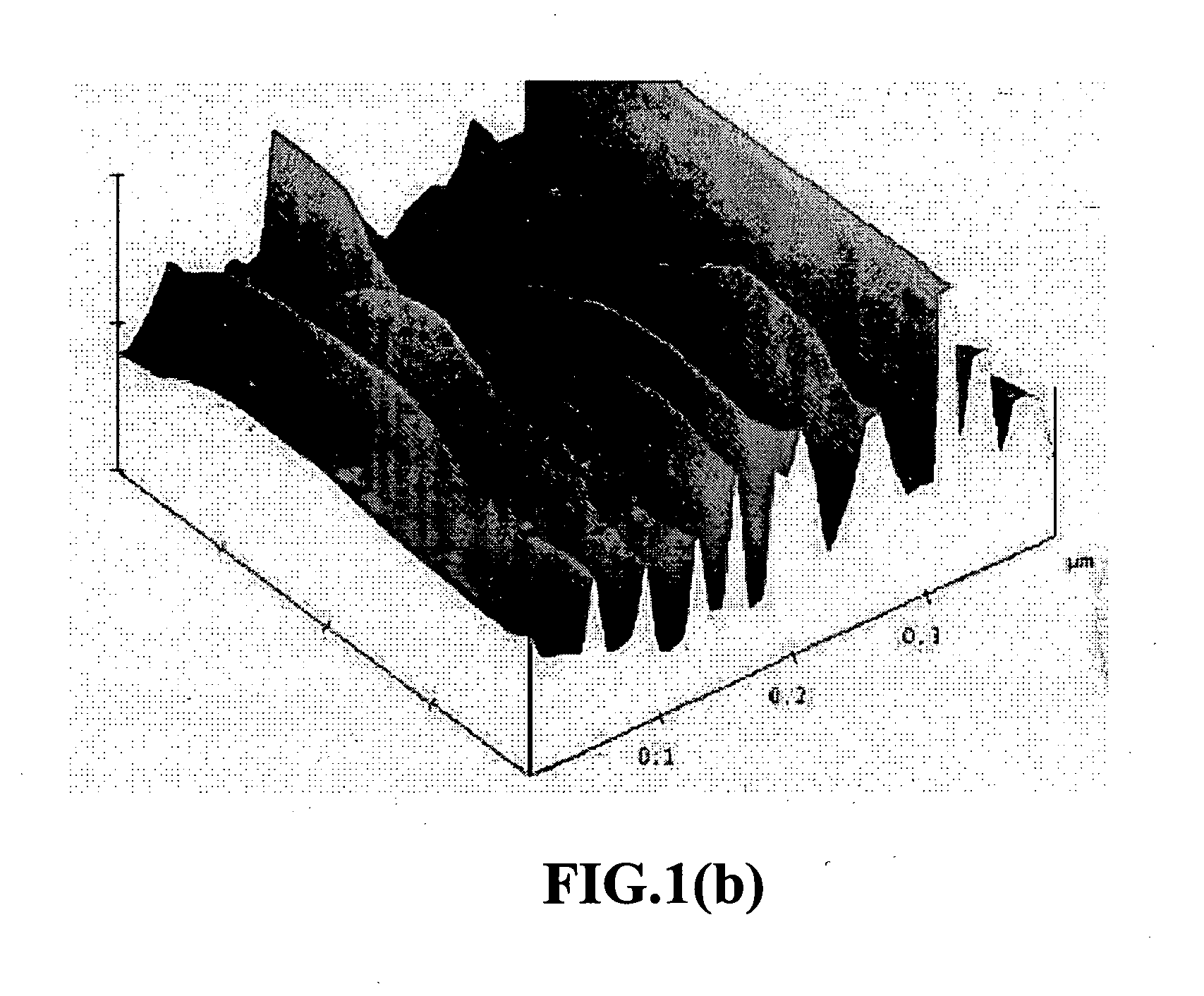

Highly conductive nano-scaled graphene plate nanocomposites and products

ActiveUS20070158618A1Improve conductivityImprove bulk conductivityMaterial nanotechnologyConductive materialElectrically conductiveNanometre

Owner:GLOBAL GRAPHENE GRP INC

Composite plastic materials produced from waste materials and method of producing same

InactiveUS7022751B2Plastic recyclingConductive materialFibre reinforcementFiber-reinforced composite

Owner:ROYAL GRP TECH LTD

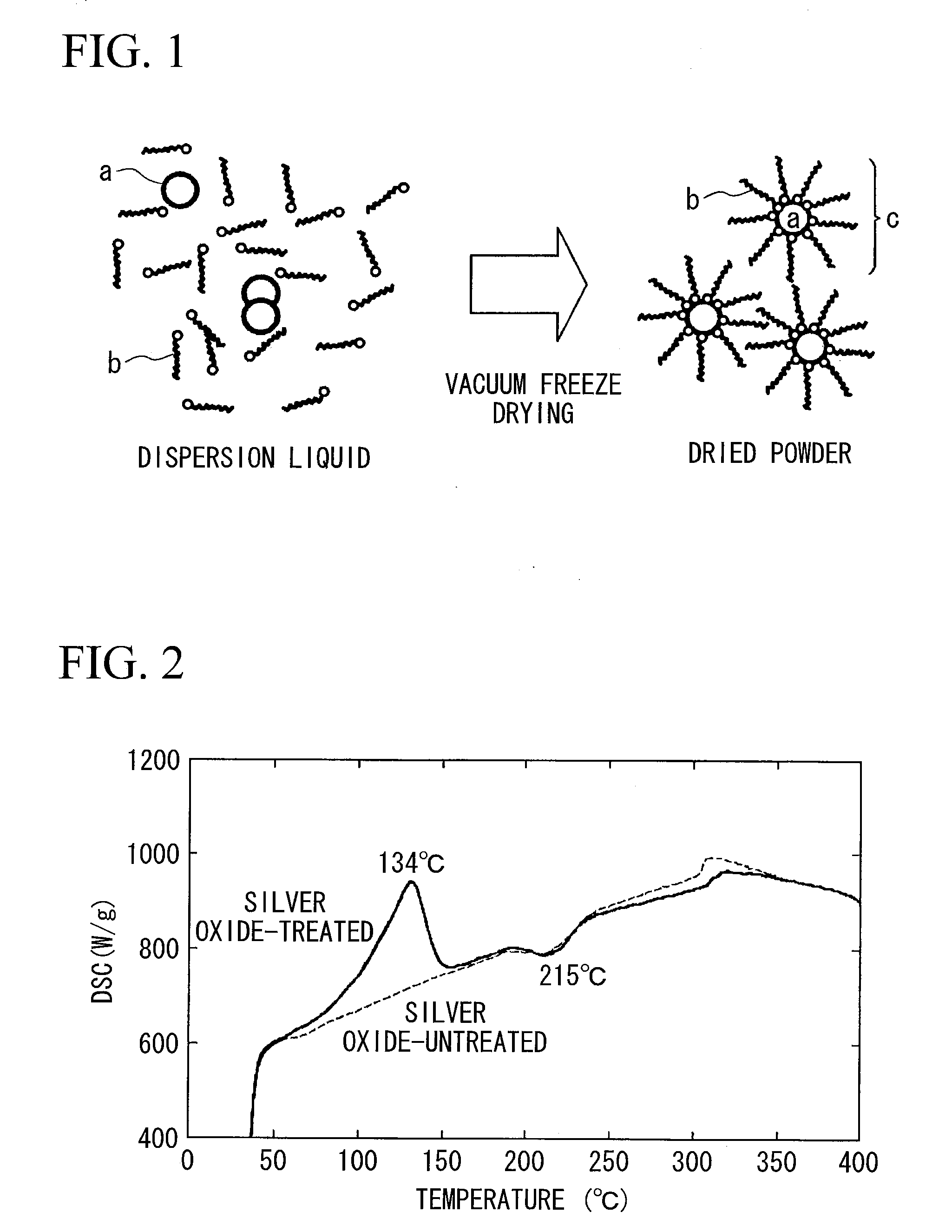

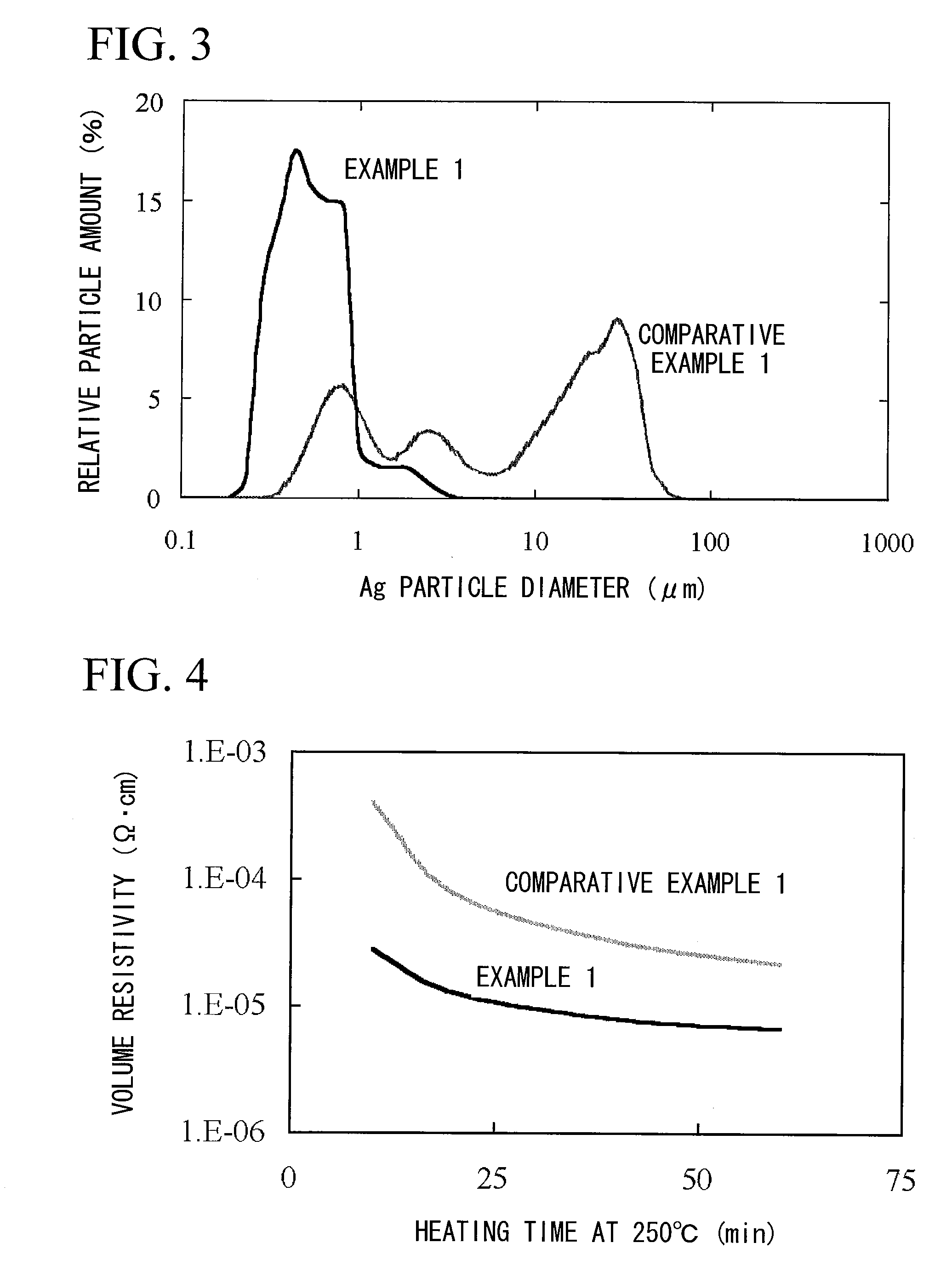

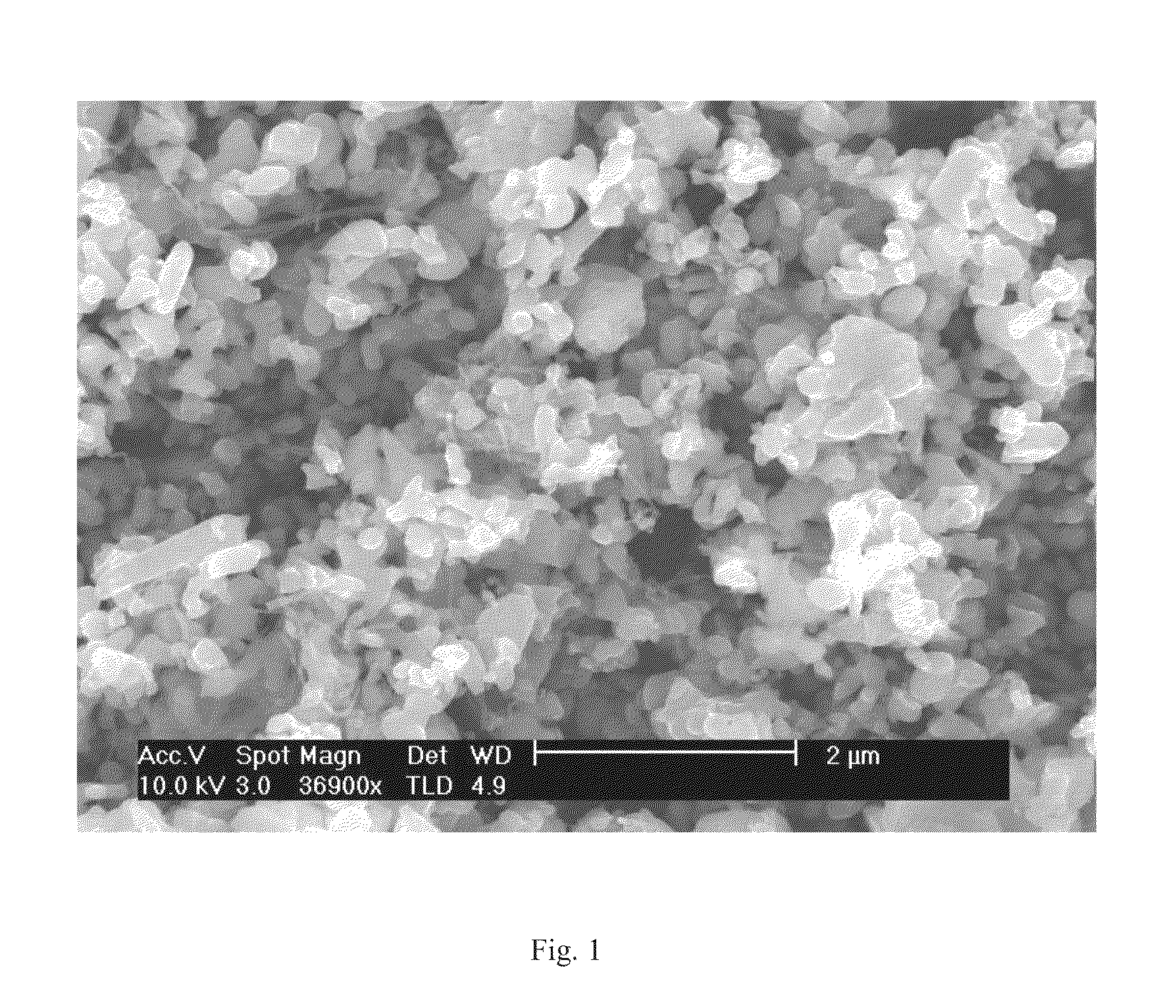

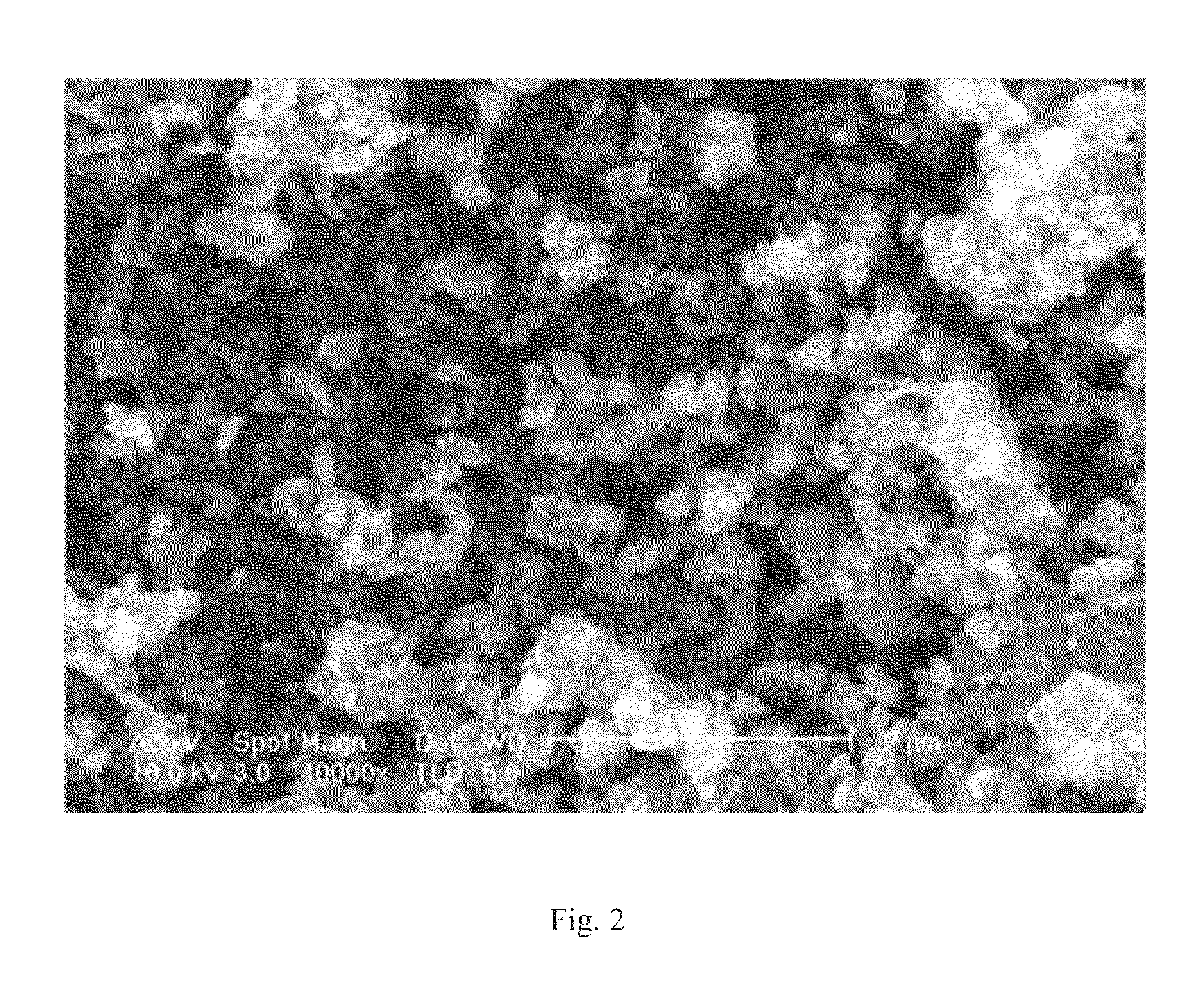

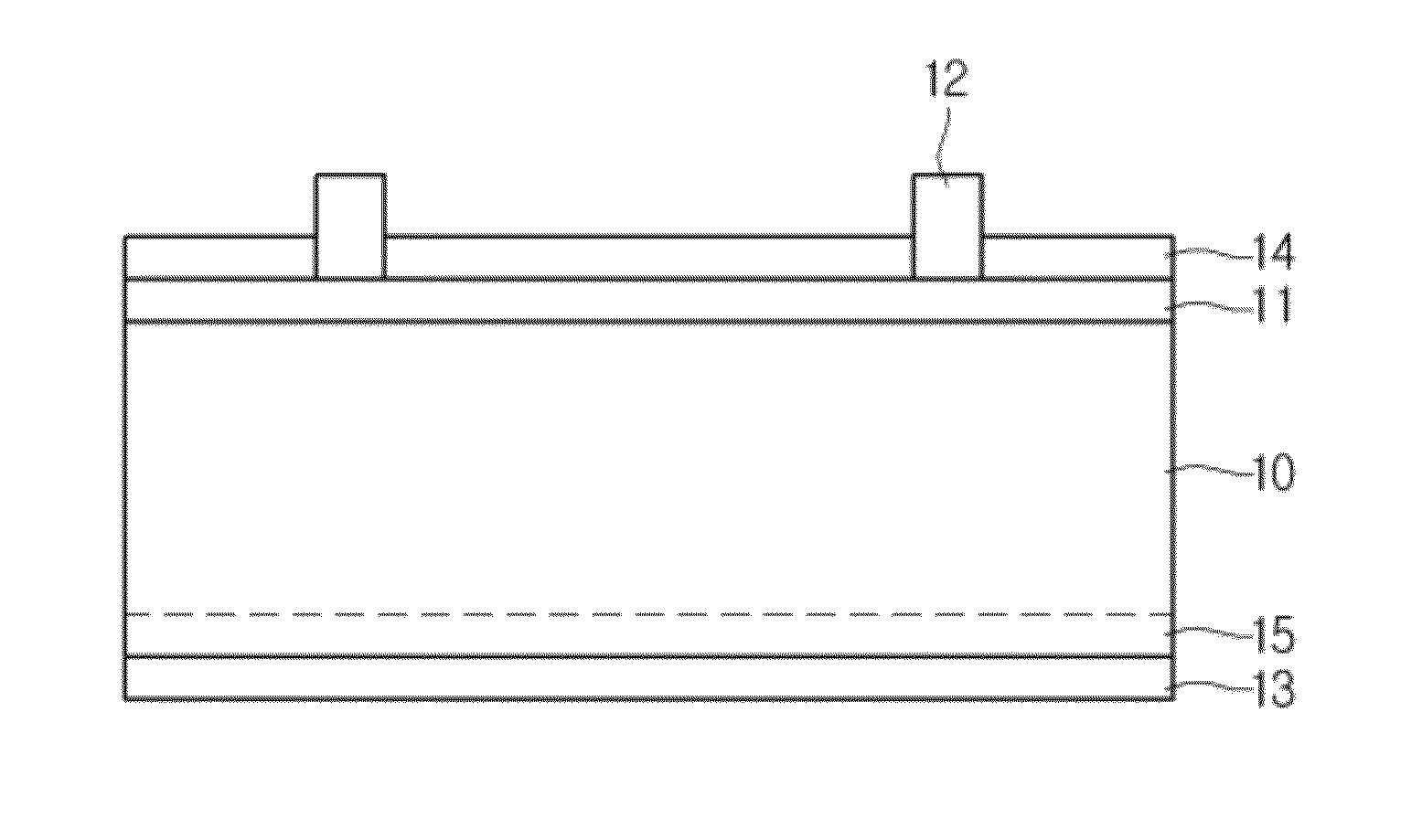

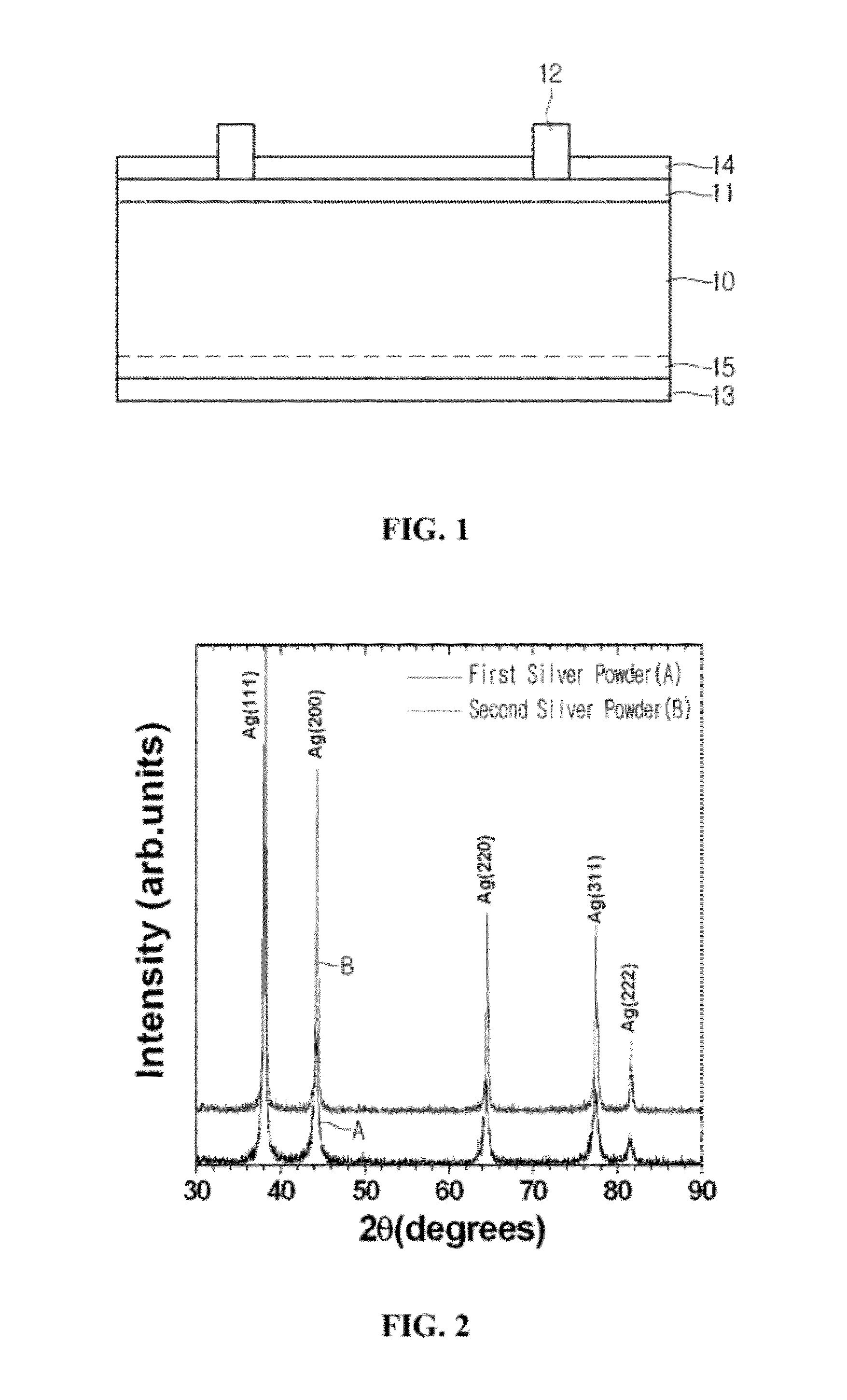

Method for producing surface-treated silver-containing powder and silver paste using surface-treated silver-containing powder

InactiveUS20090146117A1Easy to produceConvenient and stableMetal-working apparatusConductive materialSilver pastePhosphate

Owner:DAINIPPON INK & CHEM INC

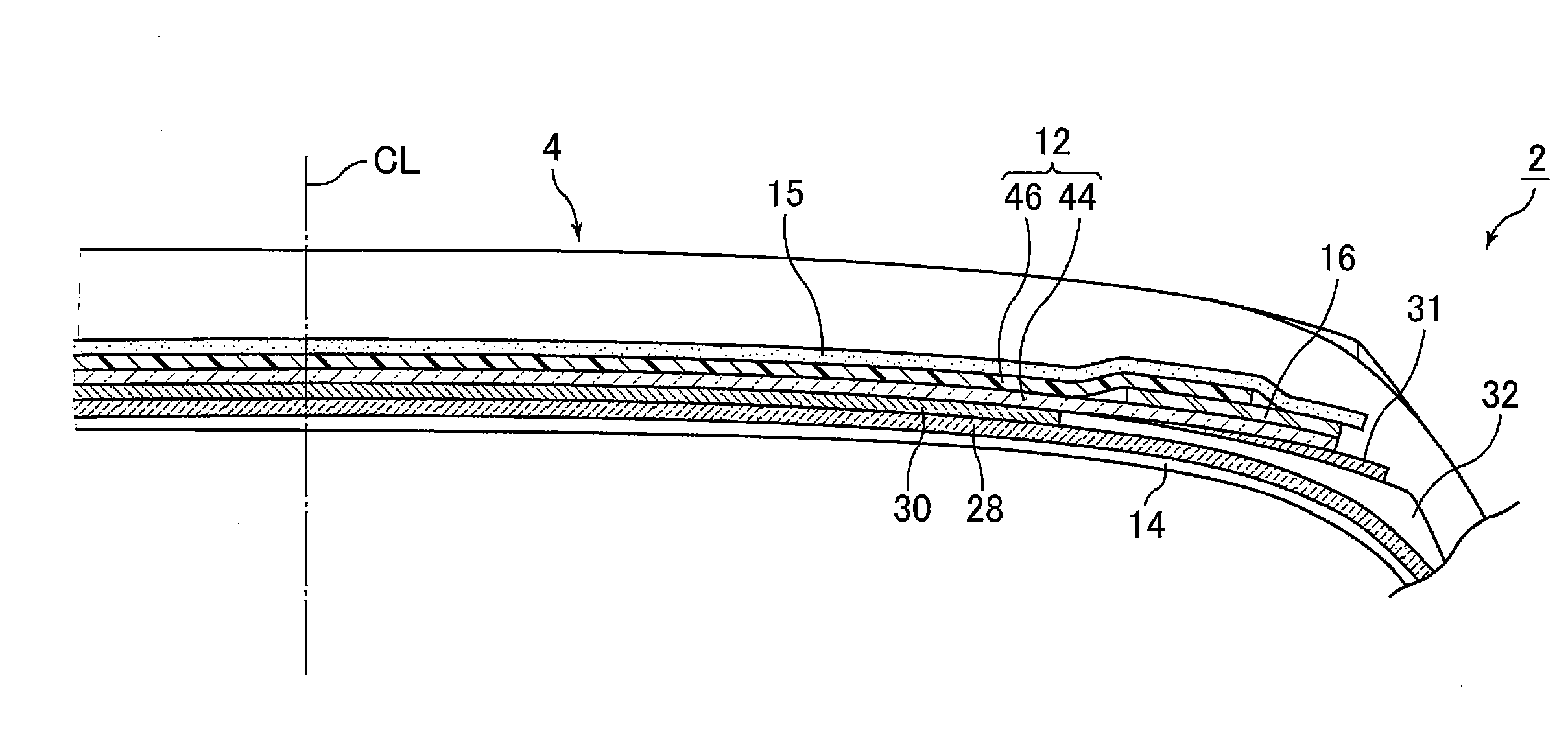

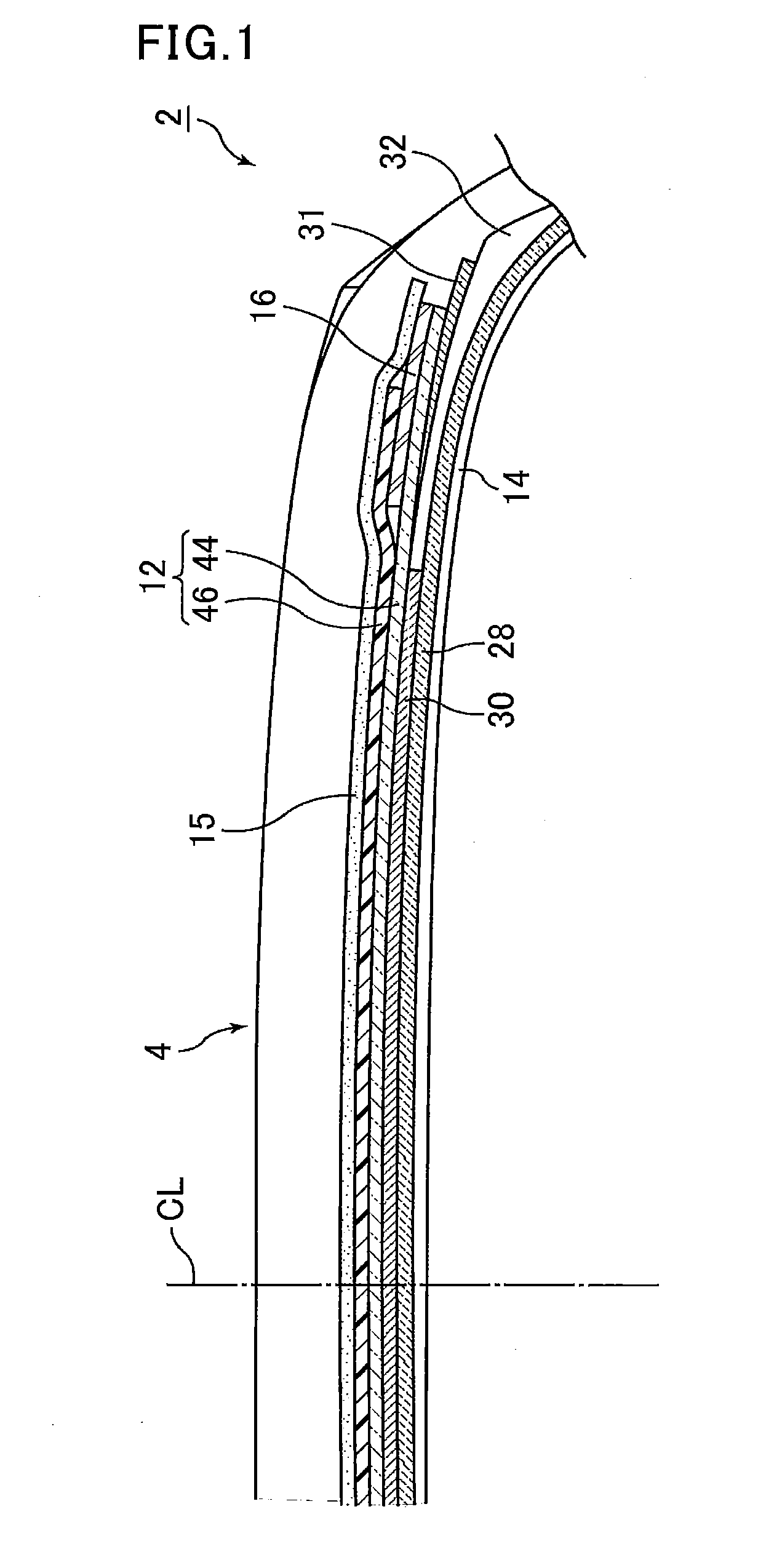

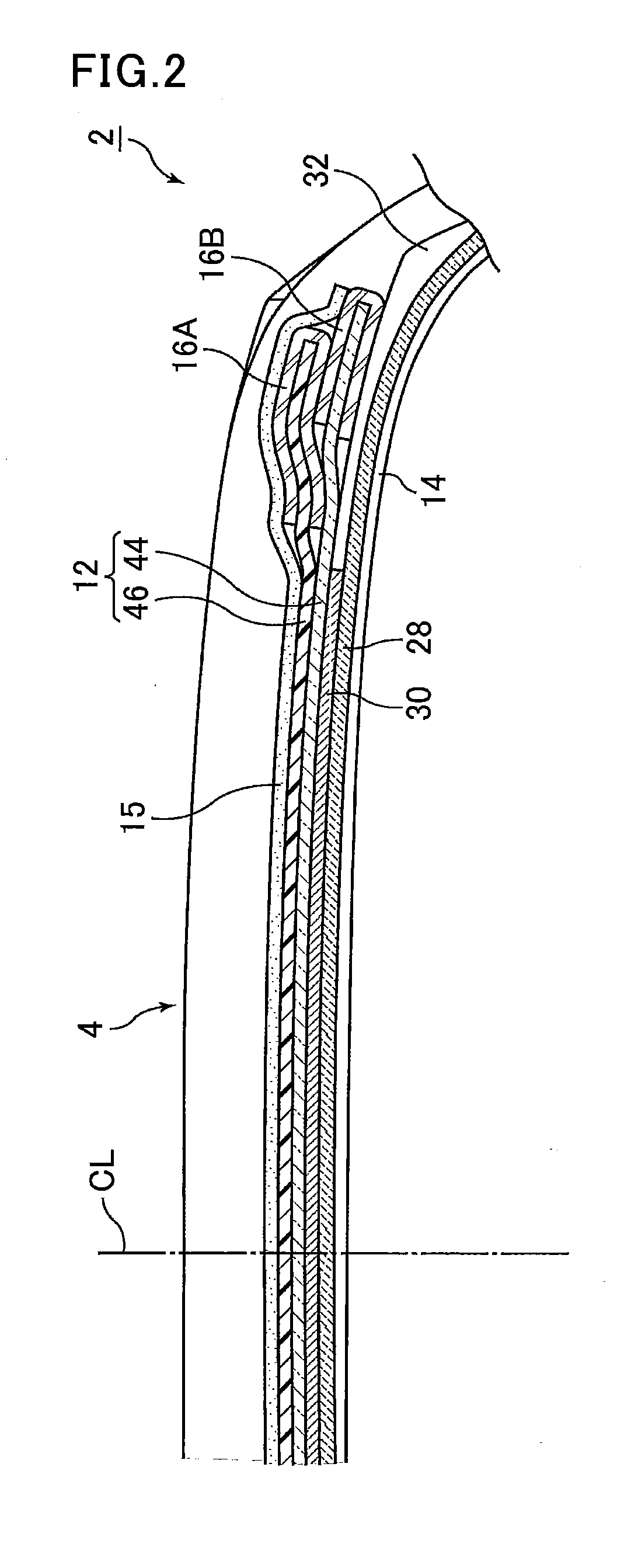

Rubber composition for tire cord coating, breaker edge strip, breaker cushion or cord-adjoining strip, and pneumatic tire

ActiveUS20140228495A1Improve adhesionIncreased durabilityConductive materialSpecial tyresAlkylphenolEngineering

Owner:SUMITOMO RUBBER IND LTD

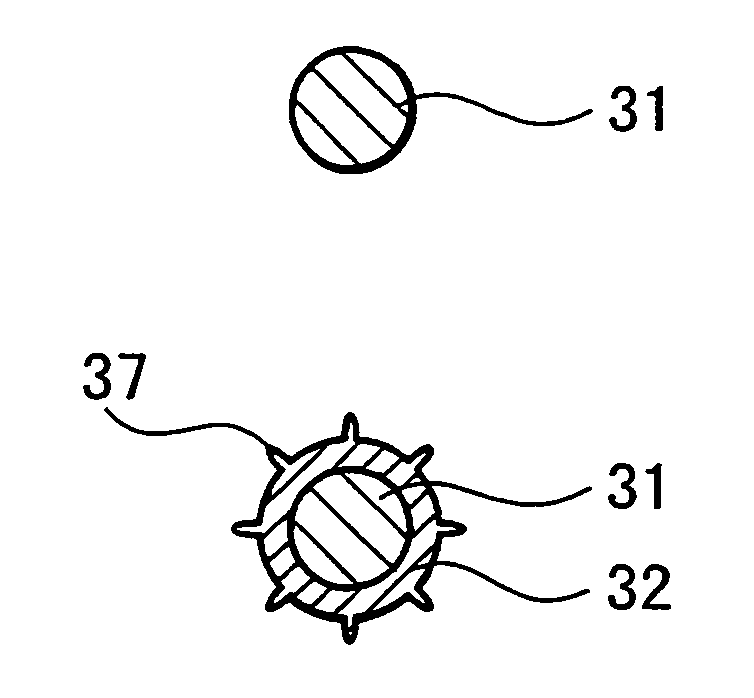

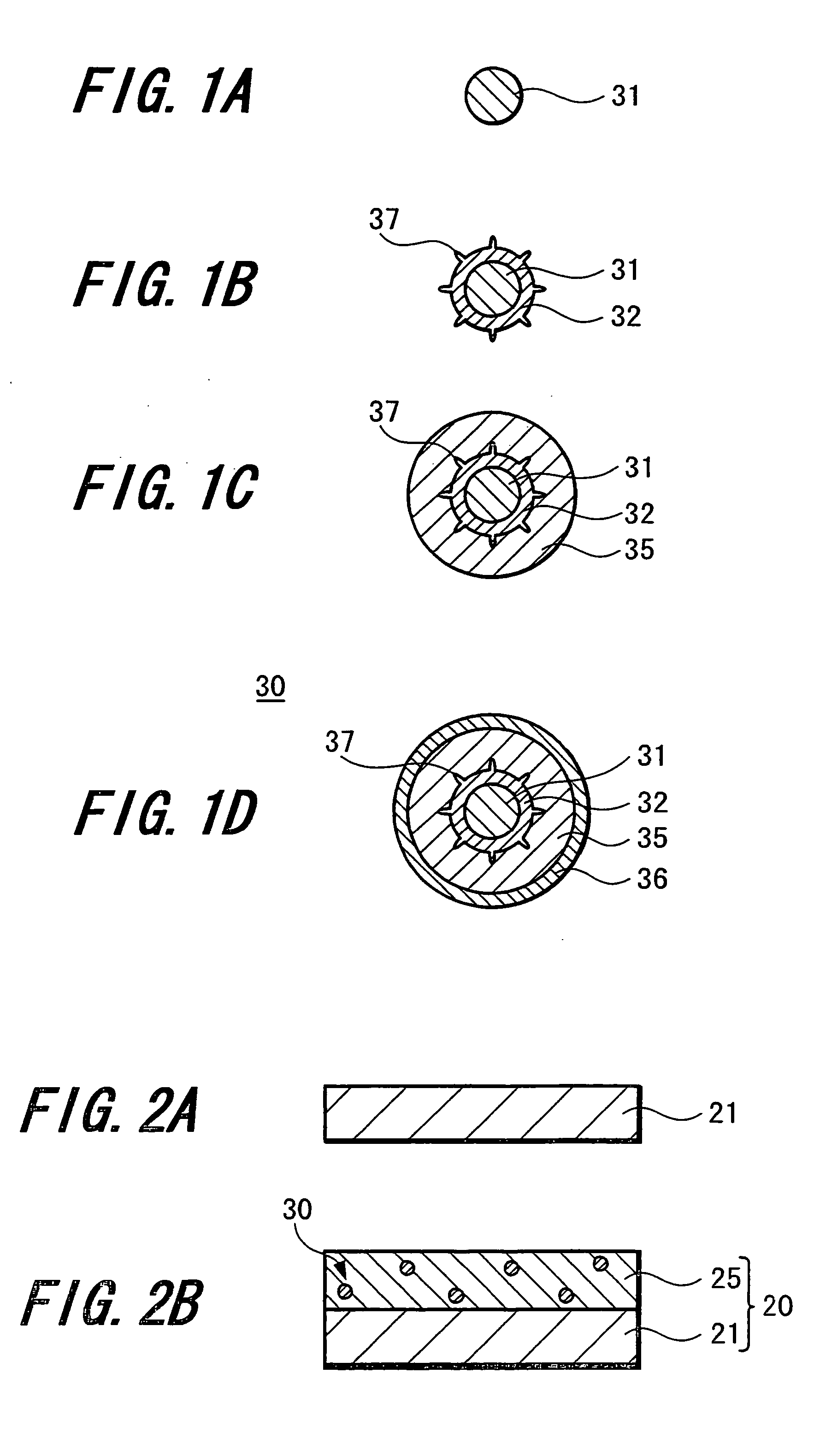

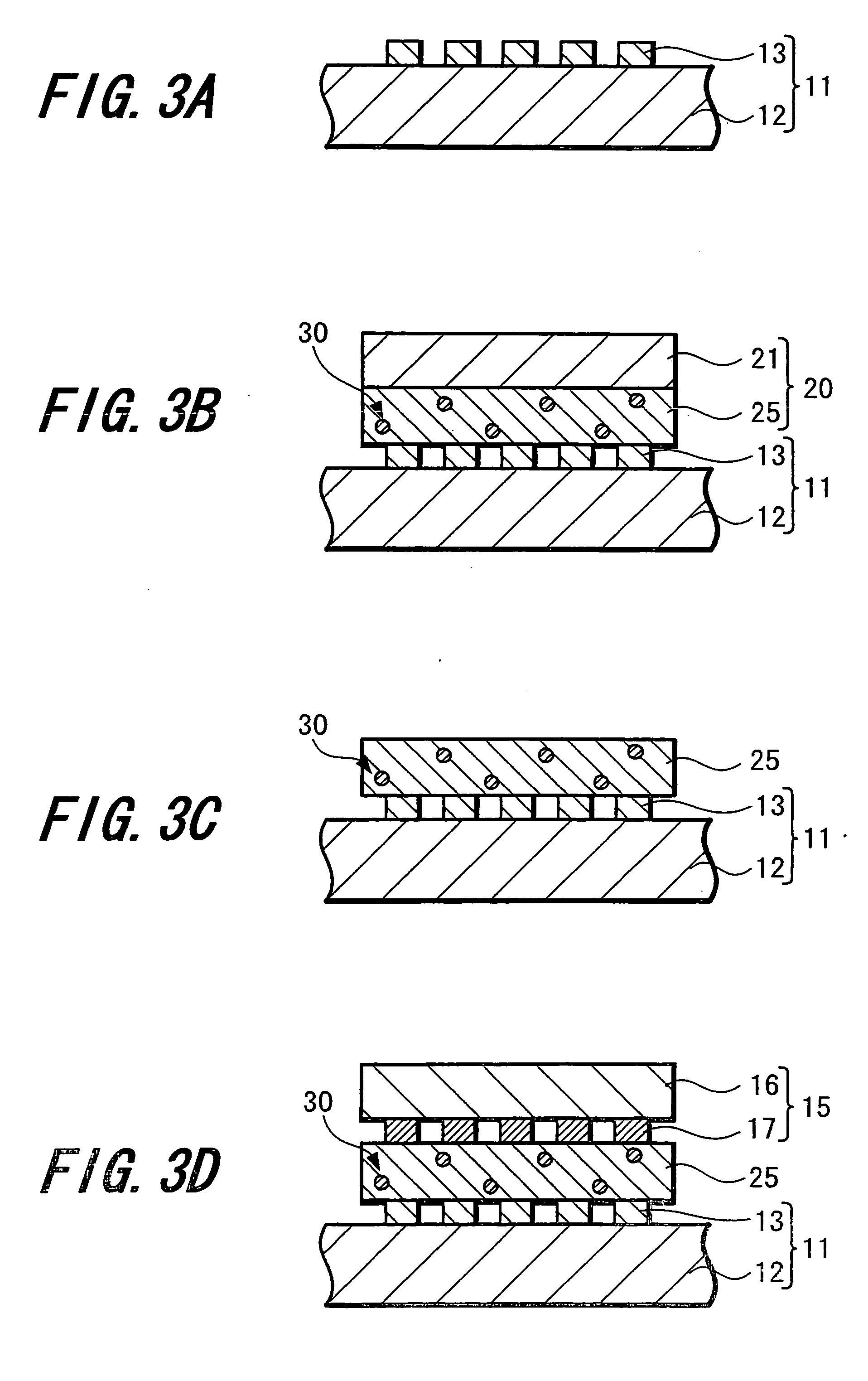

Conductive particle and adhesive agent

ActiveUS20060054867A1Avoid deformationReliable electrical connectionNon-insulated conductorsSolid-state devicesResin coatingMaterials science

Owner:SONY CORP +1

Aqueous Primer Composition

Owner:KANSAI PAINT CO LTD

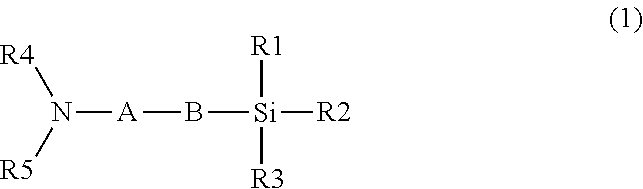

Modified Conjugated Diene Polymer, Polymerization Intitiator, Method of Producing the Same, and Rubber Composition

InactiveUS20080033110A1Improving low heat buildupEnhanced interactionNon-metal conductorsSilicon organic compoundsAlkaline earth metalEthylene Homopolymers

Owner:BRIDGESTONE CORP

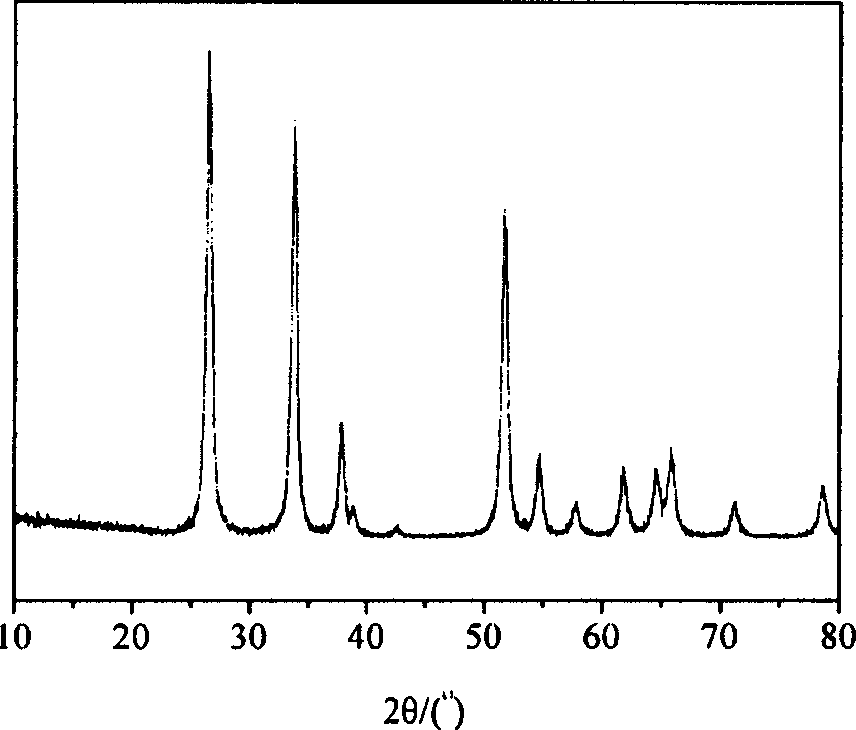

Auto-thermal evaporative liquid-phase synthesis method for cathode material for battery

InactiveUS20140239235A1Simple processReduce energy consumptionNon-metal conductorsPhosphatesInternal resistanceSynthesis methods

Owner:SHENZHEN DYNANONIC

Article and associated device

An article includes a composition including a filler dispersed in a polymeric matrix. The filler is electrically conducting in a temperature range and the filler has a Curie temperature. The composition has a trip temperature at which electrical resistance of the composition increases with increase in temperature, and the trip temperature of the composition is determined by the Curie temperature of the filler. The filler is present in the polymeric matrix in an amount determined by a property of one or both of the polymeric matrix or the filler. An associated device is provided.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Low viscosity precursor compositions and methods for the deposition of conductive electronic features

A precursor composition for the deposition and formation of an electrical feature such as a conductive feature. The precursor composition advantageously has a low viscosity enabling deposition using direct-write tools. The precursor composition also has a low conversion temperature, enabling the deposition and conversion to an electrical feature on low temperature substrates. A particularly preferred precursor composition includes silver metal for the formation of highly conductive silver features.

Owner:CABOT CORP

Enhanced oxygen barrier performance from modification of ethylene vinyl alcohol copolymers (EVOH)

Owner:CRYOVAC INC

Electrically conductive composition and fabrication method thereof

ActiveUS20110101283A1Electric discharge heatingRadiation applicationsConductive polymerConductive materials

Owner:IND TECH RES INST

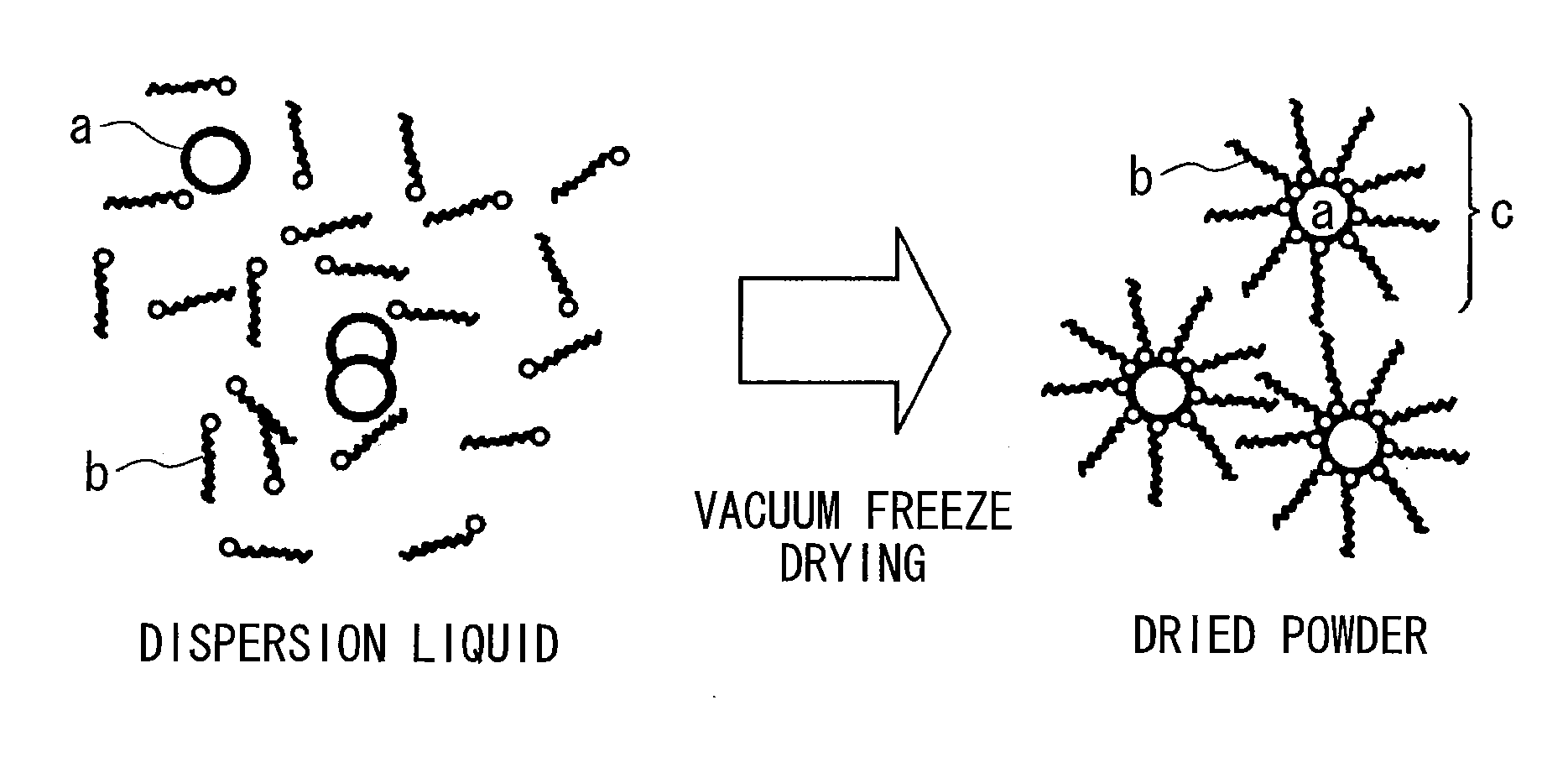

Preparation method for polymer composite electrolyte membrane

ActiveCN106816617AImprove fill rateReduce surface roughnessSolid electrolytesConductive materialPolymer electrolytesCompound a

The invention discloses a preparation method for a polymer composite electrolyte membrane. The preparation method comprises the following steps: compounding a porous membrane containing a low-viscosity polymer electrolyte A solution and a high-viscosity polymer electrolyte B solution. The viscosity of the solution is controlled, and the polymer composite electrolyte membrane prepared by the preparation method has a high filling ration and low surface roughness, so that the comprehensive performances of the polymer electrolyte are greatly improved, and the application prospect is clearer.

Owner:TORAY IND INC

High-strength high-conductivity rare earth copper-magnesium alloy contact wire and manufacturing method thereof

InactiveCN106555073AMeet performance requirementsHigh elongationSingle bars/rods/wires/strips conductorsConductive materialRare-earth elementCerium

Owner:HENAN UNIV OF SCI & TECH

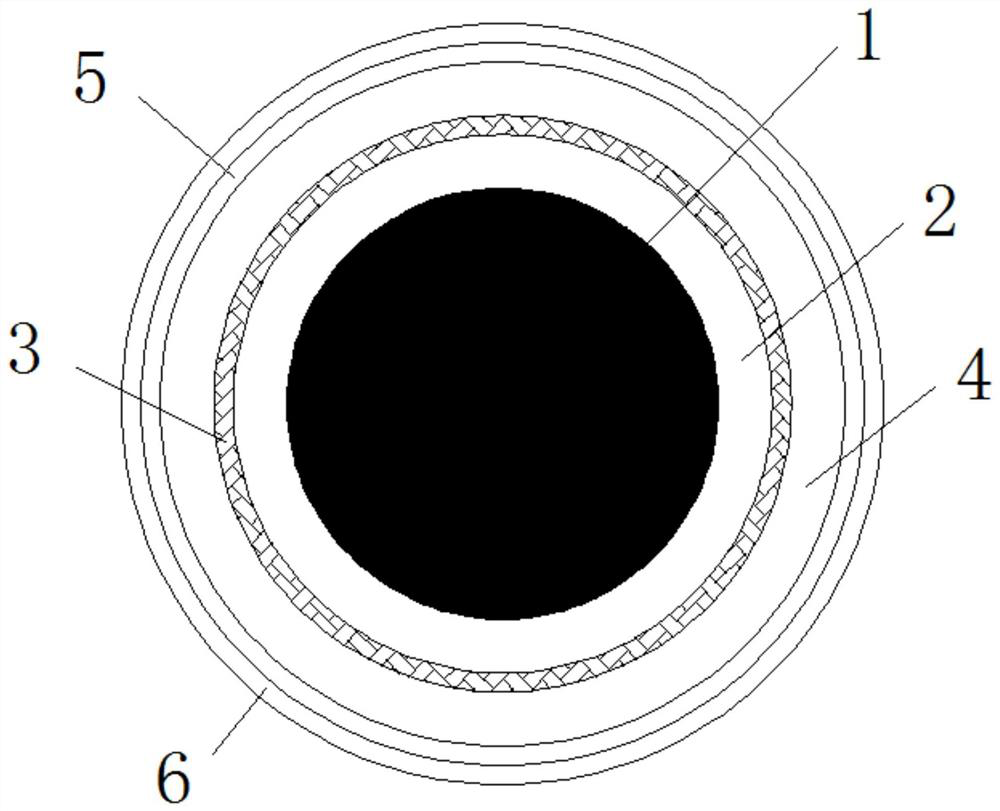

Signal detection cable for digital substation and manufacturing technology

InactiveCN108053913AGood electromagnetic shielding effectImprove securityNon-insulated conductorsConductive materialData transmissionMetal

The invention discloses a signal detection cable for a digital substation and manufacturing technology. The signal detection cable includes a protective layer, a buffering layer, an armor layer, an aluminum foil layer, an insulating layer and a conductive core. An outer wall of the conductive core wraps the insulating layer, an outer wall of the insulating layer warps the aluminum foil layer, an outer wall of the aluminum foil layer wraps the armor layer, an outer wall of the armor layer includes the buffering layer, an outer wall of the buffering layer wraps the protective layer, the buffering layer includes a rubber shock absorption layer and buffering holes, the rubber shock absorption layer wraps the outer side of the armor layer, and a plurality of buffering holes are uniformly arranged in the rubber shock absorption layer. Through the arrangement armor layer and aluminum foil layer, two metal shielding layers are formed, a good electromagnetic shielding effect is achieved, external interference signals can be effectively prevented from influencing transmission of data, and safety of data transmission is effectively improved; and through arrangement of the buffering layer, a good buffering effect is achieved, and safety of use is effectively improved.

Owner:JIANGSU CHANG CHENG CABLE

Low viscosity precursor compositions and methods for the deposition of conductive electronic features

A precursor composition for the deposition and formation of an electrical feature such as a conductive feature. The precursor composition advantageously has a low viscosity enabling deposition using direct-write tools. The precursor composition also has a low conversion temperature, enabling the deposition and conversion to an electrical feature on low temperature substrates. A particularly preferred precursor composition includes silver metal for the formation of highly conductive silver features.

Owner:CABOT CORP

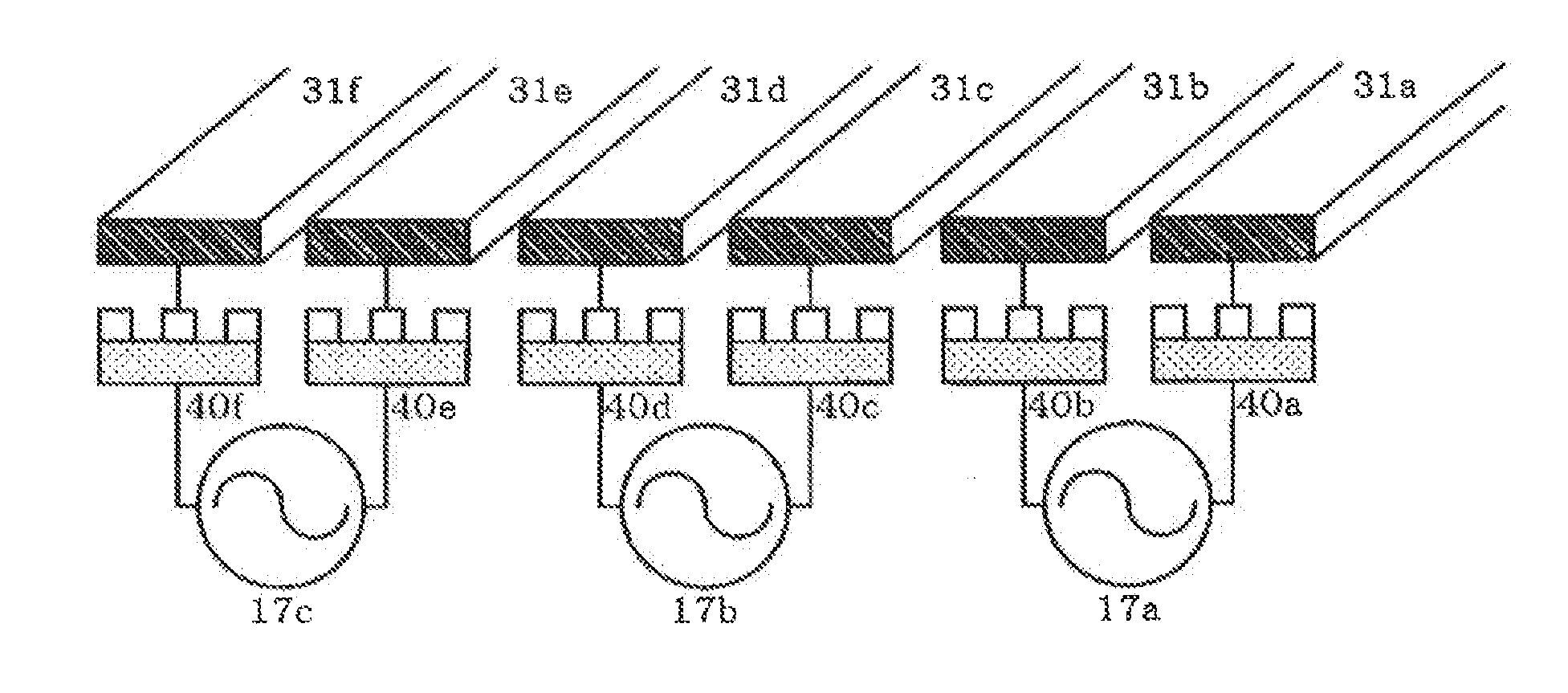

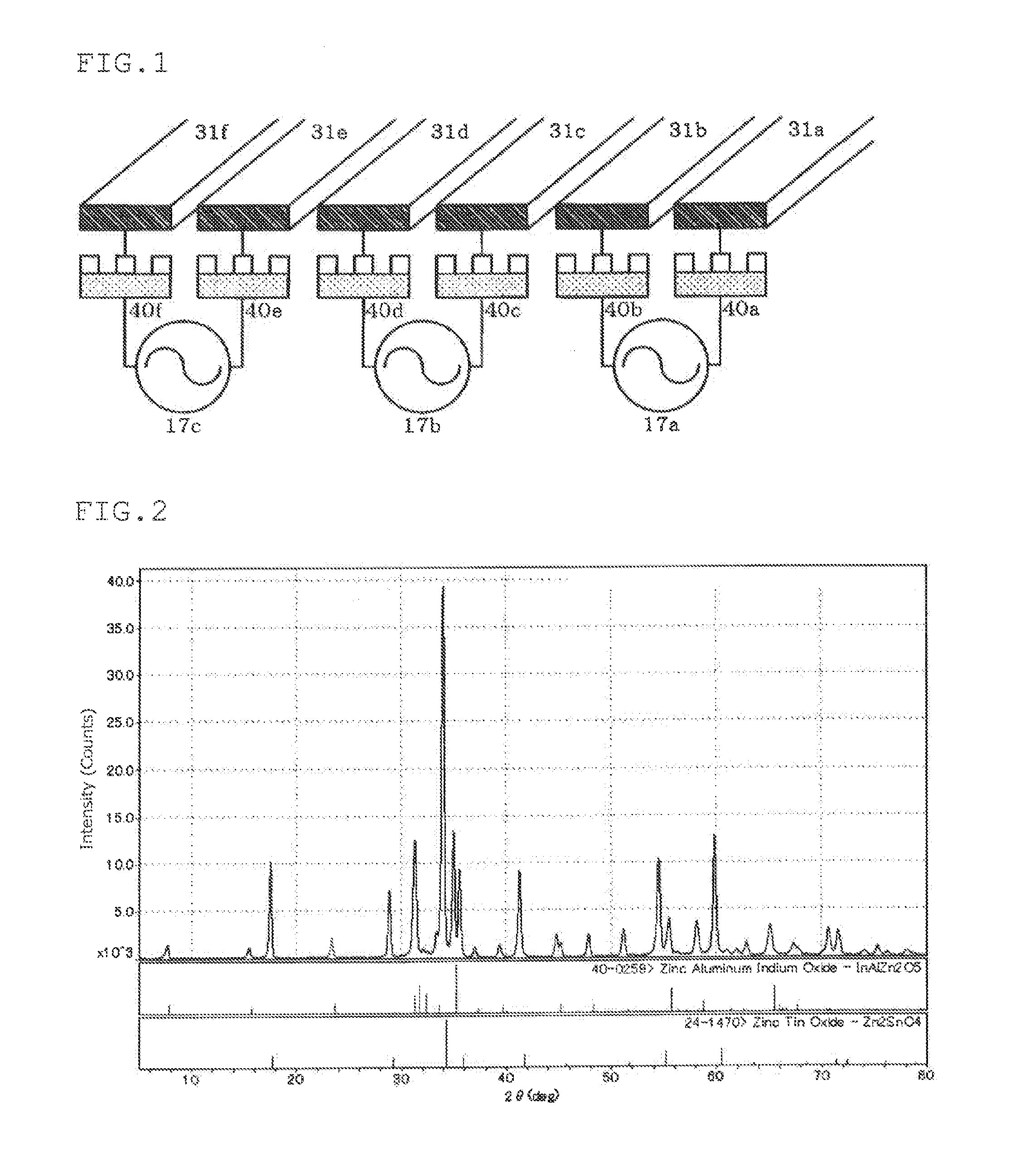

Sputtering target, oxide semiconductor thin film, and method for producing oxide semiconductor thin film

InactiveUS20150311071A1Increase productionSuppress abnormal dischargeTransistorCellsIndiumThin membrane

Owner:IDEMITSU KOSAN CO LTD

Photo-curing conductive adhesive for touch panel

InactiveUS20140284527A1Avoid wasting electricityLow curing temperatureConductive materialEster polymer adhesivesAdhesiveMetal particle

A photo-curing conductive adhesive for a touch panel includes an adhesive in an amount within the range of 20 to 30 wt % and the metal particle composition in an amount within the range of 70 to 80 wt %.

Owner:ETURBOTOUCH TECH

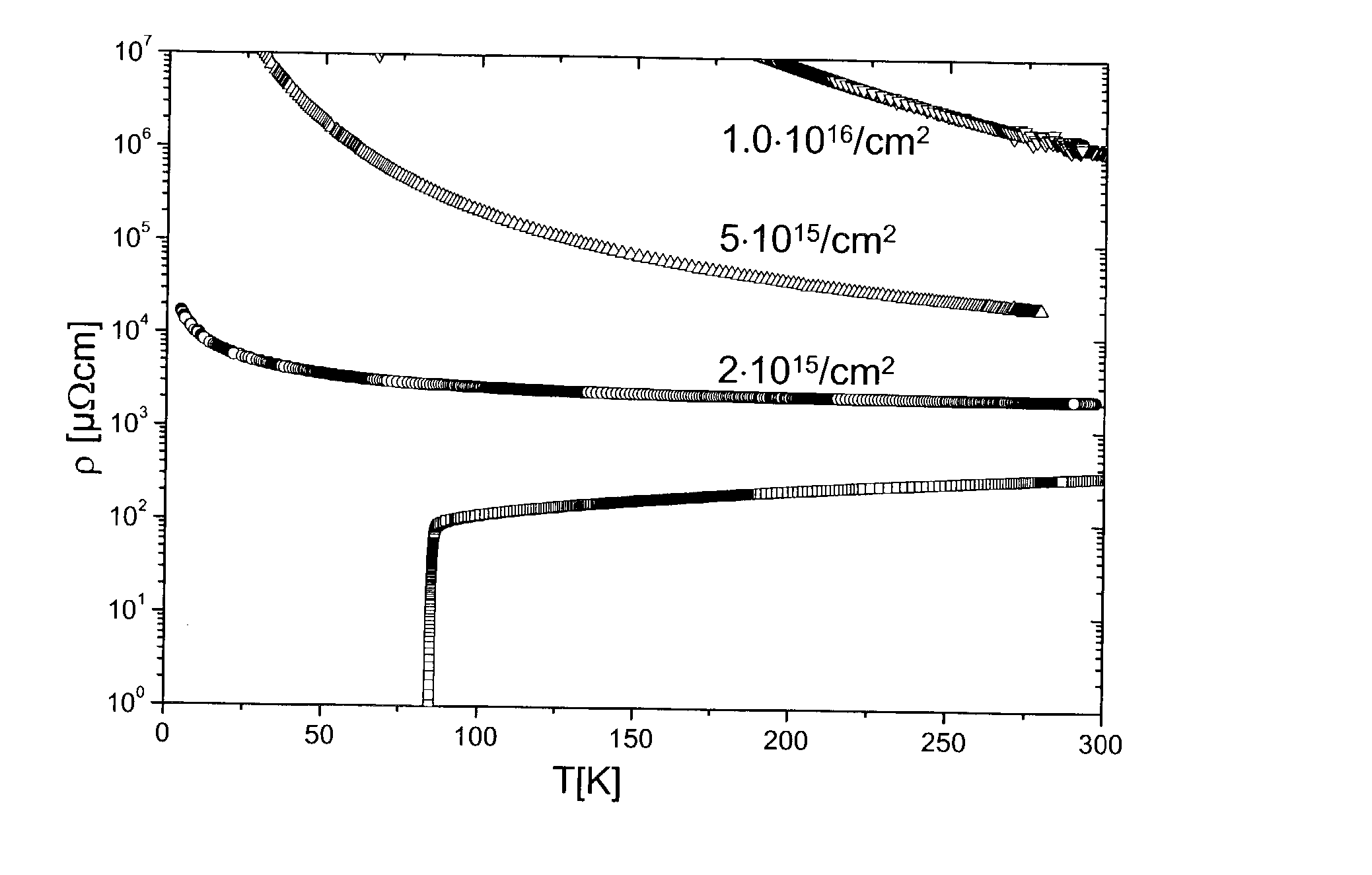

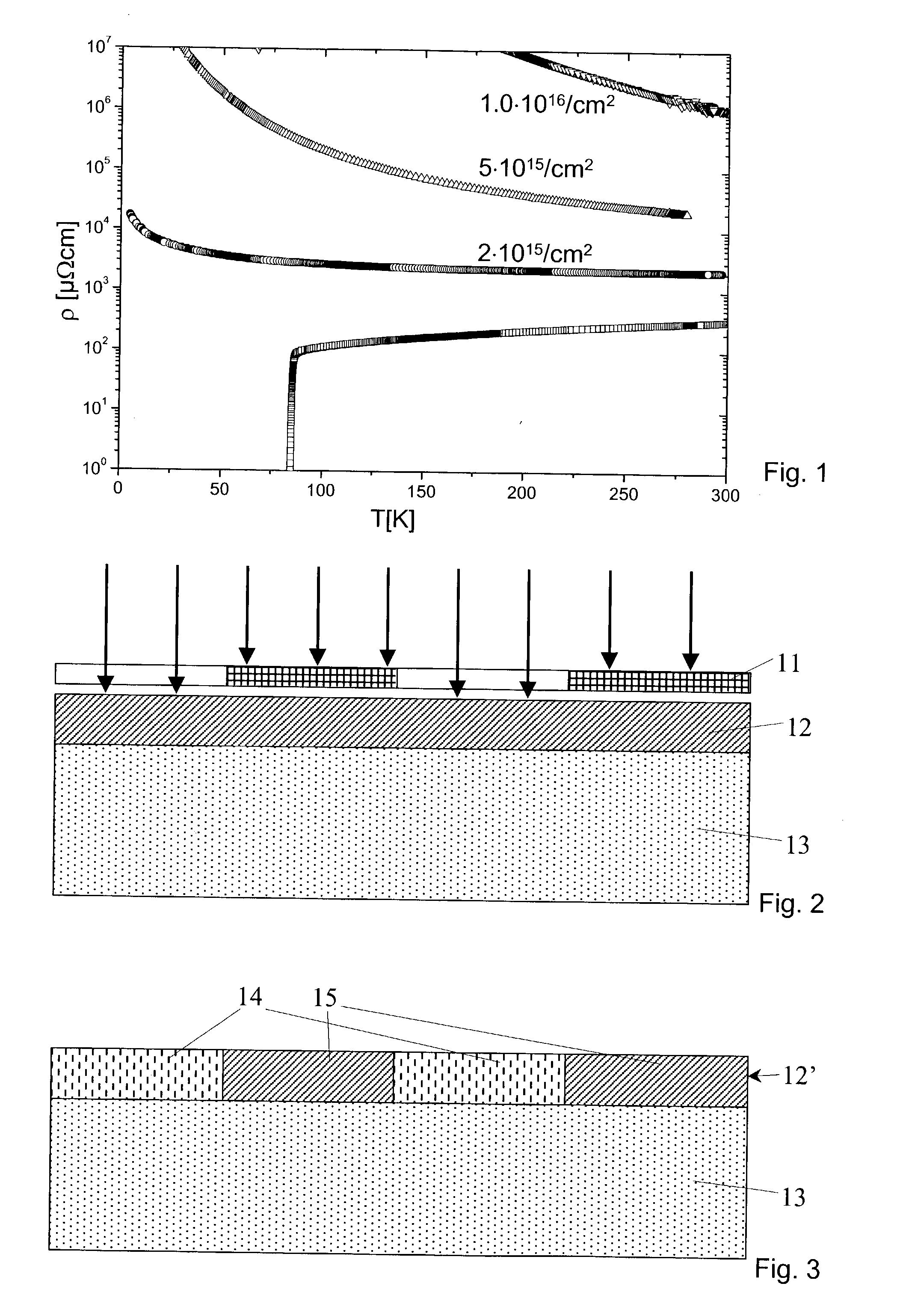

Method for producing a superconducting circuit

InactiveUS20030236169A1Increase spacingCrystallographic structure of degradedConductive materialSuperconductor device manufacture/treatmentCrystal structureOptoelectronics

Owner:IMS NANOFABTION

Material for solid oxide fuel cell interconnector, unit cell for solid oxide fuel cell, and solid oxide fuel cell

InactiveUS20100323266A1Improve air tightnessImprove reliabilityFuel cells groupingConductive materialInterconnectorFuel cells

An interconnector material having a high degree of densification, a unit cell for a solid oxide fuel cell that has a high degree of gas tightness at the contact interface between the electrolyte and the interconnector, and a solid oxide fuel cell having superior reliability are provided in an inexpensive manner. A material for a solid oxide fuel cell interconnector, comprising (SrxE1-x)TiO3 (wherein x satisfies 0.01≦x≦0.5, and E represents one or more elements selected from the group consisting of La, Pr, Nd, Sm and Gd) and Al2O3, wherein the Al2O3 content relative to the (SrxE1-x)TiO3 is not less than 2 mol % and not more than 10 mol %.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Conductive paste composite

InactiveUS20120103410A1Simple processLarge aspect ratioMaterial nanotechnologyConductive materialConductive pasteOptoelectronics

Owner:LG INNOTEK CO LTD

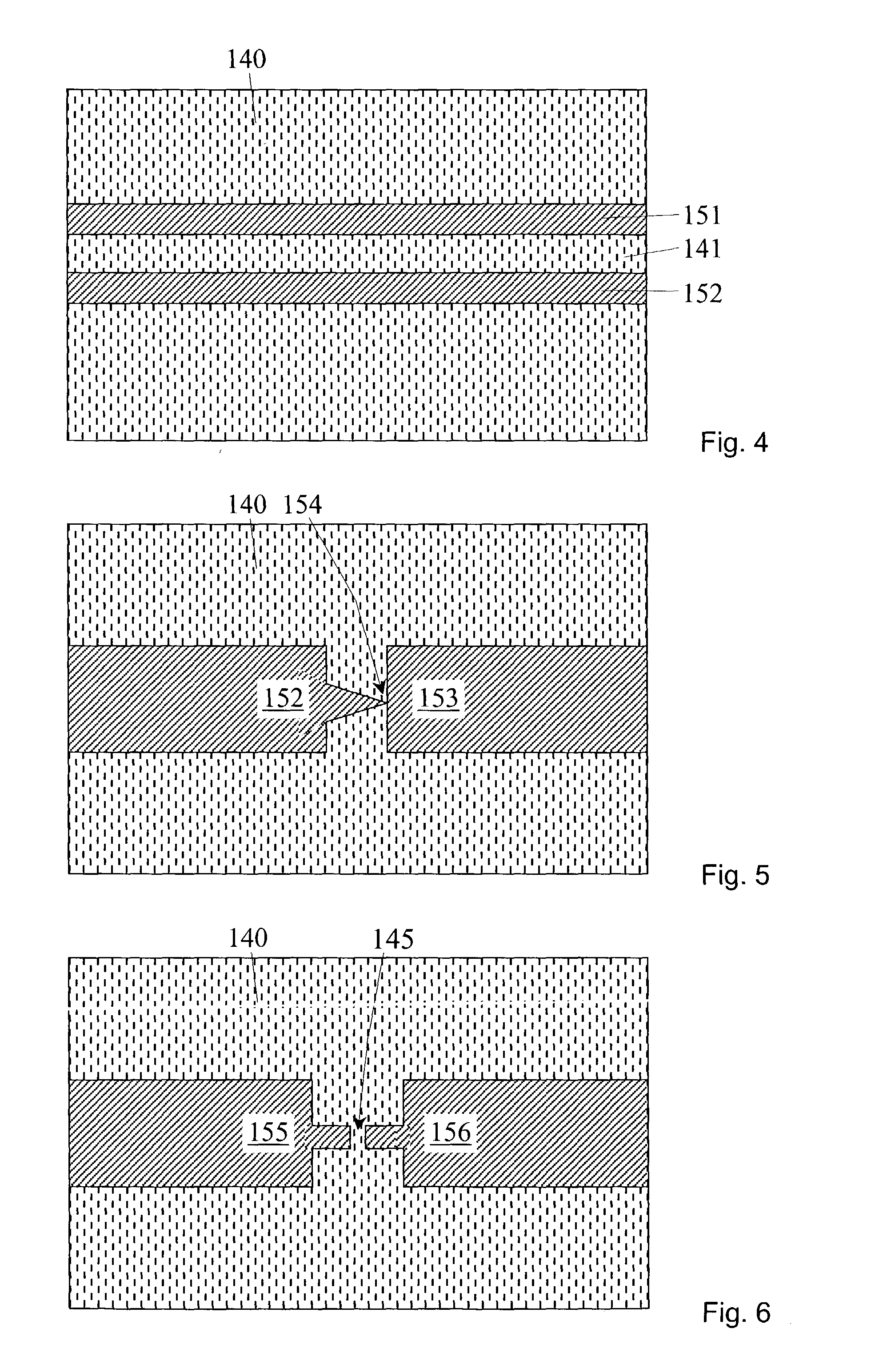

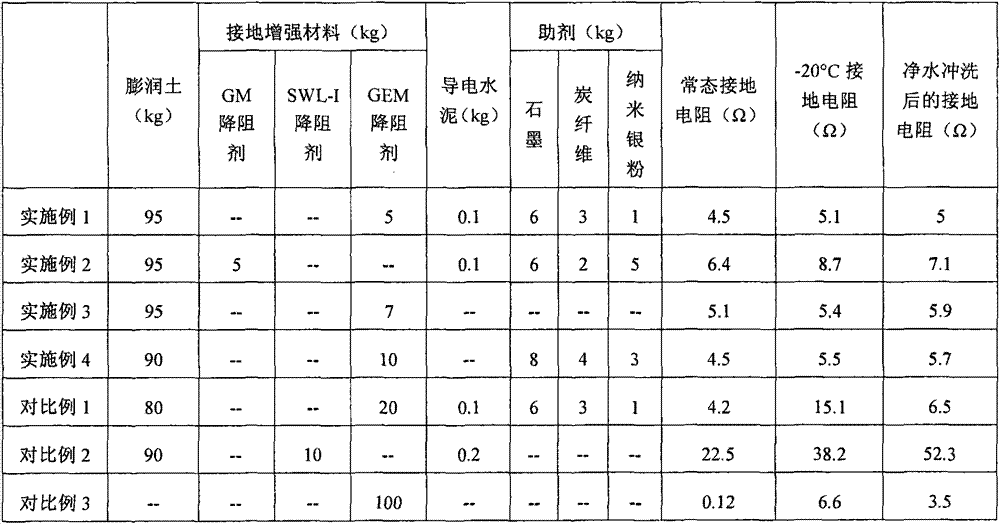

Resistance-reducing composition and application to soil thereof

Owner:STATE GRID CORP OF CHINA +2

Direct-current cable

Owner:秦川

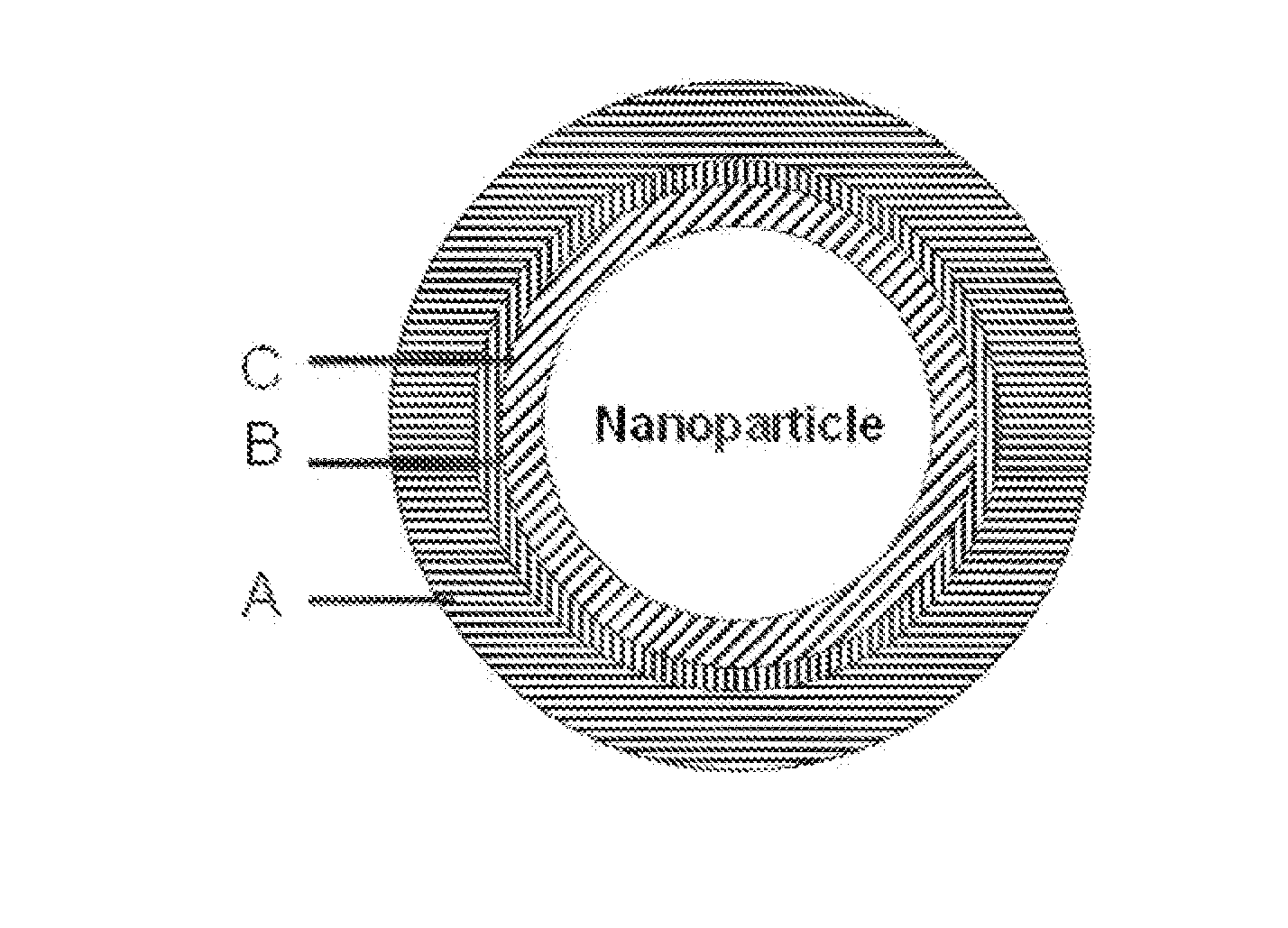

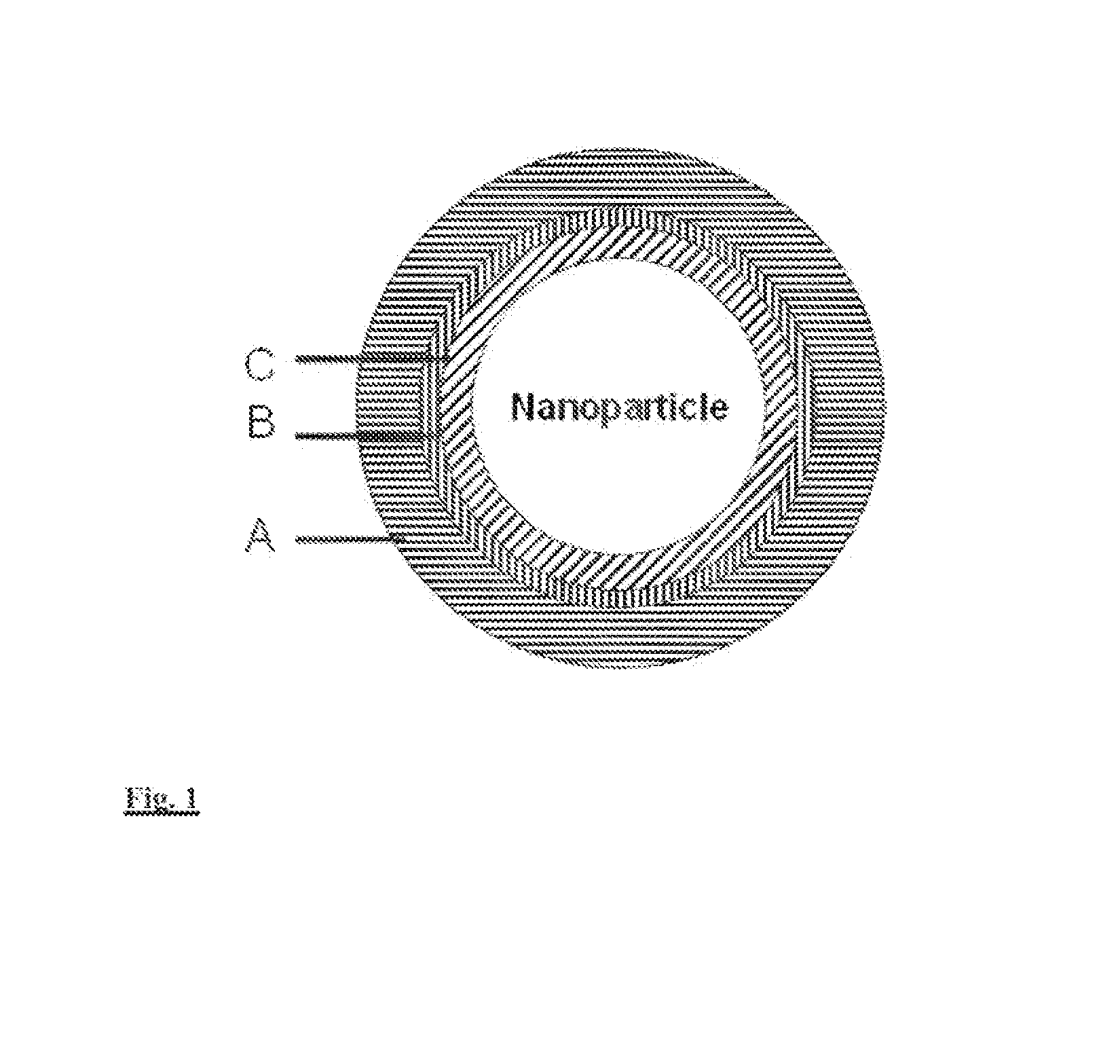

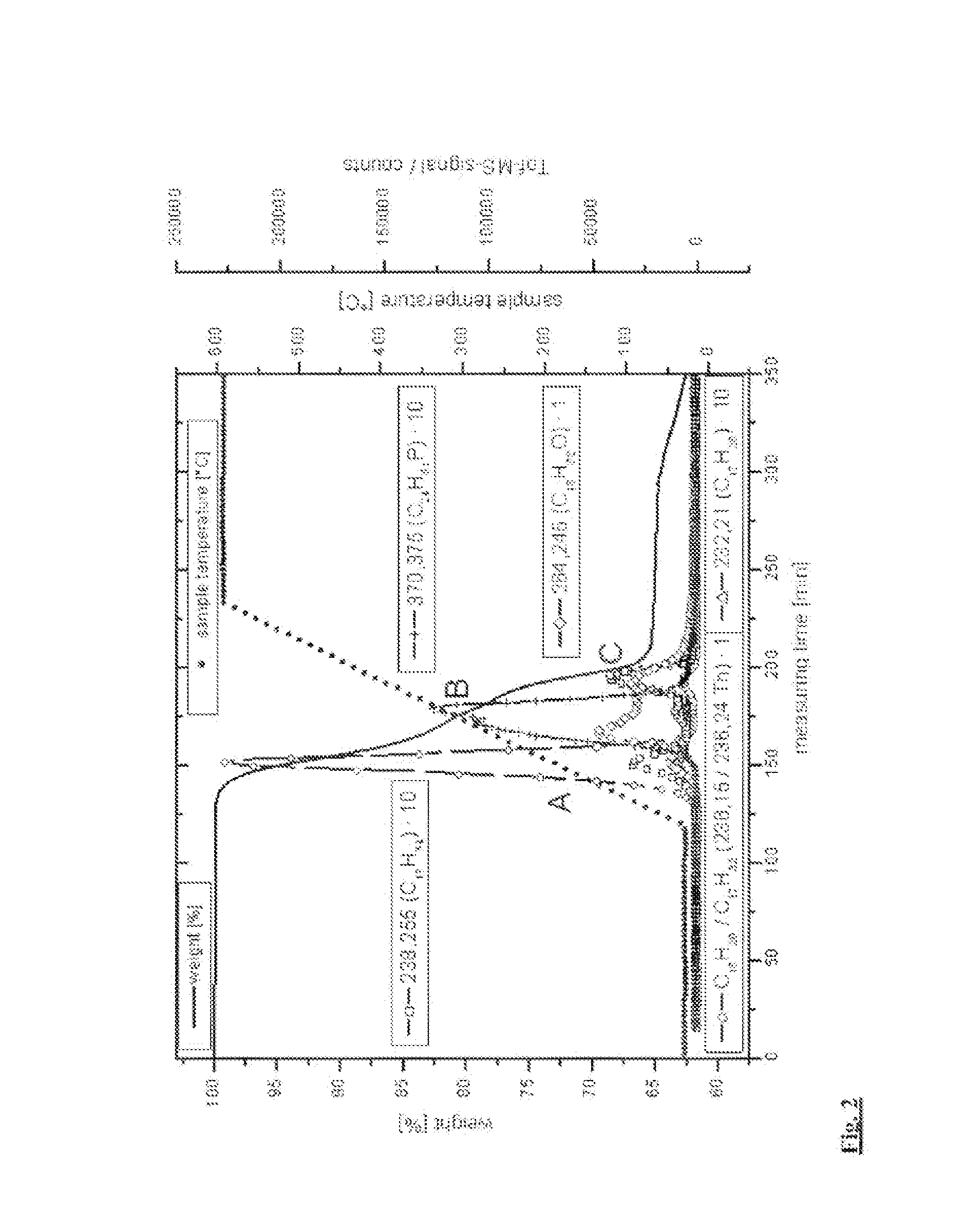

Multistage surface modification procedure of semiconducting nanoparticles for use in hybrid solar cells and printable electronics

InactiveUS20140034121A1Easy to useFatty acid chemical modificationFatty acids production/refiningNanoparticleSolvent

Owner:QUANTUM MATERIALS

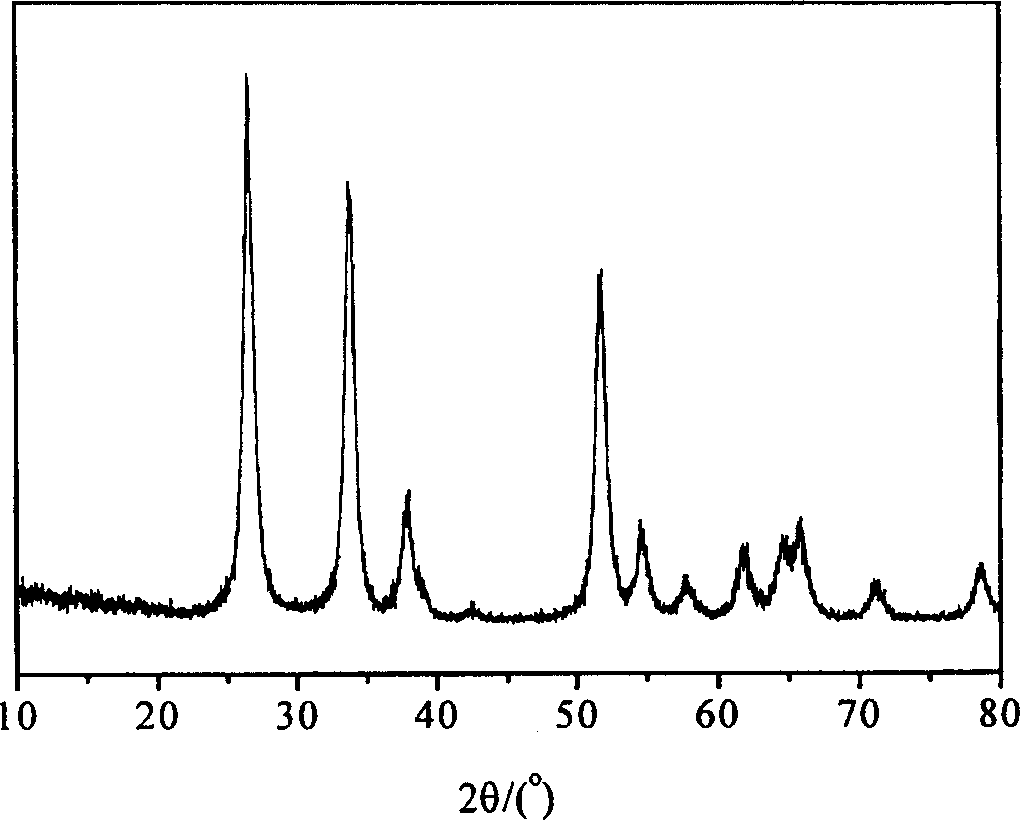

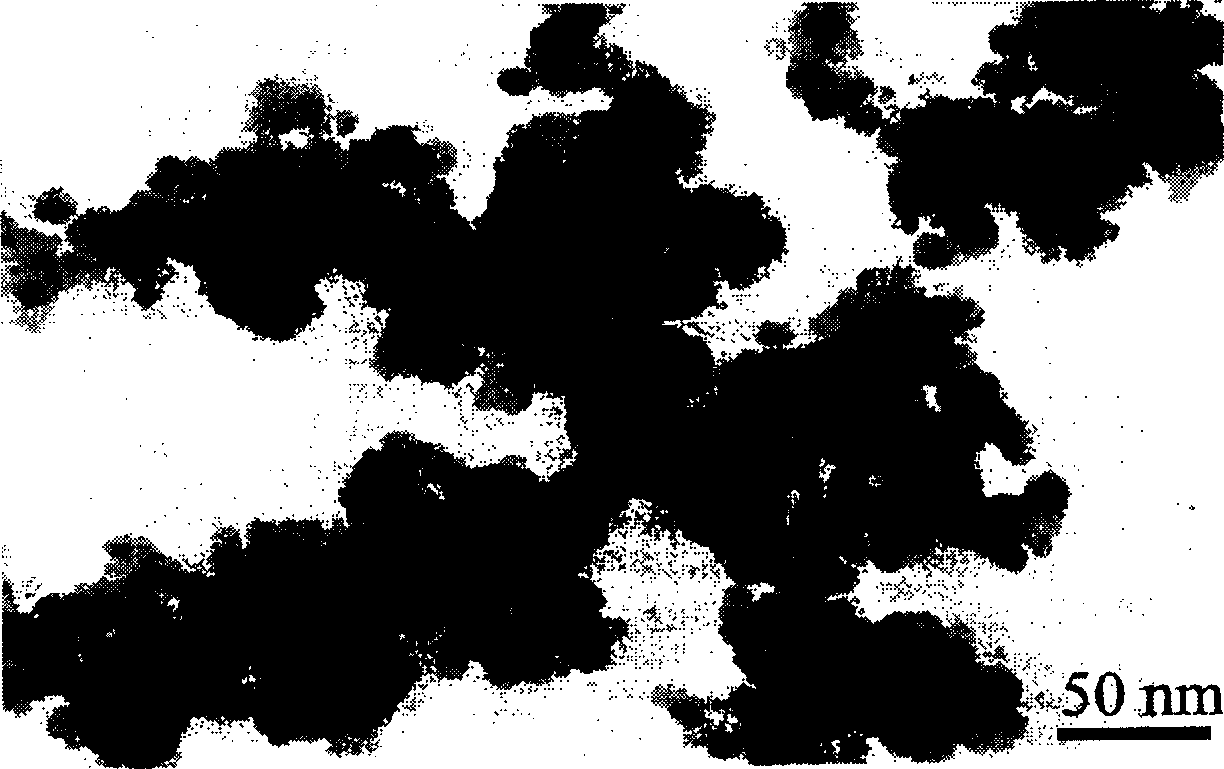

Method for preparing pale-antimony mixed nano tin-oxide powder

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

High-strength electric conduction copper rod material and preparation method

InactiveCN108950293AHigh strengthImprove conductivityConductive materialMetal/alloy conductorsNitrogen gasChromium

The invention discloses a high-strength electric conduction copper rod material and a preparation method. The preparation method comprises the following steps of selecting high-purity copper, iron, silicon, chromium, aluminum, silver, sodium, zinc, lead and nickel with the purities being 99.9% or more, and putting the raw materials into a melting furnace to be molten at the melting temperature being 1100 DEG C-1200 DEG C; continuously blowing nitrogen into the raw materials and stirring the raw materials for 25-35 min to change the raw materials into molten copper; pouring molten alloy into acasting mold cavity to conduct casting; taking out the cast raw materials from the casting mold cavity and cooling the raw materials through a cooling system to form an ingot casting; and conducting secondary heating on the cooled ingot casting and conducting thermal plastic deformation on the ingot casting. According to the preparation method the raw materials are selected and are subjected to smelting, pouring and quenching treatment to be manufactured into a high-strength electric conduction copper rod, and the problem that normal use of an instrument is affected due to the fact that most of copper rods in precise instruments are common copper rods is solved.

Owner:WUHU HAIYUAN COPPER IND CO LTD

Electrically conductive polymer compositions

The present invention relates to electrically conductive polymer compositions, and their use in organic electronic devices. The electrically conductive polymer compositions include an intrinsically conductive polymer having at least on monomer unit derived from Formula I:where:X═N, CR5 Z═N, CR6 Q=NH, S, O, Se, TeR1 through R4 can be H, F, Cl, C1-C24 alkyl, C2-C24 alkenyl, aryl, C1-C10 alkoxy, C1-C10 alkylseleno, C1-C10 alkylthio, C1-C10 alkylsilyl, NH2, or C1-C10 dialkylamino, where adjacent R groups can join together to form a 5- or 6-membered aliphatic or aromatic rings, with the proviso that at least one of R1 through R4 is NH2, and.R5 and R6 can be H, C1-C24 alkyl, C2-C24 alkenyl, and aryl.The electrically conducting polymer is doped with a fluorinated acid polymer.

Owner:EI DU PONT DE NEMOURS & CO

Tinned copper core fluorinated ethylene propylene insulated wire for aerospace and manufacturing device of tinned copper core fluorinated ethylene propylene insulated wire

Owner:深圳市金环宇电线电缆有限公司

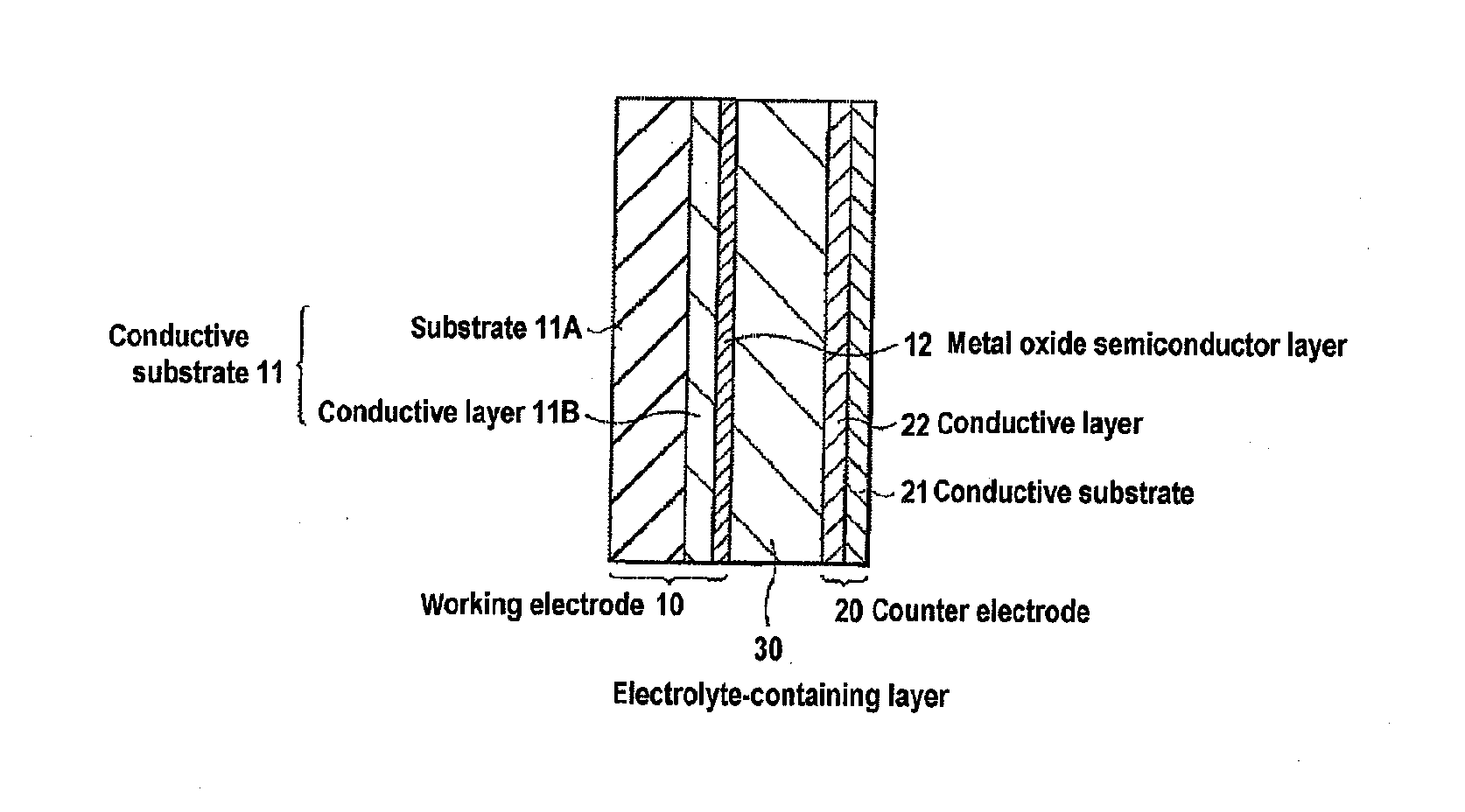

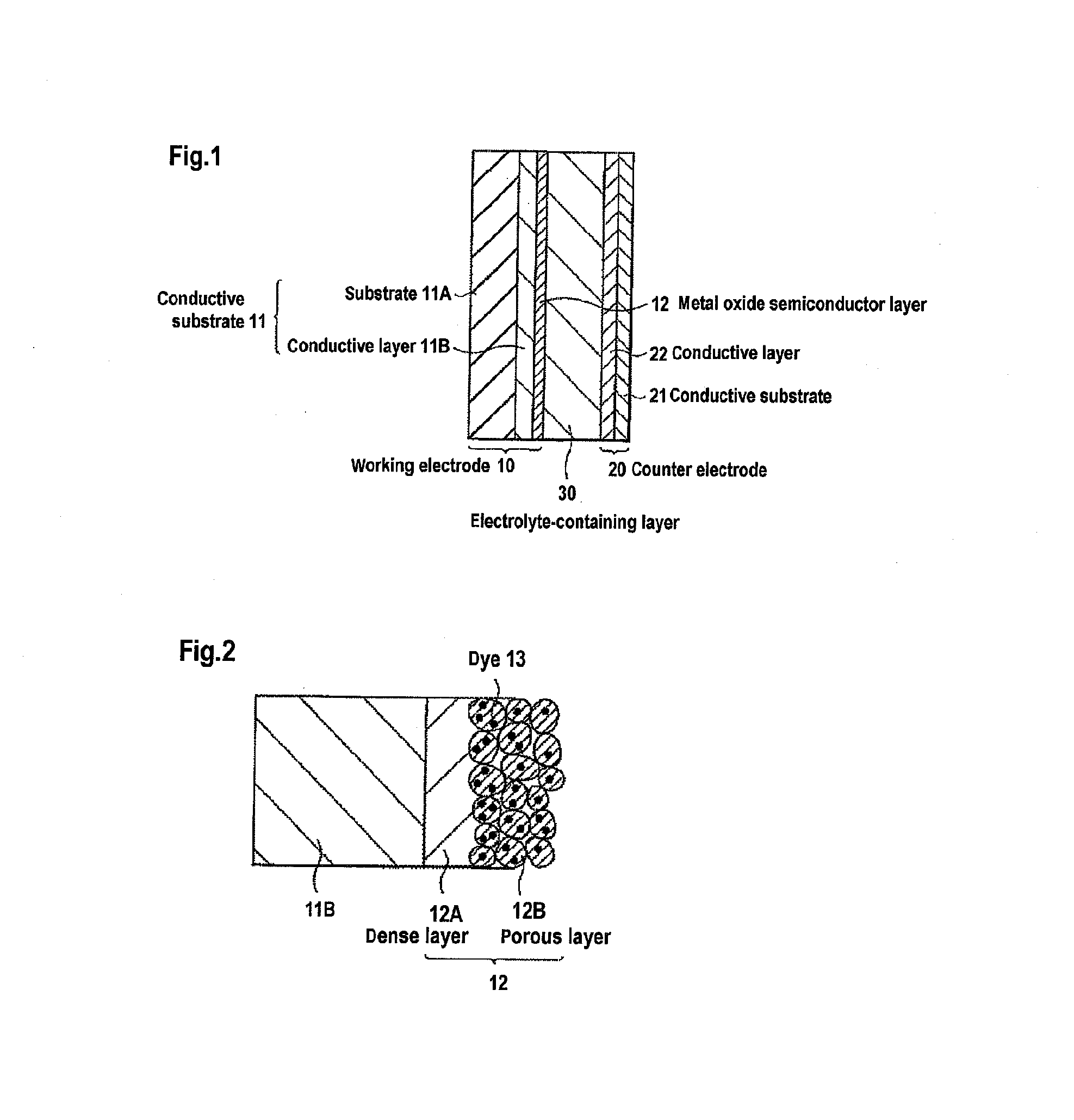

Novel compound and photoelectric conversion device

InactiveUS20130341572A1Improve adsorption capacityImprove efficiencyStyryl dyesMonoazo dyesCombinatorial chemistryPhotoelectric conversion

Owner:ADEKA CORP

Water-cooled type high-current self-destruction protection cable

Owner:上海万松电气设备有限公司

Popular searches

Non-conductive material with dispersed conductive material Domestic articles Thin material handling Semiconductor/solid-state device manufacturing Glass/slag layered products Metal layered products Semiconductor devices Printed circuit assembling Synthetic resin layered products Cellulosic plastic layered products

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap